Combustion device with safety

A combustion device and safety technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of incomplete combustion of oil lamps, unsmooth air circulation, and difficult heat loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

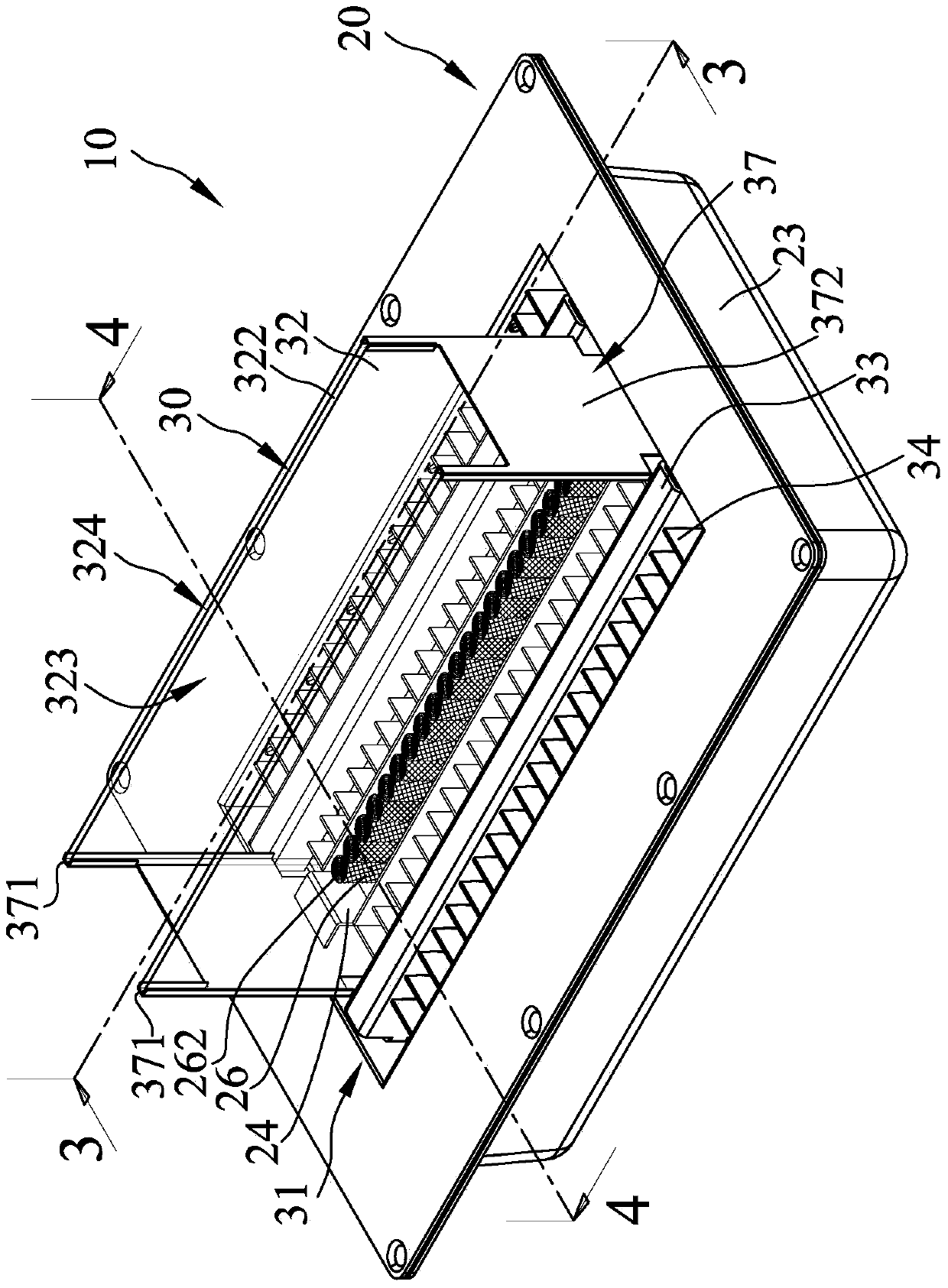

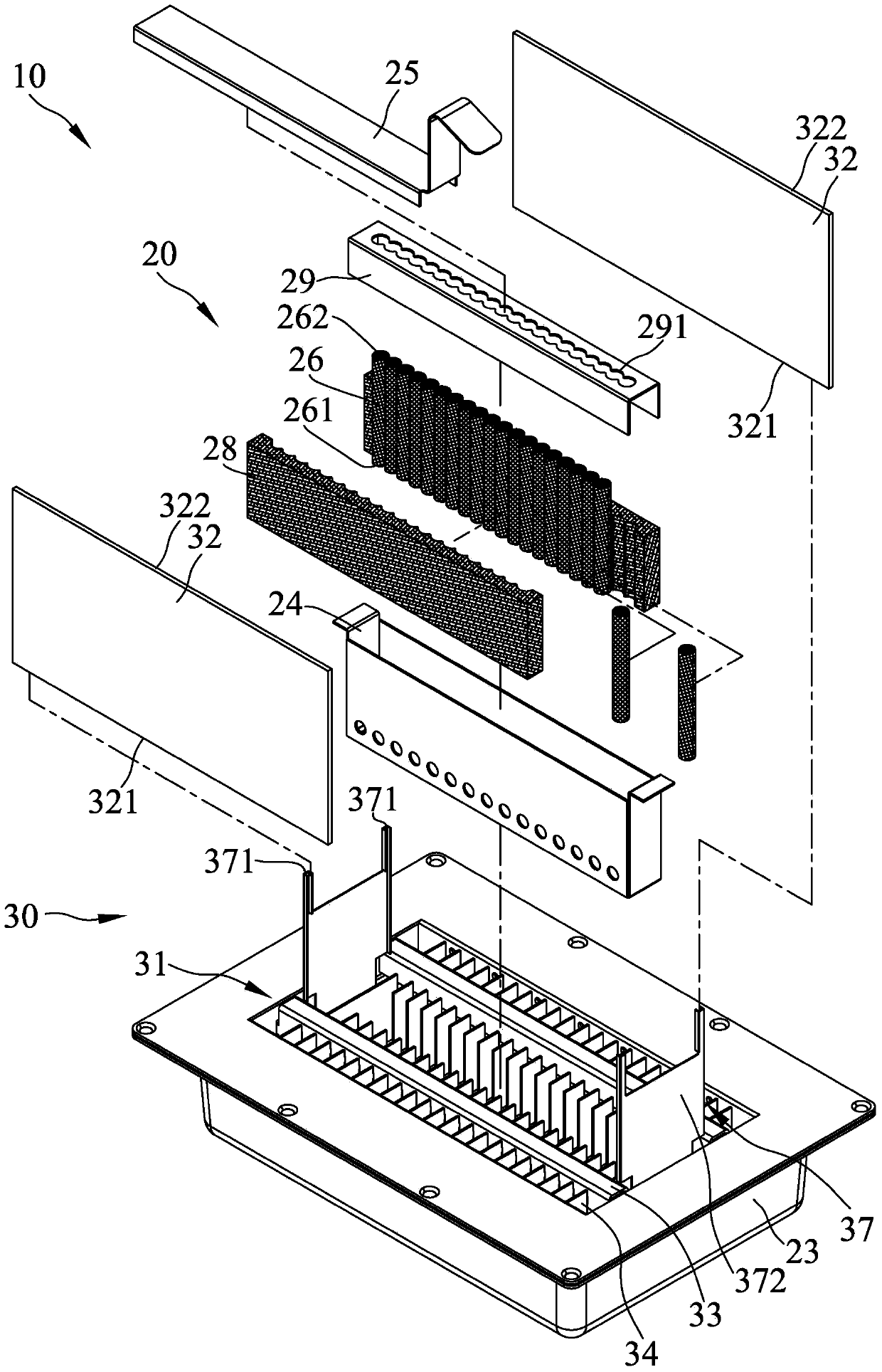

[0062] refer to figure 1 and figure 2 Shown is the three-dimensional appearance view and three-dimensional exploded view of the first embodiment of the safe combustion device of the present invention. The combustion device 10 of the present invention includes a body 20 and a flow guiding device 30; wherein:

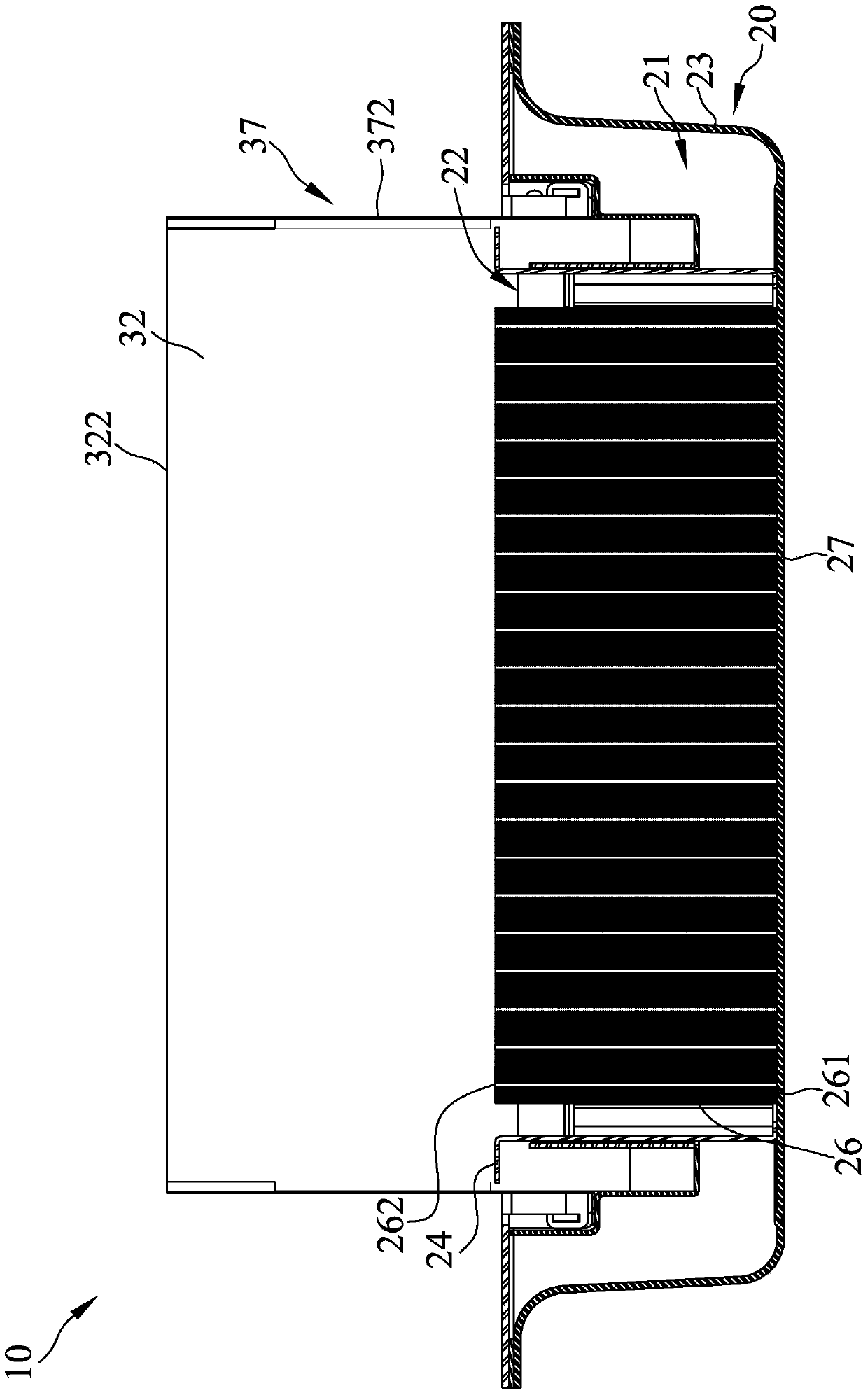

[0063] Please continue to refer to image 3 and Figure 4 Shown is the sectional structural view of the first embodiment of the safe combustion device of the present invention and the sectional structural view of another perspective. The main body 20 defines an accommodating space 21 , and the main body 20 has an opening 22 , and the opening 22 communicates the inside and the outside of the accommodating space 21 of the main body 20 . This body 20 comprises a fuel container 23 and a fixed seat 24, and this fuel container 23 can fill fuel 90 (as Figure 7 ), the fixing seat 24 is connected to the fuel container 23, the body 20 also includes a flameout cover 25, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com