Flexible pressing mechanism and pressing method thereof

A pressing mechanism and flexible technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of processing cost, reusability and adjustability, etc., and achieve low processing cost, universal applicability, The effect of a high degree of modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

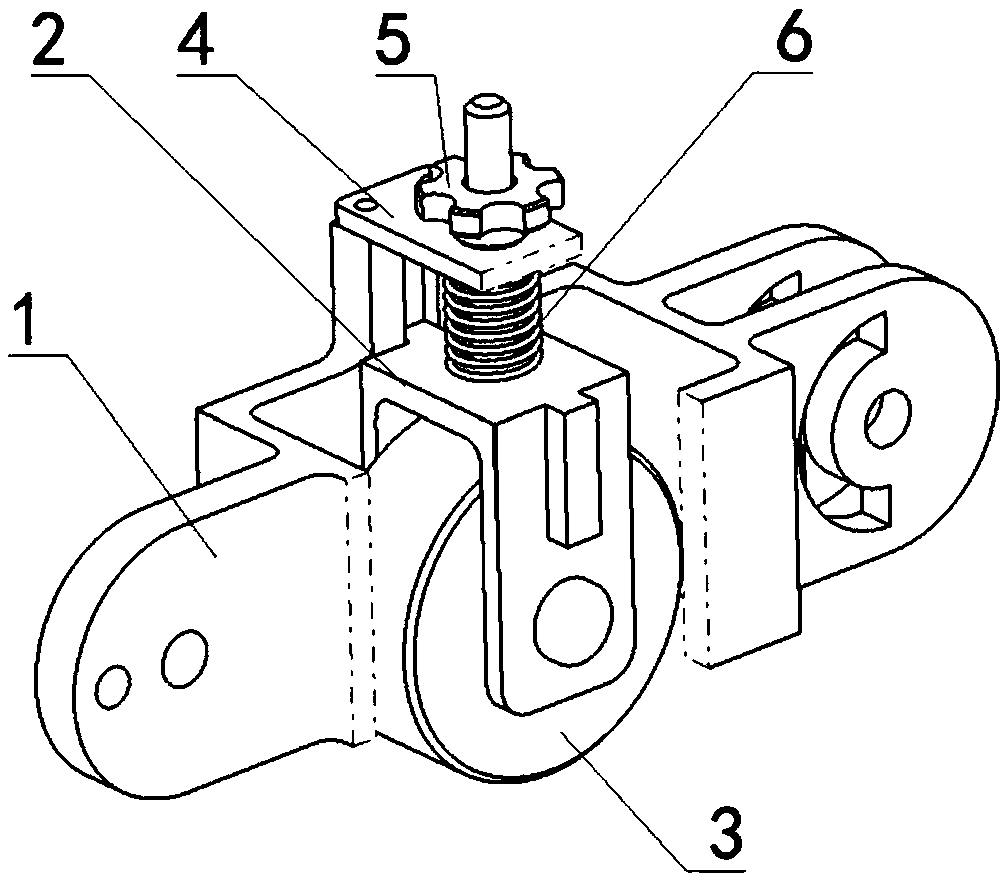

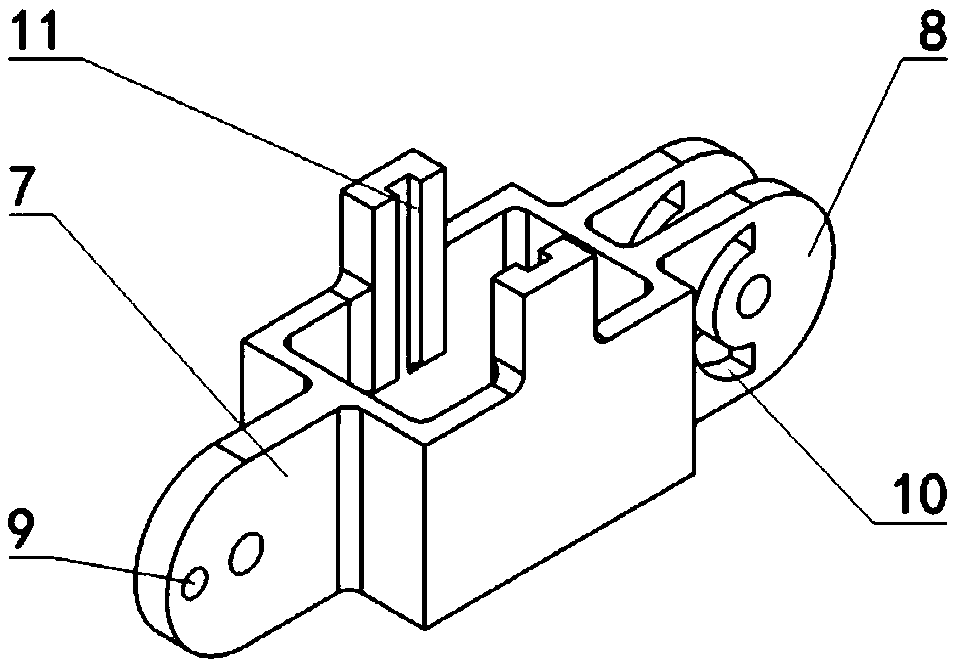

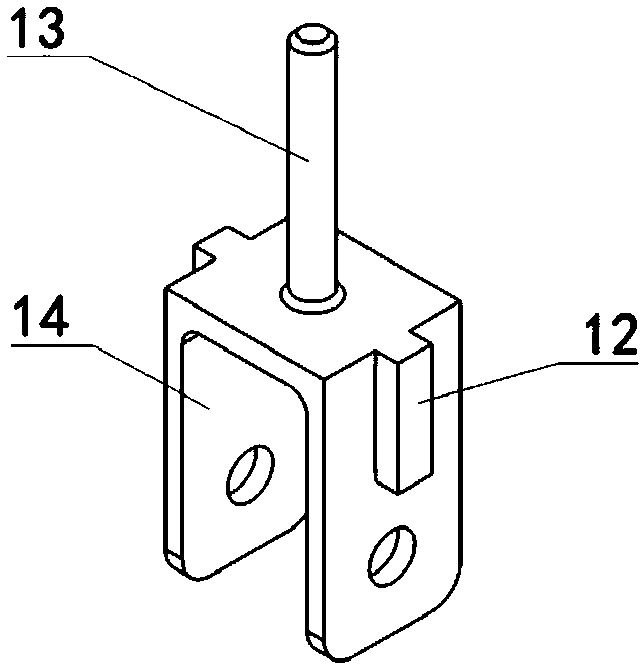

[0023] see Figure 1 to Figure 5 , a flexible compression mechanism, including a plurality of flexible compression units, the flexible compression unit includes a housing 1, a rubber wheel 3, a spring 6, and a connecting mechanism; the housing 1 is an internal hollow structure, and one end is provided with a single-ear insert 7. The other end is provided with a double-ear notch 8, and the double-ear notch 8 is provided with a limiting arc-shaped groove 10 matched with the single-ear insert 7. The rubber wheel 3 is installed on the lower part of the housing 1 through a connecting mechanism. A spring 6 is arranged above the wheel 3. Under the action of the spring 6, the rubber wheel 3 can be pressed and separated from the surface of the part to be pressed. The flexible pressing mechanism is composed of a plurality of pressing units according to the length of the part to be pressed. The previous one The one-ear insert 7 of the pressing unit is connected with the double-ear notch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com