Patents

Literature

158 results about "Briquetage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Briquetage is a coarse ceramic material used to make evaporation vessels and supporting pillars used in extracting salt from brine or seawater. Thick-walled saltpans were filled with saltwater and heated from below until the water had boiled away and salt was left behind. Often, the bulk of the water would be allowed to evaporate in salterns before the concentrated brine was transferred to a smaller briquetage vessel for final reduction. Once only salt was left, the briquetage vessels would have to be broken to remove the valuable commodity for trade.

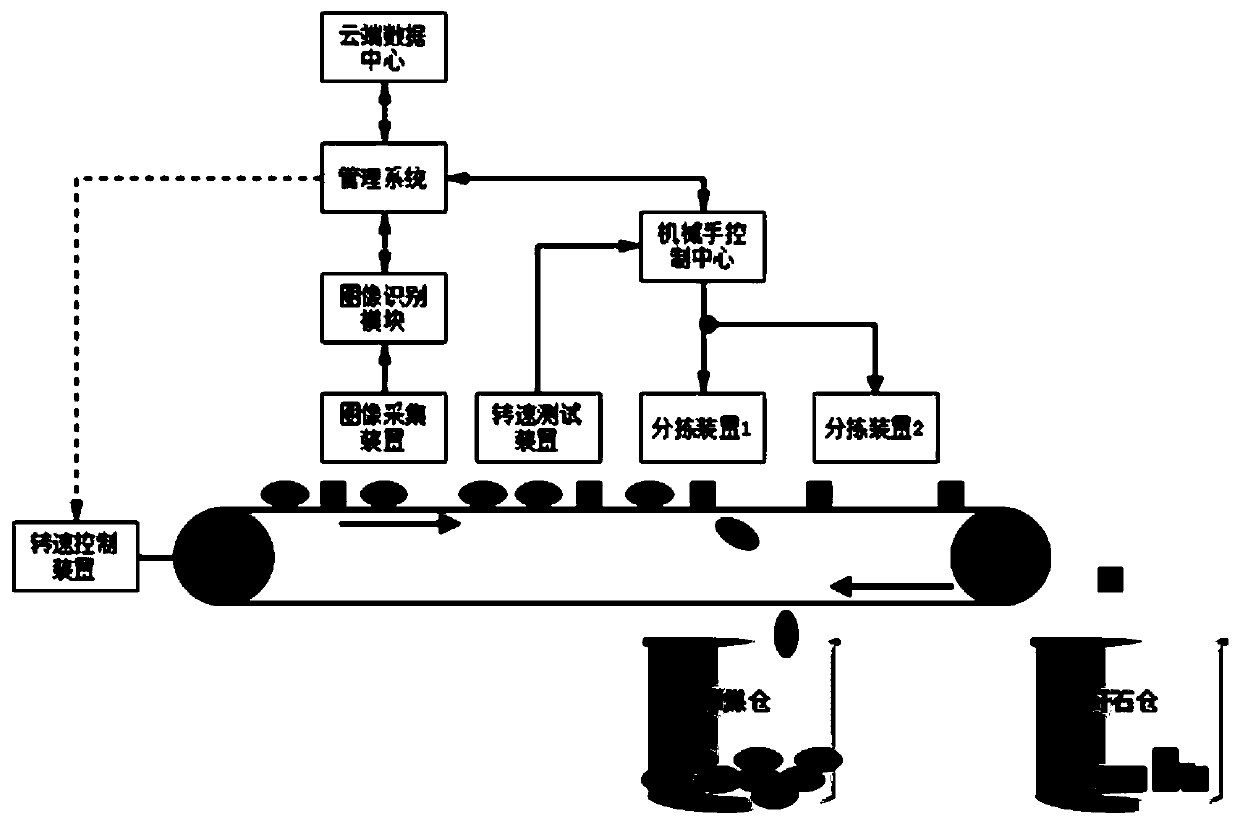

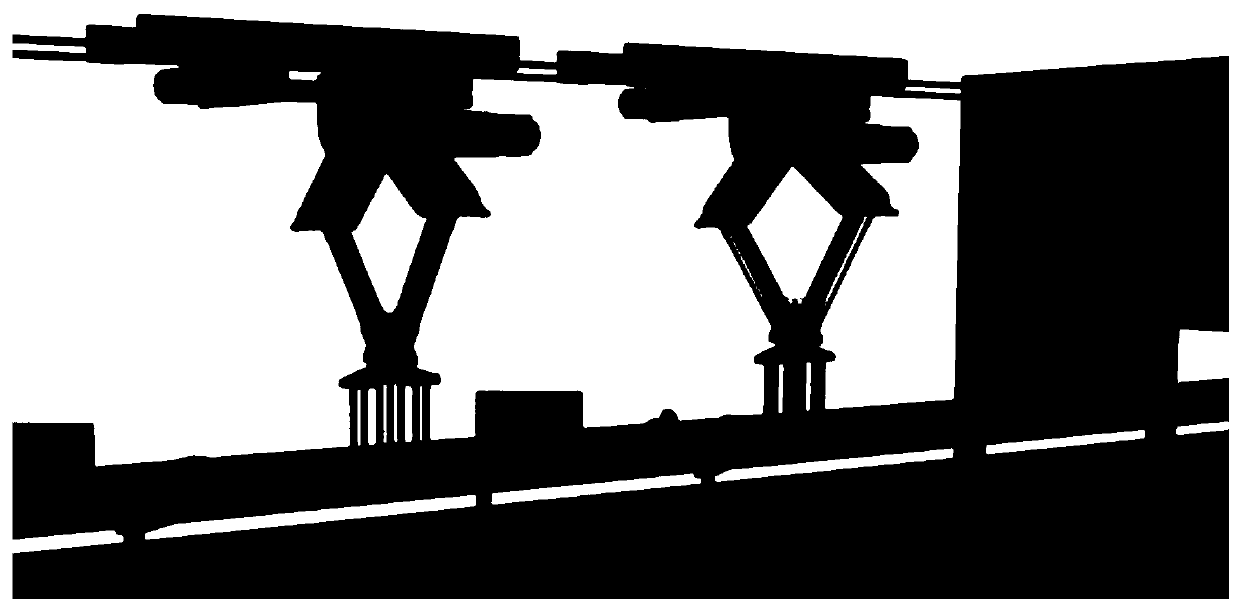

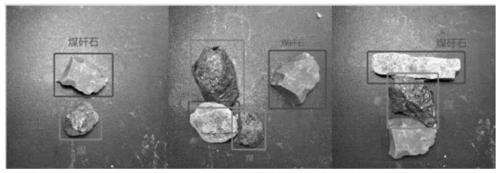

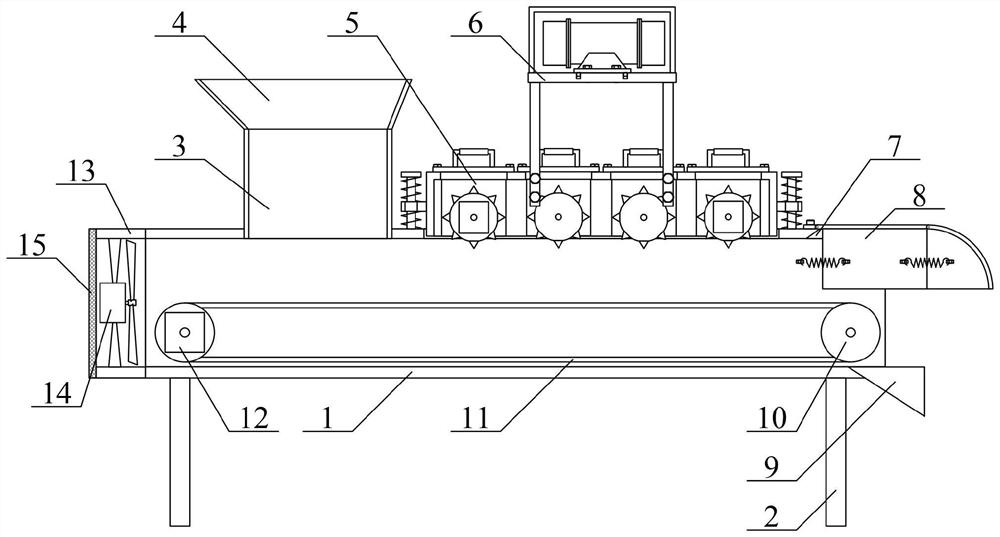

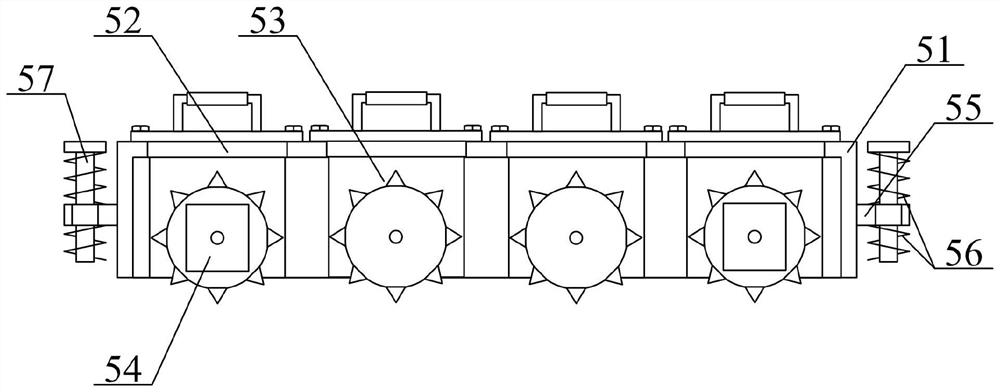

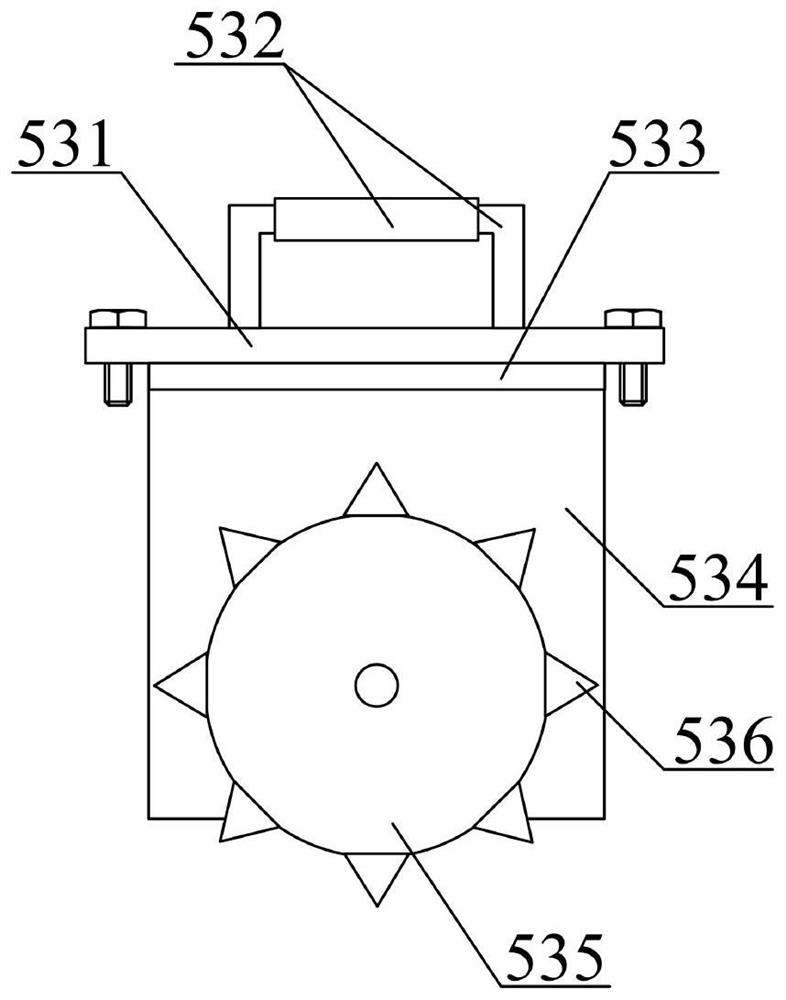

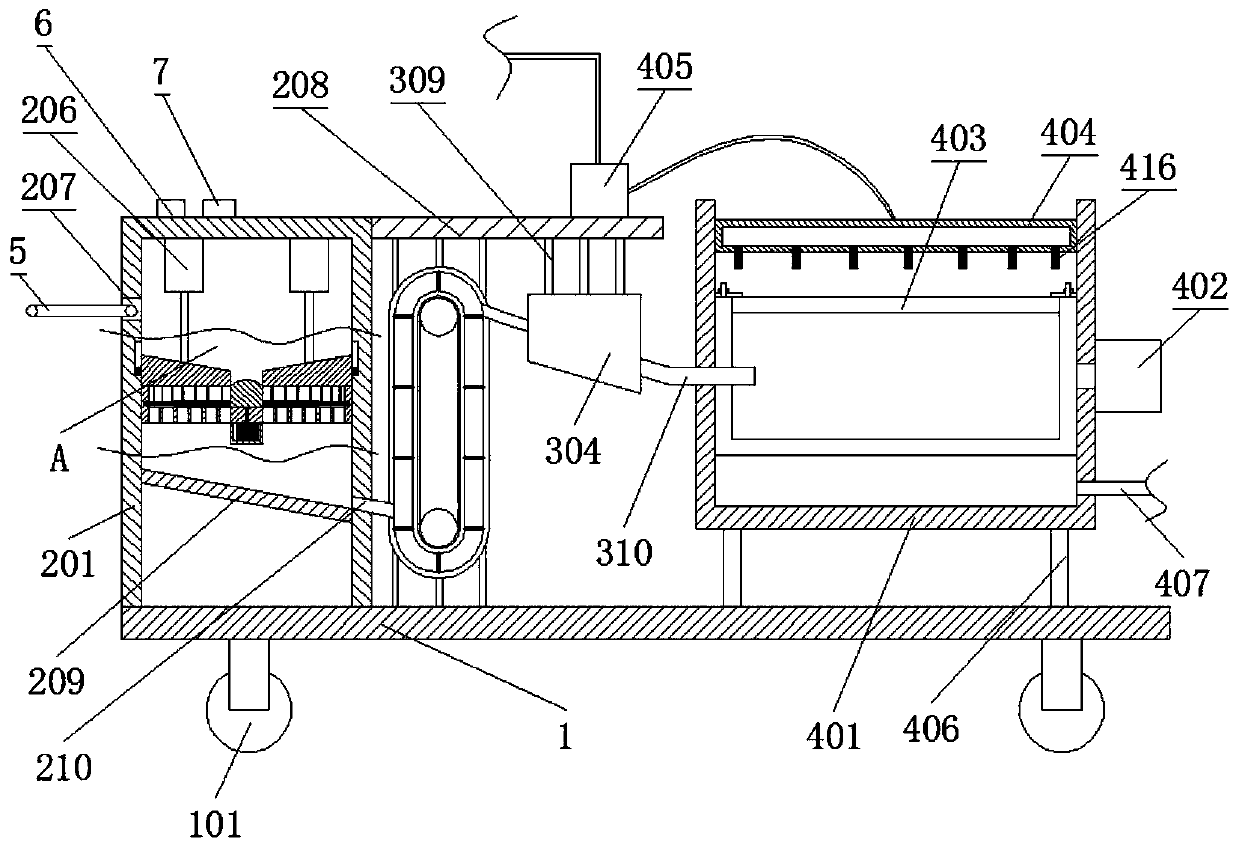

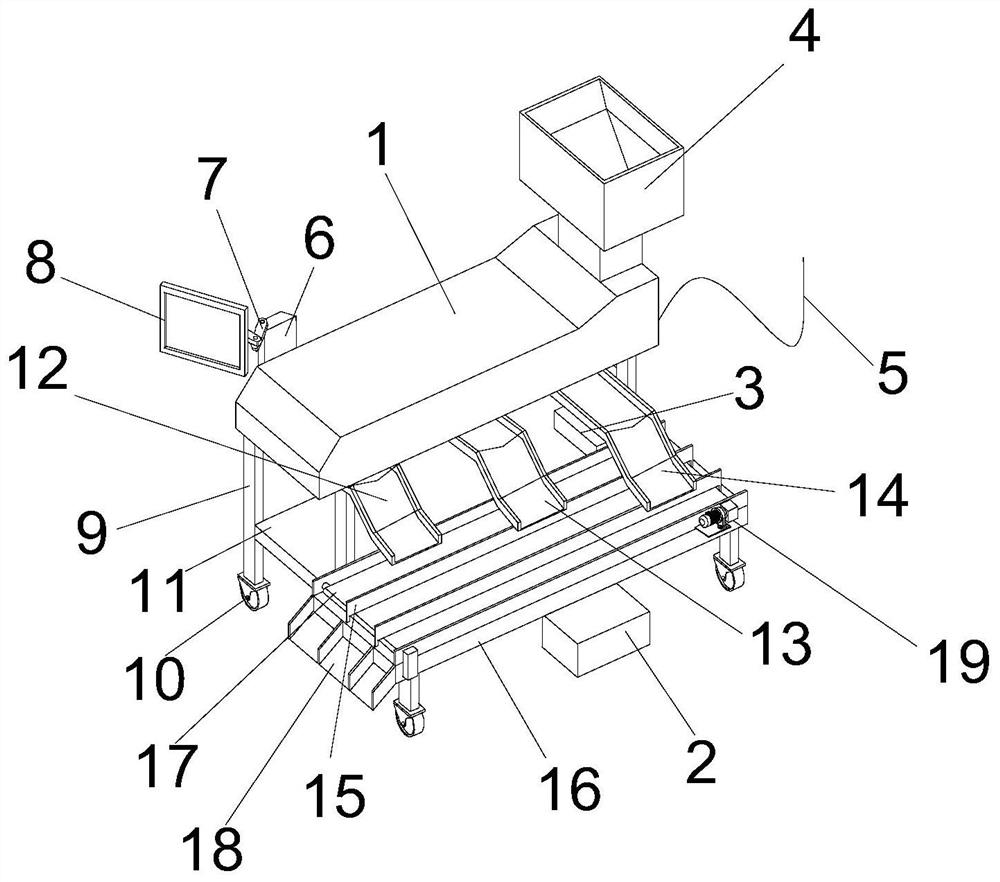

Recognizing, detecting and sorting system for coal briquettes

PendingCN111266304AImprove recognition accuracySave time and costSortingCoal briquetteMechanical engineering

Owner:唐山因泰智能科技发展有限公司

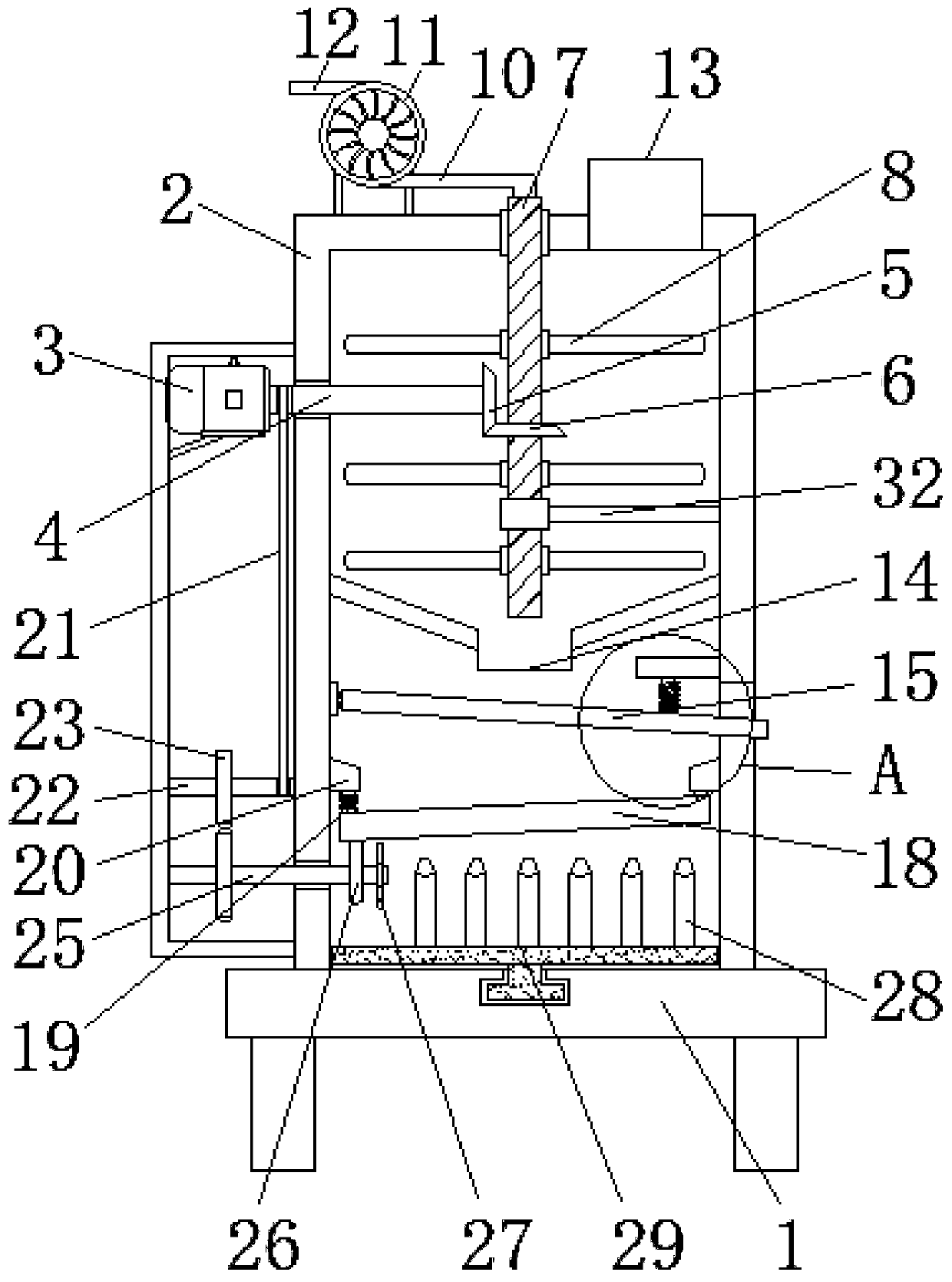

Coal briquette sorting device capable of removing impurities for coal mine processing

The invention discloses a coal briquette sorting device capable of removing impurities for coal mine processing. The coal briquette sorting device comprises a base, a motor, a hot air blower, a feeding inlet and a box door, a box body is connected to the upper part of the base in a welded mode, the motor is mounted on the left side of the box body, the output end of the motor is connected with a first rotating shaft, a first conical gear is connected to the right end of the first rotating shaft in a welded mode, a second conical gear is connected to the lower part of the first conical gear inan engaged mode, the bottoms of static rods are connected with a bottom plate, and a supporting rod is arranged on the outer wall of a second rotating shaft. According to the coal briquette sorting device capable of removing the impurities for coal mine processing, the second rotating shaft and blades communicate with each other, through holes are formed in the blades, and the second rotating shaft and an exhaust pipe are connected through a bearing so that generated hot air can be delivered into the second rotating shaft through the exhaust pipe, accordingly, the hot air is exhausted by the through holes in the blades, coal briquettes can be broken apart and dried simultaneously, and the later using rate of the coal briquettes is increased.

Owner:SHAANXI BINCHANG WENJIAPO MINING IND CO LTD

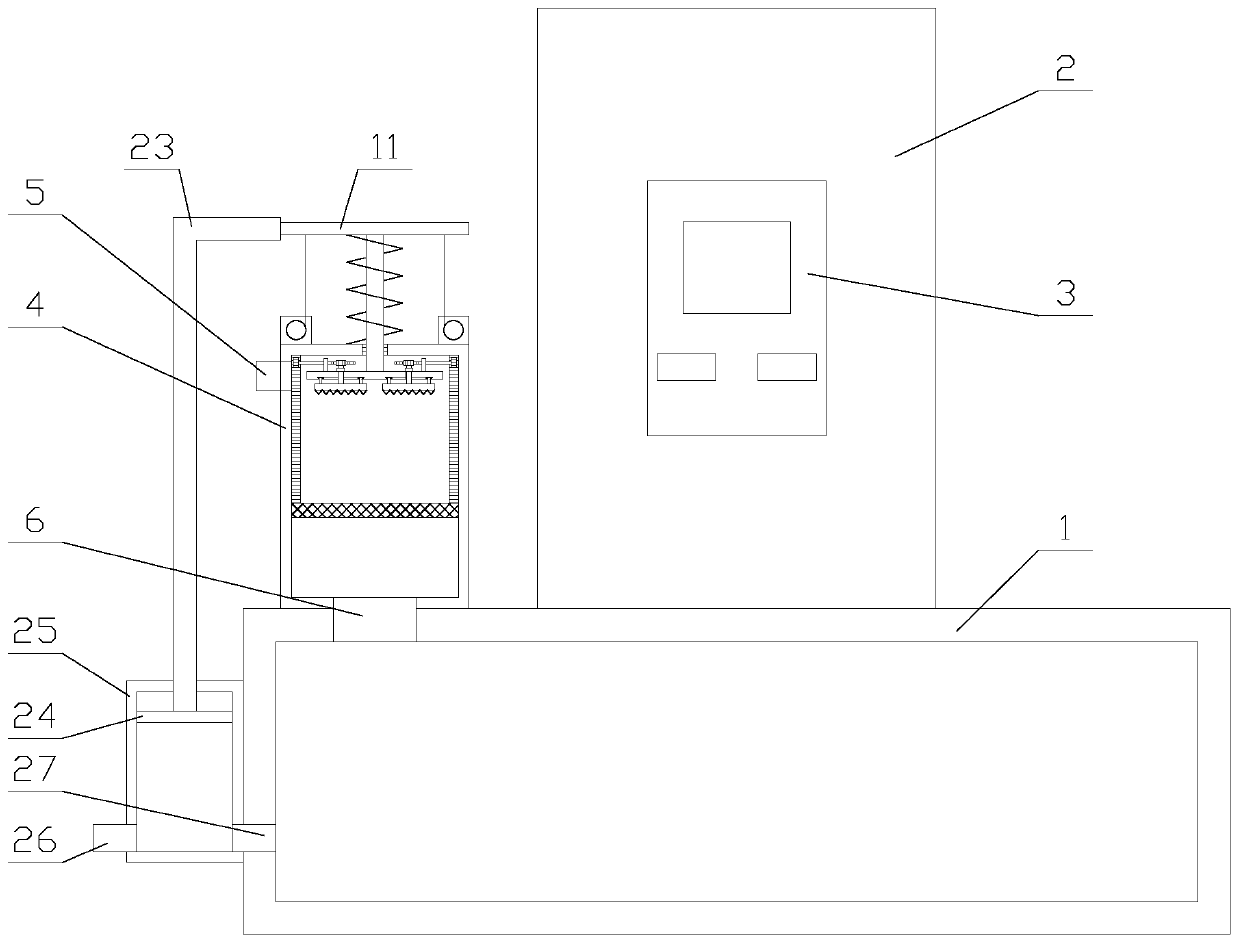

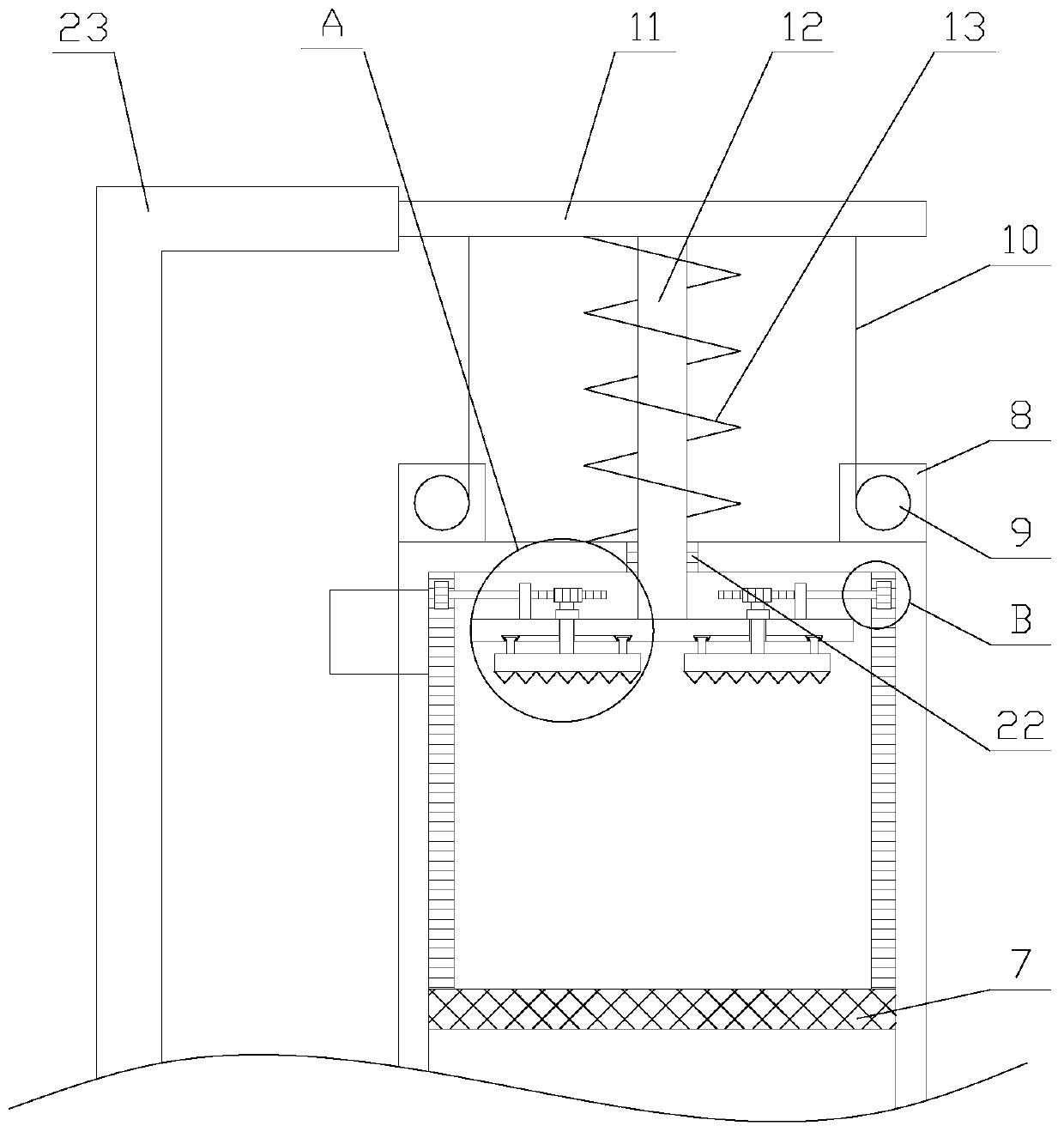

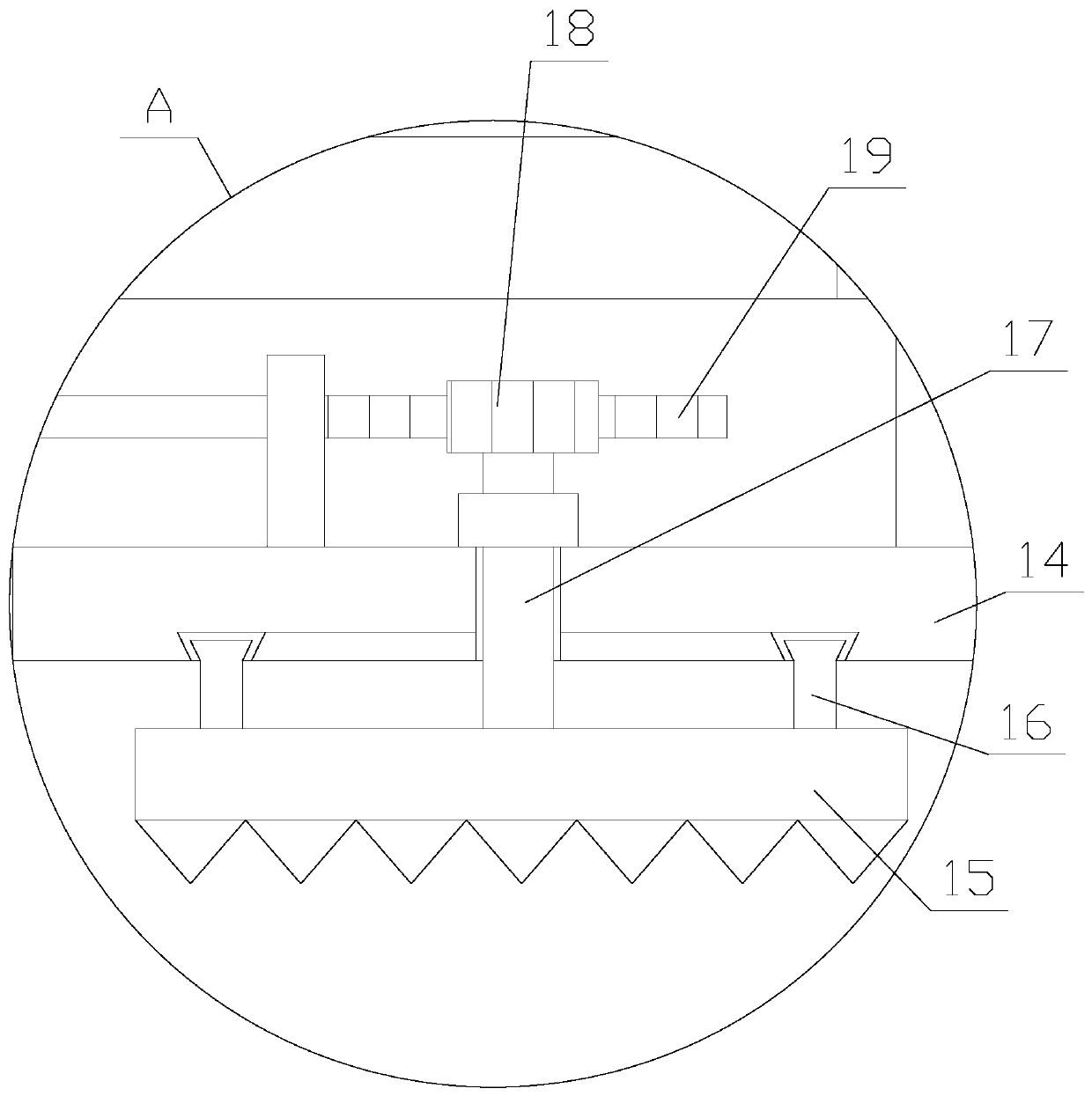

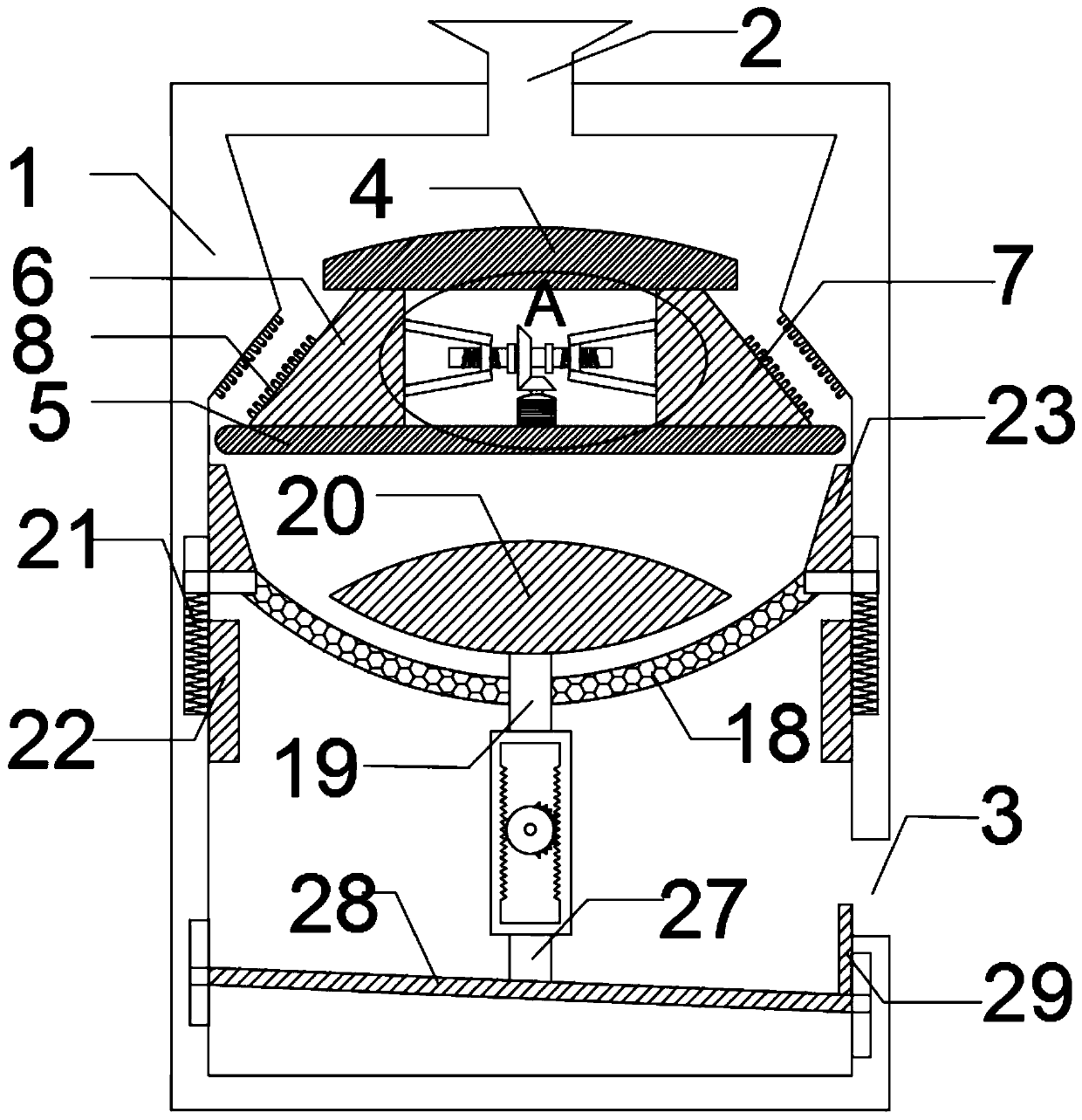

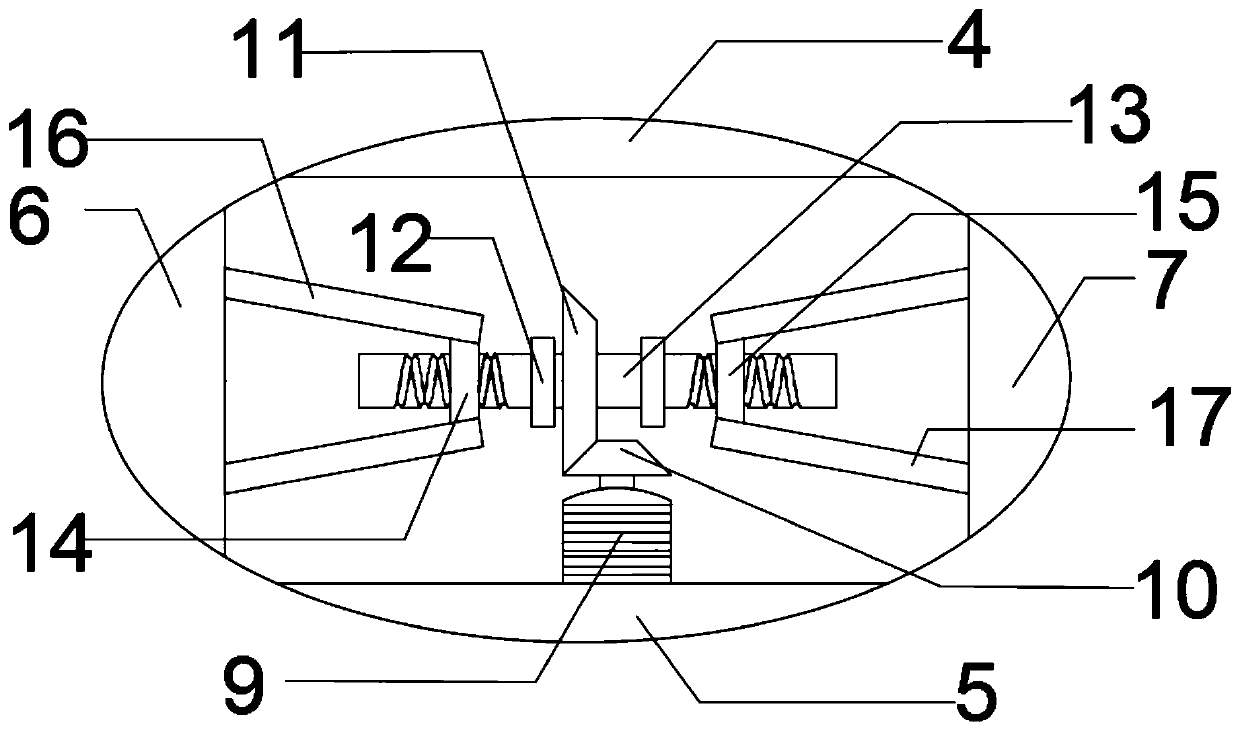

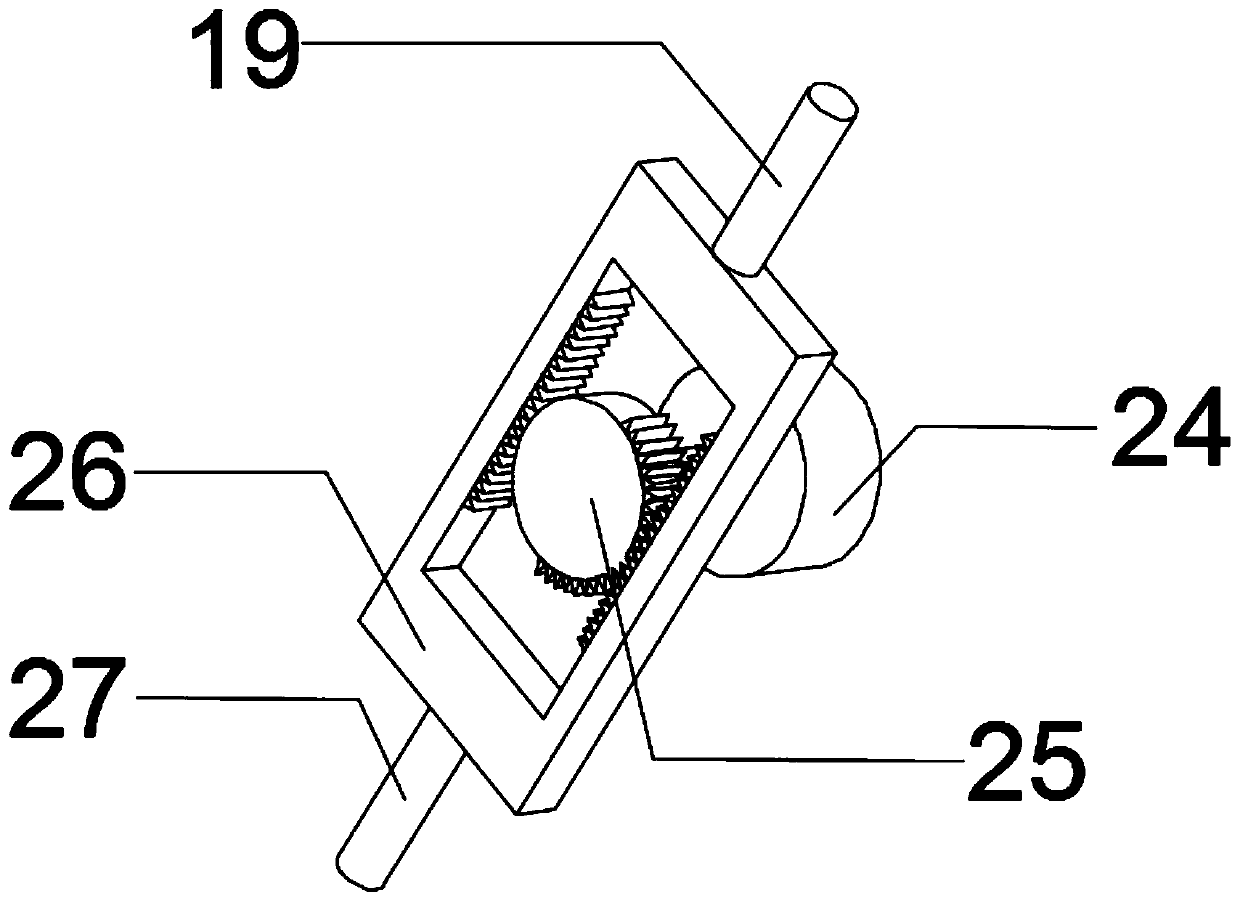

Coal grinding device for gasifier

ActiveCN110882817AEasy dischargeImprove grinding efficiencyNon-rotating vibration suppressionGrain treatmentsCoal briquetteThermodynamics

The invention discloses a coal grinding device for a gasifier. The coal grinding device comprises a device shell, a feeding hole, a discharging hole and a grinding mechanism, wherein the feeding holeand the discharging hole are formed in the upper and lower ends of the device shell; the grinding mechanism is further arranged in the device shell; the coal grinding device further comprises a smashing mechanism; and the smashing mechanism is positioned in the device shell, is above the grinding mechanism, and comprises a smashing plate, a smashing rotary shaft, a smashing drum and a pushing mechanism. Through arranging the smashing mechanism, the coal grinding device can further smash coal while grinding coal briquette to improve the grinding efficiency; and through arranging a vibrating mechanism, on one hand, the grinding effect can be improved, and on the other hand, the ground pulverized coal can be conveniently discharged.

Owner:山西晋武能源有限公司

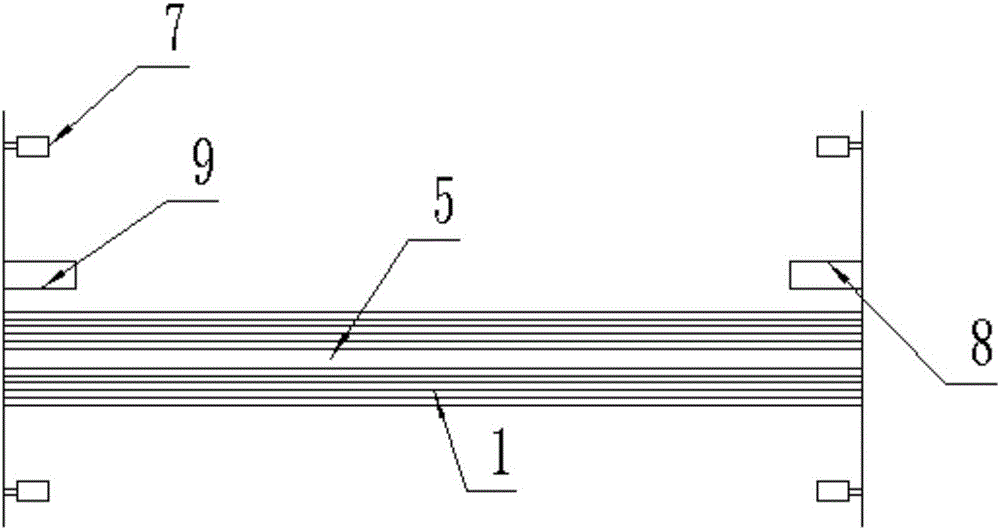

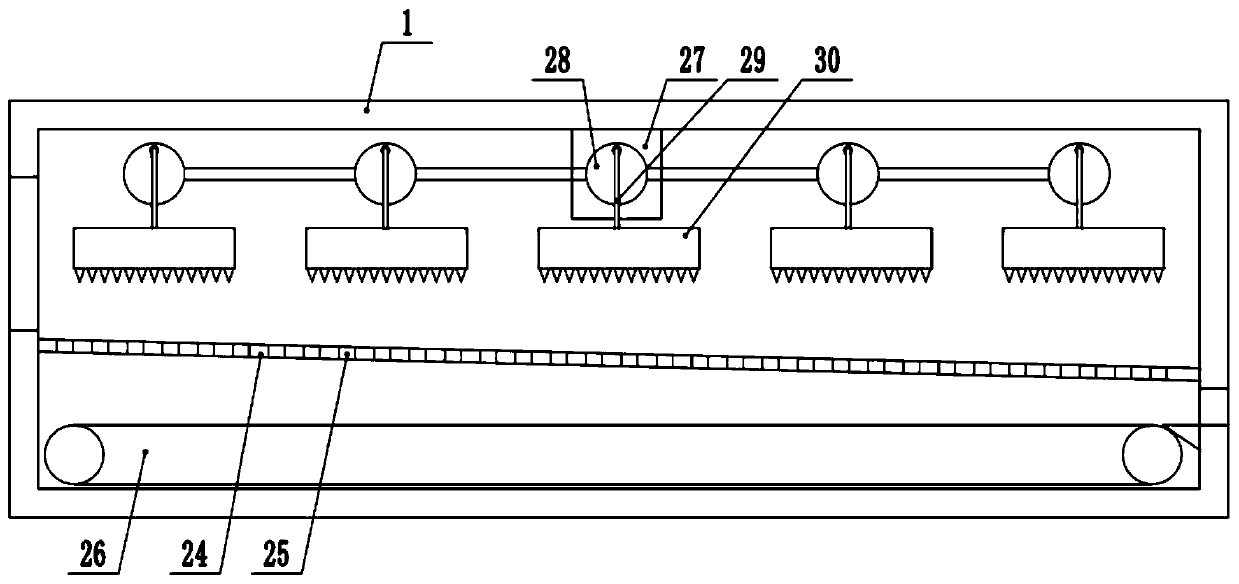

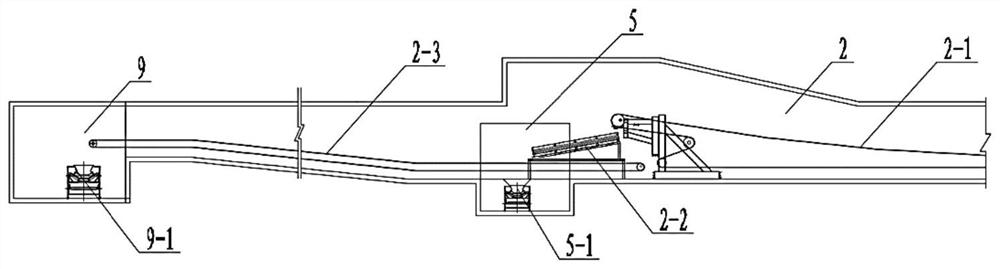

Smashing, screening and circulating coal feeding system

InactiveCN103292341AReduce insecuritySolve the problem of easy wear and tearLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationCoal briquetteThermodynamics

The invention relates to a smashing, screening and circulating coal feeding system which comprises a mixed coal bunker, a coal feeding material nozzle, an iron separator, a smasher and a number one coal feeding belt conveyor. The lower portion of the number one coal feeding belt conveyor is connected with the mixed coal bunker, the coal feeding material nozzle is positioned at the bottom of the mixed coal bunker, the lower portion of the coal feeding material nozzle is connected with the smasher, and materials after being processed are conveyed to a boiler by the belt conveyor. The smashing, screening and circulating coal feeding system is characterized in that a vibratory screening machine is additionally arranged at an outlet of the smasher, a material separating nozzle is arranged on the lower portion of the vibratory screening machine and connected with a number two below-screen belt conveyor, coal briquette with qualified granularity is conveyed to the boiler by the number two below-screen belt conveyor, materials on a screen of the vibratory screening machine are conveyed to a number three above-screen belt conveyor, and a hanging rack is arranged on the end portion of the number three above-screen belt conveyor. By the smashing, screening and circulating coal feeding system, resource waste caused by incomplete burning of large-sized coal is effectively reduced, burning efficiency of the coal briquette is improved, production cost of the boiler is reduced, and the problems of difficulty in raw coal separating and high load of the coal smasher are solved. The smashing, screening and circulating coal feeding system is suitable for closed cycle processes like smashing, screening, separating and the like of bulky materials.

Owner:TAIYUAN IRON & STEEL GROUP

Coal gangue detection method

ActiveCN111272784AThickness Accurately ObtainedSmall amount of calculationMaterial analysis by transmitting radiationCoal briquetteAttenuation coefficient

The invention provides a coal gangue detection method. By using an X-ray emitter, a receiver and a depth camera, the method comprises the following steps: processing a depth map obtained by a depth camera to obtain thickness information of a partial region in a visual range of the depth camera, selecting a plurality of points, performing curve fitting on the thickness information of the points andintensity information of X-rays obtained by an X-ray receiver by using a least square method, and distinguishing whether a target object is coal briquettes or gangue according to a fitting result. According to the method, the coal gangue is distinguished by virtue of the X-ray penetration characteristic of the coal gangue, the penetration characteristics of the coal gangue and the thickness of the coal gangue have a certain function relationship, the local thickness information of the coal gangue is obtained by adopting a depth camera, and then the thickness information of a plurality of target points and the penetration information of the X-rays at the corresponding positions are combined to solve the energy attenuation coefficient of the target so as to distinguish the coal or the coalgangue.

Owner:XI AN JIAOTONG UNIV

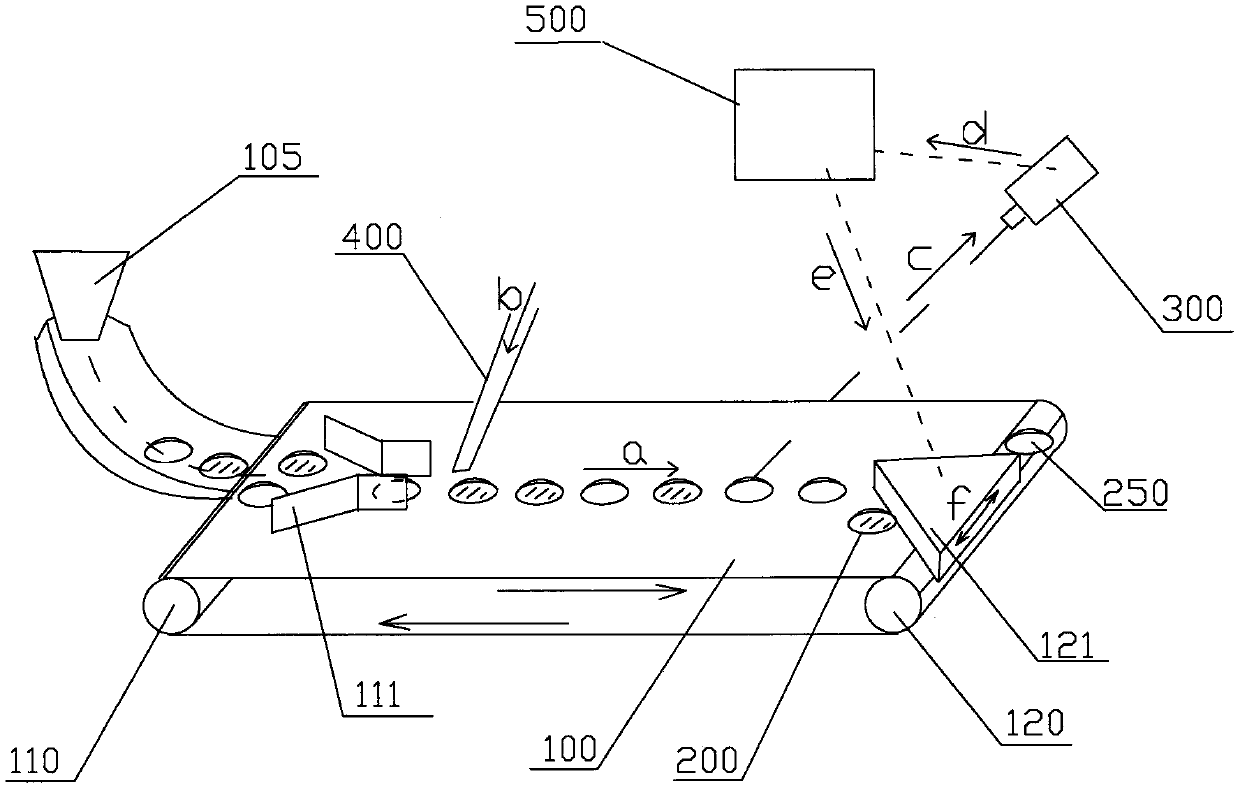

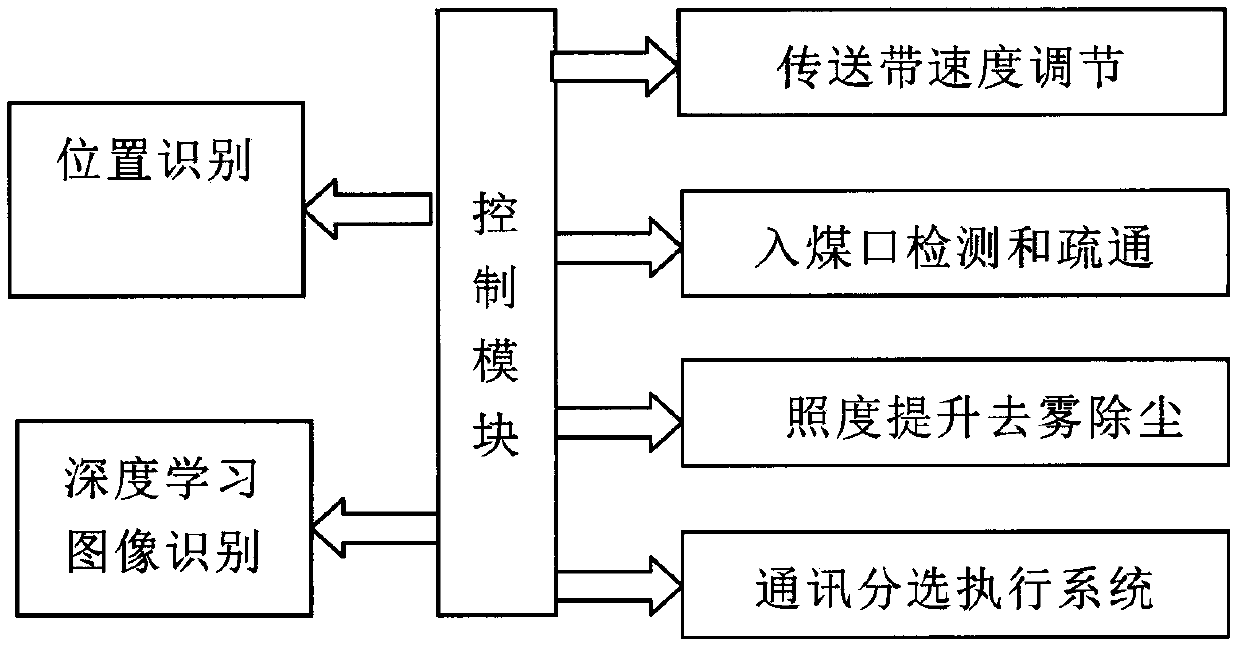

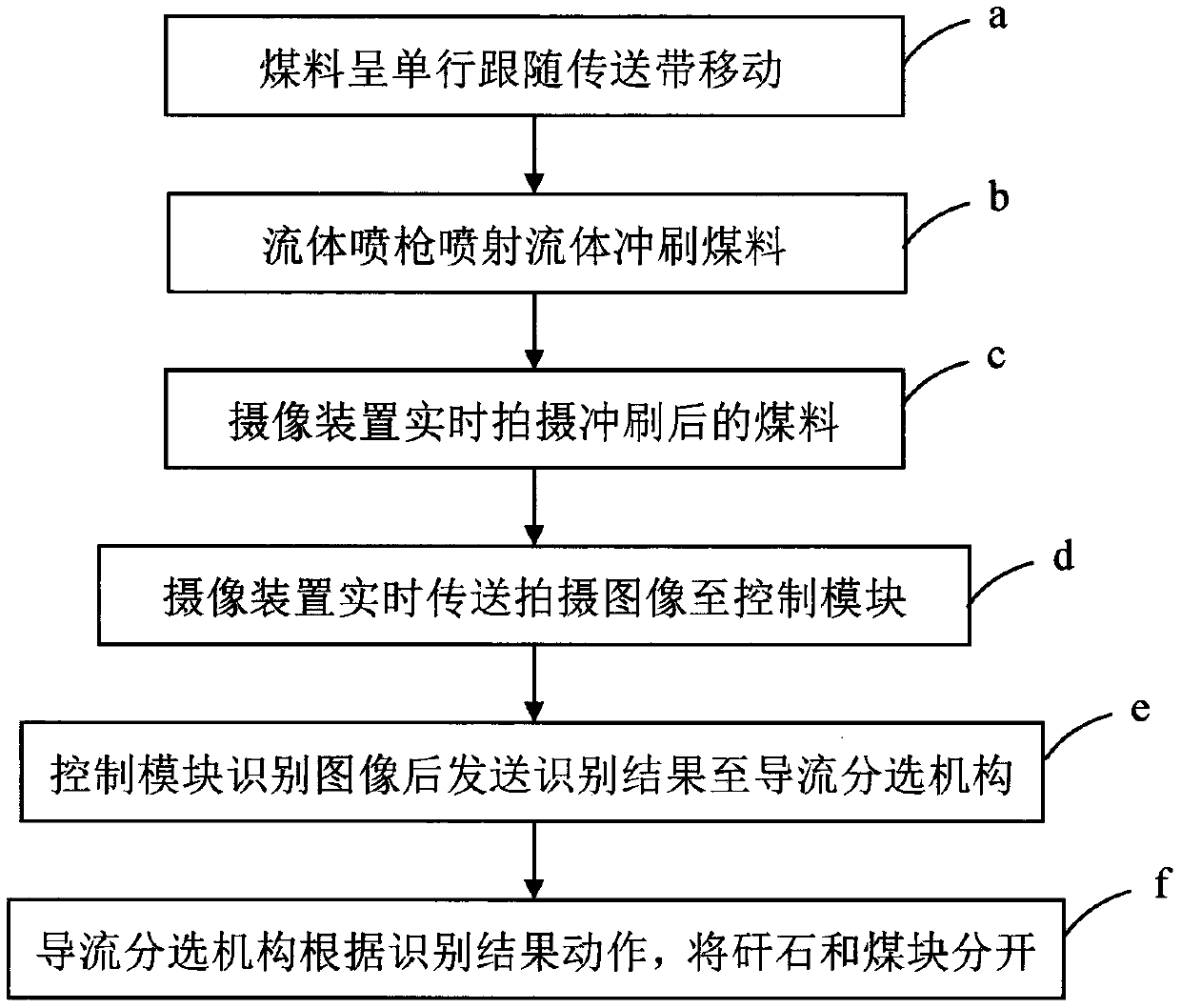

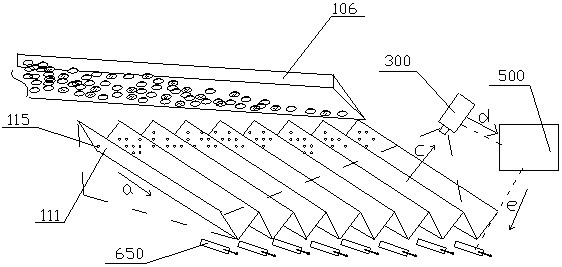

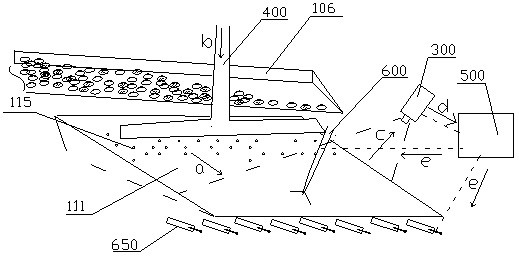

Coal dressing system and method based on artificial intelligence image recognition

The invention discloses a coal dressing system and method based on artificial intelligence image recognition. A conveying belt is arranged, coal materials move along with the conveying belt in a single-row mode, in the moving process, coal ash on the coal materials is washed by a spray gun, part of the solid surface is exposed, a camera device shoots and sends shot images to a control module in real time, gangue and coal briquettes are recognized in real time through an artificial intelligence image recognition technology, then a flow guide sorting mechanism on the downstream of the conveyingbelt is controlled to act, and the gangue and the coal briquettes are separated. The coal ash on the coal materials is washed by arranging the spray gun, so that the visual discrimination degree of the coal and the gangue is increased; then the gangue and the coal briquettes are recognized by applying the artificial intelligence visual image recognition technology of deep learning, so that the accuracy of machine vision recognition can be greatly improved, the sorting precision is high, the equipment cost is low, the processing particle size is wide, the processing capacity is high, most of manual work can be replaced, the labor cost is saved, the coal mine pollution and water consumption are reduced, and the coal loss is reduced; and the system and method are beneficial to being deployedunderground, the gangue well outlet amount is effectively reduced, and environmental protection is facilitated.

Owner:郑鸿

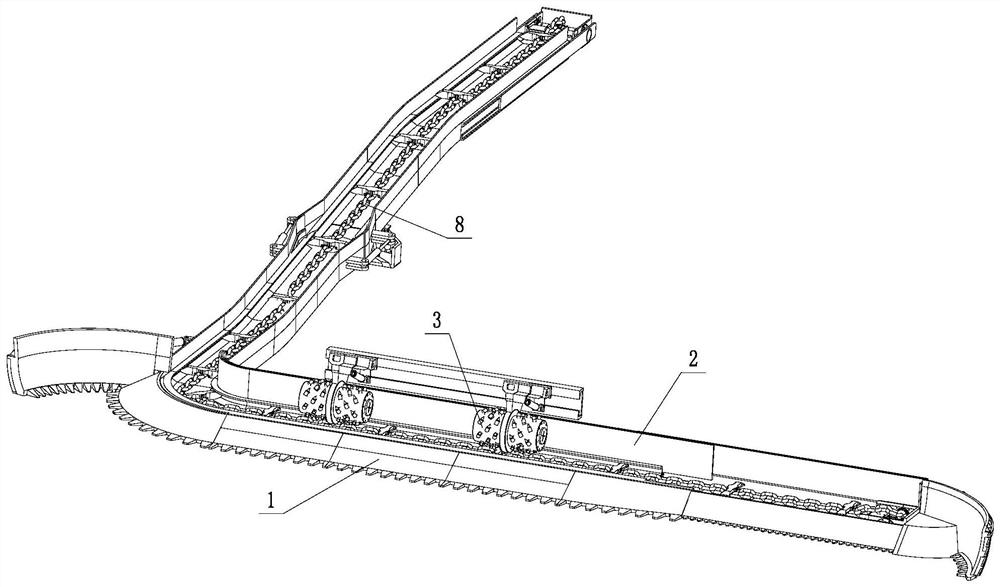

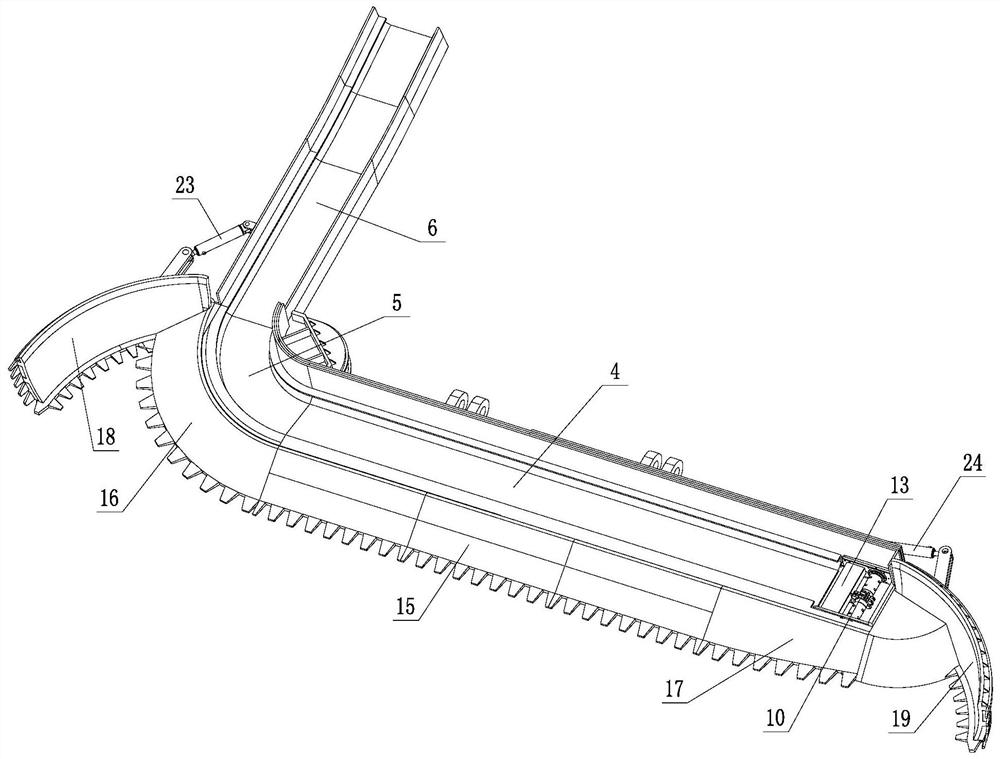

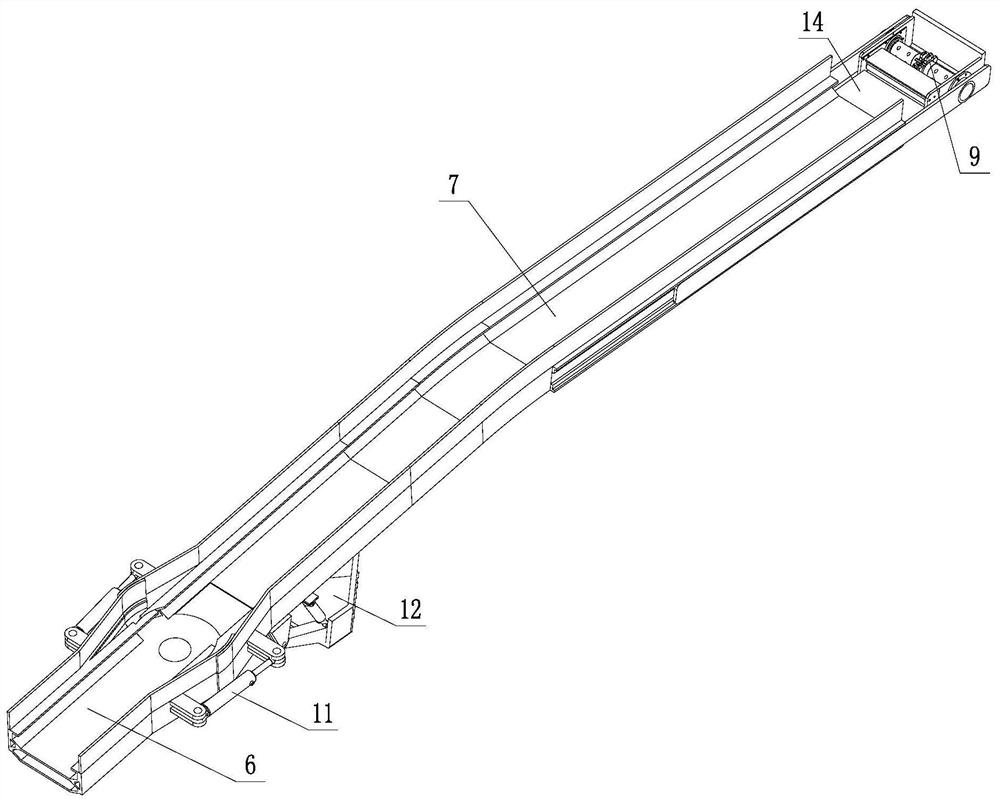

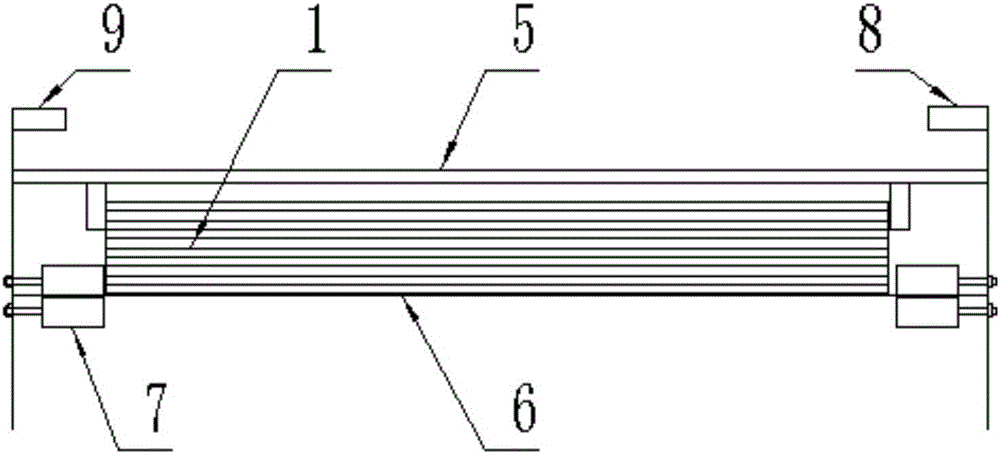

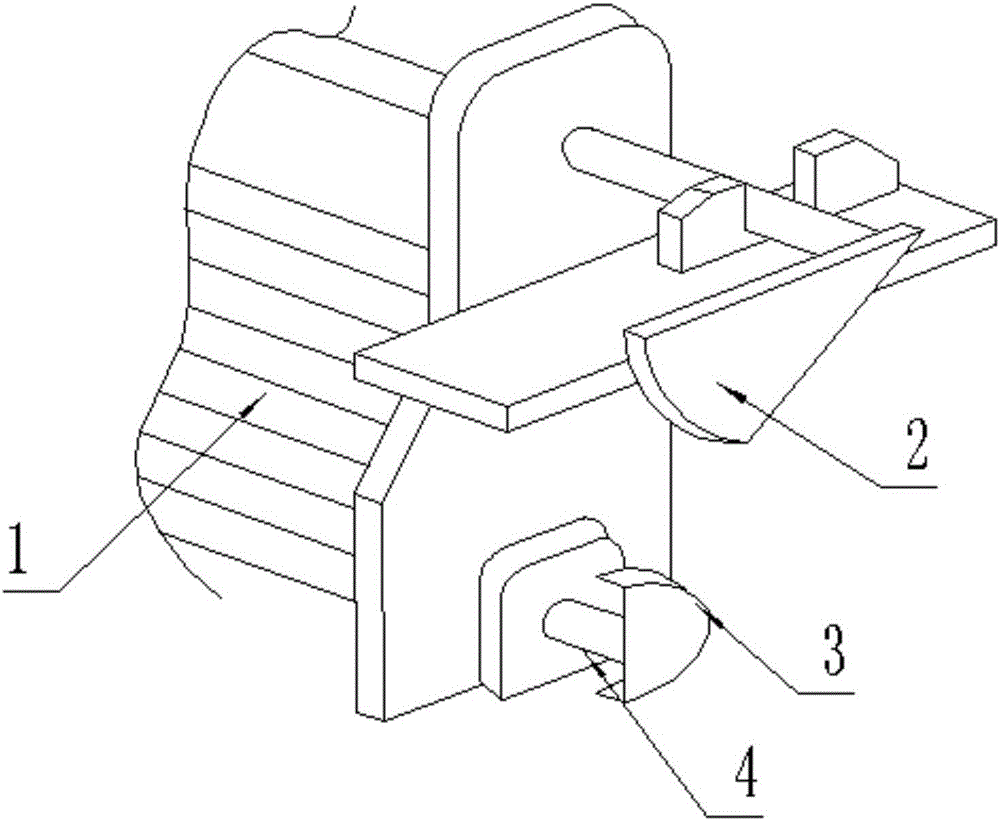

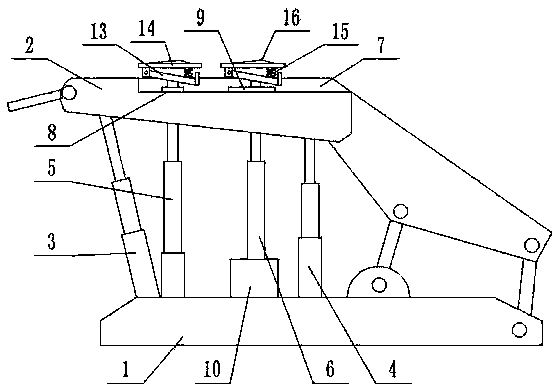

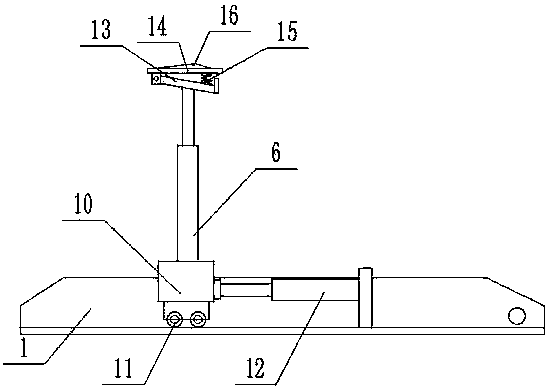

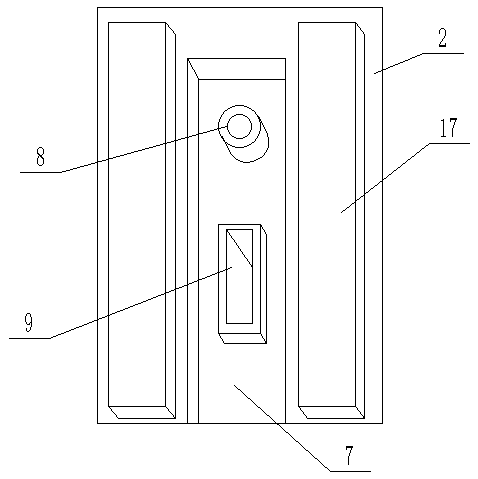

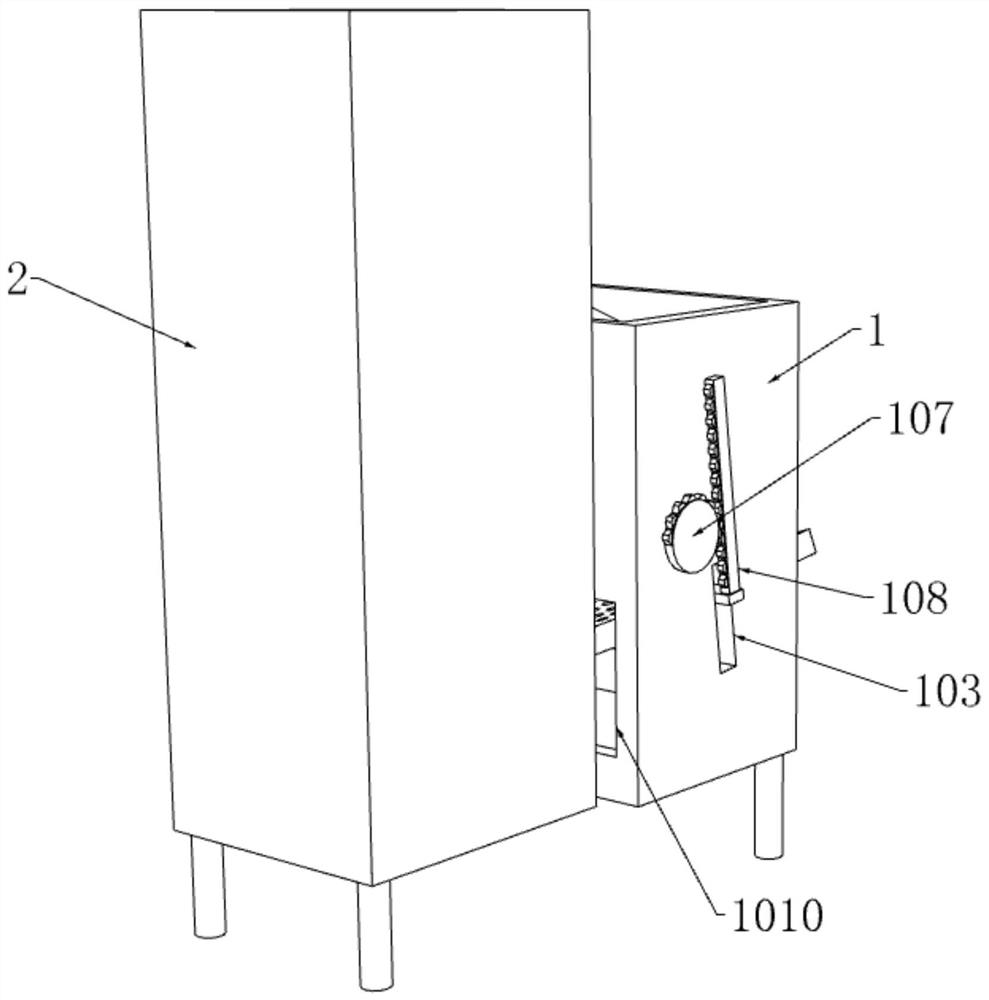

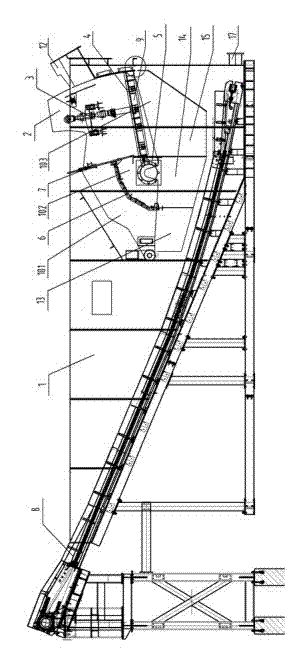

Full-section shoveling and recycling device for digging, supporting and anchoring combined unit and using method

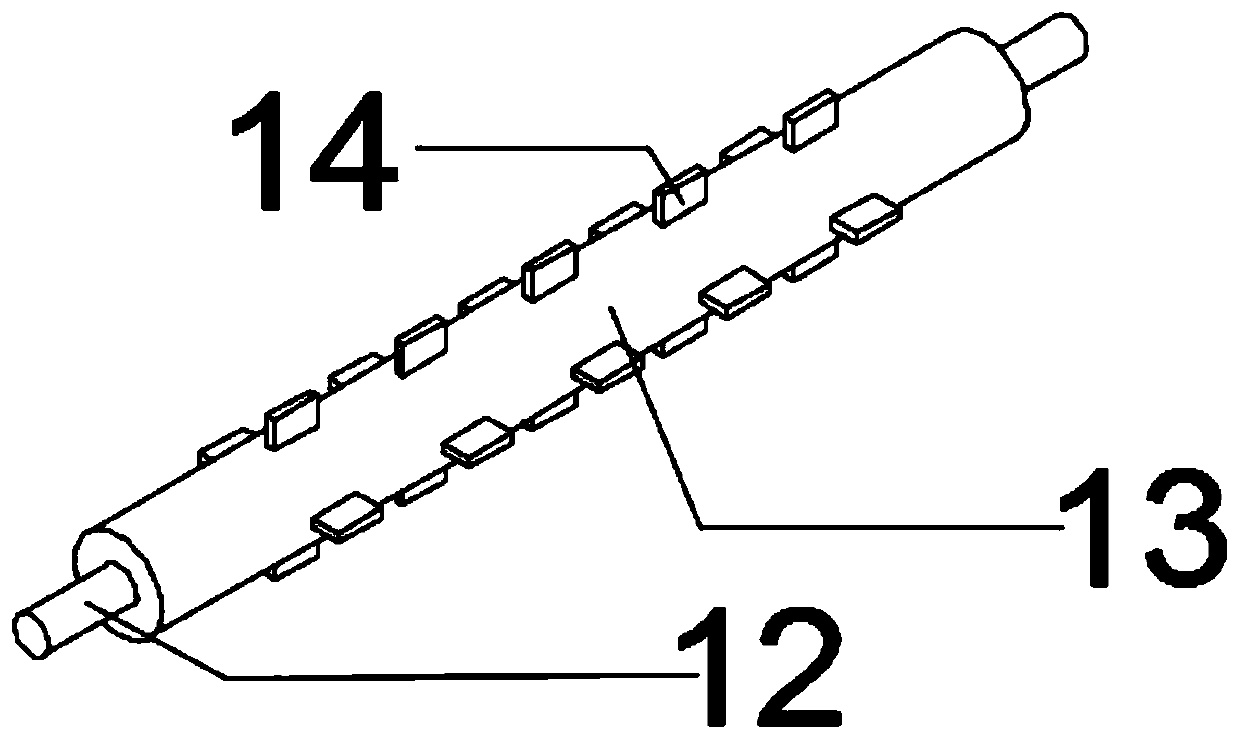

PendingCN112594001AGuaranteed tensionIncrease flexibilityMining devicesUnderground miningCoal briquetteChain link

The invention discloses a full-section shoveling and recycling device for a digging, supporting and anchoring combined unit and a using method. The full-section shoveling and recycling device comprises a shoveling plate mechanism, a conveying mechanism and an auxiliary crushing mechanism; the conveying mechanism is of a right-angle turning type structure, one supporting arm of the conveying mechanism is located at the front end of the digging, supporting and anchoring combined unit, and the other supporting arm is located on the side of the digging, supporting and anchoring combined unit; theshoveling plate mechanism is located in front of the digging, supporting and anchoring combined unit and arranged at the front end of the conveying mechanism; and the auxiliary crushing mechanism is located above the shoveling plate mechanism and arranged at the front end of the digging, supporting and anchoring combined unit. The using method comprises the steps that falling coal on the two sidesof a roadway is pushed to the shoveling plate mechanism through inward overturning of an auxiliary shovel plate, and the falling coal enters the conveying mechanism through the shoveling plate mechanism to be conveyed outwards; the extension amount of transverse telescopic end grooves is adjusted to adapt to the width of the roadway, and the extension amount of longitudinal telescopic end groovesis synchronously adjusted to maintain the tensioning state of a scraper chain; the pitching angle of an adjustable shovel plate head is adjusted to adapt to the gradient; the turning radius of the equipment is reduced by adjusting the swing angle of tail swing type conveying grooves to adapt to the turning working condition; and the size of coal briquettes is reduced through a crushing roller.

Owner:LIAONING TECHNICAL UNIVERSITY

Conveying belt tearing detecting device and method

The invention discloses a conveying belt tearing detecting device and method. The conveying belt tearing detecting device comprises a roller barrel, a swing shaft, a swing angle detecting sheet, a revolution number detecting sheet and a belt conveyor controller; the roller barrel is connected with the swing shaft through fixing plates on the two sides, the roller barrel can rotate around a center shaft connected with the fixing plates and enables the swing shaft to rotate through the fixing plates, and the revolution number detecting sheet is arranged at the head of the center shaft of the roller barrel; and the swing angle detecting sheet is arranged at the head of the swing shaft, the revolution number detecting sheet and the swing angle detecting sheet are each connected with the belt conveyor controller through a proximity switch. By means of the conveying belt tearing detecting device, continuously-falling coal and coal briquettes occasionally falling during normal work can be distinguished, and error alarming for mechanical vibration generated during work of a belt conveyor cannot be generated.

Owner:安徽智崎环保设备有限责任公司

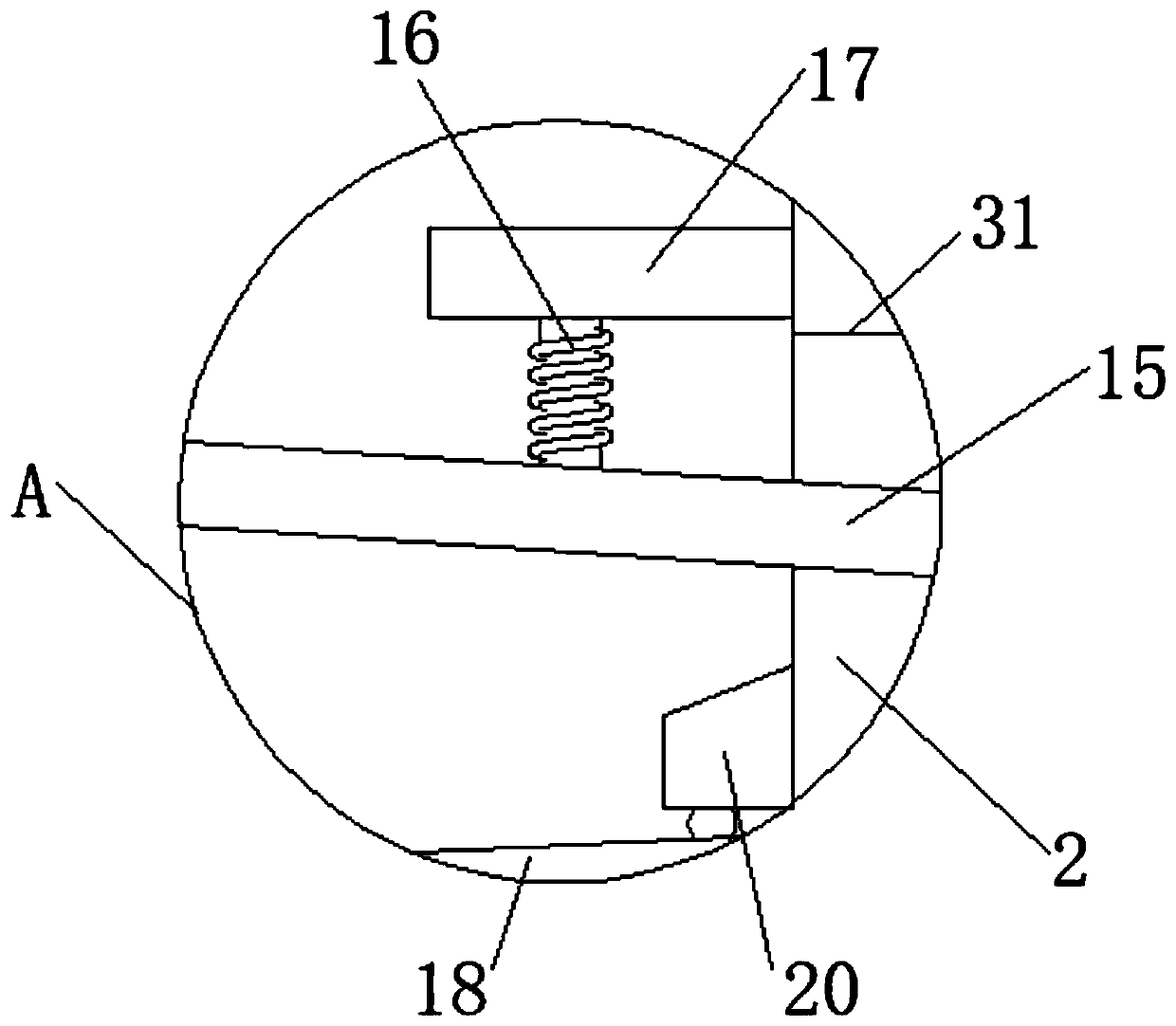

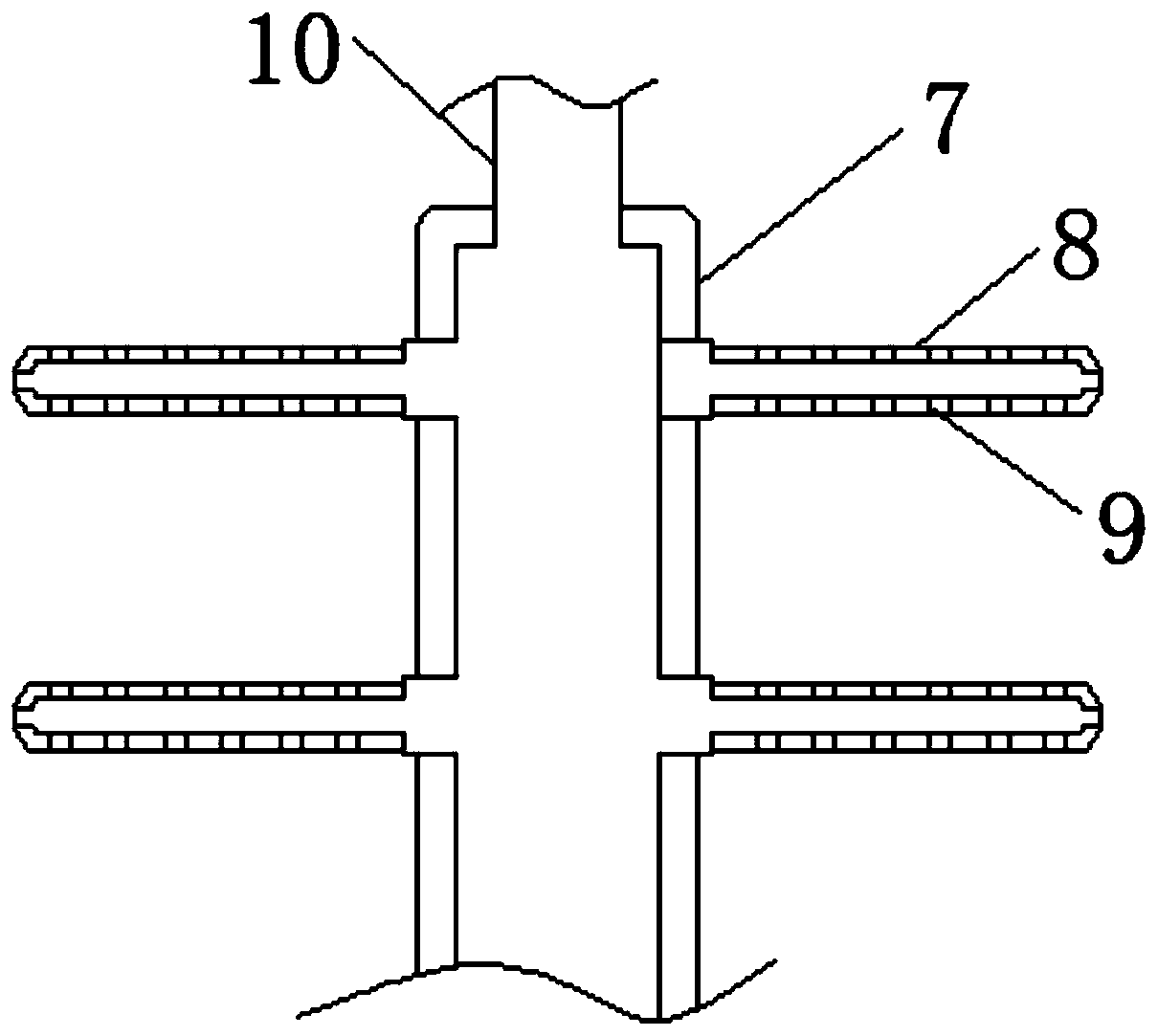

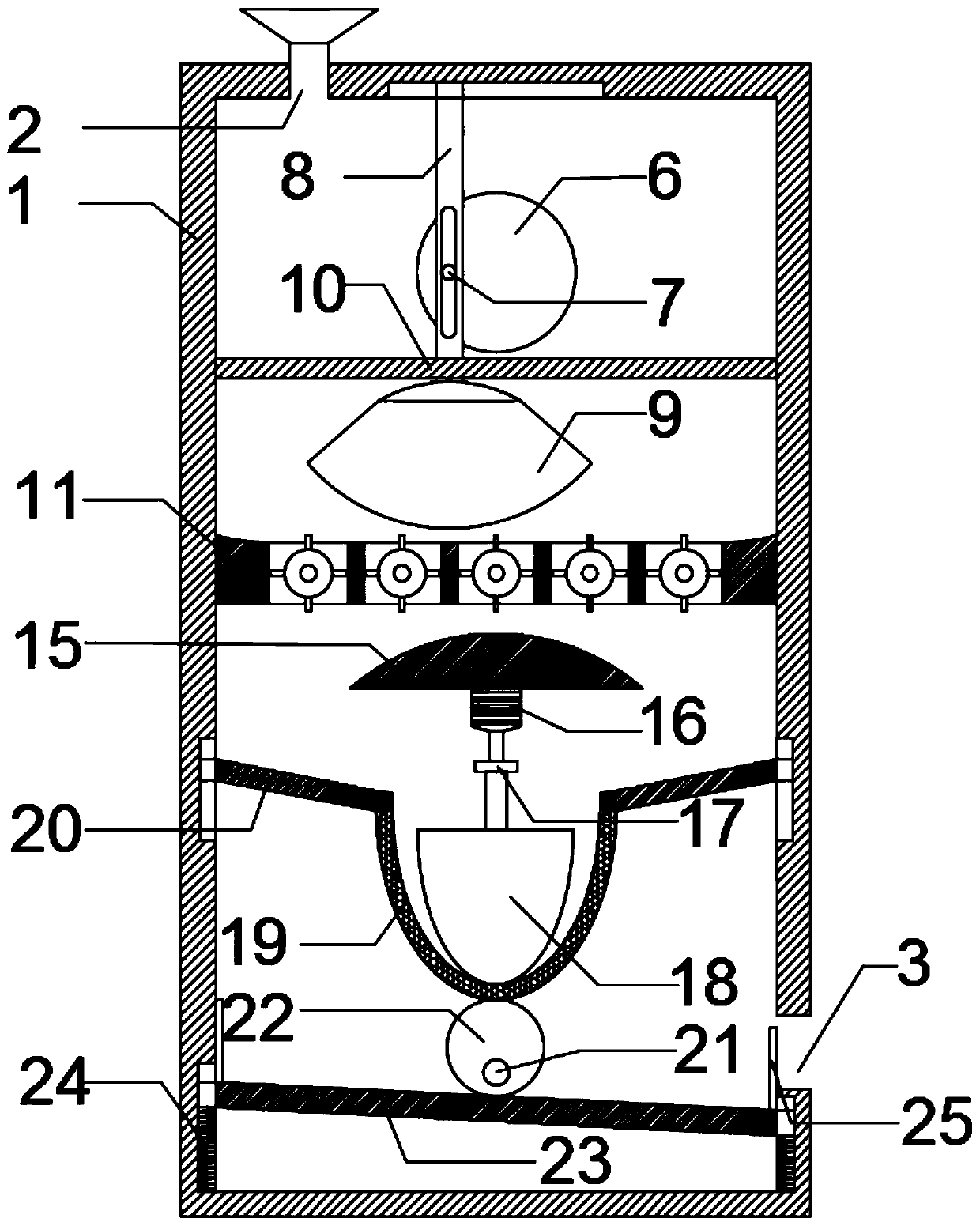

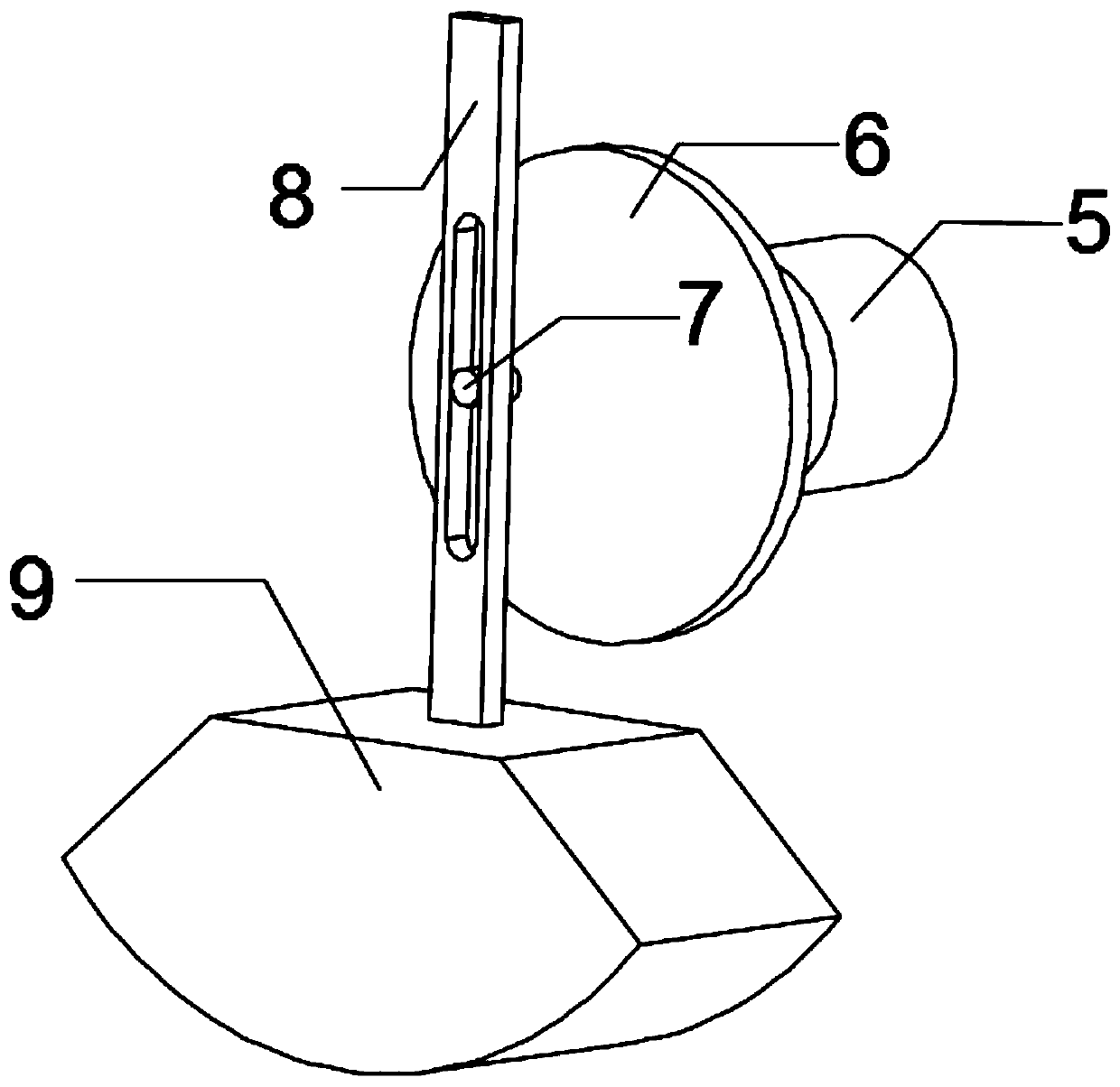

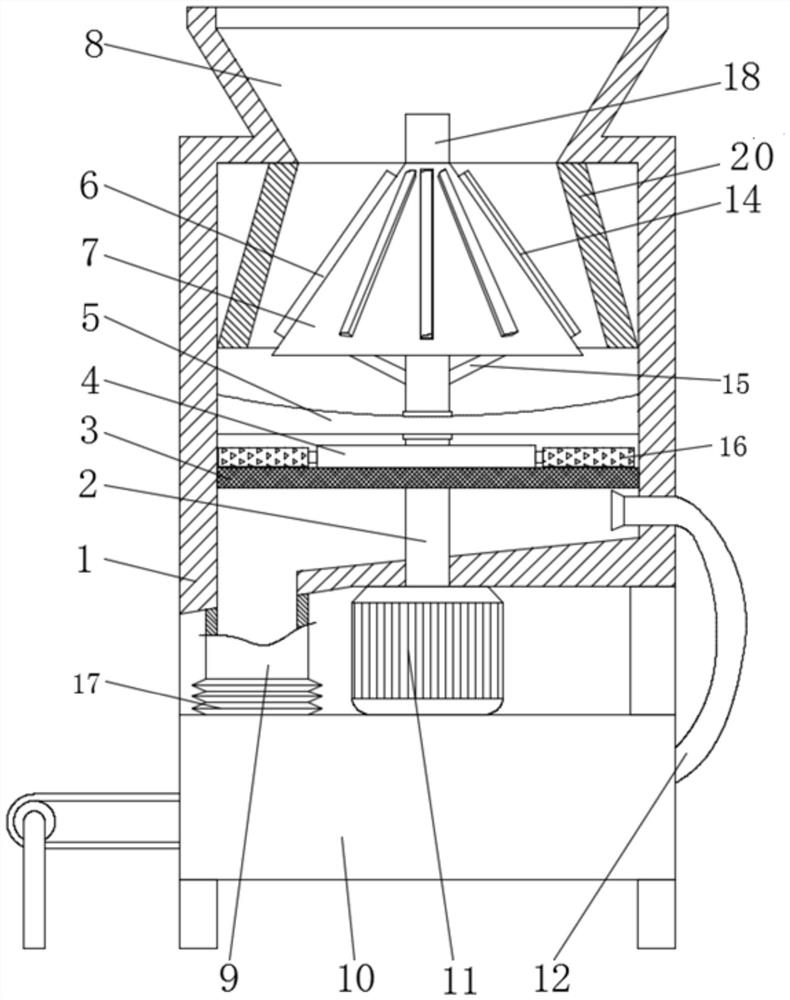

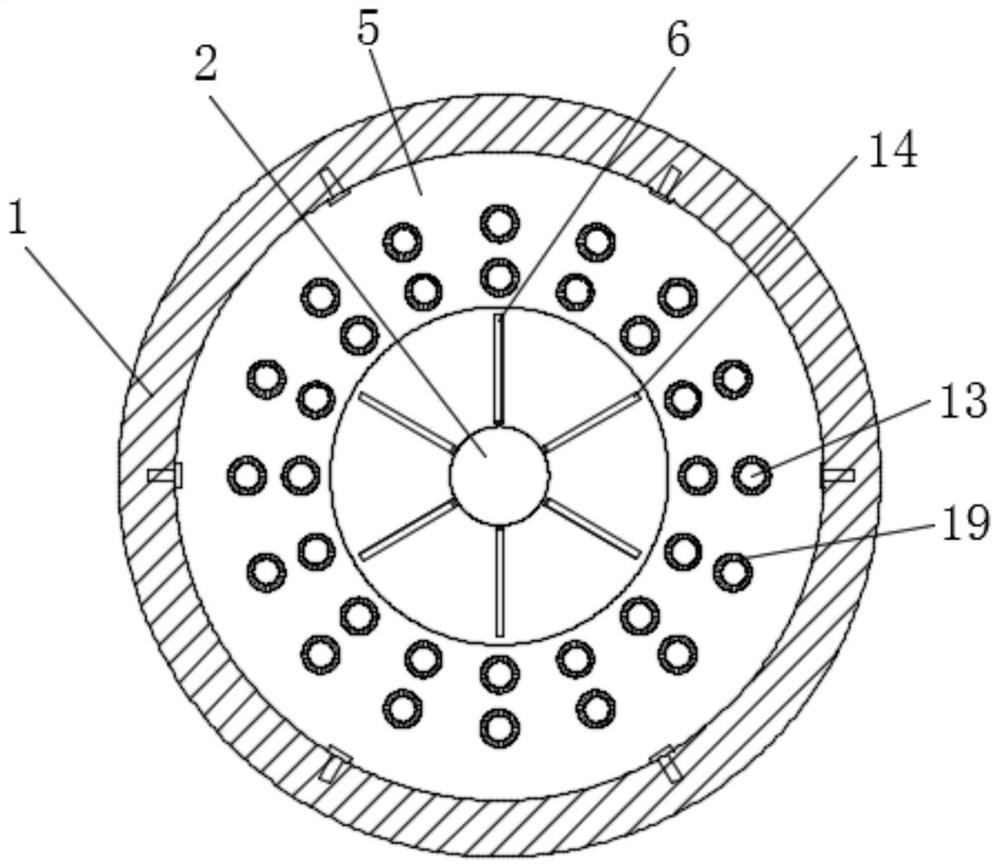

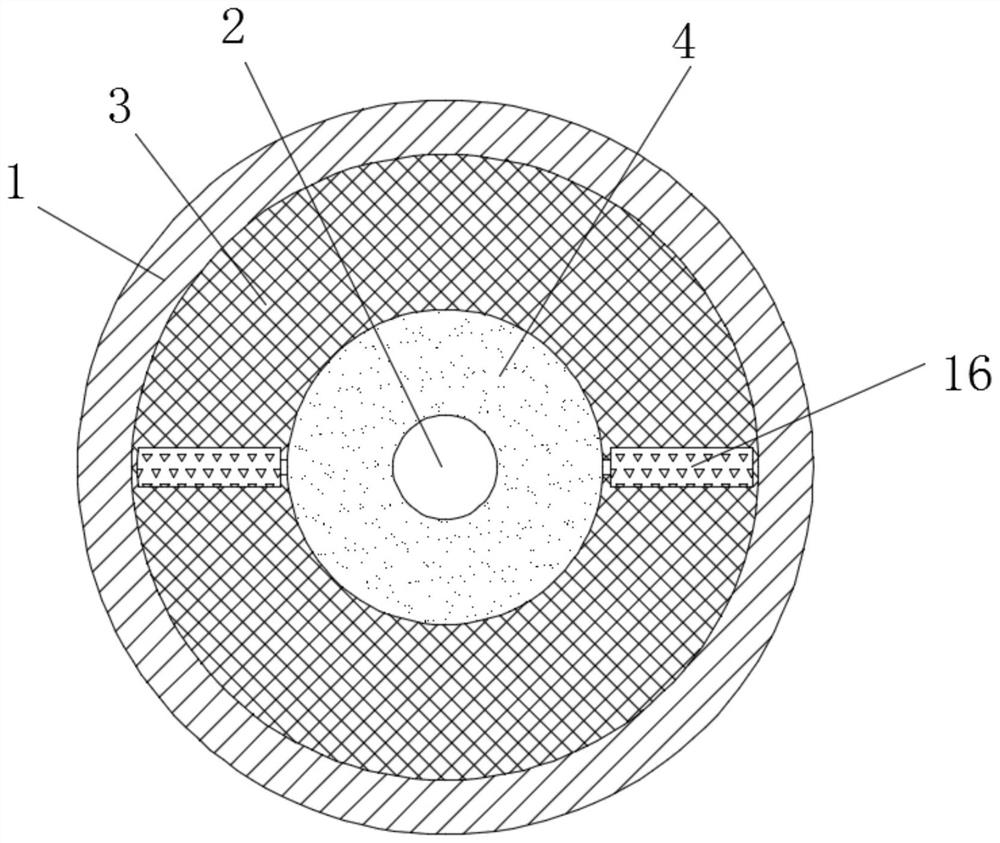

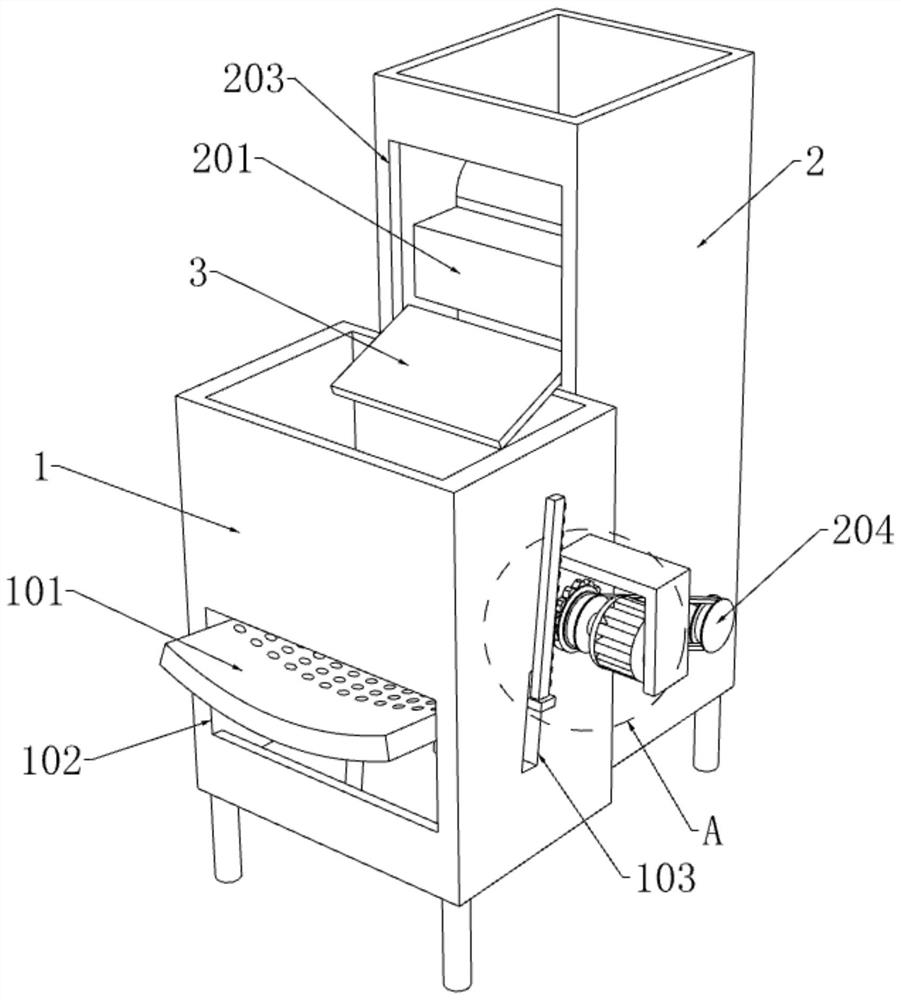

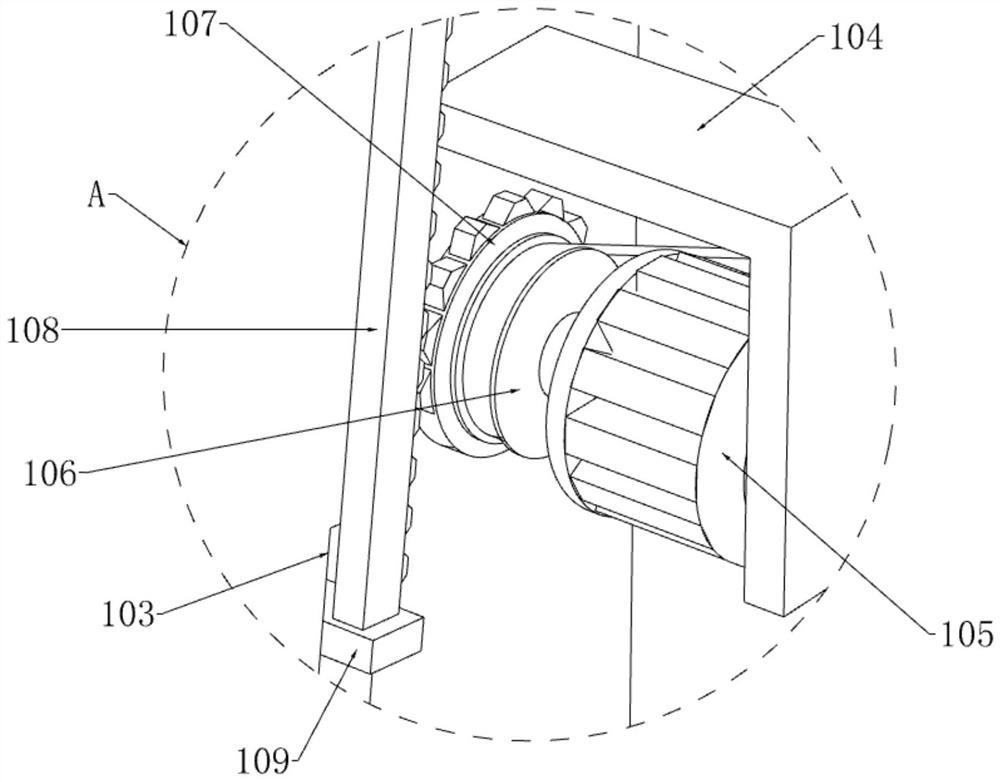

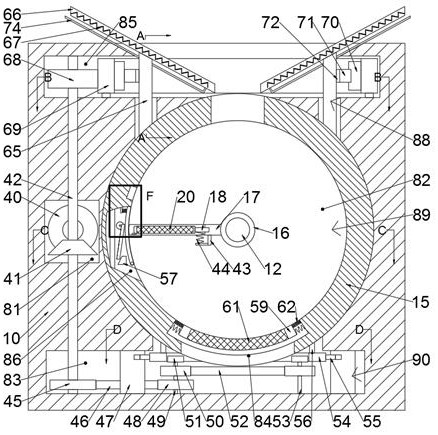

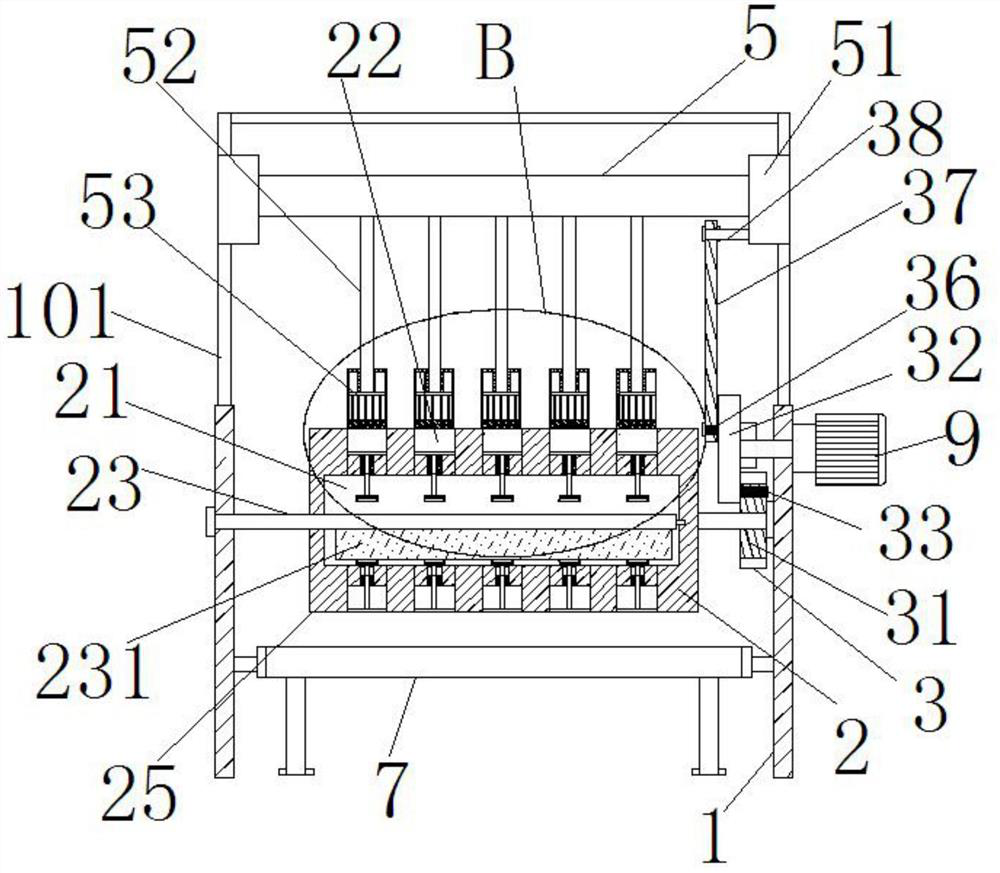

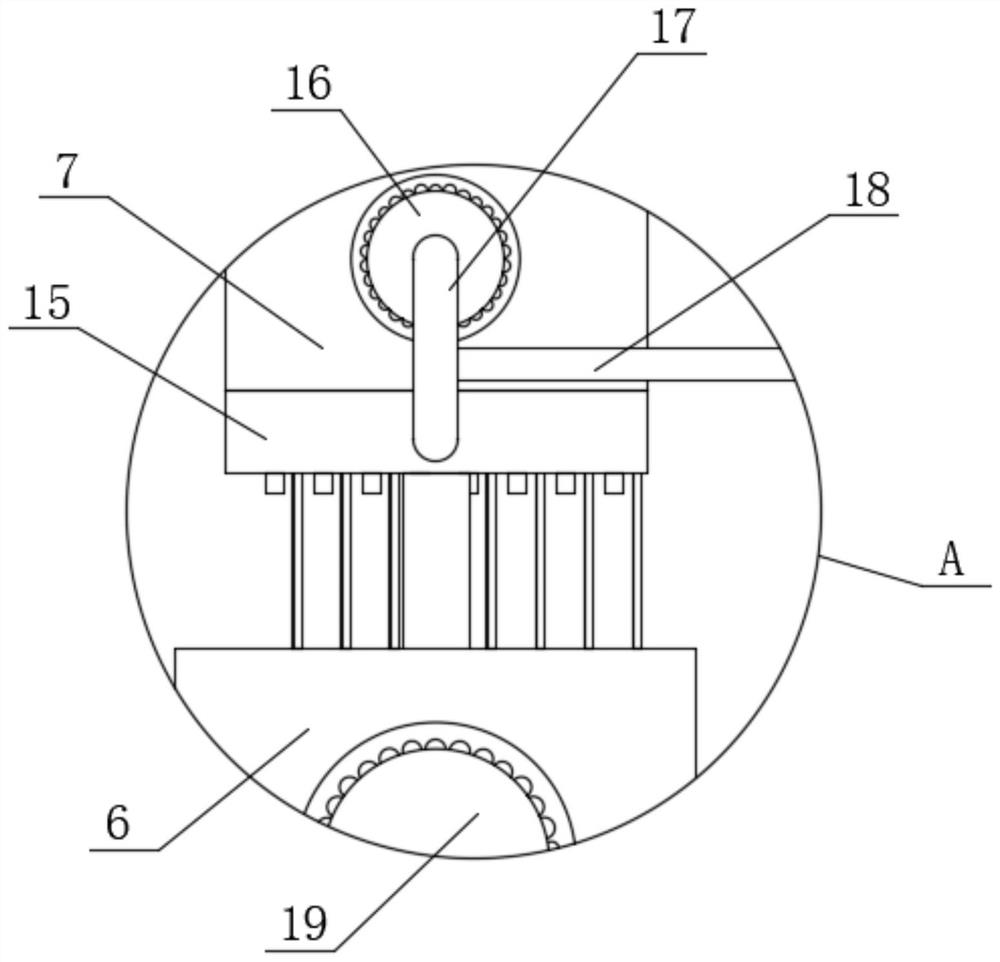

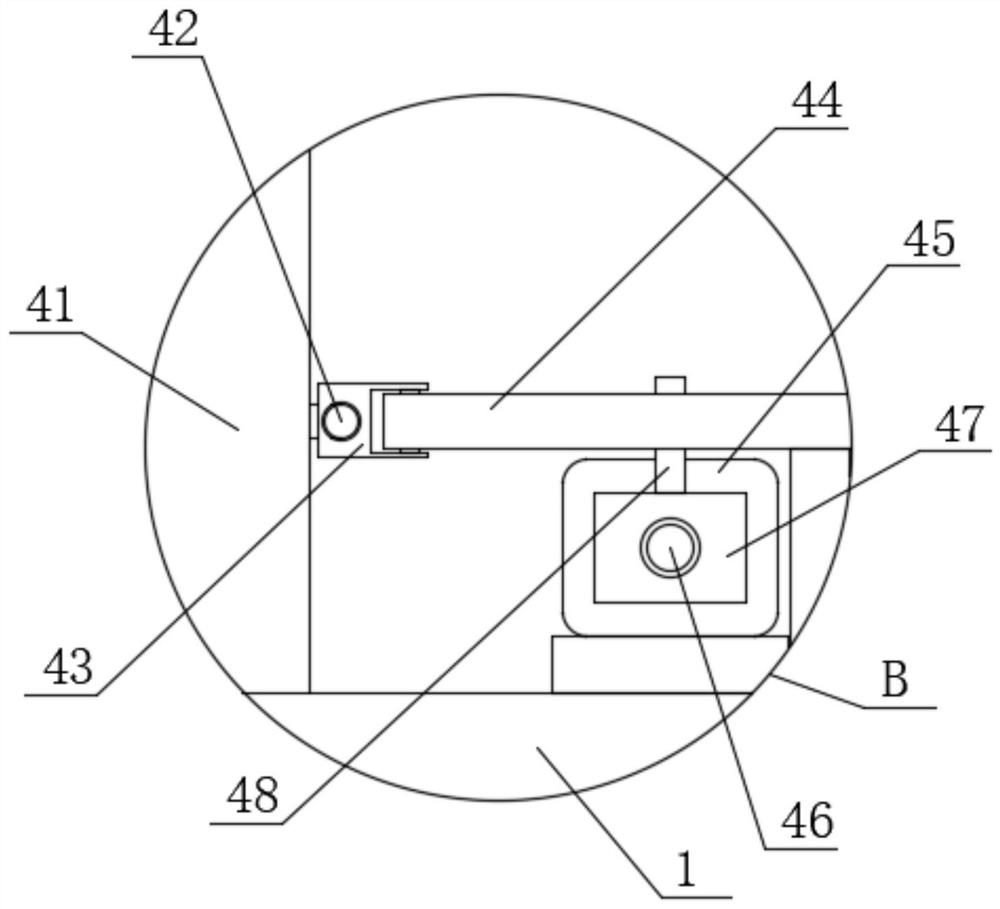

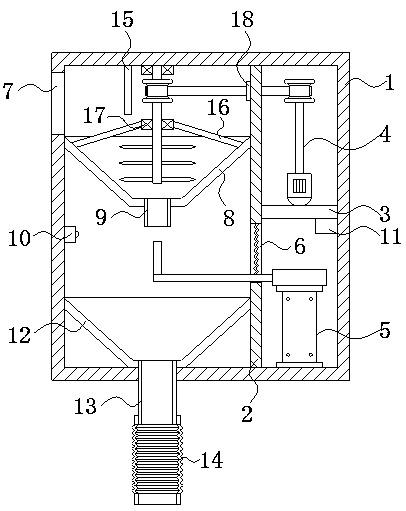

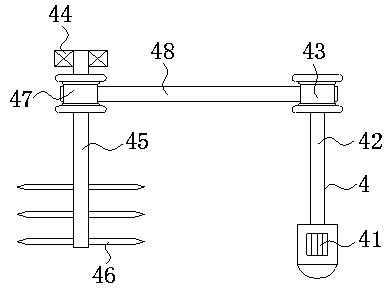

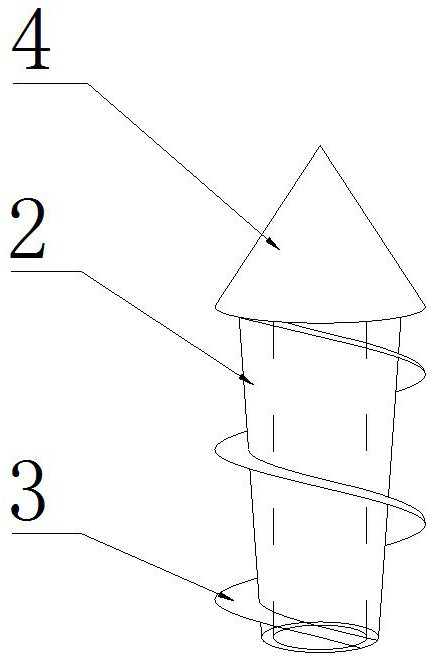

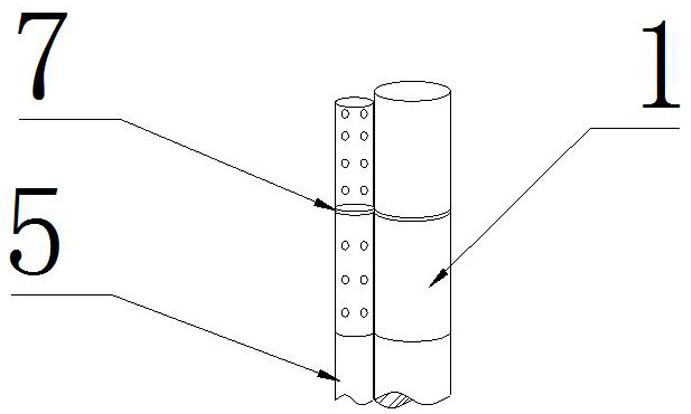

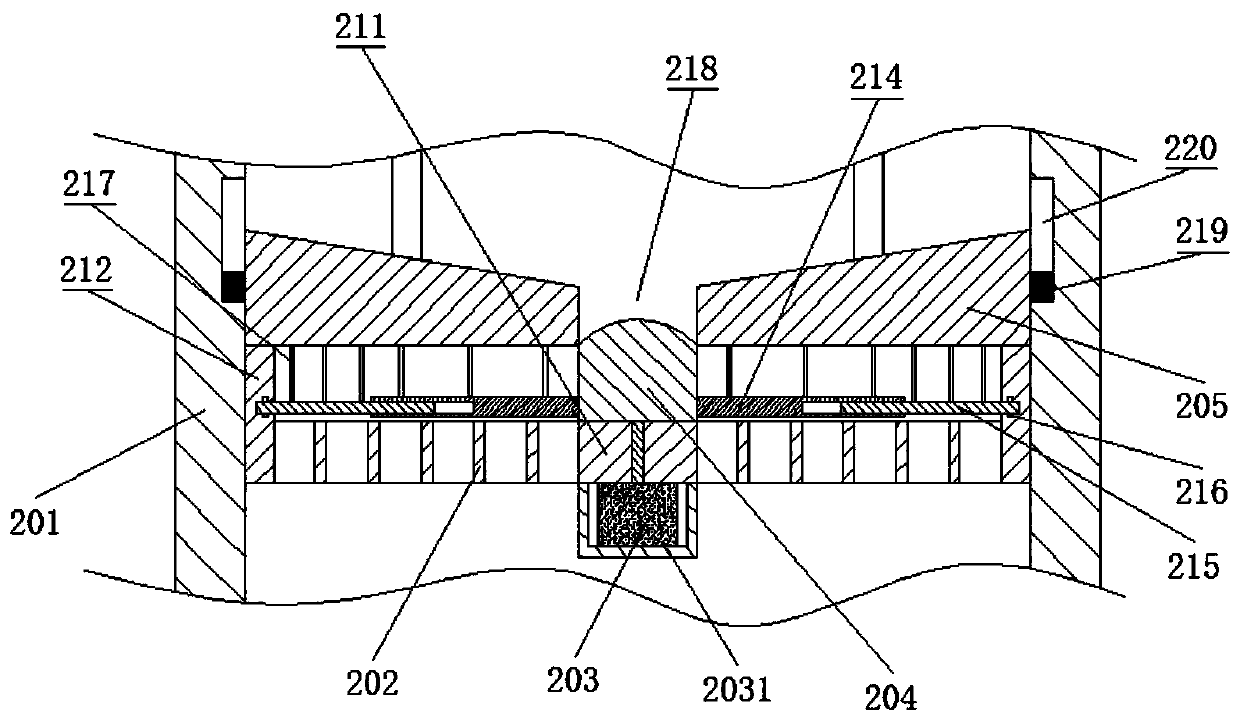

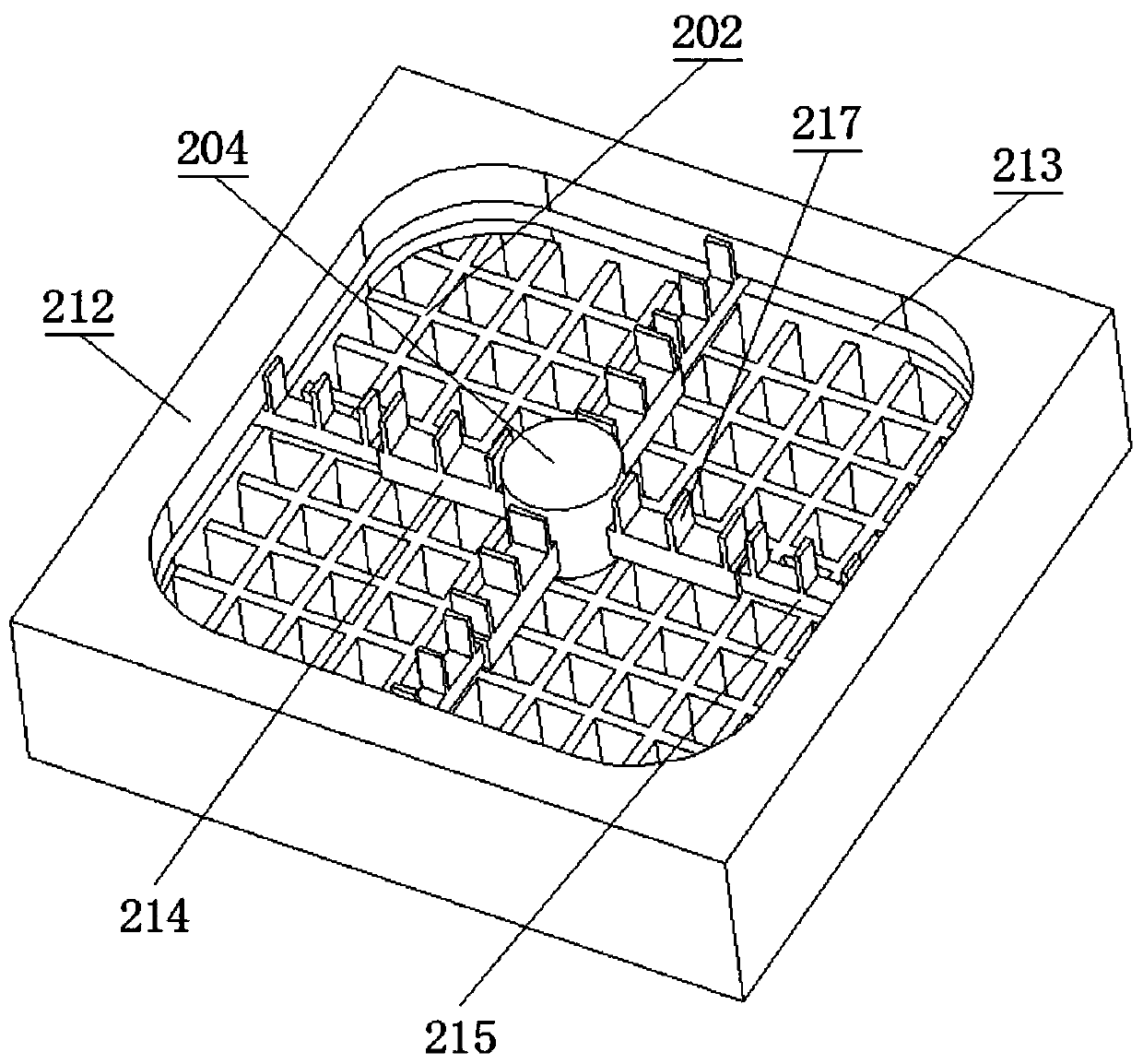

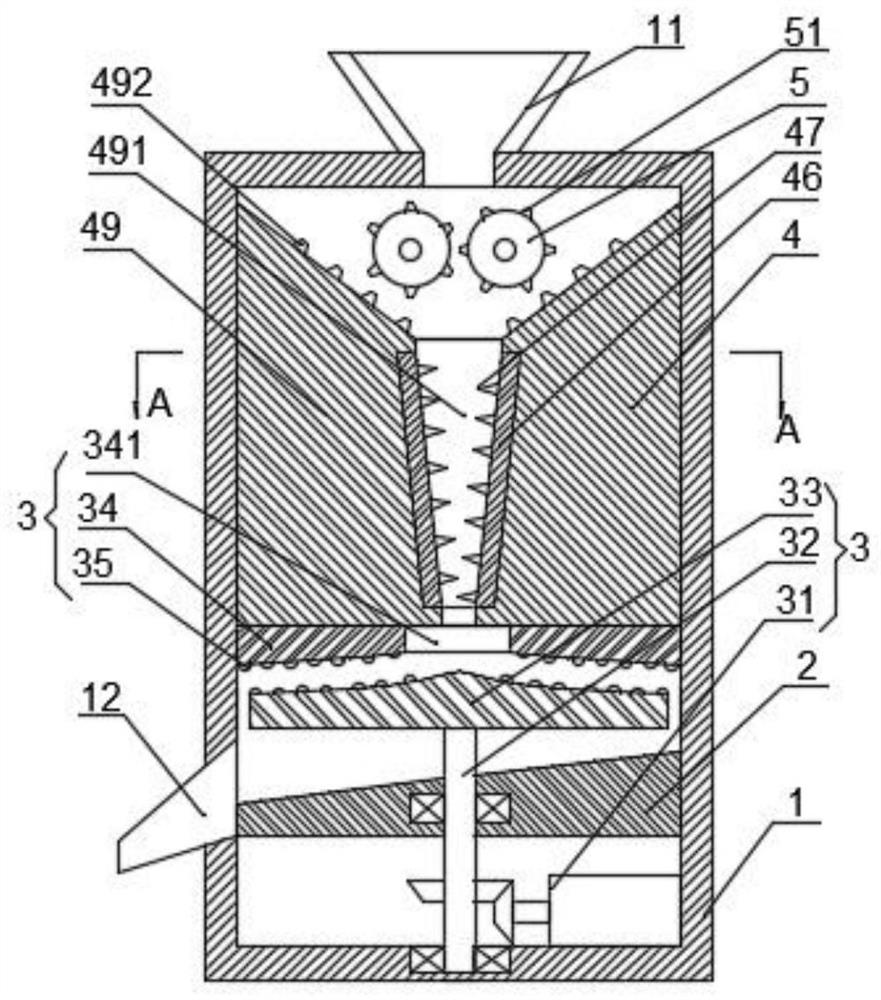

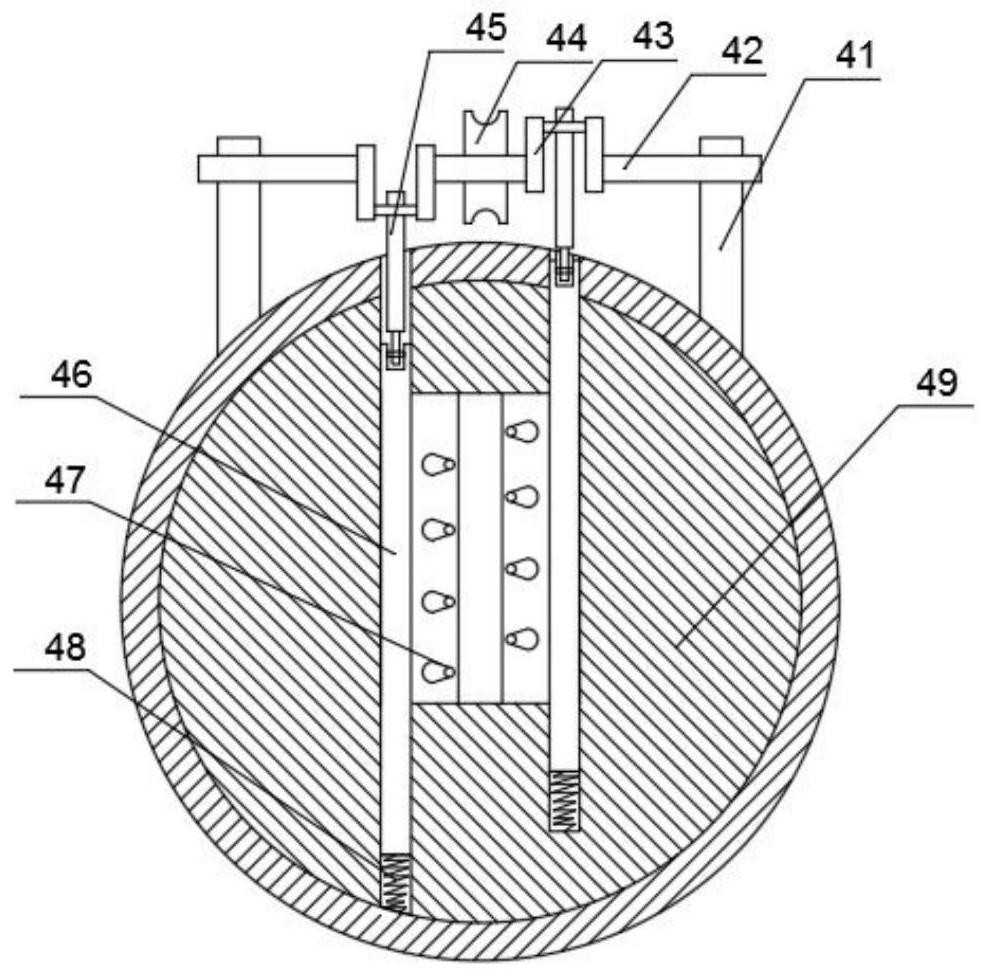

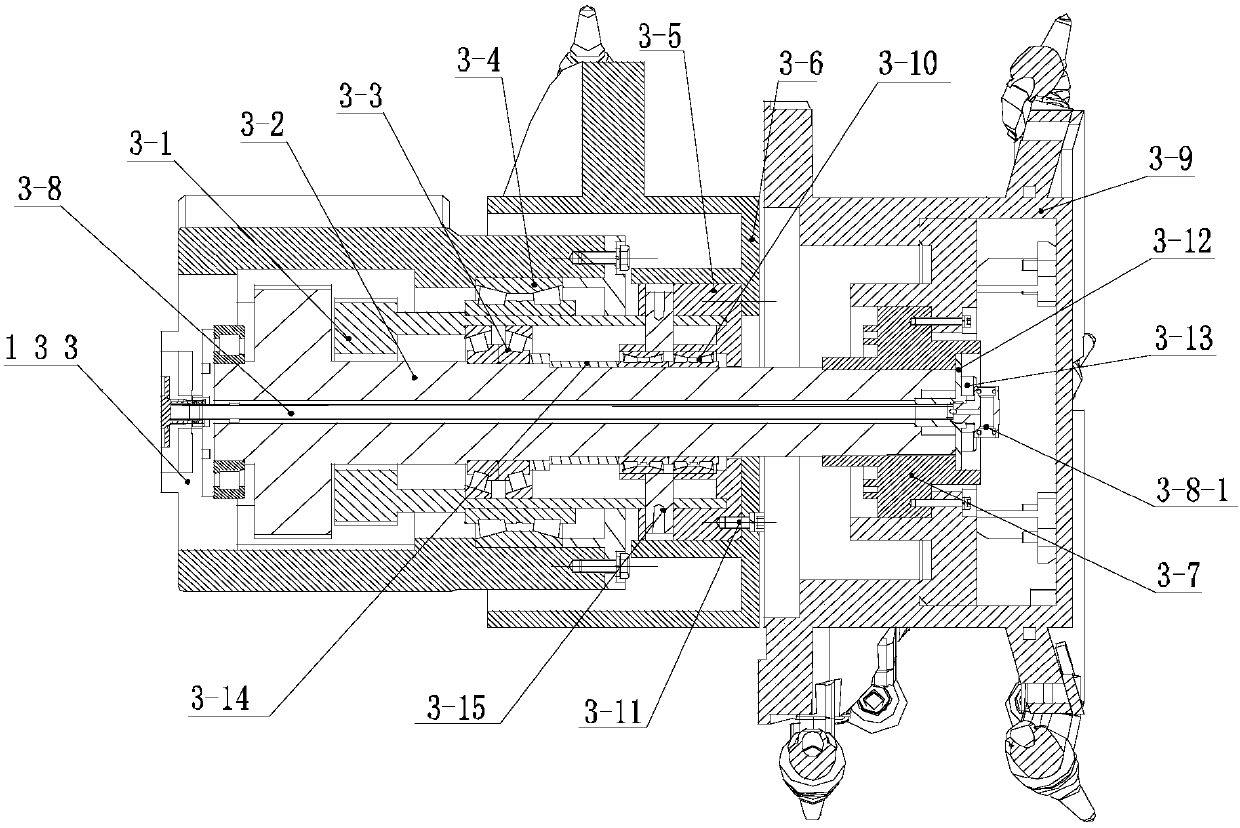

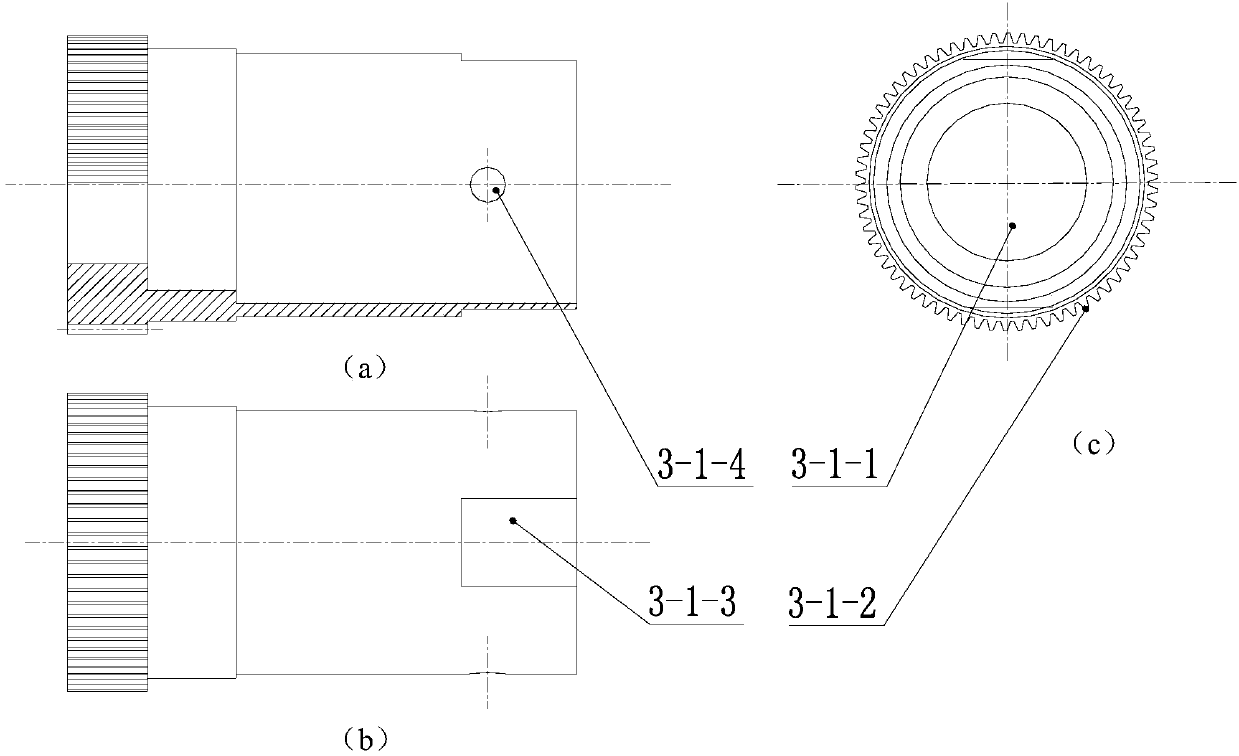

Coal briquette crushing device used for coal mining

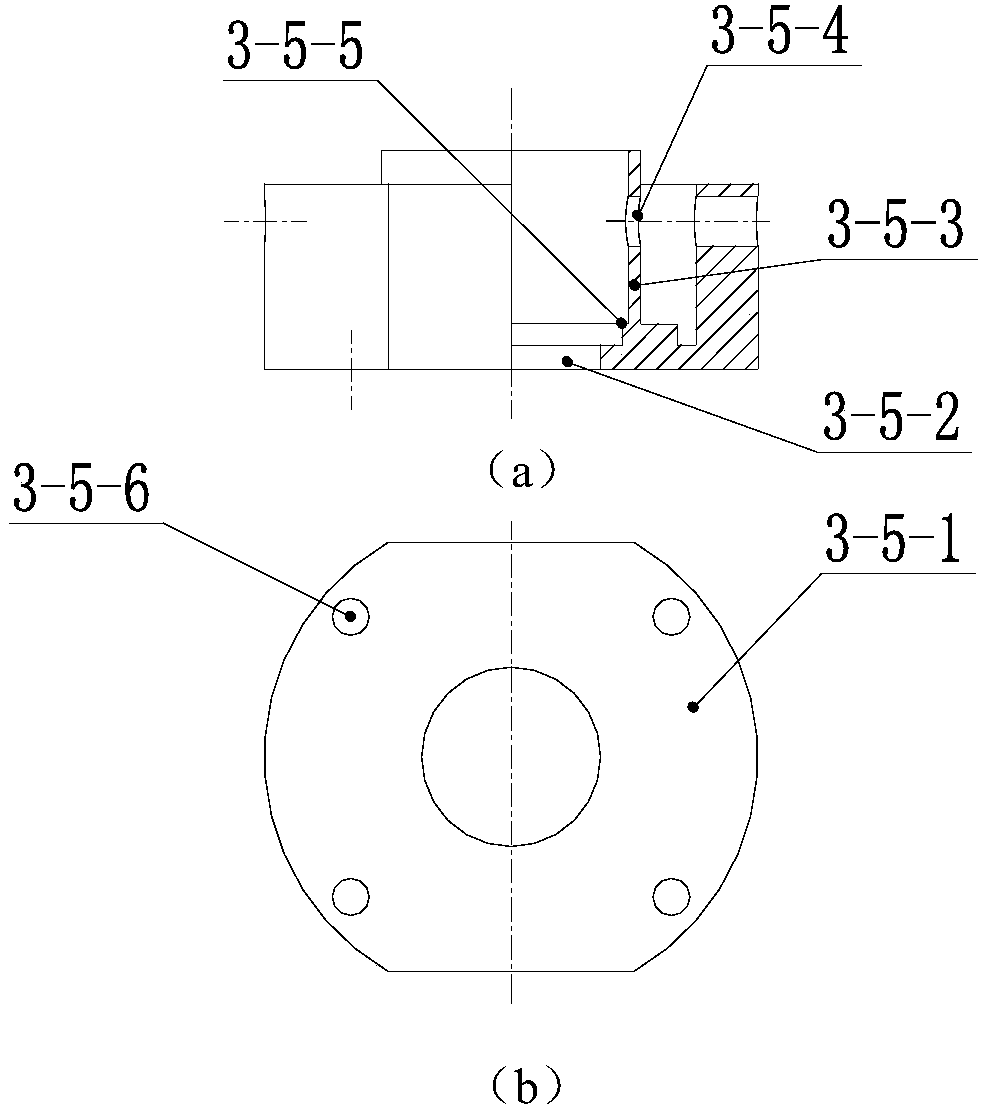

InactiveCN113856871ASmooth crushing processIncrease the degree of pre-grindingSievingScreeningCoal briquetteBriquetage

The invention discloses a coal briquette crushing device used for coal mining. The coal briquette crushing device comprises a machine body, a crushing cavity is formed in the upper portion of the machine body, a center shaft is rotationally installed at the bottom of the crushing cavity, a filter screen, a grinding plate, a filter plate and a pre-crushing cone are sequentially installed on the center shaft from bottom to top, the filter screen and the filter plate are fixedly installed on the inner wall of the crushing cavity, the middles of the filter screen and the filter plate are movably connected with the center shaft through lantern rings, the grinding plate and the pre-crushing cone are fixedly connected with the center shaft, adjustable crushing cutters and fixed crushing cutters which are distributed in a staggered manner are installed on the pre-crushing cone, and a coaxial inverted-cone-shaped impact baffle is installed on the outer side of the pre-crushing cone. By means of the coal briquette crushing device , the pretreatment degree is adjustable; the pre-crushing degree to coal briquettes is improved to a great degree, and the pretreatment efficiency is improved; and dust raising during crushing is reduced, the situation of coal briquette blockage is reduced as much as possible in the crushing process, the blocking phenomenon is reduced, and the coal briquette crushing efficiency is improved.

Owner:中煤西安设计工程有限责任公司

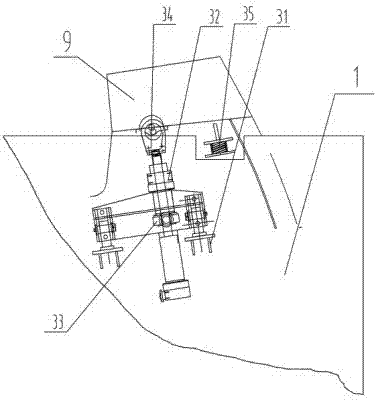

Crushing device of top coal caving hydraulic support

ActiveCN110748364APromote fragmentationAvoid smashingSlitting machinesProps/chocksBriquetageHard coal

The invention provides a crushing device of a top coal caving hydraulic support. The crushing device of the top coal caving hydraulic support comprises a base, an ejecting beam, a front telescopic stand column and a rear telescopic stand column, and further comprises an ejecting block device; the ejecting block device comprises a front telescoping ejecting column, a rear telescopic ejecting column, crushing plates at the upper end of the front telescopic ejecting column and the upper end of the rear telescopic ejecting column, wherein a crushing groove located in the middle is arranged at theupper end of the ejecting beam, a front ejecting column sleeve ring and a rear ejecting column moving groove are arranged in the crushing groove, the bottom end of the front telescoping ejecting column is fixed on the base, the telescoping end of the upper end of the front telescoping ejecting column is installed at the front ejecting column sleeve ring, the bottom end of the rear telescopic ejecting column is fixed on a sliding frame, the telescopic end of the upper end of the rear telescopic ejecting column is installed at the rear ejecting column moving groove, the lower end of the slidingframe is provided with sliding wheels, and the right end of the sliding frame is connected with a telescopic end of a movable hydraulic rod fixed on the base. According to the crushing device, a hardcoal seam is conveniently crushed, the crushing device of the top coal caving hydraulic support tightly presses against the coal seam in the moving process of the crushing device of the top coal caving hydraulic support, and the large hard coal briquette is prevented from smashing the ejecting beam.

Owner:HENAN POLYTECHNIC UNIV

Coal roadway rapid tunneling equipment

InactiveCN111425199AImprove securityRealize the excavation functionMine roof supportsGrain treatmentsCoal briquetteMining engineering

The invention discloses coal roadway rapid tunneling equipment and relates to the technical field of a coal mine roadway. The coal roadway rapid tunneling equipment comprises a collection box; the topend of the collection box is fixedly connected to an equipment platform; the top end of the equipment platform is fixedly connected to an equipment box; one end of the equipment box is fixedly connected to a fixing base; one end, away from the equipment box, of the fixing base is fixedly connected to a fixing column; one end, away from the fixing base, of the fixing column is rotatably connectedto a rotating base; the rotating base is fixedly connected to a driving rod; a telescopic end of the driving rod is rotatably connected to a main tunneling head; a crushing cutter head is arranged onthe main tunneling head; and the top end and the bottom end of the rotating base are fixedly connected to side fixing rods. Through the main tunneling head, the tunneling function can be realized; through a secondary tunnel head, the tunneling work can be assisted; through a collection device, coal briquettes generated in the tunneling process can be conveyed; and through a supporting device, thetop of the roadway generated by tunnel can be shoveled flatly and supported, and the safety of the tunneling work can be improved.

Owner:ANHUI UNIV OF SCI & TECH

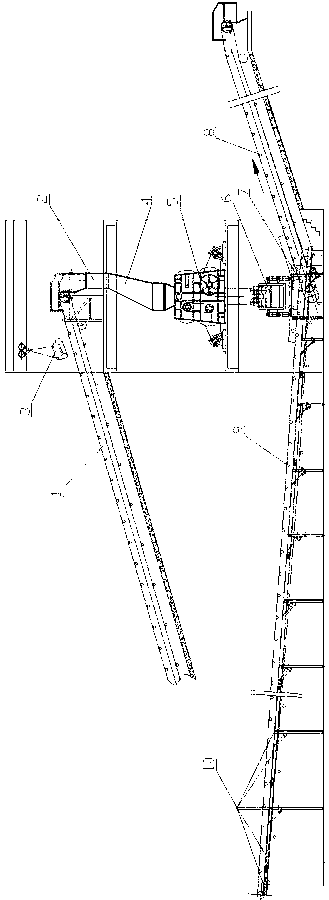

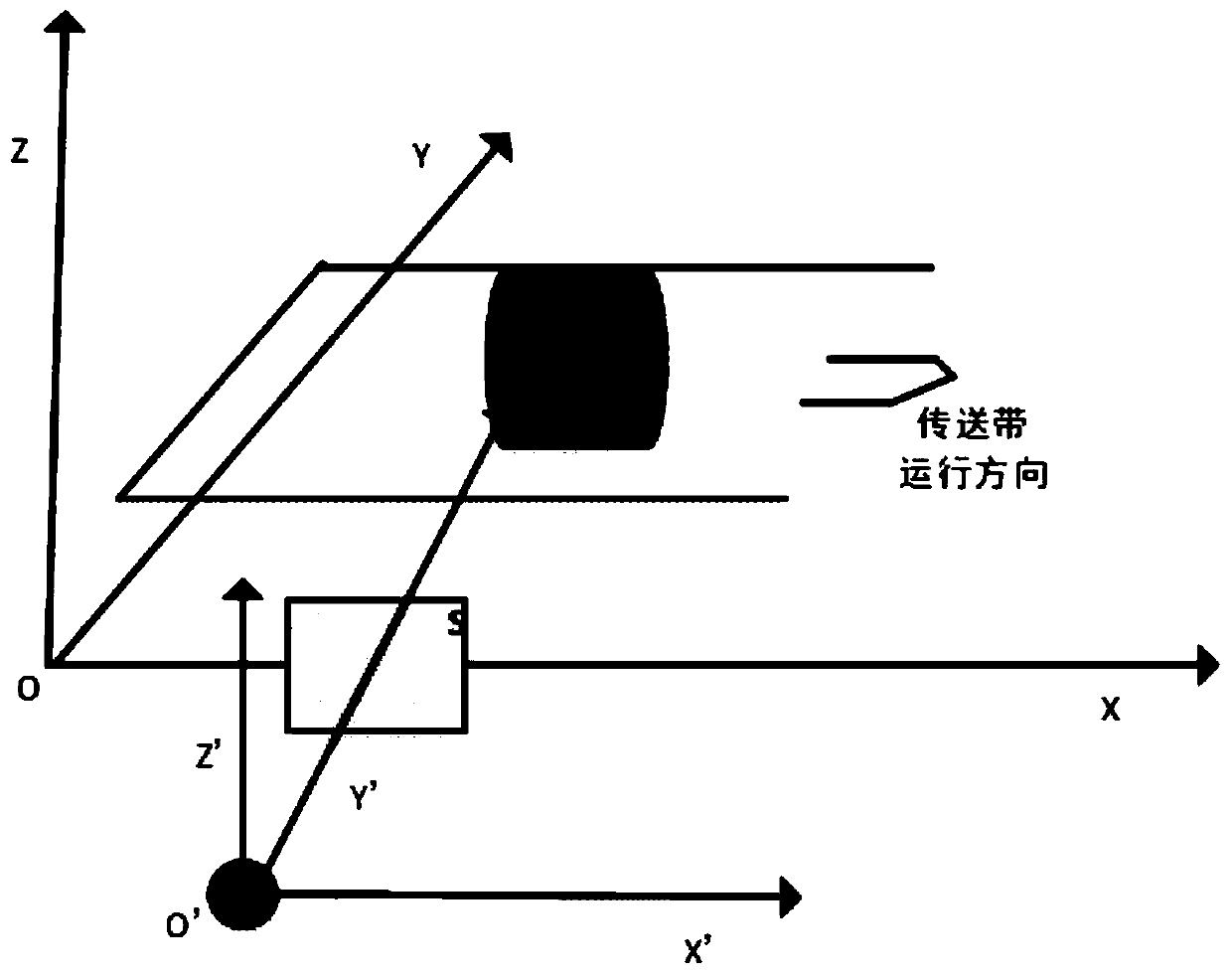

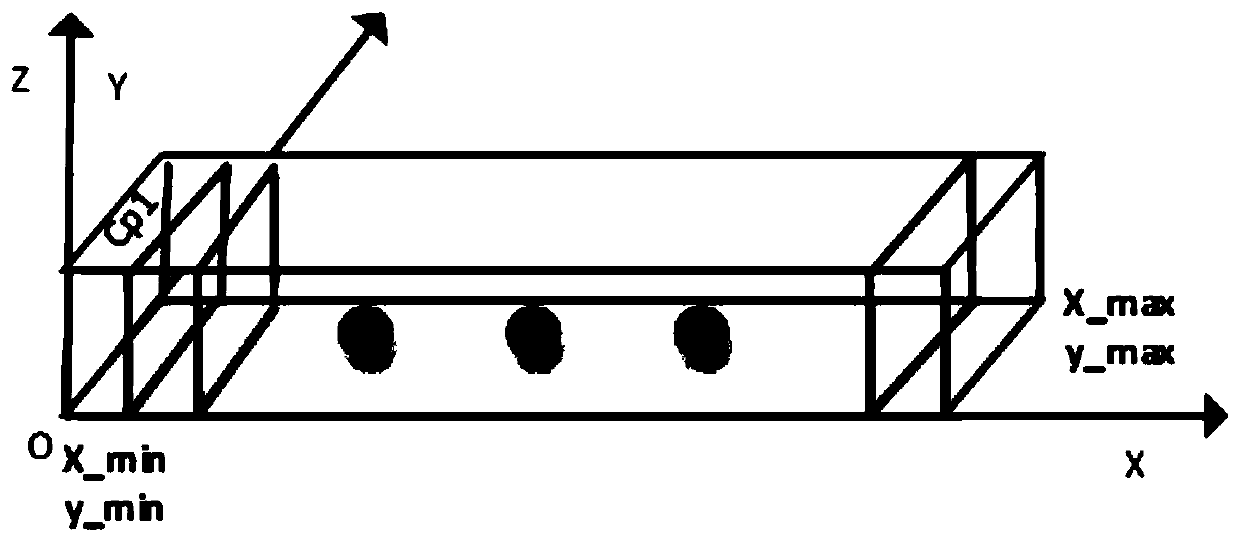

Transmission performance analysis system

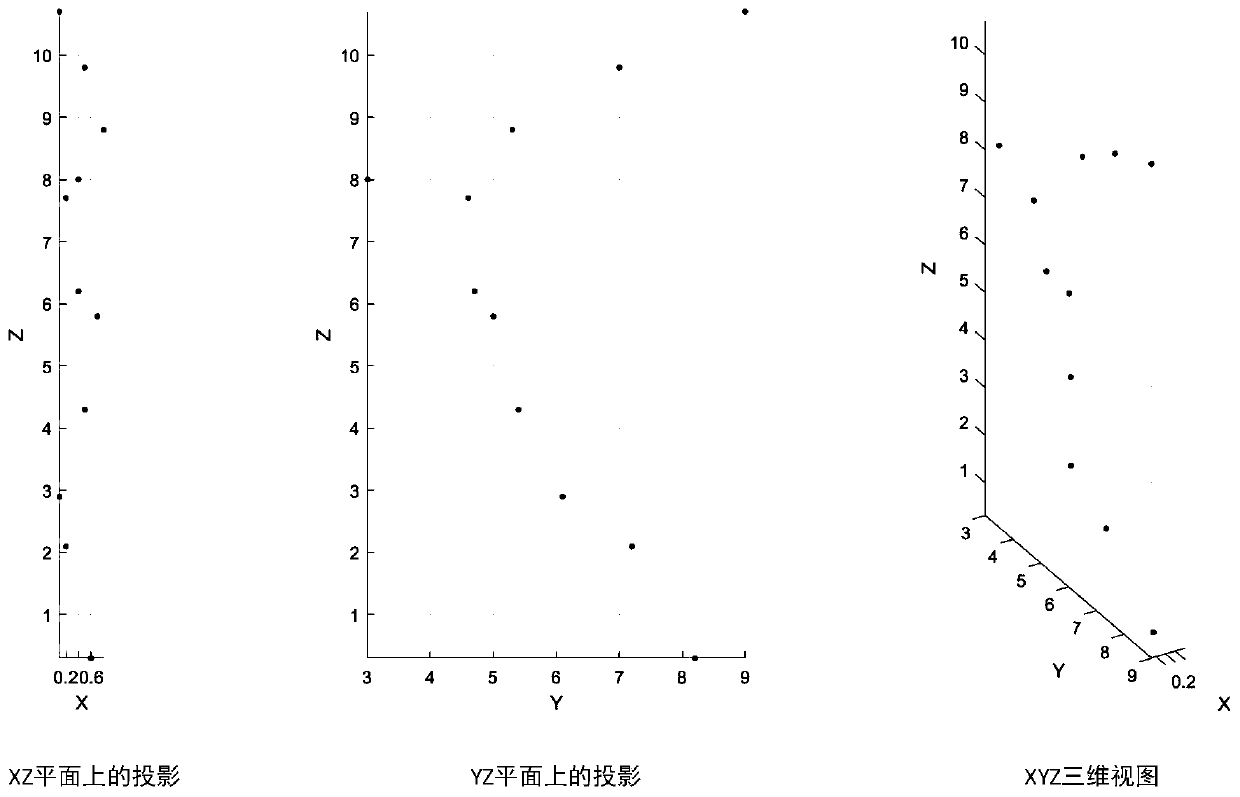

InactiveCN113066045AGuaranteed uptimeReliable dataImage enhancementImage analysisCoal briquetteEngineering

The invention relates to a transmission performance analysis system, and the system comprises a load analysis mechanism which is used for calculating the weight of a coal body corresponding to the solid volume of a three-dimensional region based on the density of the coal body and the solid volume of the three-dimensional area and outputting the weight of the coal body as the weight of a field coal body; a load analysis mechanism further used for sending out a power shortage signal when the received weight of the on-site coal body is larger than the weight of the coal body capable of being driven by the maximum output power of a conveyor belt; and volume estimation equipment used for estimating the solid volume of the three-dimensional area based on each geometric parameter of the simulated three-dimensional area. The transmission performance analysis system is stable in operation and reliable in data. Due to the fact that a targeted high-precision visual detection mechanism can be adopted for the obliquely-arranged conveyor belt facility to detect the total weight of the coal briquettes of the current load of the conveying belt, the load detection error is reduced.

Owner:无锡臻永科技有限公司

Environment-friendly mineral slag treatment equipment

ActiveCN111632716AReduce dustEasy to grind and crushDrying gas arrangementsCleaning using liquidsMining engineeringSlag

The invention discloses environment-friendly mineral slag treatment equipment which comprises a supply barrel, a supporting frame, a conveyor belt, a water tank and a servo motor, wherein the top endinner wall of the supply barrel is connected to a first fixed frame; one side of the first fixed frame is connected to a servo motor; the bottom end of the servo motor is connected to a transmission rod; the bottom end of the transmission rod is connected to a grinding block; one side surface of the grinding block abuts against a grinding base; the grinding base is connected to the inner wall of the supply barrel; the inner wall of the supply barrel is connected to an inner connecting block; the inner wall of the inner connecting block is connected to a first sealing base; one side of the first sealing base abuts against a first sealing plate; the bottom end of the first sealing plate is connected to a second connecting frame; and one side of the second connecting frame is connected to a first slide block. According to the environment-friendly mineral slag treatment equipment disclosed by the invention, the first sealing base and the first sealing plate are arranged, so that relativelygreat coal block particles can be grinded and smashed conveniently; and moreover, a first sealing base and a second sealing base can be arranged, so that dust generated during mineral slag injectioncan be effectively reduced.

Owner:南丹县鑫明金属再生有限公司

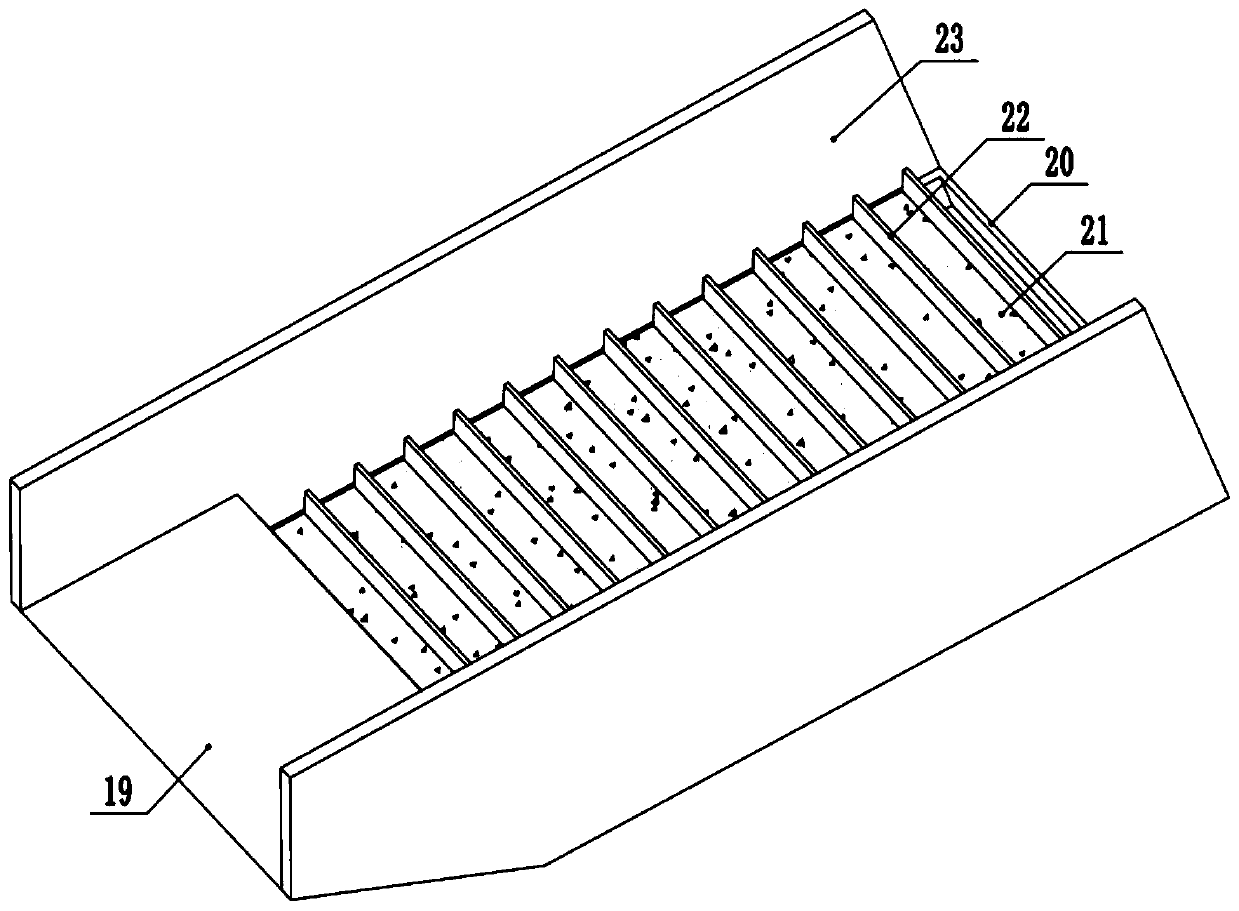

Pre-screening device for selected feed coal of coking coal

PendingCN113996387ARapid crushingEffective sieving operationSievingScreeningCoal briquetteMining engineering

The invention discloses a pre-screening device for selected feed coal of coking coal, and relates to the field of coal mining. The invention aims to overcome the problems that existing coking coal screening efficiency is low, a screen mesh is easy to block, and large-particle coal briquettes after screening cannot be subjected to secondary treatment and screening. According to a technical scheme in the invention, the pre-screening device comprises a screening box with an open top end, a limiting groove and a first discharging opening are formed in the two sides of the screening box correspondingly, a screening plate is movably installed in the screening box, the two ends of the screening plate penetrate through the limiting groove and the first discharging opening correspondingly, and a plurality of spring columns of the same structure are arranged between and fixedly connected with the bottom end of the screening plate and the inner wall of the bottom end of the screening box. According to the device, coking coal can be crushed and screened under a non-stop condition, screening holes are prevented from being blocked through vertical vibration of the screening plate, and large-particle coal briquettes which are not completely crushed can be subjected to secondary treatment, so the screening efficiency of the coking coal is effectively improved.

Owner:刘思思

Coal treatment device capable of fully crushing

The invention discloses a coal treatment device capable of fully crushing. The coal treatment device comprises a machine body, a crushing body is fixedly arranged in the machine body, a power cavity is formed in the rear side of the crushing body, a screening cavity is formed in the crushing body, a belt wheel cavity is formed in the rear side of the screening cavity, a vibration cavity is formedin the lower side of the crushing body, a discharging cavity is formed in the lower side of the machine body, and a transmission cavity is formed in the left side of the crushing body. A feeding cavity is formed in the upper side of the machine body, a crushing cavity is formed in the inner wall of the left side of the crushing body, a feeding device for screening coal briquettes in a vibrating mode is arranged on the upper side of the machine body, the feeding device comprises four fixed sliding rails which are fixedly installed on the front side and the rear side of the crushing body separately and are symmetrical in the left-right direction, and a crushing device for crushing the coal briquettes is arranged in the screening cavity. A discharging device for discharging the coal briquettes in a vibrating mode is arranged on the lower side of the machine body. According to the coal treatment device capable of fully crushing, the coal briquettes are screened and filtered through vibration, so that the large coal briquettes are crushed, the large coal briquettes can be completely crushed, and the uncrushed coal briquettes can be continuously crushed until the uncrushed coal briquettes become small-particle coal.

Owner:FUZHOU WEICHUANGLAI TECH CO LTD

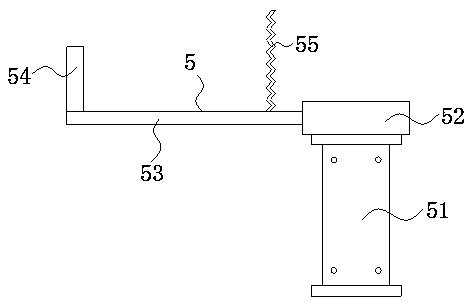

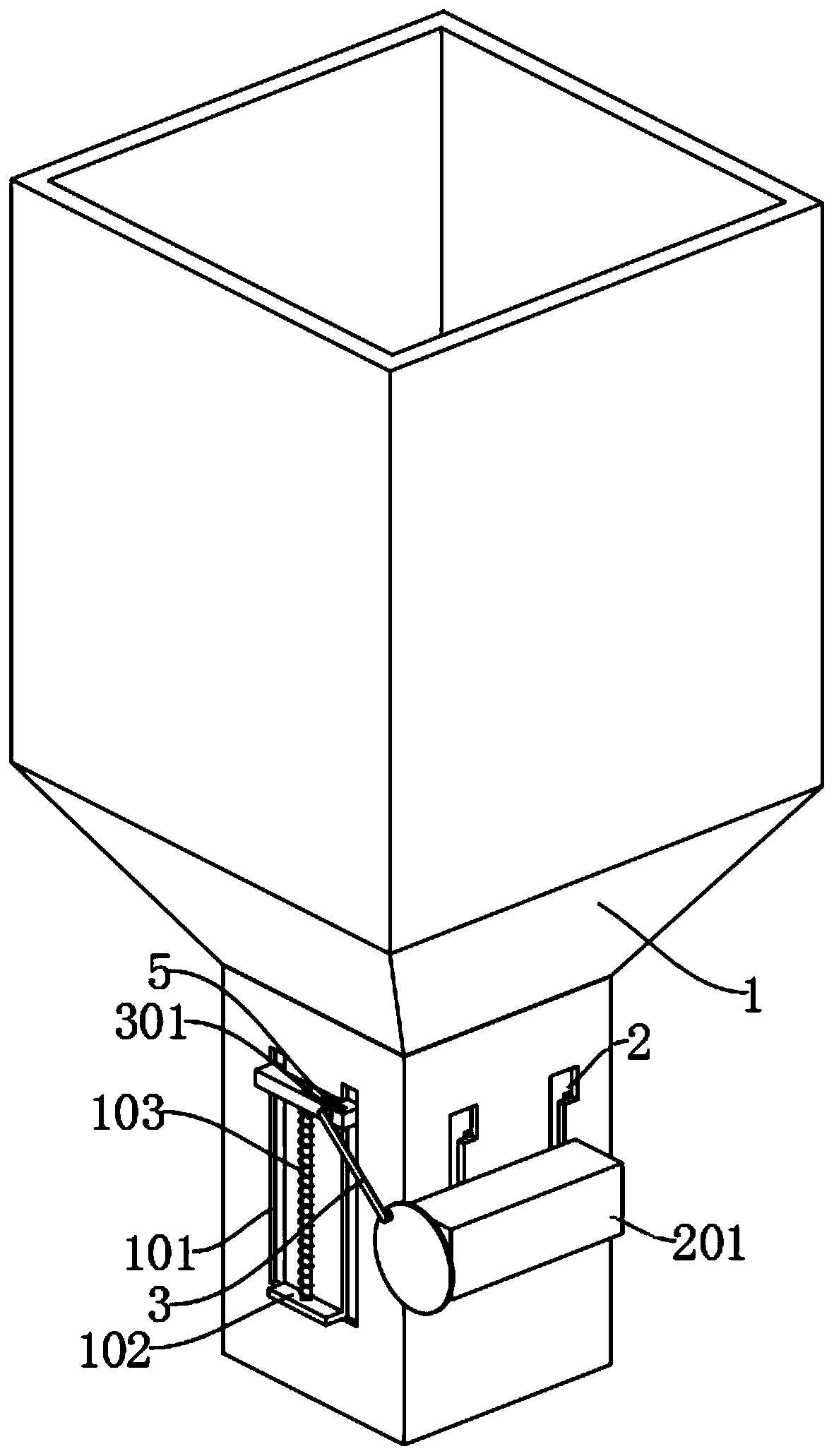

Adjustable boiler coal feeder anti-blocking device convenient to maintain

InactiveCN114275492AGood for vibratingReduce volumeConveyorsSupporting framesCoal briquetteElectric machine

The invention provides a convenient-to-maintain adjustable boiler coal feeder anti-blocking device which comprises a mounting shell, supporting legs, a feeding pipeline, a feeding hopper, a telescopic knocking frame structure, a protective vibration frame structure, a through groove, an end guide frame structure, a discharging hopper, a driving roller, a conveying belt, a driving motor, a mounting frame, a fan and a dustproof net. The supporting legs are welded to the four corners of the lower portion of the installation shell. And the feeding pipeline is in bolted connection with the left side of the upper part of the mounting shell. The coal briquette crushing device has the beneficial effects that by arranging the vibration motor, the metal fixing cover and the conical crushing thorns, the vibration motor drives the metal fixing cover to shake up and down on the upper portion of the inner side of the mounting shell, the metal fixing cover drives the conical crushing thorns to move up and down, coal briquettes can be vibrated and knocked, and the size of the coal briquettes is reduced; in addition, gaps between the coal briquettes are reduced, and the coal briquettes are prevented from blocking the inner side of the mounting shell.

Owner:JINYIMENG GRP CO LTD

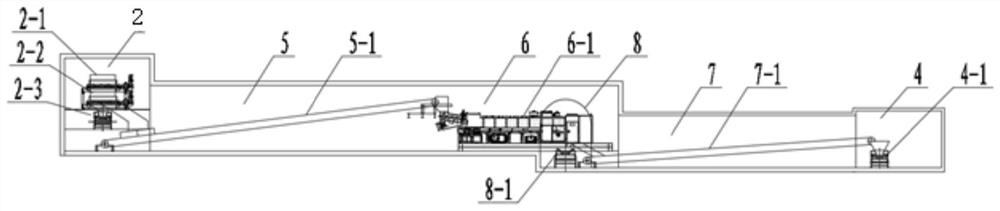

Underground coal mine working face mining, selecting and filling integrated system and use method

PendingCN113250743AImprove work efficiencyIncrease productivitySievingScreeningCoal briquetteMining engineering

The invention provides an underground coal mine working face mining, selecting and filling integrated system and a use method. Equipment and systems for screening, intelligent dry separation, gangue filling and matched transportation are additionally arranged on a working face, and raw coal screening, lump coal gangue separation and gangue goaf filling are performed in sequence, so that the underground working face mining, selecting and filling integrated system with underground coal gangue separation and onsite gangue filling is realized; the input end of an intelligent dry separation unit roadway is arranged on a main transportation roadway of the working face, the output end of the intelligent dry separation unit roadway is connected to the main transportation roadway and an air return roadway of the working face, the screening of clean coal and lump coal is effectively increased, the coal mining efficiency is improved, solid waste in coal briquettes is reduced, and the production efficiency of a mine is improved; and gangue is conveyed to a working face goaf through the air return roadway of the working face, so that solid waste treatment of the mine is effectively achieved, and economic benefits of the mine are guaranteed.

Owner:中煤能源研究院有限责任公司

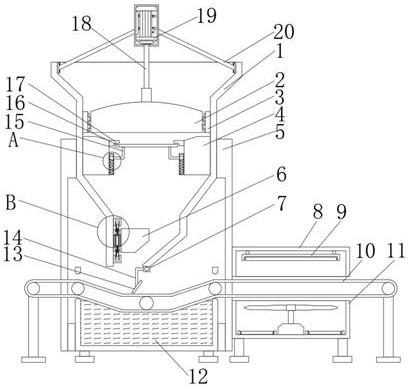

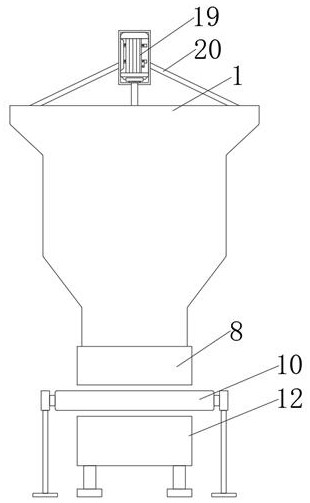

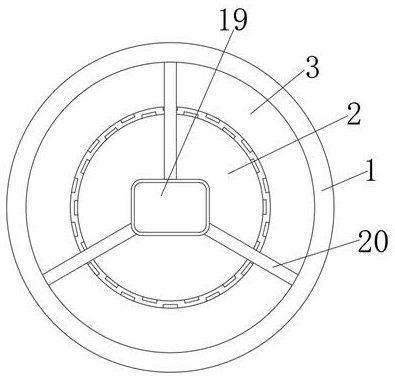

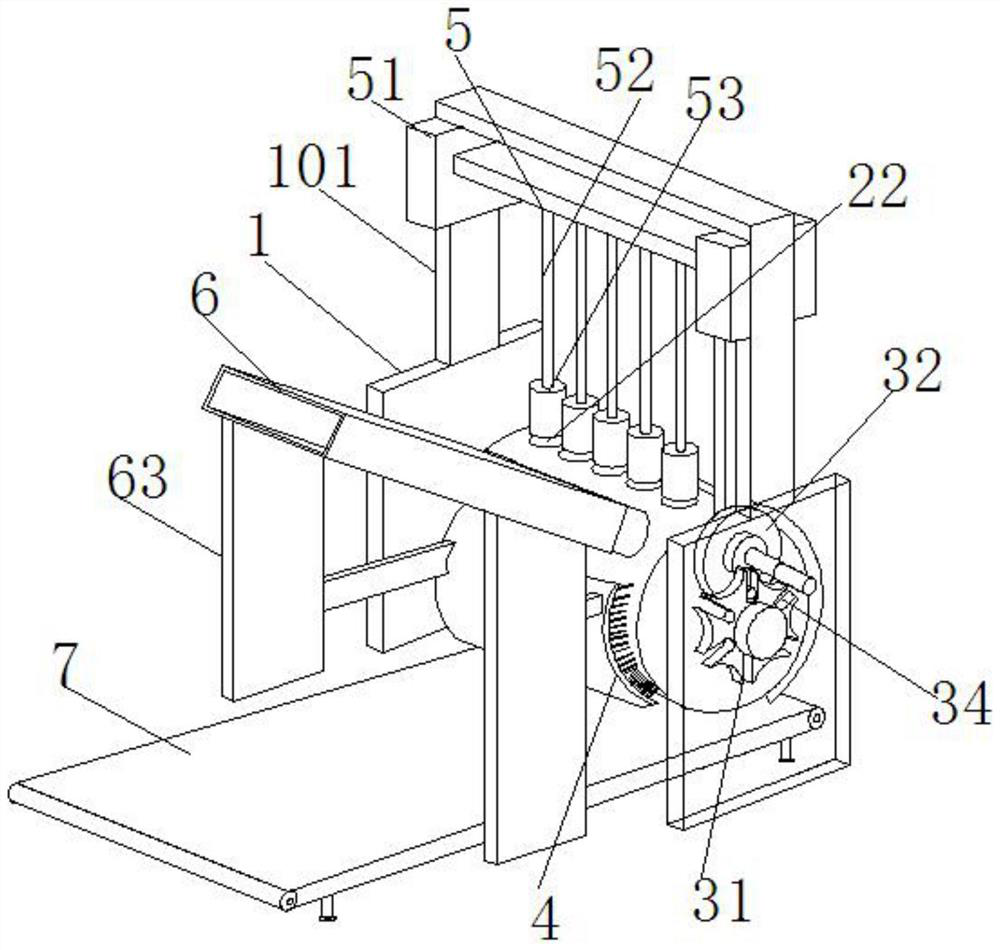

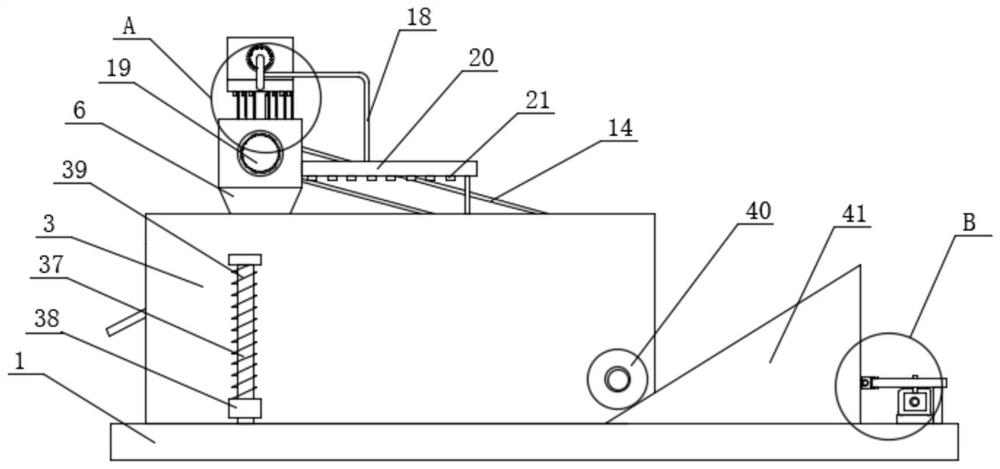

Honeycomb briquette processing equipment

InactiveCN112549622ARealize the function of pressing and formingSimple structureSolid fuelsCleaning using toolsCoal briquetteHoneycomb

The invention discloses honeycomb briquette processing equipment. The equipment comprises a rack, wherein a grooved wheel mechanism is movably arranged at one side of the rack; a conveying mechanism is movably arranged at one end of the grooved wheel mechanism; a sliding rod is fixedly connected to the top of the rack; a sliding seat is slidably connected to one side of the sliding rod; a liftingrod is fixedly connected to the side, away from the sliding rod, of the sliding seat; multiple sets of pressing rods are fixedly connected to the bottom of the lifting rod; a profiling mechanism is movably connected to the bottoms of the pressing rods; and the profiling mechanism is located above the conveying mechanism. The invention particularly relates to the technical field of honeycomb briquette production. By arranging the profiling mechanism, not only can coal cinder be subjected to extrusion forming operation, but also extruded coal briquettes can be subjected to perforating operation,so that the structure is simple, the efficiency is high, and the production efficiency is improved; and by arranging a pushing mechanism, the pushing mechanism is matched with a convex block, and thecoal briquettes produced in an inner cavity of a forming groove are automatically demolded.

Owner:亢宏海

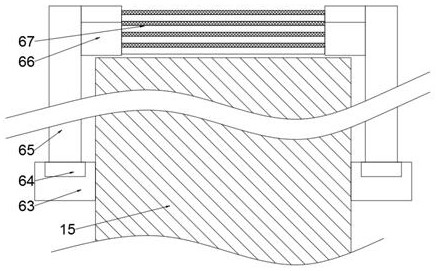

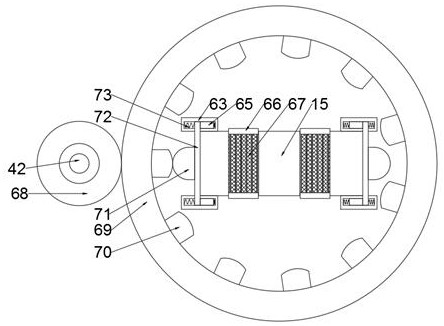

Sufficient-combustion boiler with grinding function for power generation

InactiveCN111503627ABurn fullyIncomplete combustionFuel feeding arrangementsAir/fuel supply for combustionCoal briquetteProcess engineering

The invention relates to a sufficient-combustion boiler with a grinding function for power generation. The boiler comprises a hearth and a water tank, and further comprises a grinding mechanism and aventilation mechanism, wherein the grinding mechanism comprises a feeding box, a feeding pipe, an inlet pipe, a filter screen, a lifting assembly, a moving plate and two crushing assemblies, the crushing assemblies comprise transmission units, crushing plates, limiting units, rotating shafts and first bearings, and the ventilation mechanism comprises an air cylinder, a piston, a connecting rod, anair inlet pipe and an air outlet pipe. The sufficient-combustion boiler with the grinding function for the power generation conducts crushing work on coal briquettes through the grinding mechanism intwo modes, the crushing effect is improved, the situation that the coal briquettes are large and cannot be sufficiently combusted is avoided, the utilization rate of the coal briquettes is increased,the function of ventilating the hearth is achieved through the ventilation mechanism, the oxygen content of the interior of the hearth is increased, and pulverized coal is sufficiently combusted.

Owner:王志坚

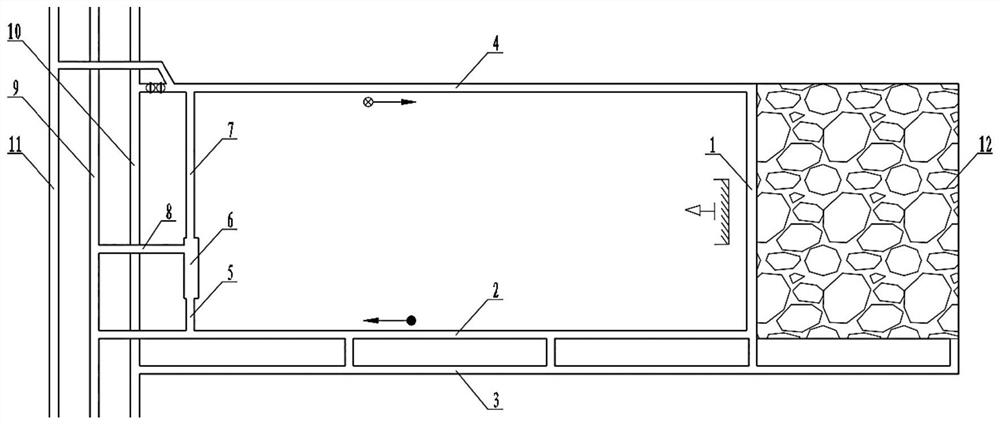

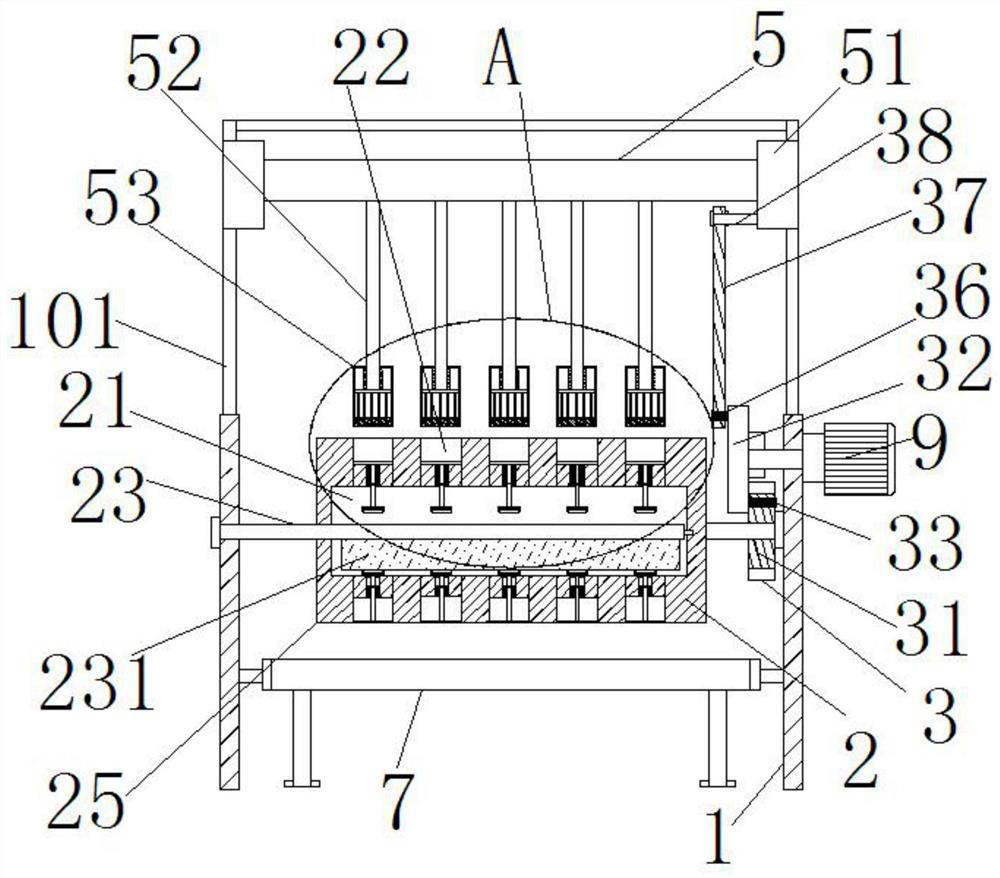

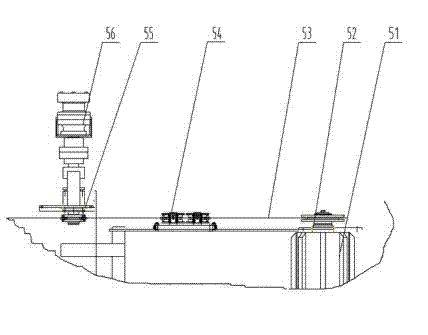

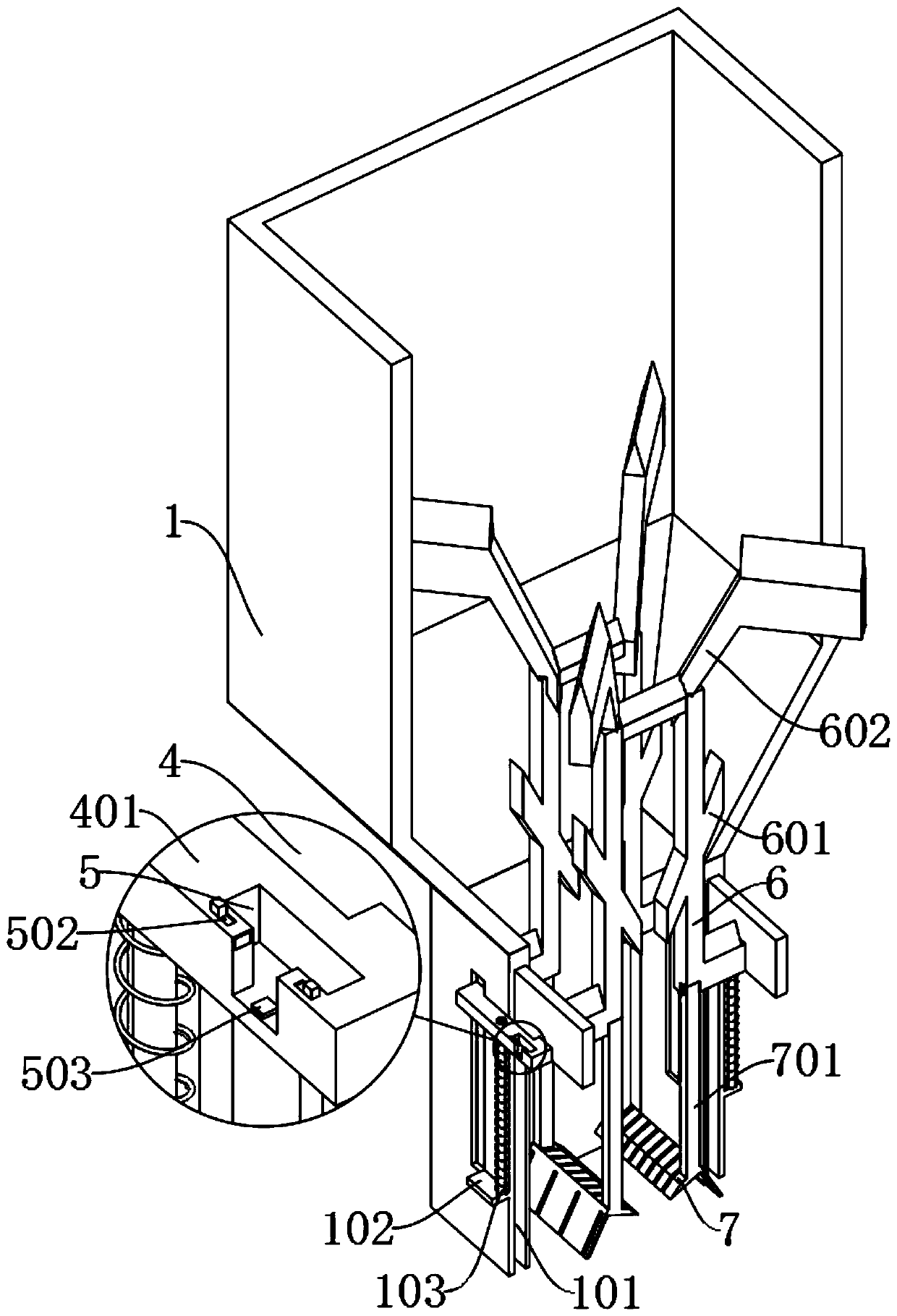

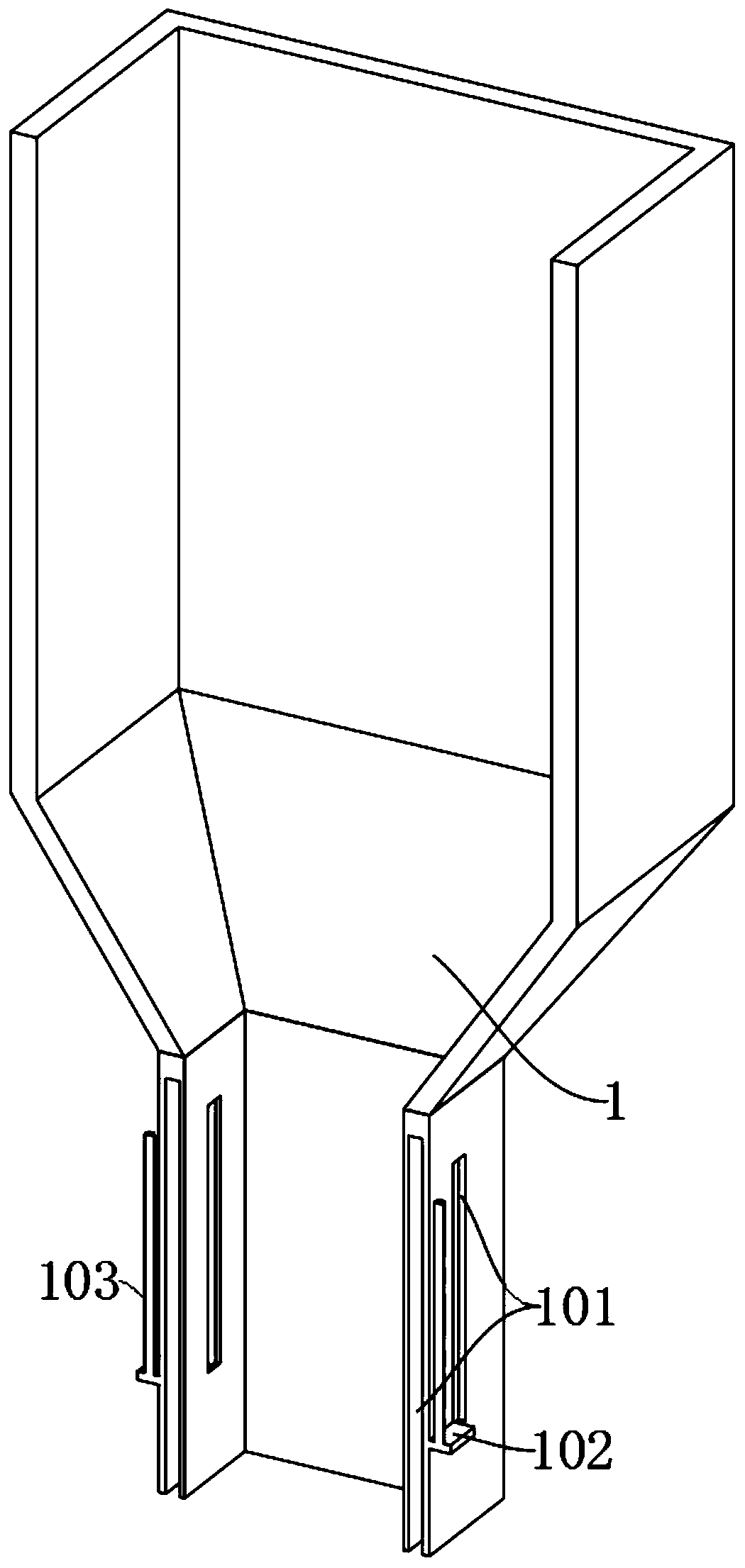

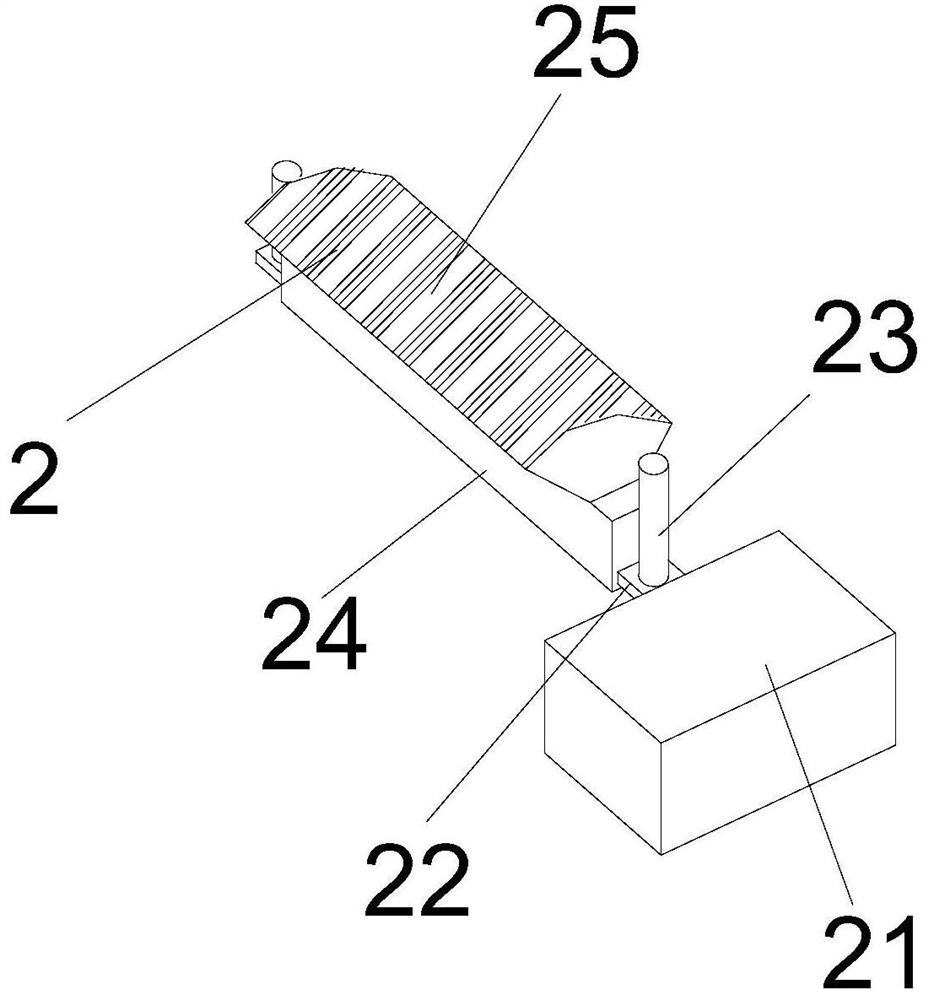

Hydraulic movable sieve jig used underground

The invention relates to a hydraulic movable sieve jig used underground, comprising a hydraulic movable sieve jig body (2), a conveyer device and a trough (1), wherein the hydraulic movable sieve jig body (2) has an upper end separating chamber (101) for separating out lump coal, a lower end separating chamber (102) for separating out gangue and a sieve plate chamber (103) for separating out fine coal; the conveyer device is used for discharging lump coal and gangue; and the trough (1) has a front chamber (13), a middle chamber (14) and a rear chamber (15) which are respectively communicated with the upper end separating chamber (101), the lower end separating chamber (102) and the sieve plate chamber (103) of the hydraulic movable sieve jig body (2); therefore, the movement stability of the sieve plate is improved, and the requirement on the granularity of the gangue and the lump coal is reduced.

Owner:SHANDONG TAIAN COAL MINING MACHINERY

Vibrating chute concentrating machine for coal mining and using method thereof

InactiveCN112076887AAvoid cloggingExpand the spraying rangeCleaning using liquidsWet separationCoal briquetteElectric machine

The invention discloses a vibrating chute concentrating machine for coal mining and a using method thereof. The vibrating chute concentrating machine comprises a base, a collecting box is fixedly mounted at the top of the base, a mounting pipe is slidably connected to the top of the base, the collecting box is located in the mounting pipe, a clamping strip is fixedly mounted in the mounting pipe,and the clamping strip is attached to the collecting box in a sealed mode. A feeding pipe is fixedly installed in the mounting pipe, the top of the feeding pipe extends to the position above the mounting pipe and is fixedly provided with a spraying assembly, and a driving motor is fixedly installed on one side of the feeding pipe. Stable feeding of coal briquettes can be achieved, so that it is guaranteed that blocking does not occur when the coal briquettes are subjected to concentrating, a conveying belt can be automatically cleaned in time when the coal briquettes are subjected to concentrating, tailings are effectively prevented from being attached to the conveying belt, and good environmental protection performance is achieved; and meanwhile, the sorted coal briquettes can be conveniently and automatically moved out, so that the technical scheme has good practicability and convenience in use.

Owner:贾兵兵

Discharging device for coal briquettes in thermal power plant

InactiveCN110732388AIncrease productivityReasonable structural designGrain treatmentsCoal briquetteProcess engineering

The invention discloses a discharging device for coal briquettes in a thermal power plant. The discharging device comprises a shell, the top of the inner wall of the shell is fixedly connected with afirst partition plate, the bottom of the first partition plate is fixedly connected with the bottom of the inner wall of the shell, the right side of the first partition plate is fixedly connected with a second partition plate, the right side of the second partition plate is fixedly connected with the right side of the inner wall of the shell, a crushing mechanism is arranged at the top of the second partition plate, an unblocking mechanism is arranged on the position, on the right side of the first partition plate, of the bottom of the inner wall of the shell, a passing opening is formed in the position, corresponding to the unblocking mechanism, of the right side of the first partition plate, and a feeding inlet is formed in the top of the left side of the inner wall of the shell. According to the discharging device for the coal briquettes in the thermal power plant, structural design is reasonable, using is convenient, discharging blockage caused by excessively large coal briquettescan be effectively prevented, manual unblocking is not needed, through a crushing device arranged in the discharging device, the blockage probability can be further decreased, the production efficiency of the thermal power plant is improved, and using demands can be met omnidirectionally.

Owner:XIAN XINGYI TECH

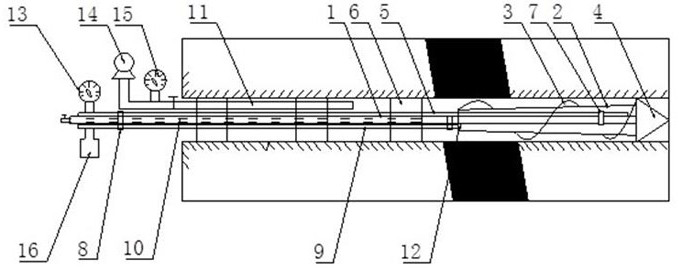

Distributed type coal mine gas pressure measuring system

InactiveCN113356840AAvoid blockingAvoid the problem of insufficient strengthSurveyDrilling rodsCoal briquetteMining engineering

The invention relates to a distributed type coal mine gas pressure measuring system. The distributed type coal mine gas pressure measuring system comprises a pressure measuring pipe, a drill rod, an air pipe and a first water pipe, a double-shaft device is arranged on the drill rod, a screw rod is arranged on the drill rod, a drill bit fixedly connected with the screw rod is arranged at one end of the drill rod, the drill rod is connected with the pressure measuring pipe and the air pipe through the double-shaft device, the first water pipe is arranged in the drill rod, and rubber water bags communicating with the first water pipe are arranged on the drill rod. According to the distributed type coal mine gas pressure measuring system, the pressure measuring pipe is arranged in the screw rod, so that the phenomenon that the pressure measuring pipe is blocked due to falling of a coal seam during drilling is avoided; and meanwhile, the screw rod rotates along with the drill rod to output falling coal briquettes outwards, then the coal briquettes are blown out of a drill hole through an air nozzle, the plurality of rubber water bags are filled with water, so that the size is increased, the friction force between the water bags and the drill hole is increased, water is injected among the water bags for water sealing, the repeated utilization rate of equipment is increased, and the cost is reduced.

Owner:HENAN INST OF ENG

Coal briquette grinding device for boiler combustion

InactiveCN111036380ASatisfy combustion needsBurning violentlyGrain treatmentsCoal briquetteThermodynamics

The invention discloses a coal briquette grinding device for boiler combustion. The device comprises a device shell, a feeding port, a discharging port and a crushing mechanism, wherein the feeding port and the discharging port are formed at an upper end and a lower end of the device shell correspondingly, the crushing mechanism is arranged in the device shell, and the crushing mechanism comprisesan upper fixing plate, a lower fixing plate, a left crushing sliding block, a right crushing sliding block and a crushing driving mechanism. The device has the advantages that through the crushing mechanism, coal briquettes can be further crushed, and thereby the combustion requirement is met; by arranging a powder grinding mechanism, the coal briquettes can be thoroughly crushed and ground intopowder, and thereby combustion of the coal briquettes is more violent.

Owner:高红

Coal mine main lifting unloading buffer coal bunker anti-blocking device

ActiveCN111573026AQuick unblockAvoid breakingLarge containersLoading/unloadingCoal briquetteMining engineering

The invention provides a coal mine main lifting unloading buffer coal bunker anti-blocking device, and relates to the field of coal bunker anti-blocking technologies. In order to solve the problems that when an existing coal bunker anti-blocking device is used, during slight blocking, the device cannot automatically bear force and be dredged, so that energy cannot be saved advantageously, the coalmine main lifting unloading buffer coal bunker anti-blocking device comprises a body, mounting grooves and a transmission plate. The body is a coal bunker body, and the periphery of the interior of the body is of an inclined structure. The mounting grooves are formed in the right side of the body side by side. The transmission plate is located on the right side of the front end of the body. A guide plate is used for being mounted in a guide groove of the body, the guide plate can receive power of a spring through a force bearing block on the outer side to be in a rising state, when coal briquettes fall, a supporting rod and an ejecting part of the guide plate can be pressed, after the guide plate falls, the spring can support the force bearing block and the guide plate for reset, thus, the coal briquettes are ejected again, and the coal briquettes can be ejected again for dredging.

Owner:伊金霍洛旗振兴煤炭有限责任公司

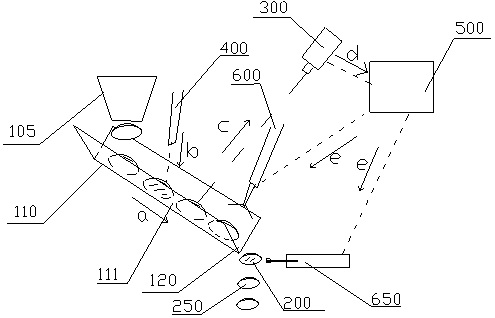

Coal preparation system based on artificial intelligence image recognition

The invention provides a coal preparation system based on artificial intelligence image recognition. A sliding chute, the lower part of the cross section of which is close to V-shape is provided; coalmaterials fall from the above to a starting section of the sliding chute and slide to the tail end of the sliding chute and are automatically arranged in a row; when the coal materials move along thesliding chute, firstly, coal ash and coal slime on the coal materials are purged by using a spray gun, so that the coal ash and coal slime are exposed to the surface of an internal solid; and when the coal materials reach the tail end, a shooting device shoots and sends shot images to a control module in real time, the control module recognizes the coal materials into gangue or coal briquettes inreal time through an artificial intelligence image recognition technology and controls a gangue eliminating mechanism to act, and the gangue is removed from the coal briquettes. According to the coalpreparation system based on the artificial intelligence image recognition provided by the invention, the gangue separation accuracy is high, equipment is simple, the processing size fraction is wide,the processing capacity is great, and most of manpower can be replaced; and the equipment is simple and easy to maintain, is convenient to be deployed under a well, the gangue is screened out and left in the well before the coal materials are hoisted out of the well, and the amount of gangue out of the well can be effectively reduced.

Owner:郑鸿

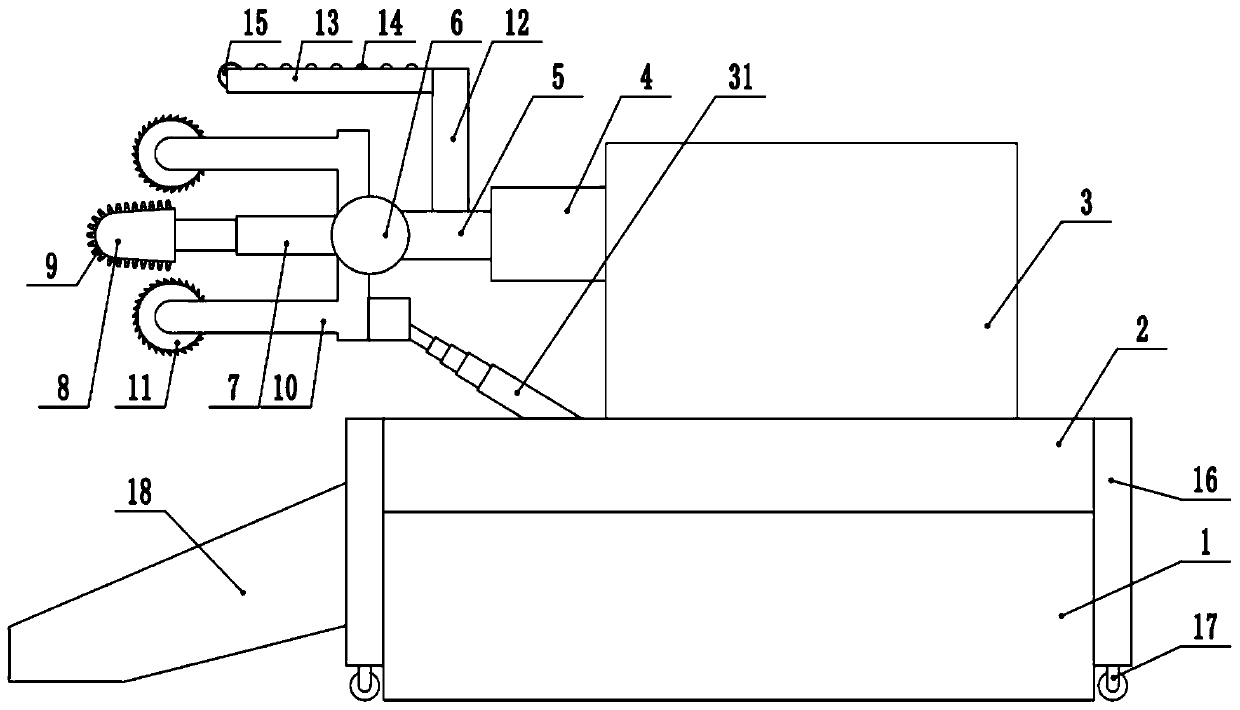

Coal briquette crushing and impurity removing machine for coal processing industry

InactiveCN111036383AEfficient separationMagnetic separationCleaning using liquidsCoal briquetteHydraulic cylinder

The invention discloses a coal briquette crushing and impurity removing machine for the coal processing industry. The machine comprises a bottom plate, a crushing mechanism, a conveyor belt, a transfer mechanism and a shower mechanism, wherein the crushing mechanism comprises a crushing chamber, a grating, a first motor, a rotating seat, a pressing seat and a hydraulic cylinder; the transfer mechanism comprises a lifting bin, a rotating roller, a belt and a transit bin; and the shower mechanism comprises a shower bin, a third motor, a shower barrel, a conversion bin and a water pump. Accordingto the machine, coal briquettes are conveyed into the crushing chamber through the conveyor belt, and under the combined action of the pressing seat and blades, the coal briquettes are crushed to fall onto a slideway through the grating and finally enter the lifting bin, and the crushed coal briquettes in the lifting bin are lifted to the transit bin by a lifting plate and enter the shower barrelthrough a discharge pipe; the shower barrel rotates under the drive of the third motor, meanwhile, spray heads spray water to shower the shower barrel, coal in the coal briquettes is dissolved in water and falls into the shower bin through through holes, and small stones in the coal briquettes are left in the shower barrel and can be removed by opening a sealing cover; and the machine can effectively separate coal from impurities in the coal briquettes.

Owner:安徽信典网络科技有限公司

Improved fuel processing device for thermal power plant

InactiveCN112774793ALarge scale useExtended service lifeCocoaGrain treatmentsCoal briquetteReciprocating motion

The invention relates to an improved fuel processing device for a thermal power plant. The device a box body and a driving structure I, the top of the box body is provided with a feed inlet, and the side wall of the lower part of the box body is provided with a discharge outlet; a rubbing and grinding crushing structure and a grinding device are sequentially arranged in the box body from top to bottom, the rubbing and grinding crushing structure comprises a supporting body, the supporting body is fixed in the position, below the feed inlet, of the box body, and a groove seam penetrating through the supporting body is formed at the top of the supporting body; and two supporting plates are oppositely arranged in the groove seam through a guide structure, and a plurality of crushing heads are evenly distributed on the opposite faces of the two supporting plates. The driving structure I is arranged outside the box body and used for driving the two supporting plates to horizontally reciprocate in the groove seam through the guide structure, and the movement directions of the two supporting plates are always opposite. The device improves the processing efficiency of coal briquettes by arranging the rubbing and grinding crushing structure, improves the processing effect, prolongs the service life of the grinding structure, and is worthy of popularization.

Owner:华能山东发电有限公司众泰电厂

Coal cutter cutting part with differential speed separation roller

The invention discloses a coal cutter cutting part with a differential speed separation roller. A motor driving part comprises a left cutting motor and a right cutting motor, both the left cutting motor and the right cutting motor are arranged in a cutting part box, and transmission connection of the left cutting motor as well as the right cutting motor and a roller output part is achieved througha gear transmission part; and the roller output part comprises a high-speed output shaft, a low-speed output shaft, a middle supporting frame, a high-speed roller, a far-end supporting frame and a low-speed roller, a cutting roller is separated into two coaxially-rotated parts, and differential speed rotating of the two parts of the roller can be achieved. The front end low-speed roller is low inrotating speed, so that cut coal briquettes have good axial mobility, and the coal briquettes can be better conveyed into a revolving area of a wheel rotating blade of the high-speed roller, the rotating speed of the high-speed roller is far higher than that of the low-speed roller, therefore, the coal briquettes can obtain the higher tangential speed and axial speed through action of the high-speed roller so that coal can cross the distance from the tail end of the high-speed roller to a middle groove of a scraper machine, and the roller conveying and coal loading processes are better finished.

Owner:SHANDONG UNIV OF SCI & TECH

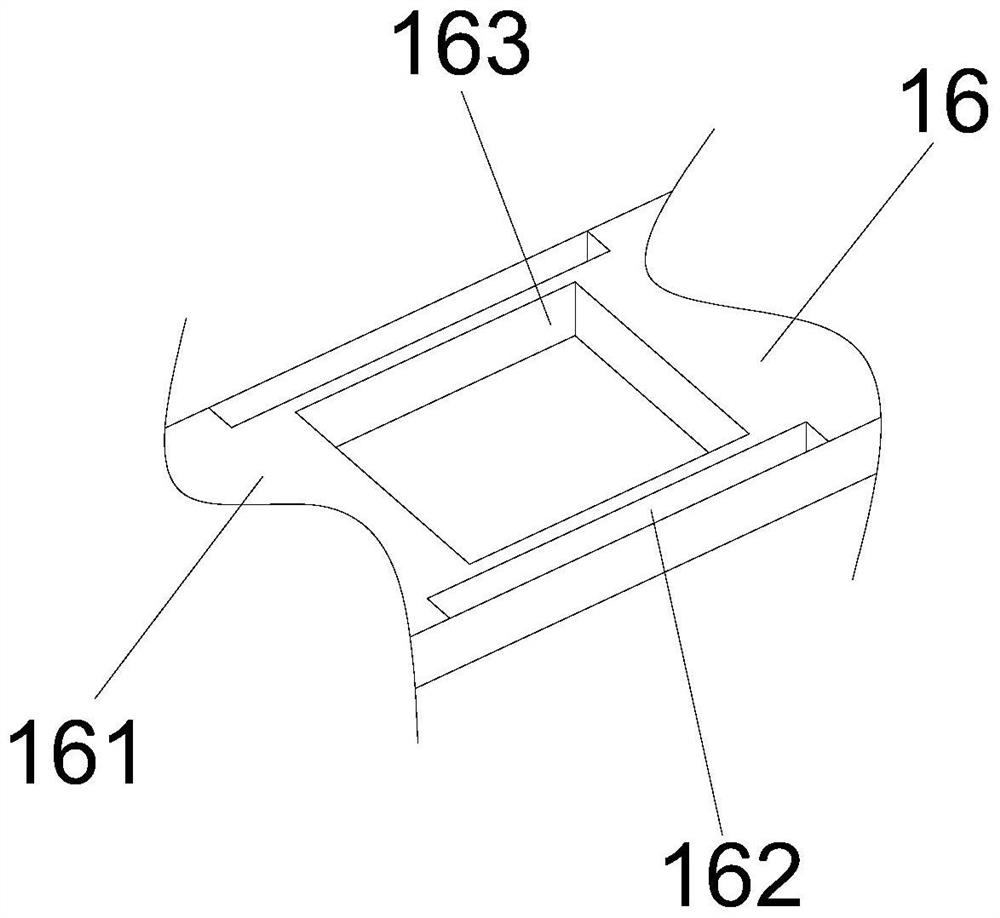

Coal briquette separation equipment with automatic transmission function

PendingCN113428615AWith automatic transfer functionEasy to cleanCleaningControl devices for conveyorsCoal briquetteAutomatic transmission

The invention discloses coal briquette separation equipment with an automatic conveying function. The coal briquette separation equipment comprises a machine body. According to the coal briquette separation equipment, a cleaning device is arranged at the bottom of a fixing frame, and when a swing device arranged in the cleaning device works, a conveying belt can be cleaned through a cleaning block, so that the workload of a user is reduced, and the user conveniently cleans the conveying belt; through a groove and sliding grooves formed in the bottom of the fixing frame, sliding rods can slide on the sliding grooves conveniently, and cleaning of the conveying belt can be better facilitated through the cleaning block; a vibration device is arranged at the upper end of a fixing plate, and when a jacking device arranged in the vibration device works, the situation that because the discharging plate is long, the discharging speed of coal briquettes is affected is avoided.

Owner:谢真

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com