A self-balancing packer and method

A self-balancing, packer technology, used in sealing/packing, earthwork drilling, wellbore/well components, etc., can solve problems such as poor unpacking effect of packers, and reduce sand sticking. Risk, the effect of quick unblocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

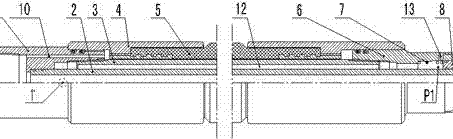

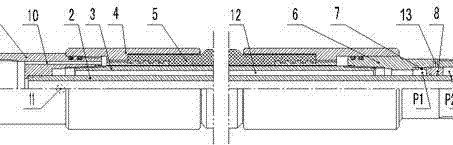

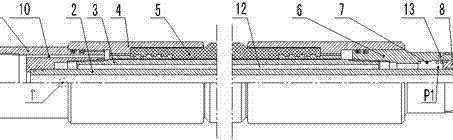

[0014] figure 1 A self-balancing packer, including an inner center pipe 2 and an outer center pipe 3 located in the packer, the outer center pipe 3 is sleeved on the inner center pipe 2, and the inner center pipe 2 and the outer center pipe 3 are formed In the first annulus, the rubber sleeve 5 is set on the outer central pipe 3. The rubber sleeve 5 divides the packer into upper and lower sections. The diameter is extended, and the diameter of the equal-diameter extension section is smaller than that of the upper and lower packing sections. The equal-diameter extension section of the rubber tube 5 is fixed on the outer central tube 3 by the upper and lower rubber tube seats 4, and the upper and lower ends of the inner central tube 2 and the upper and lower rubber tubes. The sleeve seat 4 is respectively connected to the upper joint 1 and the lower joint 6 , and a second annular space is formed between the rubber sleeve 5 and the outer central pipe 3 , and the second annular sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com