Sewage pump

A sewage pump and sewage roller technology, which is applied to pumps, pump components, non-variable-capacity pumps, etc., can solve the problems that the sewage pump cannot continue to work normally, the blades of the sewage pump are wound, and the sewage pump and the motor are damaged, etc. The effect of rapid crushing treatment, avoiding sewage blockage and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

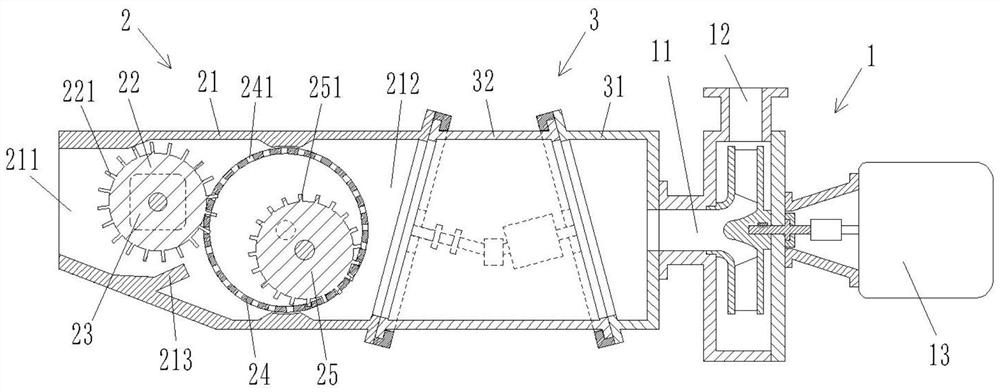

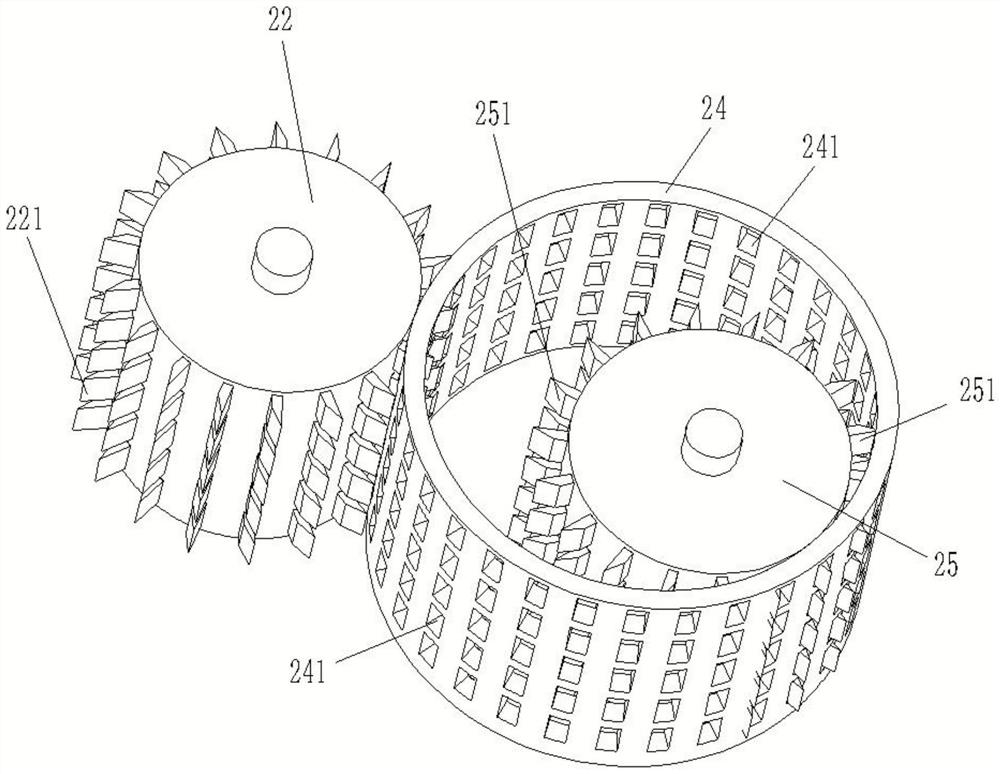

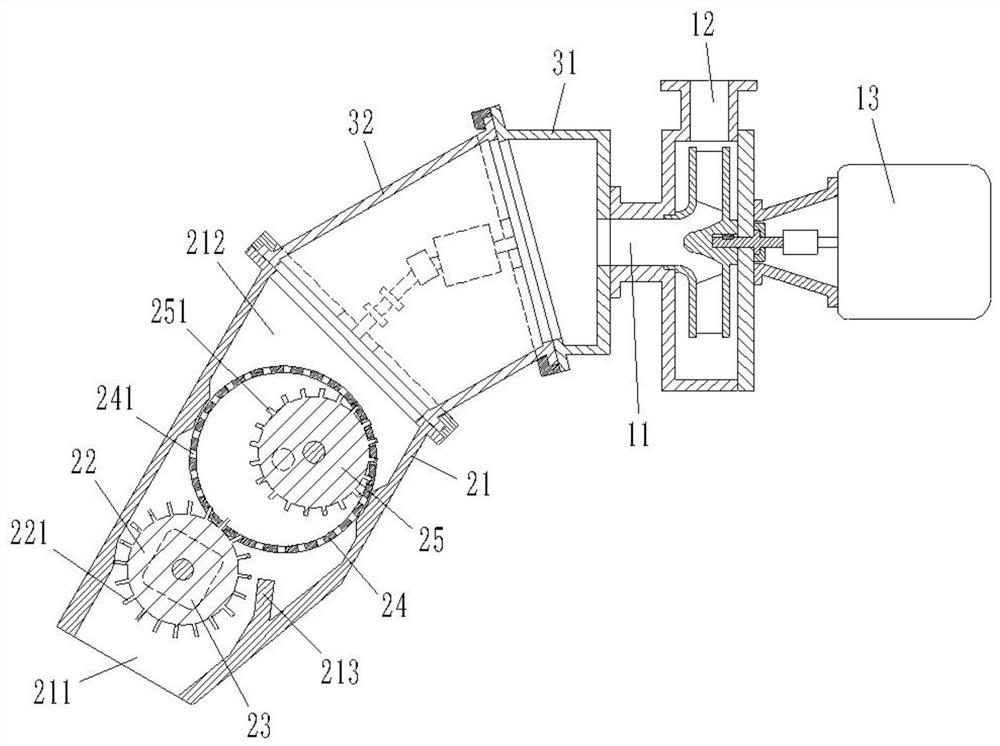

[0022] The technical solutions of the present invention will be further described in further detail below with reference to the accompanying drawings and examples.

[0023] Combine figure 1 and figure 2 As shown, the drain pump of the present embodiment includes a water pump 1 and a crushing unit 2. Among them, a water pump inlet 11 and a water pump outlet 12 are provided on the water pump 1, and the water pump 1 is driven by a water pump motor 13 to draw the sewage from the water pump inlet 11 and output from the water pump outlet 12. The crushing unit 2 is located upstream of the inlet of the water pump 1, which is used to impurity crushing of the sewage flowing toward the water pump inlet 11, thereby avoiding the impurities in the sewage directly flowing into the water pump and causes damage to the water pump or motor to ensure the smoothness of the entire sewage extraction process. Efficient is carried out.

[0024] In the present embodiment, the crushing unit 2 includes a cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com