Patents

Literature

207results about How to "Quick unblock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

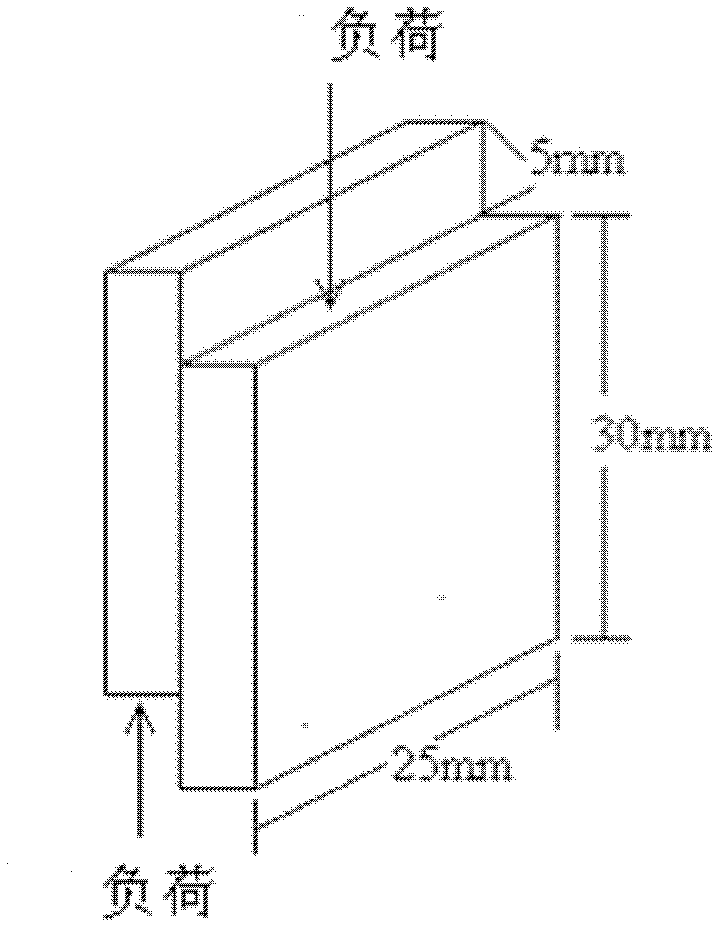

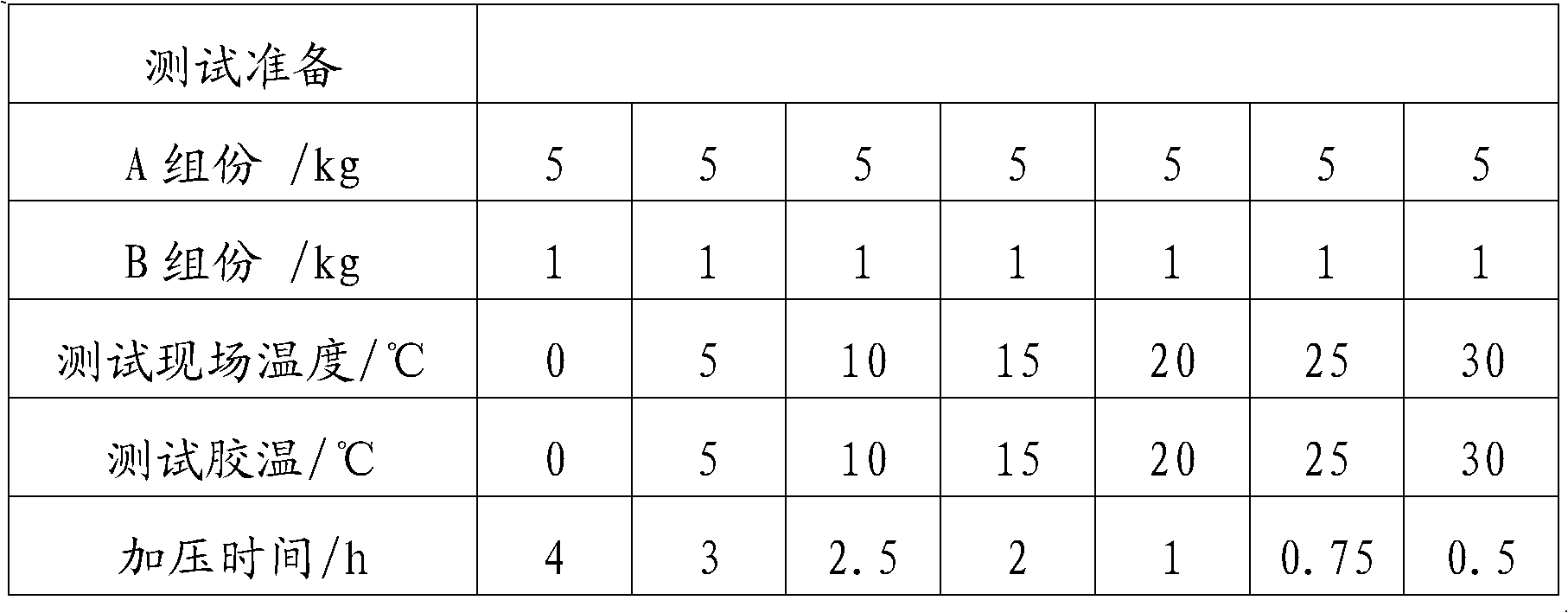

Bi-component polyurethane adhesive

ActiveCN102533200AQuick unblockSpeed up unblockingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolyol

The invention discloses a bi-component polyurethane adhesive, which consists of a component A and a component B. The component A comprises the following raw materials in percentage by weight: 0-10% of monohydric alcohol, 30-90% of polyhydric alcohol, 8-60% of pigments and fillers, 1-10% of nano-filler, 0.01-1% of catalyst and 0.1-5% of silane coupling agent, wherein the sum of the raw materials is equal to 100%; the component B is isocyanate; and the weight ratio of the component A to the component B is 1-5:1. According to the bi-component polyurethane adhesive, the shelf life of the prepared bi-component polyurethane adhesive is obviously prolonged, and the curing speed is doubled.

Owner:GUANGZHOU RETAN NEW MATERIALS & HI TECH CO LTD

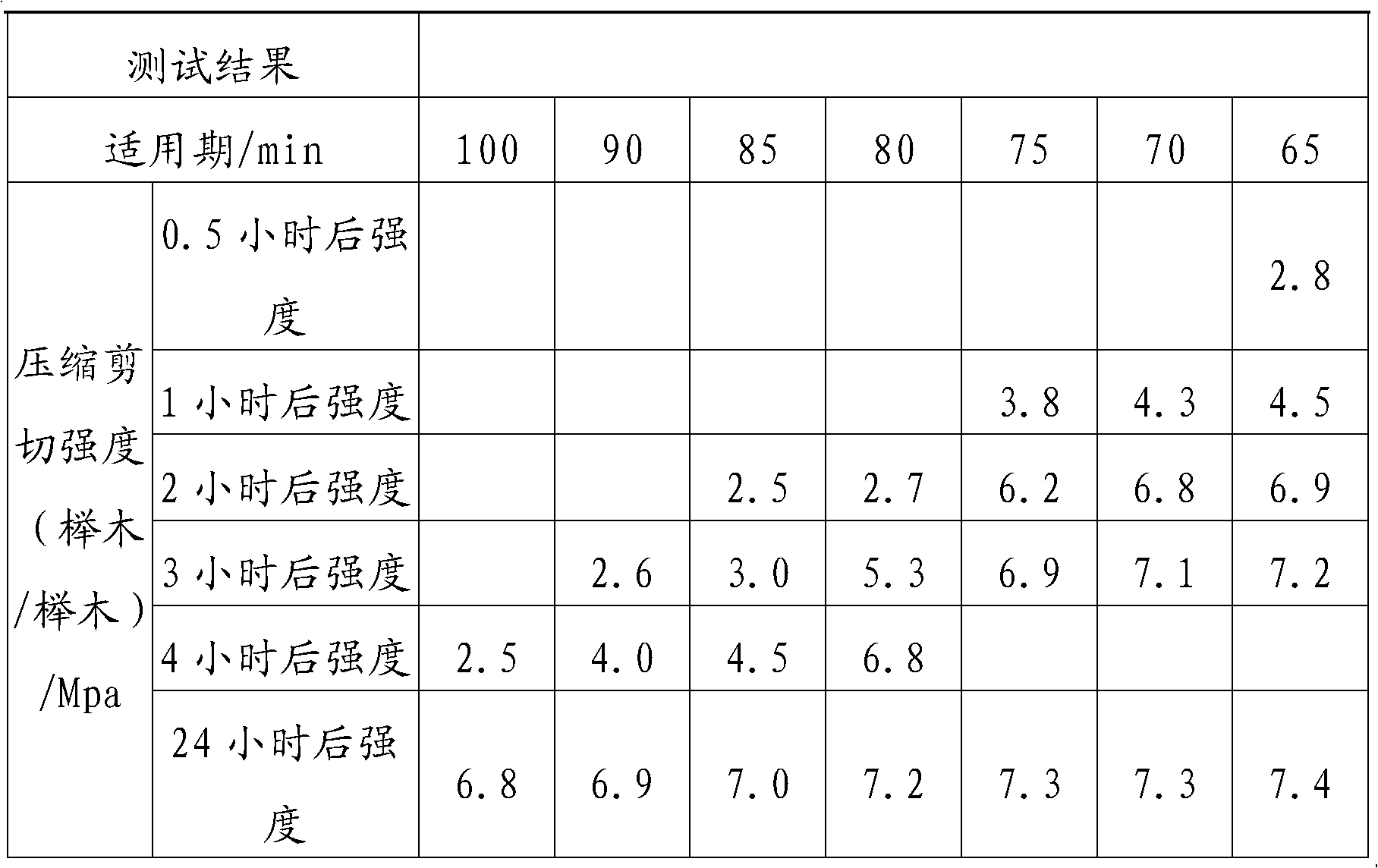

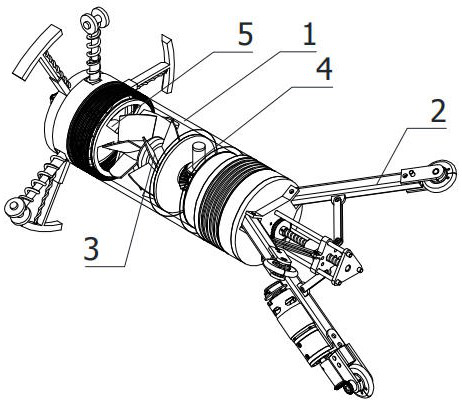

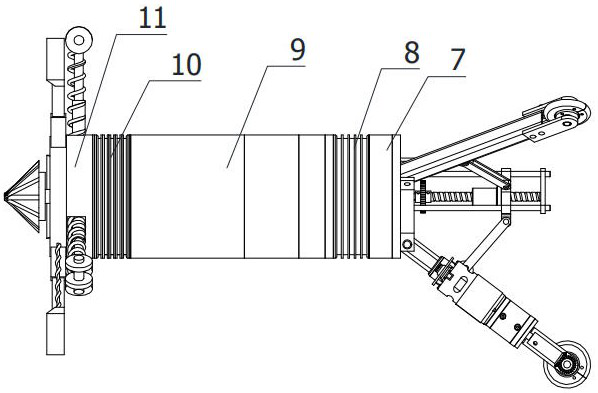

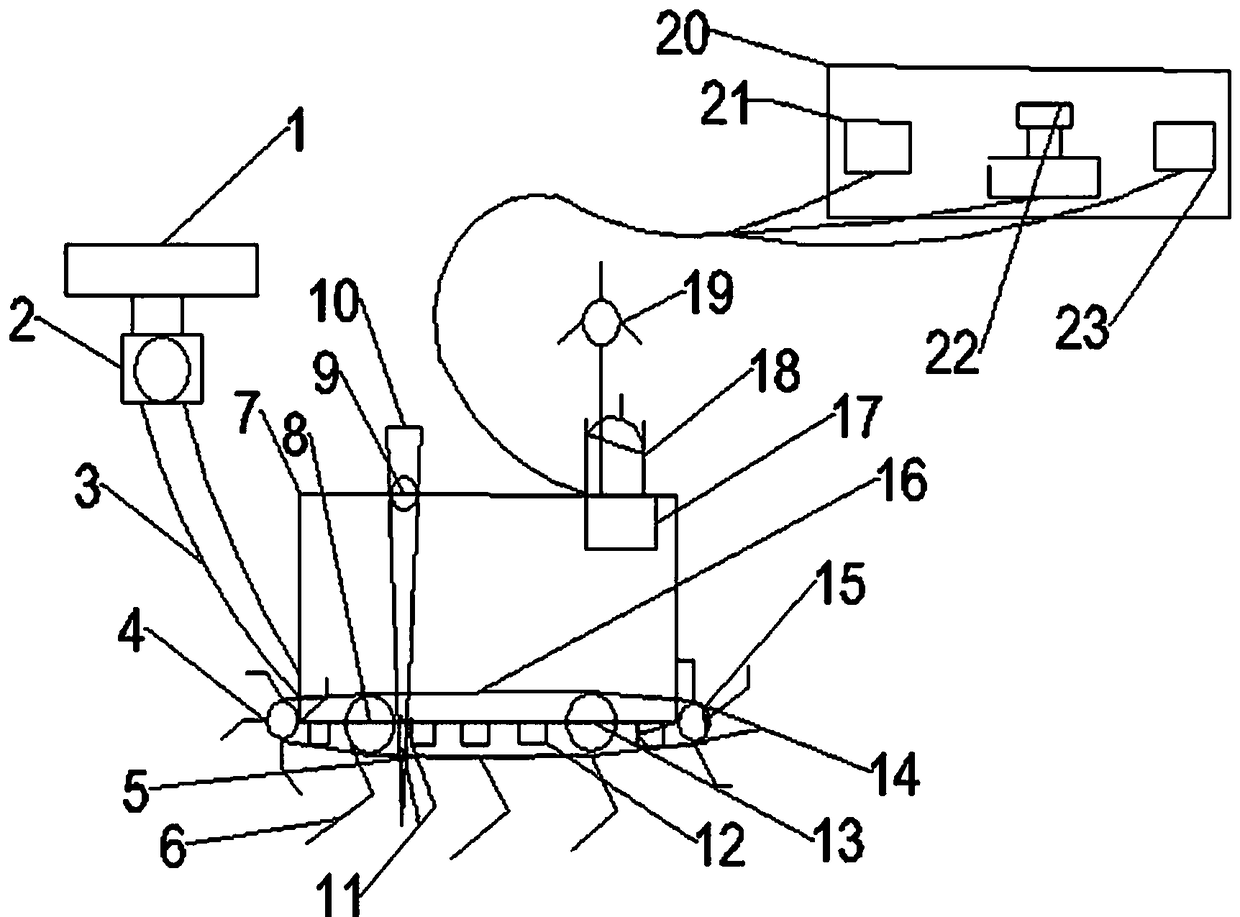

Efficient pipeline dredging equipment for sewage treatment

ActiveCN112044887AGood dredging effectImprove dredging efficiencyHollow article cleaningSewage treatmentWater treatment

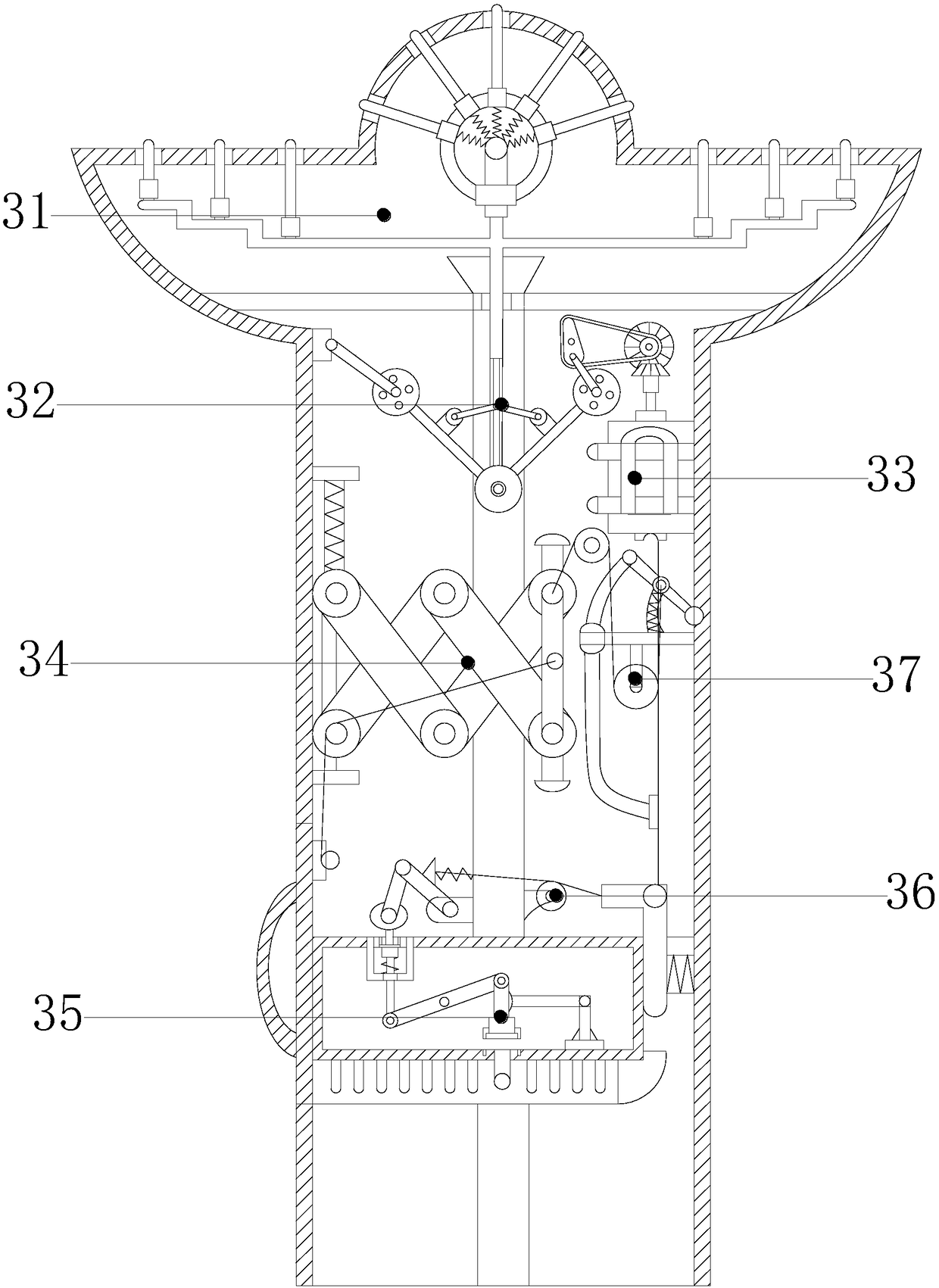

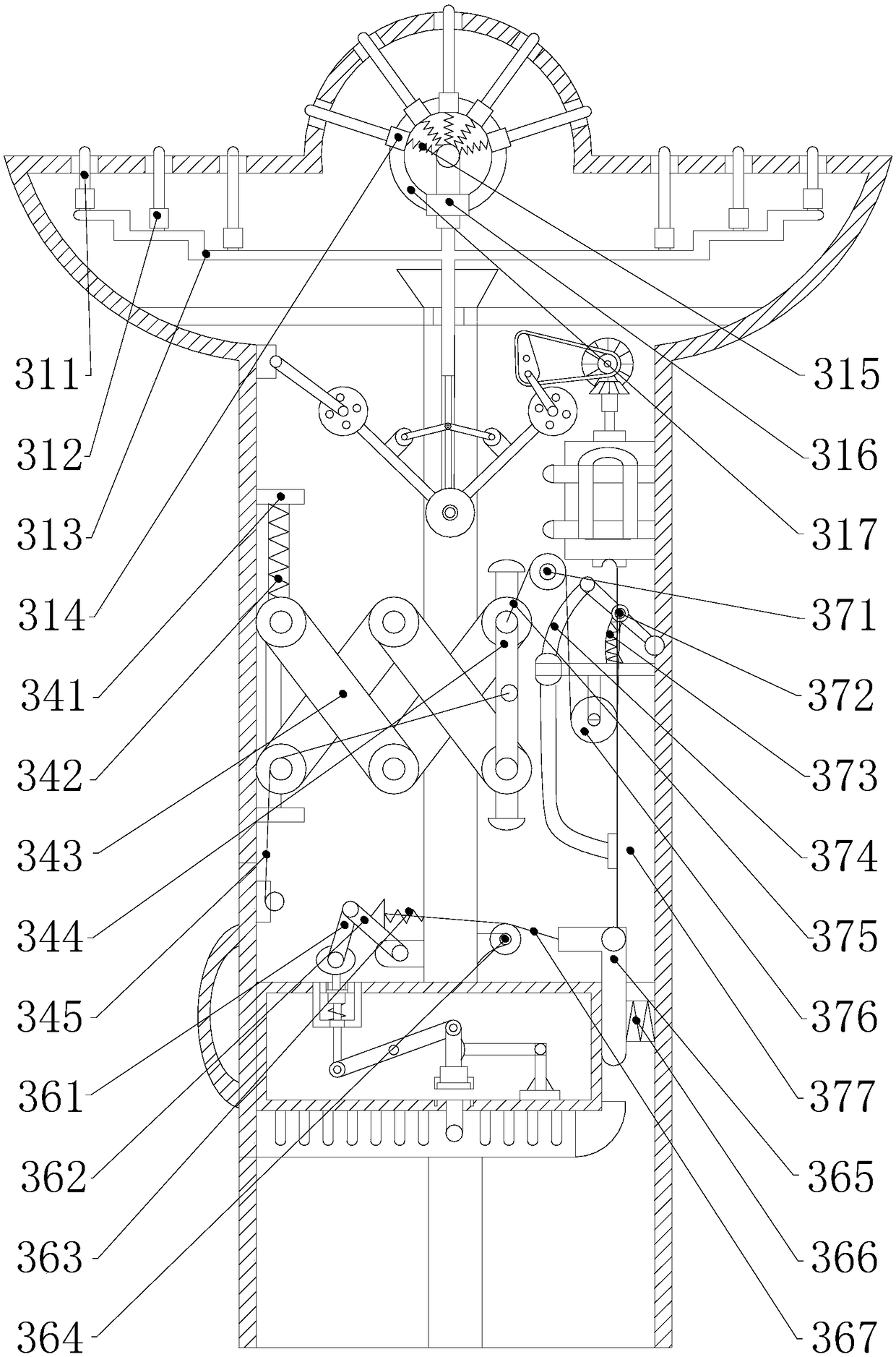

The invention relates to the technical field of pipeline sludge equipment, in particular to efficient pipeline dredging equipment for sewage treatment. The efficient pipeline dredging equipment comprises a housing, a traveling assembly, a crushing and dredging assembly, a reverse rotary mechanism and a steering drive mechanism, wherein the traveling assembly comprises a spacing regulating mechanism, a traveling drive mechanism and a front-end displacement mechanism, the spacing regulating mechanism is fixedly mounted at the tail end of the housing horizontally, and the traveling drive mechanism is fixedly mounted at the output end of the spacing regulating mechanism; the crushing and dredging assembly comprises a first crushing paddle for crushing sludge and a crushing mechanism for crushing sludge blocks, and the first crushing paddle is arranged at the front end of the housing. The efficient pipeline dredging equipment for sewage treatment disclosed by the invention can automaticallytravel in a pipeline, can quickly dredge sludge blocked in the pipeline, can flexibly turn in the pipeline, can clear sludge around the corner of the pipeline, can further perform crushing treatmenton large pieces of sludge, prevents secondary accumulation, and improves dredging effect.

Owner:安徽泽安智成科技有限公司

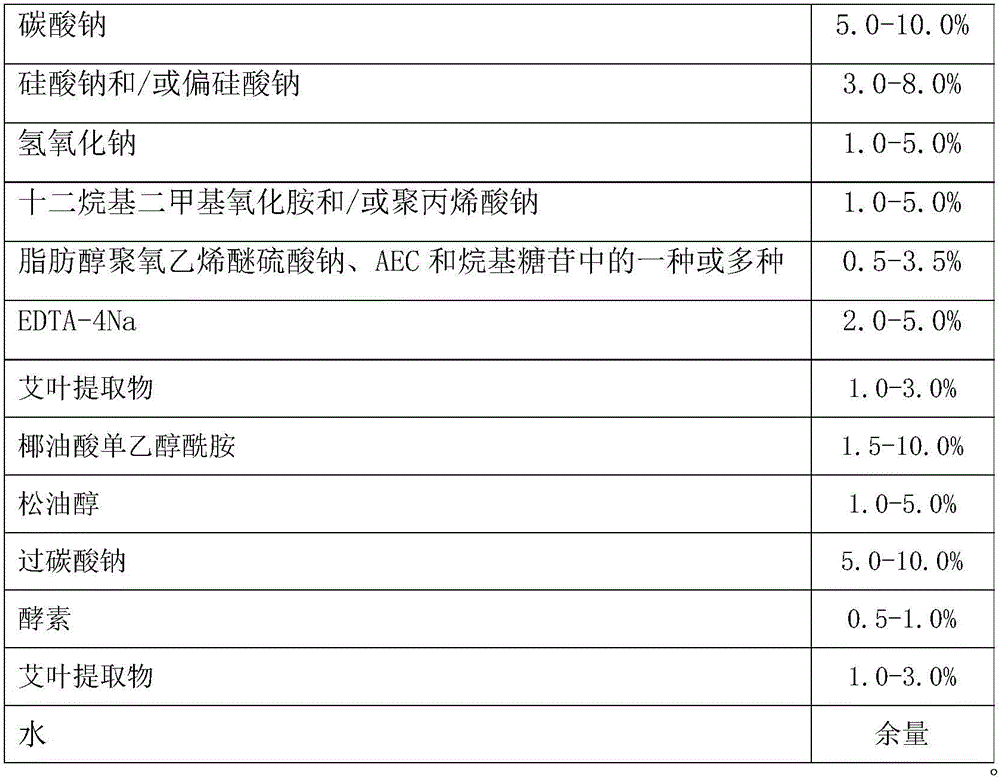

Peculiar smell-removal efficient liquid pipe dredging agent and preparation method thereof

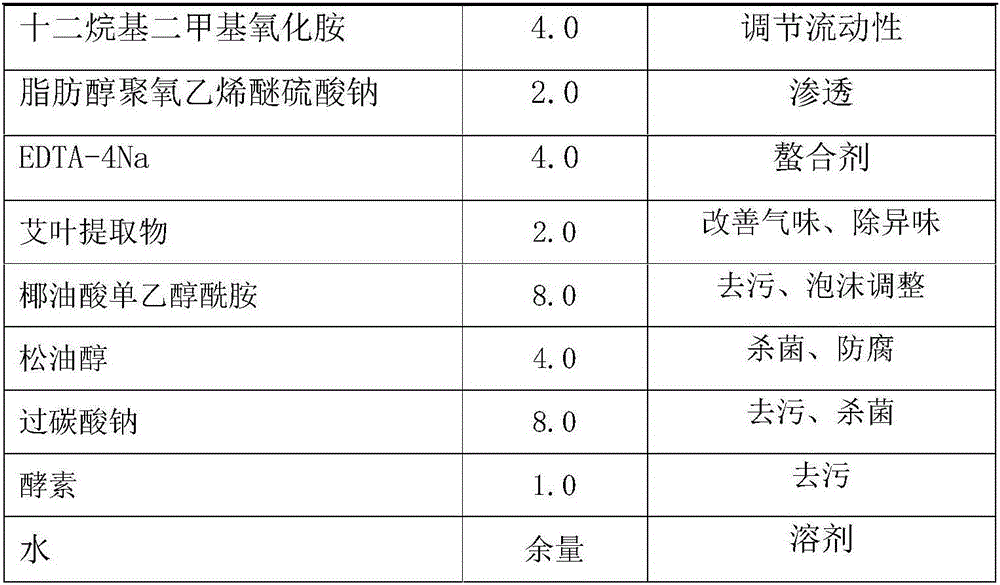

InactiveCN106479718ASolve the problem of secondary blockageQuick unblockInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium polyacrylateChemistry

The invention relates to a peculiar smell-removal efficient liquid pipe dredging agent and a preparation method thereof. The preparation method comprises adding water to a blending tank, carrying out stirring, adding sodium hydroxide, sodium carbonate, sodium metasilicate, sodium silicate, lauryl dimethyl amine oxide, sodium polyacrylate, sodium alcohol ether sulphate, AEC, EDTA-4Na, folium artemisiae argyi extract, coconut oil monoethanolamide, terpineol, sodium percarbonate and enzyme into the blending tank, carrying out uniform stirring, carrying out settling for 24 hours and carrying out filtration. The dredging agent solves the problem of secondary clogging of the existing pipe dredging agent. The liquid product can quickly reach the clogging site and dissolve the clogging material and is especially suitable for use in winter.

Owner:长兴净安环保科技有限公司

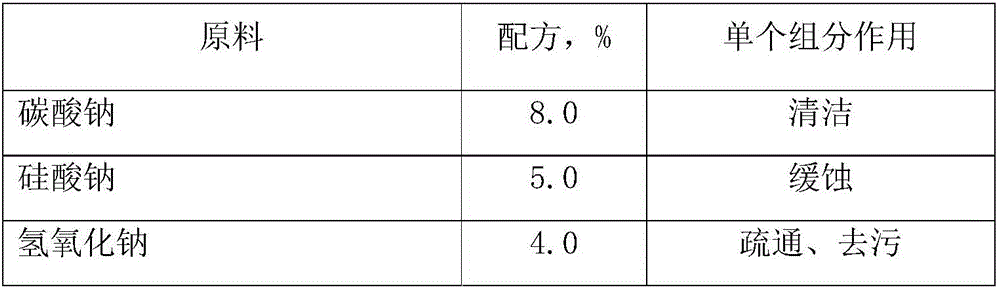

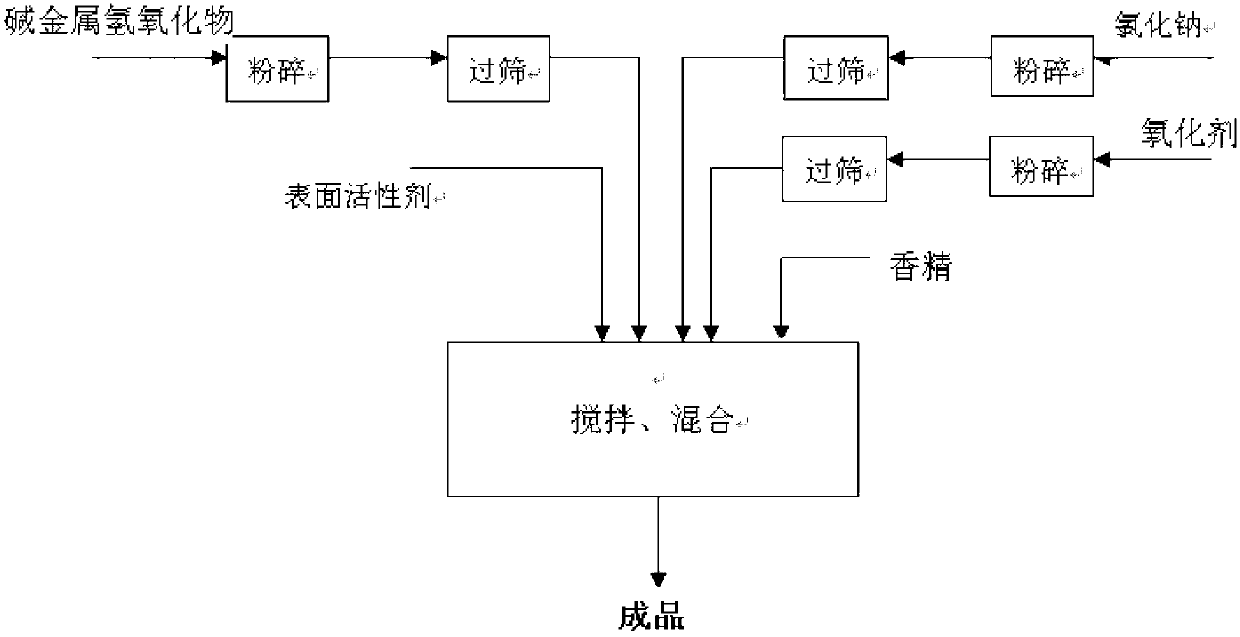

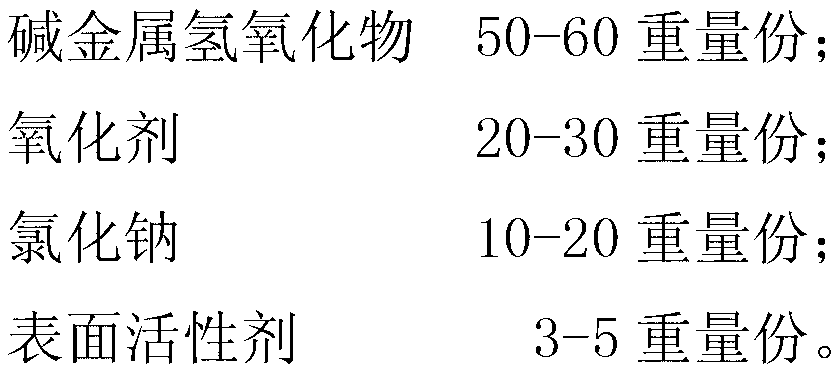

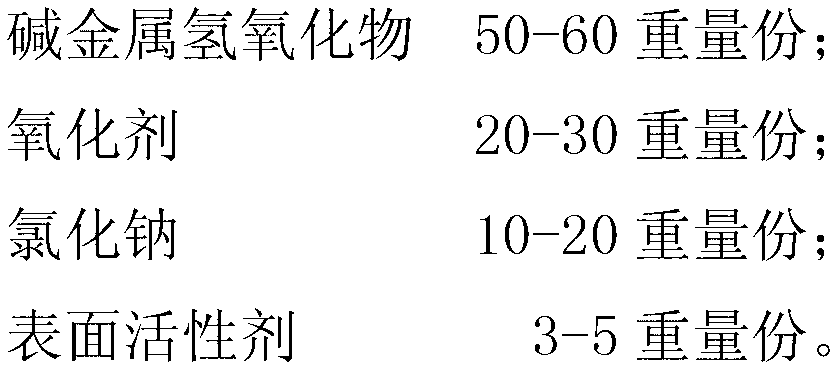

Hydroxide solid pipeline dredging maintenance agent and its preparation technology

InactiveCN103131567AImprove decontamination abilityHas the effect of decontamination and descalingHollow article cleaningSurface-active non-soap compounds and soap mixture detergentsActive agentEnvironmental engineering

The invention relates to a hydroxide solid pipeline dredging maintenance agent. The hydroxide solid pipeline dredging maintenance agent is characterized in that the hydroxide solid pipeline dredging maintenance agent comprises 50-60 parts by weight of an alkali metal hydroxide, 20-30 parts by weight of an oxidant, 10-20 parts by weight of sodium chloride, and 3-5 parts by weight of a surfactant. The invention also relates to a preparation technology of the hydroxide solid pipeline dredging maintenance agent. The hydroxide solid pipeline dredging maintenance agent has the advantages of scientific and reasonable component compatibility, rapid dredge effect, small alkali metal hydroxide content, small pollution to the environment, safe and convenient use, low cost, and wide use range.

Owner:天津市南开区房产公司

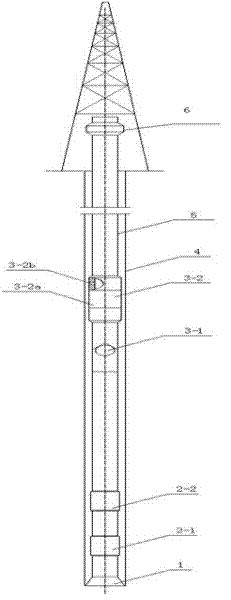

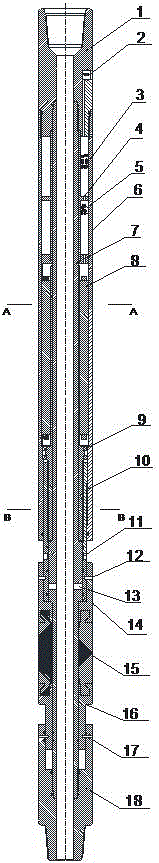

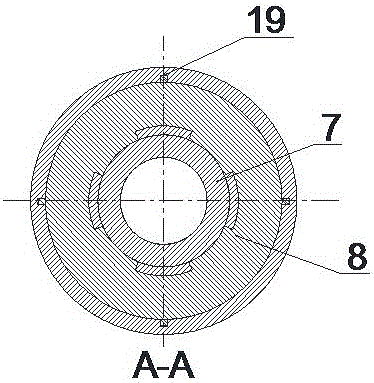

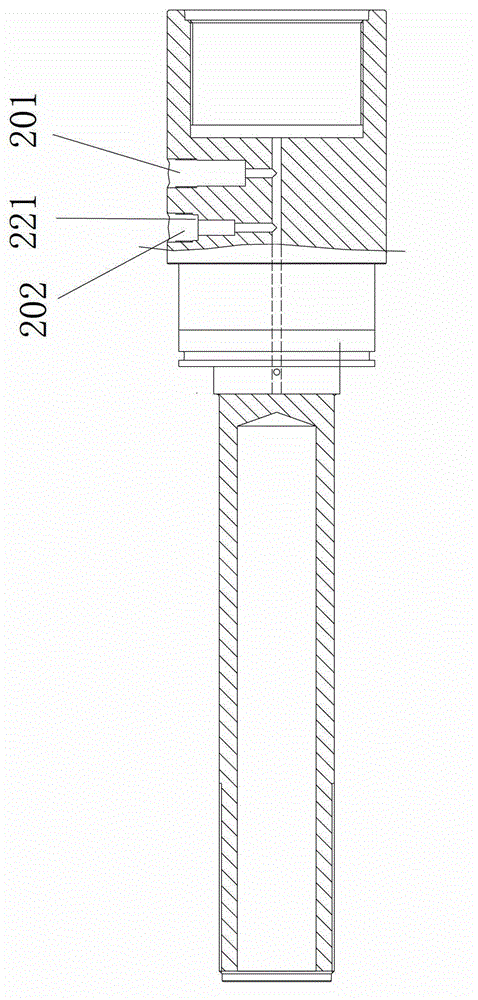

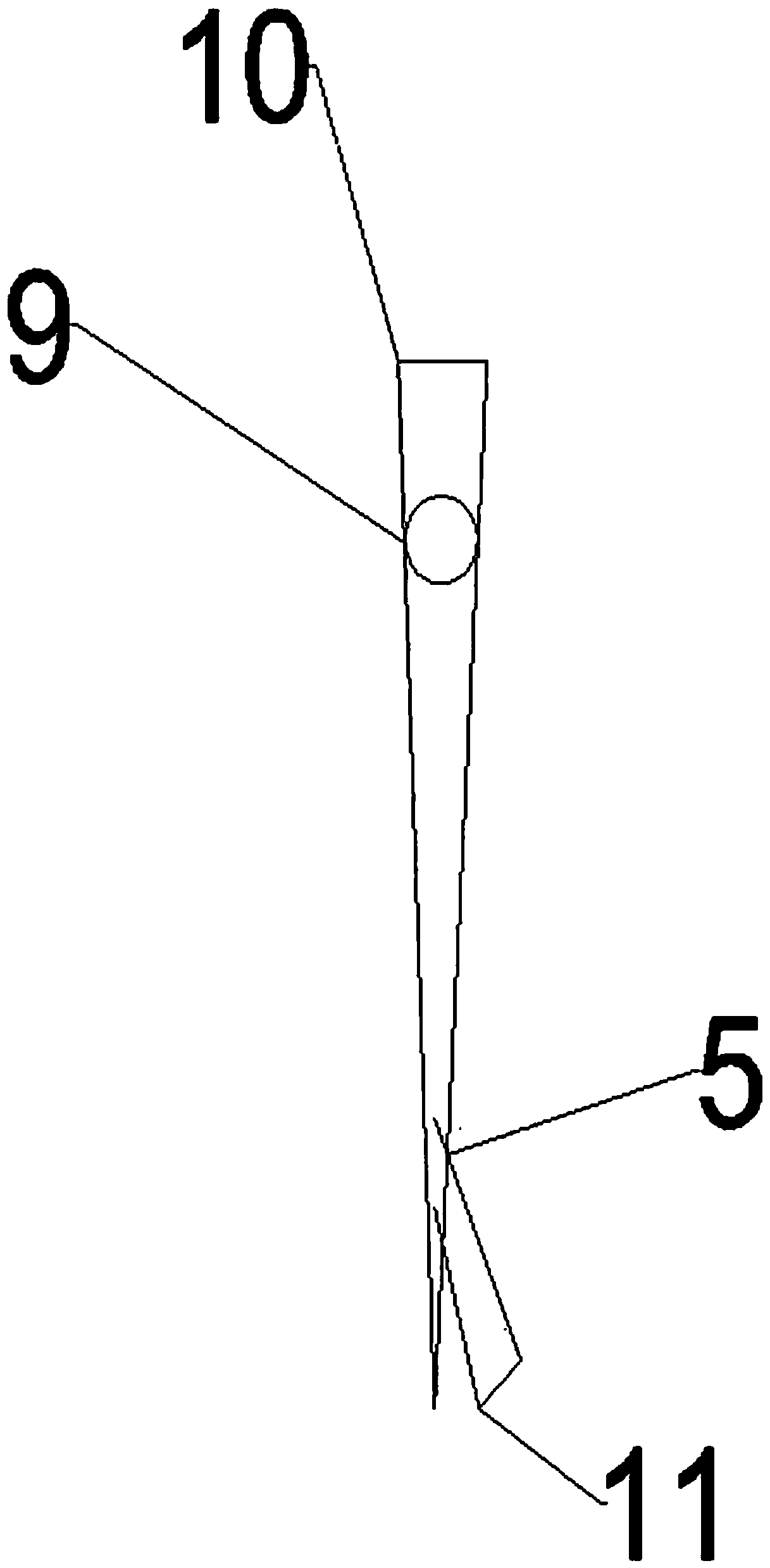

Drill string equipped with downhole blowout preventer and working method thereof

InactiveCN102226377AEasy to prevent blowout sealingFast transfer speedSurveyDrilling rodsBlowout preventerAlarm signal

The invention discloses a downhole blowout prevention technology and belongs to the technical field of downhole blowout prevention. The invention relates to a drill string equipped with a downhole blowout preventer, and the drill string comprises a drill string body, wherein a drill bit is arranged at the bottom of the drill string body. The drill string is characterized in that the downhole blowout preventer is mounted on the drill string body, at least one pressure monitoring and signal generating device is arranged at one end, adjacent to the drill bit, of the drill string body, a signal receiving and alarm generating device is arranged at the upper part of the top of the drill string body, and the signal receiving and alarm generating device is matched with the pressure monitoring andsignal generating device. By adopting the drill string equipped with the downhole blowout preventer, downhole well kick or blowout can be effectively monitored; and furthermore, the alarm signal transfer speed is fast, measures can be timely and effectively adopted for implementing well sealing, the blowout preventer is positioned above a neutralization point, the blowout preventer is in a tension state, the purposes of placing a pipe column downwards for setting and lifting the pipe column upwards for unsealing can be realized, and the well kick or the blowout can be effectively prevented.

Owner:SOUTHWEST PETROLEUM UNIV

Healthcare bathing medicine and medicine liquid and preparation method thereof

InactiveCN103463173AQuick unblockUnblock thoroughlyNervous disorderMetabolism disorderBalsamDrug product

The invention discloses a healthcare bathing medicine which comprises the following components in parts by weight: 10-30 parts of folium artemisiae argyi, 10-30 parts of herba lycopodii, 10-30 parts of garden balsam stem and 5-10 parts of safflower. The healthcare bathing medicine liquid comprises the following components: 10-30g of folium artemisiae argyi, 10-30g of herba lycopodii, 10-30g of garden balsam stem, 5-10g of safflower and 15-25L of water. A preparation method of the healthcare bathing medicine liquid comprises the following steps: (a) putting 10-30g of folium artemisiae argyi, 10-30g of herba lycopodii, 10-30g of garden balsam stem and 5-10g of safflower into the 15-25L of water; (b) boiling for 1-2 hours to obtain the healthcare bathing medicine liquid.

Owner:崔永堂

Pipeline oil stain cleaning agent and preparation method thereof

ActiveCN105542986AEffective emulsificationEfficient degradationOrganic detergent compounding agentsNon-ionic surface-active compoundsAdditive ingredientCleansing Agents

The invention provides a pipeline oil stain cleaning agent and a preparation method thereof, and relates to an oil stain cleaning treatment technology. The pipeline oil stain cleaning agent is characterized in that the effective ingredients of the pipeline oil stain cleaning agent comprise a compound microorganism preparation, and microorganisms in the compound microorganism preparation comprise Bacillus stearothermophilus and Brevibacillus sp.. In further improvement, the effective ingredients of the pipeline oil stain cleaning agent further comprise an enzyme preparation, a low-molecular-weight peptide and a glycolipid biological surfactant. The microorganism preparation takes grease ingredients existing in pipelines as the main carbon source and can emulsify and degrade the grease ingredients in the pipelines through metabolism and reproduction activities of the microorganisms themselves; meanwhile, the microorganism preparation can restrain reproduction of harmful bacteria in the environment, facilitate growth and reproduction of endogenous good bacteria in the environment and prevent the odor problem and other problems from occurring, and therefore the effects for achieving long-time and effective oil removing and pipeline dredging can be achieved; the fermentation technology is simple, easy to control and low in production cost.

Owner:中林山水(北京)生态科技有限公司 +1

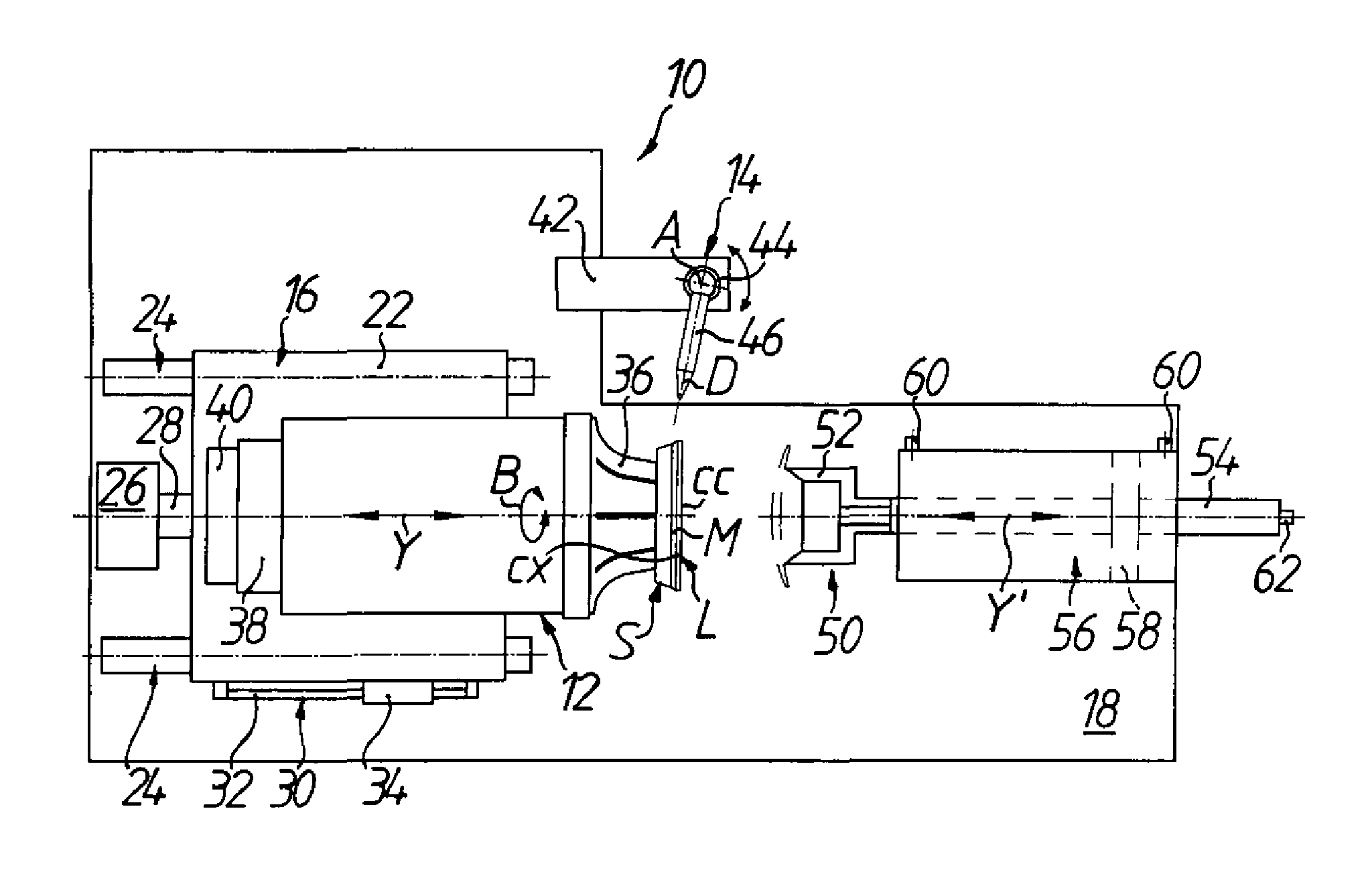

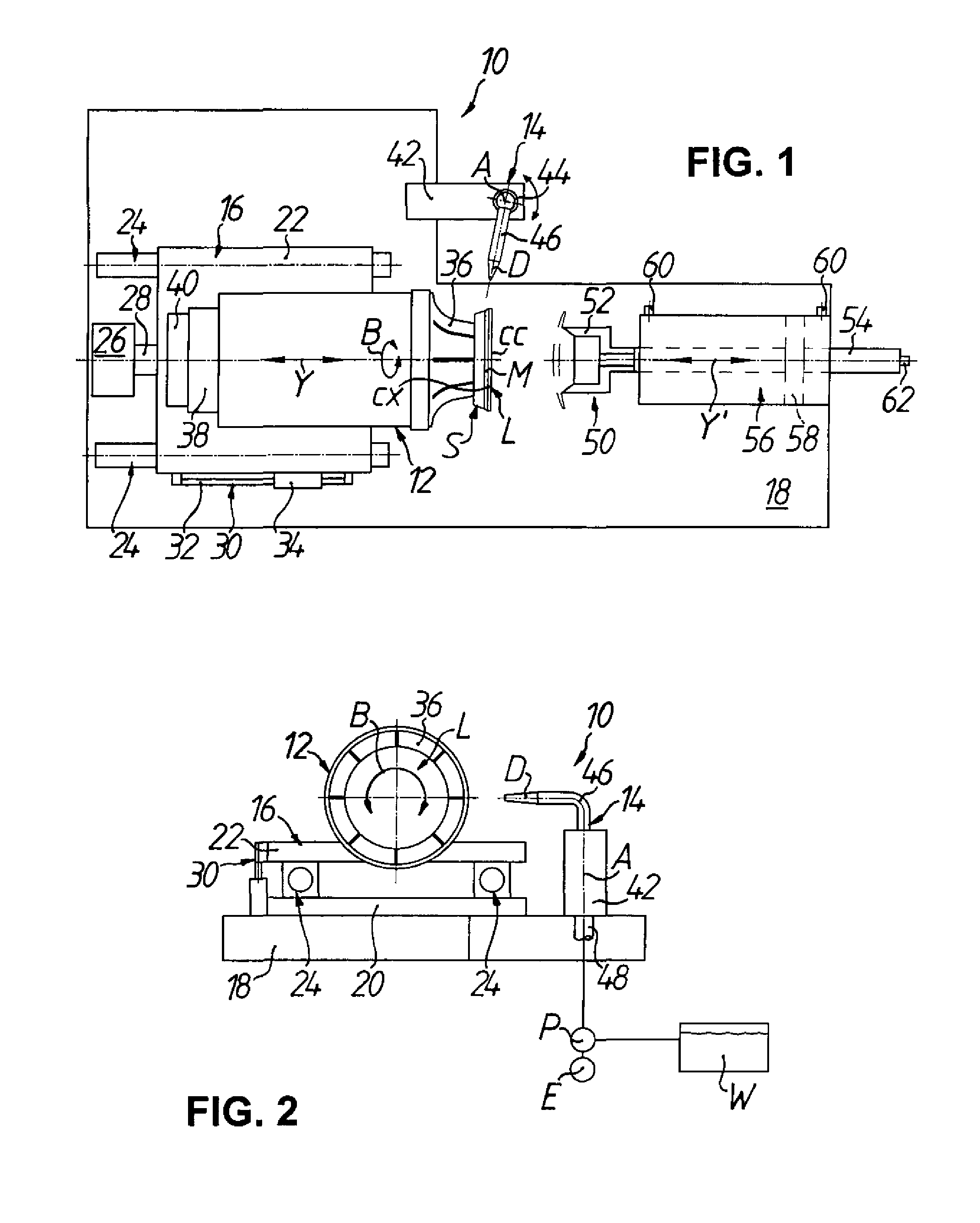

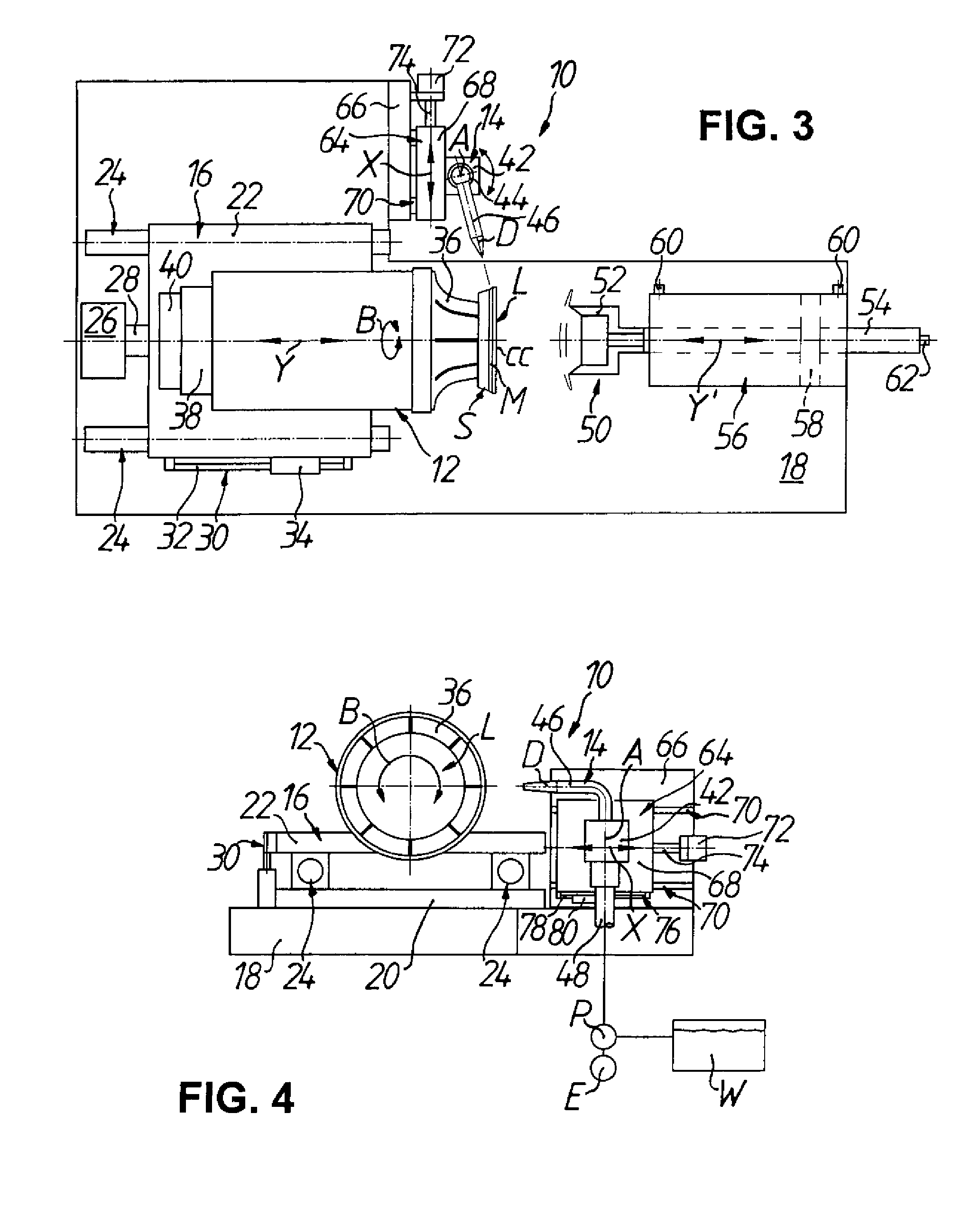

Device and method for deblocking optical workpieces, in particular spectacle lenses

ActiveUS8931769B2Quickly deblockAvoid scanningOptical surface grinding machinesOptical articlesRotational axisEyeglass lenses

The invention relates to a deblocking device and an associated method for deblocking optical workpieces, for example, eyeglass lenses. The deblocking device has a first moving apparatus for rotating a workpiece blocked on a block piece about a workpiece rotational axis, a nozzle assembly having a nozzle for discharging a high-pressure pressure medium jet in a direction substantially perpendicular to the workpiece rotational axis onto an edge area between the workpiece and block piece, and a second moving apparatus for generating a relative motion between the workpiece and the nozzle along the workpiece rotational axis.

Owner:SATISLOH AG

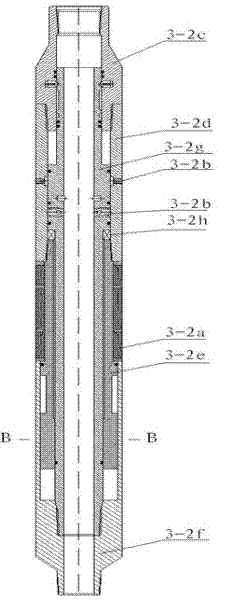

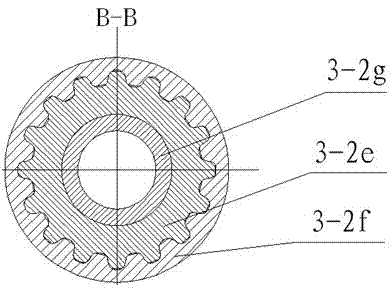

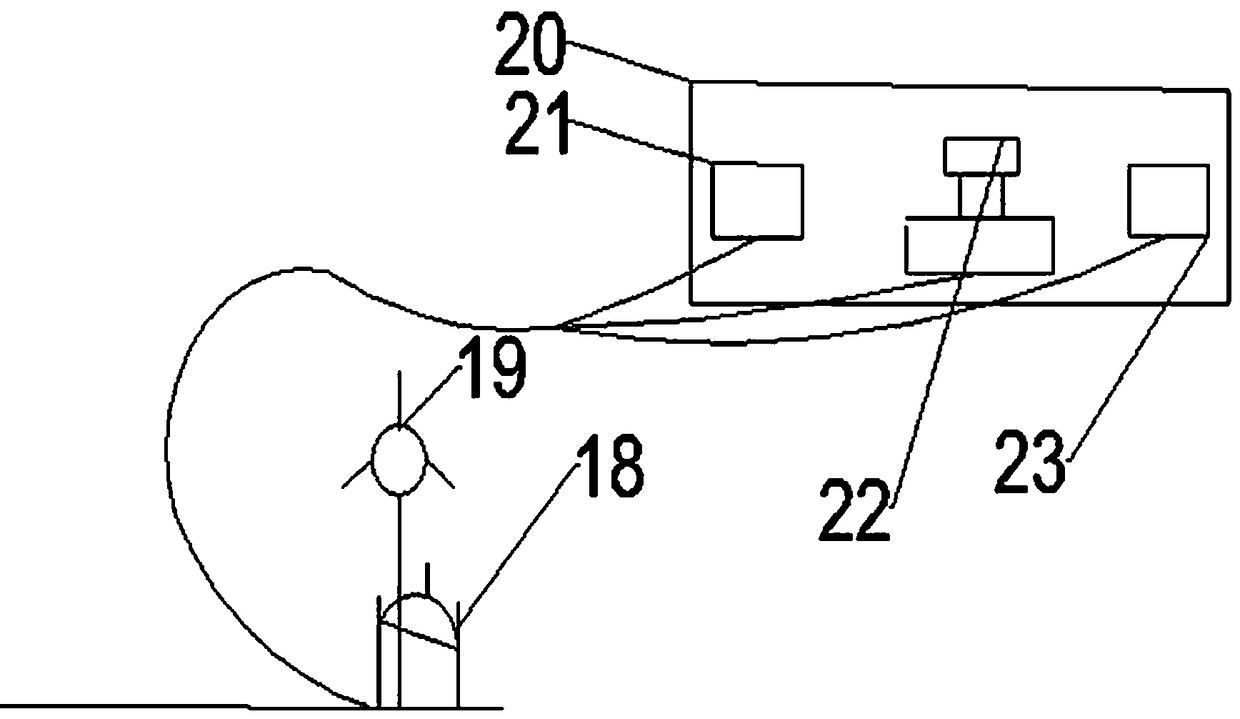

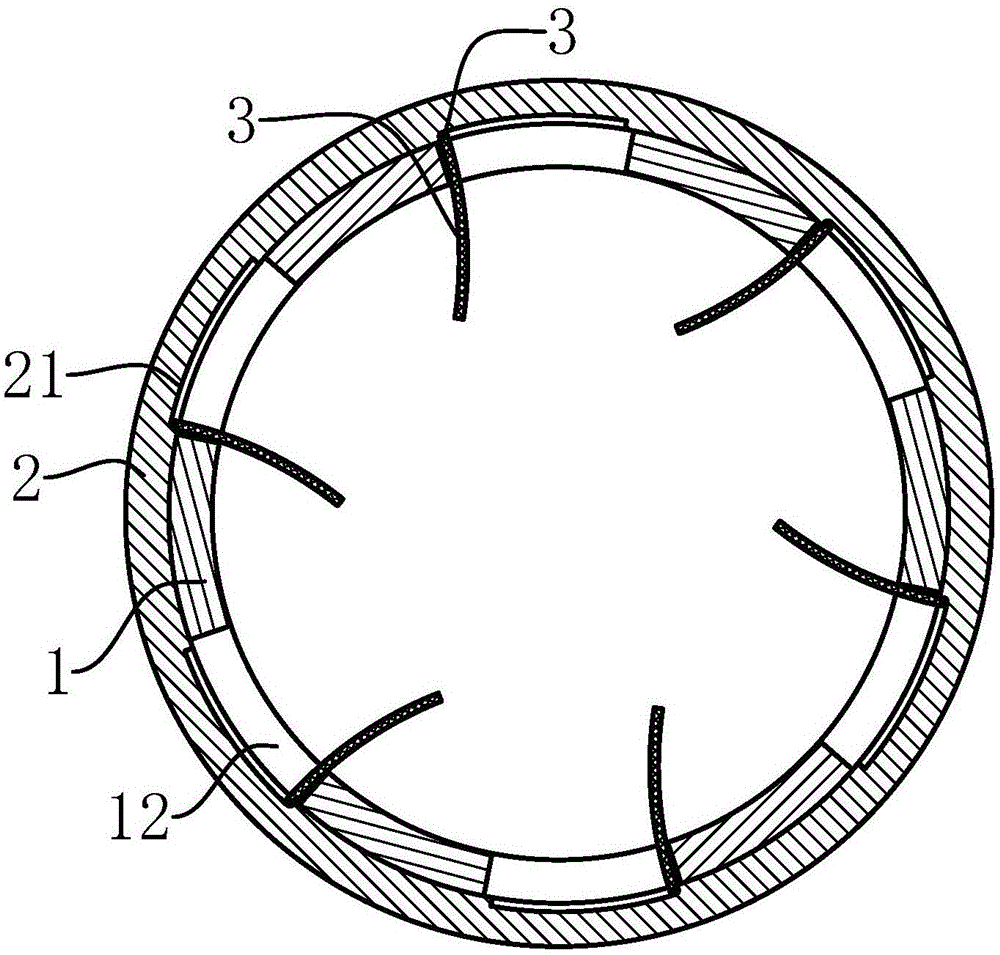

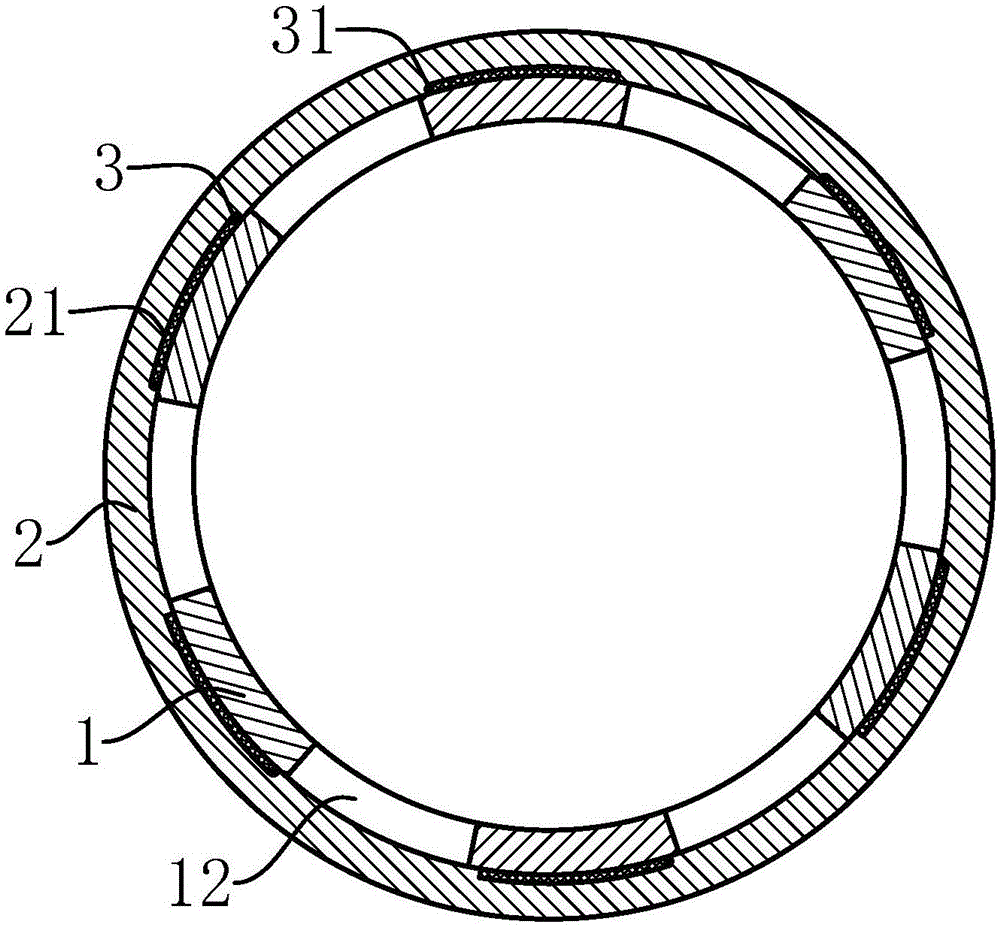

Motor-driven extrusion-type underground annular blowout preventer and communication method thereof

ActiveCN105822251ASimple structureEasy to operateSealing/packingAutomatic control for drillingMotor driveComputer module

The invention discloses a motor-driven extrusion-type underground annular blowout preventer, and belongs to the technical field of underground blowout prevention. The motor-driven extrusion-type underground annular blowout preventer mainly comprises a communication module, a control module, a power module and an execution module. By the motor-driven extrusion-type underground annular blowout preventer, positive and negative rotation of a motor is achieved under the control of the control module; power is transmitted to a compression tube of the power module; and the compression tube compresses a rubber tube or reversely drags the rubber tube to achieve sealing and unsealing of the blowout preventer. The motor-driven underground annular blowout preventer can be repeatedly used, is suitable for a plurality of well types, can be used in a whole well section, and is driven by the motor; sealing and unsealing are relatively easy, and the efficiency is relatively high; and the application prospect is wide.

Owner:SOUTHWEST PETROLEUM UNIV

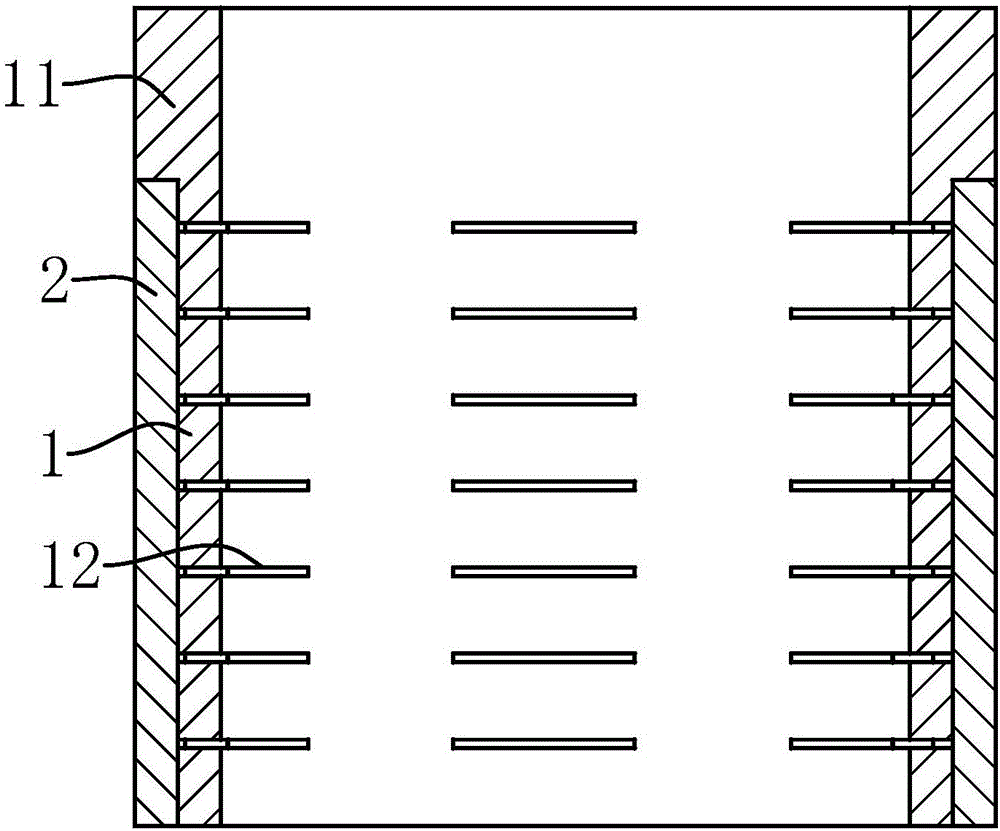

Tablet particles screening machine for preventing blockage of powder

InactiveCN108160468AImprove work efficiencySolve the easy to cause blockageSievingScreeningEngineeringVibration motor

The invention relates to the technical field of pharmaceutical production equipment, and discloses a tablet particles screening machine for preventing blockage of powder. The tablet particles screening machine comprises two supporting plates, the opposite sides of the two supporting plate are both provided with movable holes, the inner portion of the two movable holes are movably connected with asieve plate, the left and right sides of the bottom of the sieve plate are both fixedly connected with springs arranged equidistantly, the top of the sieve plate is provided with sieve holes distributed uniformly, the left side of the top of the sieve plate is provided with a vibration motor, a top plate is fixed connected between the two supporting plates, a cross-shaped conduit is fixedly connected on the top of the top plate, and the top of the cross-shaped conduit is fixedly connected with a receiving hopper. The tablet particles screening machine for preventing blockage of powder has theadvantages that it is avoided that the blocked sieve holes cause the filtering rate to slow down, thereby the work efficiency of the screening machine is reduced, a lot of time and labor to clean up the blocked sieve holes are saved, unnecessary troubles are avoided, and the work efficiency of the tablet particles screening machine is improved.

Owner:盐城市瑞普医药化工有限公司

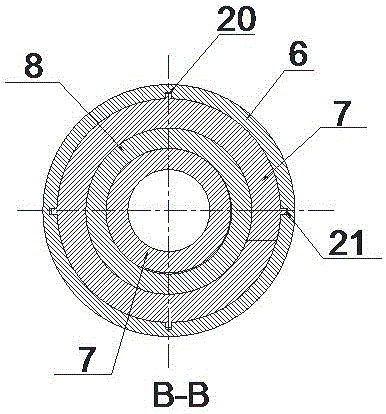

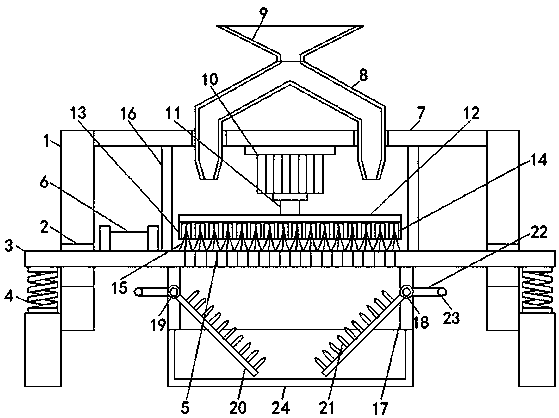

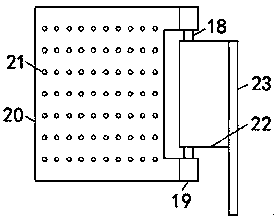

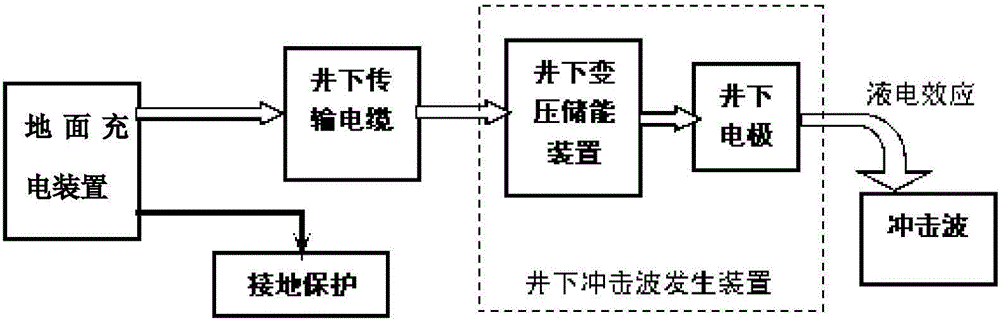

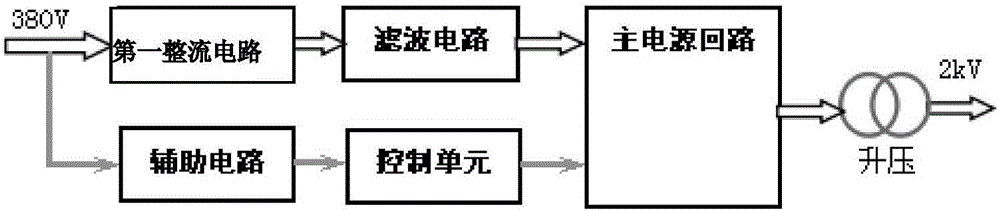

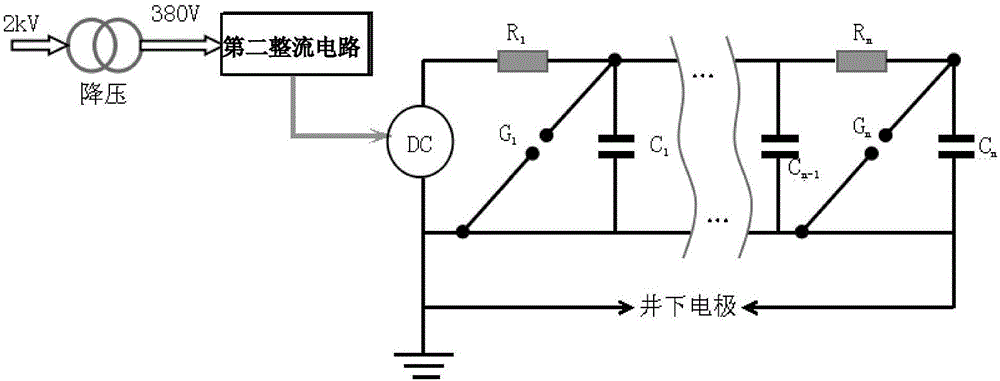

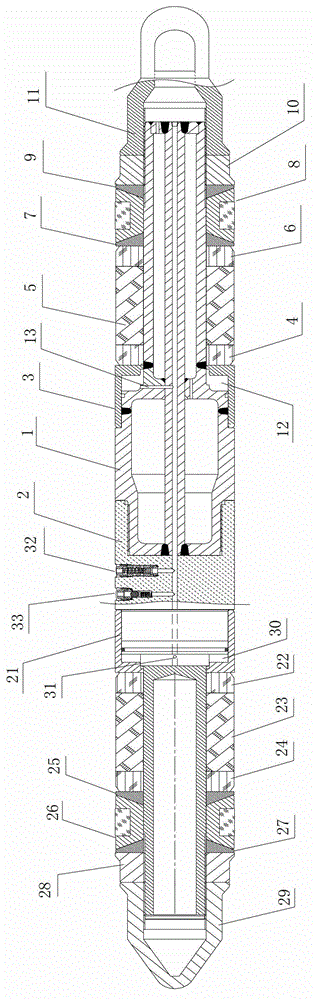

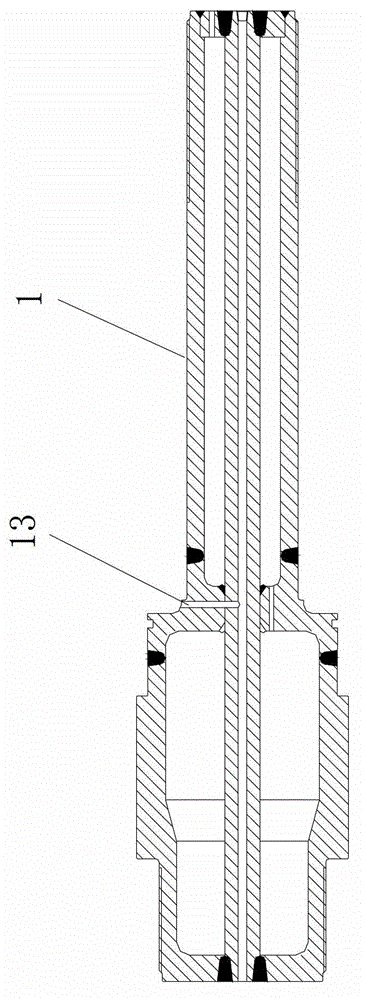

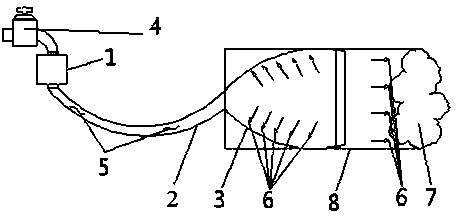

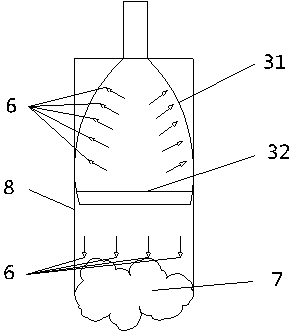

Oil and gas reservoir permeation-increasing and plugging-releasing device based on liquid-electric effect

The invention discloses an oil and gas reservoir permeation-increasing and plugging-releasing device based on a liquid-electric effect. The device includes a ground charging device which configured to transmit electric power to a downhole, a downhole device which is configured to store electric energy delivered by the ground charging device and capable of generating the liquid-electric effect to produce shock waves, and at least a downhole shock wave generating device, wherein the downhole shock wave generating device comprises a downhole variable pressure energy storage device and downhole electrodes, and is configured to lower the transmission voltage of the ground charging device to a charge voltage and then store the electric energy delivered by the ground charging device, accordingly, the charging voltage can be instantly increased by several times before being loaded to the downhole electrode to allow the downhole electrodes to generate the liquid-electric effect. The device is based on the electric spark explosion formed by the liquid-electric effect between downhole electrodes, and the periodic impact waves are excited to the surrounding strata, therefore, formation conditions can be improved, an oil permeation channel can be quickly dredged, and permeability of an oil well can be improved.

Owner:苏州峰极电磁科技有限公司

Substrate-free low temperature reactive hot melt adhesive tape and glue used by same, and preparation methods of hot melt adhesive tape and glue

ActiveCN108250993AQuick unblockSave equipment costPolyureas/polyurethane adhesivesMacromolecular adhesive additivesKetoneSolvent

The invention discloses a formula and a preparation method of substrate-free low temperature reactive hot melt adhesive tape. The adhesive tape consists of substrate-free dry glue and a double-sided release film or double-sided release paper; the glue is prepared from 100-150 parts of thermoplastic polyurethane, 50-150 parts of rosin glyceride, 1-40 parts of a blocked crosslinking agent, 1-10 parts of a wetting leveling agent, 1-10 parts of a defoaming agent, 1-10 parts of a rheological agent, 0.1-5 parts of an anti-aging agent and 100-400 parts of a mixed solvent of ketones and esters; the substrate-free low temperature reactive hot melt adhesive tape is prepared by coating a substrate with the glue, drying, winding, and cutting. By designing the deblocking temperature of the crosslinkingagent and the softening point of the resin, the adhesive tape can be stored and transported at room temperature, and can realize a bonding strength of 2-3 N / mm<2> at a lower heating temperature (90-110 DEG C) and a lower pressure (1-2 bar). Therefore, the substrate-free low temperature reactive hot melt adhesive tape can solve the problems that the existing low-temperature hot melt adhesive is low in bonding strength, and the low-temperature reactive hot-melt adhesive requires special storage and transportation conditions; the substrate-free low temperature reactive hot melt adhesive tape cangreatly reduce the raw material storage and transportation costs of the electronic device manufacturer, and meets the bonding requirements for small parts of the current electronic products.

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

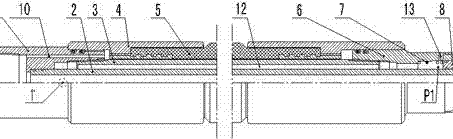

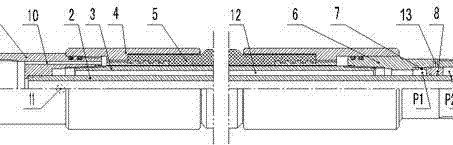

Pressure device for airtightness detection of casing and manufacturing method thereof

ActiveCN102944370AEasy to useEasy to carryDetection of fluid at leakage pointEngineeringHigh pressure

The invention discloses a pressure device for airtightness detection of a casing, and a manufacturing method of the pressure device. The pressure device for the detection comprises a casing body formed in a manner that a first casing is connected with a second casing, wherein the tail end of the second casing is closed; two packer components set by the action of high pressure gas and pressure energy storage rings are arranged on the first casing and the second casing correspondingly; a first one-way valve and a second one-way valve that are opposite in conduction direction are arranged on the casing body between the two packer components; the first casing is provided with an annular hollow structure; and the second casing is provided with a hollow structure. The pressure device for the detection is convenient to use and carry, and can detect the airtightness of the casing on a construction site.

Owner:通奥检测集团股份有限公司

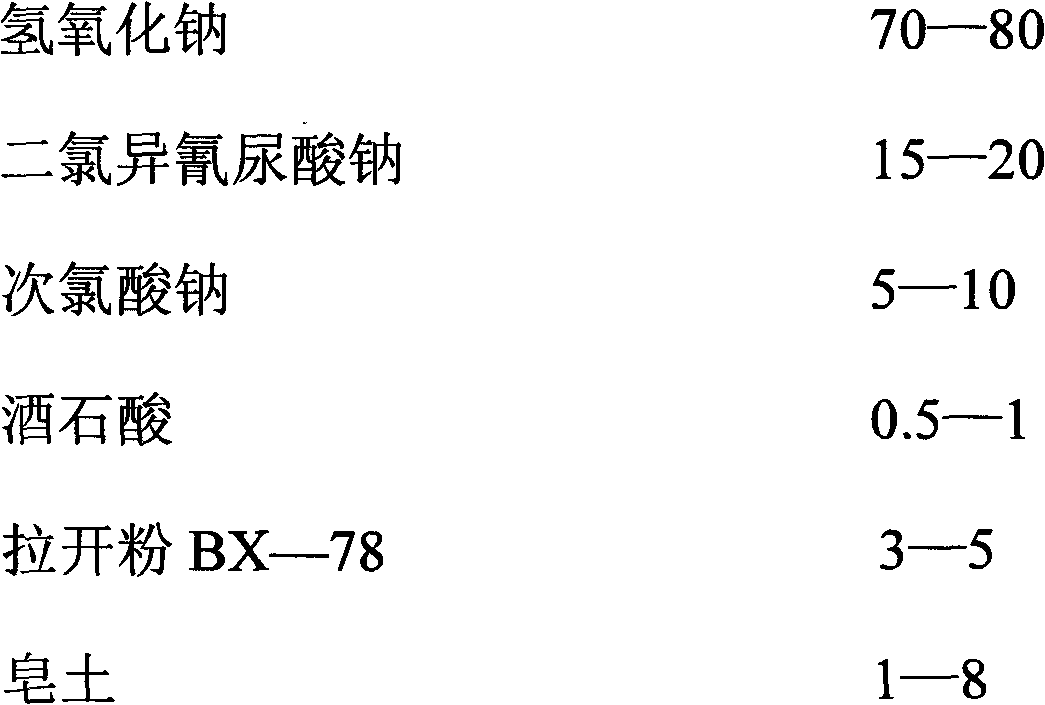

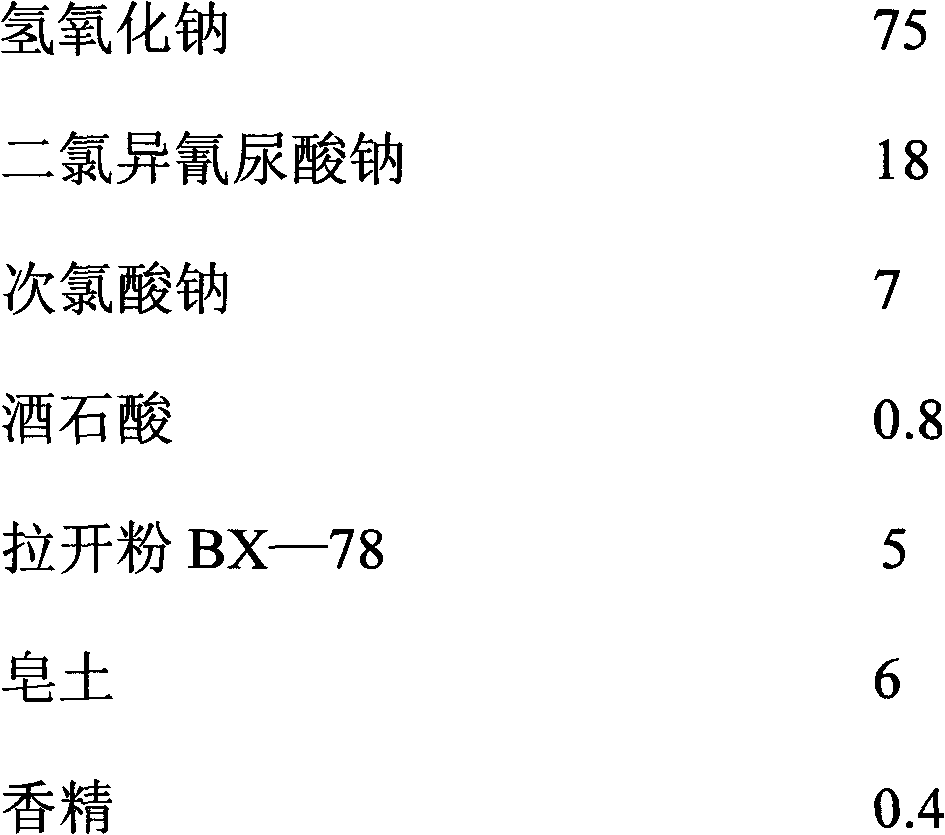

Pipeline dredge agent

InactiveCN103666852AEliminates odors and odorsEasy to makeHollow article cleaningInorganic non-surface-active detergent compositionsChemistrySewerage

The invention discloses a pipeline dredge agent. The pipeline dredge agent is a granular mixture which is prepared by mixing the following raw materials in parts by weight: sodium hydroxide, sodium dichlorocyanurate, sodium hypochlorite, tartaric acid, Nekal BX-78, bentonite and perfume. In case of blockage of a sewer, a pack of pipeline dredge agent is poured into the sewer, the inside of the sewer seems boiling immediately, blocking objects in the pipeline start to be decomposed and softened, and the blocking objects can be removed by rinsing the pipeline with water 10-15 minutes later, thus ensuring that the pipeline is unblocked. The pipeline dredge agent is high in dredge speed, remarkable in effect and low in price, thus being a pipeline dredge agent worthy of popularization.

Owner:焦趁英

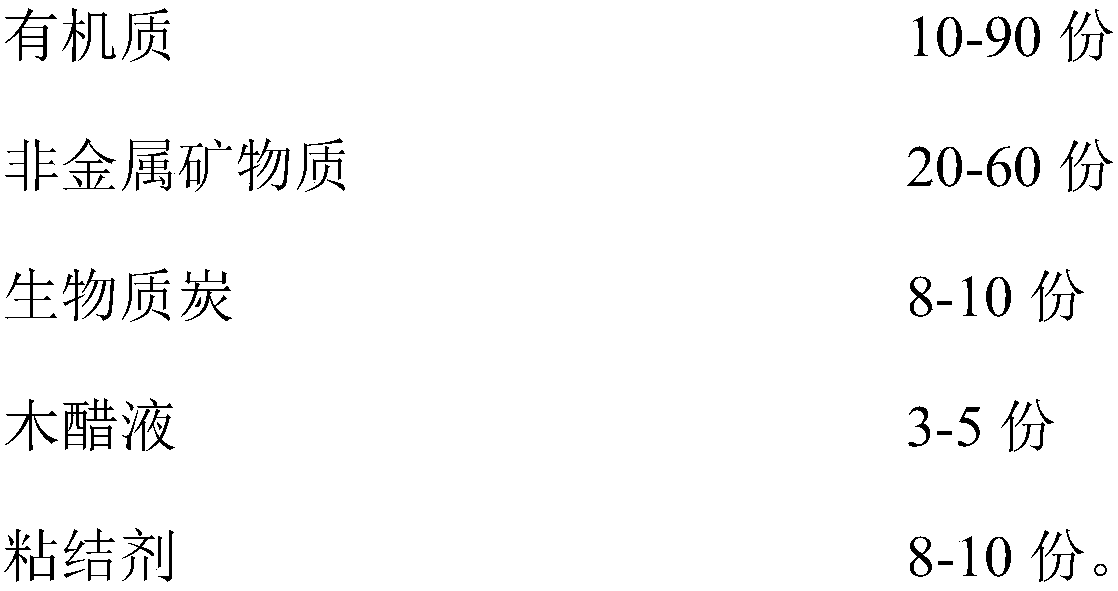

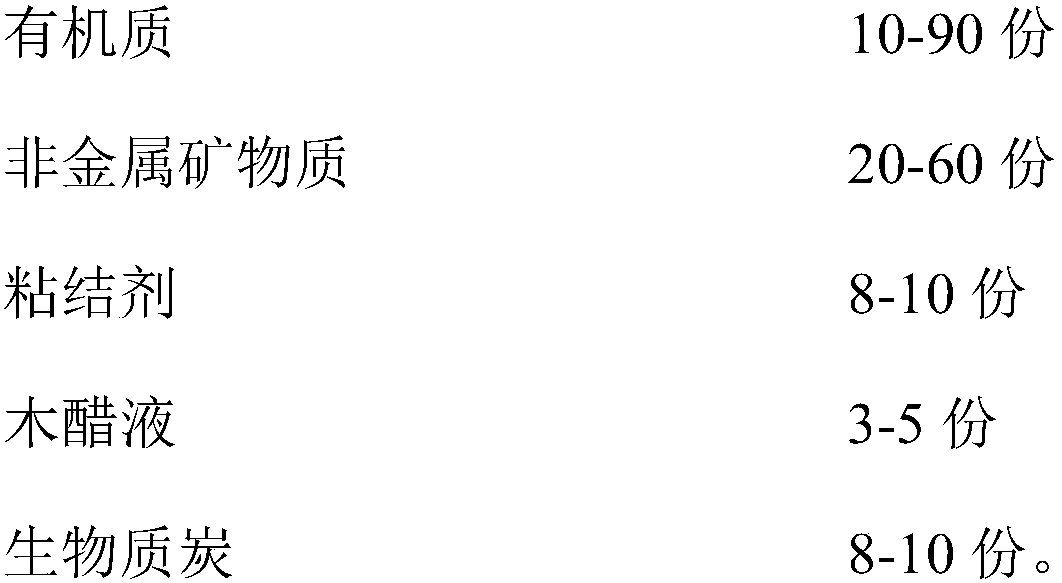

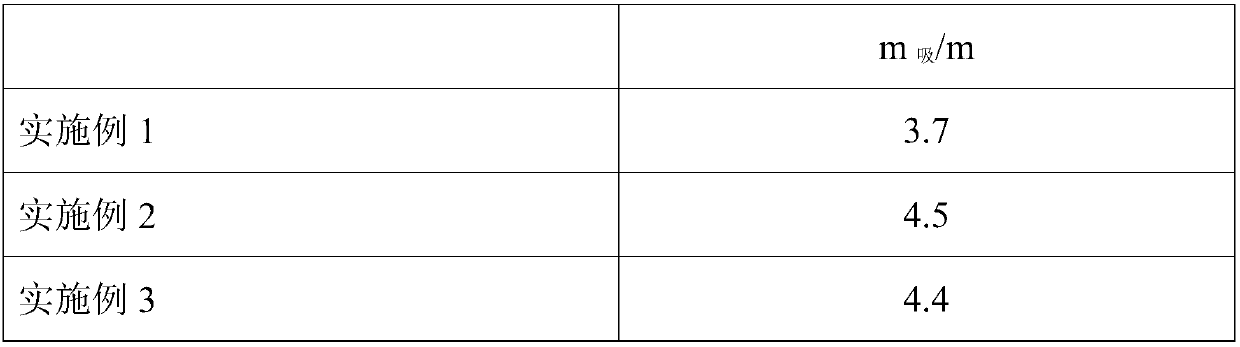

Culture substrate and preparation method thereof

InactiveCN107581023AImprove water retention and breathabilityReduce cloggingGrowth substratesCulture mediaParticulatesOxygen

The invention discloses a culture substrate and a preparation method thereof. According to the culture substrate, an organic matter, non-metallic minerals, an adhesive, pyroligneous liquor and biomasscharcoal with special proportion are adopted and are matched with one another; in the blending process, the ingredients and aggregations between the ingredients grow up through the binding effect ofa binder, and the blockage for holes of small particulate matters is reduced; holes of the culture substrate are balanced by utilizing biomass charcoal; the pyroligneous liquor is sprayed to the culture substrate, and penetrates into the culture substrate, the culture substrate is loosened, the ventilation and water retaining capability of the culture substrate can be enhanced, the condition thatroots have sufficient oxygen and water can be guaranteed, and the growth of crops is promoted. In addition, the culture substrate contains rich organic matters and microelements, so that nutrients needed by the crops can be provided, and the germination rate is increased due to sufficient oxygen and water.

Owner:BEIJING SANJU GREEN ENERGY TECH CO LTD

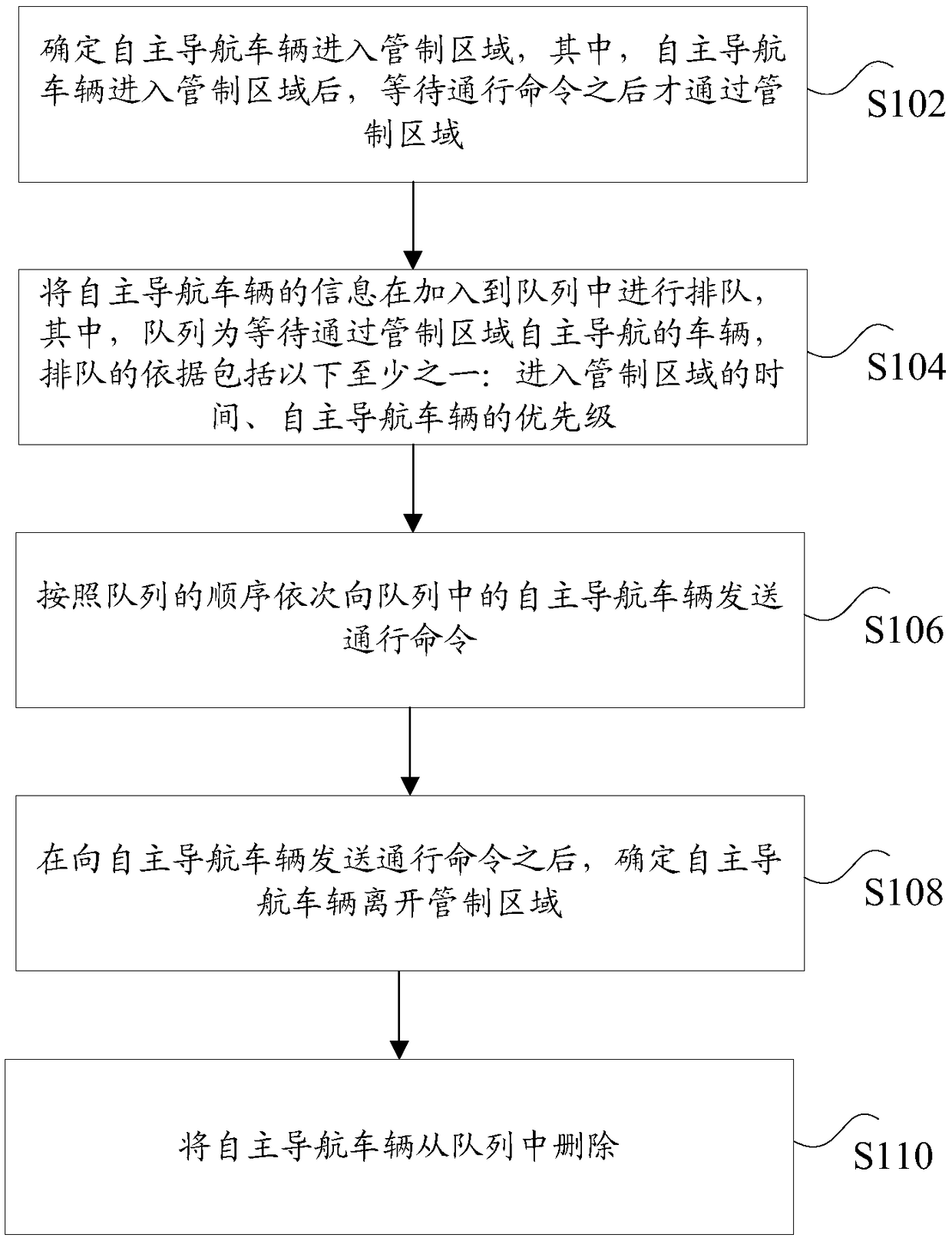

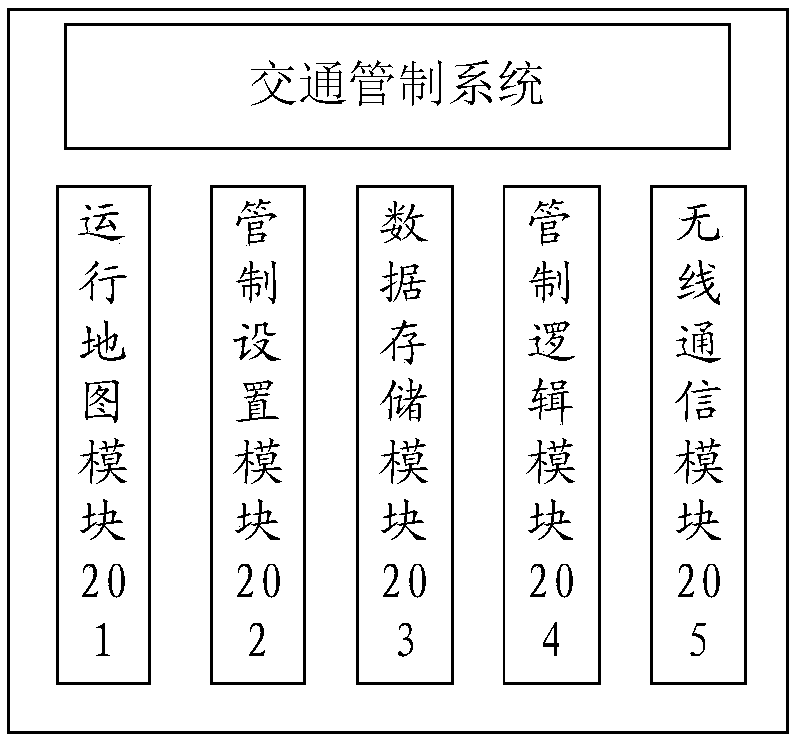

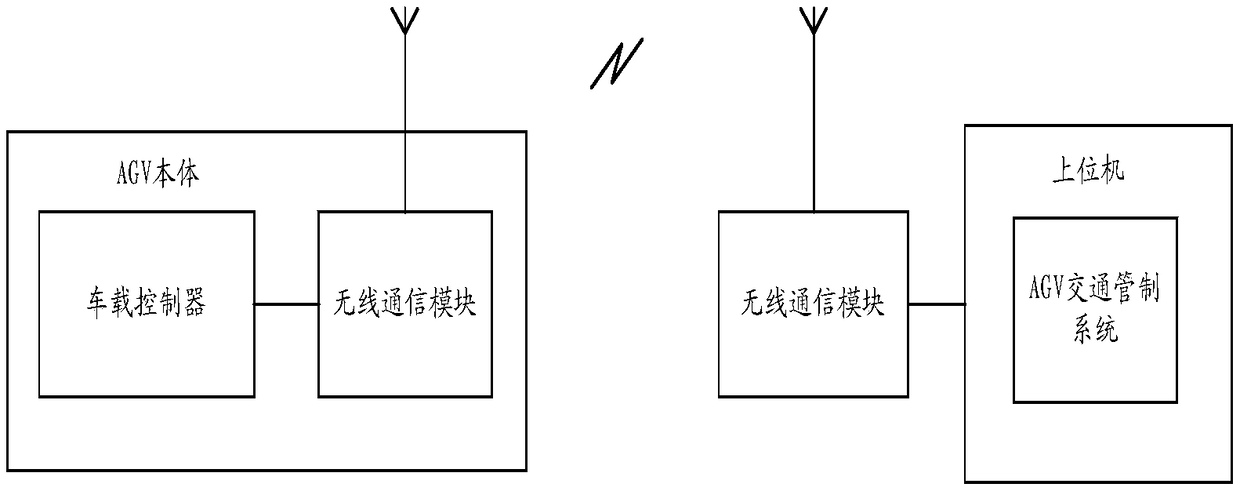

Traffic processing method and device

InactiveCN108898825ARealize automatic drivingQuick unblockAnti-collision systemsControl areaComputer science

The invention discloses a traffic processing method and device. The method comprises the following steps: determining that an autonomous navigation vehicle enters a control area; after the autonomousnavigation vehicle enters the control area, waiting for a passing command and then passing through the control area; adding information of the autonomous navigation vehicle into a queue and queuing, wherein the queue comprises the autonomous navigation vehicle waiting for passing through the control area, and queuing evidence comprises at least one of time of entering the control area and the priority of the autonomous navigation vehicle; sending the passing command to the autonomous navigation vehicle in the queue in sequence according to a queuing sequence; after sending the passing commandto the autonomous navigation vehicles, determining that the autonomous navigation vehicle leaves away from the control region; deleting the autonomous navigation vehicle from the queue. According to the traffic processing method and device, the technical problems in the relative technology that the autonomous navigation vehicle cannot effectively navigate so that the traffic jam is caused are solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

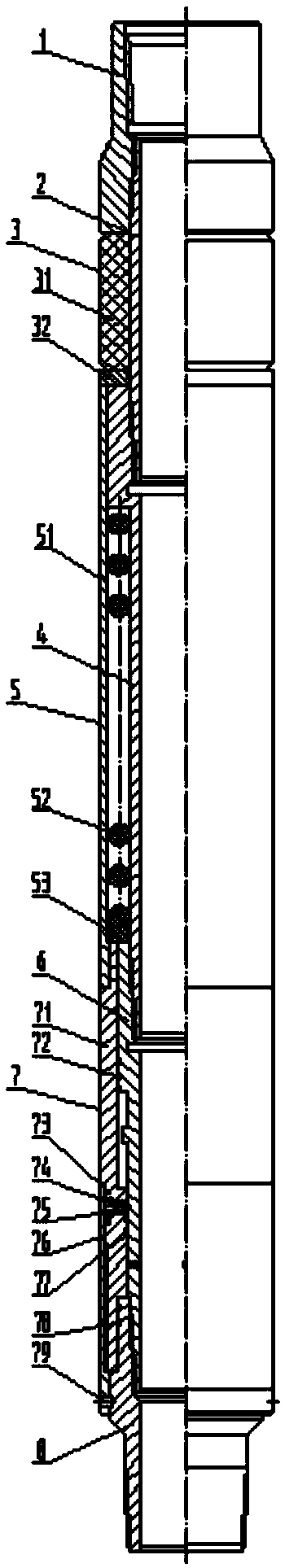

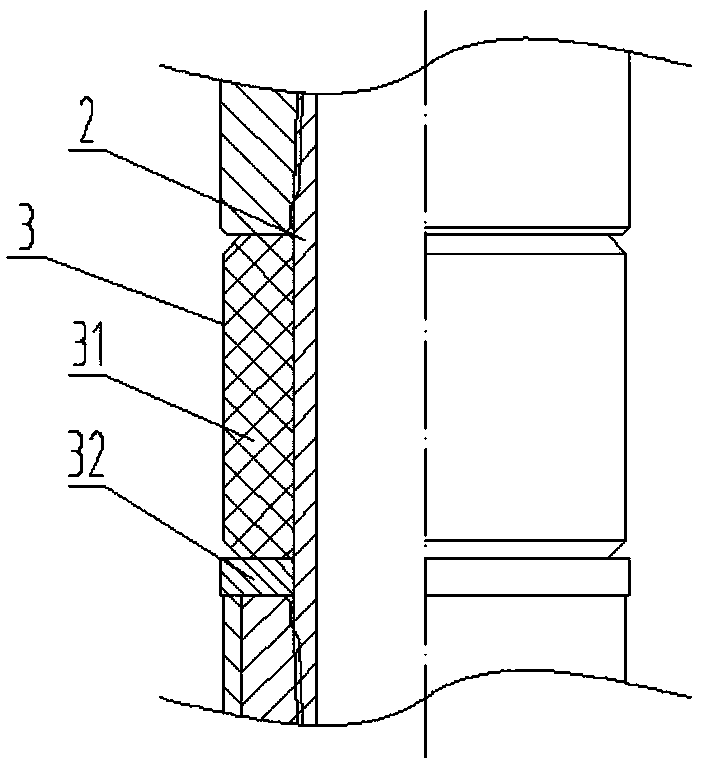

Non-throttling self-service unsealed packer

InactiveCN109538182AEasy to controlWithstand large pressure differenceFluid removalSealing/packingDual effectEngineering

The invention discloses a non-throttling self-service unsealed packer which comprises an upper connector, an upper central pipe, a sealing mechanism, a spring central pipe, a spring self-service unsealing mechanism, a lower central pipe, a setting-dissoluble unsealing mechanism and a lower connector. No throttling or setting needs to be conducted for the non-throttling self-service unsealed packer, and the setting process is convenient to control; limiting steps are arranged in the packer, it is avoided that the sealing effect is affected by the excessive compression of a rubber cylinder; by means of the compressed rubber cylinder, the borne pressure difference is large, and the setting effect is good and stable; large-discharge and large-scale cracking construction refitting can be realized; by means of the spring self-service unsealing mechanism, unnecessary advanced setting generated in the pipe column put-down process is avoided; after cracking construction ends, the rubber cylinder of the packer is rapidly unsealed under the dual effects of the rebound force of the rubber cylinder and the self-service unsealing force of a spring; by means of the setting-dissoluble unsealing mechanism, under the high pressure in a well, the rapid unsealing of the packer can still be ensured.

Owner:CNPC BOHAI DRILLING ENG

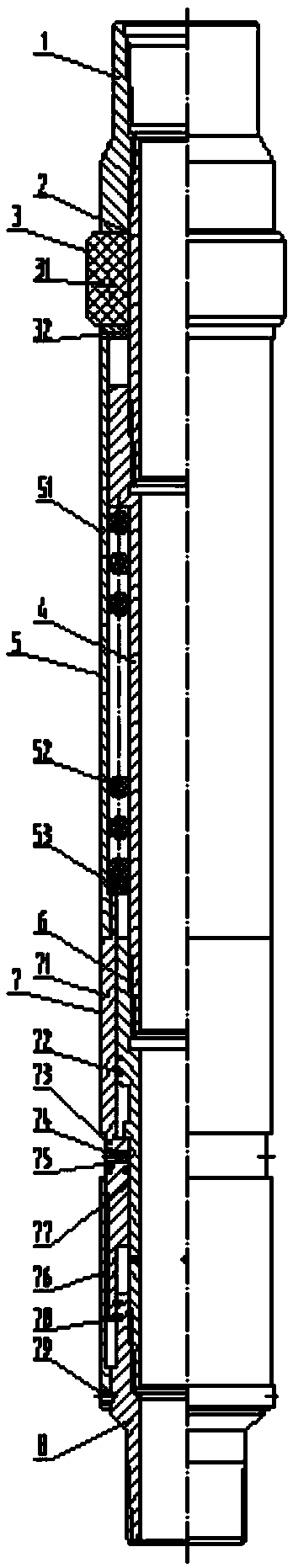

A self-balancing packer and method

The invention relates to a self-balanced packer and belongs to the technical field of oil and gas field reservoir reformation. The self-balanced packer is characterized by comprising an inner central tube and an outer central tube which are positioned in the packer, wherein the outer central tube is sleeved on the inner central tube; a first annular space is formed between the inner central tube and the outer central tube; a packing element is sleeved on the outer central tube, and separates the packer into an upper section structure and a lower section structure; a packing section of the packing element has a large outer diameter; two ends of the packing section of the packing element extend upwards and downwards in an equal diameter manner; the diameter of an equal diameter extension section is smaller than that of an upper and lower packing section; the equal diameter extension section of the packing element fixes the packing element on the outer central tube through upper and lower packing element seats; the upper and lower ends of the inner central tube and the upper and lower packing element seats are connected with an upper joint and a lower joint; a second annular space is formed between the packing element and the outer central tube, and is communicated with a seat packing pressure transfer hole in the upper joint; and the lower joint is provided with a lower annular space pressure introducing hole facing downwards in the radial direction. The self-balanced packer solves the problem that the conventional packer has a poor effect.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

Intelligent stirring-smashing-type sewer dredging device

InactiveCN108193766AGreat suctionDesilting is widely applicableSewer systemsEngineeringHigh pressure water

The invention relates to an intelligent stirring-smashing-type sewer dredging device and belongs to the technical field of engineering machinery. According to the device, a combination dredging methodof high-pressure water jet, drill bits and monitoring is adopted, firstly, a drill bit device is used for stirring and smashing a blocking part of a sewer, a high-pressure water jet device is used for flushing the stirred and smashed blocking part and the pipe wall, and then a suction method is used for sucking loose debris; meanwhile, a camera shooting device and a detection illuminating lamp are arranged on a vehicle body, a row of cutting blades are arranged at each edge of the vehicle body, the stirring-smashing drill bits are arranged on a vehicle head, if the large-sized debris such asplastic bags, straw and stone blocks exist, stirring-smashing and cutting are facilitated, and the debris is quickly conveyed upwards by using the suction device and a conveying belt; a large quantityof human resources, physical resources and financial resources are saved, the device is widely suitable for sewer dredging, blocking unchoking and dredging of deep ditches and deep wells in small-sized and medium-sized cities, the cost is saved, the dredging efficiency is improved, and the device has wide application prospects.

Owner:唐林元

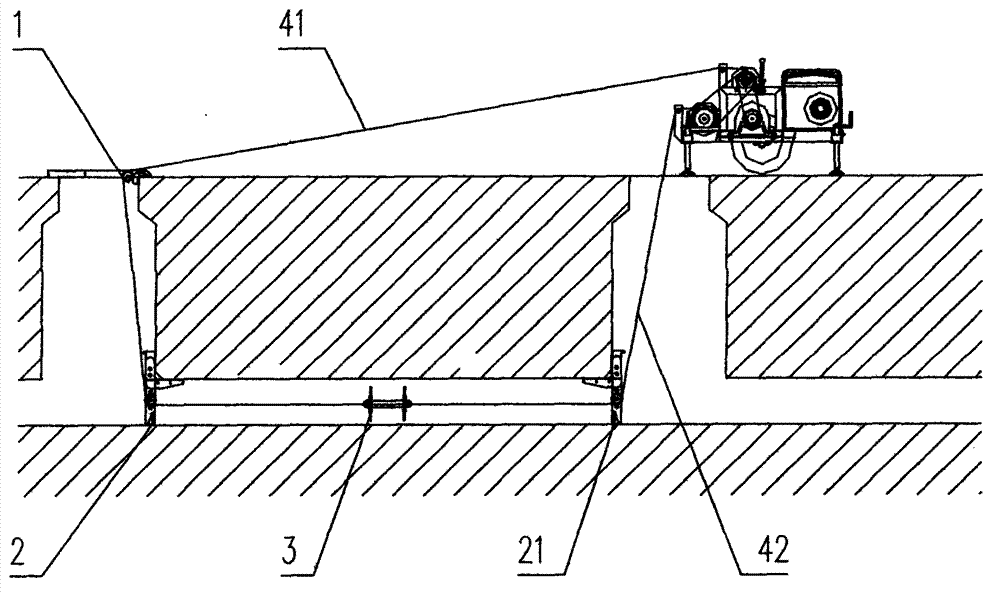

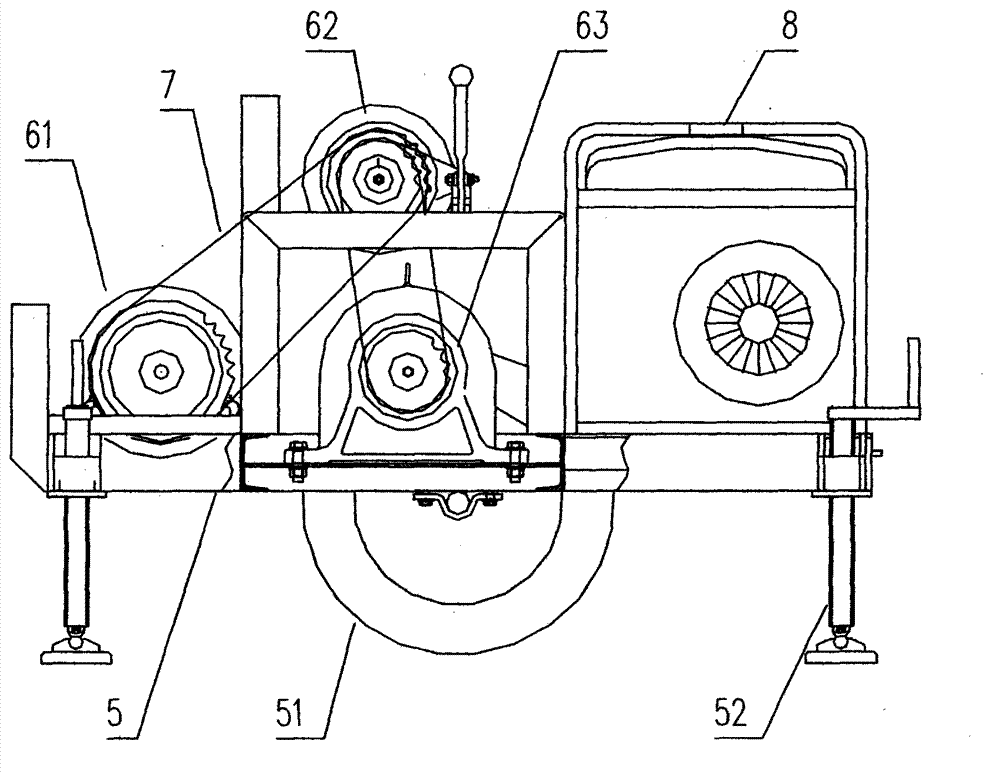

Multifunctional underground pipe dredging power winch

The invention discloses a multifunctional underground pipe dredging power winch, which is provided with a chassis. A power generator, a power machine, a speed reducer, a first transmission wheel, a second transmission wheel, a dragging drum and a pulling-back drum are arranged on the chassis. A clutch is arranged between the first transmission wheel and the second transmission wheel. Steel wire ropes are respectively arranged on the two drums. The two steel wire ropes are fixedly connected with the two ends of a pipe dredging tool in a pipe through a well mouth guide rack and a pipe mouth guide rack. Walking wheels and adjustable-height supporting legs are arranged below the chassis. A rotary advancement guide rod machine and a guide rod are additionally arranged on the chassis. An operating panel is additionally arranged on the chassis of the winch. The multifunctional underground pipe dredging power winch is suitable for underground pipe dredging, is self-provided with a power supply, can be moved for operation, is convenient to transport and maintain, is convenient and flexible to use, is simple and light to operate, can reduce labor intensity and can realize dredging more thoroughly and rapidly.

Owner:BEIJING DRAINAGE EQUIP

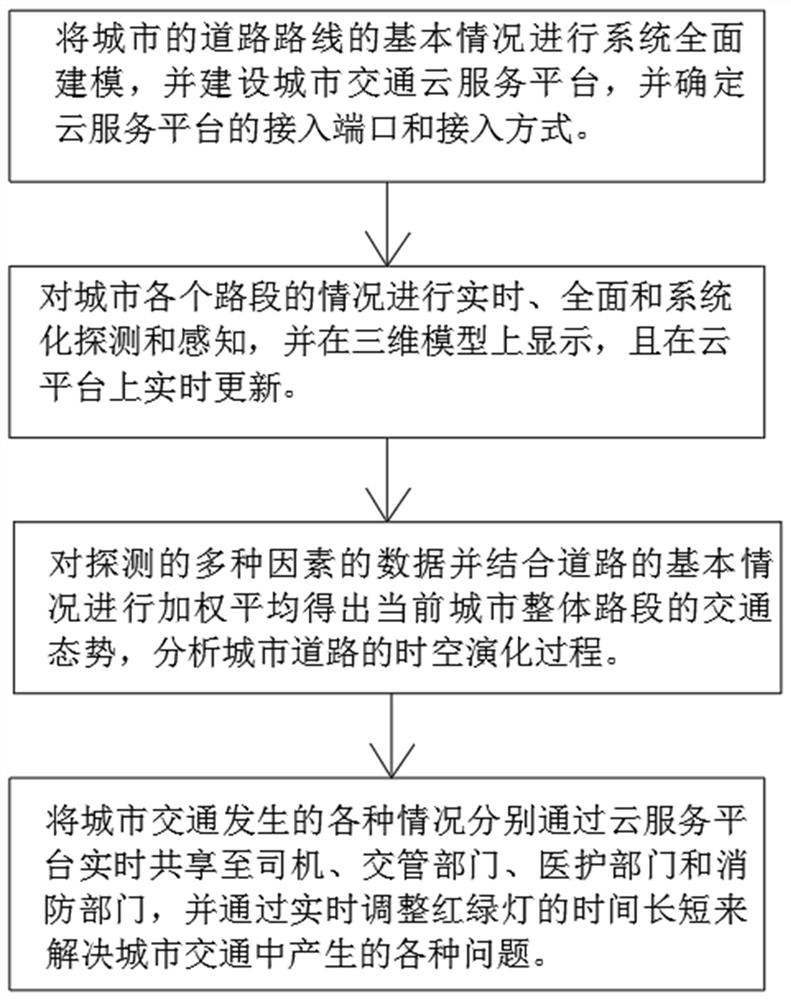

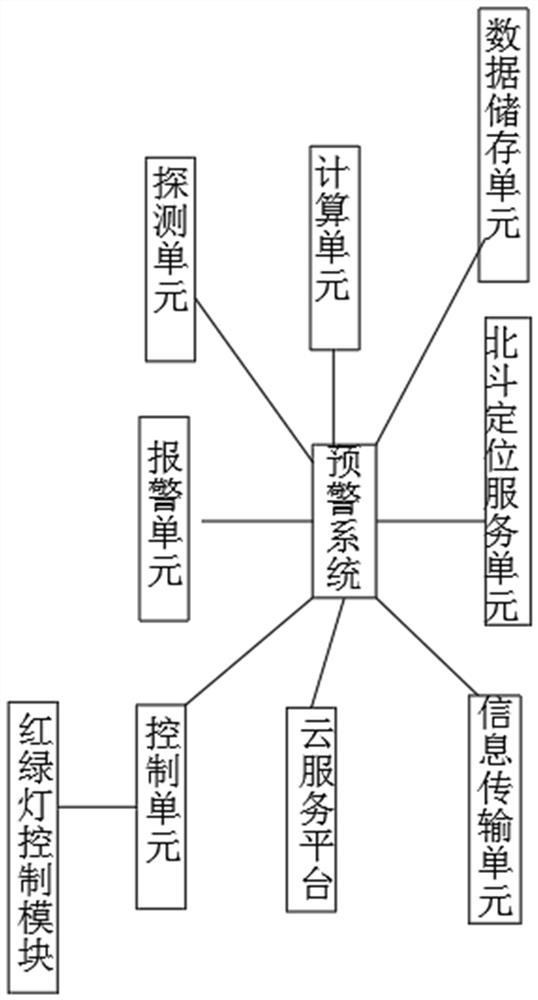

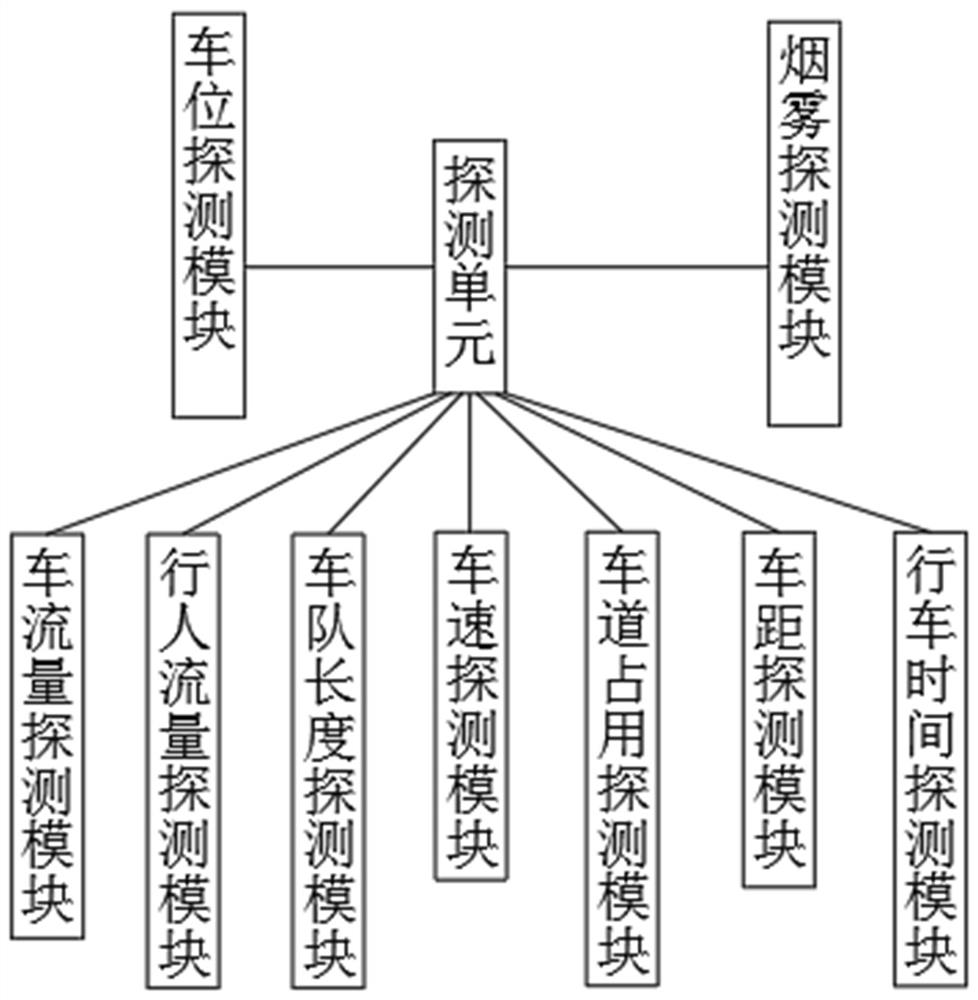

Urban traffic situation awareness method and early warning system based on big data

InactiveCN112037509AImprove rescue efficiencyExpresswayControlling traffic signalsDetection of traffic movementParking spaceMetadata

The invention discloses an urban traffic situation awareness method and an early warning system based on big data. The system mainly comprises a detection unit, an alarm unit, a control unit, a cloudservice platform, an information transmission unit, a Beidou positioning service unit, a data storage unit, and a calculation unit. The detection unit is suitable for carrying out real-time, comprehensive and systematic detection and perception on the condition of each road line of a city through a plurality of detection modules. According to the urban traffic situation awareness method and earlywarning system based on big data, through the cooperation of the arranged cloud service platform and the detection unit, the detection unit collects data of parking spaces, smoke, vehicle flow, pedestrian flow, fleet length, vehicle speed, lane occupation, vehicle distance and driving time which influence urban road traffic through big data, and performs weighted averaging in combination with basic conditions of roads to obtain a traffic situation of a current urban whole road section. In this way, the overall situation of urban traffic can be accurately reflected.

Owner:淮北市盛世昊明科技股份有限公司

Hydraulic pipe cleaner and cleaning method thereof

InactiveCN104213617AImprove sealingStrong anti-shedding abilityDomestic plumbingFilling materialsWater diversion

Provided are a hydraulic pipe cleaner and a cleaning method thereof. The pipe cleaner comprises an elastic rubber water diversion tube, one end of the elastic rubber water diversion tube is connected to a booster pump, and the other end of the elastic rubber water diversion tube is connected to a self-expanding nozzle. The method includes the steps of connecting the booster pump and the self-expanding nozzle to both ends of the elastic rubber water diversion tube respectively, wherein the self-expanding nozzle is composed of a guide ring and a horn-shaped bag, a large opening of the horn-shaped bag is connected to the guide ring, and a small opening of the horn-shaped bag is connected to the other end of the elastic rubber water diversion tube; inserting the self-expanding nozzle into a pipe to be cleaned, wherein the guide ring of the self-expanding nozzle forms preliminary sealing to the pipe wall of the pipe to be cleaned and slides in the pipe to be cleaned to drive the horn-shaped bag of the self-expanding nozzle to enter the pipe to be cleaned and settle down; starting the booster pump and filling water to the pipe to be cleaned to constantly increase the pressure of the cleaning water until clogging material in the pipe to be cleaned can be washed away by the high pressure cleaning water.

Owner:NANJING COMM INST OF TECH +1

Anti-clogging drain pipe

The invention provides an anti-clogging drain pipe, and belongs to the technical field of drain pipes. The problem that existing drain pipes having no dredging device is solved. The anti-clogging drain pipe comprises an inner pipe and an outer pipe, wherein an adjusting ring is arranged at the top end of the inner pipe, a plurality of arc-shaped mounting grooves are formed in an inner wall of the outer pipe, a hinge portion is arranged at one end of each mounting groove, a plurality of arc-shaped punched holes are formed in the inner pipe, an anti-clogging rod with a pin fixedly arranged at one end is comprised, the pin is movably connected with the hinge portion, an outer wall of the inner pipe props up an anti-clogging rod, so that the entire anti-clogging rod is arranged in the mounting groove, a torsional spring is arranged between the pin and the hinge portion, the adjusting ring can be rotated clockwise to drive the inner pipe to rotate, so that the mounting groove is aligned with a perforated hole, the torsional spring drives the anti-clogging rod to rotate around the pin, so that the anti-clogging rod stretches into the inner pipe, the inner pipe is rotated clockwise continuously, so that a hole wall at one end of the perforated hole props up a rod wall of the anti-clogging rod and drives the anti-clogging rod to rotate, and finally the anti-clogging rod is reset in the mounting groove. The anti-clogging drain pipe is provided with an anti-clogging structure, and can be dredged quickly, and influence on normal drainage can be avoided.

Owner:泉州台商投资区昇一科技有限公司

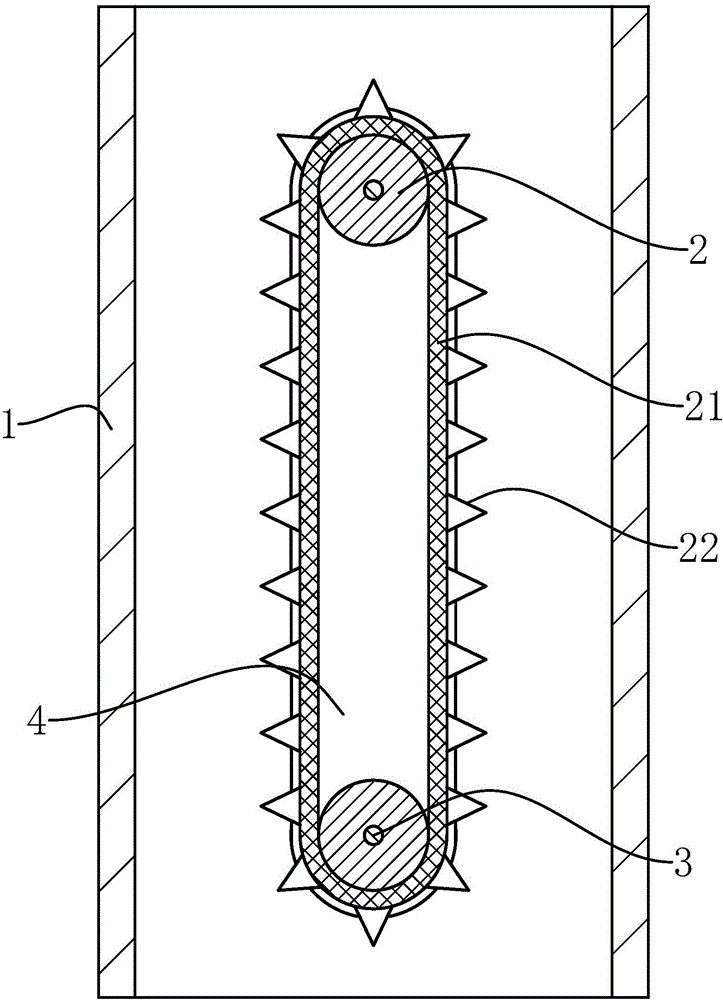

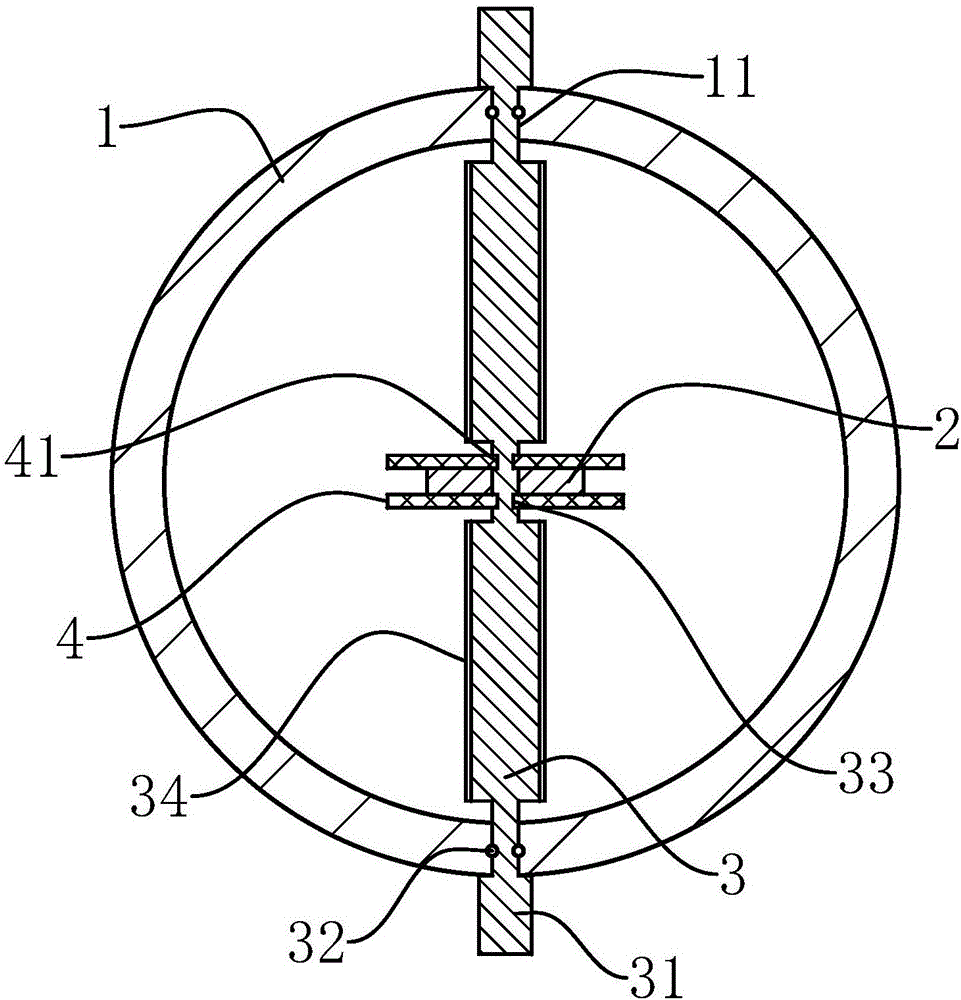

Anti-blocking sewer pipe

The invention discloses an anti-blocking sewer pipe and belongs to the field of pipes. The anti-blocking sewer pipe solves the problem that an existing prior pipe is prone to blockage and difficult to dredge. The anti-blocking sewer pipe comprises a tubular pipe body and a dredging structure arranged in the pipe body, the dredging structure comprises two same gears, the axial line position of each gear is fixedly provided with a rotating rod, the rotating rods are arranged along the pipe body in the radial direction, the gears are located in the axial line position of the pipe, and the two gears are parallel to each other along the axial line. Both ends, extending out of the pipe body, of each rotating rod are fixedly provided with rotary knobs respectively. The anti-blocking sewer pipe further comprises a belt. The belt is arranged between the two gears in a driven mode, the belt and each gear are provided with mutually meshed internal teeth and external teeth, and the outer side of the belt is fixedly provided with a plurality of blades. When the inside of the pipe is blocked, by pinching the rotary knobs and rotating the rotating rods, the rotating rods drive the gears to rotate, so as to enable the belt to move up and down in the pipe, the blockage is cut by the blades, the blockage is thus smaller, so that the pipe can be fast dredged, and operation is very easy.

Owner:XINCHANG YUANZHOU IND DESIGN CO LTD

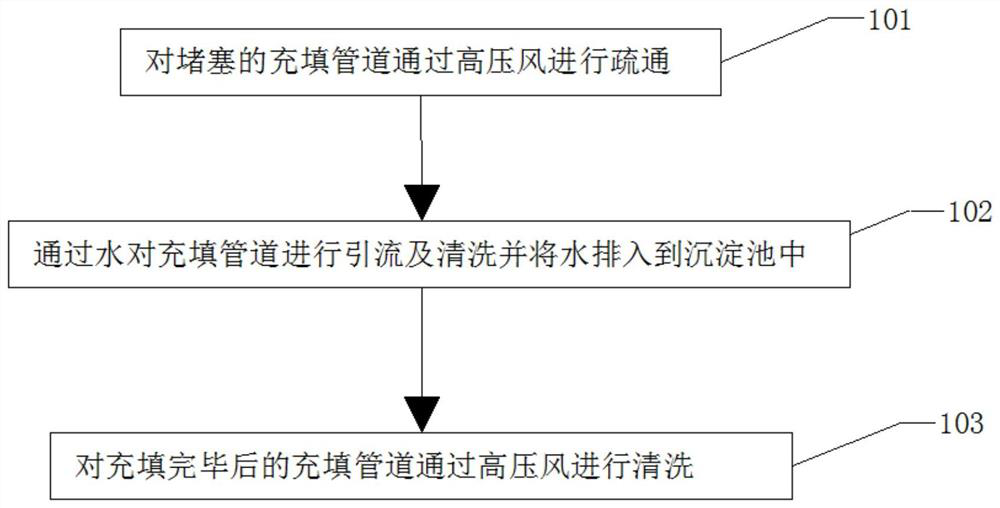

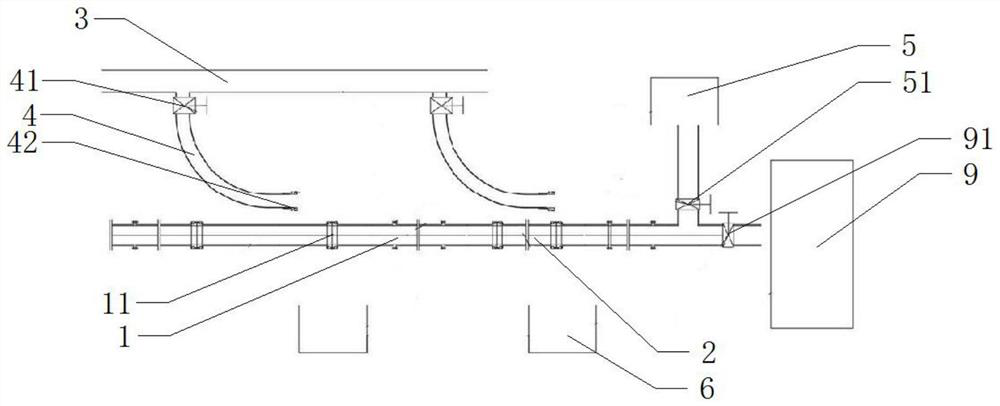

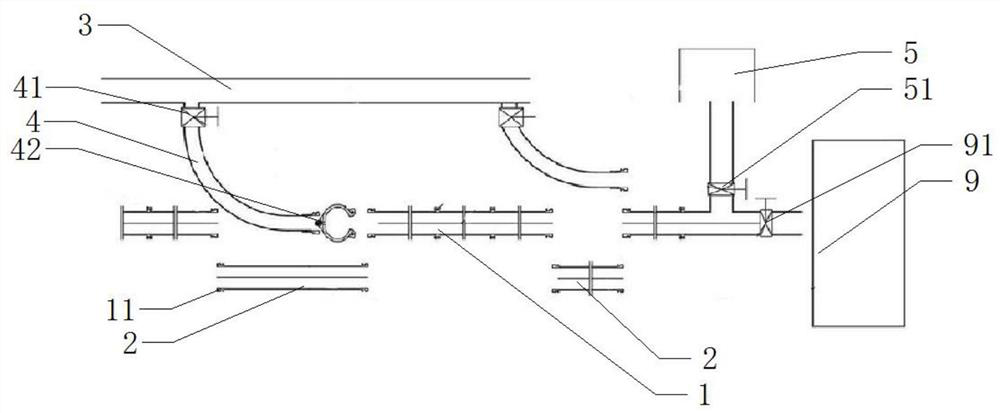

Treatment method and device for paste filling pipeline

PendingCN113738440AReduced risk of cloggingReduced time to deal with clogged pipesMaterial fill-upCouplingsSoil scienceGeotechnical engineering

The invention discloses a treatment method and device for a paste filling pipeline, relates to the technical field of mining area backfilling, and mainly aims to provide the treatment method for the paste filling pipeline. The method can quickly block and dredge the filling pipeline and can prevent water for drainage and cleaning from entering a stope in the paste filling process. According to the main technical scheme, the treatment method for the paste filling pipeline comprises the steps: dredging the blocked filling pipeline through high-pressure air; conducting drainage and cleaning on the filling pipeline through water, and discharging the water into the sedimentation tank; and cleaning the filling pipeline after filling through high-pressure air. The method is mainly used for mining area backfilling.

Owner:新疆喀拉通克矿业有限责任公司 +1

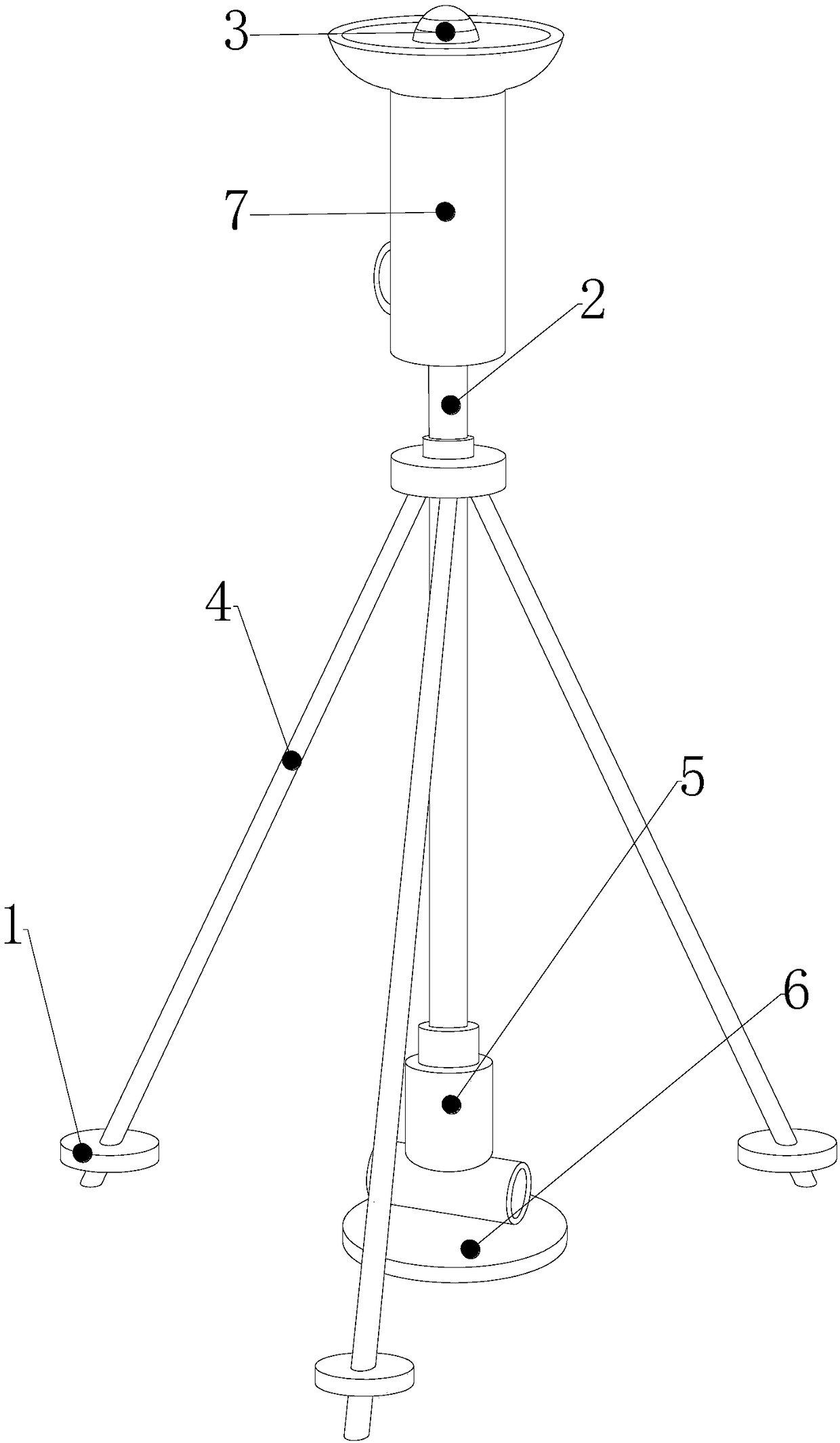

Water conservancy irrigation device based on solar power generation

ActiveCN108353760APromote hydrationQuick unblockWatering devicesRenewable energy machinesElectricityEngineering

The invention discloses a water conservancy irrigation device based on solar power generation. The water conservancy irrigation device structurally comprises a mounting piece, a water guiding pipe, anautomatic dredging sprinkling device, a triangular supporting frame, a three-way pipe, a base plate and a solar energy conversion waterproof casing. The lower end of the automatic dredging sprinklingdevice is embedded and installed at the upper end of the solar energy conversion waterproof casing and positioned on the same axis. The upper end of the water guiding pipe is embedded and installed at the lower end of the solar energy conversion waterproof casing and positioned on the same axis, the water guiding pipe passes through the upper end of the triangular supporting frame, the lower endof the triangular supporting frame is embedded and mounted at the middle of the mounting piece, and the lower end of the water guiding pipe is embedded and mounted in the upper end of the three-way pipe and is perpendicular to the upper end of the three-way pipe. According to the water conservancy irrigation device based on solar power generation, a blocked spray head can be quickly dredged through solar automatic power storage, the loss caused by the failure to timely irrigate crops resulting from the blockage of the spray head is reduced, a chemical adding mechanism is arranged, required chemicals can be placed in the device, and automatic chemical adding for spraying can be performed automatically.

Owner:ZHEJIANG CANYUAN HOME TEXTILE

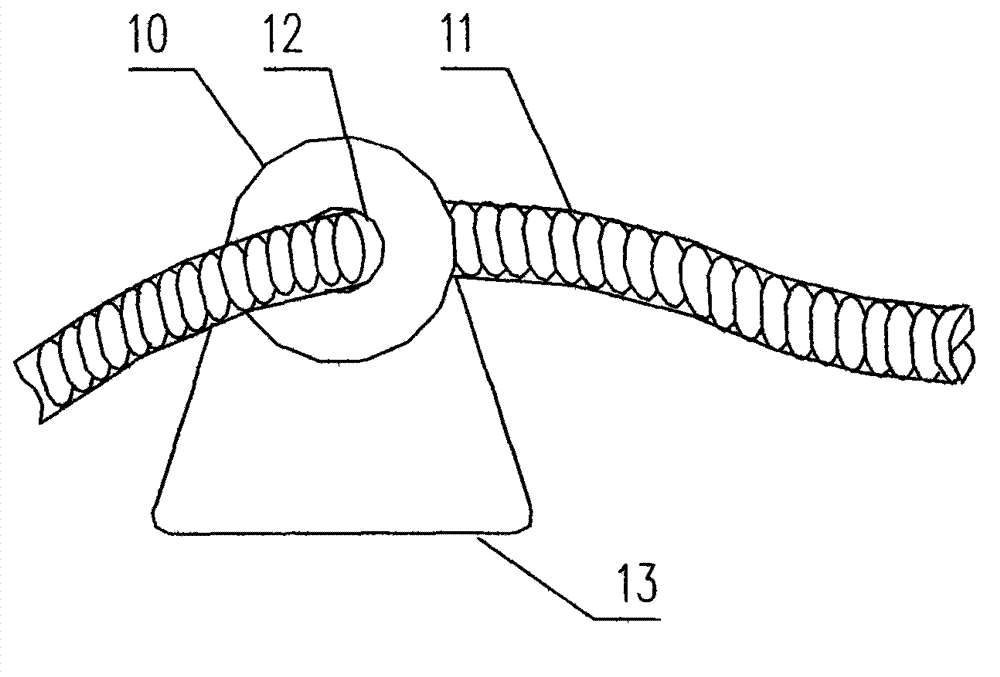

Manual system for dredging heavy turning pipeline

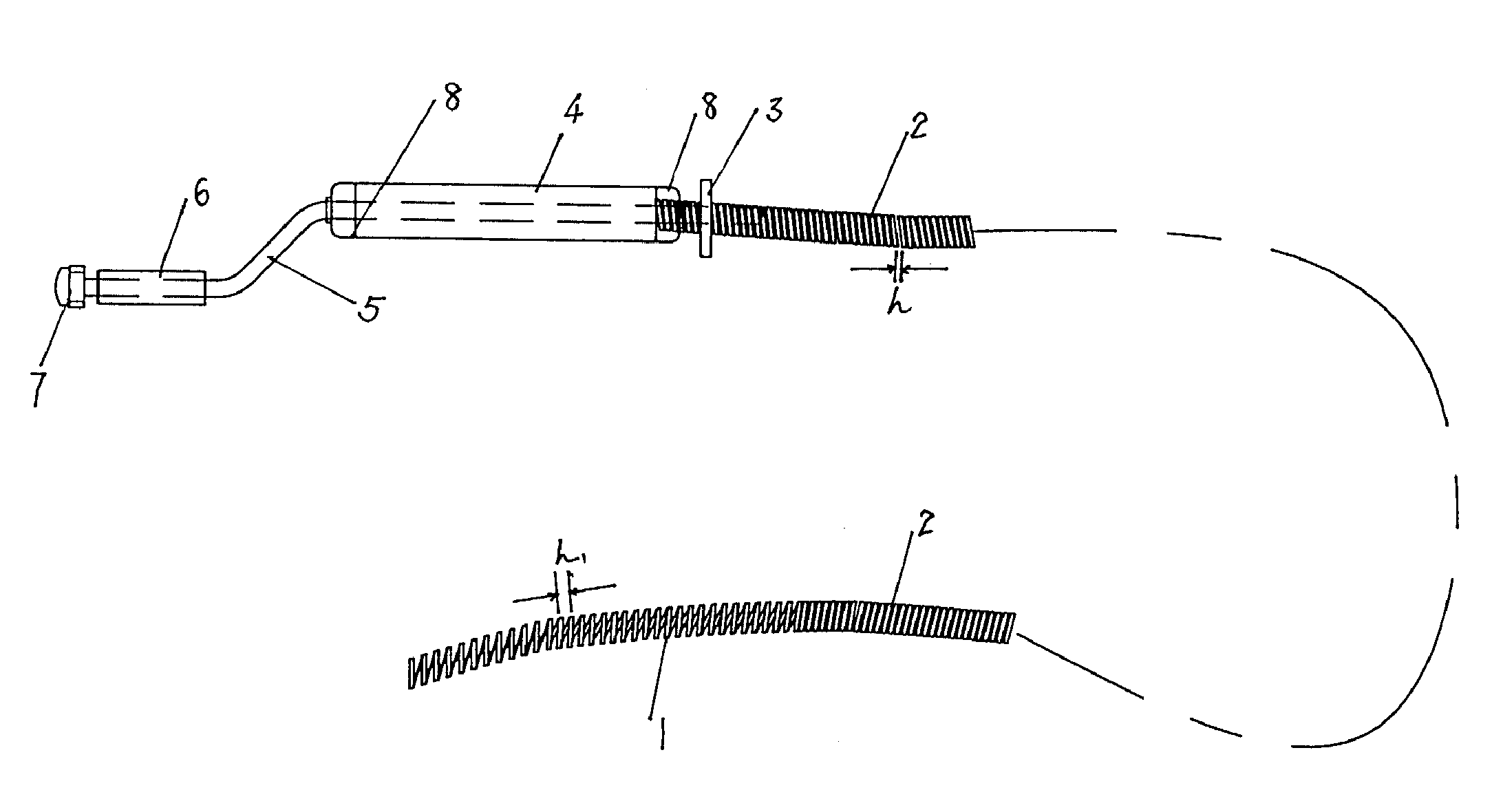

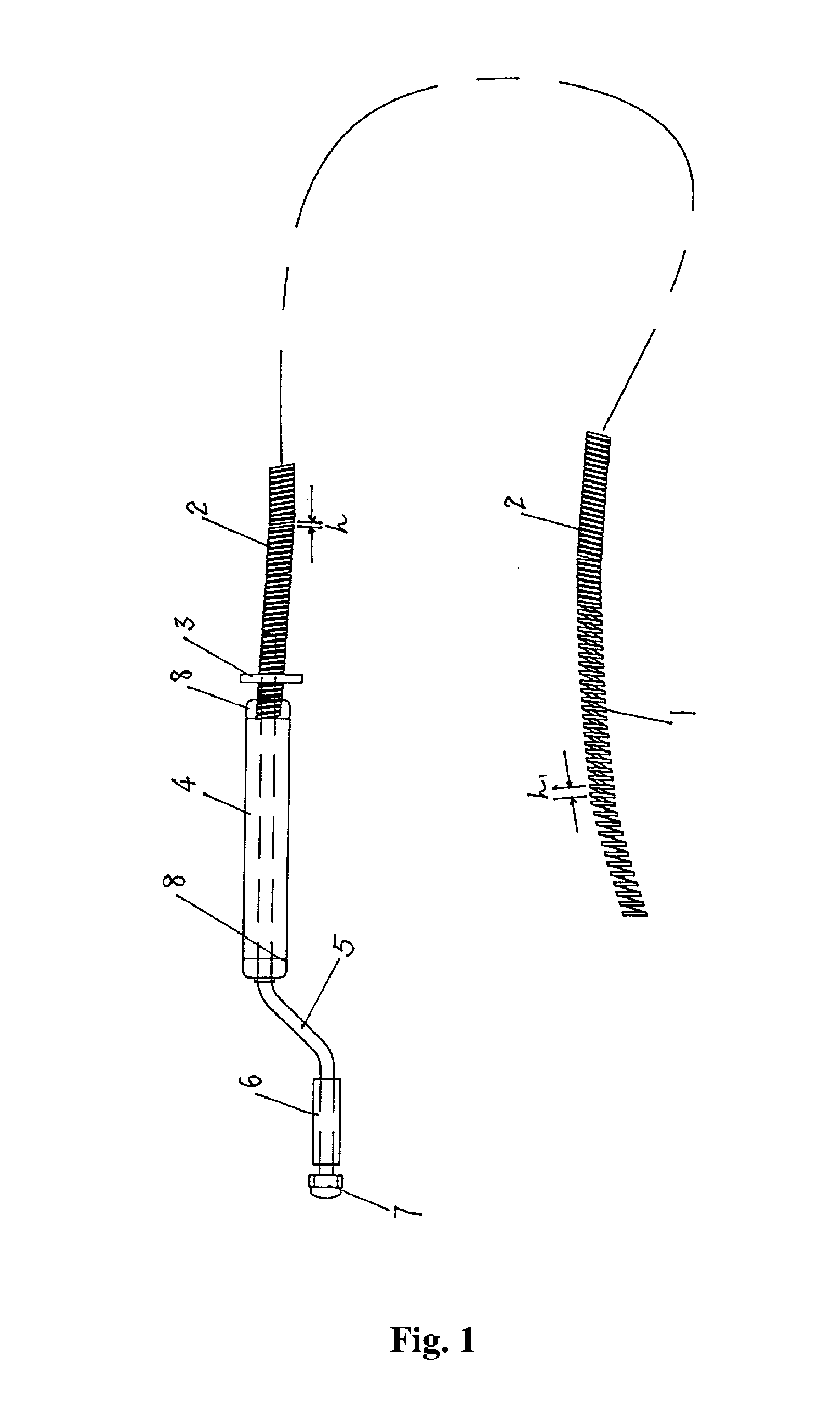

InactiveUS20080173332A1Efficient windingIncrease flushing powerSewer cleaningHollow article cleaningGear wheelEngineering

Provided is a manual system for dredging a heavy-turning pipeline, comprising a pipeline dredger and a water-pressure dredge pipe comprising a rocker and a spring-type dredge pipe connected thereto; wherein a spring-type dredge bit is disposed on an end of the spring-type dredge pipe; the water-pressure dredge pipe is a hollow hose having an back end that may be inserted into a pipeline to be dredged; and a cross section of the dredge bit has a cog or a sharp corner. In a process of dredging a pipeline, the cog or the sharp corner may easily winds blocking objects, so that it is possible to quickly dredge the pipeline and improve dredging efficiency. Furthermore, since an opening having a diameter less than the water-pressure dredge pipe is disposed at an end of the water-pressure dredge pipe, water column with higher pressure may be formed, and sprayed water column has enhanced scouring force. In addition, since openings with different spraying directions are used, the end of the water-pressure dredge pipe is capable of spraying at different angles, and thus dredging efficiency is improved.

Owner:ZHANG JIAYI

Hair-nourishing liquid shampoo

InactiveCN106691926AQuick unblockPromote circulationCosmetic preparationsHair cosmeticsOrganic acidSide effect

The invention discloses hair-nourishing liquid shampoo which is mainly prepared from the following raw materials in parts by weight: cacumen biotae, mulberry leaves, green tea, polygonum multiflorum, ginger, Chinese honeylocust fruits and tea seed oil. Raw materials of pure natural plants, Chinese herbal medicines and the like are adopted, so that the hair-nourishing liquid shampoo is safe to a human body, free of side effect and rich in proteins, amino acids, vitamins, organic acids and compounds thereof and multiple microelements beneficial to hair nourishing and protecting, and has the effects of improving the hair quality, protecting the hair and nourishing the brain.

Owner:GUANGXI UNIV FOR NATITIES

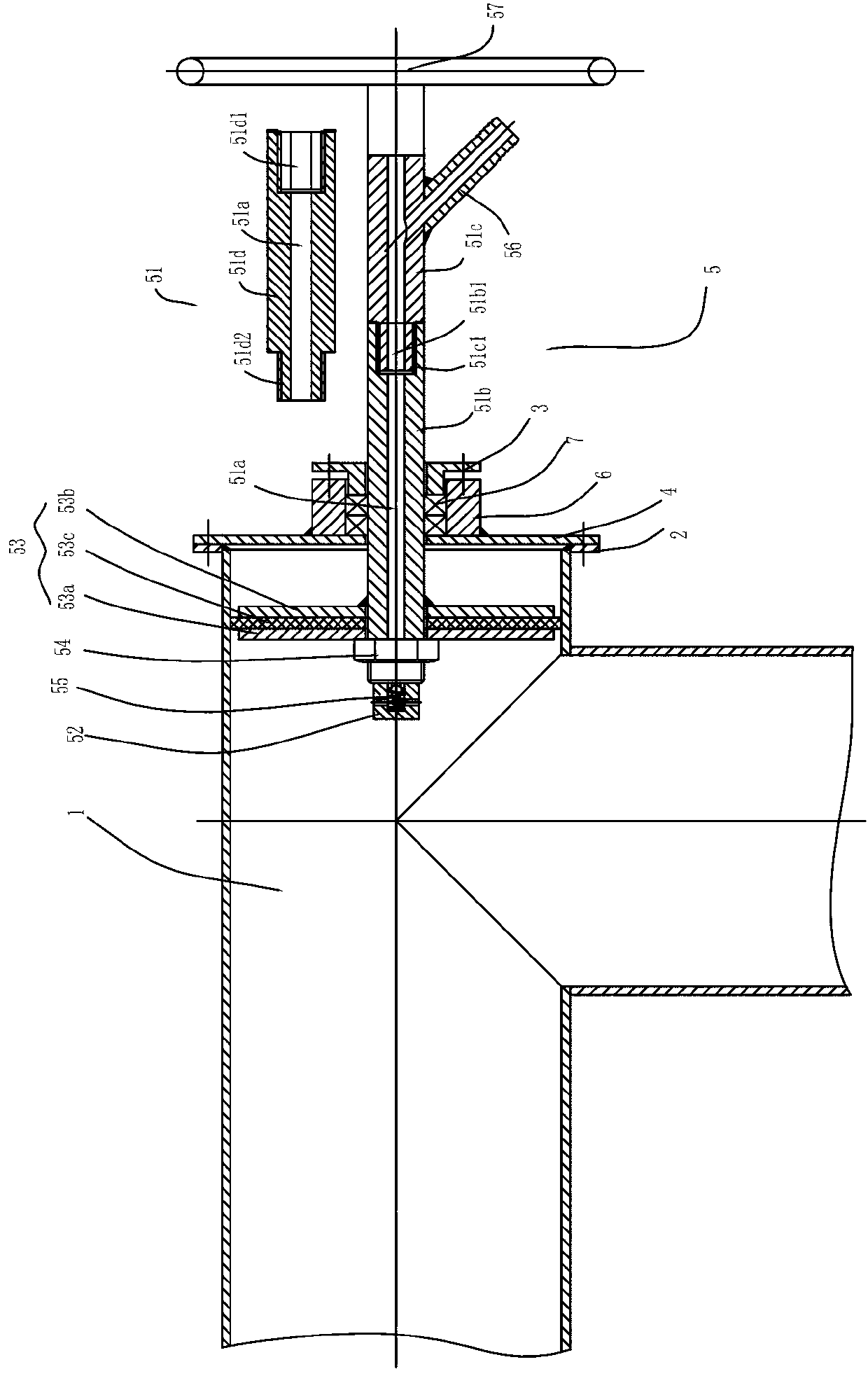

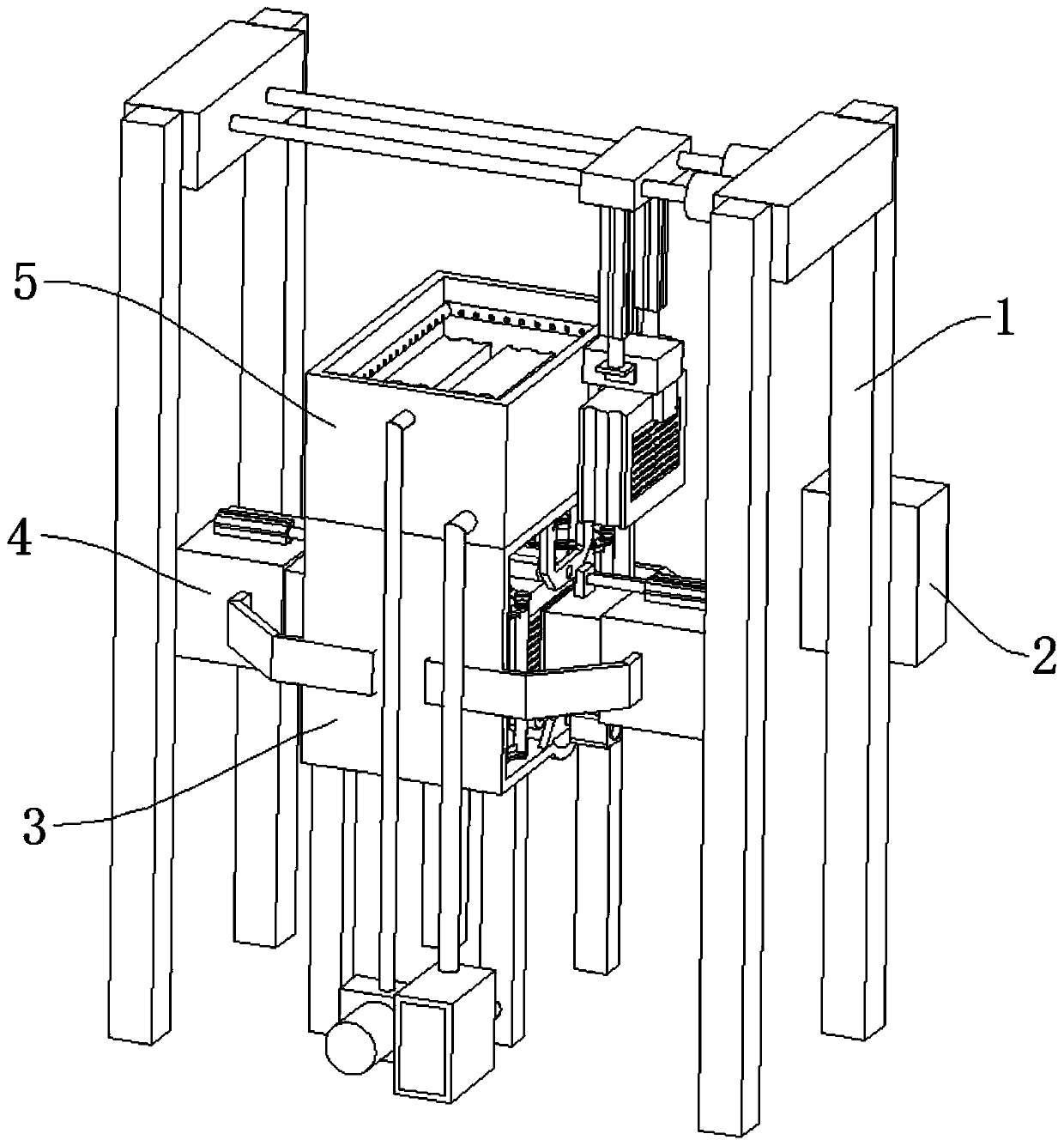

Ammonium phosphate slurry pipeline compound dredging method

ActiveCN103128082AEasy to push and pullReasonable designHollow article cleaningSlurry pipelineMechanical engineering

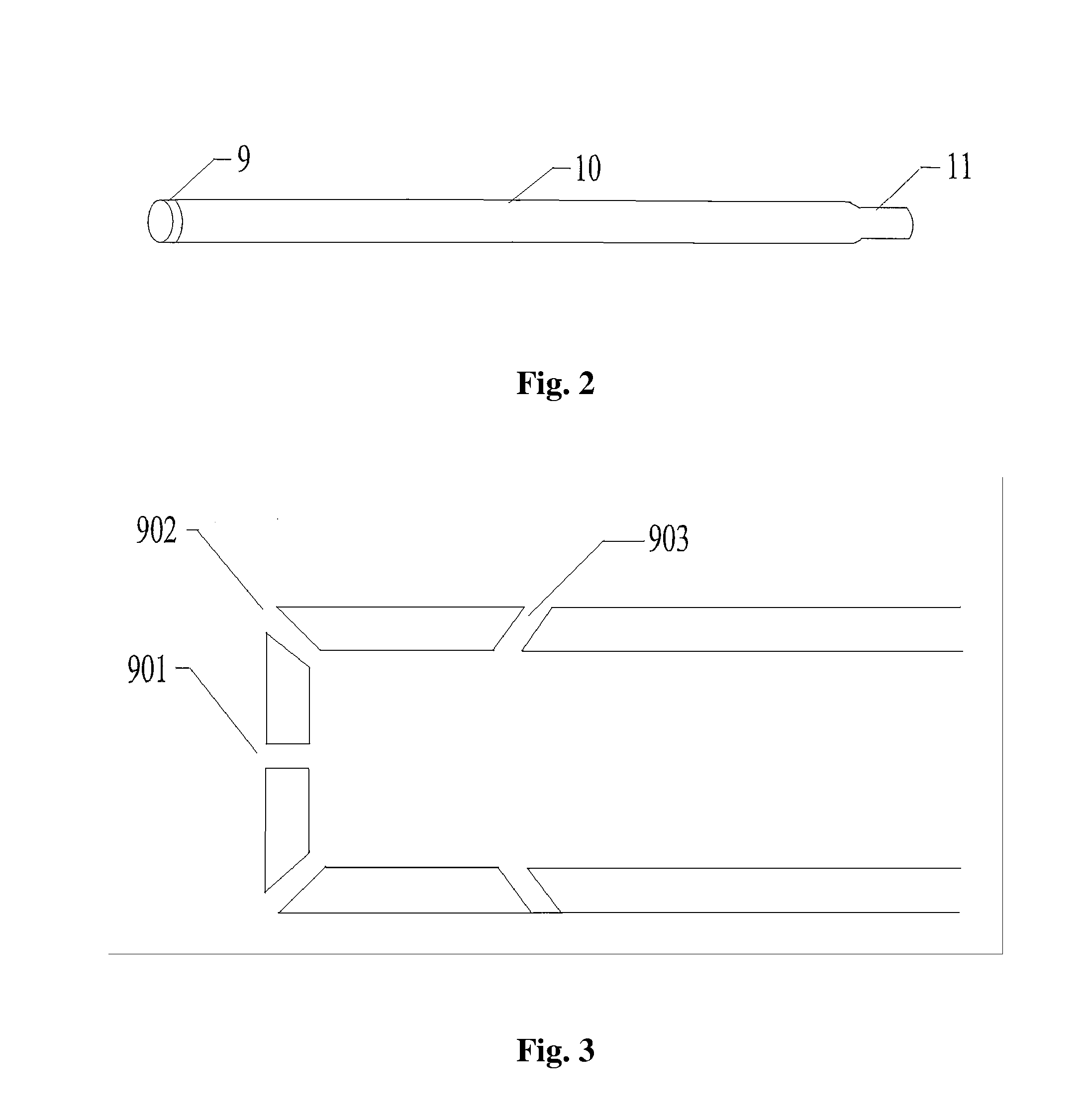

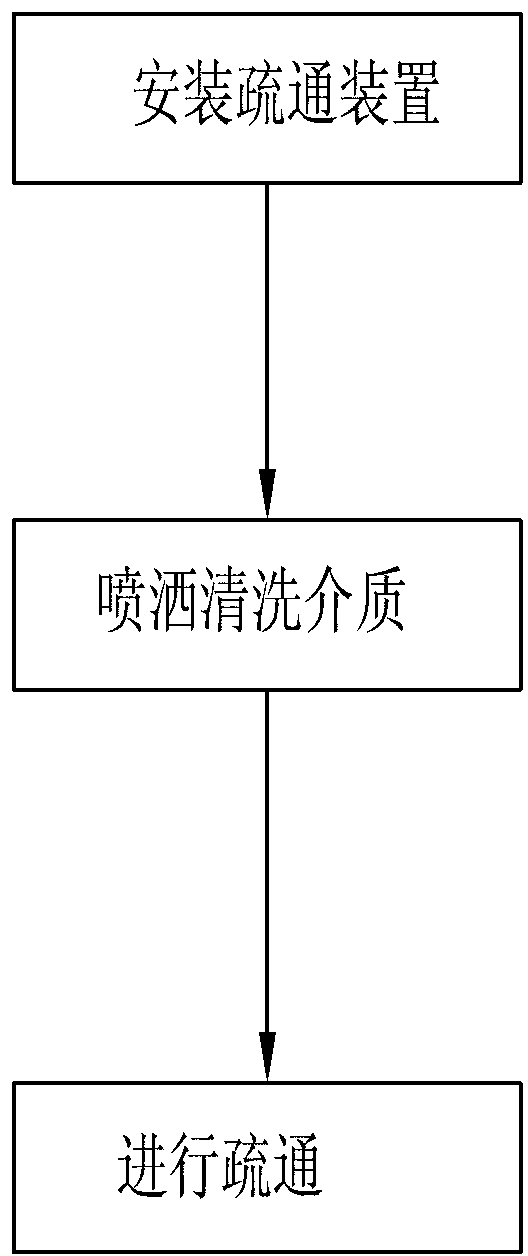

The invention discloses an ammonium phosphate slurry pipeline compound dredge method which includes a first step of installing a dredging device, wherein a flange mounting seat is arranged on an opening of the tail end of a pipeline for producing ammonium phosphate slurries, a flange plate is fixed on the flange mounting seat, and the dredging device is supported on the flange plate, a second step of spraying cleaning media, wherein a portion, located inside the pipeline, of the dredging device can carry out spraying of the cleaning media on the inner wall of the pipeline, and the cleaning media soaked with the dissolving slurries can dissolve scale layers on the inner wall of the pipeline, and a third step of carrying out dredging, pushing a dredging rod in the process of spraying the cleaning media, and enabling a cleaning disc to move to clean the inner wall of the pipeline. Through the method, the pipeline does not need to be dismantled, and workers can carry out on-line dredging on the clogged pipeline, so the ammonium phosphate slurry pipeline compound dredge method can greatly reduce labor intensity of the maintenance workers, improves working efficiency, reduces safety risks in the operation process of the maintenance workers, shortens down time, and improves on-stream rate.

Owner:中化重庆涪陵化工有限公司

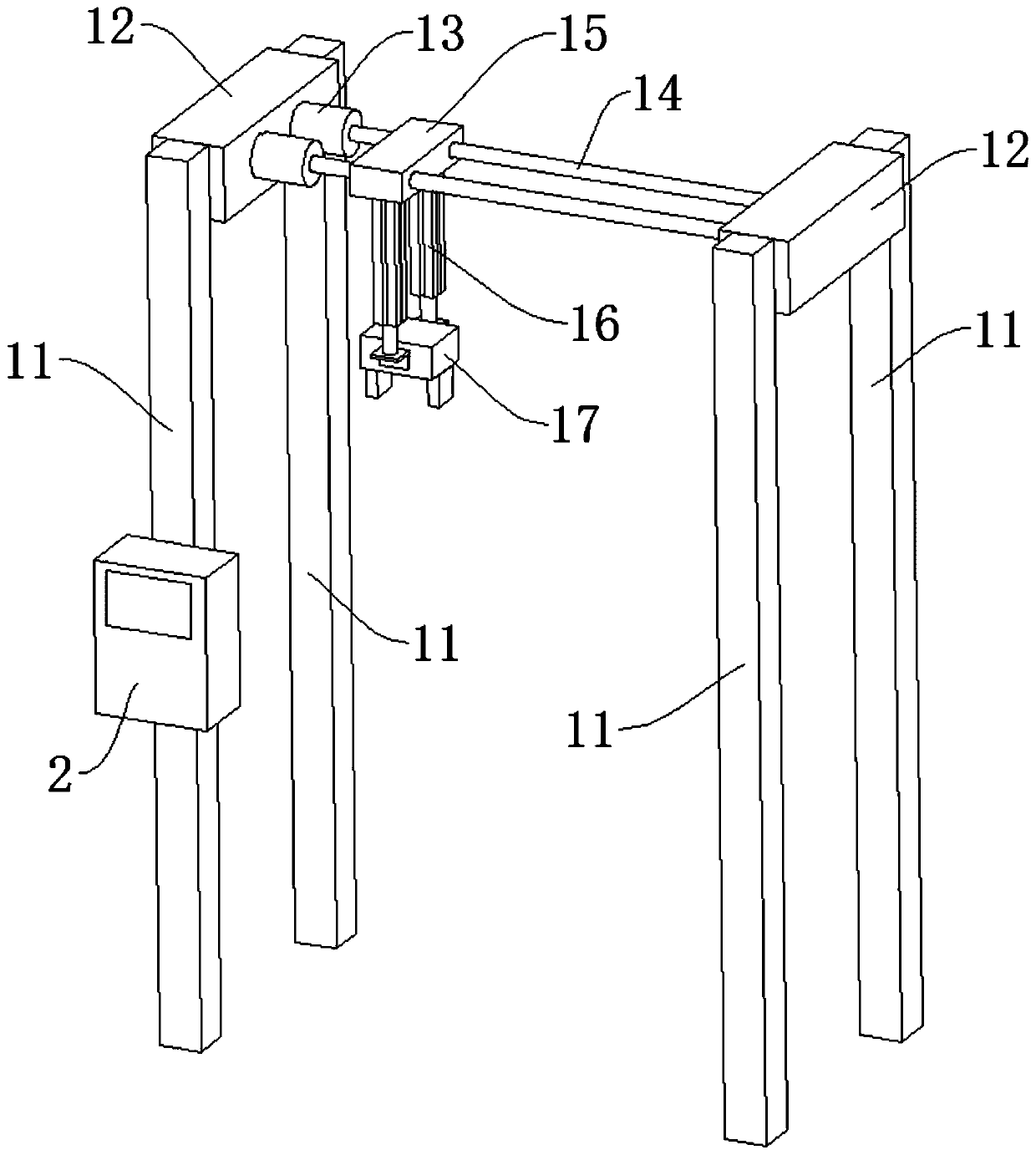

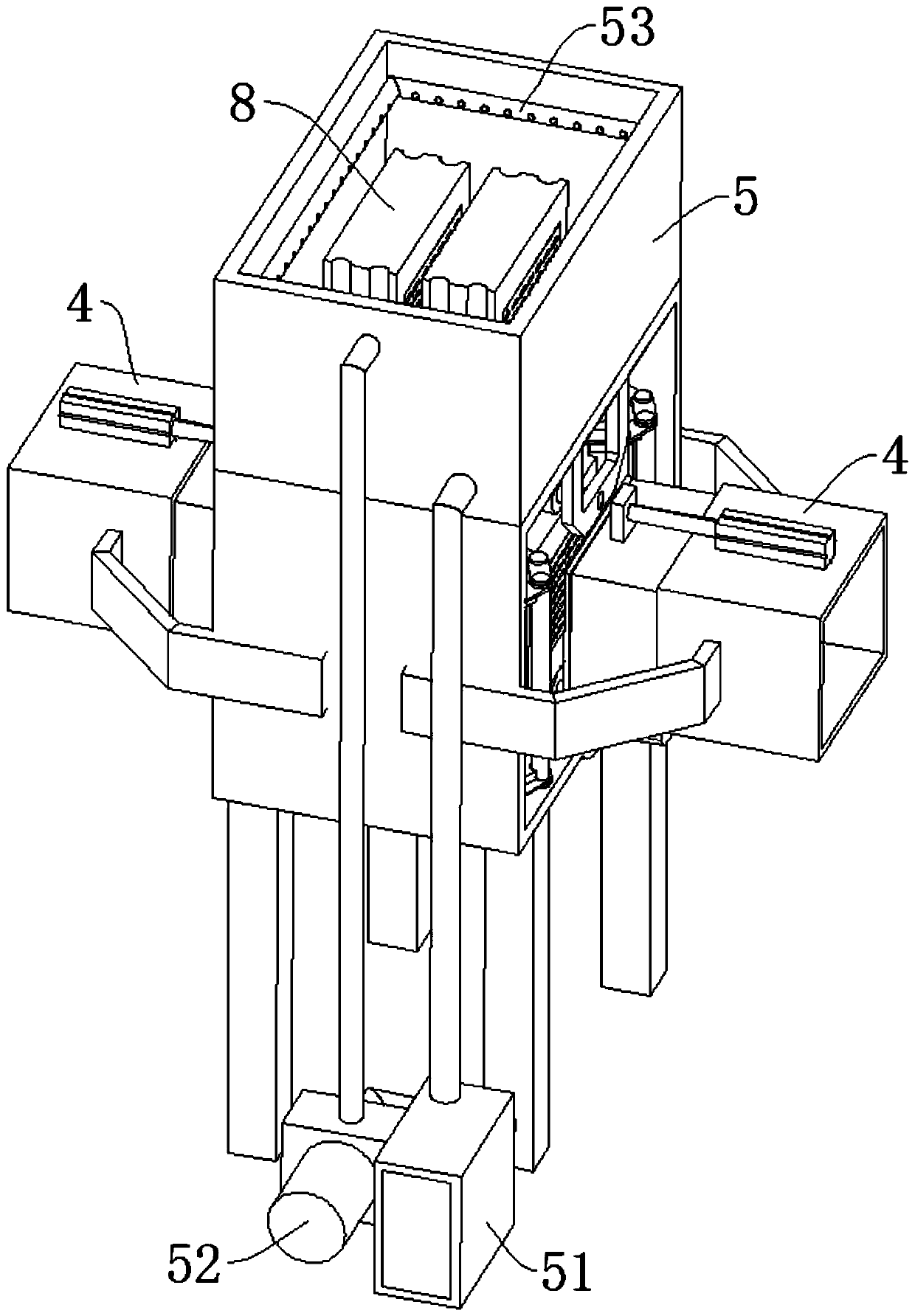

Working method of automatic net changing structure for plastic blow molding

ActiveCN111497174AIncrease the level of automationRealize automatic replacementBlow moldingEngineering

The invention discloses a working method of an automatic net changing structure for plastic blow molding, and relates to the technical field of plastic blow molding machines. A blow molding machine towhich the working method relates comprises a conveying device and a net changing box, wherein an electric control box is fixedly connected to one side wall of the conveying device; a cleaning box isfixedly connected to the top of the net changing box; two butt joint devices are fixedly connected to the two sides of the net changing box; two driving devices are arranged in the interior of the netchanging box; the inner bottom surface and inner top surface of the net changing box are both fixedly connected with lifting devices; and three filtering devices are movably connected between the twodriving devices. According to the working method, the driving devices and the conveying device are matched with one another, so that the automatic replacement of the filtering devices is realized, and the replaced filtering devices are sprayed and cleaned in the interior of the cleaning box to facilitate the recycling; the lifting devices can change the overlapping area of filtering holes and thereby changing the sizes of the filtering holes, so that impurities with different sizes and diameters are filtered away; and the impurities can also be sheared through the relative sliding of the filtering holes, and the rapid dredging can be realized.

Owner:广西膜宝包科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com