Simple cam press device

A technology of pressing device and cam, which is applied in the direction of positioning device, workpiece clamping device, clamping, etc., can solve the problems of small lift and unsuitable processing requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

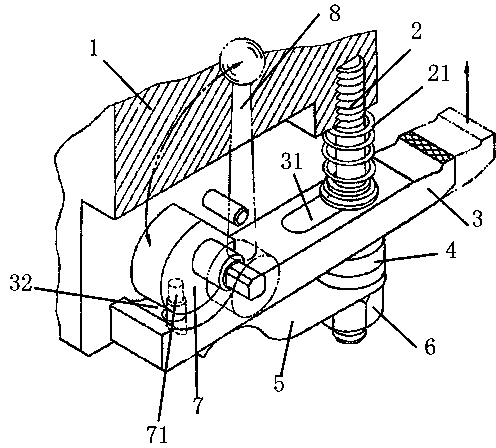

[0010] Such as figure 1 As shown, the simple cam pressing device of the present invention includes a fixed seat 1, on which there is a threaded hole, and a stud bolt 2 is connected in the threaded hole. The lower end of the stud bolt 2 is provided with a pressure plate 3, a spherical washer 4, a leaf spring 5 and a lock nut 6 in sequence, and a compression spring 21 is sleeved between the stud bolt 2 between the fixing seat 1 and the pressure plate 3. There is a bar hole 31 in the middle of the pressure plate 3 for the stud bolts to pass through. One end of the pressure plate 3 is a chuck for clamping the workpiece, and the other end is provided with a cam groove 32, and a cam 7 is placed in the cam groove 32. , a handle 8 is fixed on the cam 7. The rotating shaft of the handle 8 is fixed on the fixed seat 1; the bottom of the cam groove 31 is located between the cam 7 and the leaf spring 5 and a through hole is drilled, and the cam 7 is provided with a pressing plate ejector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com