Raw material rapid treating equipment for carbon powder manufacturing

A processing equipment and carbon powder manufacturing technology, which is applied in the field of rapid processing equipment for raw materials for carbon powder production, can solve the problems of slow processing speed, poor processing effect, time-consuming and labor-intensive, etc., and achieve the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

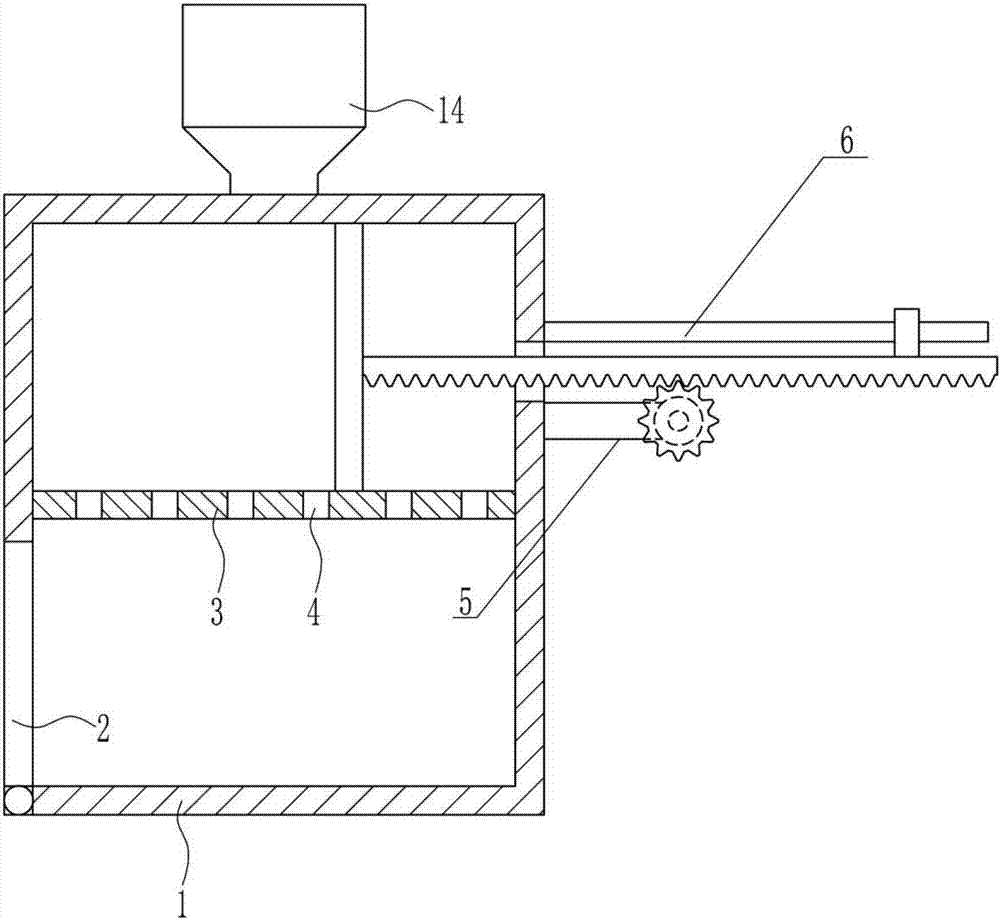

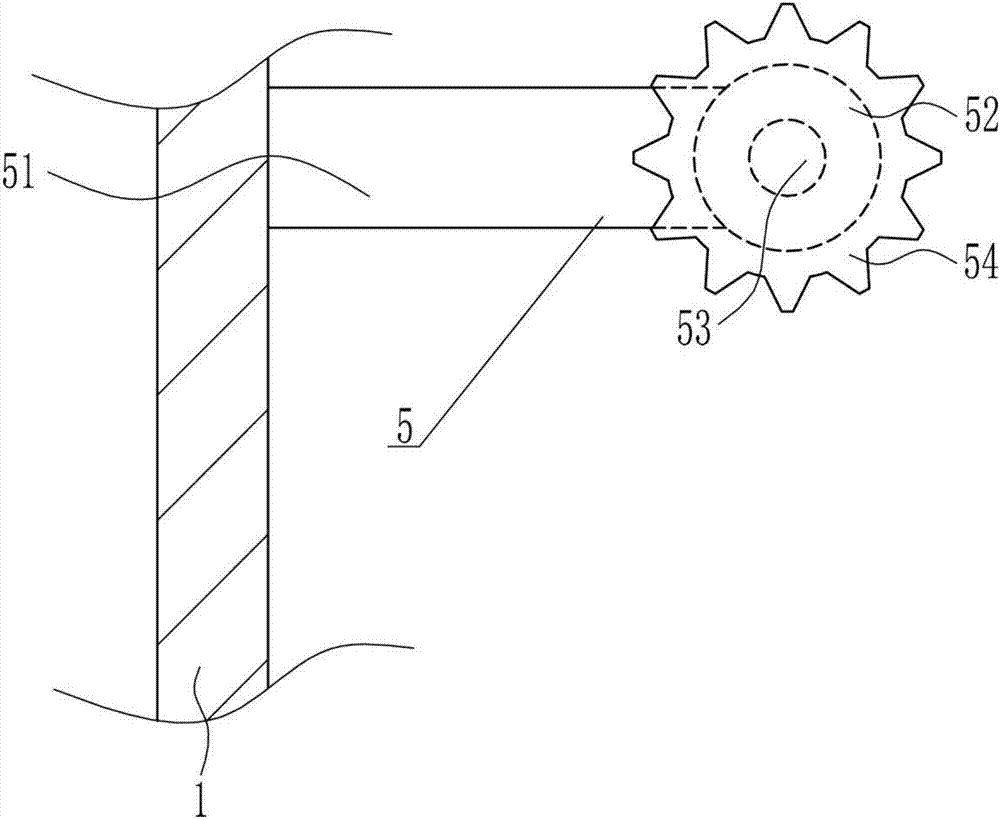

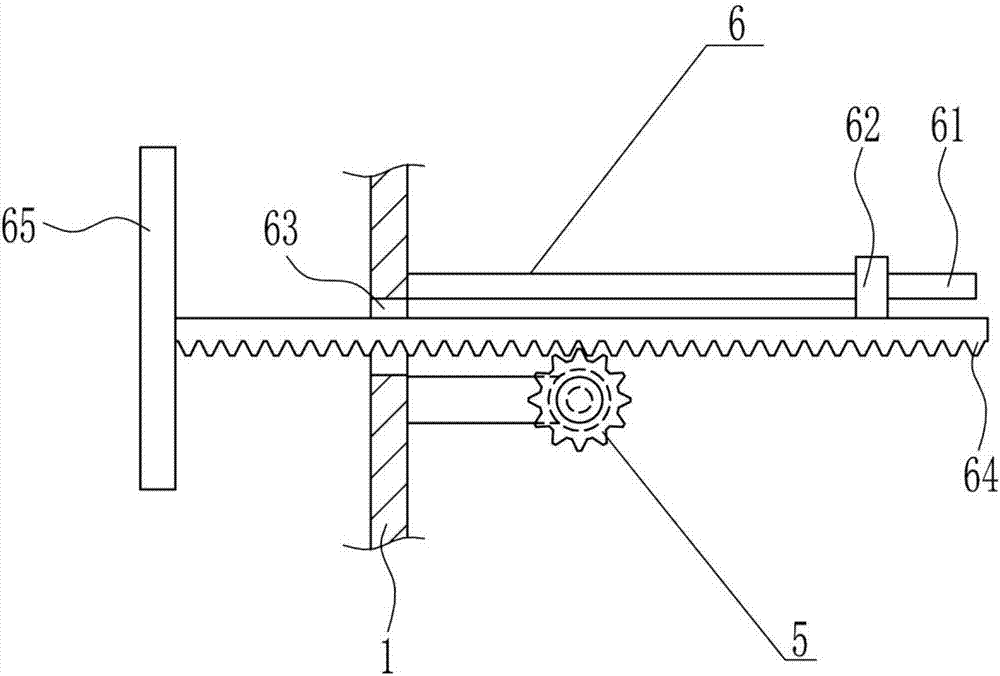

[0036] A rapid processing equipment for raw materials for carbon powder production, such as Figure 1-8 As shown, it includes a box body 1, a baffle plate 2, a partition plate 3, a driving device 5, a processing device 6 and a lower hopper 14, and the bottom of the left side of the box body 1 is hinged with a baffle plate 2 through a pin shaft, and the baffle plate 2 is connected to the The box body 1 is matched, and the middle part of the box body 1 is horizontally connected with a partition 3 by means of bolt connection, and a discharge hole 4 is opened on the partition board 3, and a driving device 5 and a processing device 6 are arranged on the upper right side of the box body 1, The driving device 5 is located below the processing device 6, and the driving device 5 cooperates with the processing device 6. The processing components of the processing device 6 are located above the partition plate 3 in the casing 1, and a lower hopper 14 is installed between the tops of the c...

Embodiment 2

[0038] A rapid processing equipment for raw materials for carbon powder production, such as Figure 1-8 As shown, it includes a box body 1, a baffle plate 2, a partition plate 3, a driving device 5, a processing device 6 and a lower hopper 14, and the bottom of the left side of the box body 1 is hinged with a baffle plate 2 through a pin shaft, and the baffle plate 2 is connected to the The box body 1 is matched, and the middle part of the box body 1 is horizontally connected with a partition 3 by means of bolt connection, and a discharge hole 4 is opened on the partition board 3, and a driving device 5 and a processing device 6 are arranged on the upper right side of the box body 1, The driving device 5 is located below the processing device 6, and the driving device 5 cooperates with the processing device 6. The processing components of the processing device 6 are located above the partition plate 3 in the casing 1, and a lower hopper 14 is installed between the tops of the c...

Embodiment 3

[0041] A rapid processing equipment for raw materials for carbon powder production, such as Figure 1-8 As shown, it includes a box body 1, a baffle plate 2, a partition plate 3, a driving device 5, a processing device 6 and a lower hopper 14, and the bottom of the left side of the box body 1 is hinged with a baffle plate 2 through a pin shaft, and the baffle plate 2 is connected to the The box body 1 is matched, and the middle part of the box body 1 is horizontally connected with a partition 3 by means of bolt connection, and a discharge hole 4 is opened on the partition board 3, and a driving device 5 and a processing device 6 are arranged on the upper right side of the box body 1, The driving device 5 is located below the processing device 6, and the driving device 5 cooperates with the processing device 6. The processing components of the processing device 6 are located above the partition plate 3 in the casing 1, and a lower hopper 14 is installed between the tops of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com