Treatment method and device for paste filling pipeline

A treatment method and paste filling technology, which are applied to filling materials, safety devices, earthwork drilling and mining, etc., can solve the problems of affecting filling effect, reducing filling quality, and difficulty in dredging, etc., so as to shorten the processing time of pipeline blockage and reduce The effect of filling water and reducing the risk of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

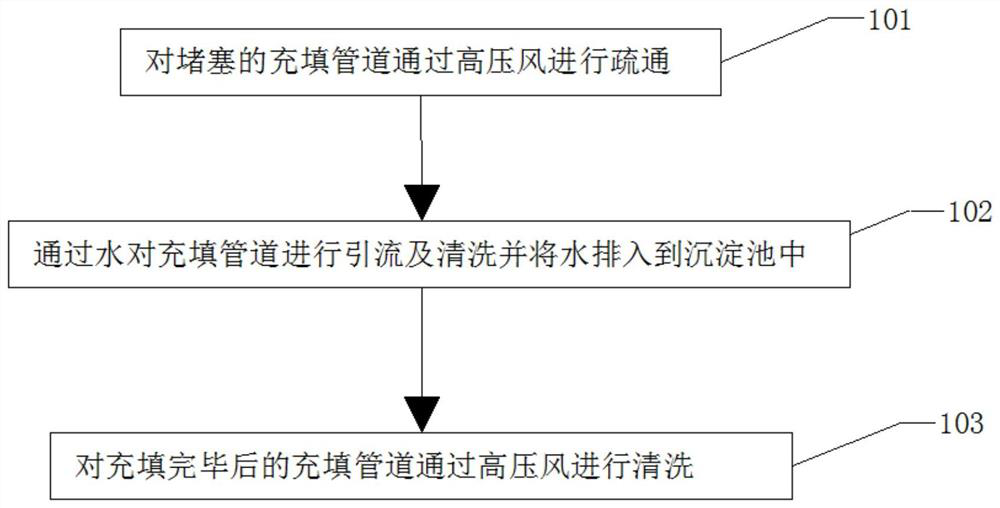

[0045] On the one hand, if Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a treatment method for filling pipelines with paste, the method comprising:

[0046] Use high-pressure air to dredge the blocked filling pipe;

[0047] Drain and clean the filling pipe with water and discharge the water into the sedimentation tank;

[0048] After filling, the filling pipeline is cleaned by high-pressure air.

[0049] 101. Dredge the blocked filling pipeline with high-pressure air.

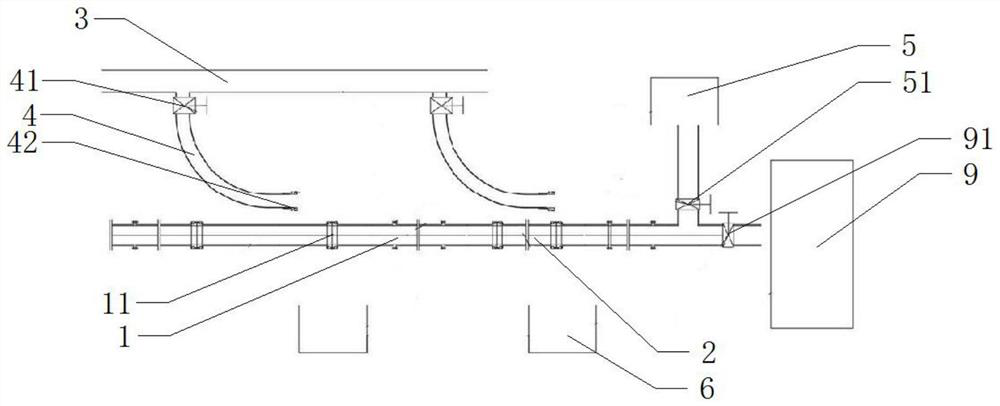

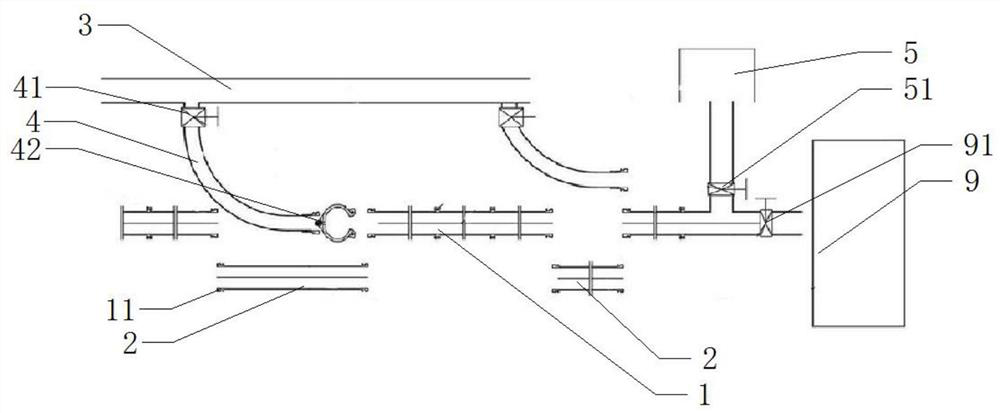

[0050] Such as figure 2 As shown, multiple emergency pipelines and high-pressure pipelines are pre-installed, and multiple emergency pipelines are arranged on the filling pipeline at intervals, that is, a filling pipeline is set between two emergency pipelines, and multiple emergency pipelines are installed at intervals on the filling pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com