Pressure device for airtightness detection of casing and manufacturing method thereof

A pressurization device and casing gas technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the problems of inability to detect air tightness, increase transportation costs, and failure of oil and gas fields Problems such as the realization of the construction site, to achieve the effect of eliminating potential safety hazards, simple structure, easy to move and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

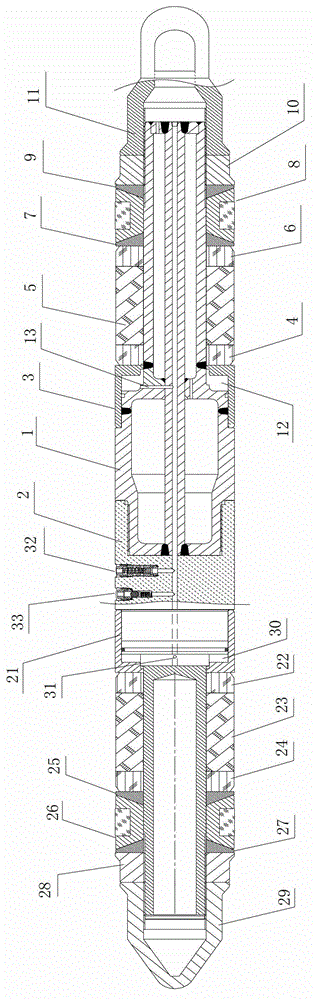

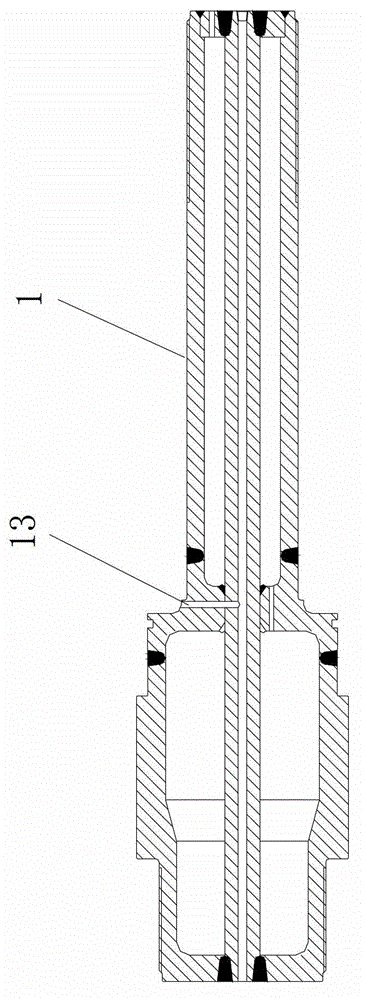

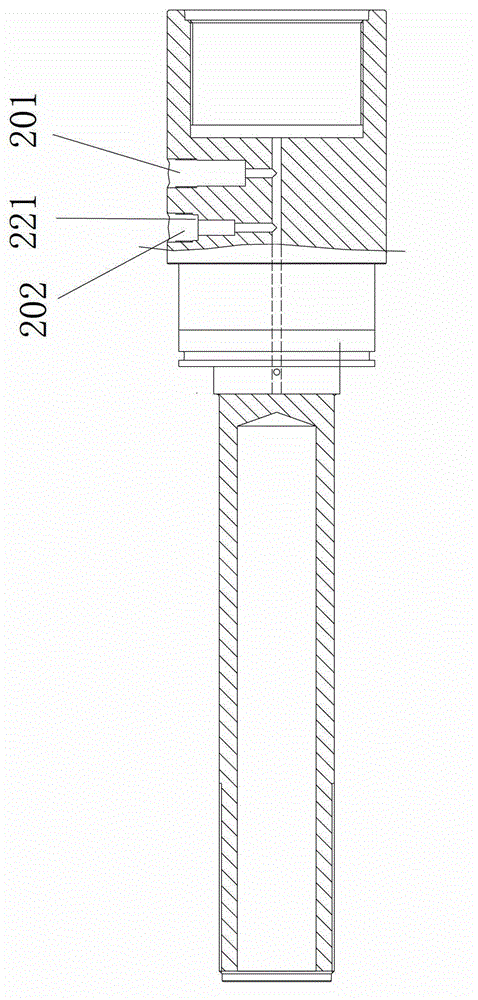

[0039] figure 1 It is a structural sectional view of a preferred embodiment of the casing air tightness detection pressurization device of the present invention; figure 2 It is a structural cross-sectional view of the first casing of the preferred embodiment of the casing air tightness testing pressurization device of the present invention; image 3 It is a structural cross-sectional view of the second casing of the preferred embodiment of the pressure device for testing the casing air tightness of the present invention. like Figure 1 to Figure 3 As shown, the pressure device for testing the air tightness of the casing includes: a pipe body formed by connecting the first casing 1 and the second casing 2, and the end of the second casing 2 is closed; From the middle of the pipe bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com