Smashing, screening and circulating coal feeding system

A technology of crushing, screening, and coal supply, which is applied in the directions of fuel supply, block/powder supply/distribution, and combustion methods. The effect of transmission load and machine weight, meeting the requirements of transmission strength and stiffness, and reducing unsafe factors for cleaning coal blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

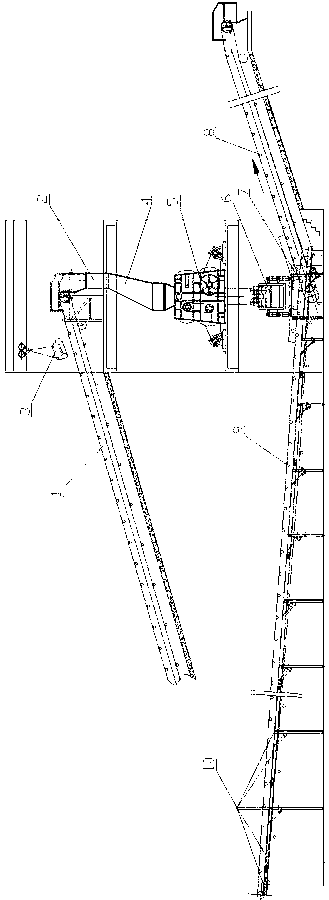

[0028] Such as figure 1As shown, a crushing and screening circulating coal supply system includes a mixed coal bunker, a coal feeding nozzle, an iron remover, a crusher, and a 1# coal supply belt conveyor, and the lower part of the 1# coal supply belt conveyor 1 is connected to the mixed coal bunker 2. The head of the mixed coal bunker 2 is equipped with an iron remover 3, the mixed coal bunker 2 is funnel-shaped, the coal supply nozzle 4 is located at the bottom of the mixed coal bunker 2, the lower part of the coal supply nozzle 4 is connected to the crusher 5, and the material is processed by The belt conveyor is sent to the boiler; it is characterized in that: a vibrating screening machine 6 is added at the outlet of the crusher 5, and the lower part of the vibrating screening machine 6 is provided with a separating material nozzle 7, which is connected to the belt conveyor 8 under the 2# screen, and the coal with a qualified particle size Sent to the boiler through the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

| Horizontal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com