Method for expanding and optimizing compression ignition operation range of internal combustion engine applying variable valves

A technology of operating range and optimization method, which is applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of scarce fuel, narrow operating range of homogeneous compression ignition, engine knocking, etc., to reduce harmful emissions and The effect on fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

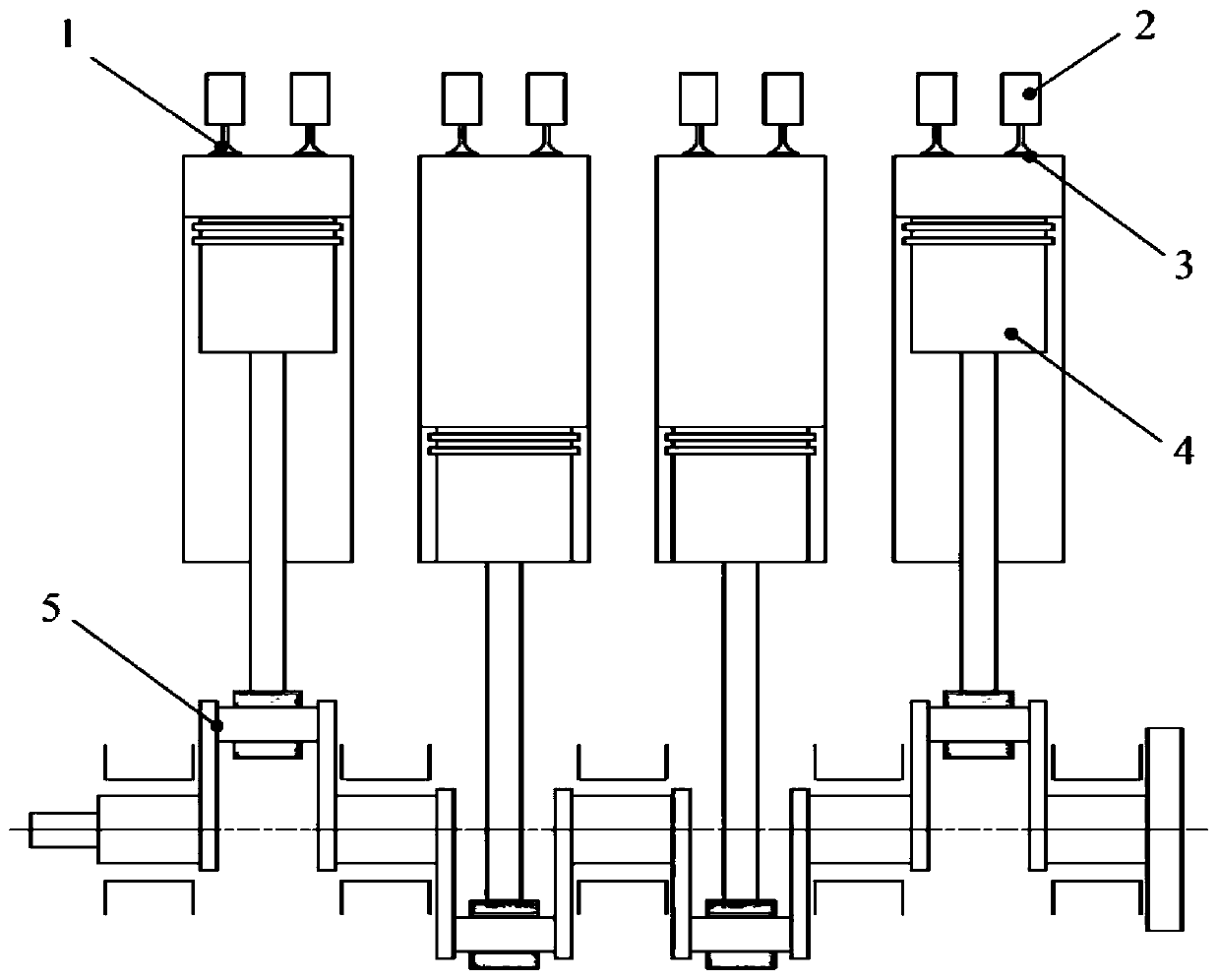

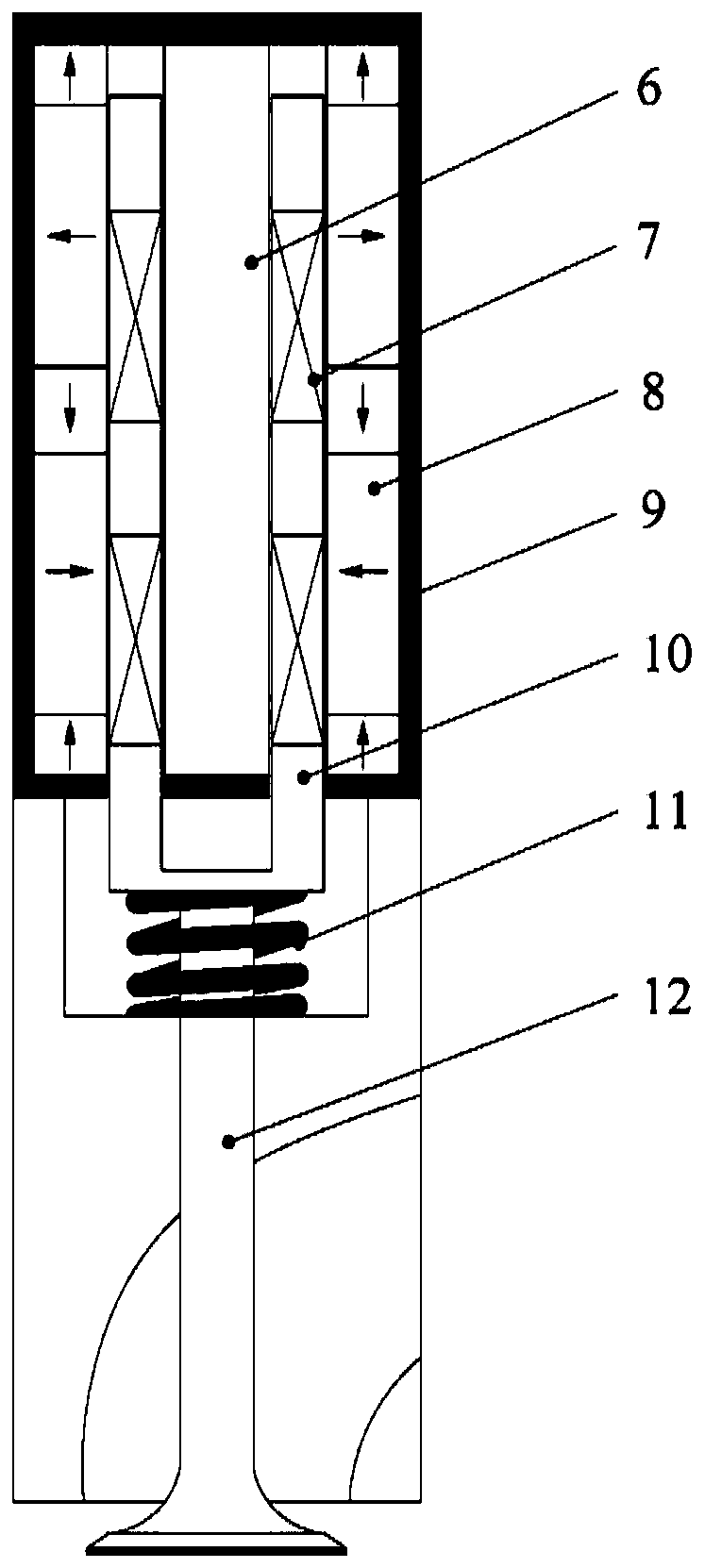

[0017] A gasoline engine homogeneous compression ignition method using electromagnetic fully variable valve, combined with figure 1 , the internal combustion engine includes an intake valve 1, an exhaust valve 3 and an electromagnetic fully variable valve device 2, and each intake valve 1 and exhaust valve 3 are respectively provided with a valve for controlling its opening lift and opening The electromagnetic fully variable valve device 2 with phase angle, the electromagnetic fully variable valve device 2 drives the exhaust valve 3 to open during the exhaust stroke stage, so that the exhaust gas starts to be discharged out of the cylinder, and at a certain moment in the middle of the exhaust stroke, the electromagnetic fully variable valve device The variable valve device 2 drives the intake valve 1 to open, so that part of the exhaust gas f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com