Coal briquette crushing and impurity removing machine for coal processing industry

A pulverizing mechanism and industry technology, applied in cleaning methods and utensils, cleaning methods using liquids, magnetic separation, etc., can solve problems such as poor pulverized coal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

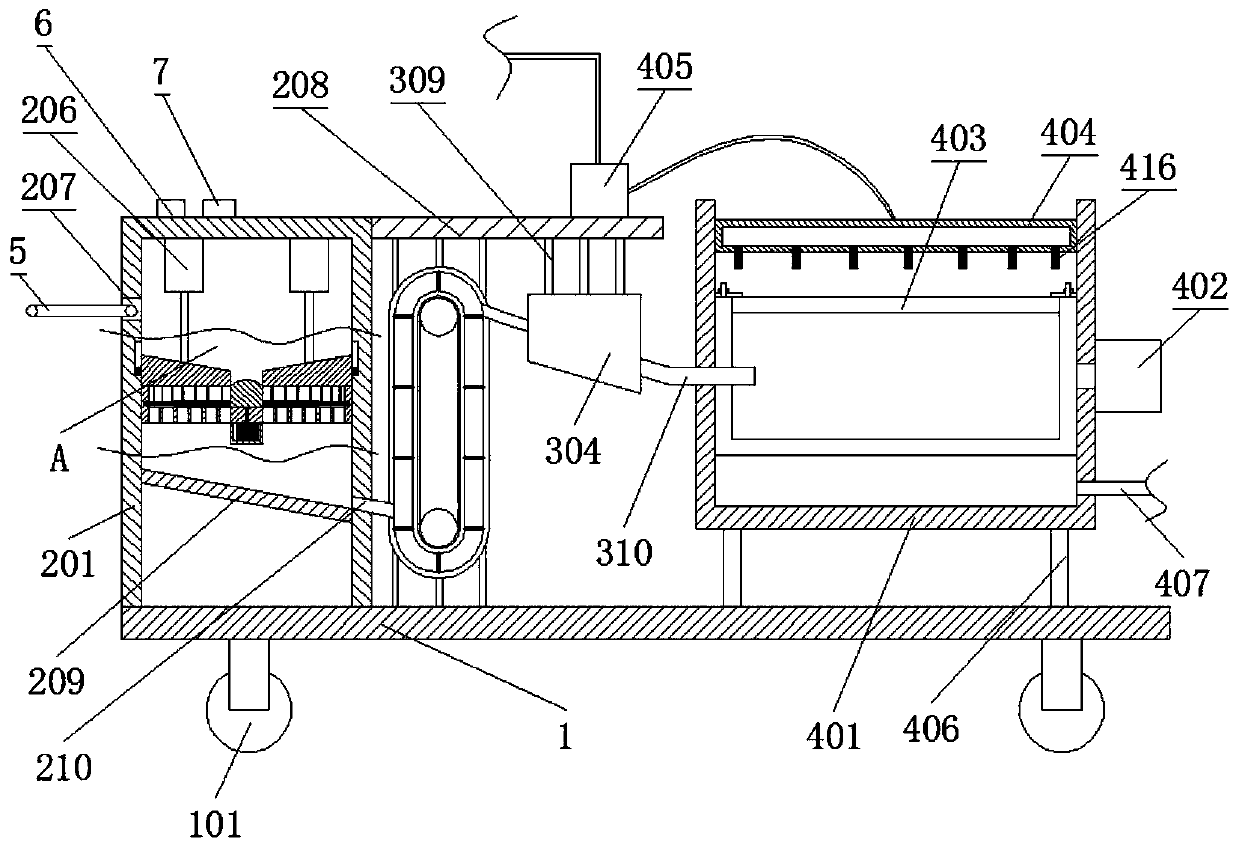

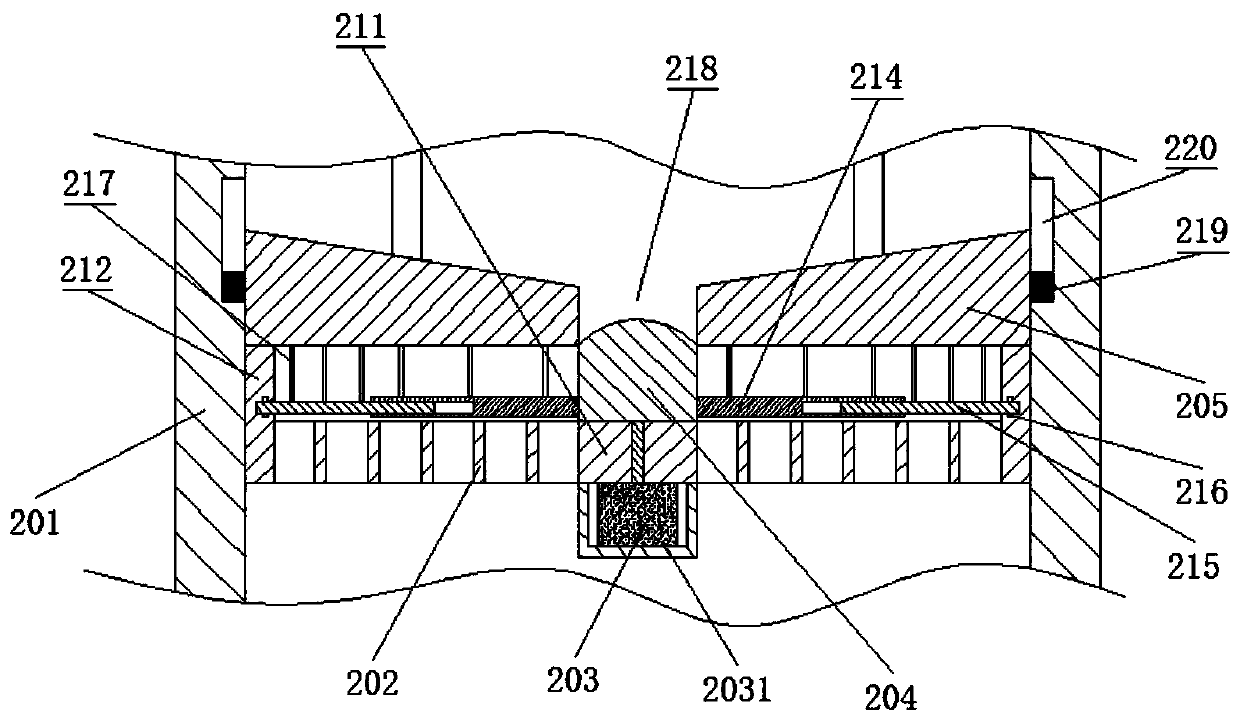

[0047] During use, the first controller 6 controls the work of the first motor 203, the second motor, the third motor 402 and the water pump 405, the second controller 7 controls each hydraulic cylinder 206 to work synchronously, and the hydraulic rods of each hydraulic cylinder 206 operate synchronously. Reciprocating circular motion in the vertical direction.

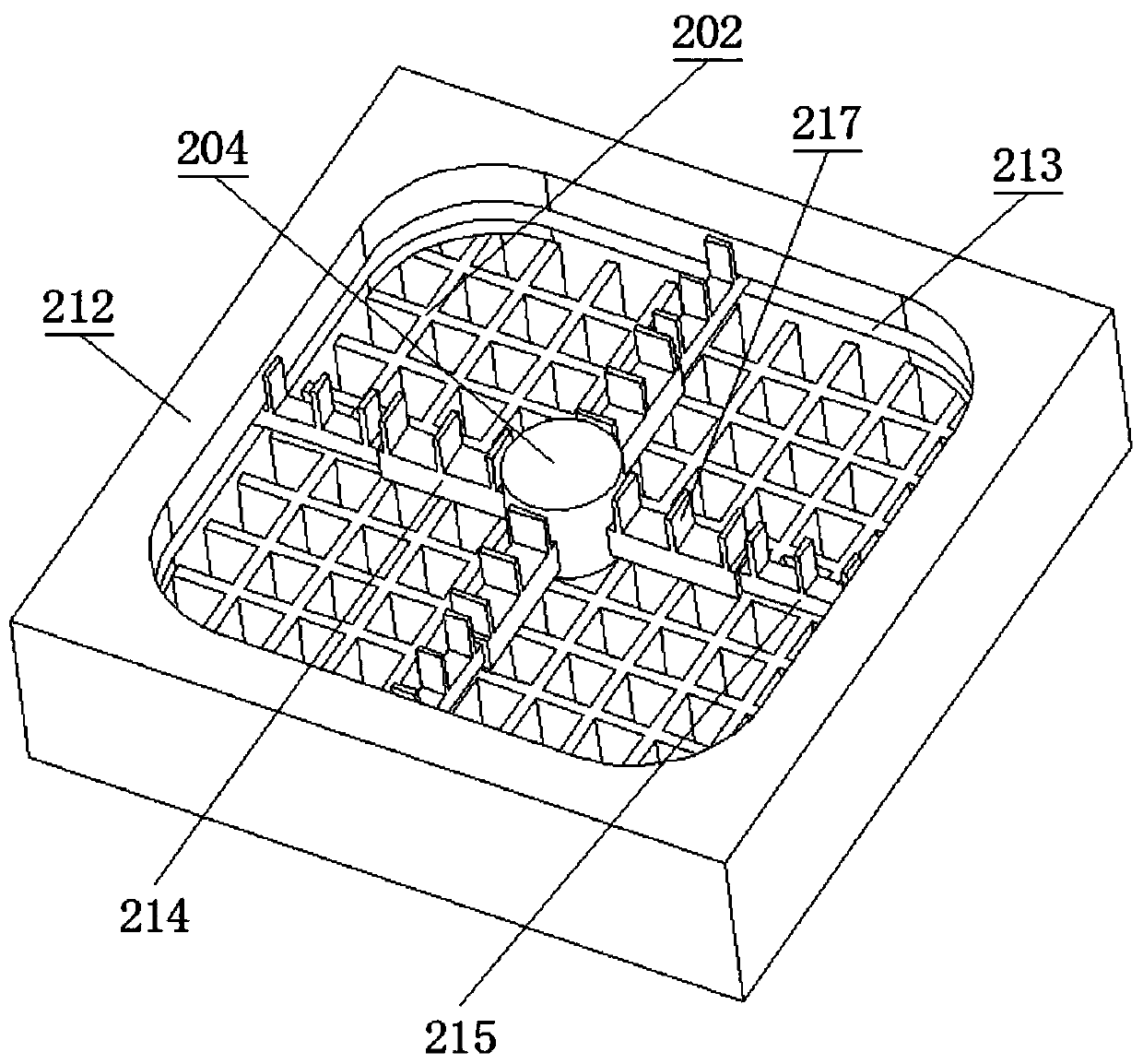

[0048] The collected coal is transported to the crushing chamber 201, and the pressure seat 205 is driven by the hydraulic rod of the hydraulic cylinder 206 to perform vertical circular movement. , the coal block enters on the grille 202 through the blanking port 218, and when the pressure seat 205 descends, the coal block is rolled and compacted. The block is crushed, and the crushed coal block falls onto the slideway 209 through the grid 202, the first motor 203 drives the swivel seat 204, and during the synchronous rotation of the fixed rod 214, the sliding rod 215 and the crushing blade 217, the track groove 213 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com