Hydraulic movable sieve jig used underground

A dynamic sieve jig and mine underground technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of affecting production efficiency, increasing investment, and low efficiency, so as to reduce mining costs and ensure mine safety safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

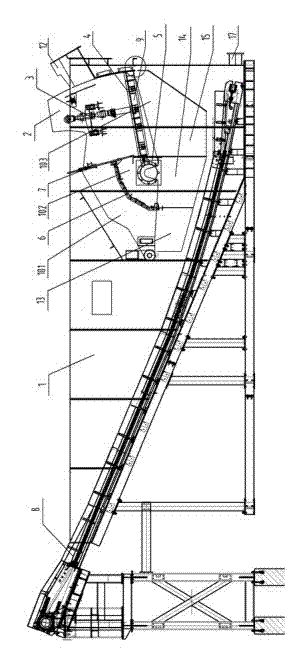

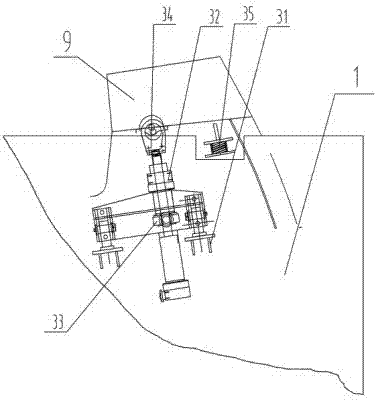

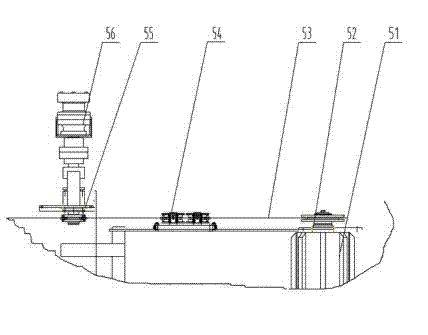

[0017] The accompanying drawing is an embodiment of the present invention, which is specifically described in conjunction with the accompanying drawings. It includes a hydraulic dynamic screen jig body 2, a tank body 1 and a scraper conveyor 8, and the tank body 1 is provided with an upper side port 12, The lower side port 17, the front cavity 13, the middle cavity 14 and the rear cavity 15, the front cavity 13, the middle cavity 14 and the rear cavity 15 are arranged in sequence in the tank body 1, the upper side port 12 and the lower side Ports 17 are respectively set at the upper and lower ends of the rear cavity 15, the hydraulic dynamic screen jig body 2 and the scraper conveyor 8 are set in the tank body 1, and the scraper conveyor 8 is set in two groups and one end is respectively front cavity 13 and the bottom of the middle chamber 14, the outlet of the upper sorting cavity 101 of the hydraulic dynamic screen jig body 2 is set to communicate with the front cavity 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com