Bi-component polyurethane adhesive

A two-component polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems affecting the later operation, short pot life, slow curing speed, etc., to improve the curing speed , extend the validity period, and accelerate the effect of unblocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The two-component polyurethane adhesive described in this embodiment consists of component A and component B:

[0036] The raw material composition and weight percentage of component A are: 60% polyether polyol I-stick polyol138, 35% quartz powder, 2% nano-calcium carbonate, 0.03% catalyst dibutyltin dilaurate, 2% Silquest A-187 by wt, DF 691 at 0.97% wt.

[0037] Component B is Suprasec 5005 with NCO content of 31%;

[0038] The weight ratio of component A to component B is 5:1.

[0039] The preparation method of above-mentioned two-component polyurethane adhesive comprises the steps:

[0040] (1) To prepare component A, accurately weigh each raw material according to the weight percentage, pour polyether polyol I-stick polyol 138 into the stirring tank, then add quartz powder filler and stir well, then heat the stirring tank and Vacuum until the vacuum degree is -0.1Mpa. When the temperature reaches 100°C, continue to maintain the vacuum for 1h, then add nano-calci...

Embodiment 2

[0043] The two-component polyurethane adhesive described in this embodiment consists of component A and component B:

[0044] The raw material composition and weight percentage of component A are: 2%wt neopentyl alcohol, 10%wt polyester polyol Bayercoll DS 1165, 25% polyether polyol I-stick polyol 138, 56% kaolin , 4% nano-titanium dioxide, 0.05% catalyst tetraethylenetriamine, 1%wt Silquest A-187, 1%wt Silquest A-Link 597, 0.95%wt DF 691.

[0045] Component B is Desmodur E21 with NCO content of 16%;

[0046] The weight ratio of component A to component B is 2:1.

[0047] The preparation method of above-mentioned two-component polyurethane adhesive comprises the steps:

[0048] (1) To prepare component A, accurately weigh each raw material according to the weight percentage, pour polyester polyol Bayercoll DS 1165 and polyether polyol I-stick polyol 138 into the stirring tank, then add kaolin filler and stir well , then heat the stirred tank and evacuate it to a vacuum degr...

Embodiment 3

[0050] Embodiment 3 application experiment

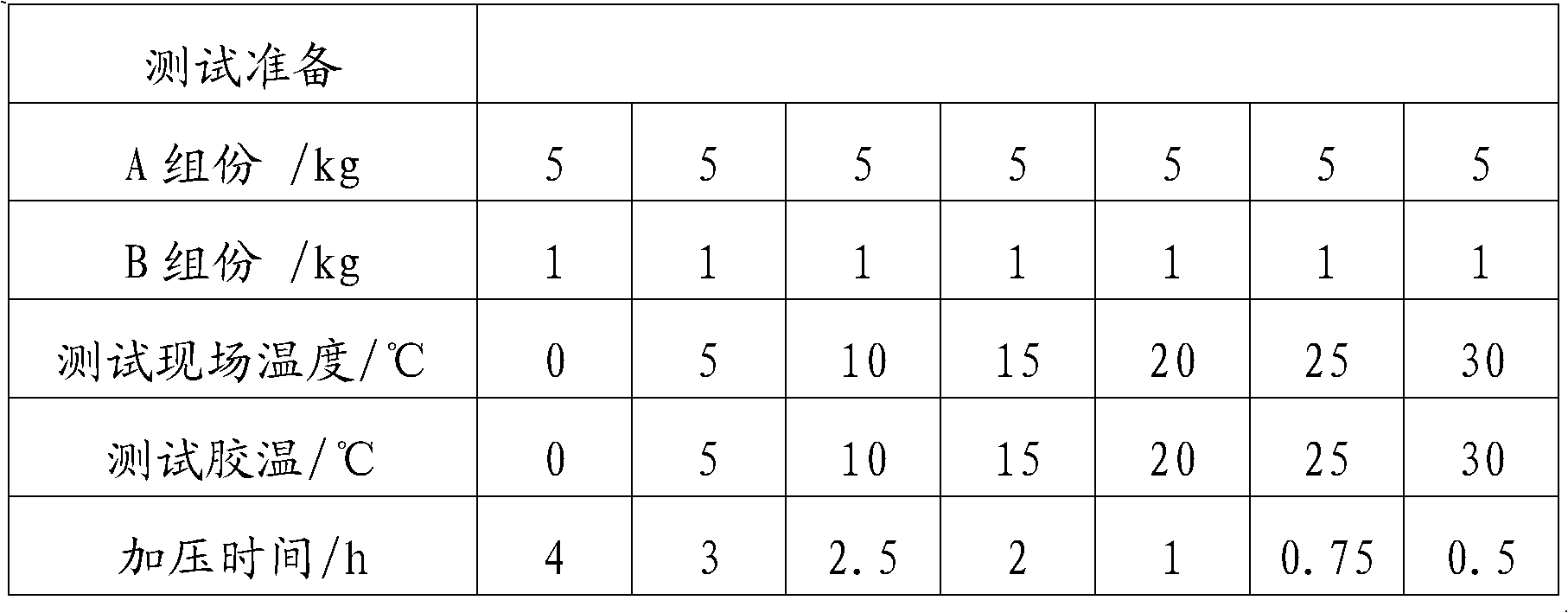

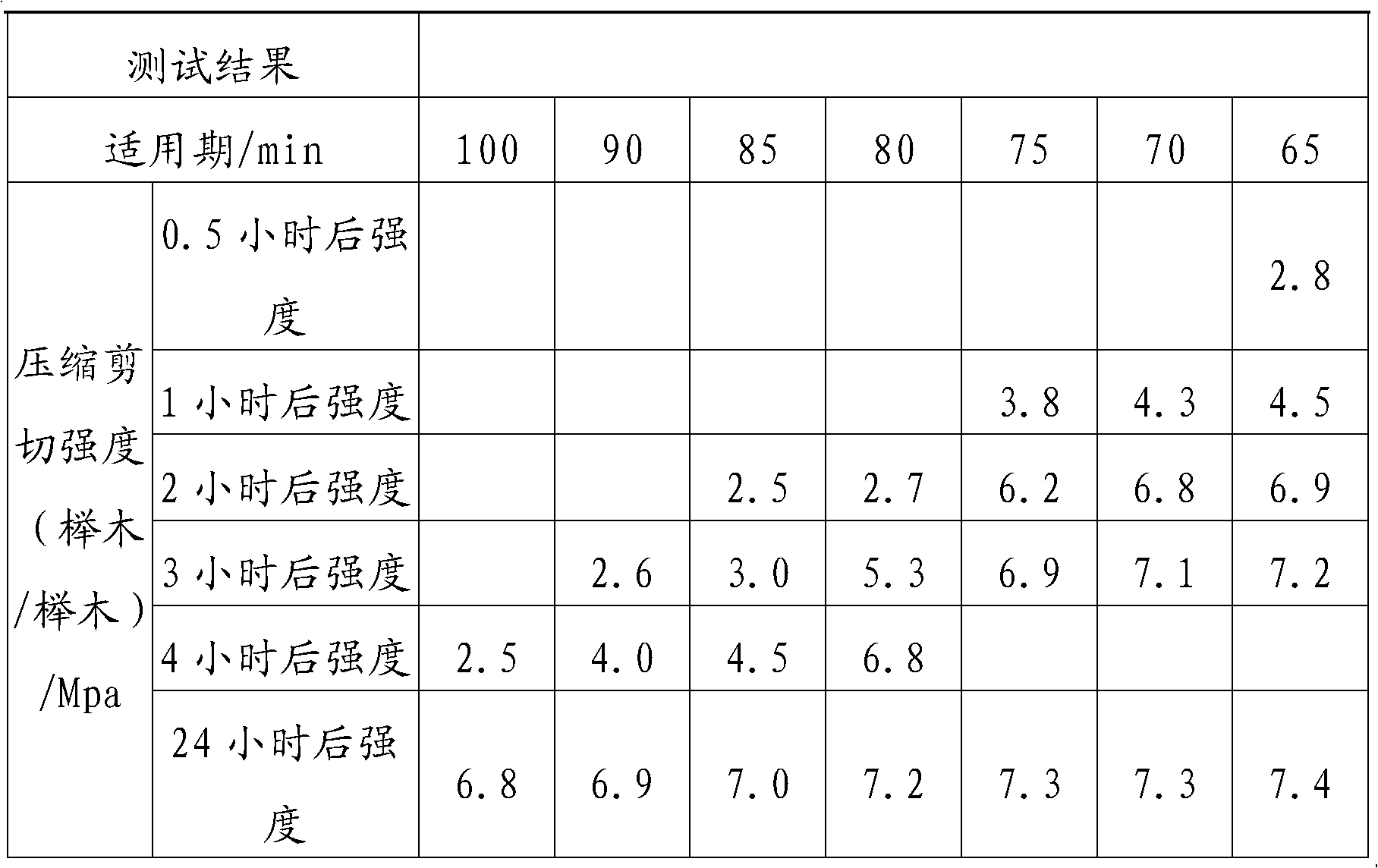

[0051] 1. Test method for pot life: refer to GB / T 2794-1995

[0052] The components A and B prepared in Examples 1 and 2 were mixed uniformly by a disperser (stirred at 1500rpm for 3 minutes) at the on-site temperatures shown in Tables 1 and 2, respectively. Then start the stopwatch and test the viscosity value of the glue after mixing every one minute. When the viscosity of the glue reaches or just exceeds 100,000mpa.s, it is defined as the end point, and the time at this time is the pot life.

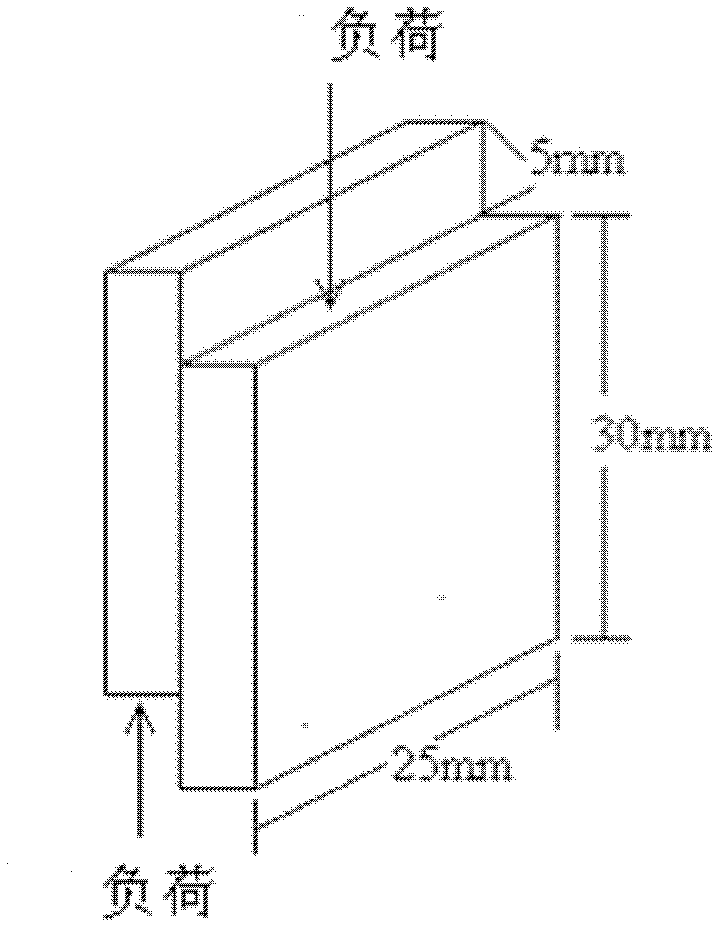

[0053] 2. Shear strength performance test (see figure 1 ): Refer to GB 7124-1986.

[0054] Instruments: automatic air press, stretching machine, measuring tools with an accuracy of 1mm.

[0055] Test piece: moisture content 10±2%, density 700±100Kg / m 3 beech wood (25 x 30 x 10).

[0056] Sample preparation: apply glue on the bonding surface, the bonding area is 25mm×25mm, the amount of glue applied is 100g / m2, and the two test pieces a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com