Environment-friendly waste incinerator

An incineration device and waste technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of increasing incineration time, single structure, polluting the environment, etc., and achieve the effect of increasing permeability and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

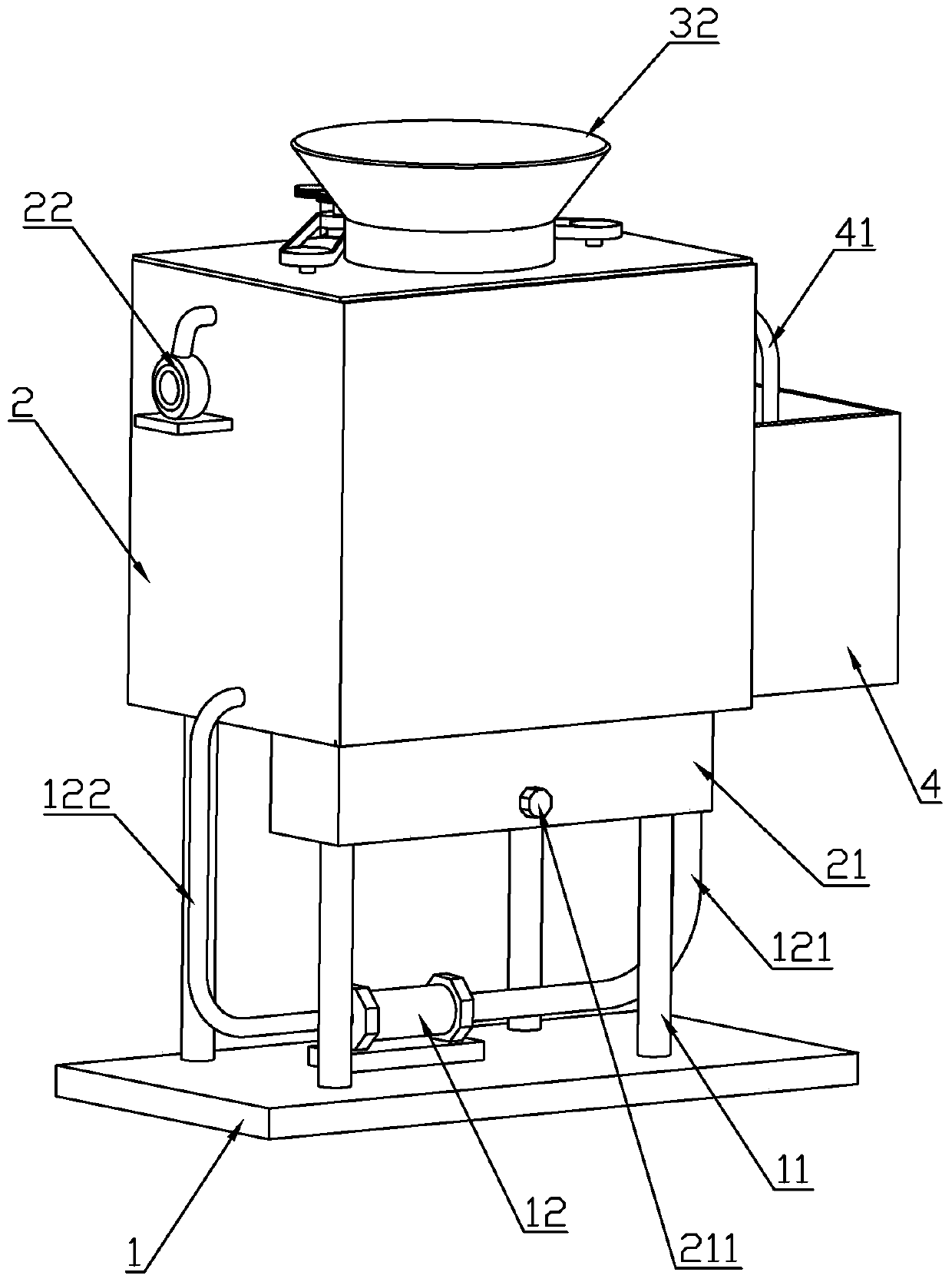

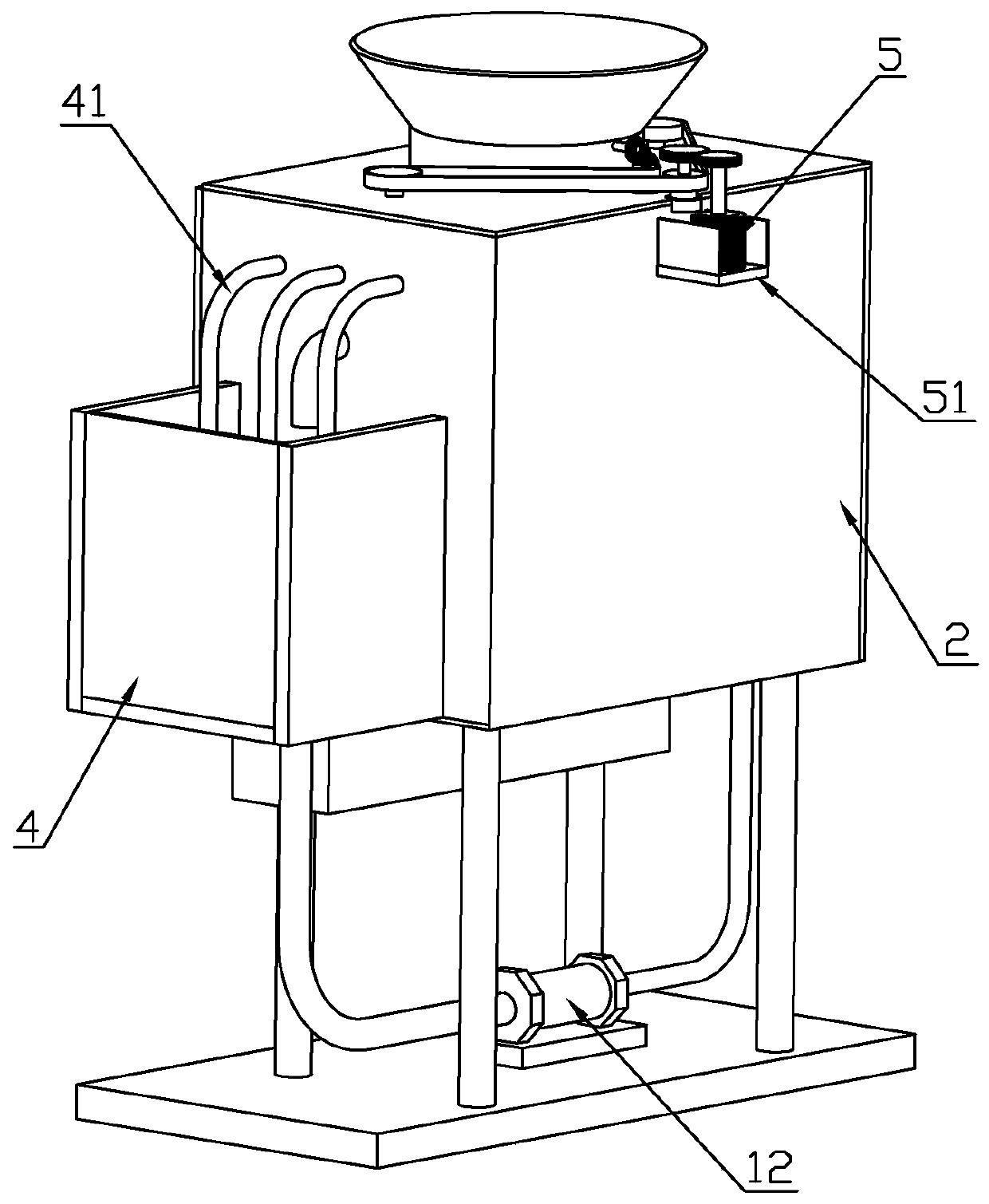

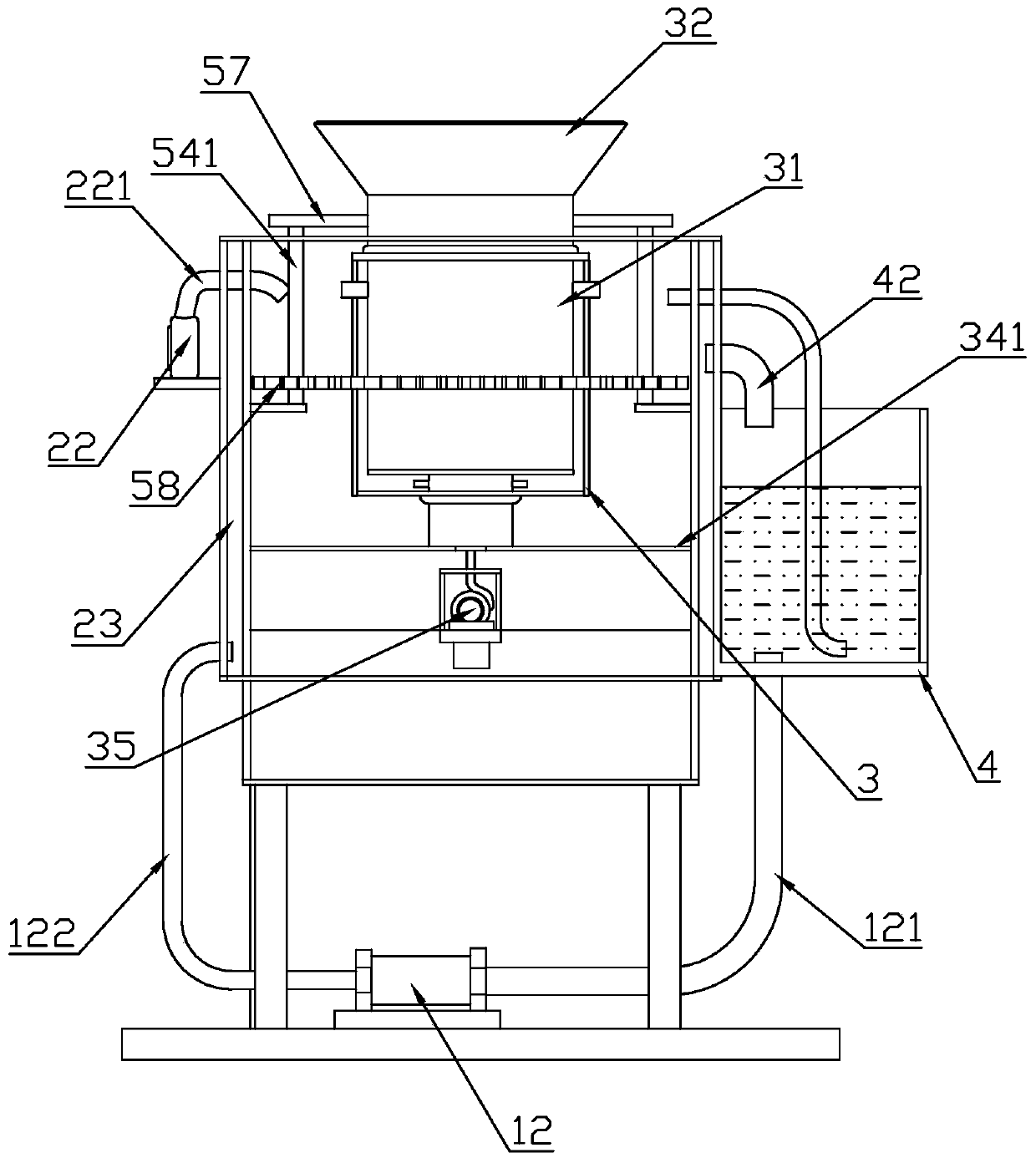

[0029] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-8 , to further specifically describe the technical solution of the present invention.

[0030]An environmentally friendly waste incineration device, including a base plate 1, a heat insulation box 2, an incineration outer cylinder 3, a cold water tank 4, and a transmission motor 5. The base plate 1 is placed on the ground to stably support the device. The base The top side of the plate 1 is provided with a number of support columns 11, and the top of the support columns 11 is connected with a heat insulation box 2, and the heat insulation box 2 is a double-layer structure with a heat insulation interlayer 23 inside. A cold water tank 4 is fixedly connected, and the cold water tank 4 is used to hold cooling water. The bottom side of the cold water tank 4 is provided with a water delivery pipe 121. One end of the water delivery pipe 121 extends sealingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com