Vibrating chute concentrating machine for coal mining and using method thereof

A vibrating and concentrator technology, applied in the field of coal mining machinery, can solve problems such as environmental pollution, easy blockage, tailings that cannot be processed in time, and achieve the effect of increasing the spraying range and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

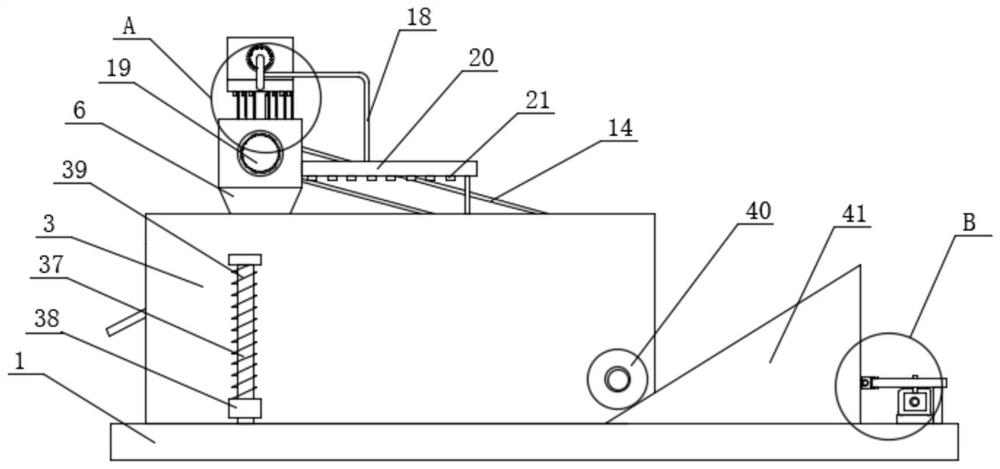

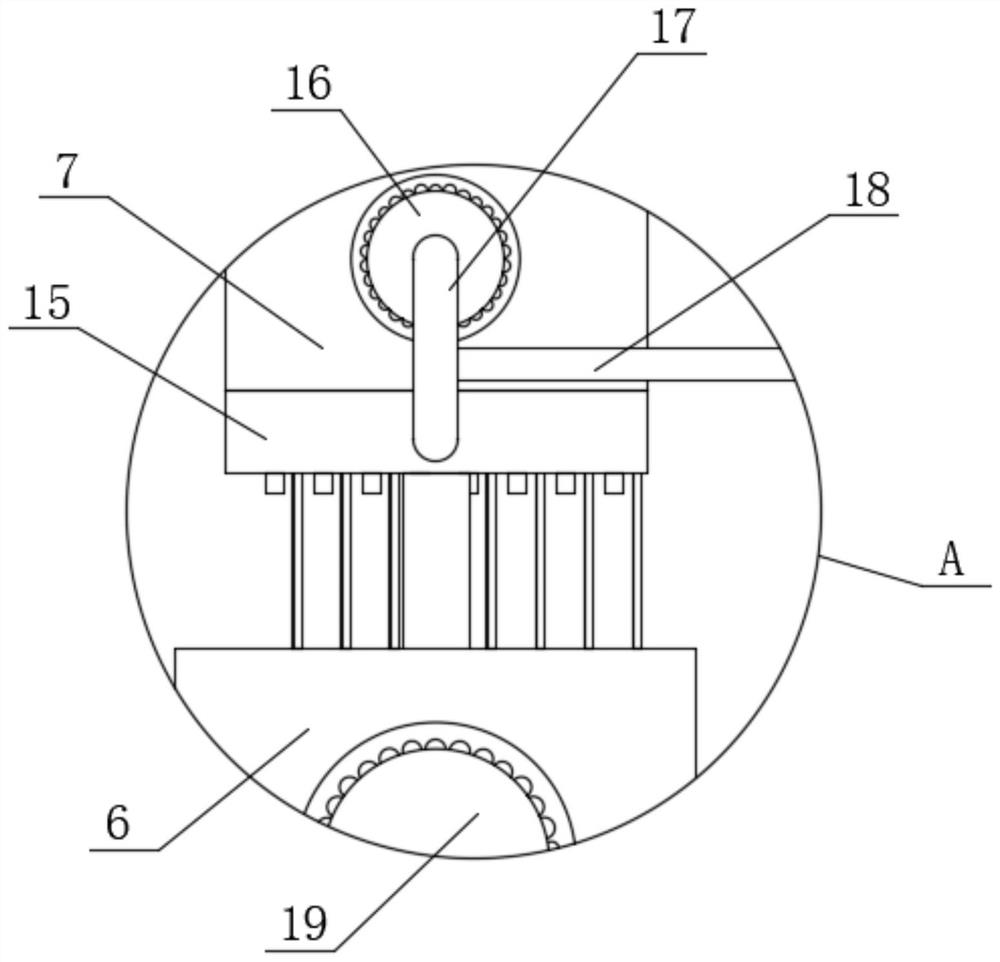

[0045] Embodiment one: if Figure 1-10 As shown, a vibrating chute concentrator used in coal mining includes a base 1, and the top of the base 1 is fixedly installed with a collection box 2 and is slidably connected with an installation pipe 3, and the collection box 2 is located in the installation pipe 3, and the installation pipe 3 is fixedly installed with a clip 4, which is sealed and bonded to the collection box 2, and a feeding pipe 6 is fixedly installed inside the installation pipe 3, and the top of the feeding pipe 6 extends to the top of the installation pipe 3 and is fixedly installed with a spray assembly , one side of the feeding pipe 6 is fixedly installed with a drive motor 19, the feeding pipe 6 is provided with a feeding assembly, the output shaft of the driving motor 19 extends into the feeding pipe 6 and is connected to the feeding assembly in transmission, and the transmission connection in the installation pipe 3 There is a material transfer component, an...

Embodiment 2

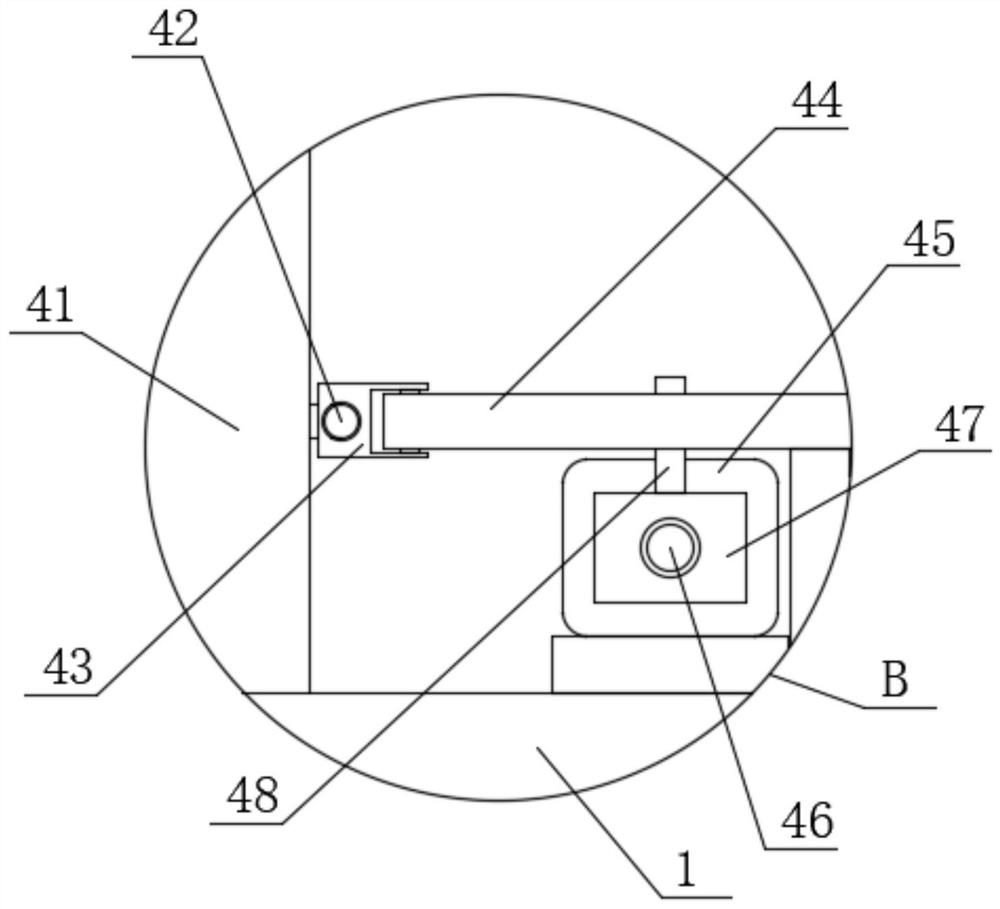

[0058] Embodiment two: if Figure 11-15 As shown, a vibrating chute concentrator used in coal mining, the difference between this embodiment and Embodiment 1 is that the driving assembly includes a transmission motor 45 fixedly installed on the top side of the base 1, and the output shaft of the transmission motor 45 is fixed Drive screw rod 46 is installed, and threaded plate 47 is threadedly connected on the drive screw rod 46, and the top of thread plate 47 is fixedly installed with stop shaft 48, and the top side of base 1 is connected with drive ring 44 in rotation, and the sliding connection in drive ring 44 is limited. Position plate 65, stop shaft 48 runs through limit plate 65 and is connected with limit plate 65 in rotation, one side of drive ring 44 is connected with slide plate 43 in rotation, one side of U-shaped inclined plate 41 is fixedly installed with connecting rod 42, connecting rod 42 runs through the slide plate 43 and is slidably connected with the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com