Preparation method of high-purity propolis soft capsule

A soft capsule, high-purity technology, applied in the field of preparation of high-purity propolis soft capsules, can solve the problems of difficulty in increasing the content of propolis active ingredients, unfavorable human health, and unfavorable absorption, so as to improve the crushing effect, improve efficiency, and facilitate absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

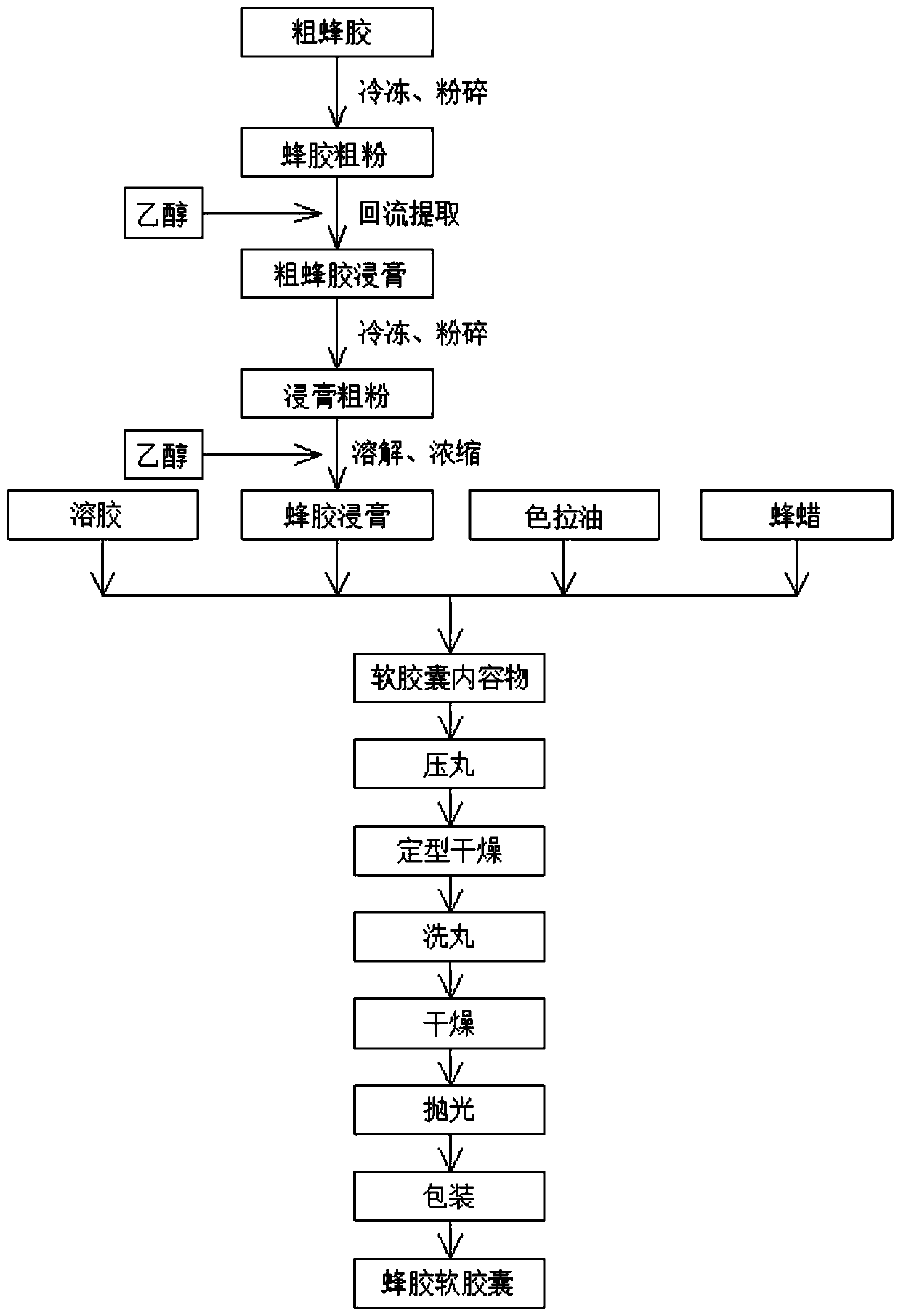

[0053] A preparation method of high-purity propolis soft capsules, the steps are as follows:

[0054] 1) filtering the crude propolis to filter out impurities in the crude propolis;

[0055] 2) After freezing the filtered coarse propolis, crush it into 40-100 mesh propolis coarse powder;

[0056] 3) using ethanol to carry out reflux extraction of propolis coarse powder, filter after extraction, and decompress and recover ethanol from the extract after filtration to obtain crude propolis extract;

[0057] 4) After freezing the crude propolis extract, crush it into a 50-mesh extract powder, use ethanol to soak and dissolve at room temperature, filter, and then concentrate to a relative density of 1.42 to obtain propolis extract;

[0058] 5) Weighing 10-15 parts of gelatin, 5-8 parts of glycerin and 15-20 parts of water respectively according to the ratio of parts by weight, and stirring evenly at a temperature of 50-60°C to obtain a sol;

[0059] 6) Keep the temperature of the...

Embodiment 2

[0064] Based on the preparation method of the high-purity propolis soft capsule of Example 1, in step 2), a crushing device is used to crush the frozen crude propolis.

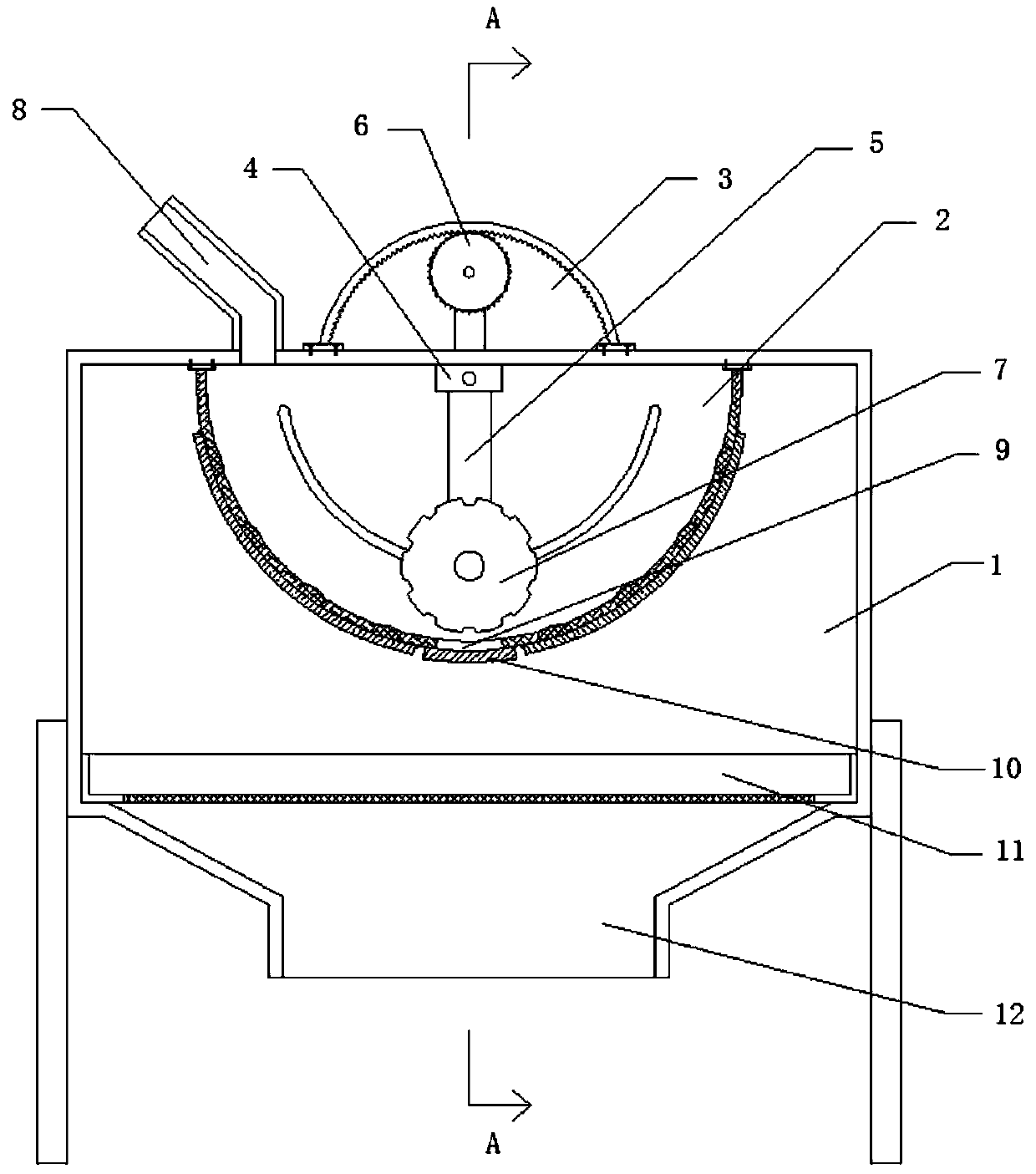

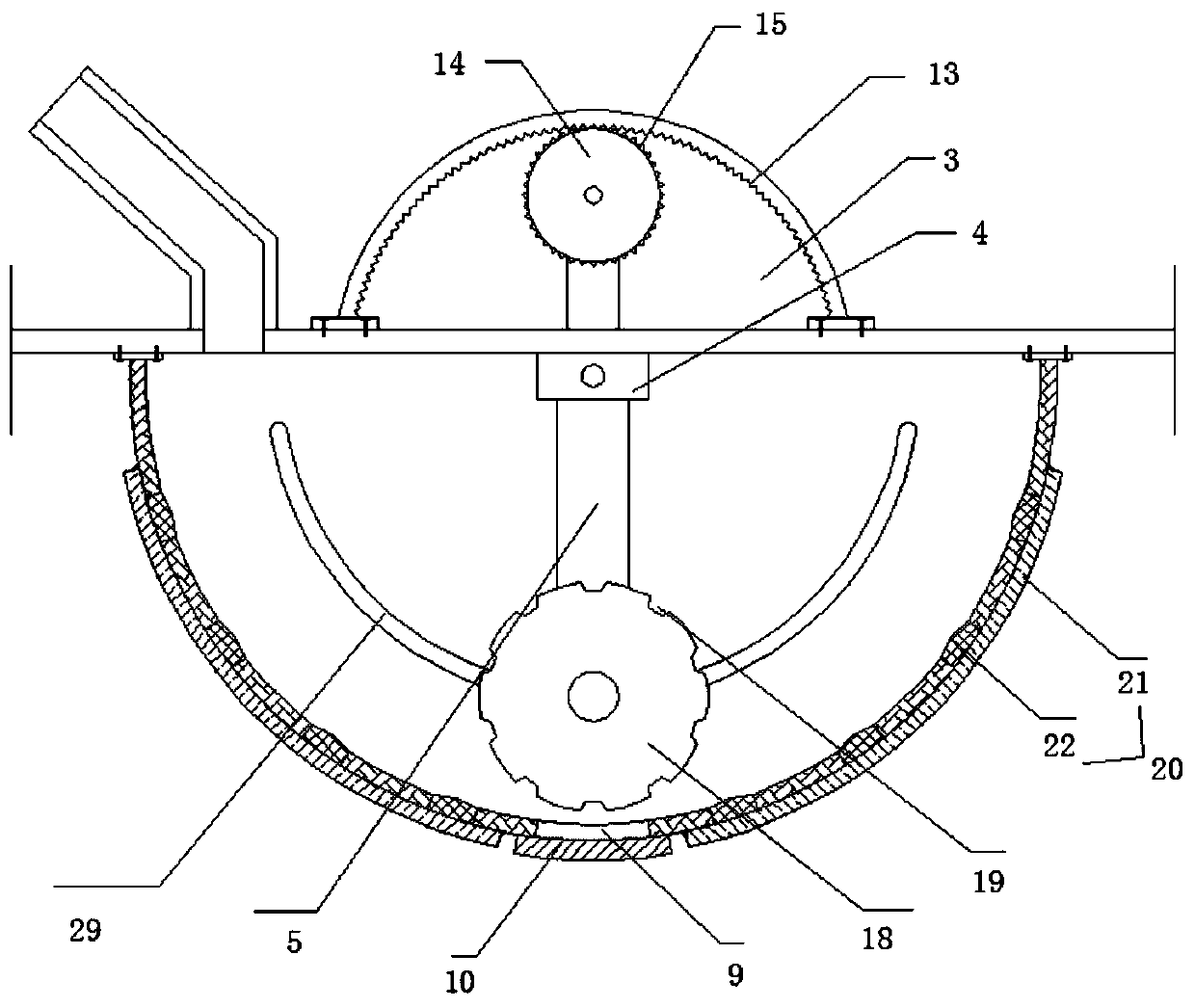

[0065] As shown in the figure, the crushing device includes a device shell 1. The bottom of the top plate of the device shell is provided with a crushing chamber 2 with a semi-cylindrical structure. The top of the top of the device shell is fixed with a transmission chamber 3 with a semi-cylindrical structure. Above the crushing chamber, the transmission chamber is coaxially arranged with the crushing chamber, and the inner diameter of the transmission chamber is smaller than the inner diameter of the crushing chamber;

[0066] A supporting column 4 is coaxially arranged on the axis of the crushing chamber, and the supporting column is arranged along the length direction of the crushing chamber;

[0067] The front and rear ends of the support column are respectively rotatably fixed with a crank arm 5, one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com