Hydraulic pipe cleaner and cleaning method thereof

A pipe dredger, hydraulic type technology, applied in indoor sanitary pipeline installations, water supply devices, buildings, etc., can solve the problems of insufficient suction, unsatisfactory dredging effect, and easy crushing of the pipe wall of the spring dredger, achieving Delicate dredging, small space occupation, fast dredging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

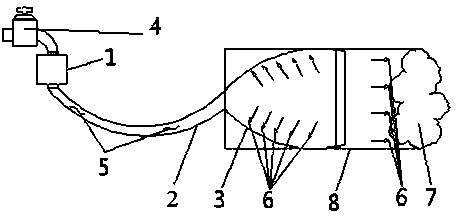

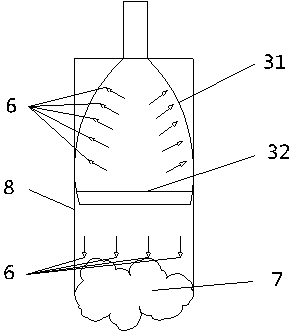

[0020] A hydraulic pipe dredger, comprising: an elastic rubber water guide pipe 2, a booster pump 1 is connected to one end of the elastic rubber water guide pipe 2, and a self-expanding nozzle 3 is connected to the other end of the elastic rubber water guide pipe 2. In this example,

[0021] The self-expanding nozzle 3 is made up of a guide ring 31 and a horn-shaped bag 32, the large opening of the horn-shaped bag 32 is connected with the guide ring 31, and the small opening of the horn-shaped bag 32 is connected with the other end of the elastic rubber water guide pipe 2. One end is connected, and the shape of the trumpet-shaped capsule 32 presents a spherical crown.

Embodiment 2

[0023] A hydraulic pipeline dredging method, comprising the following steps:

[0024] Step 1 Take an elastic rubber tube as the elastic rubber aqueduct 2, connect the booster pump 1 and the self-expanding nozzle 3 at both ends of the elastic rubber aqueduct 2, and the self-expanding nozzle 3 is composed of a guide ring 31 and a trumpet-shaped bag 32, the large opening of the trumpet-shaped bag 32 is connected with the guide ring 31, and the small opening of the trumpet-shaped bag 32 is connected with the other end of the elastic rubber water guide pipe 2,

[0025] Step 2 Insert the self-expanding nozzle 3 into the pipeline to be dredged, the guide ring 31 in the self-expanding nozzle 3 forms a preliminary seal with the pipe wall of the pipeline to be dredged and slides on the pipeline to be dredged, driving the self-expanding nozzle 3 The trumpet-shaped bag 32 enters the pipeline to be dredged and falls into place. In this process, the guide ring 31 plays a guiding role, guidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com