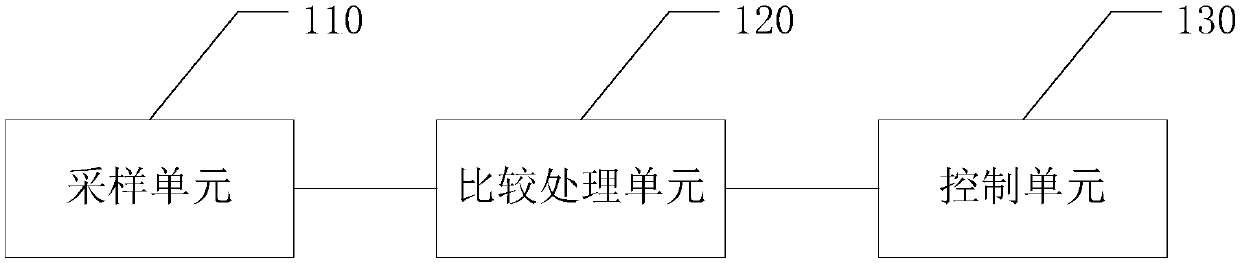

Protection circuit of DC motor

A technology for protecting circuits and DC motors, applied to emergency protection circuit devices, electrical components, etc., can solve problems such as motor winding overheating, motor overheating damage, and timely restart, and achieve strong anti-interference ability, strong applicability, and flexible adjustment and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

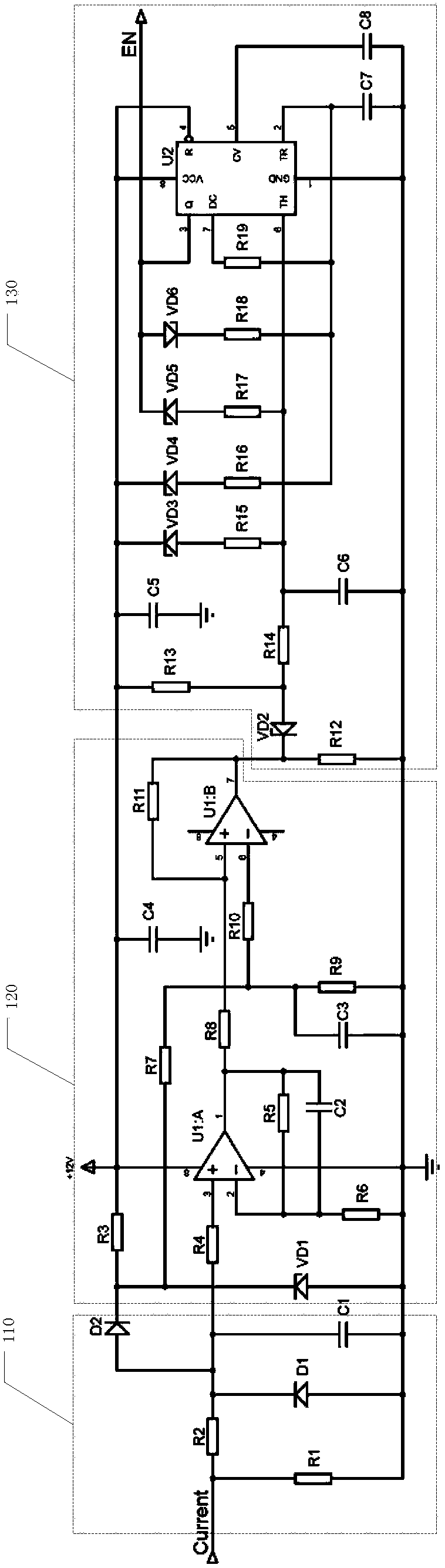

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

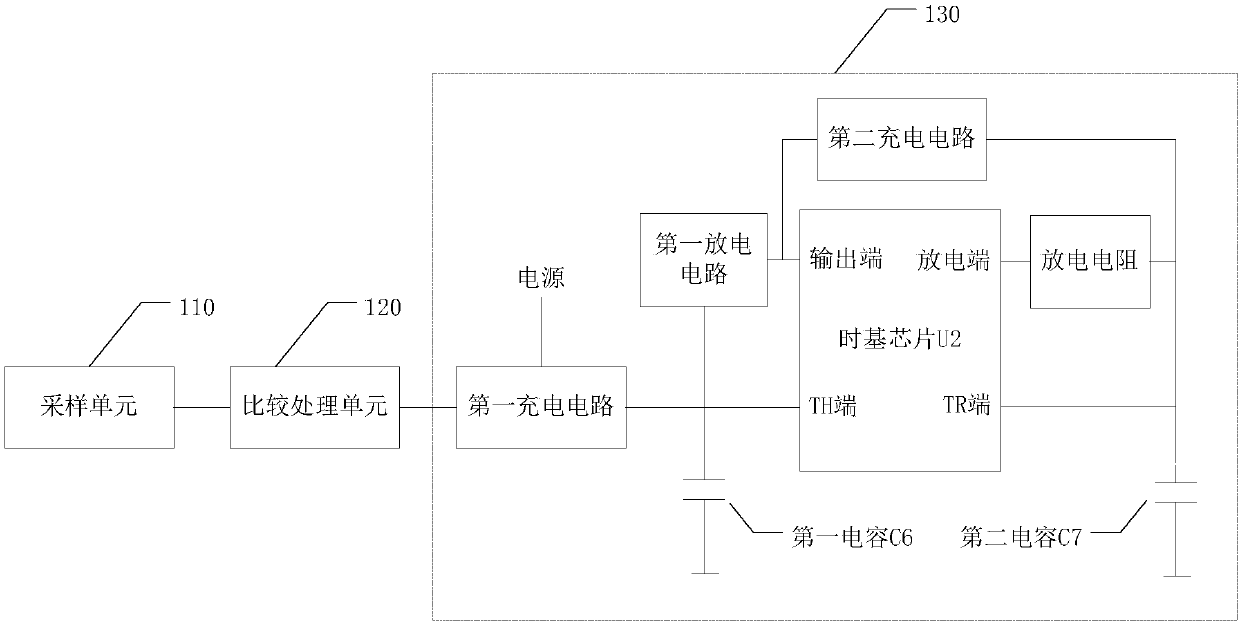

[0034] The basic concept of the present invention is to sample the current of the DC motor to obtain the sampled voltage value, compare the sampled voltage value with the reference voltage value, when the sampled voltage value is higher than the reference voltage value for the first preset time, then determine If the motor has faults such as stalling or short circuit, the motor is shut down to prevent the motor from overheating, and the motor is restarted after a second preset time to continue working. Among them, the protection delay time and the hiccup restart time of the protection circuit, that is, the first preset time and the second preset time, are respectively set by the independent first capacitor module and the second capacito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com