X-ray image destroying device for imaging department

A technology for destroying devices and light sheets, applied in presses, chemistry, grain processing, etc., can solve the problems of waste of resources, environmental pollution, occupying space, etc., and achieve the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

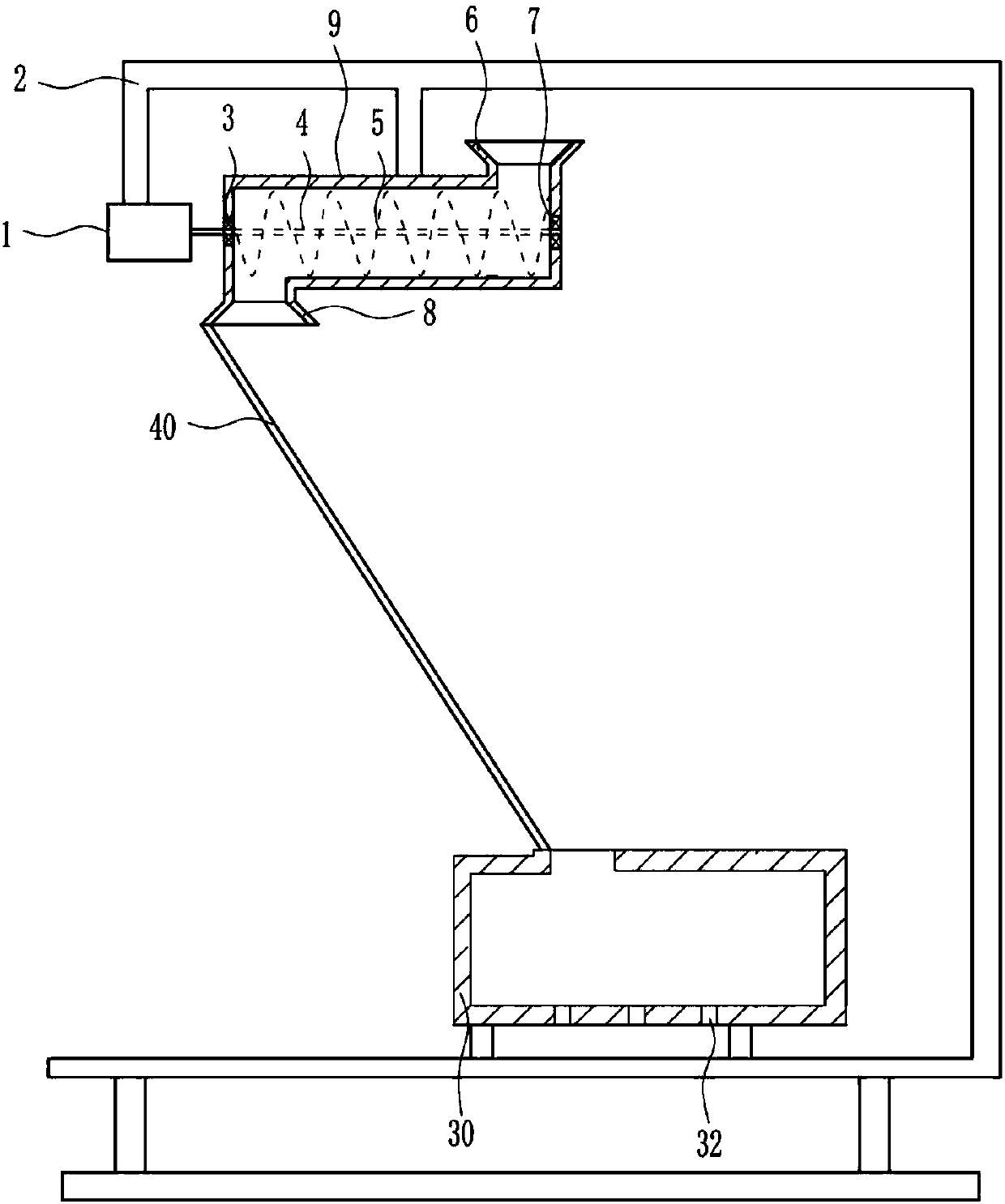

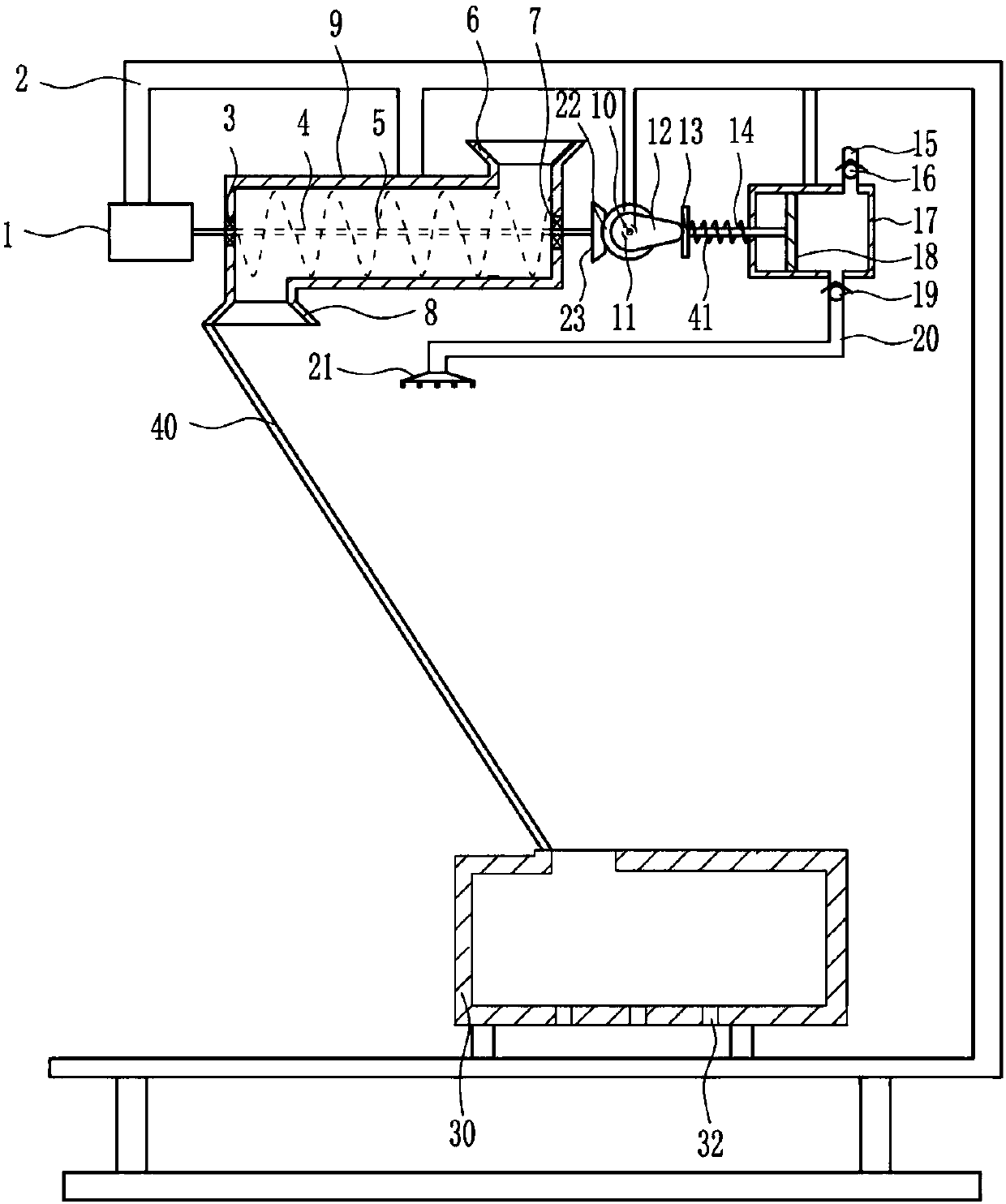

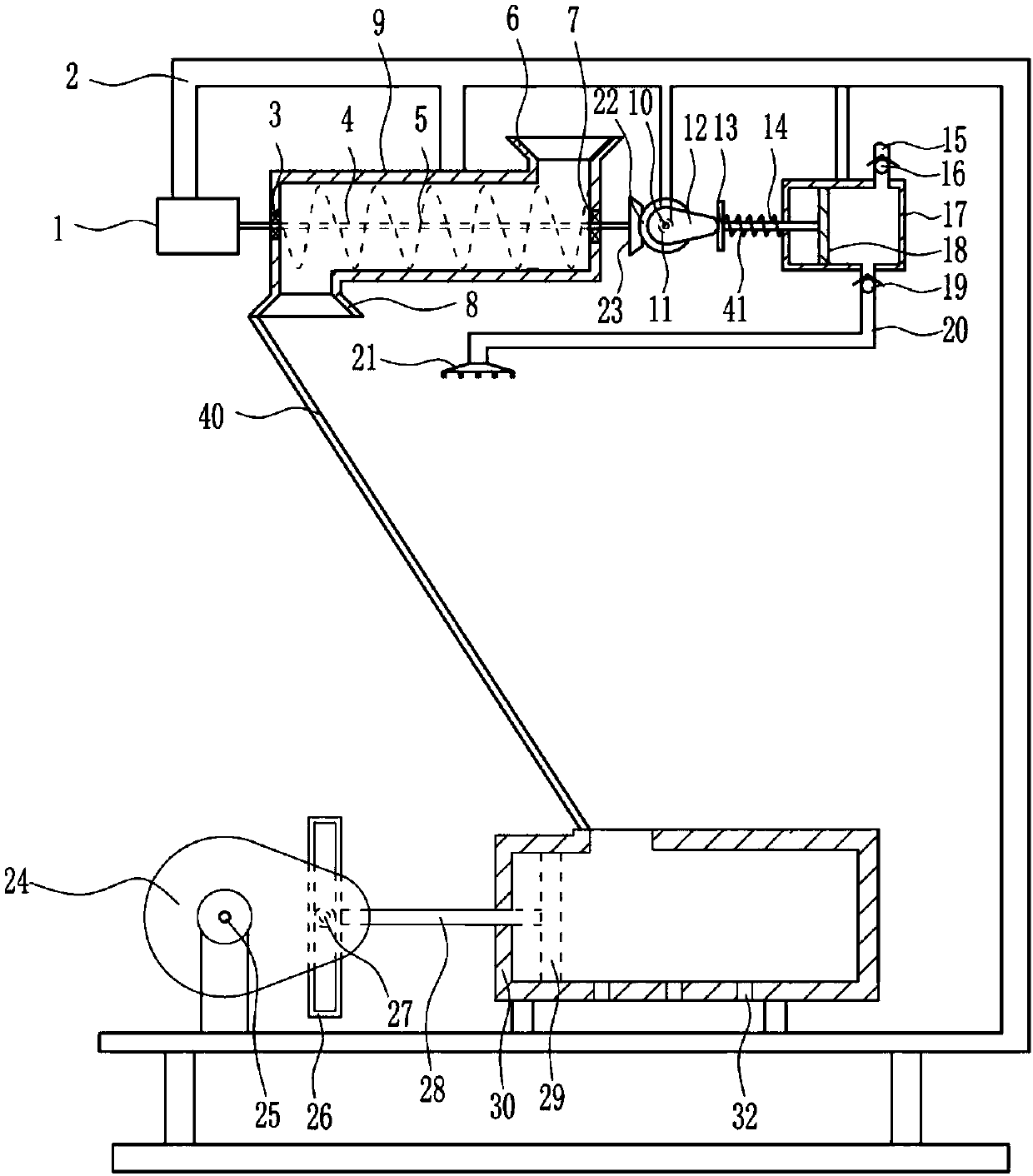

Embodiment 1

[0026] A device for destroying radiographic X-ray films, such as Figure 1-5 As shown, it includes a first motor 1, a fixed frame 2, a first bearing seat 3, a first rotating shaft 4, a helical blade 5, a feeding hopper 6, a second bearing seat 7, a hopper 8, a crushing tank 9, and a collection box 30 and guide plate 40, the lower side of the upper wall of the fixed frame 2 is provided with a first motor 1 and a crushing tank 9 in turn from left to right, the first motor 1 is provided with a first rotating shaft 4 through a coupling, and the left and right sides of the crushing tank 9 The first bearing seat 3 and the second bearing seat 7 are respectively provided, the first bearing seat 3 and the second bearing seat 7 are provided with a first rotating shaft 4 through an interference connection, and the first rotating shaft 4 is provided with a helical blade 5 for crushing The blade is located inside the crushing tank 9, the upper right part of the crushing tank 9 is provided ...

Embodiment 2

[0028] A device for destroying radiographic X-ray films, such as Figure 1-5 As shown, it includes a first motor 1, a fixed frame 2, a first bearing seat 3, a first rotating shaft 4, a helical blade 5, a feeding hopper 6, a second bearing seat 7, a hopper 8, a crushing tank 9, and a collection box 30 and guide plate 40, the lower side of the upper wall of the fixed frame 2 is provided with a first motor 1 and a crushing tank 9 in turn from left to right, the first motor 1 is provided with a first rotating shaft 4 through a coupling, and the left and right sides of the crushing tank 9 The first bearing seat 3 and the second bearing seat 7 are respectively provided, the first bearing seat 3 and the second bearing seat 7 are provided with a first rotating shaft 4 through an interference connection, and the first rotating shaft 4 is provided with a helical blade 5 for crushing The blade is located inside the crushing tank 9, the upper right part of the crushing tank 9 is provided ...

Embodiment 3

[0031] A device for destroying radiographic X-ray films, such as Figure 1-5 As shown, it includes a first motor 1, a fixed frame 2, a first bearing seat 3, a first rotating shaft 4, a helical blade 5, a feeding hopper 6, a second bearing seat 7, a hopper 8, a crushing tank 9, and a collection box 30 and guide plate 40, the lower side of the upper wall of the fixed frame 2 is provided with a first motor 1 and a crushing tank 9 in turn from left to right, the first motor 1 is provided with a first rotating shaft 4 through a coupling, and the left and right sides of the crushing tank 9 The first bearing seat 3 and the second bearing seat 7 are respectively provided, the first bearing seat 3 and the second bearing seat 7 are provided with a first rotating shaft 4 through an interference connection, and the first rotating shaft 4 is provided with a helical blade 5 for crushing The blade is located inside the crushing tank 9, the upper right part of the crushing tank 9 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com