Pre-screening device for selected feed coal of coking coal

A screening device and technology for coking coal, which are applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problems of inability to screen large-particle coal after secondary treatment, screen blockage, low screening efficiency, etc. To achieve the effect of stable up and down vibration, avoid clogging of screen holes, and improve screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

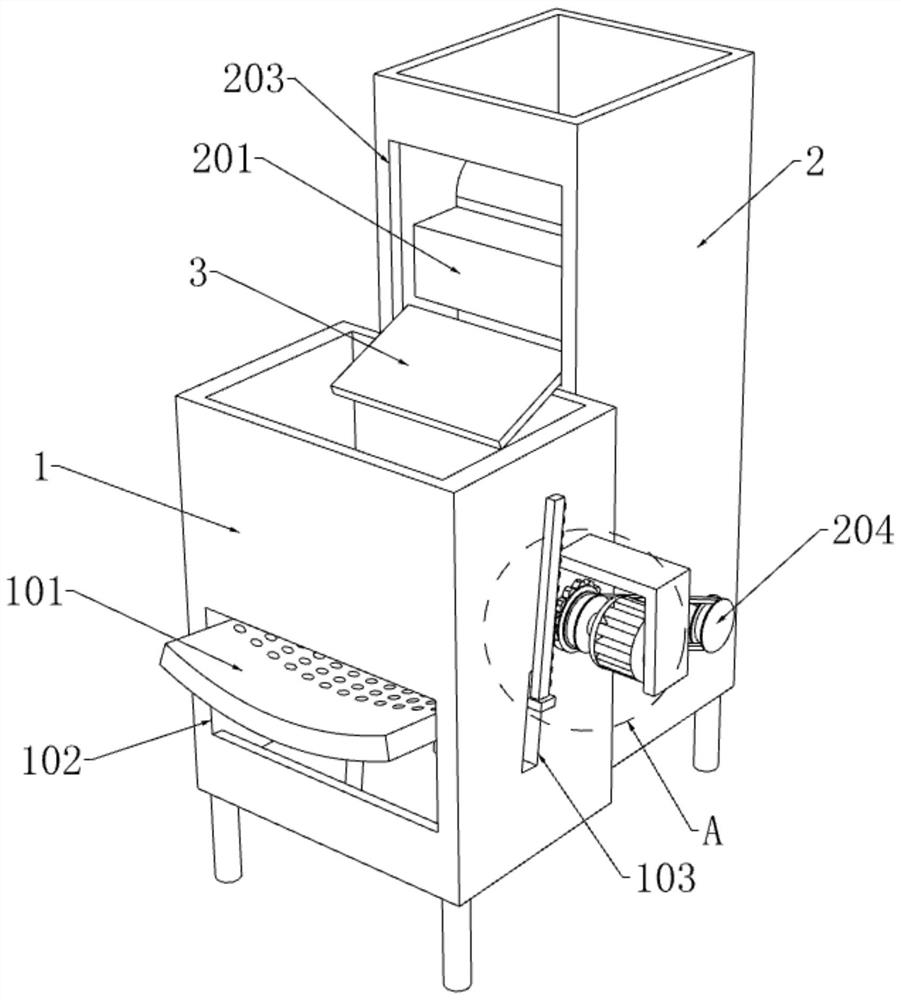

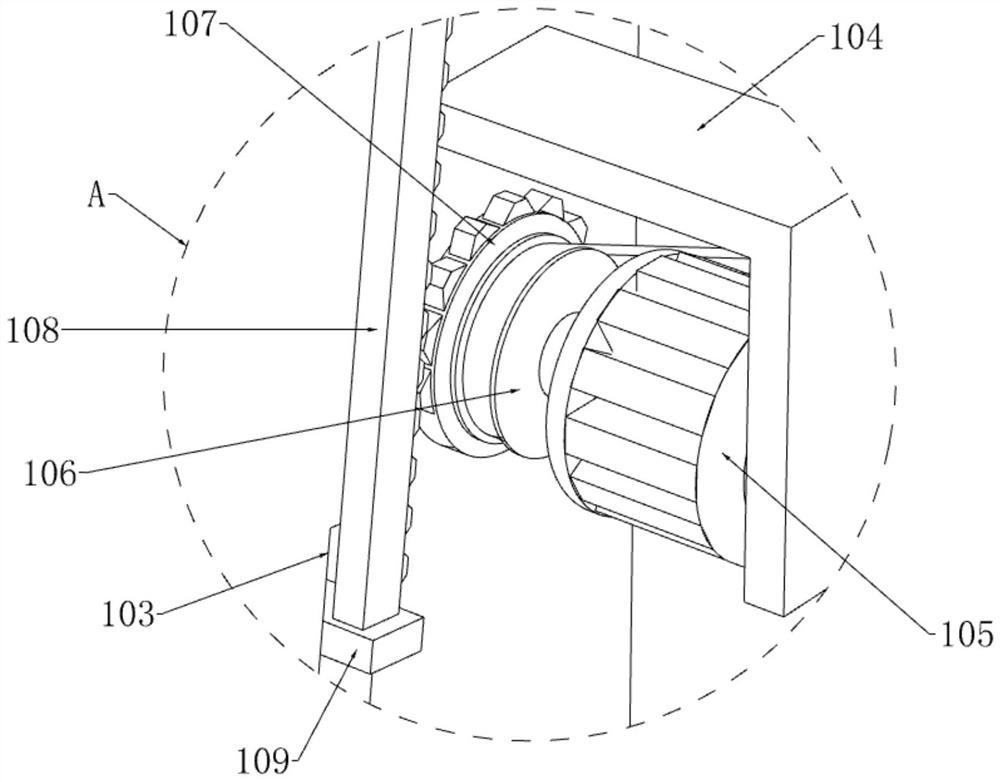

[0037] refer to figure 1 , image 3 and Figure 5 , a coking coal pre-screening device for selecting raw coal, comprising a screening box 1 with an open top, and a limiting groove 102 and a first discharge port 1010 are respectively set on both sides of the screening box 1, and the screening box 1 A sieve plate 101 is movable inside, and the sieve plate 101 is inclined, and the section of the sieve plate 101 is arc-shaped. The ends respectively pass through the limiting groove 102 and the first discharge port 1010, and a plurality of spring columns 1012 with the same structure are fixedly connected between the bottom end of the sieve plate 101 and the inner wall of the bottom end of the screening box 1. The coking coal is put into the screening box 1, and it is effectively filtered through the sieve plate 101 inside the screening box 1, and then the unscreened large-grained coal lumps are passed through the first discharge port 1010 through the inclined sieve plate 101 expo...

Embodiment 2

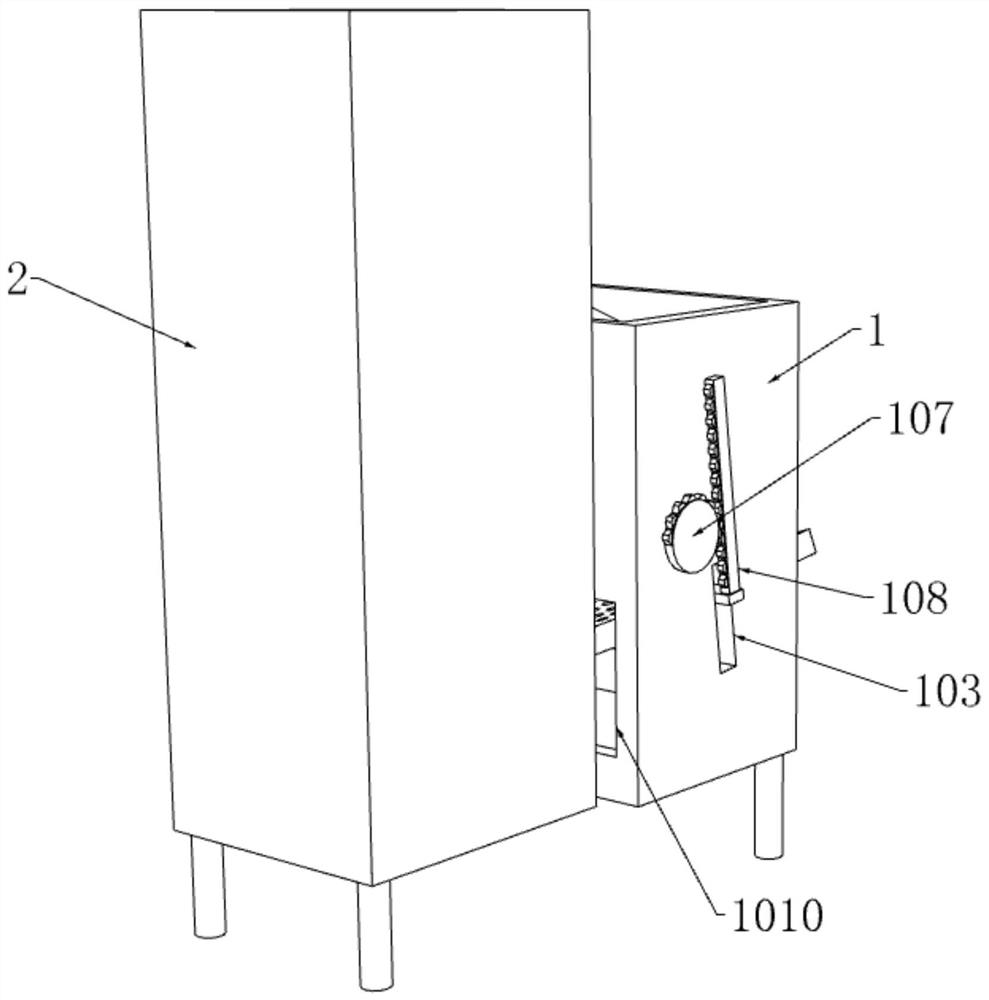

[0044] In this embodiment, a return box 2 is added on the basis of Example 1 to recover the unbroken and screened large coal lumps, and then import them into the screening box 1 for secondary treatment. figure 1 and Figure 5 , a coking coal pre-screening device for selecting raw coal, further comprising a return box 2, the return box 2 is fixedly connected to the screening box 1, and a material guide port is opened on the side of the return box 2 close to the screening box 1 203 and the second discharge port 205, the material guide port 203 is located above the second discharge port 205, and the second discharge port 205 communicates with the first discharge port 1010, so that the unbroken and screened large coal lumps It can enter the inside of the return box 2 through the first material outlet 1010 and the second material outlet 205 .

[0045] refer to Figure 4-6 , two symmetrically distributed drive rollers 206 are rotated between the inner walls on both sides of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com