Patents

Literature

34results about How to "Reduce incomplete combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compression ignition internal combustion engine, glow plug, and injector

InactiveUS8156911B2Increasing chemical activity and chemical reactivityReduce energy lossElectrical controlIncandescent ignitionCombustion chamberNuclear engineering

The invention provides a practical diesel engine that uses plasma formed by microwave emissions. In a compression-ignition internal combustion engine, fuel is sprayed by an injector in the combustion chamber in which compressed oxidizing gas is present, and the fuel is compressed and ignited. The engine has one antenna or a plurality of antennas in the combustion chamber, and when the oxidizing gas or moisture and charged particles are present in the combustion chamber, an electromagnetic wave is emitted using the antenna in a space in which the oxidizing gas and the charged particles are present, and plasma is generated in the space by the energy fed to the charged particles.

Owner:MAGINEERING INC

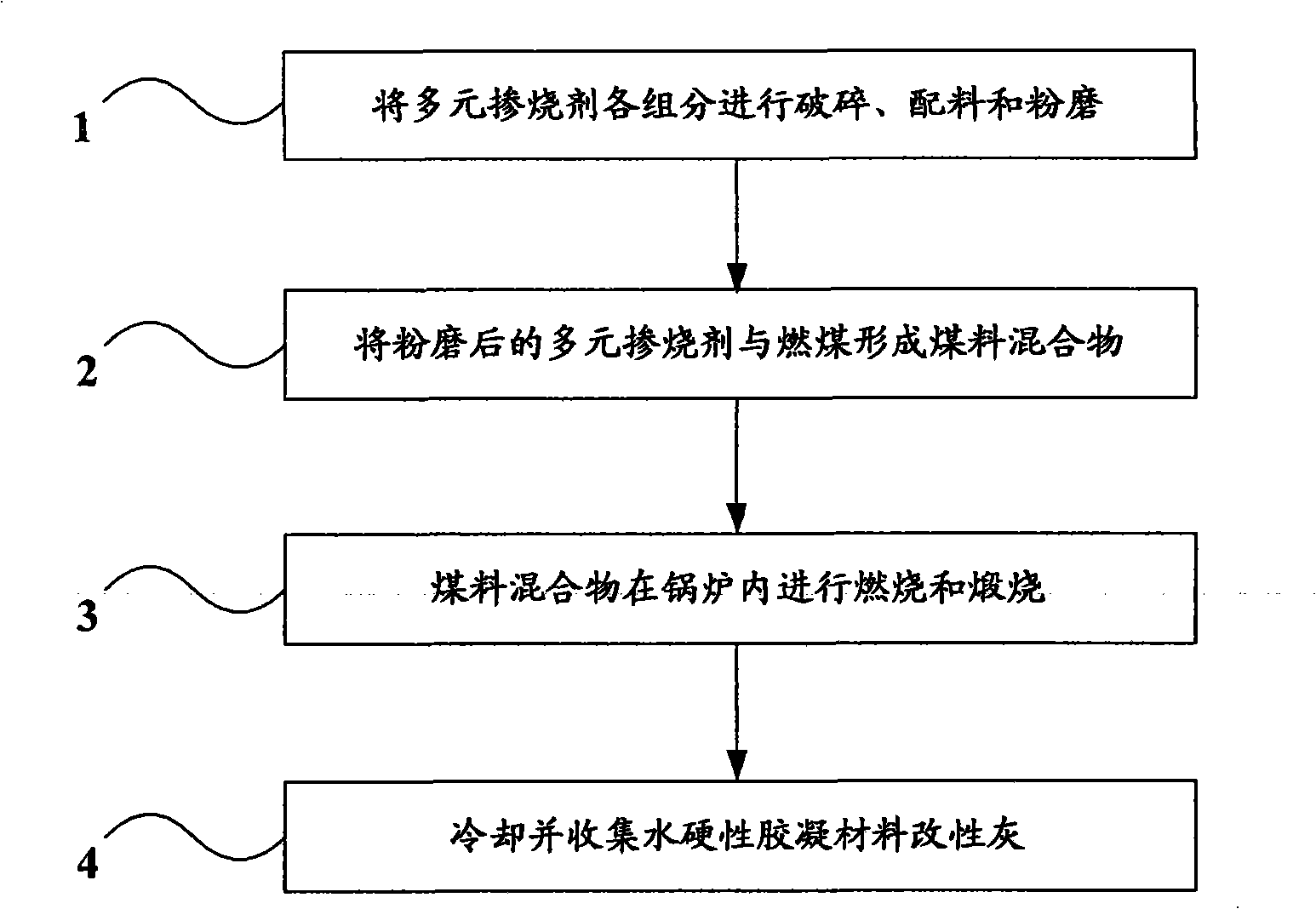

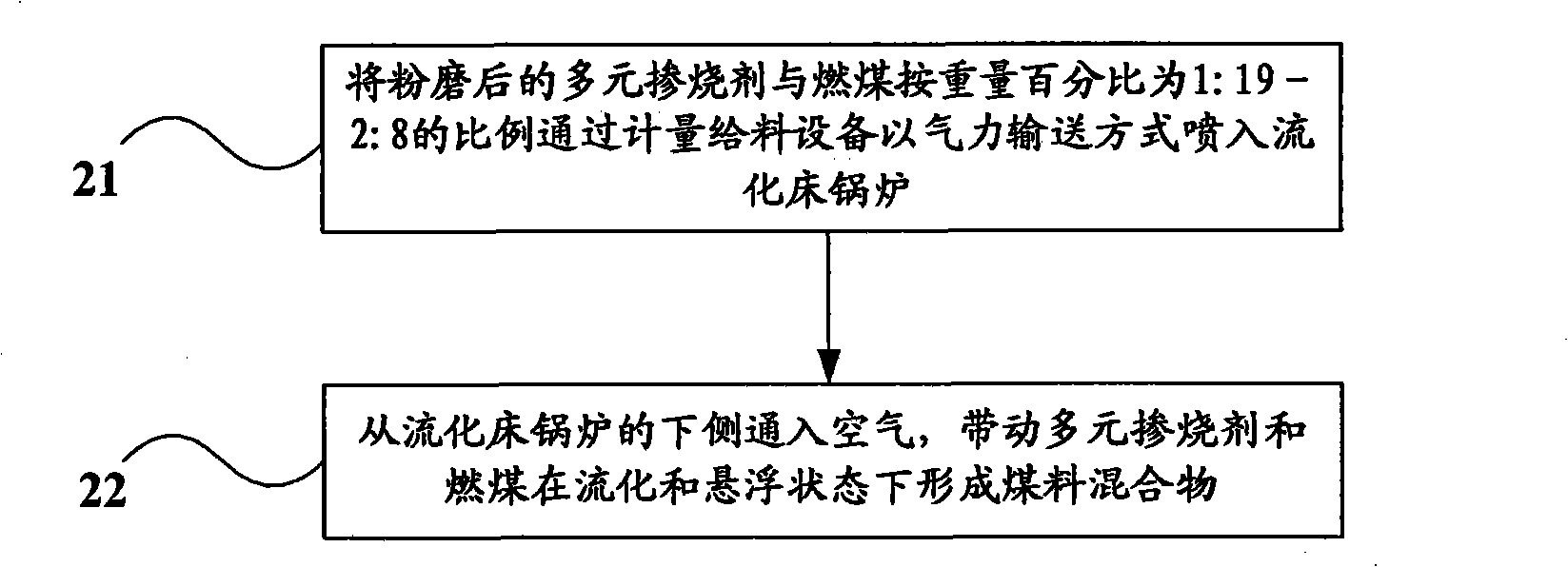

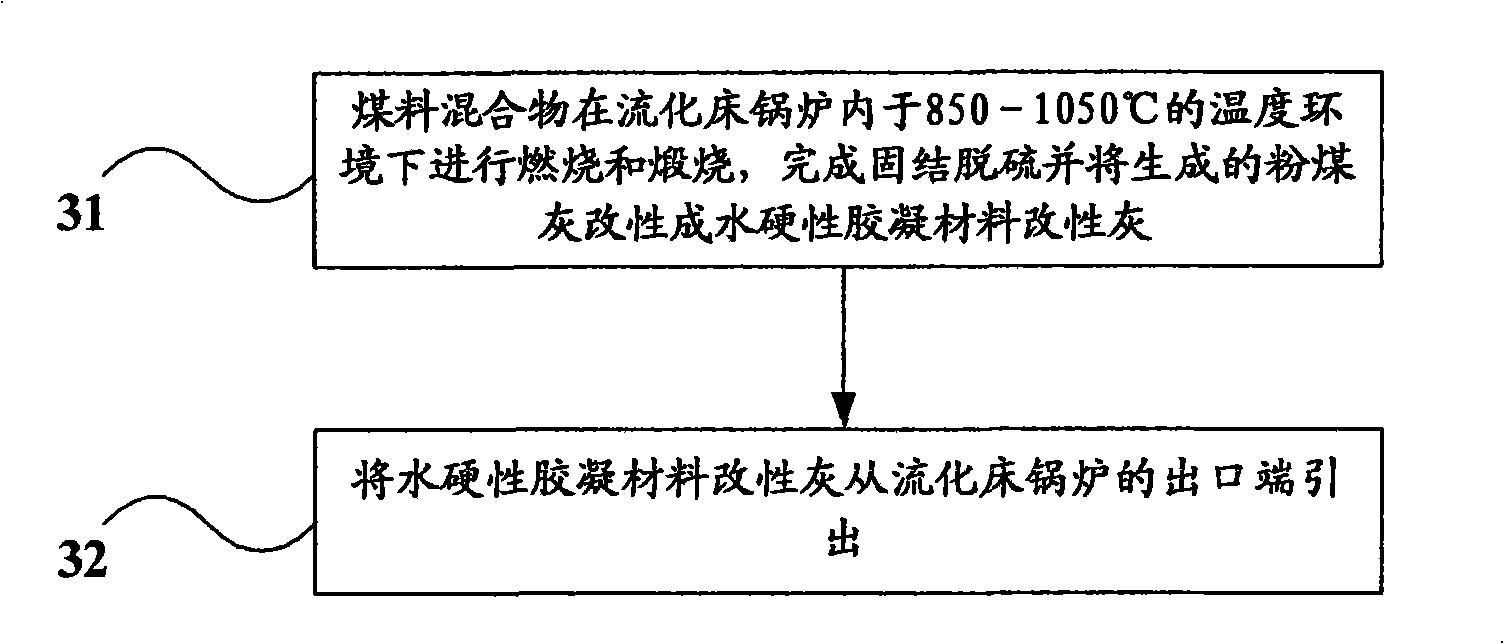

Multicomponent co-combustion agent and use method thereof

ActiveCN101314742AIncreased Strength and DurabilityLower combustion temperatureSolid fuelsSlagCoal fired

The invention relates to a multi-doped sintering agent and the usage thereof. The multi-doped sintering agent consists of a main material and a core material, wherein the main material includes one or any combination of carbide slag, soda slug, quick lime or limestone; the core material includes mineralizer, salt-melting medium and coke slag bulking agent. The usage of the multi-doped sintering agent comprises the following steps: crushing, mixing and pulverizing each component of the multi-doped sintering agent; mixing the pulverized multi-doped sintering agent with coal to form a coal mixture; burning and calcining the coal mixture in a boiler; and cooling and collecting hydraulic binding material modified ash. The multi-doped sintering agent can reduce the carbon content of fly ash and reduce the coal consumption of the boiler and can achieve high-efficiency solid desulfurization. The hydraulic binding material active ash produced after the coal burning has wide purposes, thus achieving multiple purposes of one boiler and achieving good effects of fluidized-bed combustion boiler such as environment protection, energy conservation and high-efficiency waste utilization.

Owner:中科院科技服务有限公司

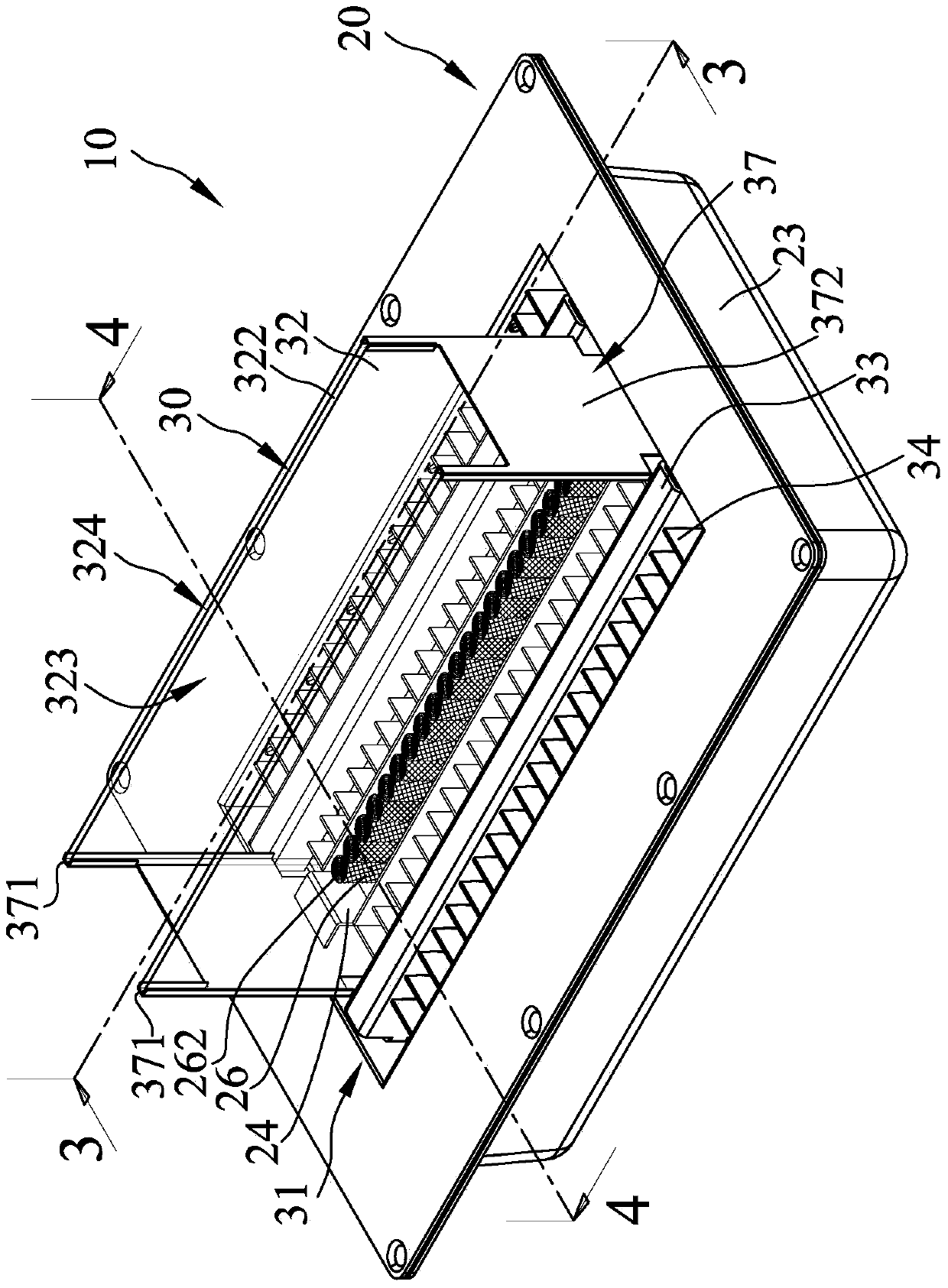

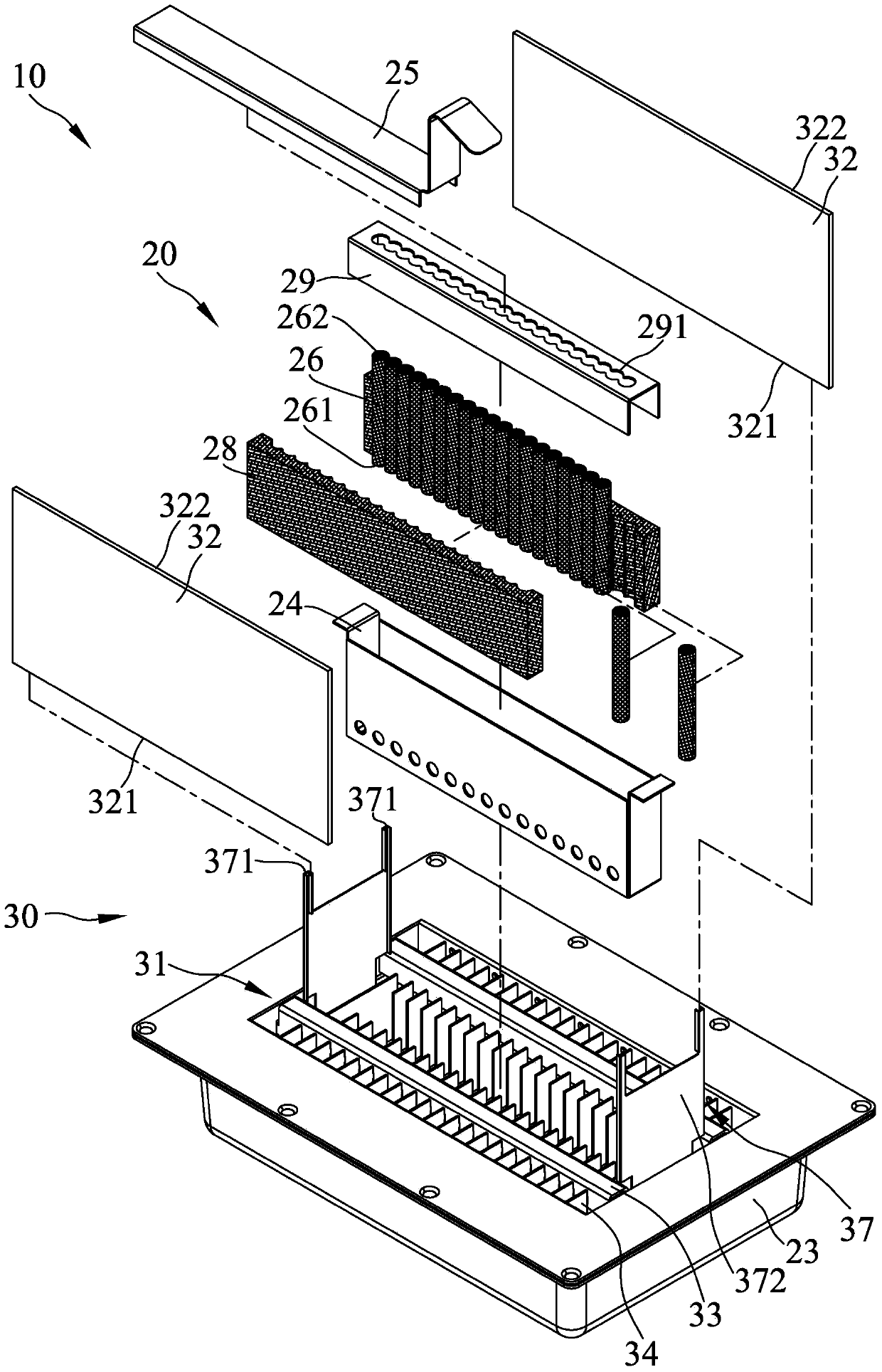

Combustion device with safety

The invention discloses a combustion device with safety. The combustion device comprises a body and a flow guiding device, wherein the body is provided with a containing space and a group of lampwick; the lampwick is arranged in the containing space; the body is provided with a bottom surface; the lampwick comprises a top end; a first distance is arranged between the top end and the bottom surface of the lampwick; the flow guiding device is connected to the body and comprises a first shielding part which comprises a bottom side and a top side; a second distance longer than the first distance is arranged between the bottom side and the bottom surface of the first shielding part; a third distance longer than the first distance is arranged between the top side and the bottom surface of the first shielding part; the flow guiding device also comprises a first airflow channel for communicating the inner side and the outer side of the first shielding part. The combustion device disclosed by the invention has the advantages that in combustion, air is sucked through the airflow channel, and not only is the combustion provided, but also the airflow is controlled to pass through the surface of the combustion device so as to provide cooling; the shape of flame is controlled and stabilized by a first flow guiding part.

Owner:PRO IRODA INDS

Smoke flavoring for roast smoking of preserved meat

ActiveCN105660815AImprove flammabilityFlammableMeat/fish preservationFood ingredient as flavour affecting agentBiotechnologyCinnamomum camphora

Disclosed is a smoke flavoring for roast smoking of preserved meat.The smoke flavoring is made of, by weight, 30-50 parts of pine wood, 5-10 parts of cinnamomum camphora wood, 5-10 parts of dried orange peel, 30-50 parts of dried corn stalk, 2-3 parts of illicium verumm 2-3 parts of cortex cinnamomi, 3-5 parts of brown sugar and 7-10 parts of kaolin.The raw materials of the smoke flavoring are easily available, cost is low, industrial production is facilitated, fire behavior is controllable, the preserved meat is not easy to burn, industrial batch production for roast smoking of the preserved meat becomes possible, and the smoke flavoring can also reduce production and deposition of harmful substances and conforms to the concept of green and sound development.

Owner:山东大树欧亚天然调味品有限公司

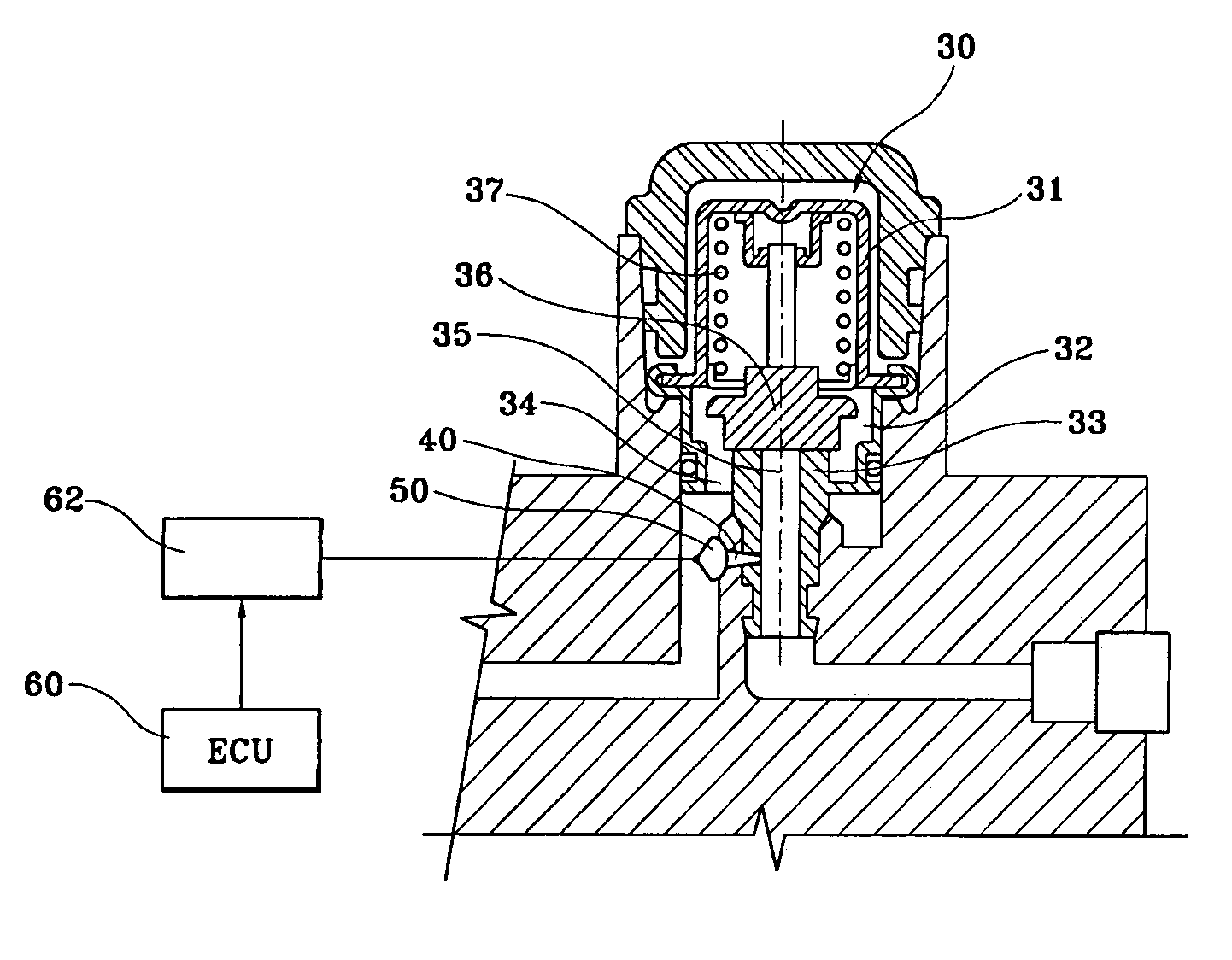

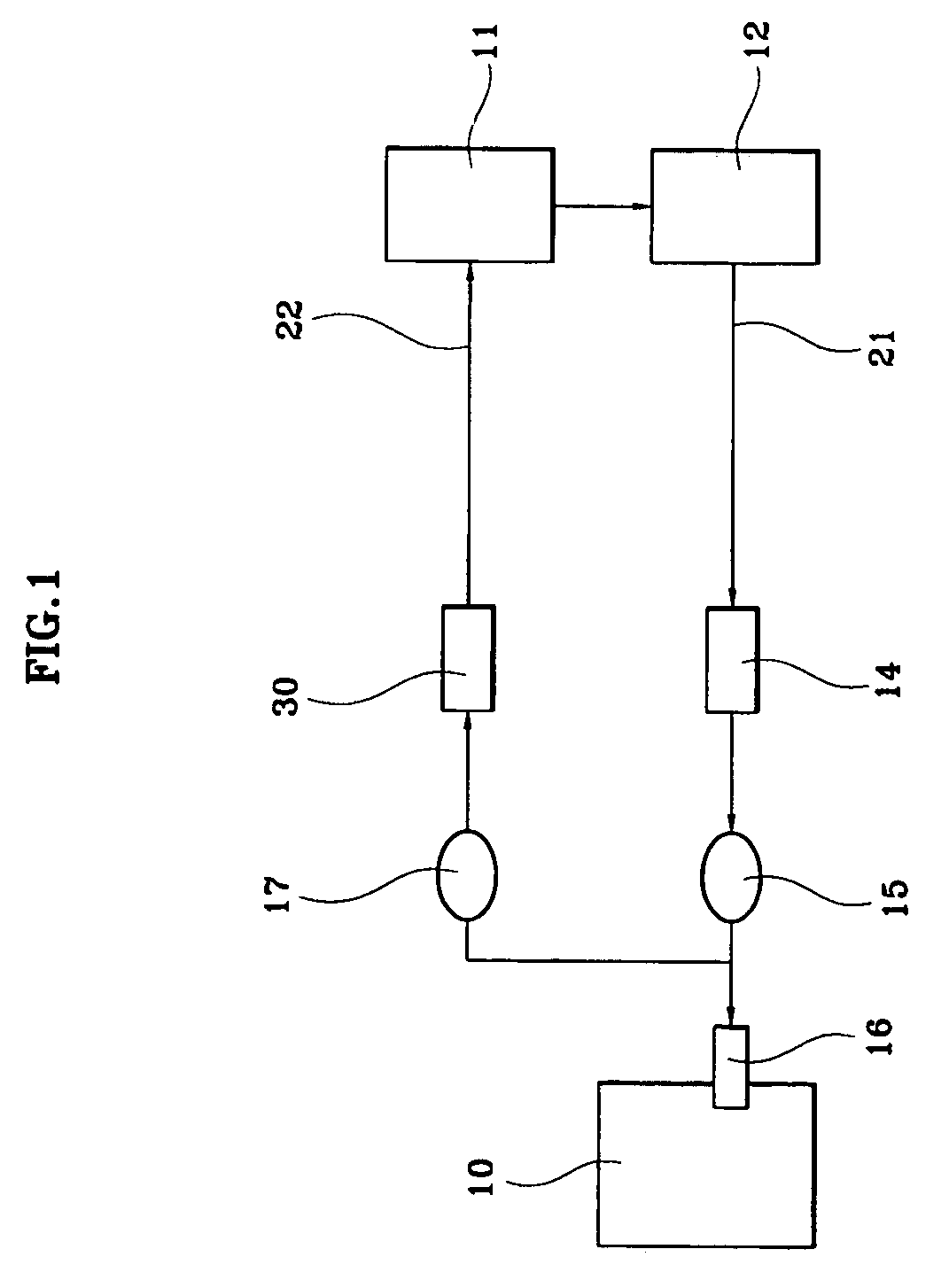

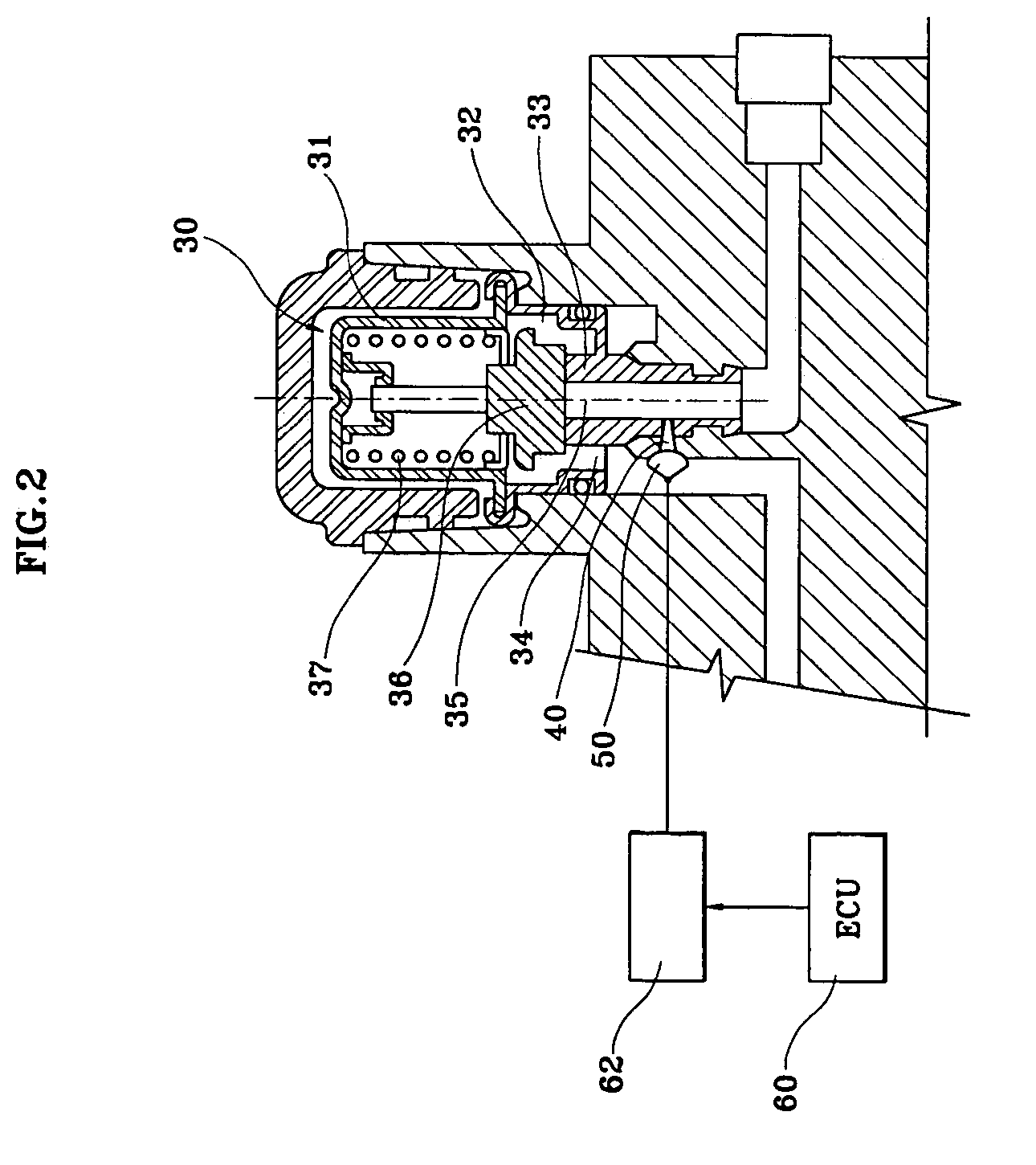

Fuel drain structure in fuel line

InactiveUS6966307B2Reduce incomplete combustionEffective drainageElectrical controlLow pressure fuel injectionRotary valveFuel line

A fuel drain structure in a fuel line comprising a bypass channel for connecting a fuel influx side and a fuel efflux side of a regulator, and a rotary valve for opening and closing the bypass channel, contributing to a prevention of fuel remaining in the fuel line from entering the engine when the engine stops running, and minimization of pollution occurring when the engine is re-started.

Owner:HYUNDAI MOTOR CO LTD

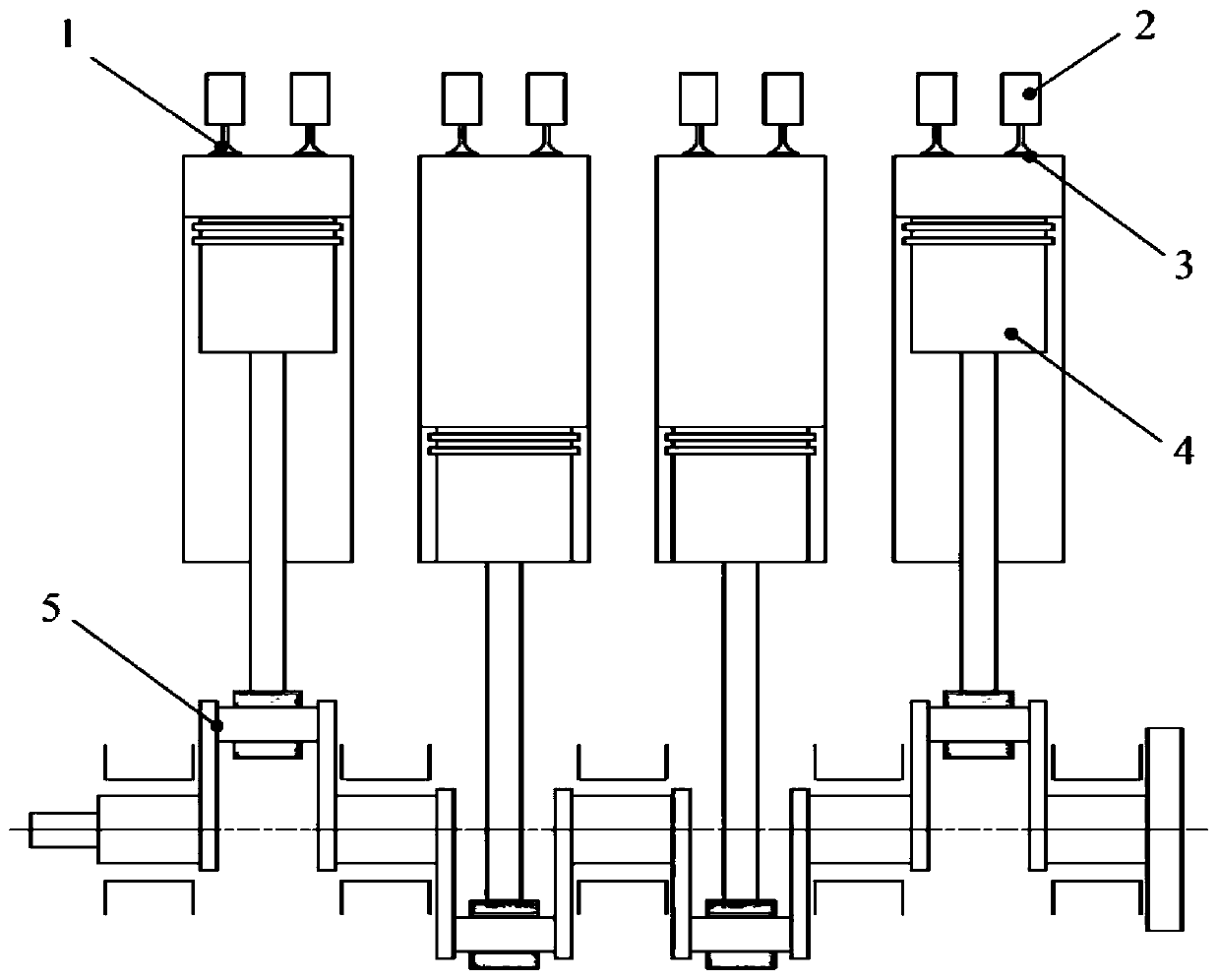

Method for expanding and optimizing compression ignition operation range of internal combustion engine applying variable valves

InactiveCN110469411AAdjustable EGR rateFlexible and adjustableInternal combustion piston enginesOutput powerHomogeneous charge compression ignitionExhaust valve

The invention provides a method for expanding and optimizing compression ignition operation range of an internal combustion engine applying variable valves. The internal combustion engine comprises intake valves, exhaust valves and electromagnetic full-variable valve devices, the intake valves and the exhaust valves are respectively provided with the electromagnetic full-variable valve devices forcontrolling the opening lift size and the opening phase angle of the intake valves and the exhaust valves; the electromagnetic full-variable valve devices drive the exhaust valves to open during an exhaust stroke period, so that exhaust gas starts to be discharged out of a cylinder; at some point of the exhaust stroke, the intake valves are driven to open, so that part of exhaust gas flows back into an intake manifold; and the lift for controlling the opening of the intake valves by the electromagnetic full-variable valve devices is decreased as the engine load is increased. According to themethod for expanding and optimizing compression ignition operation range of the internal combustion engine applying the variable valves, the small EGR rate can be adopted at high load to reduce severecombustion or knocking in the homogeneous compression ignition process, and the larger EGR rate can be adopted at low load to reduce incomplete combustion or misfire in the homogeneous compression ignition process, so that the homogeneous compression ignition operates in a larger operating range.

Owner:NANJING UNIV OF SCI & TECH

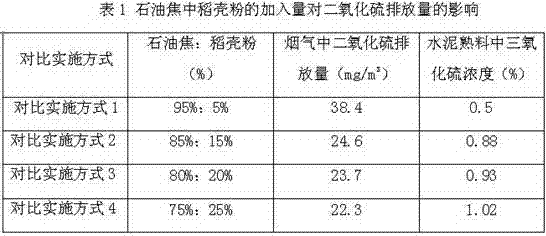

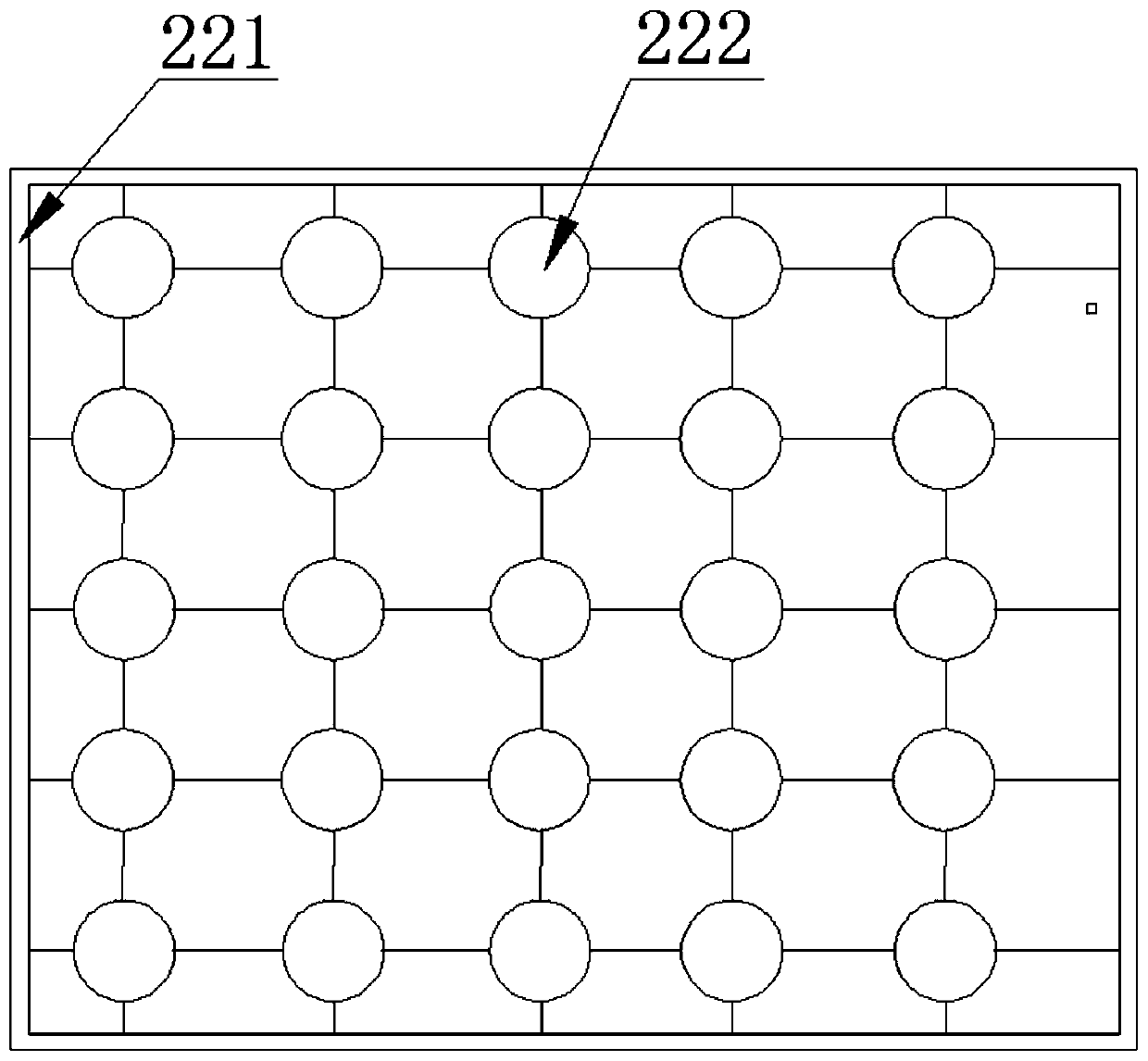

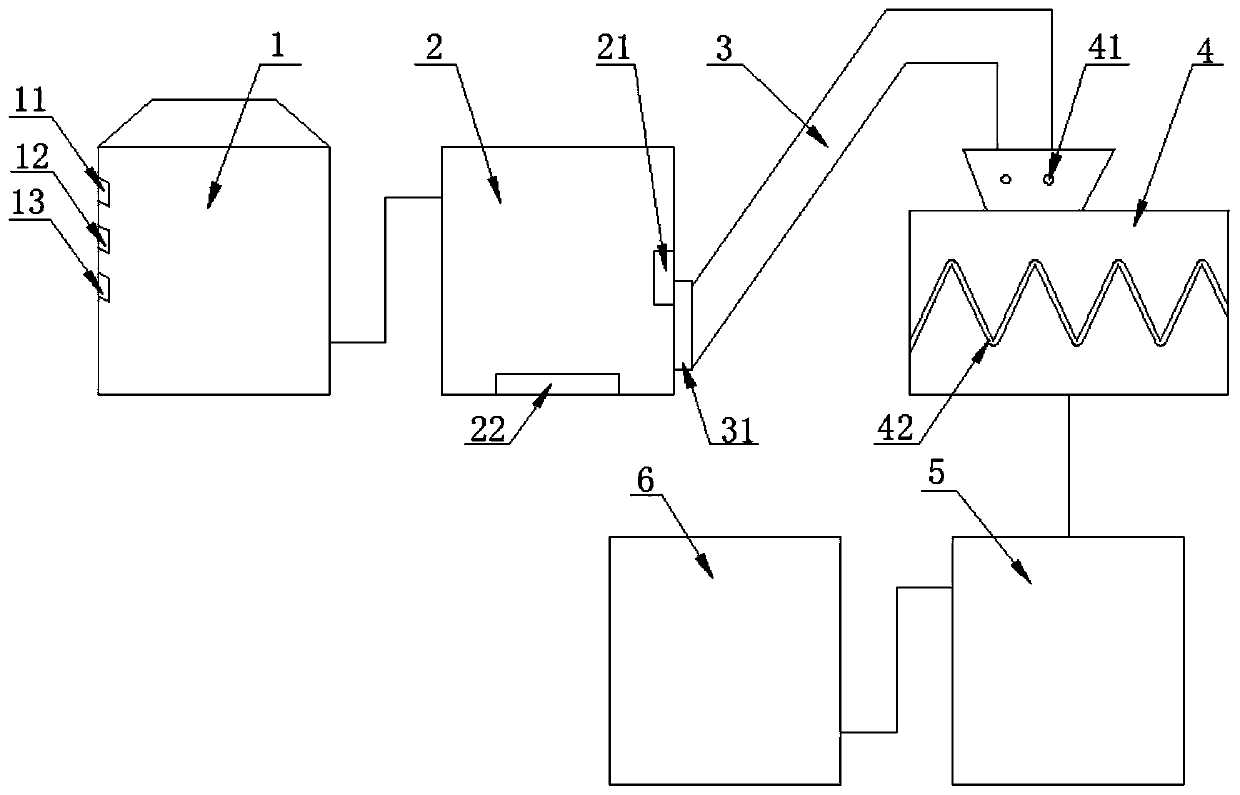

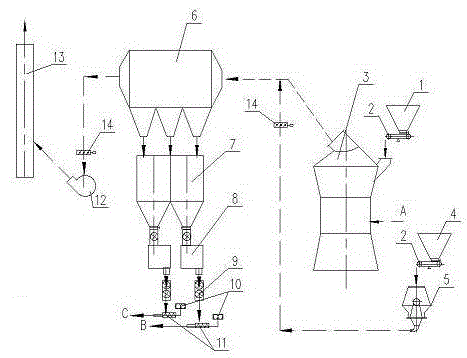

Process of calcining mixed fuel in white cement rotary kiln by using rice hull powder and petroleum coke powder

The invention relates to a process of calcining mixed fuel in a white cement rotary kiln by using rice hull powder and petroleum coke powder. The process comprises the following steps: crushing rice hulls to rice hull powder in a crusher, sucking the crushed rice hull powder into a bag type dust collector by an exhaust fan of a petroleum coke grinding system, mixing and collecting the petroleum coke powder entering into the bag type dust collector and feeding the mixture into a mixed fuel cabin, and then, respectively feeding the mixed fuel to a decomposing furnace and a combustor at the head of the rotary kiln to combust; and discharging purified gases to the atmosphere by the exhaust fan through a chimney. The ignition point and burnout temperature of the mixed fuel doped with rice hull powder and petroleum coke powder can be reduced, the incomplete combustion phenomenon of the fuel is greatly reduced, and the calcining heat loss of white cement clinker is remarkably lowered. The white cement clinker is beneficial to calcination due to the characteristics of high heat value and low ash content of petroleum coke, iron pollution brought by ash content can be avoided, and the strength and whiteness of the white cement are facilitated. According to the process, crushed rice hulls can be doped into petroleum coke powder to prepare the mixed fuel, so that the process is suitable for calcining the white cement clinker in a new dry process cement kiln.

Owner:江西银杉白水泥股份有限公司

Low-heating-value coal gangue combustion method

InactiveCN111023107ABurn fullyImprove combustion conditionsIncinerator apparatusGrain treatmentsCombustionProcess engineering

The invention provides a low-heating-value coal gangue combustion method, belongs to a coal combustion method, and aims to provide the low-heating-value coal gangue combustion method capable of improving the coal gangue combustion efficiency and reducing polluted gas emission. A biomass, a combustion improver and a sulphur-fixing agent are added according to a certain mass ratio, and are aged fora certain time after being uniformly mixed to obtain fuel for a coal-fired boiler, and three-times air supply is performed forcedly at the bottom of a fire grate of the coal-fired boiler when the fuelis fed at constant speed according to the fire coal amount required in combustion of the boiler by a mechanical coal feeding device, so that the sufficient combustion of the fuel of the coal-fired boiler is ensured. By improving the concentrations of oxygen and carbon dioxide, the rate of dissociation of carbon dioxide in fume is reduced, the content of carbon monoxide is reduced, the chemical incomplete combustion loss is reduced, the combustion burnout degree is beneficially improved, the heating value requirements of thermal power generation fuel are met, and finally the heating efficiencyof low-heating-value coal gangue can be improved by 30%-50%.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Shelf-stable biofuel granule and preparation method thereof

The invention discloses a shelf-stable biofuel granule and a preparation method thereof. The shelf-stable biofuel granule is prepared from, by weight, 10-12 parts of slab edgings, 15-20 parts of saw dust, 1-5 parts of a swelling agent, 0.1-0.5 part of an antibacterial agent and 0.1-0.5 part of a catalyst. The invention further discloses the preparation method of the shelf-stable biofuel granule. The shelf-stable biofuel granule is high in heat value, good in fire effect, easy to produce, low in cost and suitable for long-term storage.

Owner:龙门县景龙生物能源有限公司

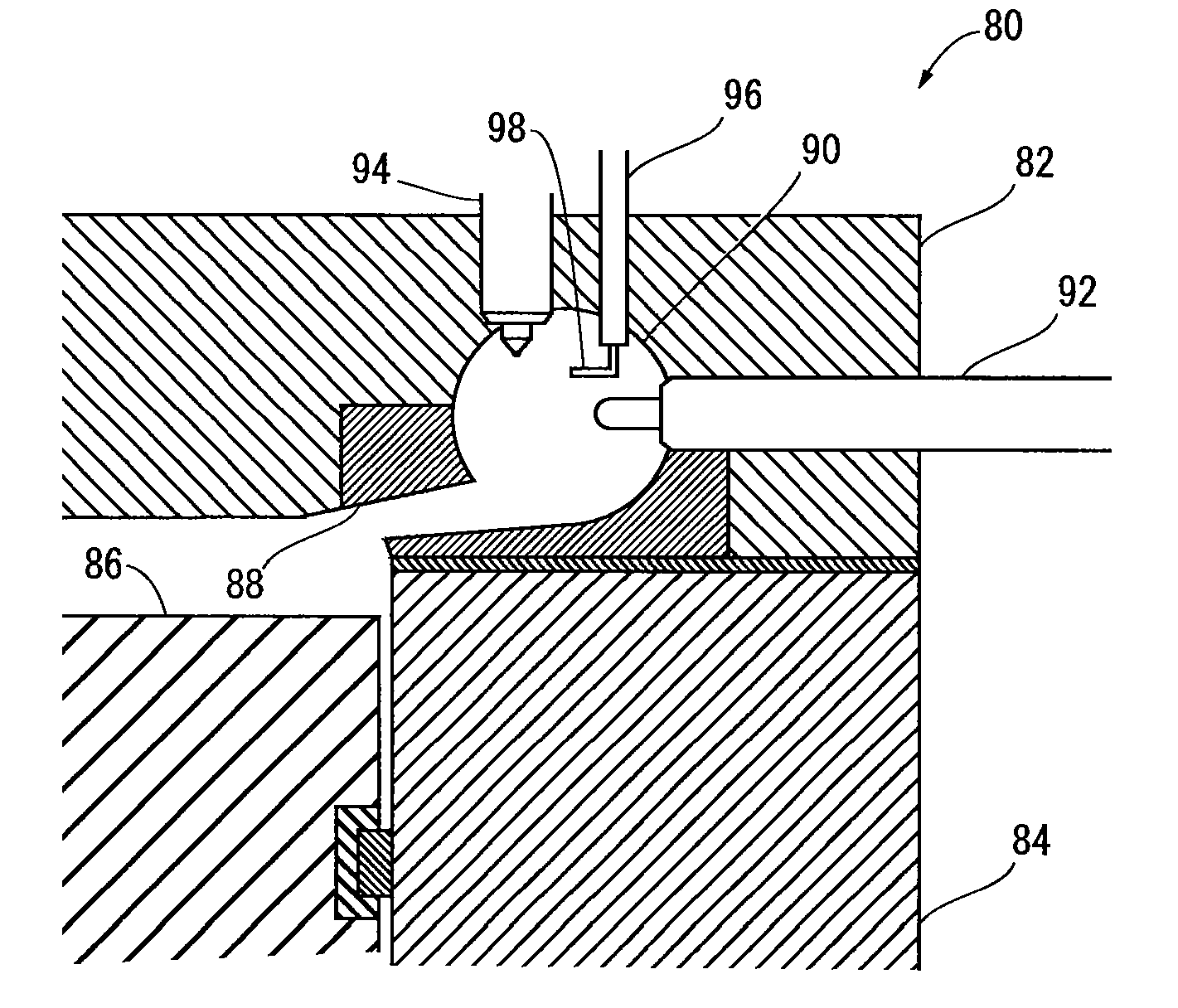

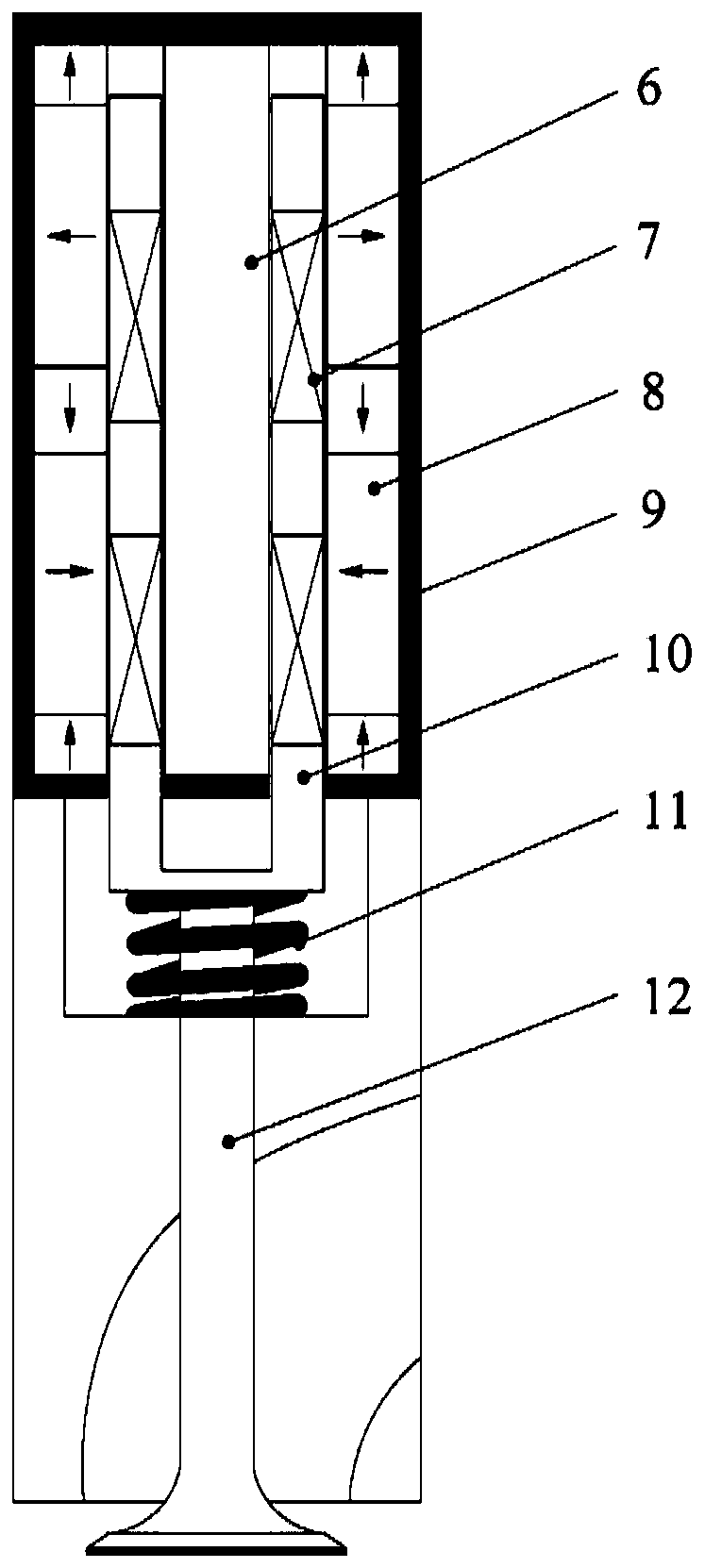

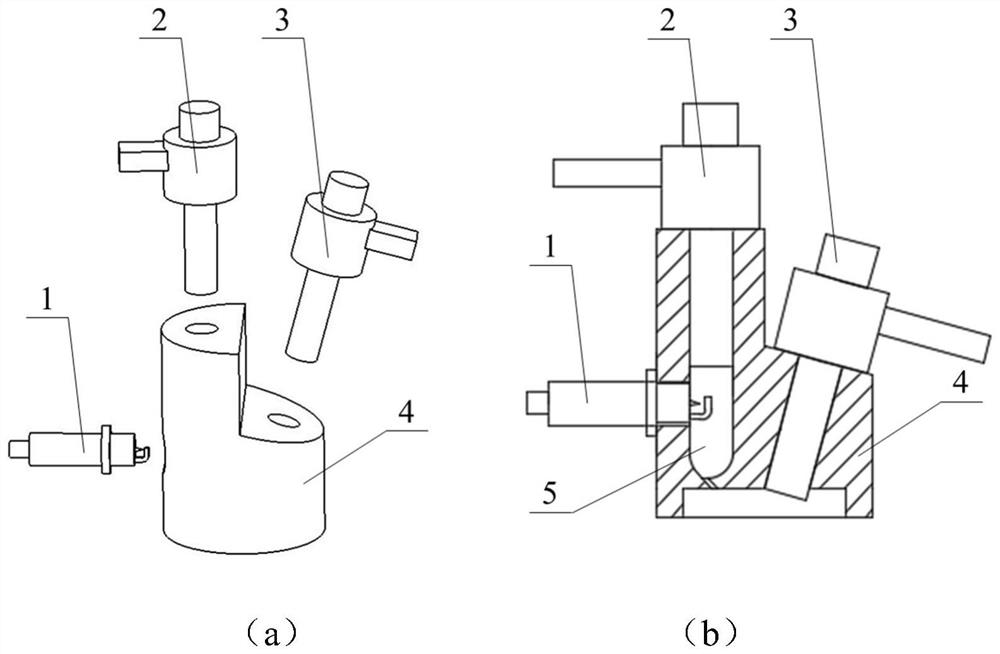

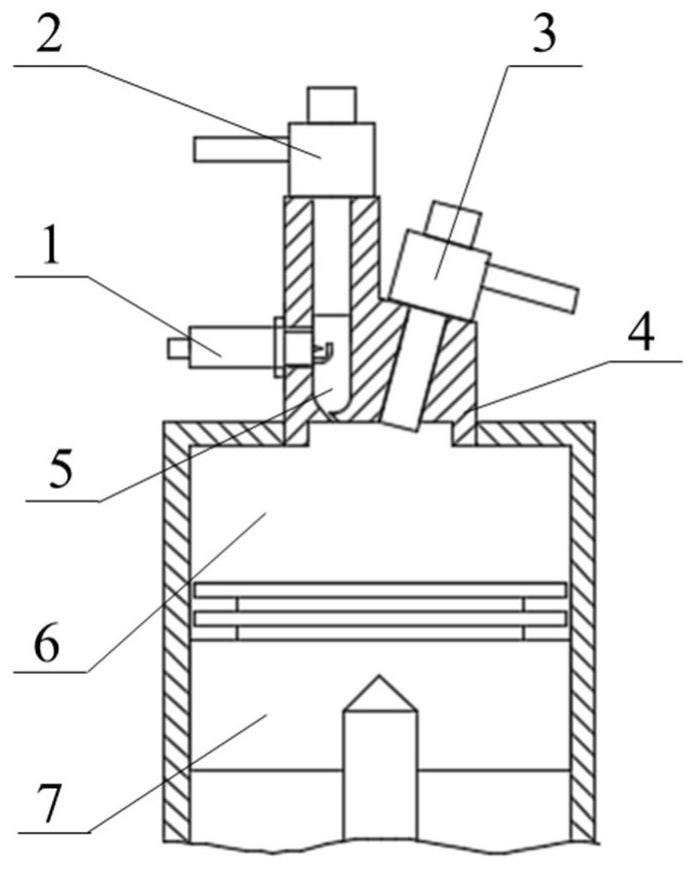

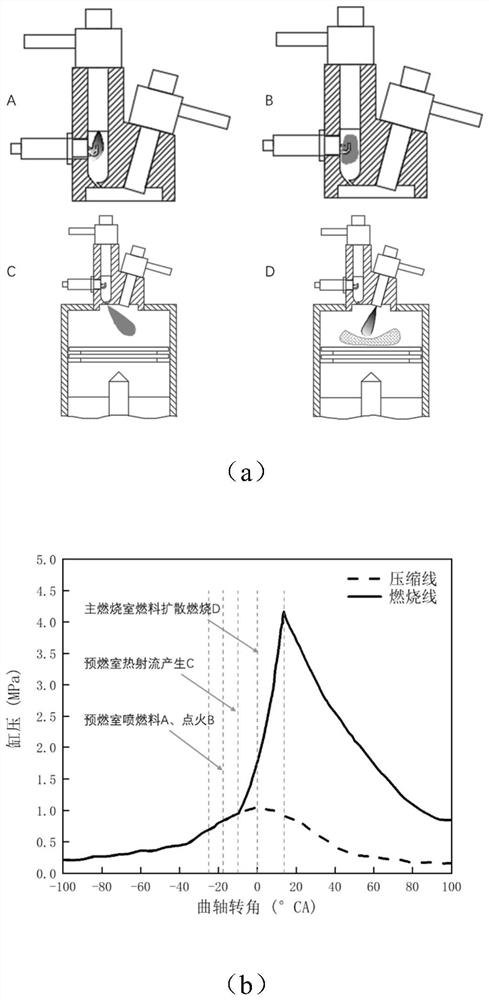

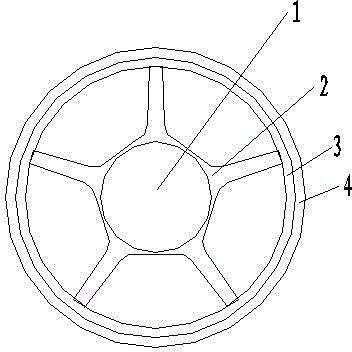

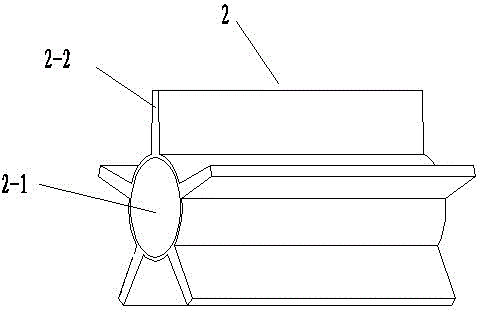

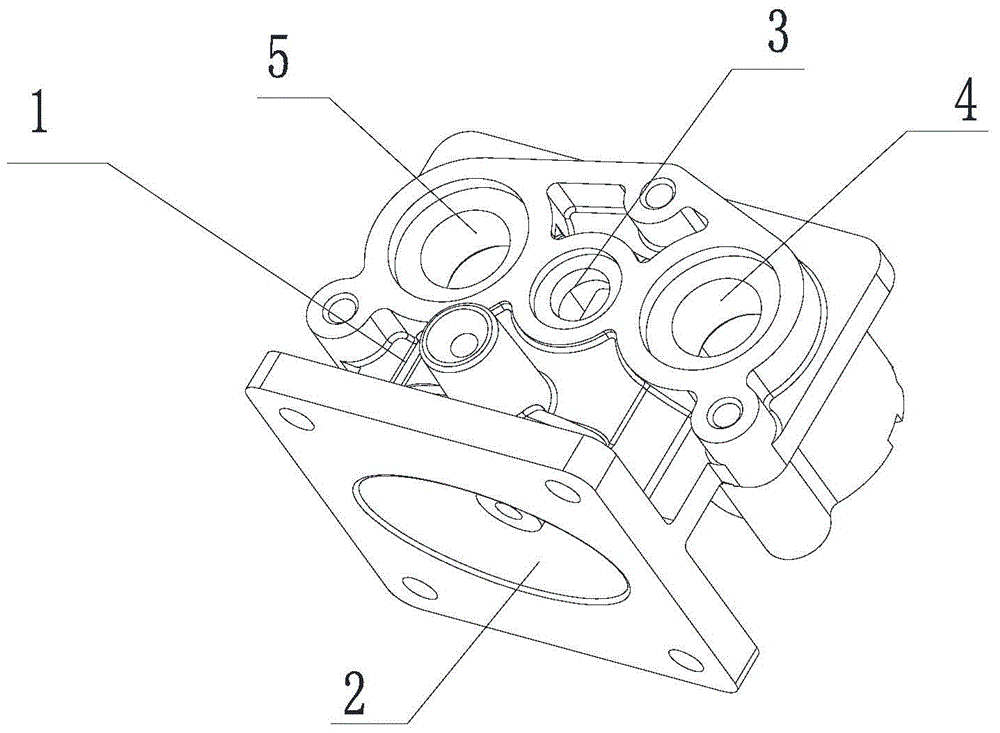

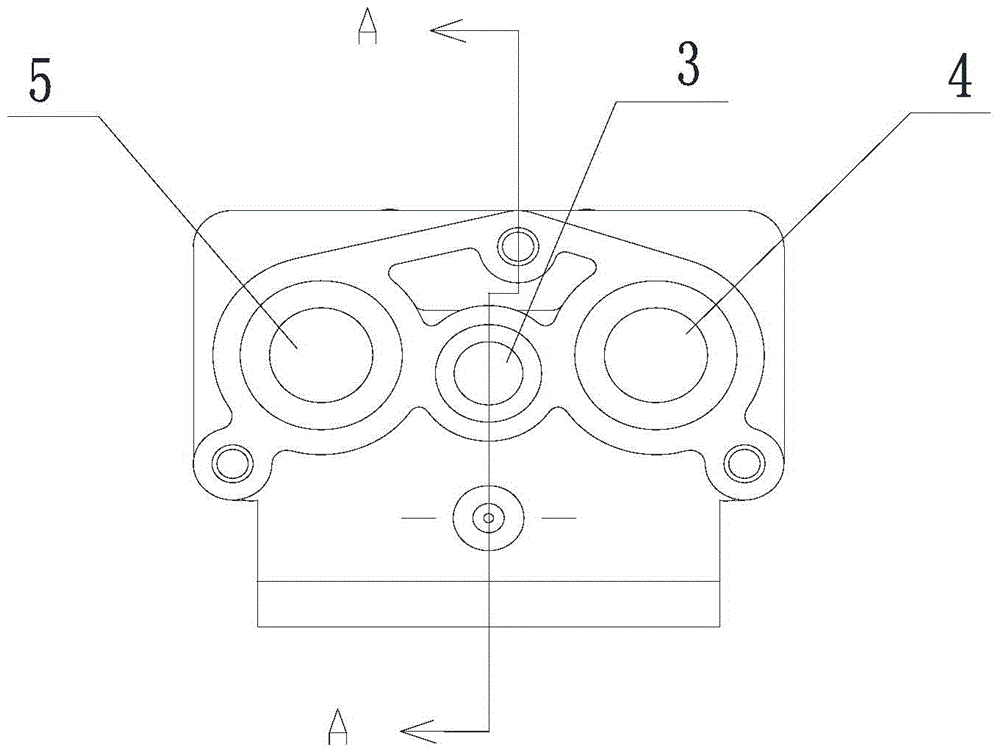

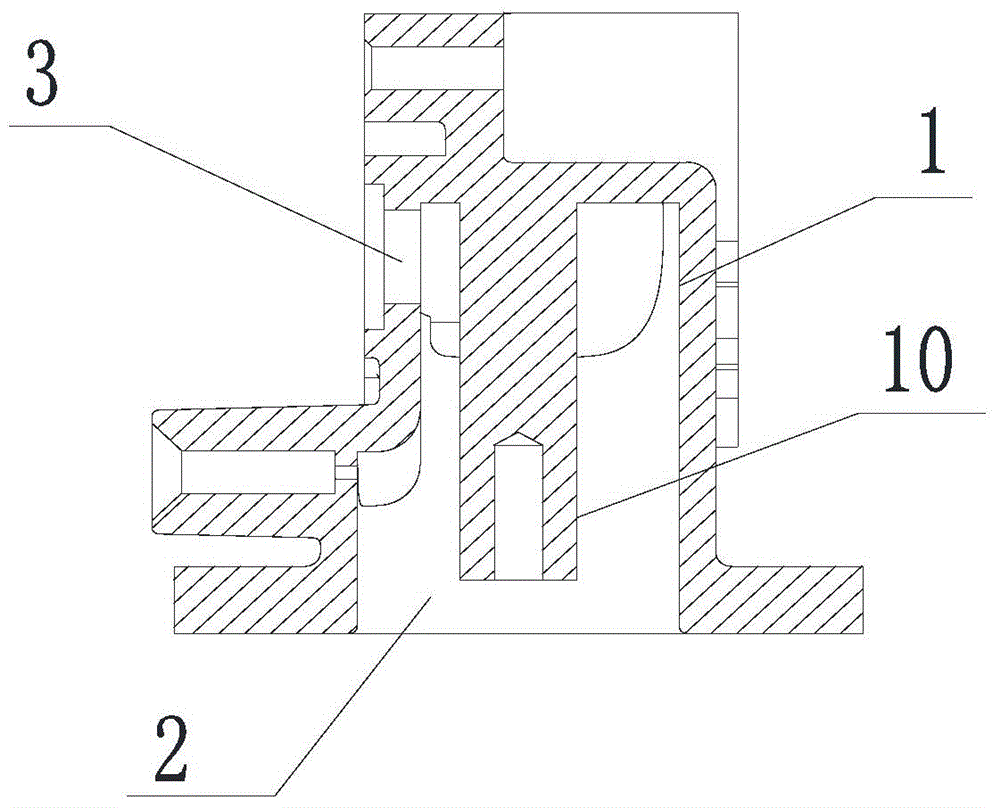

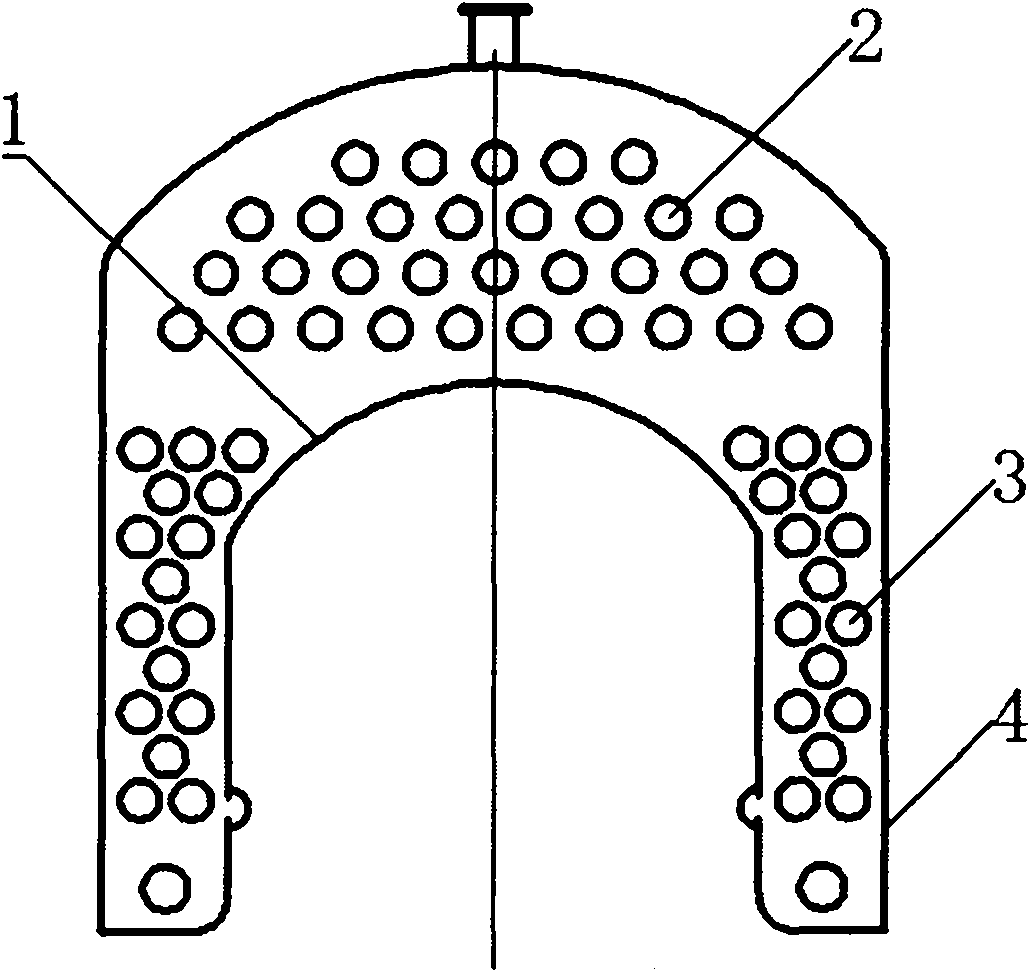

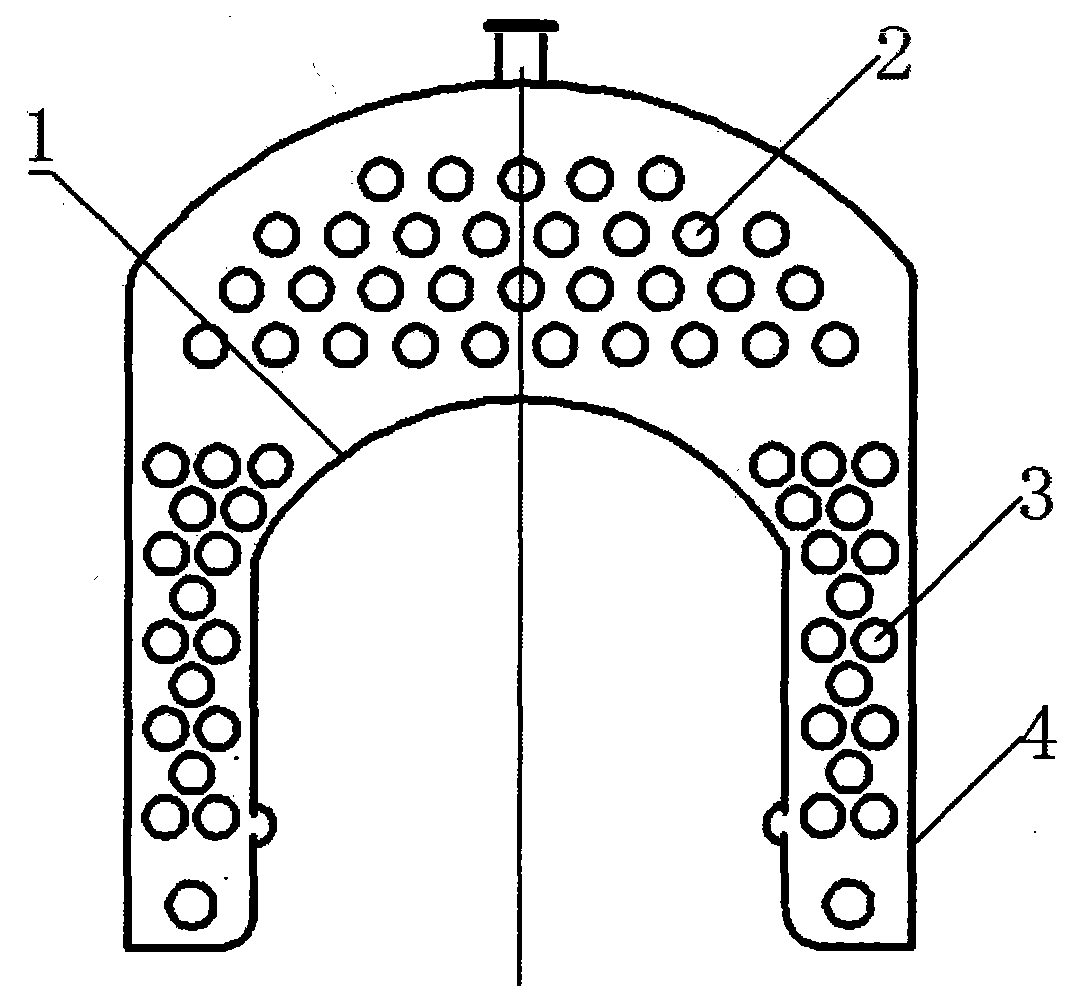

High-ignition-point fuel compression ignition and combustion regulation and control device based on flame jet flow control

PendingCN114278426ASolve high load knockingIncreased turbulence intensityInternal combustion piston enginesGaseous engine fuelsAutomotive engineeringInjector

The invention discloses a high-ignition-point fuel compression ignition and combustion regulation and control device based on flame jet flow control. The high-ignition-point fuel compression ignition and combustion regulation and control device comprises a spark plug (1), a pre-combustion chamber ejector (2), a main combustion chamber ejector (3) and a pre-combustion chamber body (4). The pre-combustion chamber main body (4) is arranged on the main combustion chamber (6), a pre-combustion chamber cavity (5) is formed in the pre-combustion chamber main body (4), the pre-combustion chamber ejector (2) and the pre-combustion chamber spark plug (1) are installed at two different positions on one side of the pre-combustion chamber main body (4) respectively, and the head of the pre-combustion chamber ejector (2) and the head of the pre-combustion chamber spark plug (1) extend into the pre-combustion chamber cavity (5). The pre-combustion chamber cavity (5) is communicated with the main combustion chamber (6) through a spray hole; the main combustion chamber ejector (3) is fixed to the other side of the pre-combustion chamber body (4), and the head of the main combustion chamber ejector (3) extends into the main combustion chamber (6). The use performance of the low-carbon zero-carbon fuel can be effectively widened, and wide popularization and application are facilitated.

Owner:XI AN JIAOTONG UNIV

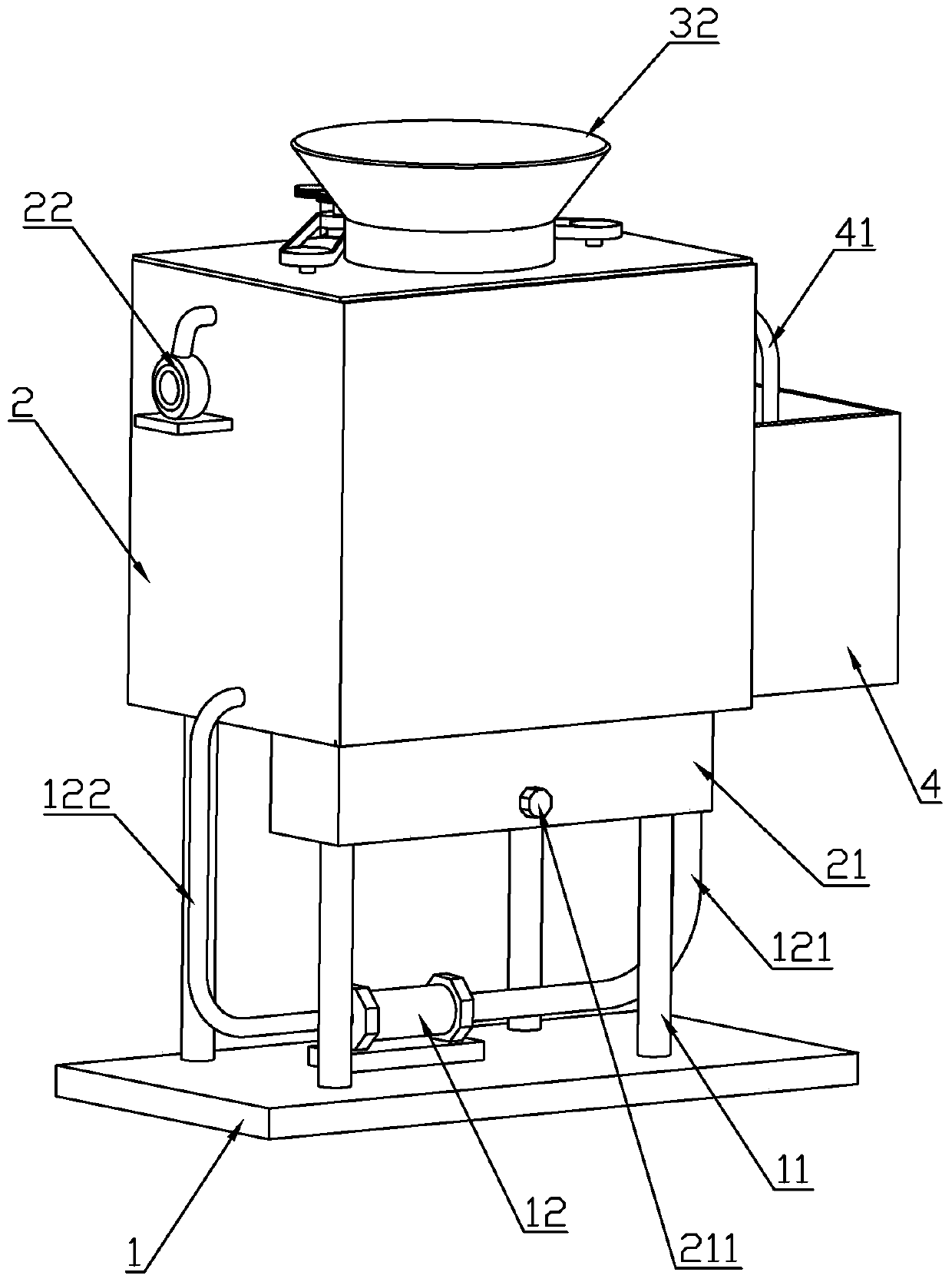

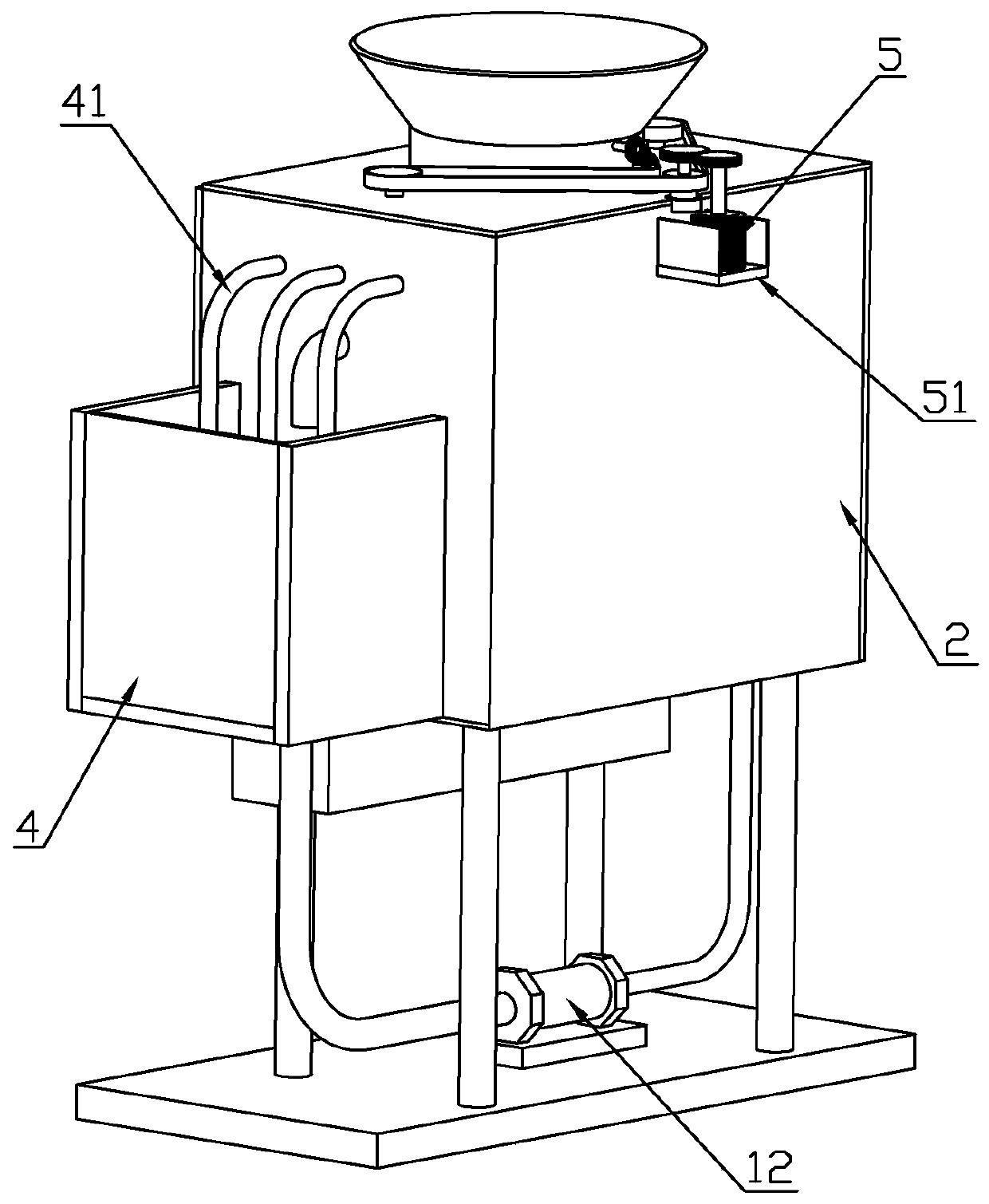

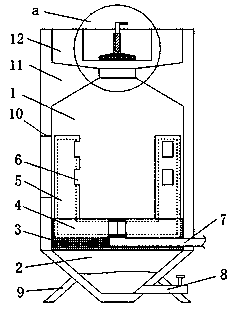

Environment-friendly waste incinerator

InactiveCN109899806AReduce incomplete combustionImprove permeabilityIncinerator apparatusDrive motorAir blower

The invention discloses an environment-friendly waste incinerator. The environment-friendly waste incinerator comprises a base plate, a heat insulated box, an incineration outer barrel, a cooling water tank and a driving motor. The base plate is flatly placed on the ground and used for stably supporting the device. The top side of the base plate is provided with a plurality of supporting columns.The top ends of the supporting columns are connected with the heat insulated box. The heat insulated box is of a double-layer structure and is internally provided with a heat insulation interlayer. One side of the heat insulated box is fixedly connected with the cooling water tank. The cooling water tank is used for containing cooling water. The top end of the incineration outer barrel is connected with a transition barrel. The incineration outer barrel is rotatably connected with the transition barrel. The transition barrel penetrates through the heat insulated box in a sealed mode. The top end of the transition barrel is fixedly connected with a feed port. An air blower I is arranged on one side of the heat insulated box. The air blower I is connected with an air pipe I. The air pipe I extends into the heat insulated box in a sealed mode. The environment-friendly waste incinerator is reasonable in structure, facilitates thorough incineration on waste and can filter waste gas.

Owner:刘妍

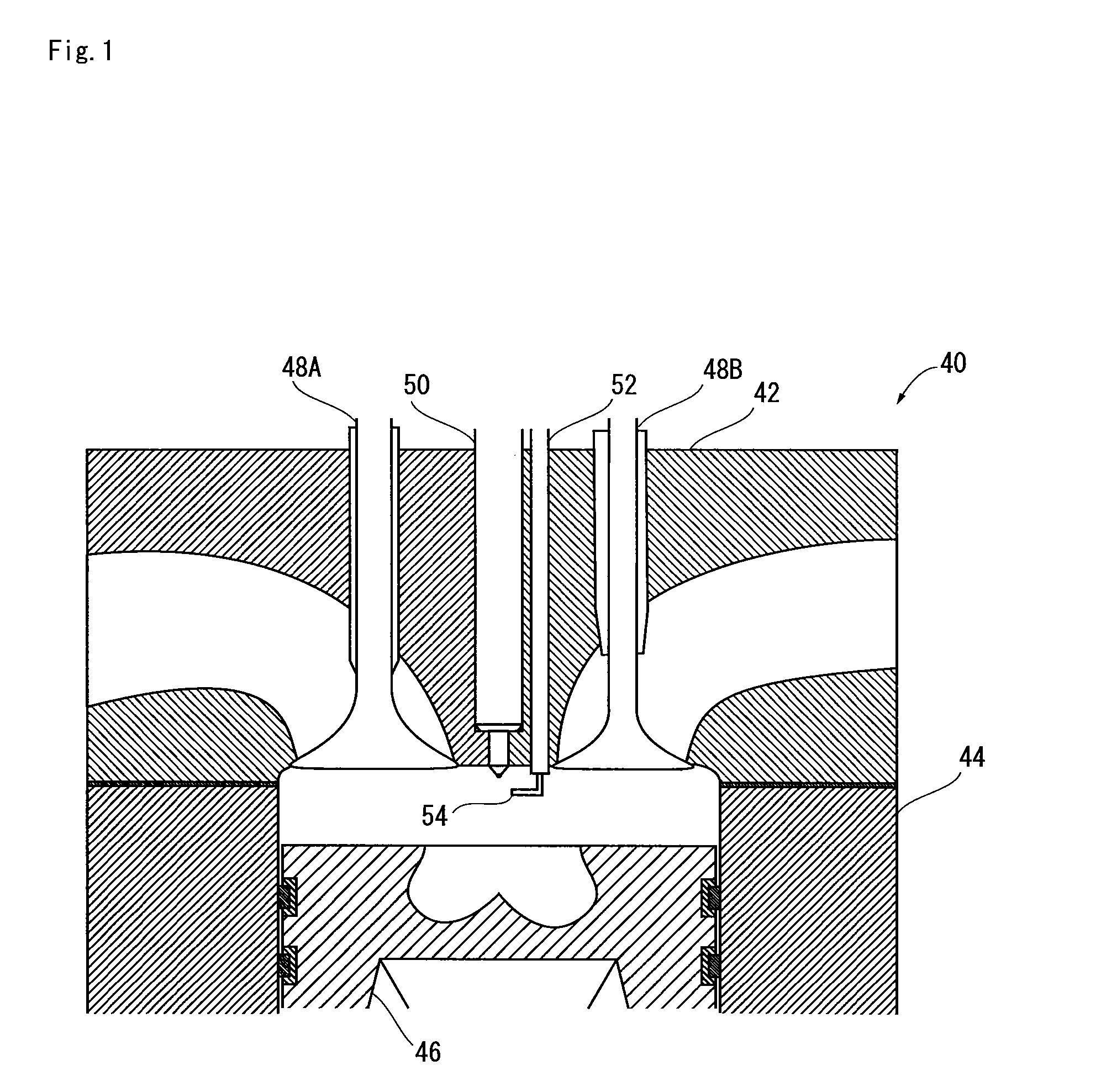

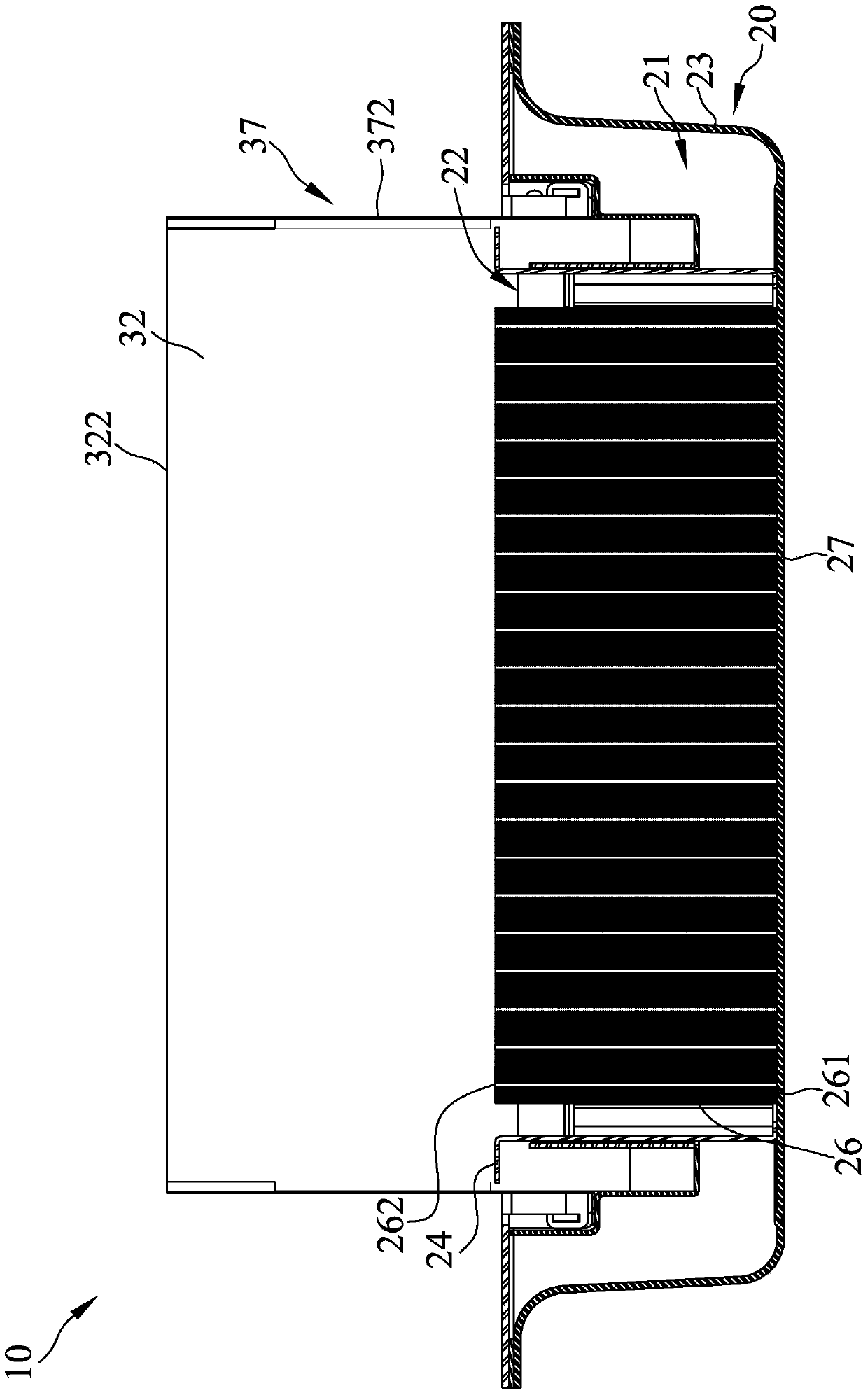

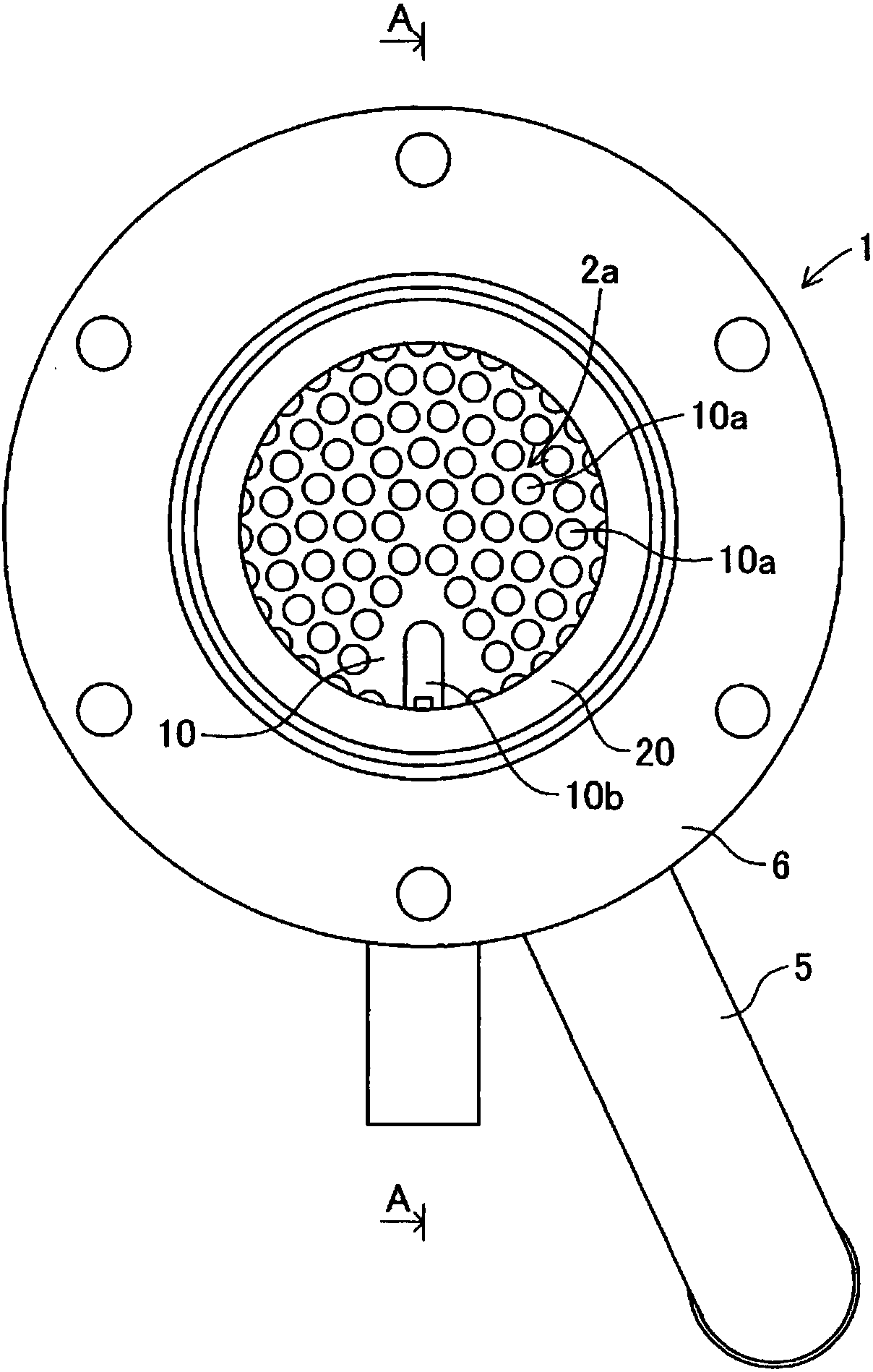

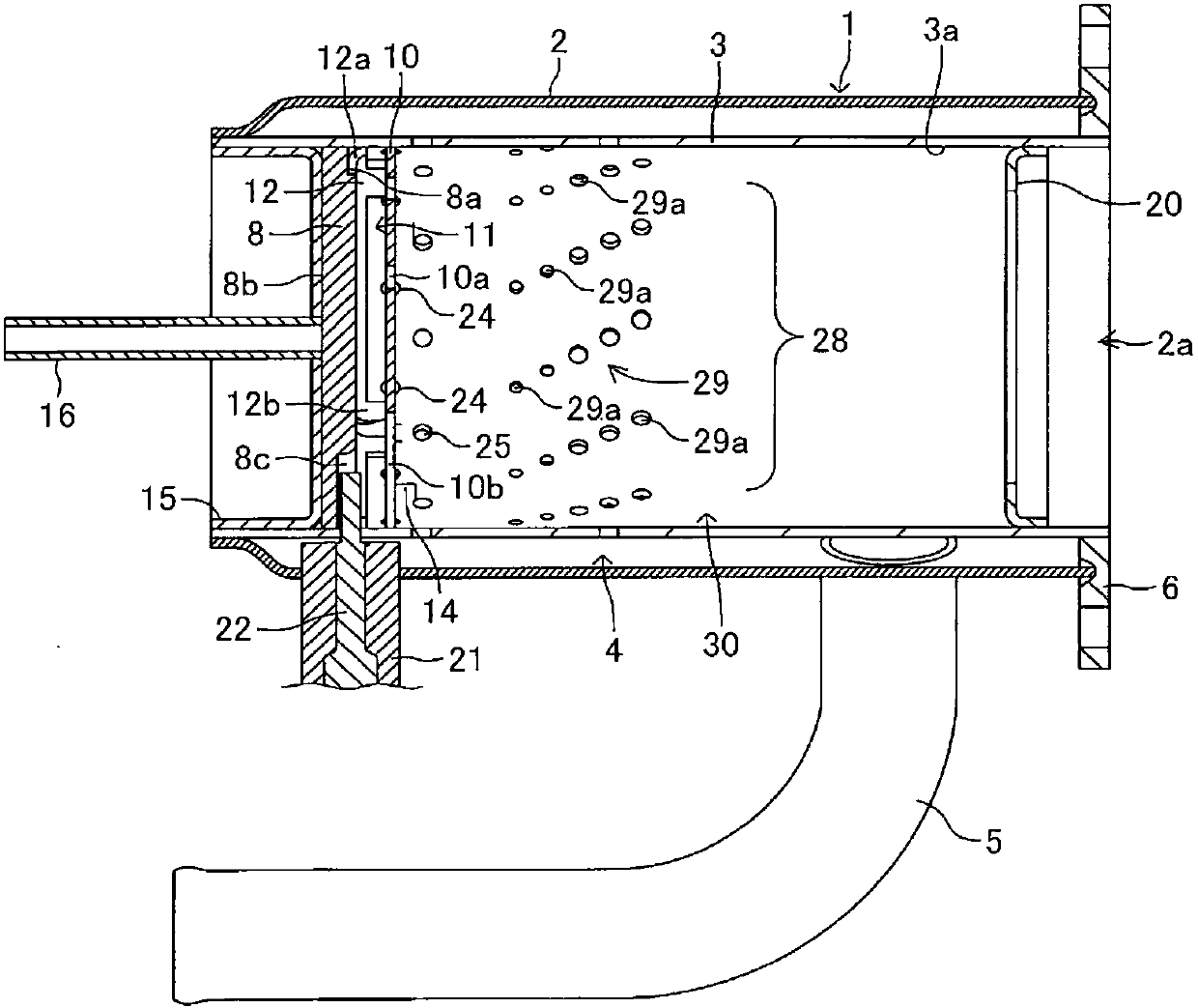

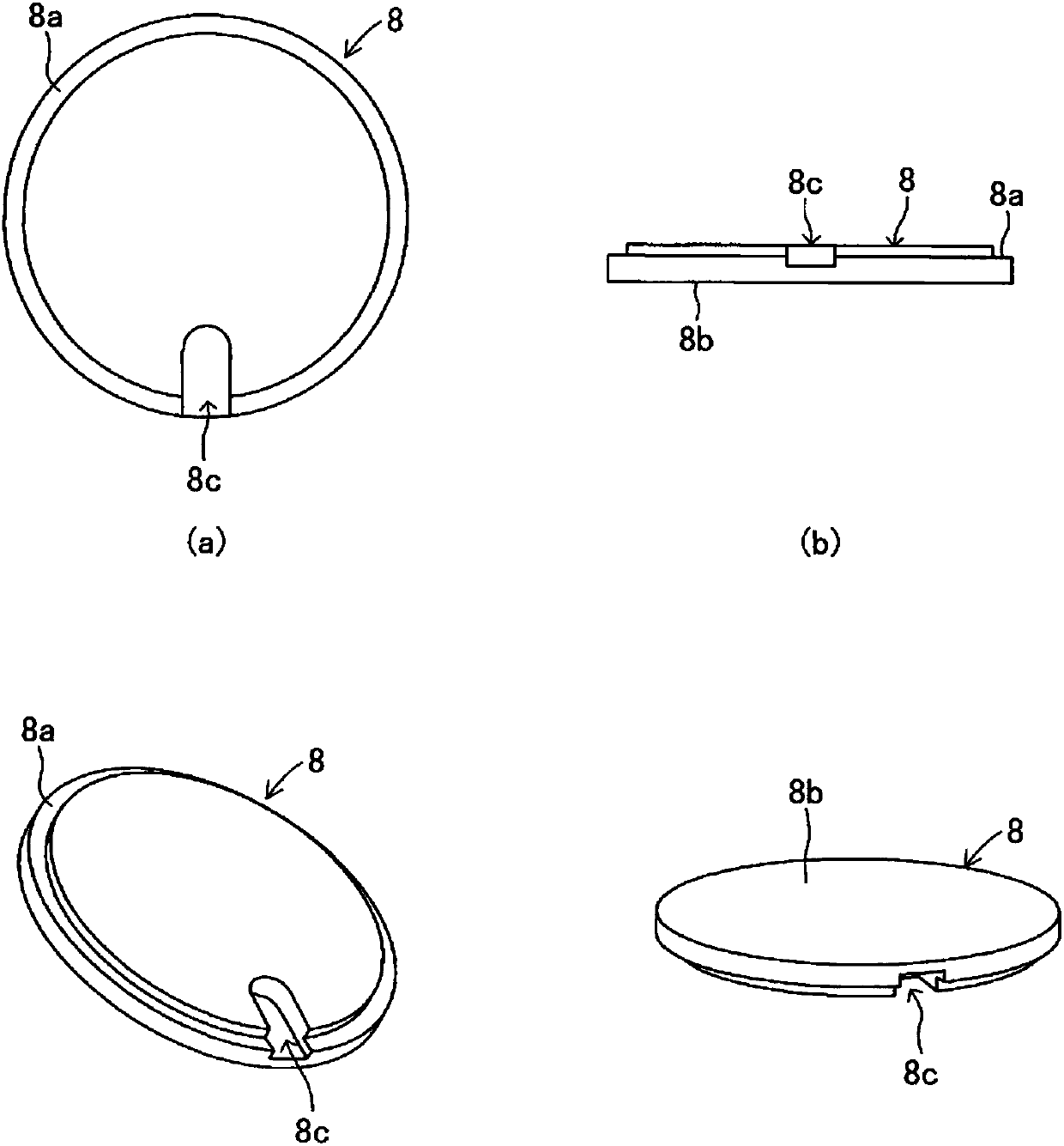

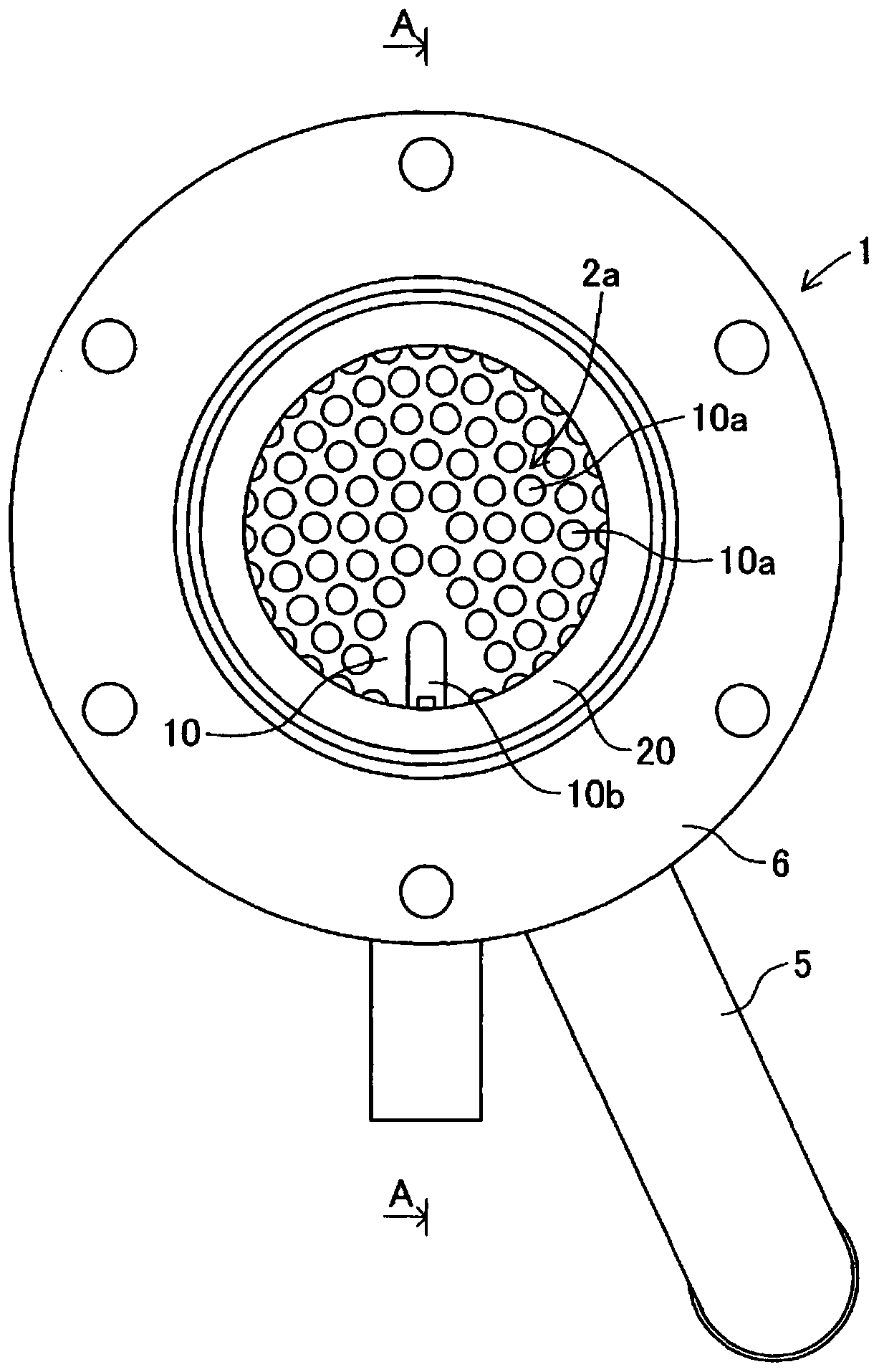

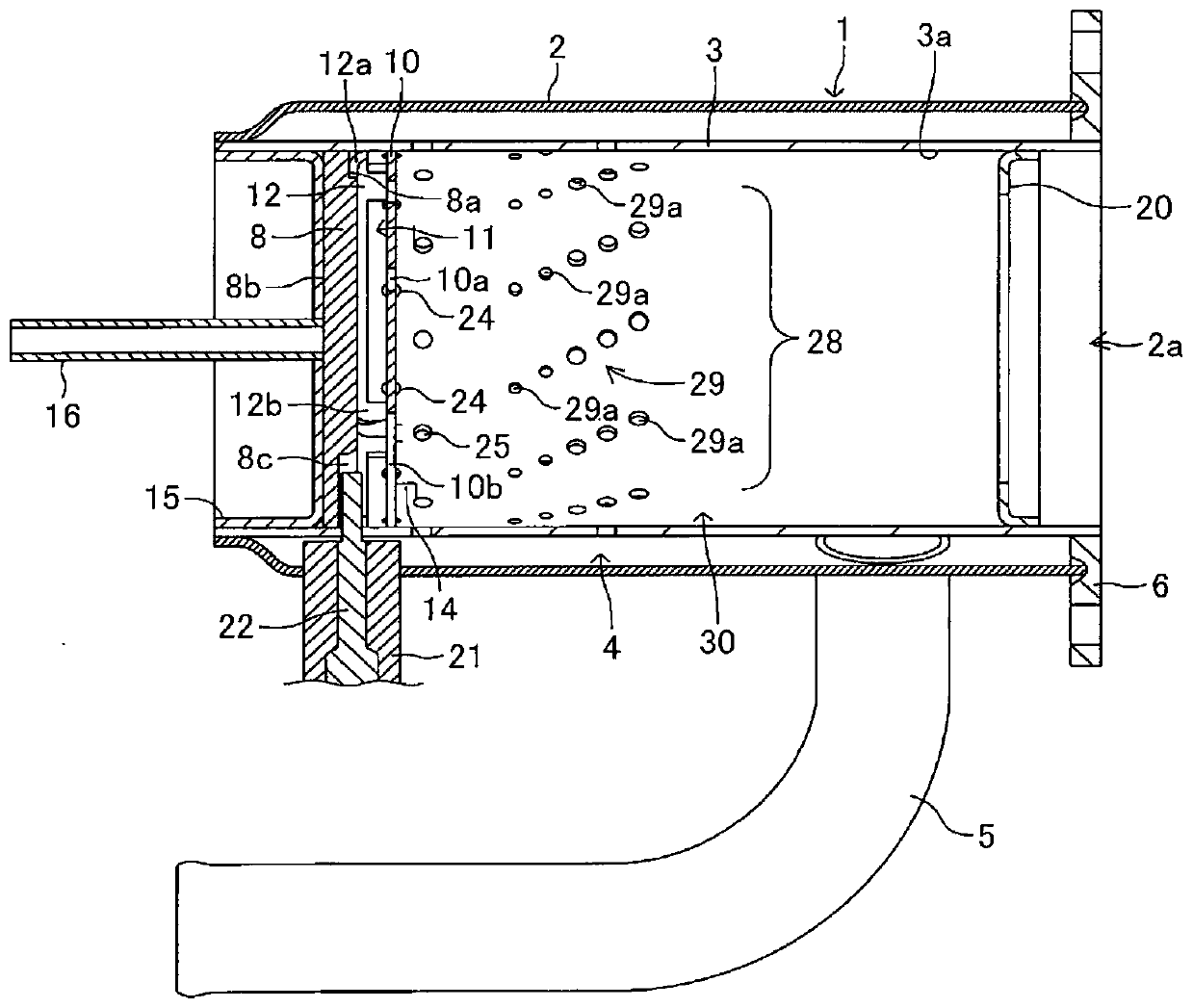

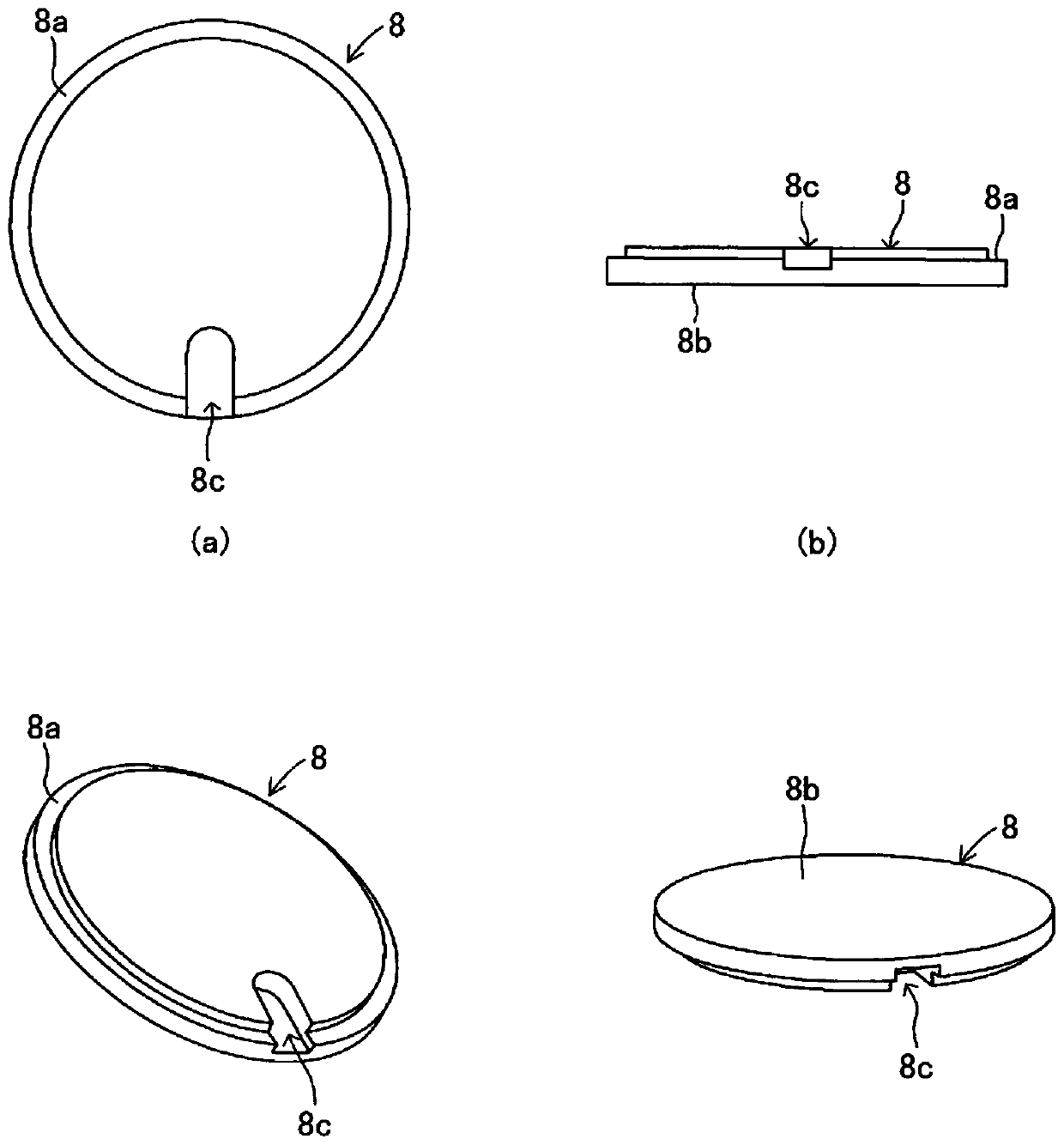

Evaporative-type burner

ActiveCN107614975AImprove fire resistanceExtend your lifeIncandescent ignitionCapillary burnersCombustorCombustion chamber

Disclosed is an evaporative-type burner. An acceleration member (10) is disposed across a prescribed gap on an impregnation member (8) that is installed on the upstream end of a combustion chamber (30), an ignition device (22) and a first air supply port (24) are provided in an ignition space upstream from the acceleration member (10), and a second air supply port (28) is provided in a combustionspace downstream from the acceleration member (10). Fuel is supplied to the smooth surface of the impregnation member (8), and at least part of the ignition device (22) is accommodated in a recess (8c) or notch (32) formed in the impregnation member (8). A configuration is adopted such that the flow of air supplied to the combustion space from the second air supply port (28) increases further downstream. This improves ignition performance in the evaporative-type burner (1), and minimizes incomplete combustion of fuel on the downstream side of the combustion chamber (30).

Owner:SANGO CO LTD

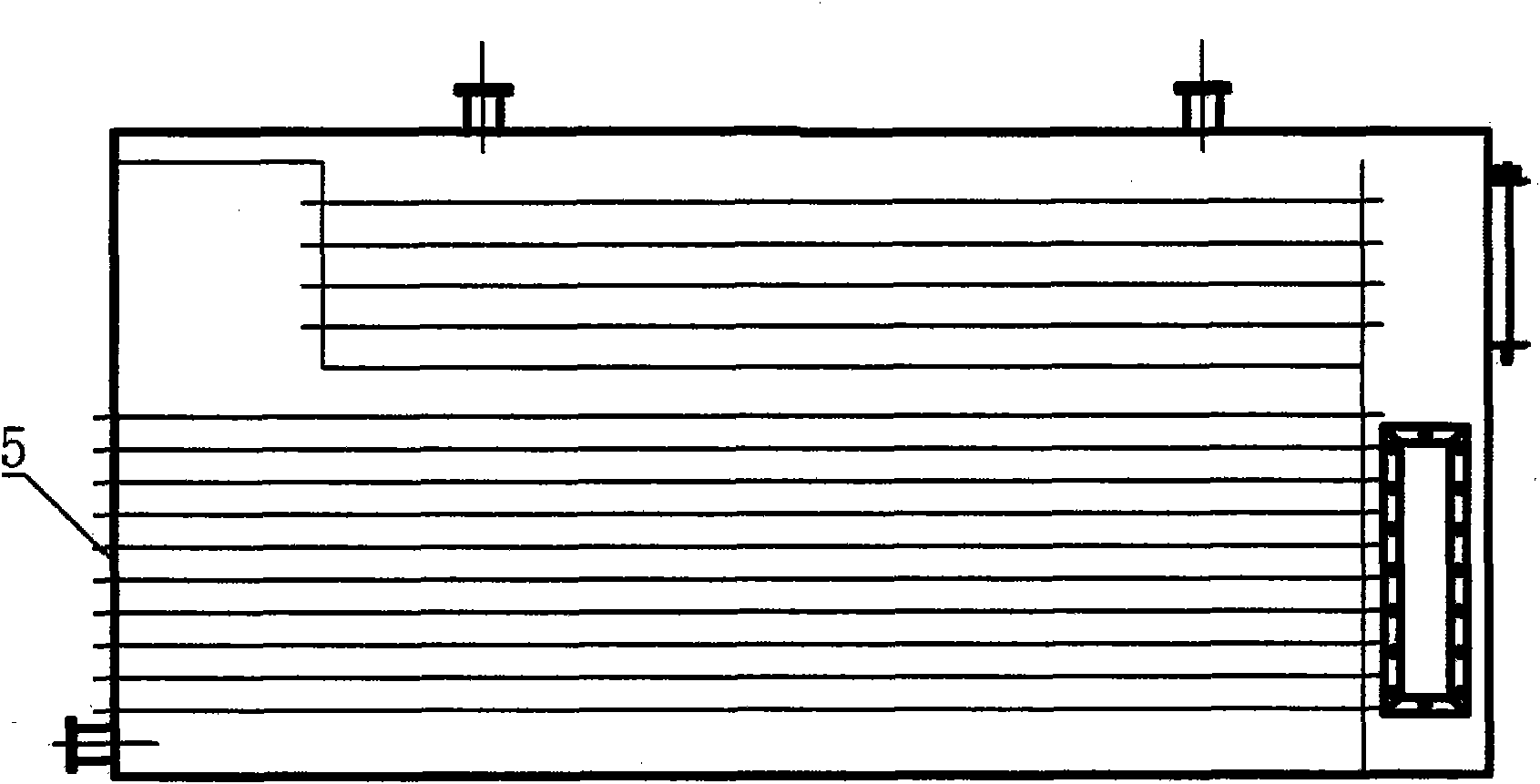

Counter current heat exchanging water-fire tube boiler capable of saving energy and protecting environment

InactiveCN102116526AReduce incomplete combustionReduce lossesWater heatersCombustion chamberFlue gas

The invention relates to a counter current heating exchanging water-fire tube boiler capable of saving energy and protecting the environment, which comprises a boiler shell, a containing box, a convection tube, a smoke-fire tube, a smoke separating wall, a combustion chamber and a convection tube flue, wherein high-temperature flue gas with two return trips firstly passes through a position with higher water temperature at the water side of the smoke-fire tube in the boiler shell for exchanging heat, then lower-temperature flue gas with three return trips passes through the convection tube with lower temperature at the water side of the convection tube flue for exchanging heat, and the flue gas is discharged out of the boiler body after the heat exchange; the original downstream heat exchanging means is completely changed; counter current heat exchange is realized; energy sources are saved; carbon dioxide emission is reduced; the purposes of saving energy and protecting the environment are achieved; the counter current heating exchanging water-fire tube boiler can be produced by adopting a normal boiler production technology; and the reconstruction of an existing boiler can be realized by only changing the flow of the flue gas.

Owner:陈雅华

High flame retarding radio frequency cable and manufacturing method

InactiveCN102931461BReduce weightMeet electrical energy requirementsWaveguidesElectrical conductorEngineering

The invention relates to a high flame retarding radio frequency cable and a manufacturing method. A center of a cross section of a polygonal polyethylene framework type half air insulating layer is a tubular body; a plurality of convex ribs are arranged on the outer wall of the tubular body; a conductor inside a copper-clad aluminum conductor is arranged inside a pipe core of the tubular body of the polygonal polyethylene framework type half air insulating layer; and a wrinkled copper pipe outer conductor and an extruded layer PVDF (Polyvinylidene Fluoride) jacket are sequentially arranged on the convex ribs of the polygonal polyethylene framework type half air insulating layer. The manufacturing method comprises the following steps of: 1, manufacturing an insulating manner, 2, machining an outer conductor, and 3, machining a jacket. The high flame retarding radio frequency cable and the manufacturing method provided by the invention have the characterized in that the entire weight of the cable is reduced; and the cost is reduced. Compared with strip type half air insulation, a machining process is reduced by using the polygonal polyethylene framework type half air insulating layer; and the insulating layer can be manufactured by forming a single polyethylene insulation material in one step. With the adoption of the PVDF jacket, the fire retardance level of the cable reaches the highest CMP (Corrugated Metal Pipe) fire retarding level of the UL (Underwriter Laboratories Inc).

Owner:TIANJIN ASCEND TECH

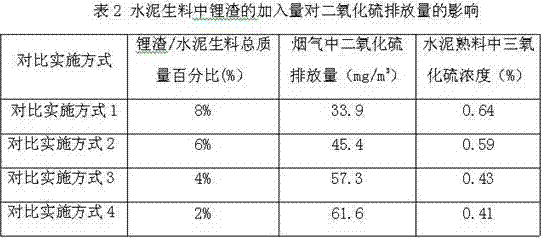

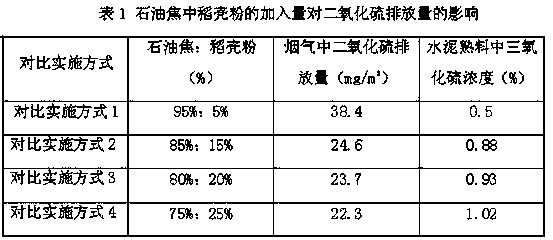

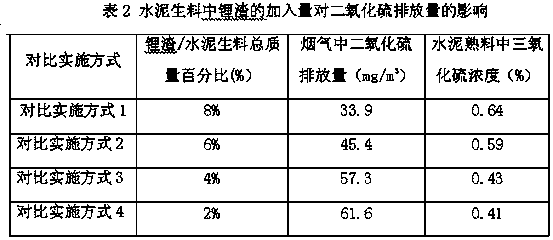

Desulphurization method for petroleum coke fuel for dry process rotary cement kiln

The invention provides a desulphurization method for a petroleum coke fuel for a dry process rotary cement kiln. The method comprises the following steps: adding rice hull powder into petroleum coke to be uniformly mixed to form a mixed fuel; and meanwhile, adding lithium slag into cement raw meal. According to the desulphurization method, on one hand, an alkali metal oxide with very high chemical activity in the rice hull powder can chemically react with sulfur in the petroleum coke in a combustion process to generate sulfate to be deposited in cement clinker, and on the other hand, the alkali metal oxide in the lithium slag can absorb sulfur oxide volatilized in gas in suspended preheating and decomposing processes of the cement raw meal to generate sulfate to be deposited in the cement clinker, so that the discharge of sulfur dioxide in tail kiln flue gas is reduced. According to the desulphurization method provided by the invention, the discharge of sulfur dioxide in the tail kiln flue gas can be reduced to 20.0mg / m<3> below.

Owner:NANCHANG GANHENGXING TECH DEV CO LTD

Compositions and methods to reduce global warming caused by gasoline and spark ignited internal combustion engines

ActiveUS9540991B1Lowering global warmingReduce incomplete combustionCombustion enginesLiquid carbonaceous fuelsSpark-ignition engineGlobal warming

Combustion charge compositions comprised of a gasoline-like fuel and air for use in spark ignited internal combustion engines and methods to reduce global warming are described.

Owner:MARIE TALBERT +1

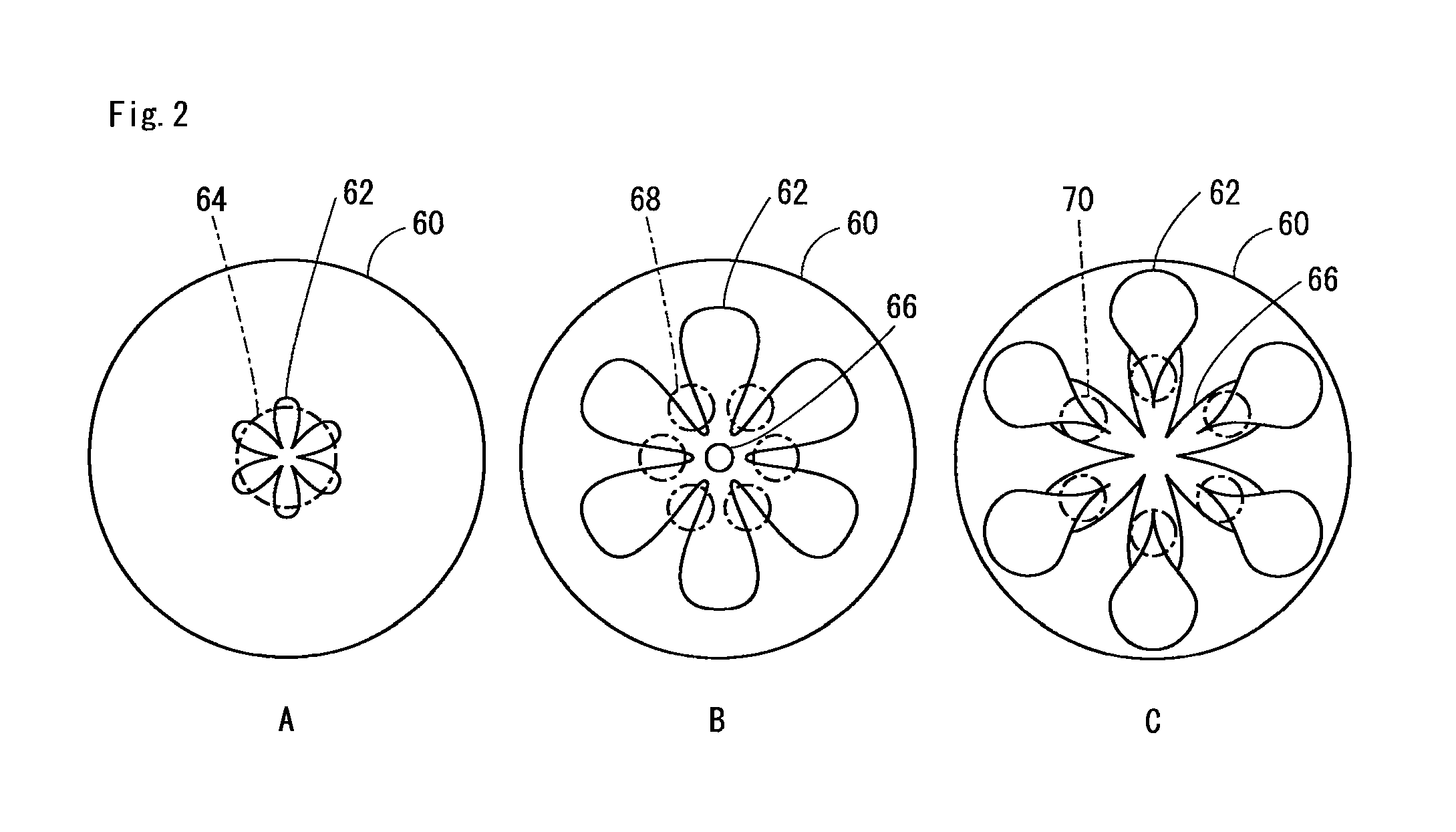

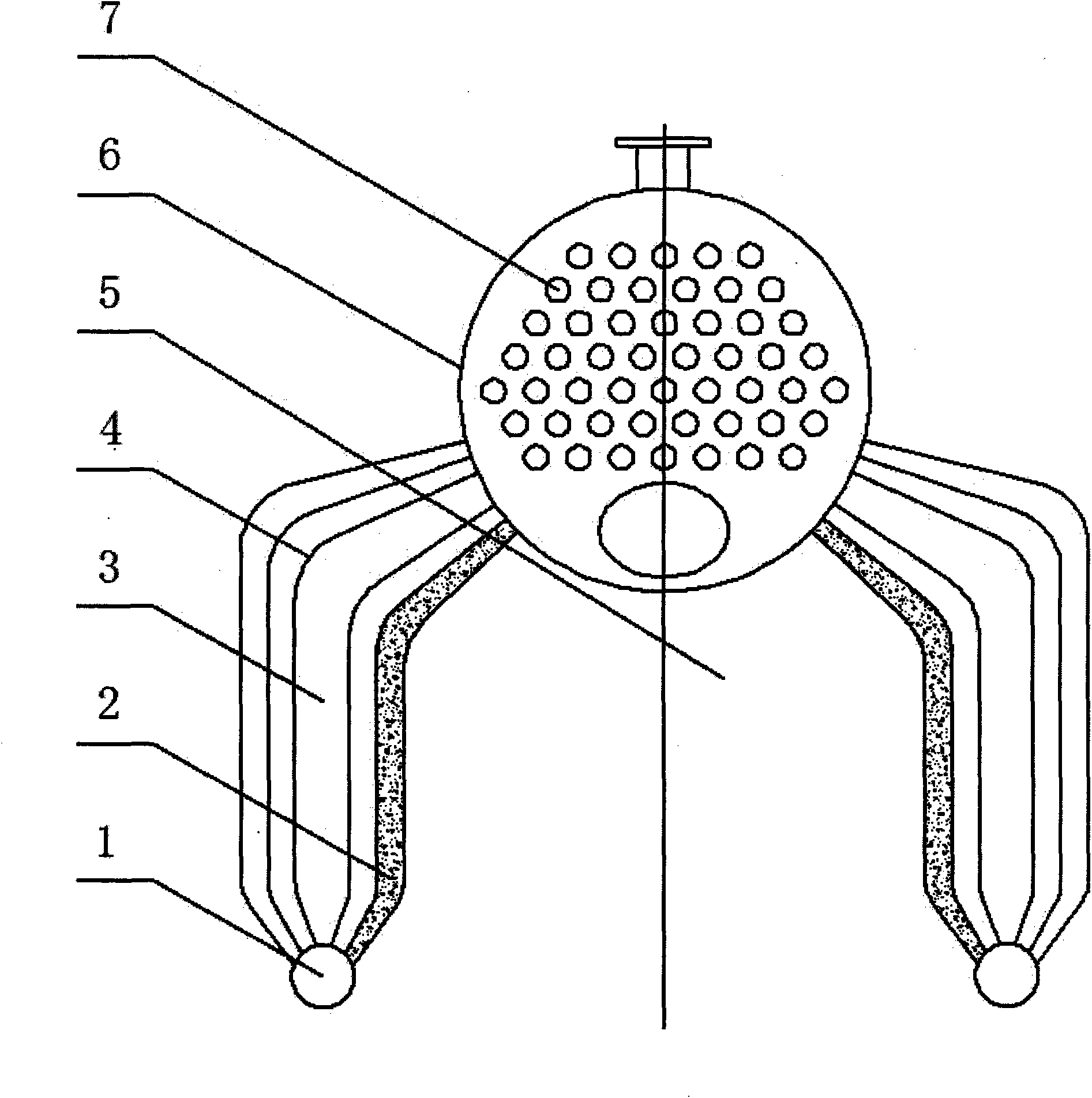

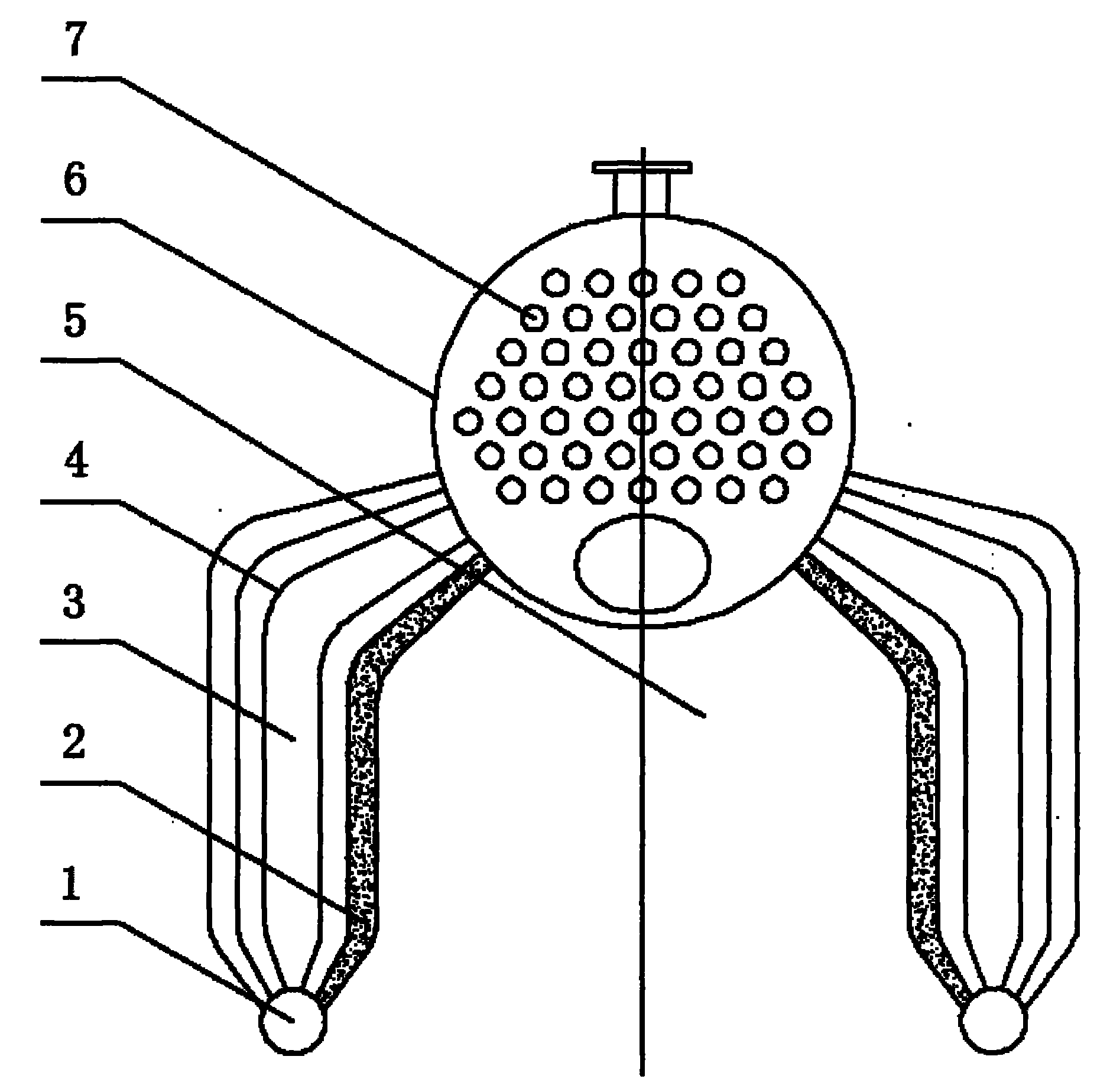

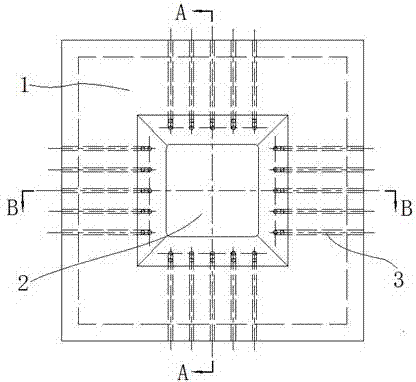

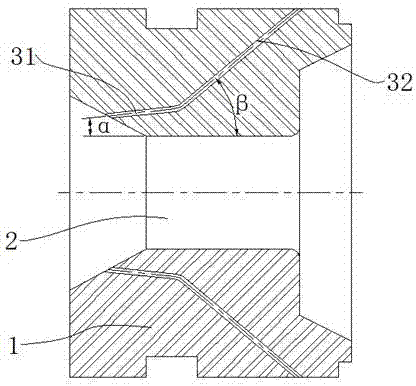

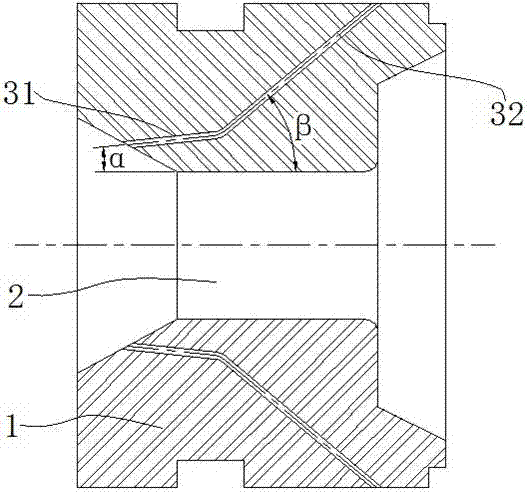

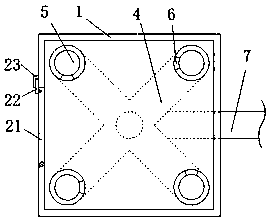

Circumferentially distributed burner of natural gas channels

InactiveCN102777915AReduce incomplete combustionImprove effective utilizationIndirect carbon-dioxide mitigationGaseous fuel burnerThermodynamicsCombustor

The invention discloses a circumferentially distributed burner of natural gas channels and belongs to the technical field of non-premixed gas combustor. The circumferentially distributed burner comprises a burner block body, an oxidizing air channel and the natural gas channels, wherein the oxidizing air channel is a tubular structure inside the burner block body, and two or more natural gas channels are circumferentially distributed around the oxidizing air channel and embedded in the burner block body. A central axial included angle alpha is formed between a burner section at the front end of each natural gas channel and the oxidizing air channel, the alpha is not smaller than zero degree and not larger than ninety degrees, and the burner sections are distributed in the same direction with the oxidizing air channel and join with the oxidizing air channel at the front end of the burner. The circumferentially distributed burner of the natural gas channels can thin and split the natural gas, enlarge contact area of the natural gas and oxidizing air, reduce incomplete combustion amount of the natural gas, and reduce CO (carbon monoxide) content in discharge smoke. Compared with a conventional natural-gas heat accumulating type burner, the circumferentially distributed burner can save energy by 8-10% and has remarkable energy conservation effect, and the service life of the burner is greatly prolonged.

Owner:MAANSHAN TIANZHOU ENERGY SAVING ENG TECH

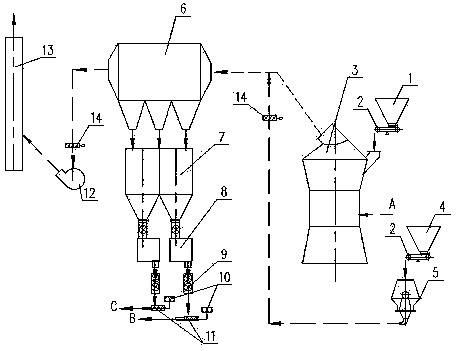

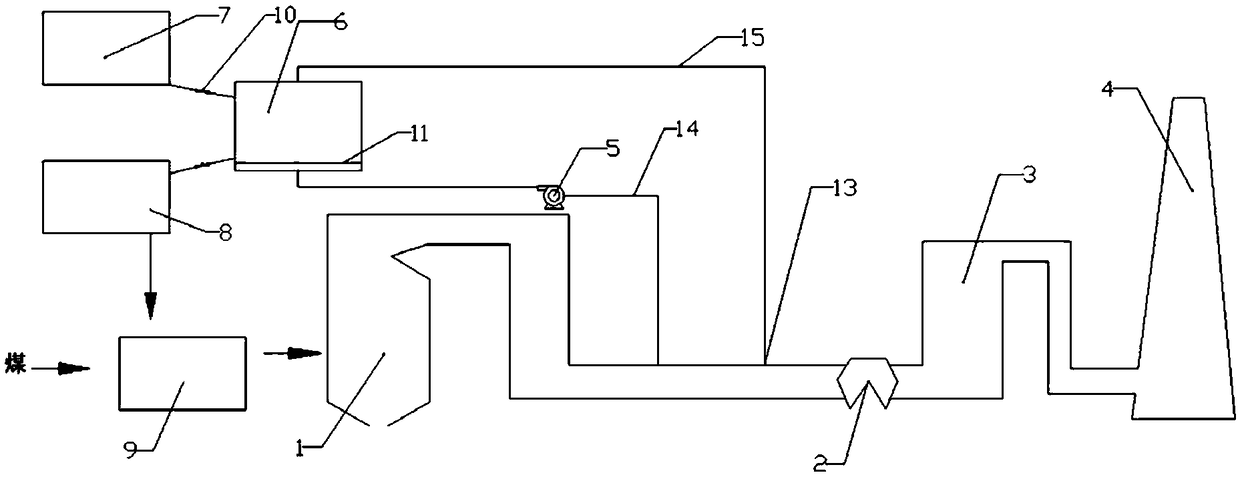

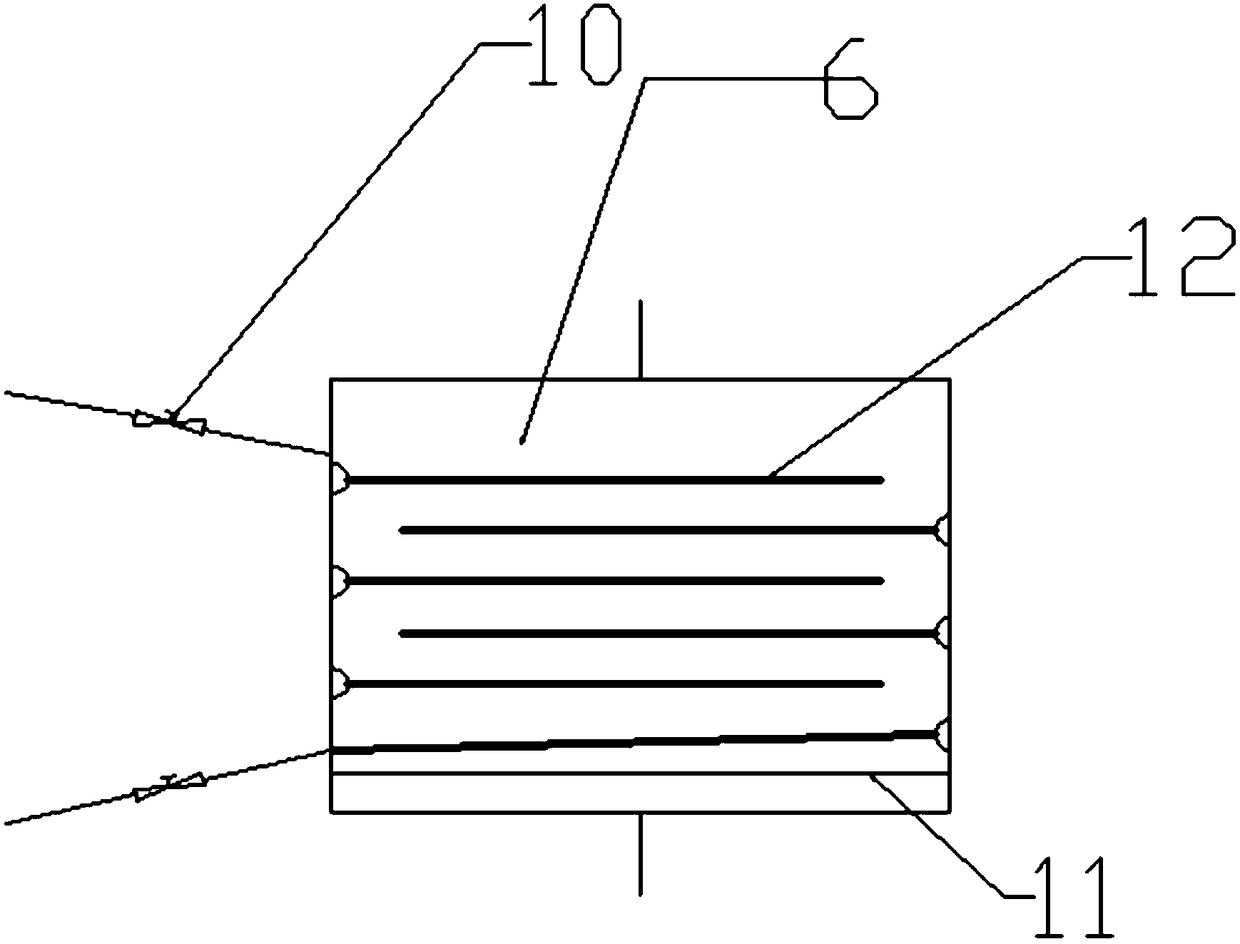

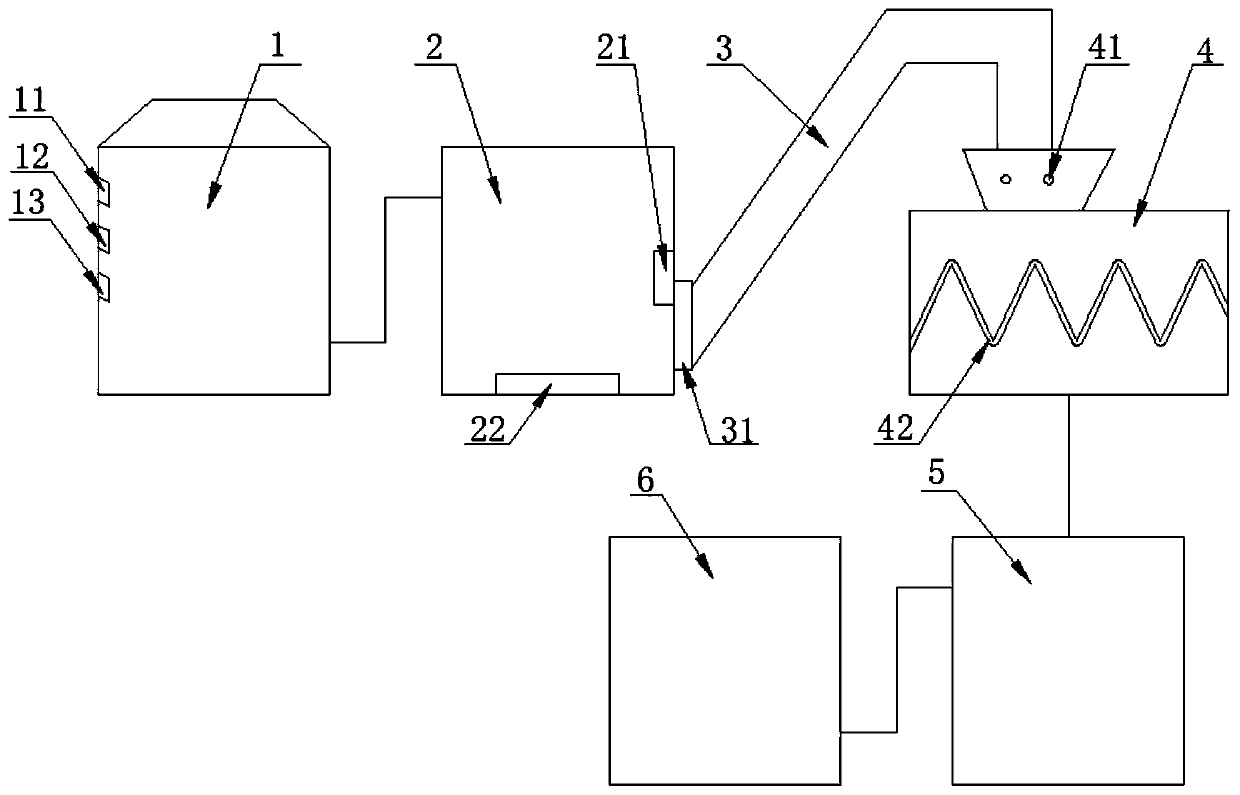

Coal-fired power plant online sludge drying and mixing combustion system and application method thereof

PendingCN108800162ALower exhaust gas temperatureReduce smoke lossIncinerator apparatusCombined combustion mitigationSludgeAir pump

The invention relates to a coal-fired power plant online sludge drying and mixing combustion system and an application method thereof. The coal-fired power plant online sludge drying and mixing combustion system comprises a boiler hearth, a dust collector, a desulfurizing tower, a chimney, a stacking tank, a drying tank, a to-be-mixed tank and a mixing combustion conveyer. The boiler hearth is connected with a flue. An outlet of the stacking tank is connected with a sludge feed port of the drying tank. A sludge discharge port of the drying tank is connected with an inlet of the to-be-mixed tank. An outlet of the to-be-mixed tank is connected with the mixing combustion conveyer. The mixing combustion conveyer conveys a mixture of dry sludge and coal to the boiler hearth to be combusted. A flue gas inlet of the drying tank is connected with an outlet flue of the boiler hearth through an air pumping pipeline. A flue gas outlet of the drying tank is connected with the outlet flue of the boiler hearth through an air return pipeline. The coal-fired power plant online sludge drying and mixing combustion system guides flue gas to get into the sludge drying tank to dry sludge to achieve secondary utilization of the flue gas and online drying of the sludge. Under the condition of not affecting the boiler efficiency, real-time drying and real-time mixing combustion of the sludge are realized. The cost of drying and mixing combustion at different time and different places and the sludge transportation cost in the drying and mixing combustion process are reduced.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

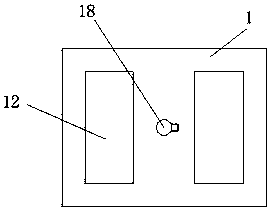

Four-section proportional valve for gas water heater

The invention discloses a four-section proportional valve for a gas water heater. The four-section proportional valve is characterized by comprising a valve body, an air inlet formed in the valve body, a normally-open air outlet communicated with the air inlet, a first sectioning air outlet and a second sectioning air outlet. A proportional valve and a stop valve are arranged on the air inlet. The first sectioning air outlet and the second sectioning air outlet are provided with a first sectioning valve and a second sectioning valve respectively. Compared with the prior art, the four-section proportional valve has the advantages that the two sectioning air outlets and one normally-open air outlet are arranged, and four-section control over gas can be achieved just by simple arrangement and combination; the four-section proportional valve is simple in structure, convenient to control and beneficial to wide-range adjustment of the gas amount; meanwhile, the proportional valve is arranged on the air inlet so that the gas amount at the normally-open air outlet can be freely adjusted; proportion adjustment is convenient, so that fire transfer faults and incomplete combustion in the sectional adjusting process are greatly reduced.

Owner:广东金美达实业有限公司

Fuel tank for motor vehicle and method for producing the same

InactiveUS6926964B2Prevent oxidationReduce clusteringEnvelopes/bags making machineryPretreated surfacesFuel tankCombustibility

Disclosed is a fuel tank for a motor vehicle whose inner face is processed with an inorganic coating agent comprising (A) fine particles carrying silver and / or copper and (B) inorganic fine particles, and the tank inhibits oxidation of the fuel such as gasoline or light oil, and further decreases the cluster of gasoline or light oil to make finer the particle size of atomized fuel, thereby improving ignitionability and combustibility, which makes it possible to decrease imperfect combustion and to decrease substantially the consumption of the fuel.

Owner:NIPPANKENKYUSHO

Fuel oil additive with cleaning effect and preparation method thereof

PendingCN110028993AHigh flash pointPlay a protective effectTransportation and packagingMixer accessoriesEthylenediamineGlycerol

The invention discloses a fuel oil additive with a cleaning effect, and belongs to the technical field of petrochemical additives. The fuel oil additive comprises the following raw materials in partsby weight: 60-90 parts of ethylene glycol, 1-5 parts of industrial glycerol, 1-5 parts of kitchen oil, 1-3 parts of n-butyl alcohol, 1-3 parts of artemisia apiacea oil and 0.2-0.8 part of Artemisia argyi oil. The invention further discloses a preparation method of the fuel oil additive. The preparation method comprises the following steps of 1, mixing n-butyl alcohol, kitchen oil and industrial glycerol together, and pouring the formed mixture into a closed reaction kettle for a stirring reaction, wherein the stirring rotation speed is 2000-3500 r / min, and the stirring time is 4-24 h; 2, conducting standing for 10 hours or more after a stirring machine stops rotating, and then filtering and separating substances in the stirring machine to obtain ethylenediamine generated in the stirring reaction process of n-butanol, kitchen oil and industrial glycerol; 3, mixing and stirring the ethylenediamine obtained in the step 2 with artemisia apiacea oil and Artemisia argyi oil, wherein the stirring rotating speed is 4500 to 5500 r / min; and 4, adding ethylene glycol into the mixed solution obtained in the step 3, and conducting standing, so as to obtain the fuel oil additive after the ethylene glycol and the mixed solution are completely dissolved and mixed.

Owner:贵州贵和隆醇基燃油开发有限公司

A method for desulfurization of petroleum coke fuel for dry process cement rotary kiln

The invention provides a desulphurization method for a petroleum coke fuel for a dry process rotary cement kiln. The method comprises the following steps: adding rice hull powder into petroleum coke to be uniformly mixed to form a mixed fuel; and meanwhile, adding lithium slag into cement raw meal. According to the desulphurization method, on one hand, an alkali metal oxide with very high chemical activity in the rice hull powder can chemically react with sulfur in the petroleum coke in a combustion process to generate sulfate to be deposited in cement clinker, and on the other hand, the alkali metal oxide in the lithium slag can absorb sulfur oxide volatilized in gas in suspended preheating and decomposing processes of the cement raw meal to generate sulfate to be deposited in the cement clinker, so that the discharge of sulfur dioxide in tail kiln flue gas is reduced. According to the desulphurization method provided by the invention, the discharge of sulfur dioxide in the tail kiln flue gas can be reduced to 20.0mg / m<3> below.

Owner:NANCHANG GANHENGXING TECH DEV CO LTD

Counter current heat exchanging smoke-fire constant pressure boiler capable of saving energy and protecting environment

The invention relates to a counter current heat exchanging smoke-fire constant pressure boiler capable of saving energy and protecting the environment, which makes use of the counter current heat exchanging principle and comprises a boiler furnace, an upper smoke-fire tube, a lower smoke-fire tube, a boiler shell and a tube sheet, wherein high-temperature flue gas with two return trips firstly passes through a position with higher water temperature at the water side of the upper smoke-fire tube in the boiler shell for exchanging heat, then lower-temperature flue gas with three return trips passes through a position with lower water temperature at the water side of the lower smoke-fire tube in the boiler shell for exchanging heat. The flue gas is discharged out of the boiler body after the heat exchange; the original downstream heat exchanging means is completely changed; counter current heat exchange is realized; energy sources are saved; and carbon dioxide emission is reduced; as the constant pressure design is adopted, steel consumption is reduced, and the purposes of saving energy and protecting the environment are achieved; and the counter current heat exchanging smoke-fire constant pressure boiler can be produced by adopting a normal boiler production technology.

Owner:陈雅华

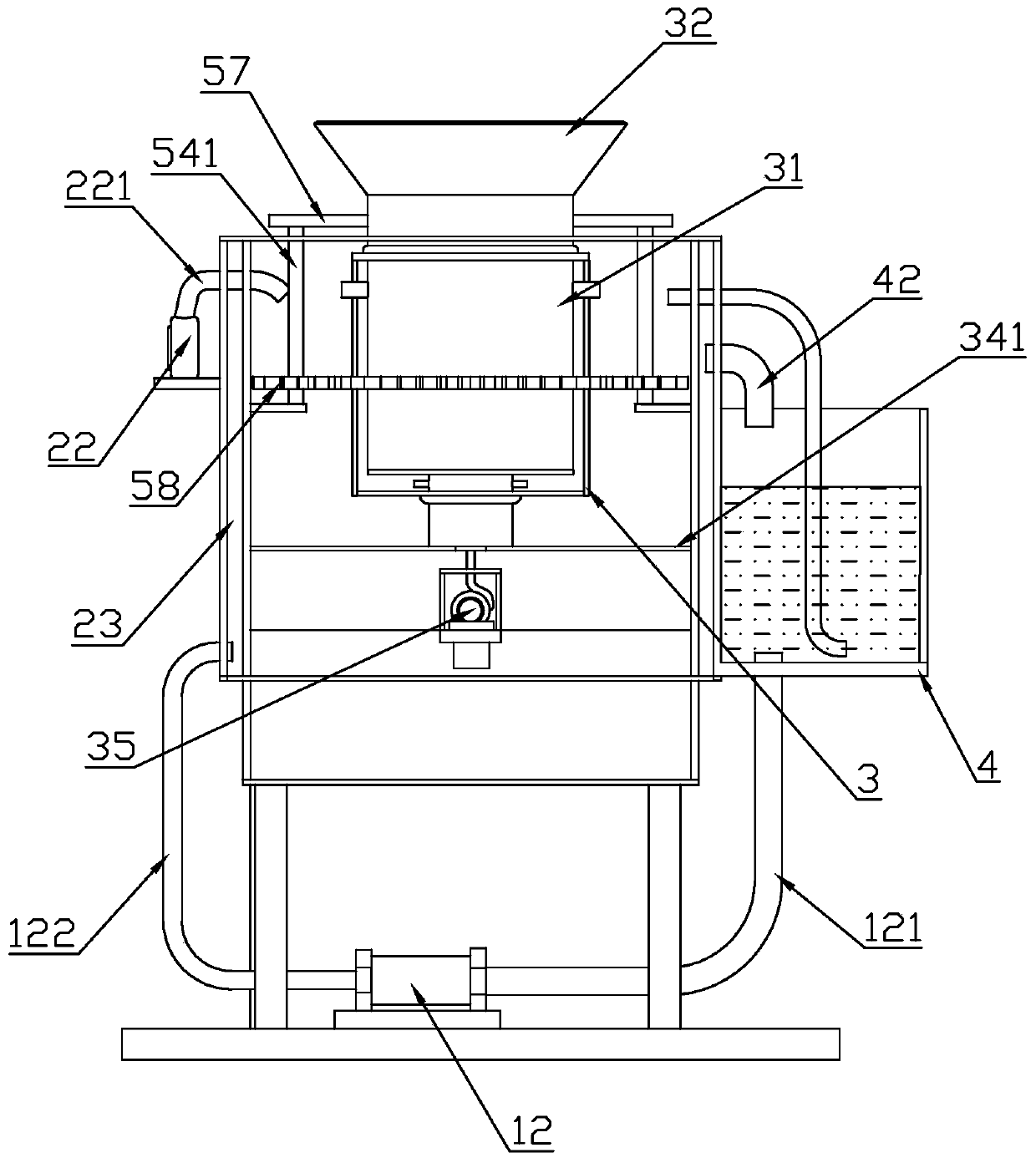

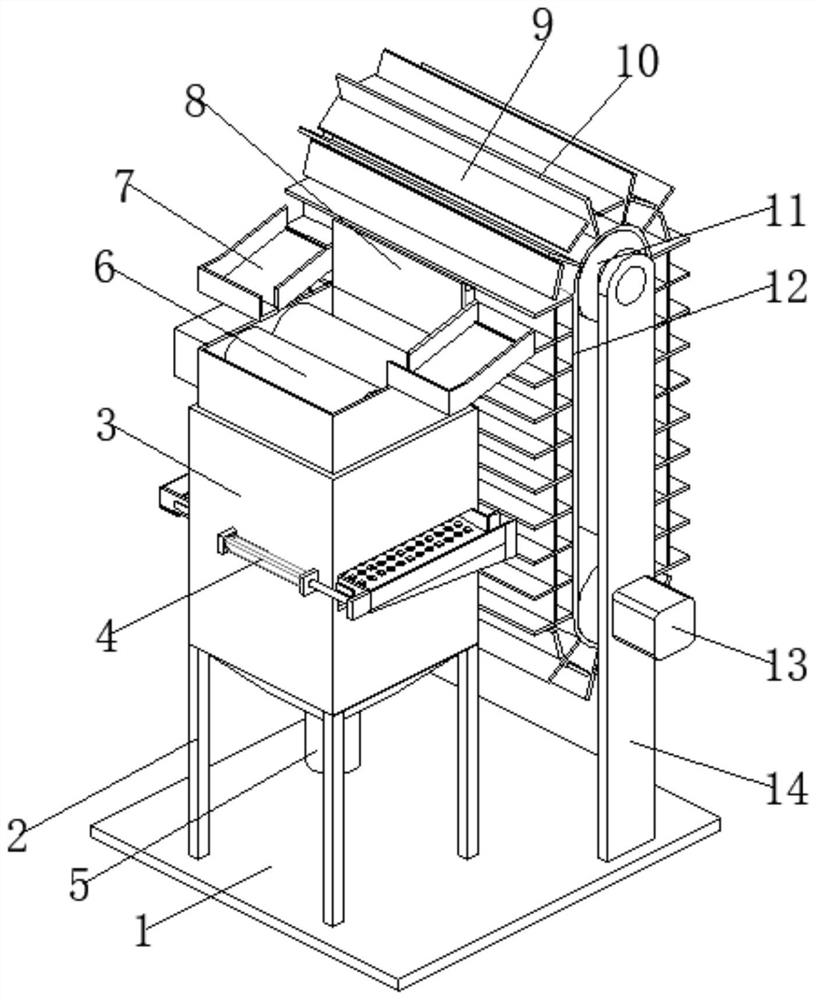

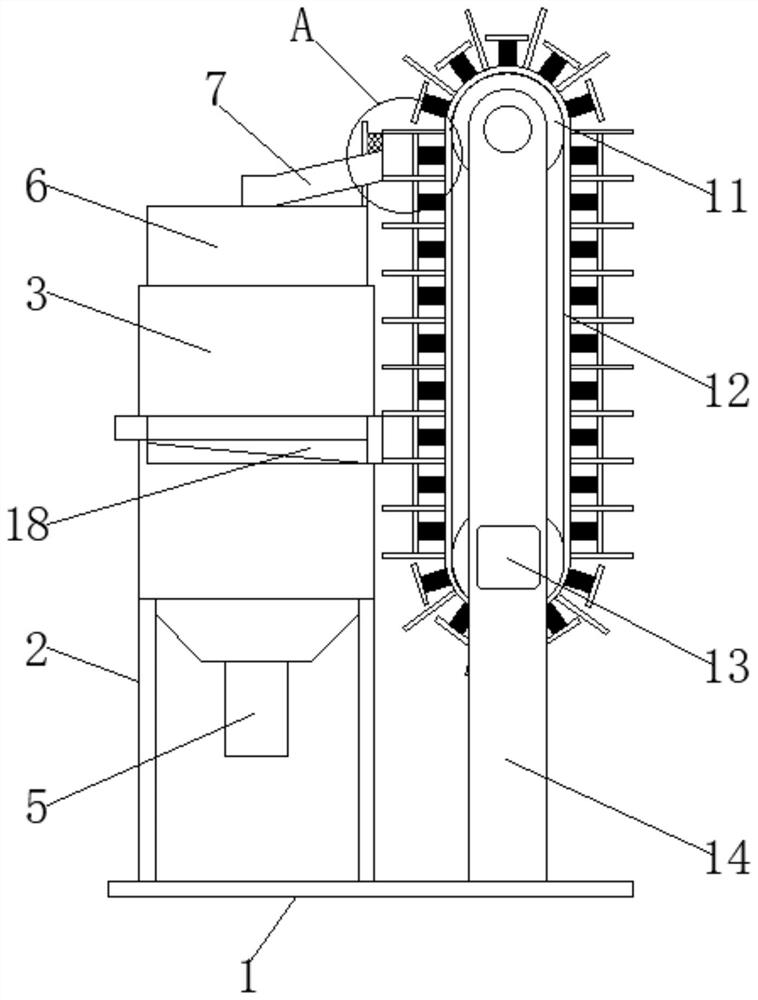

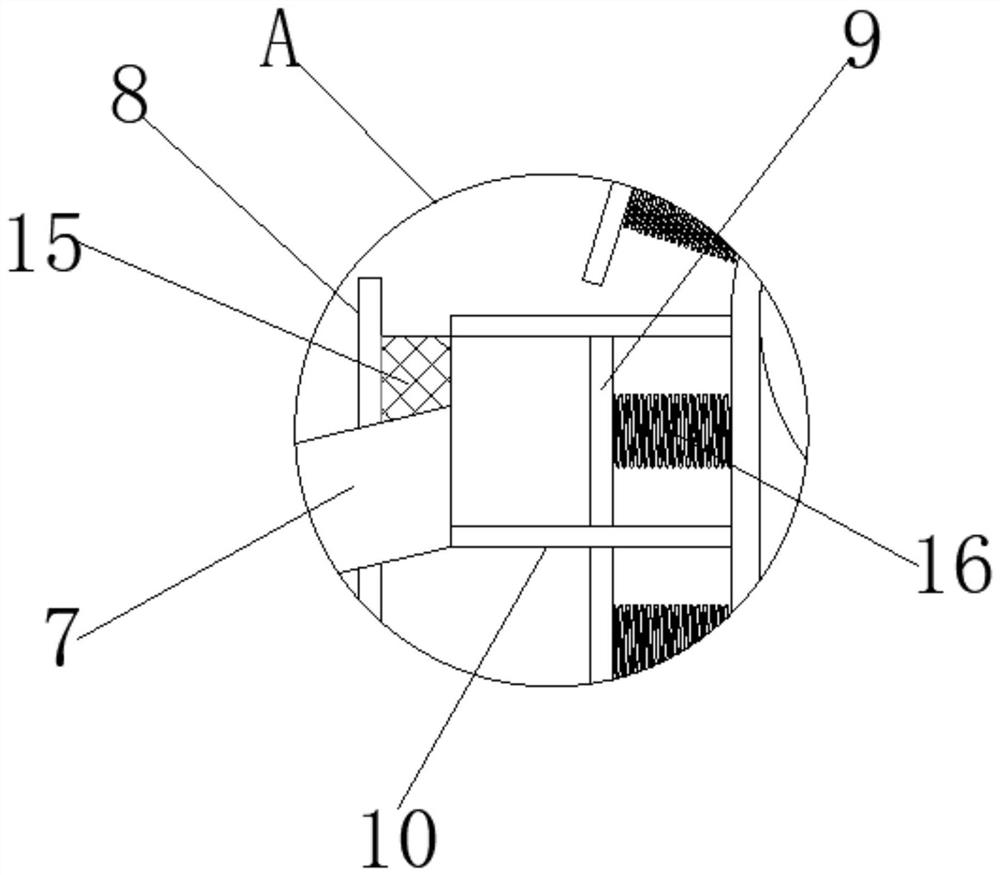

Solid waste treatment equipment and solid waste treatment method

InactiveCN112354598AReduce incomplete combustionEasy to useSievingScreeningEnvironmental engineeringWaste treatment

The invention provides solid waste treatment equipment and a solid waste treatment method, and relates to the field of waste treatment equipment. The solid waste treatment equipment comprises a base,wherein a shell is arranged above the base, the bottom of the shell is fixedly connected with supporting legs, the bottoms of the supporting legs are fixedly connected with the base, the top of the shell is fixedly connected with a crushing mechanism, the bottom of the shell is fixedly connected with a discharging pipe, a screening mechanism is arranged in the shell, and a recycling mechanism is arranged on one side of the shell. According to the solid waste treatment equipment, through the arrangement of the screening mechanism, waste particles with large particles and small particles can beseparated, then the large particles of the waste particles are conveyed to a lifting plate of the recycling mechanism, through the arrangement of the recycling mechanism, the large particles of the waste particles can be guided into the crushing mechanism again to be crushed, until all the waste is crushed into qualified small particles, the small particle waste is subjected to combustion treatment, incomplete combustion can be effectively reduced, and use is convenient.

Owner:绍兴市晟途环保科技有限公司

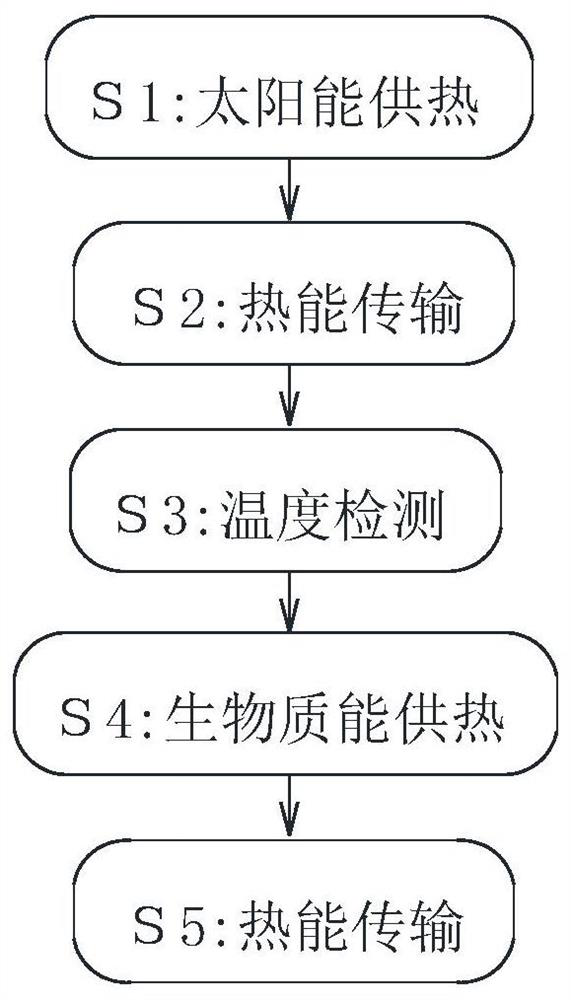

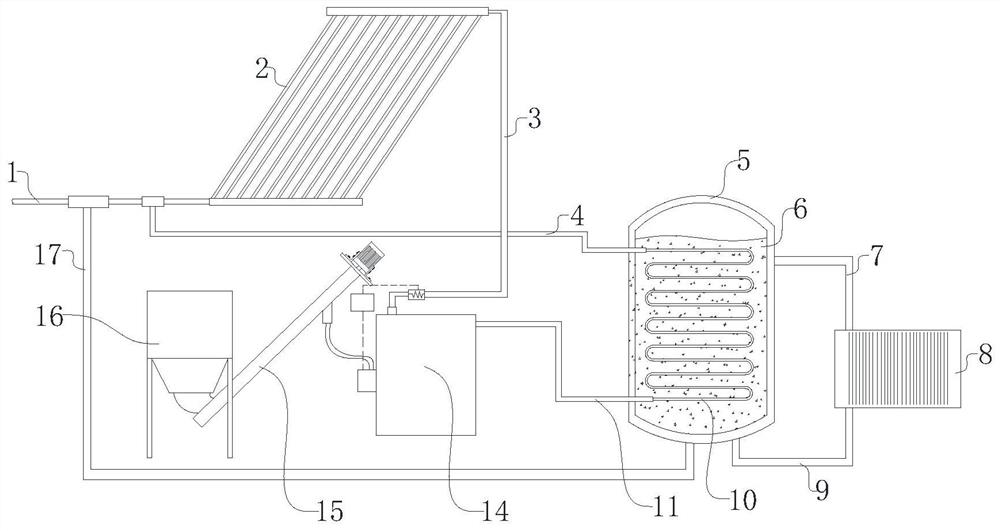

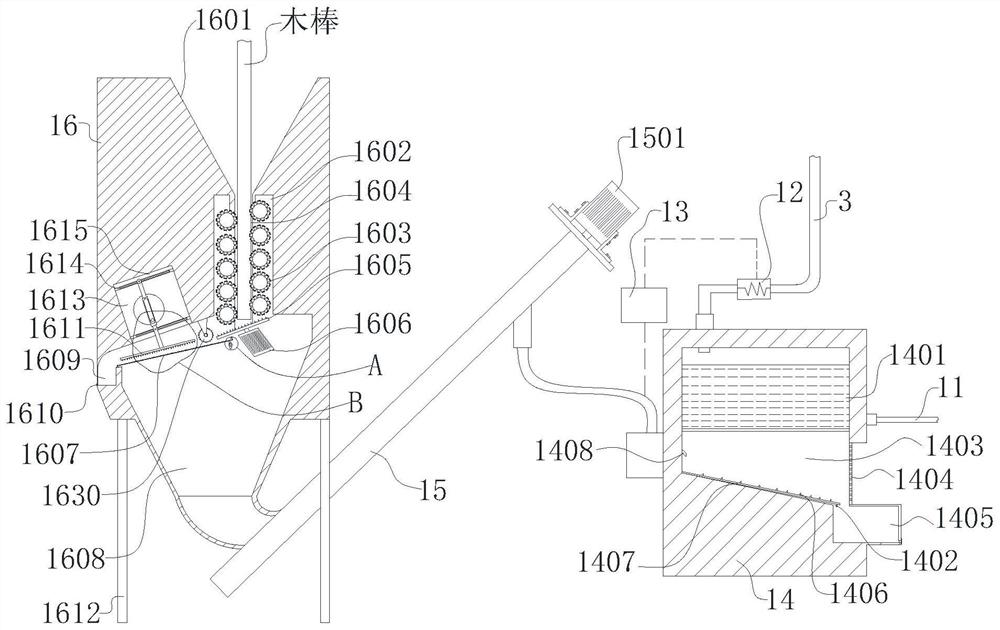

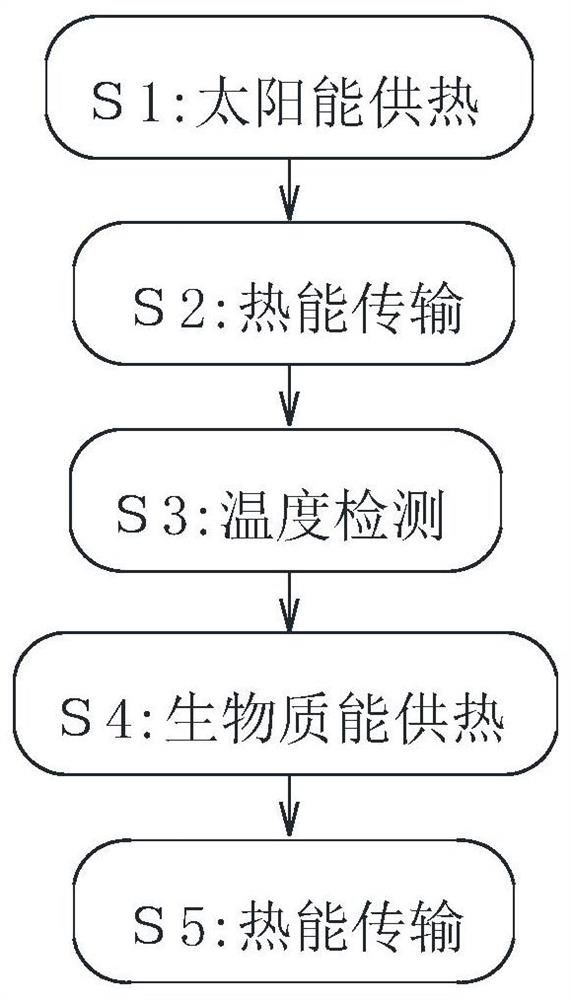

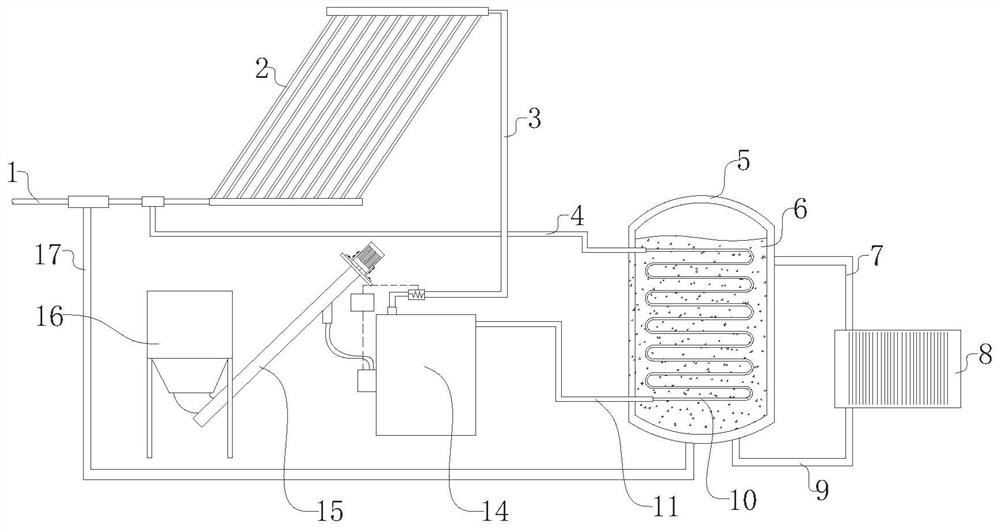

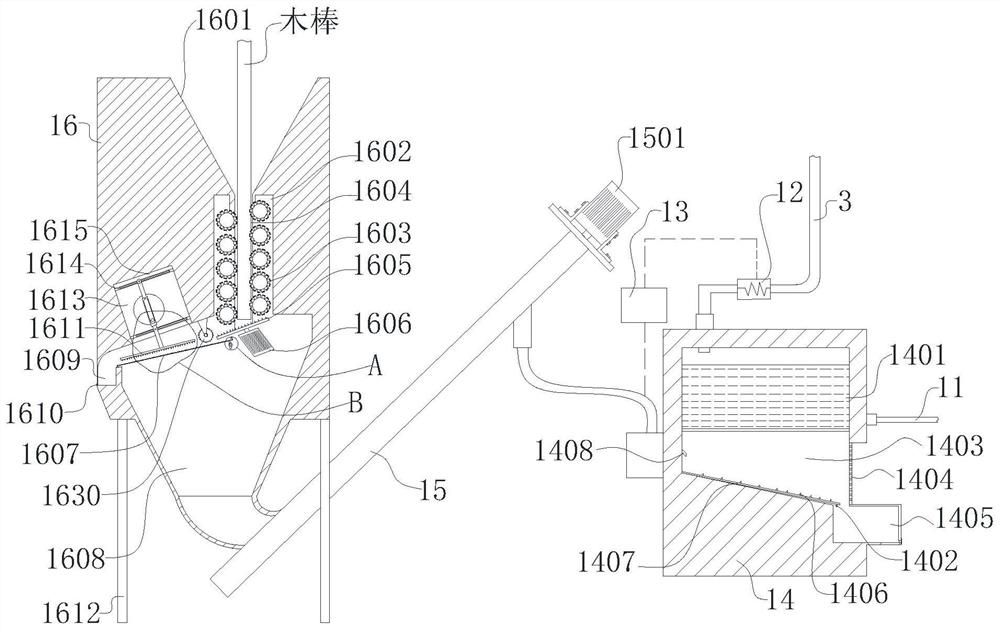

Method for conveying energy to heat pump by utilizing biomass energy

ActiveCN112066554AStable jobGood application effectSolar heating energySolar heat collector controllersThermodynamicsThermal water

The invention provides a method for conveying energy to a heat pump through biomass energy and relates to the technical field of biomass energy. The method for conveying energy to the heat pump through biomass energy comprises the following steps that S1, solar heat supply is conducted, specifically, a cold water source is provided for a solar heat absorption pipe through a cold water conveying pipe, the solar heat absorption pipe absorbs heat energy of sunlight and heats cold water flowing through the solar heat absorption pipe, and heated hot water is discharged through a solar hot water pipe. According to the method, a slag collecting box is arranged at the lower end of an obliquely-placed spreading plate, through reciprocating shaking of the spreading plate, biomass fuel rolls at the top end of the obliquely-placed spreading plate, incomplete combustion of the biomass fuel is reduced through uniform spreading, when the biomass fuel is shaken to the lower end of the spreading plate,burnt ash is formed, and the burnt ash is collected via the slag collecting box, so that the pollution to the surrounding environment is reduced.

Owner:金华智果智能科技有限公司

Storage-resistant grain waste regenerated biofuel particles and preparation method thereof

The invention discloses storage-resistant grain waste regenerated biofuel particles and a preparation method thereof. The storage-resistant grain waste regenerated biofuel particles include, by weightparts, 10-15 parts of soybean meal waste, 5-8 parts of corn waste, 10-12 parts of soybean waste, 15-20 parts of wheat waste, and 1-5 parts of leavening agent, 0.1-0.5 parts of antibacterial agent and0.1-0.5 part of catalyst. The invention also discloses the preparation method thereof. The regenerated biofuel particles are high in calorific value, good in combustion effect, easy to produce and low in cost.

Owner:郝兴

A method of utilizing biomass energy for energy transport of heat pump

ActiveCN112066554BStable jobGood application effectSolar heating energySolar heat collector controllersThermodynamicsEngineering

The invention provides a method for energy delivery to heat pumps using biomass energy, which relates to the technical field of biomass energy. The method for energy delivery to heat pumps using biomass energy includes the following steps: S1, solar heating: through The cold water delivery pipe provides cold water to the solar heat-absorbing pipe, and the solar heat-absorbing pipe absorbs the heat energy of sunlight, heats the cold water flowing through the solar heat-absorbing pipe, and the heated hot water is discharged through the solar heat-absorbing pipe; There is a slag collection box at the lower end of the inclined spreading board. Through the reciprocating shaking of the spreading board, the biomass fuel rolls on the top of the inclined spreading board. By spreading evenly, the waste of biomass fuel is reduced. Complete combustion, when the biomass fuel is shaken to the lower end of the spreading board, the dried ash has been formed, which is collected through the slag collection box to reduce the pollution to the surrounding environment.

Owner:金华智果智能科技有限公司

A process of using rice husk powder and petroleum coke powder as mixed fuel for calcining white cement rotary kiln

A mixed fuel process using rice husk powder and petroleum coke powder as white cement rotary kiln for calcination. The rice husk is crushed into rice husk powder in a pulverizer, and the crushed rice husk powder is sent by the exhaust fan of the petroleum coke grinding system. The suction bag filter is mixed with the petroleum coke powder that enters the bag filter at the same time, and then sent to the mixed fuel bin, and then the mixed fuel is sent to the calciner and the rotary kiln head burner for combustion; the purified gas is produced by The exhaust fan exhausts into the atmosphere through the chimney. The mixed fuel mixed with rice husk powder and petroleum coke powder can reduce the ignition point and embers temperature of the fuel, greatly reduce the phenomenon of incomplete combustion of the fuel, and significantly reduce the calcining heat consumption of white cement clinker. The high calorific value and low ash content of petroleum coke are beneficial to the sintering of white cement clinker, and can avoid iron pollution brought by ash, which is very beneficial to the strength and whiteness of white cement. This process can mix crushed rice husks into petroleum coke powder to make mixed fuel, which is suitable for calcination of white cement clinker in new dry process cement kilns.

Owner:江西银杉白水泥股份有限公司

Smokeless combustion heating furnace

InactiveCN109323295AReduce the possibility of incomplete combustionProtect the indoor environmentLighting and heating apparatusStove/ranges for heating waterEngineeringSmall particle

The invention discloses a smokeless combustion heating furnace. The smokeless combustion heating furnace comprises a furnace body, a water containing shell is integrally formed on the lower side wallof the furnace body, a separation net is fixedly installed on the inner side wall of the lower end of the furnace body, an X-shaped pipe is installed in the inner wall of the upper side of the separation net in an embedded mode, air outlet pipes are fixedly installed on the upper side wall of ports of the X-shaped pipe, moreover, the number of the air outlet pipes is four, air outlets are formed in the side walls of the air outlet pipes, an air inflation pipe is installed in the inner walls of the furnace body and the separation net in an embedded mode, and the air inflation pipe communicateswith the X-shaped pipe. According to the smokeless combustion heating furnace, the furnace body with an inner cavity capable of blowing circumferential air is arranged so that a combustion object canbe in better contact with air when being combusted, the possibility of incomplete combustion is reduced, then the effect of smokeless emission is achieved, and the indoor environment is protected; andthrough the cooperation of the separation net and the water containing shell, small-particle residues generated by the combustion object can be well recovered, and then the problem of environmental pollution caused by the fact that the residues are discharged into the room is solved.

Owner:山东家家乐电器科技有限公司

evaporative burner

ActiveCN107614975BEasy to soakImprove fire resistanceIncandescent ignitionCapillary burnersCombustion chamberCombustor

A promotion member is disposed a predetermined distance apart from an impregnation member disposed at an upstream side end of a combustion chamber, and an ignition device and a first air supply opening are prepared on an upstream side from the promotion member in an ignition space, and a second air supply opening is prepared on a downstream side from the promotion member in the ignition space. Fuel is supplied to a smooth surface of the impregnation member, and a concave part or cutout is formed in the impregnation member to house at least a part of the ignition device. A flow rate of air supplied to the combustion space through the second air supply opening becomes larger toward the downstream side. Thereby, ignitability in an evaporation type burner is improved and incomplete combustion of fuel on the downstream side of the combustion chamber is reduced.

Owner:SANGO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com