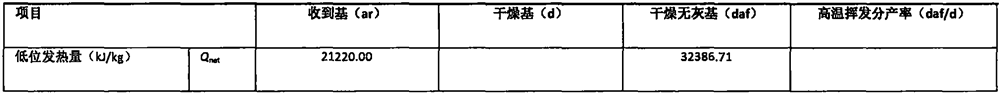

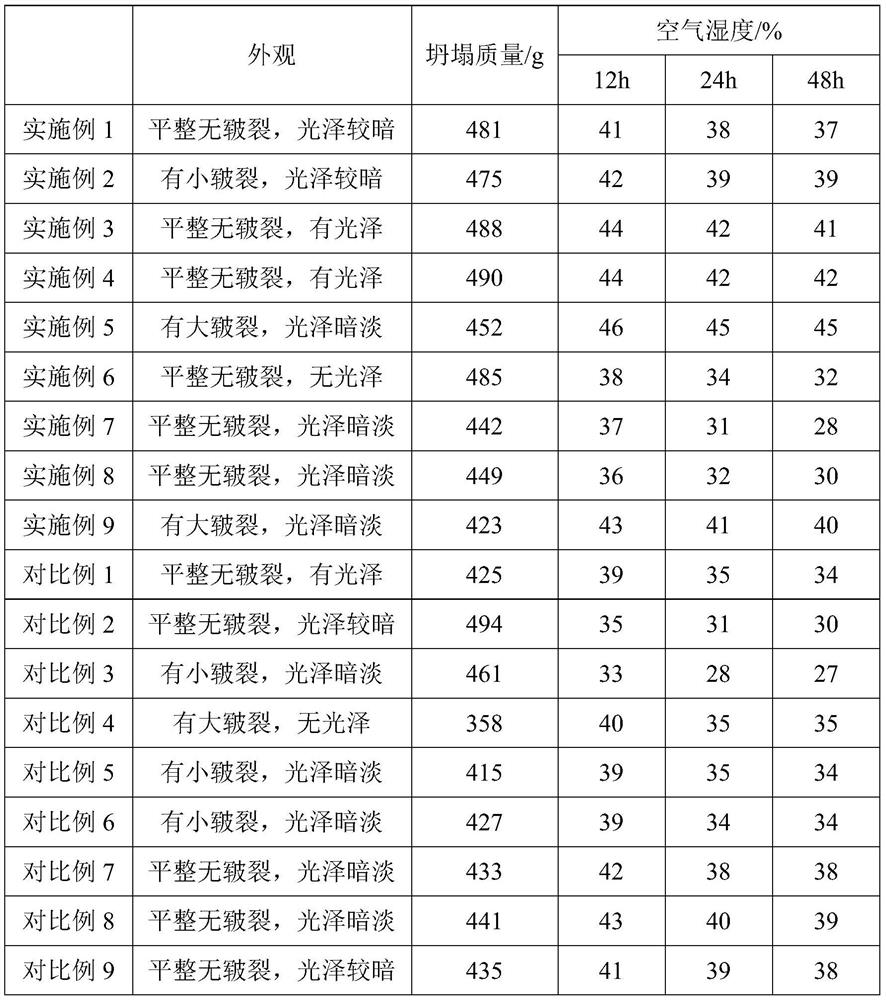

Patents

Literature

36results about How to "Play a combustion-supporting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

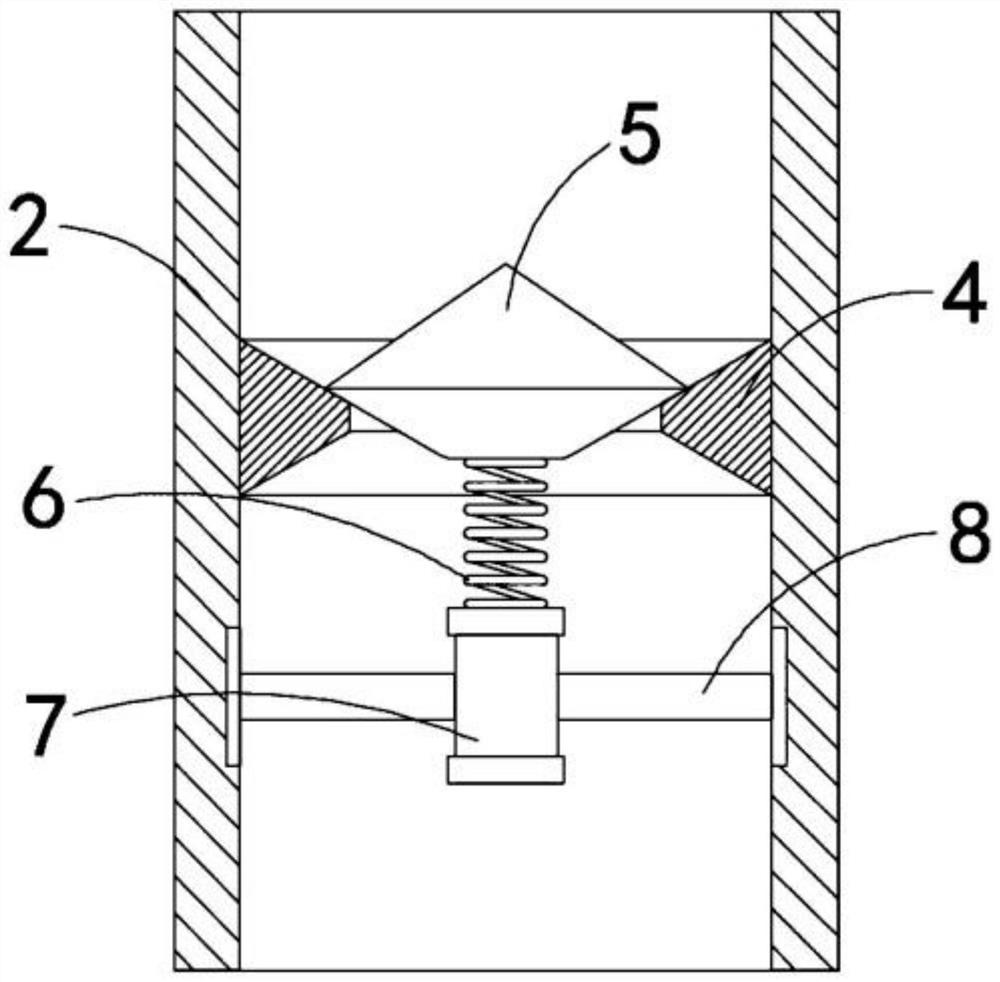

Biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device

ActiveCN106918039ASolve cokingSolve slaggingSolid fuel combustionLump/pulverulent fuel feeder/distributionGas solidSlag

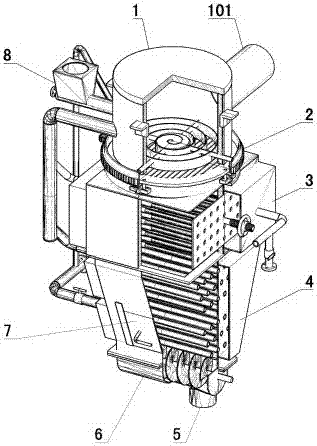

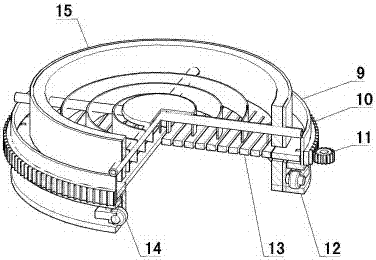

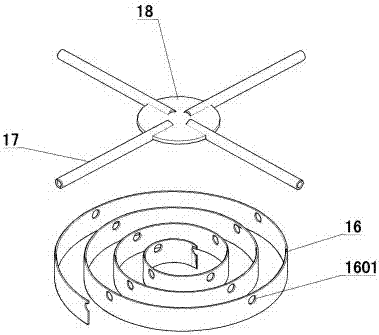

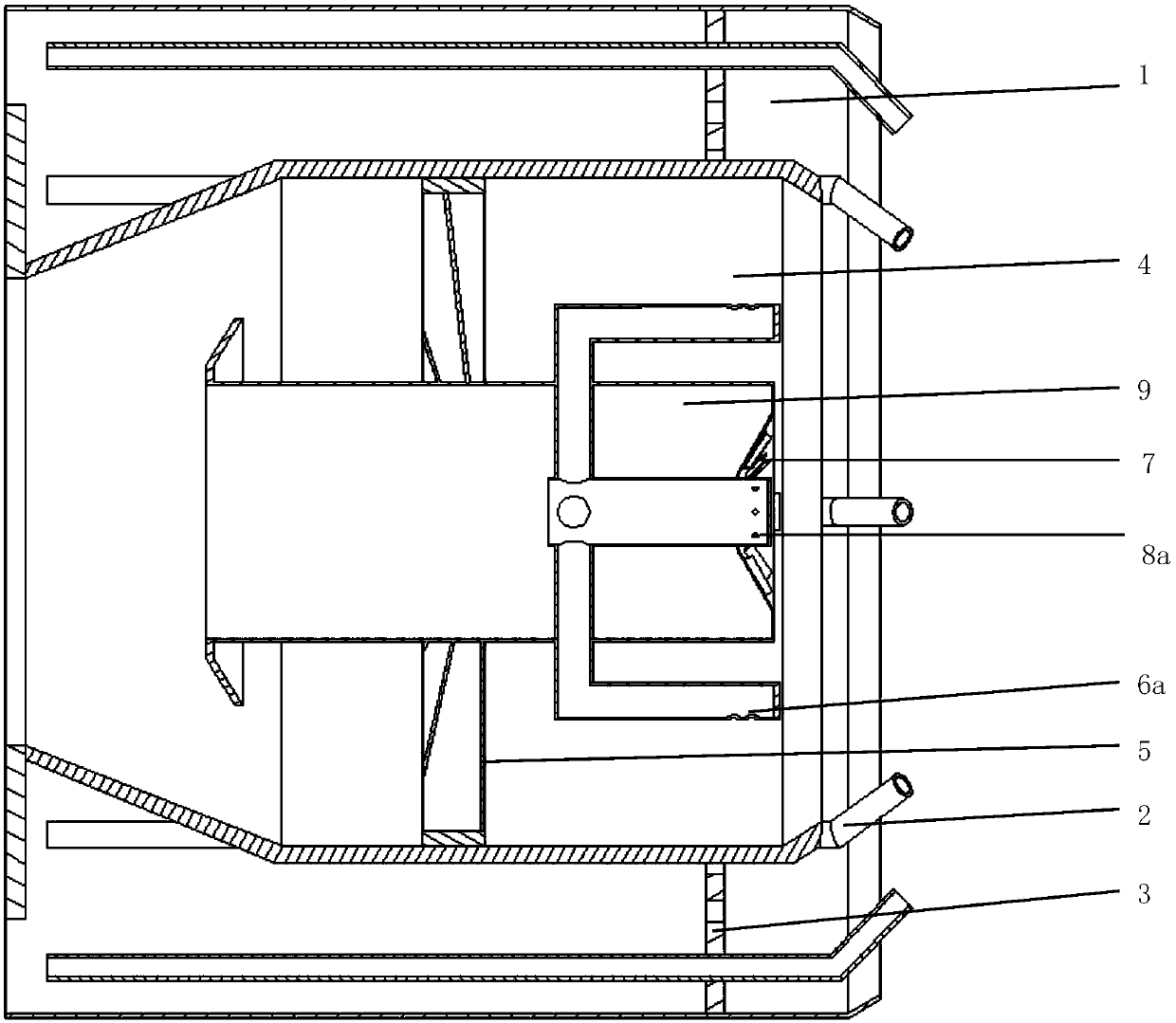

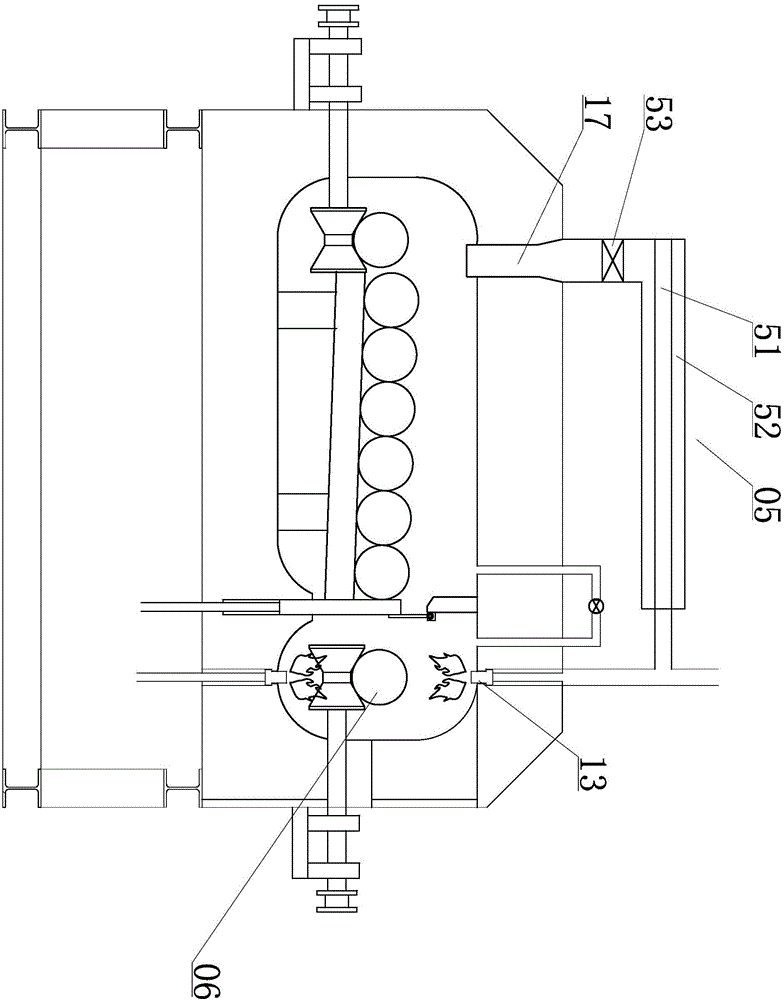

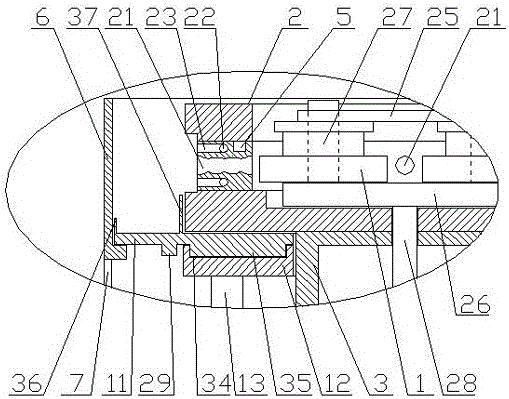

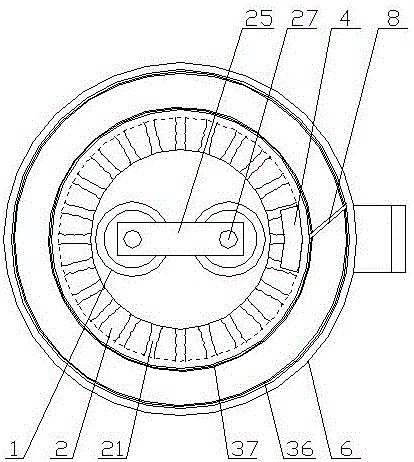

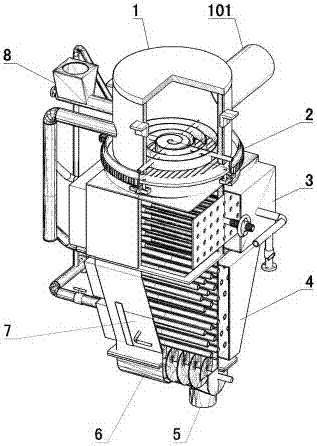

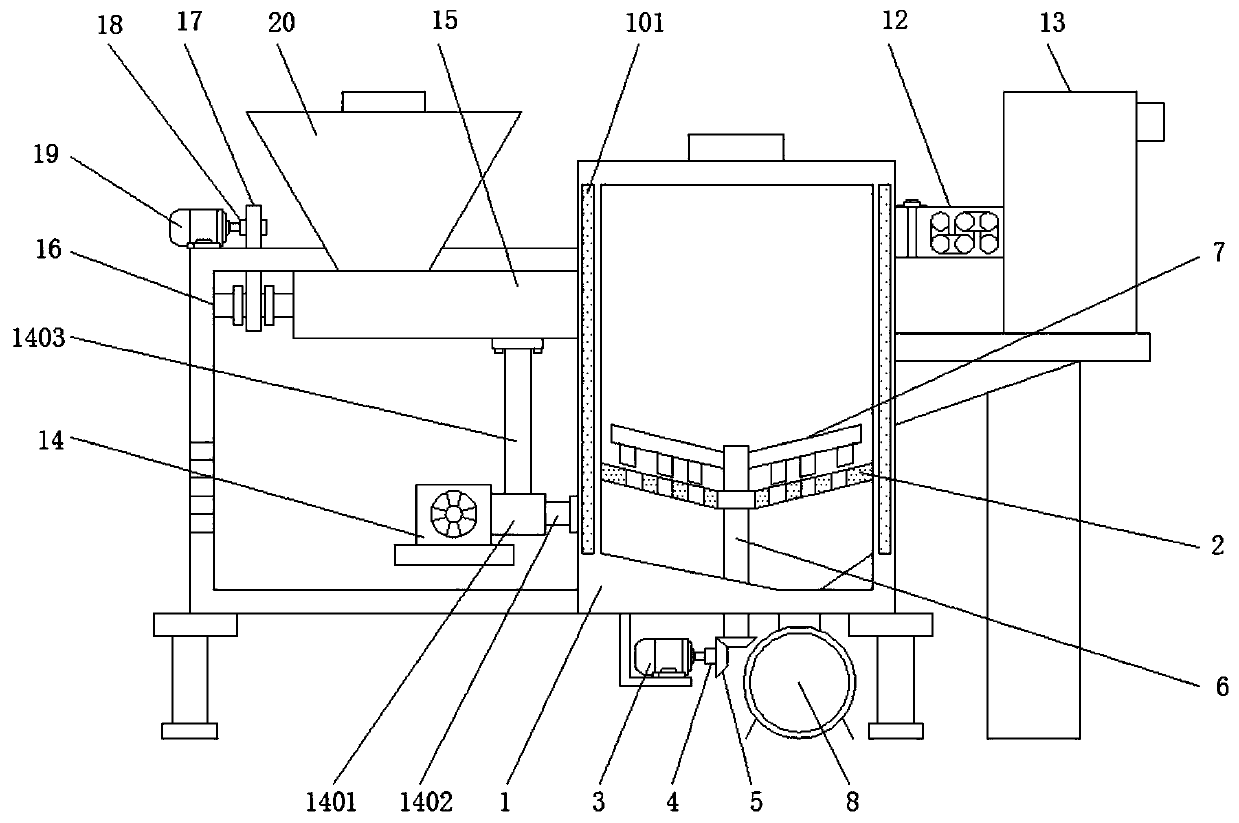

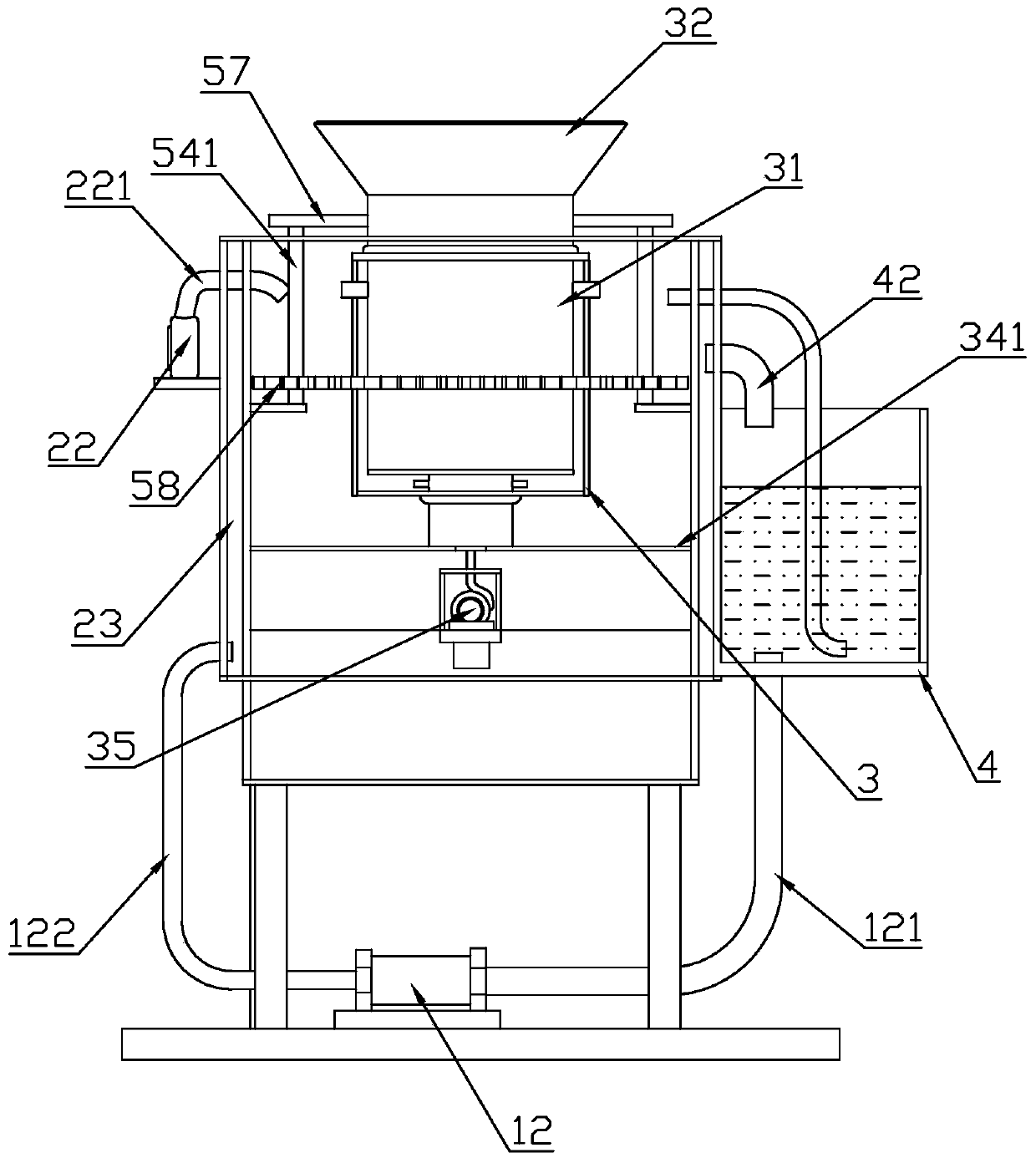

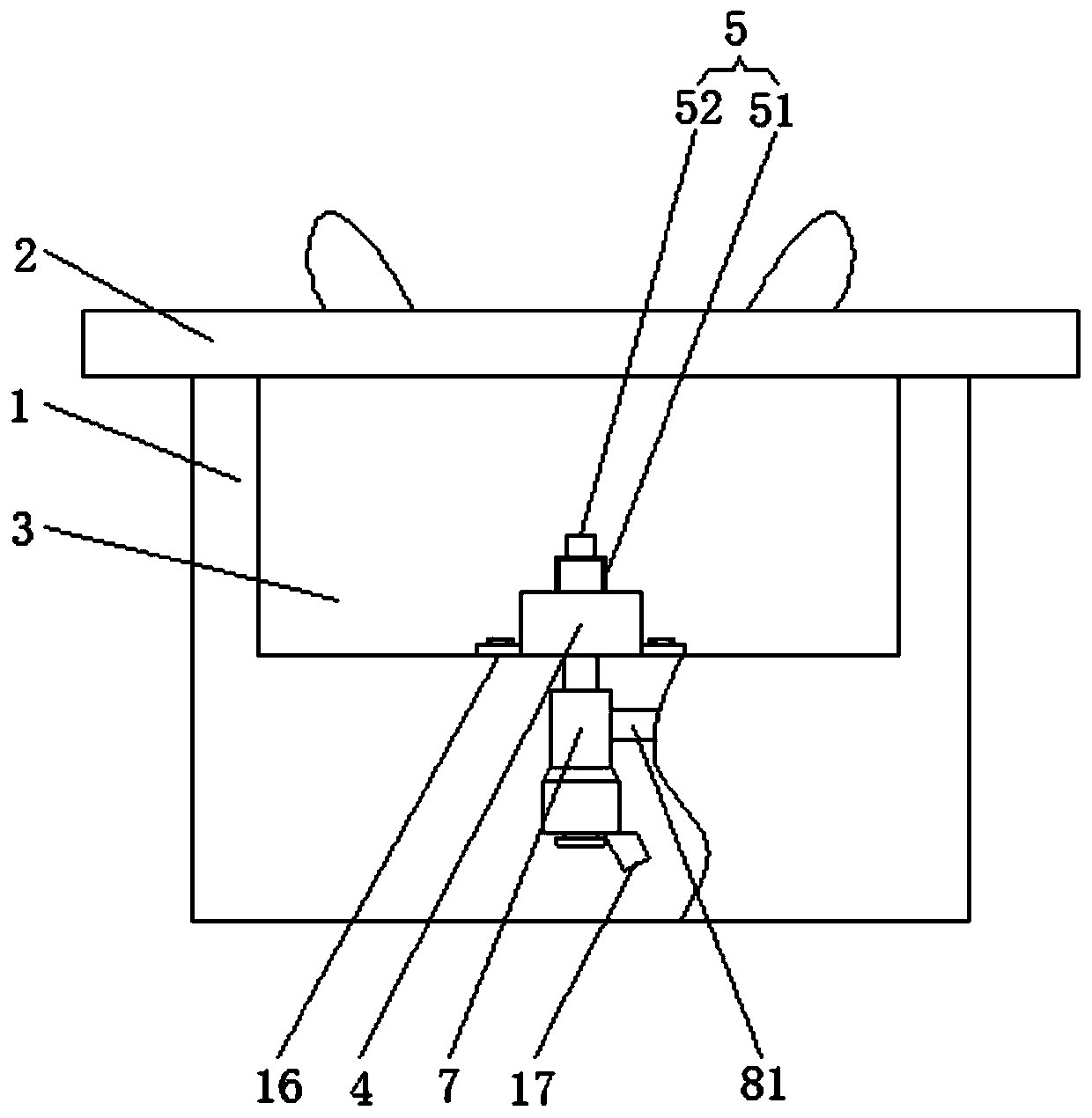

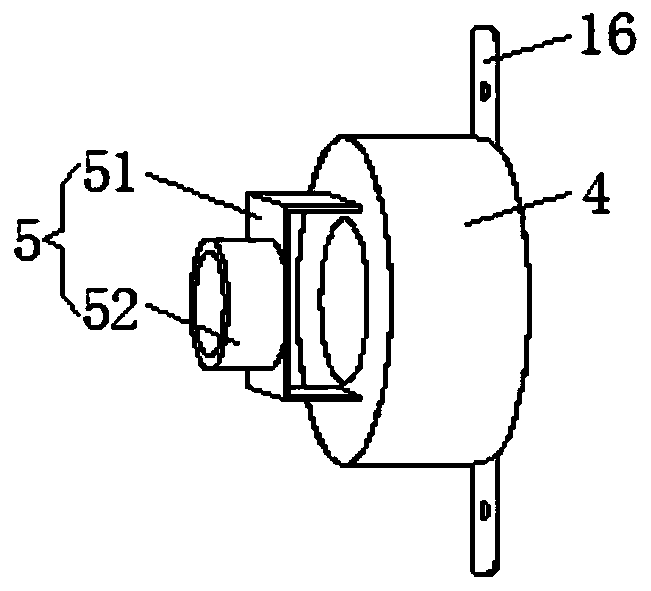

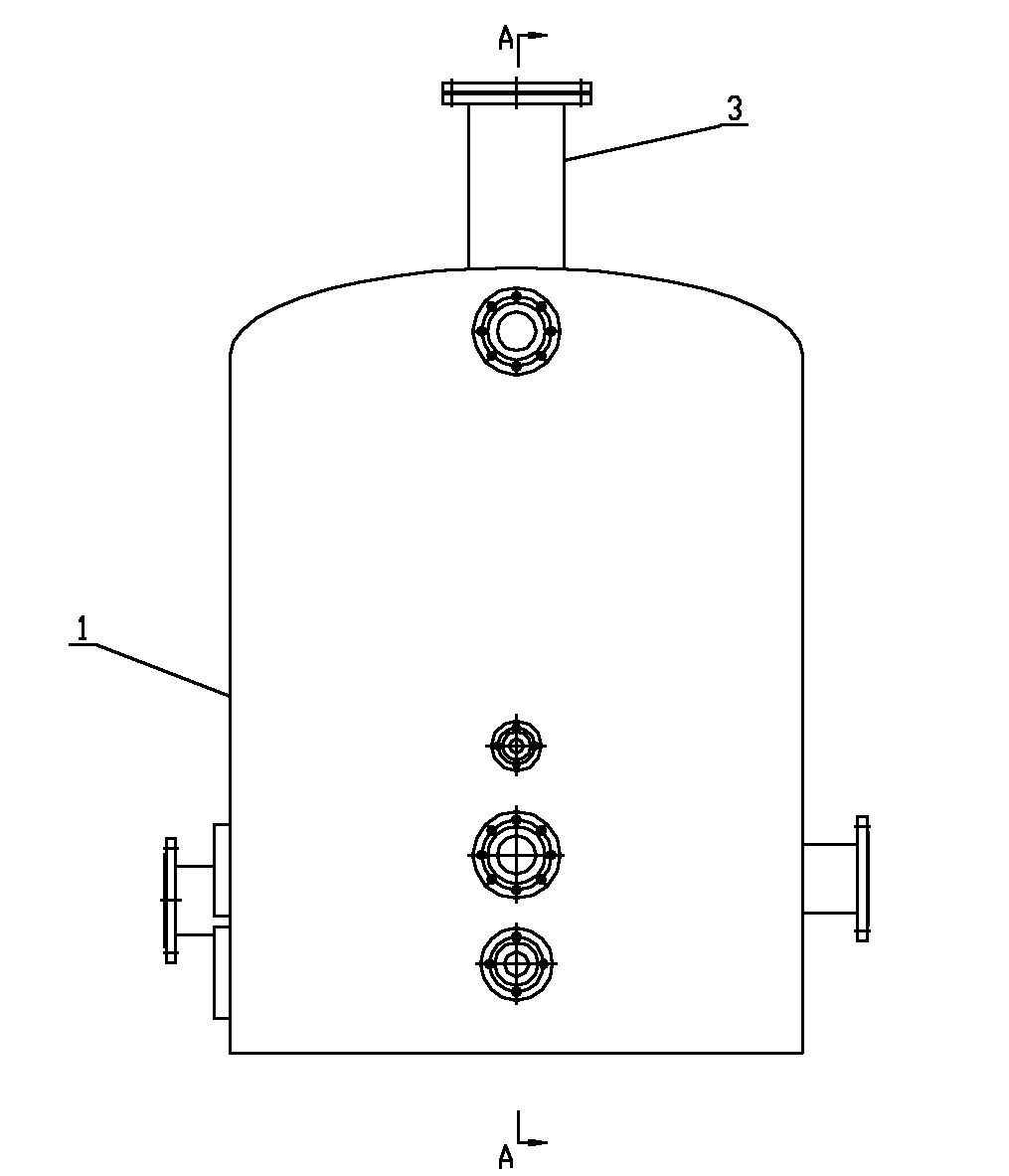

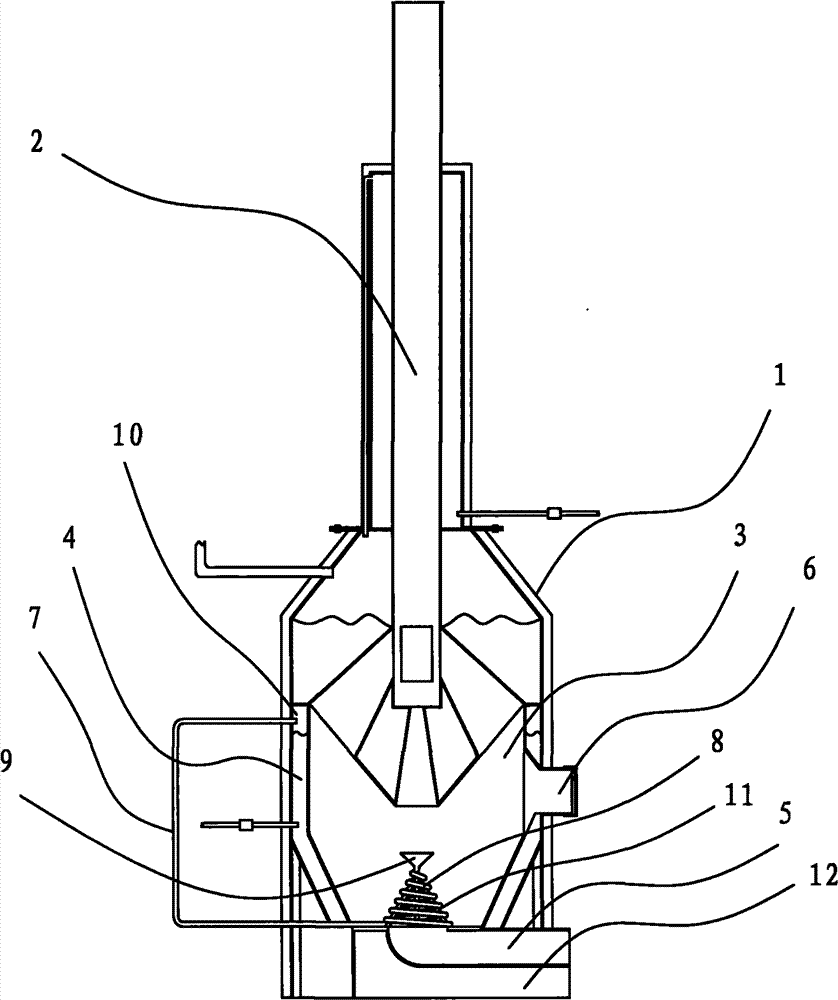

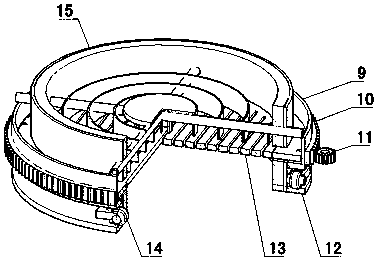

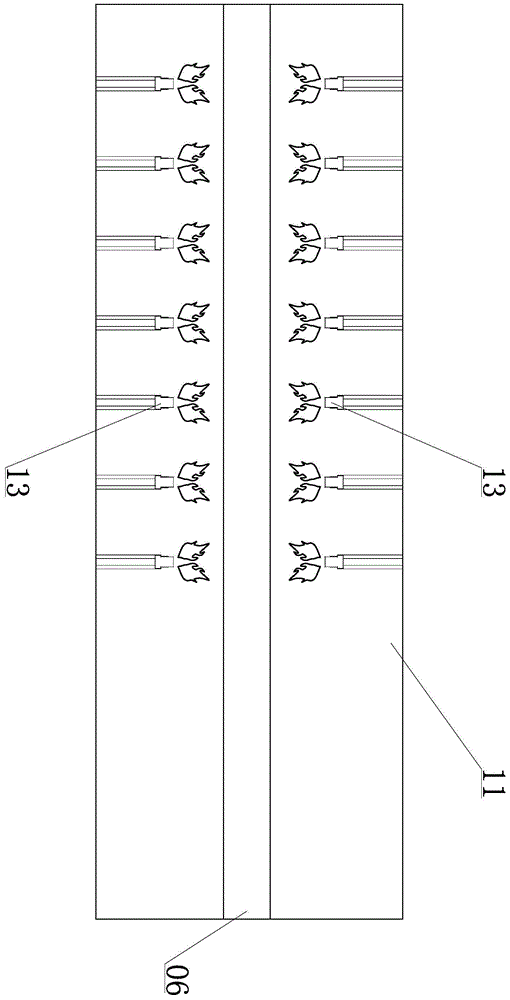

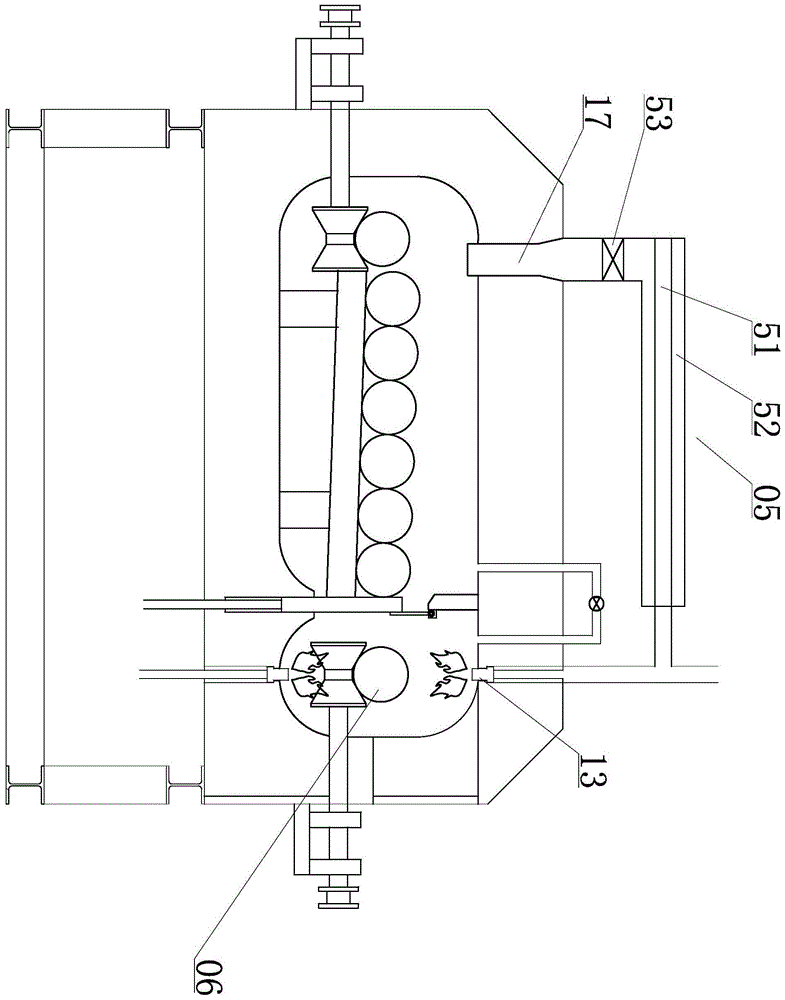

The invention provides a biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device and belongs to the technical field of biomass combustion. The biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device is characterized in that a feeding opening of a smoldering region (3) communicates with a discharging opening of a hearth (1), a discharging opening of the smoldering region (3) communicates with a cooling region (4), a furnace grate (13) is arranged on the lower portion of the hearth (1), a crushing mechanism (2) for crushing materials is arranged on the furnace grate (13), the furnace grate (13) is connected with a rotating mechanism for disturbing biomass fuel so that carbon powder can fall into the smoldering region (3) to be smoldered, meanwhile the block-shaped biomass fuel is made to move to the middle of the furnace grate (13), and the crushing mechanism (2) is used for crushing the block-shaped biomass fuel into the carbon powder and then enabling the carbon powder to fall into the smoldering region (3) to be smoldered. By the adoption of the biomass forming fuel solid-phase low-temperature gas-phase high-temperature combustion device, the problems of coking, slag bonding, the high gas-solid pollutant emission and invalid ash fertilizer existing in combustion equipment for agricultural waste such as straw are solved fundamentally.

Owner:SHANDONG UNIV OF TECH

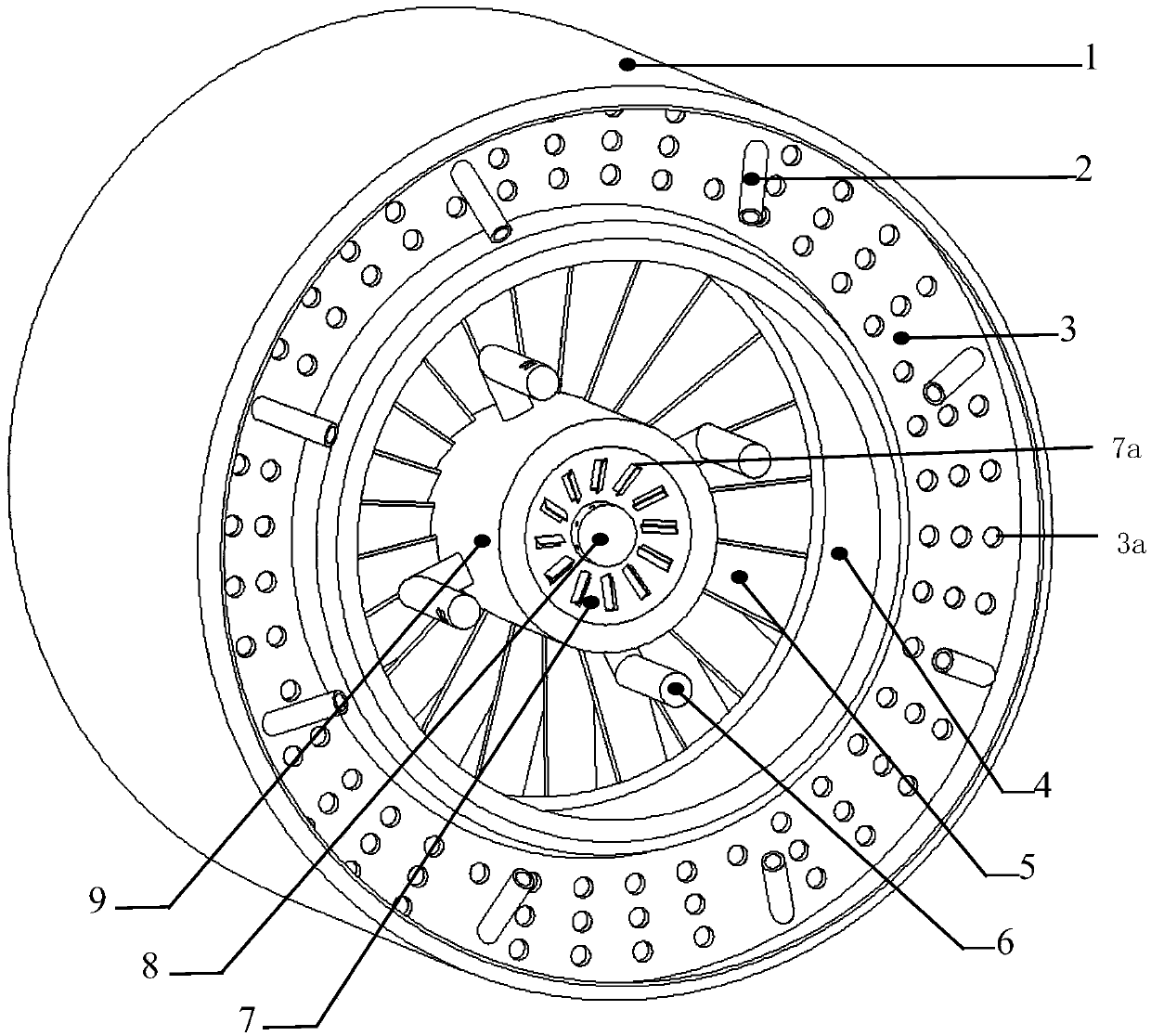

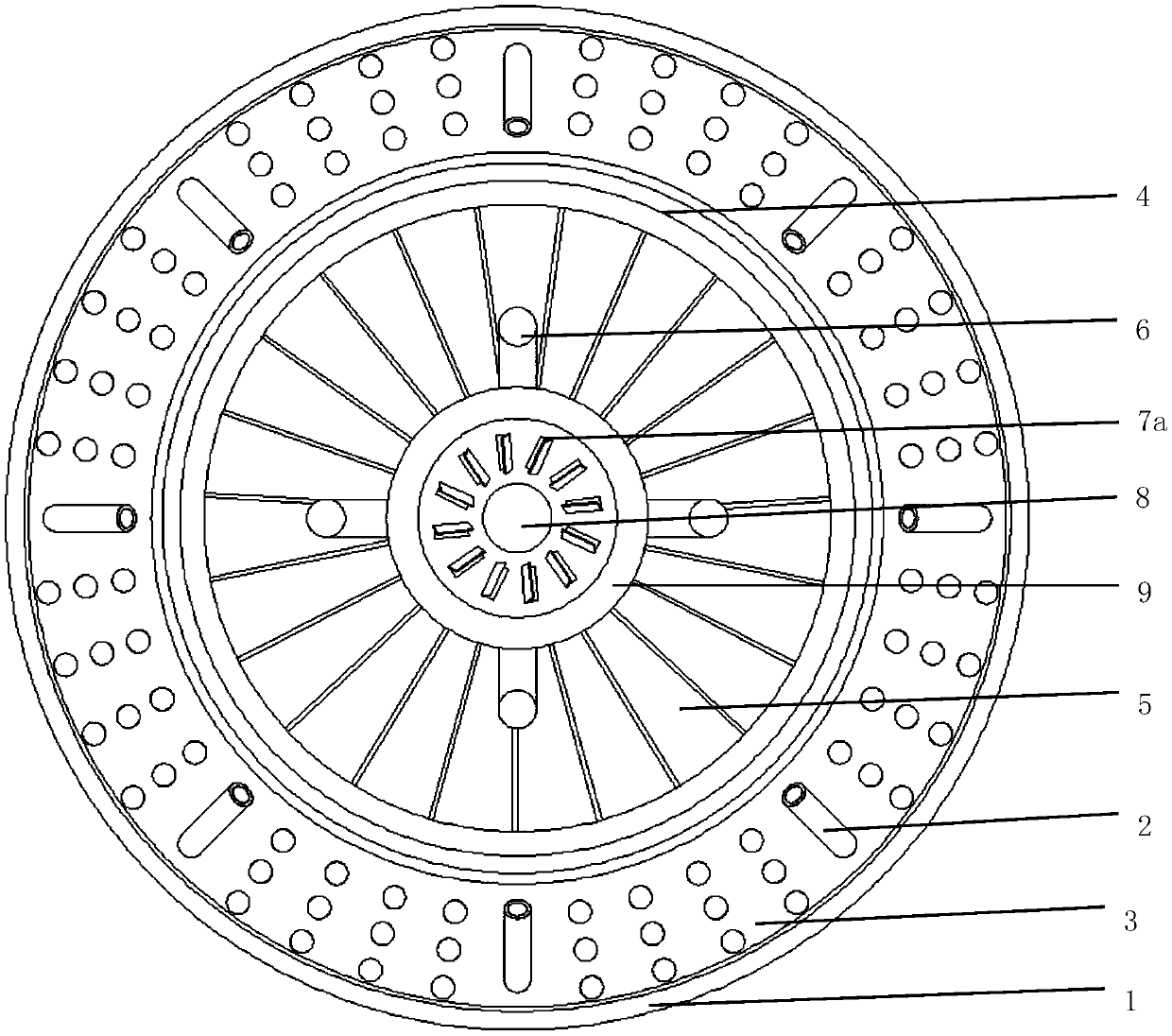

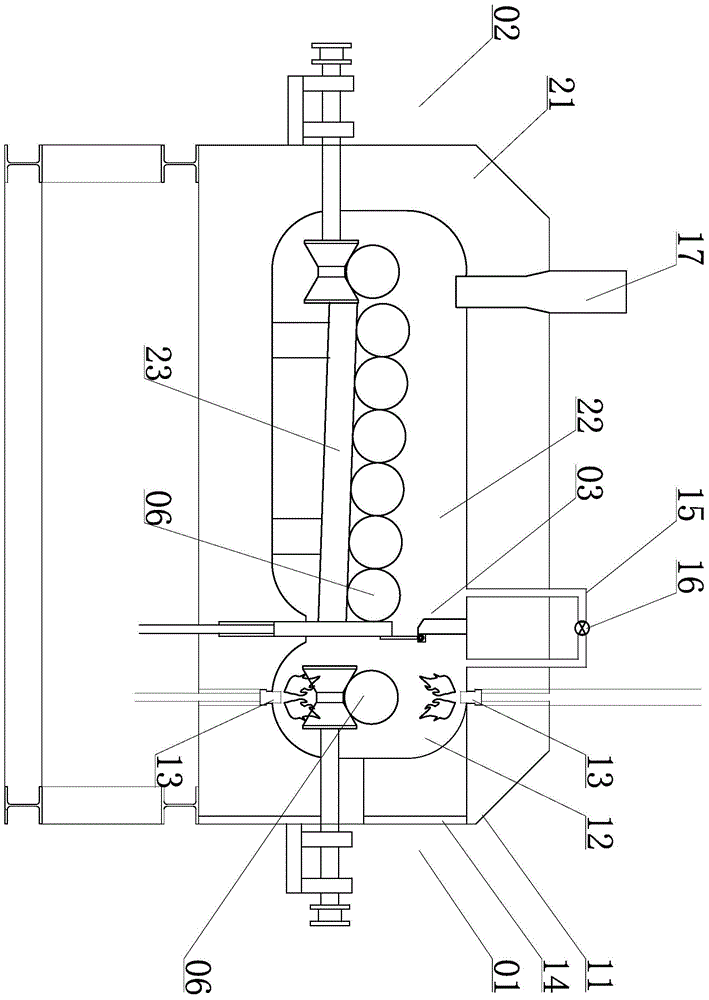

Multistage gas reverse swirl burner

PendingCN109611835AEfficient mixingStable combustion characteristicsPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationPollutant emissionsEngineering

The invention discloses a multistage gas reverse swirl burner. The multistage gas reverse swirl burner comprises a fuel spraying pipe and an air guide barrel set; the air guide barrel set comprises afirst-stage air guide barrel, a second-stage air guide barrel and a third-stage air guide barrel, the air outlet end of the first-stage air guide barrel is provided with a flame stabilizing disc to output first-stage swirl gas, the first-stage air guide barrel is sleeved with the second-stage air guide barrel, the second-stage air guide barrel is provided with multiple second blades to output second-stage swirl gas, the first-stage swirl gas and the second-stage swirl gas are opposite in swirl direction, the second-stage air guide barrel is sleeved with the third-stage air guide barrel, the third-stage air guide barrel is provided with a porous plate to output high-speed straight-through flow gas, the fuel spraying pipe set comprises a first-stage fuel spraying pipe, a second-stage fuel spraying pipe and a third-stage fuel spraying pipe, the first-stage fuel spraying pipe is located on the first-stage air guide barrel to spray fuel to the first-stage swirl gas, the second-stage fuel spraying pipe is located on the second-stage air guide barrel to spray fuel to the second-stage swirl gas, and the third-stage fuel spraying pipe is located on the third-stage air guide barrel. The airand gas mixing degree can be greatly improved, gas mixing is more uniform, combustion is more sufficient, and pollutant emission is lower.

Owner:HUAQIAO UNIVERSITY

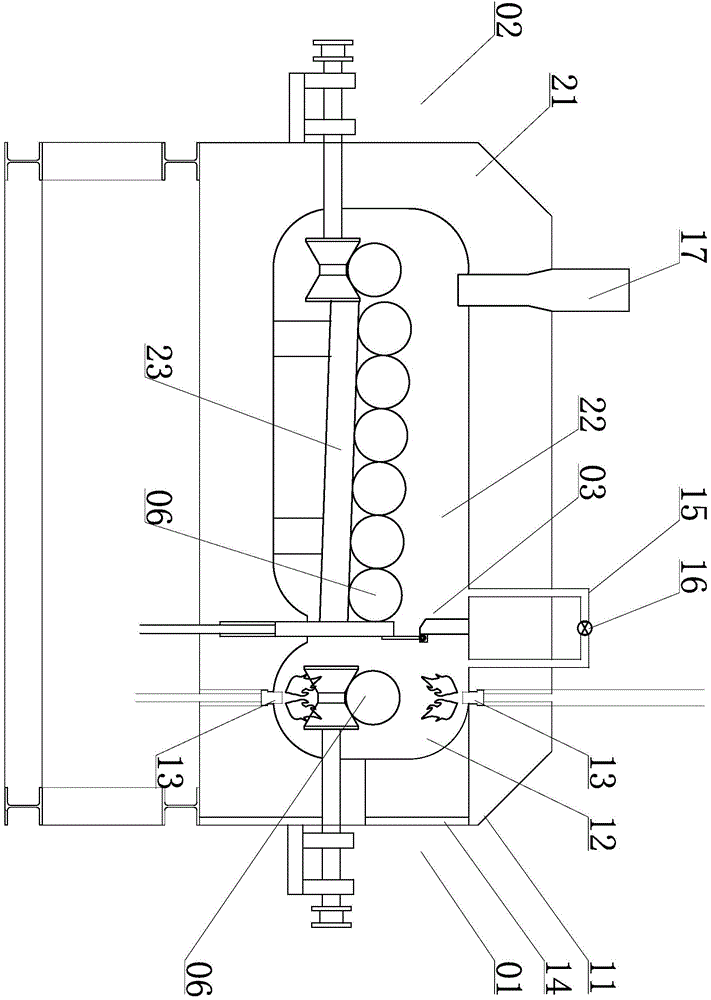

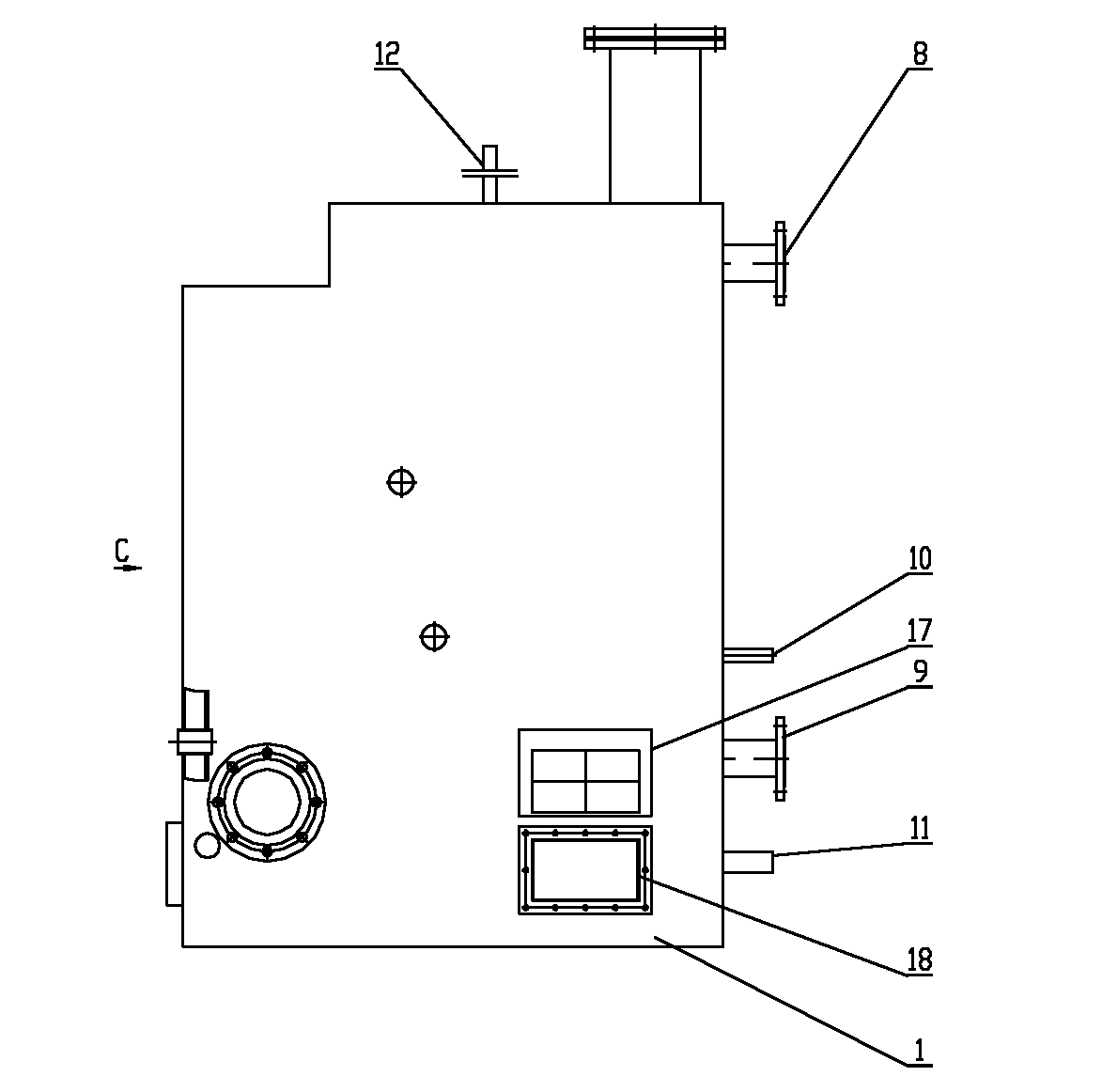

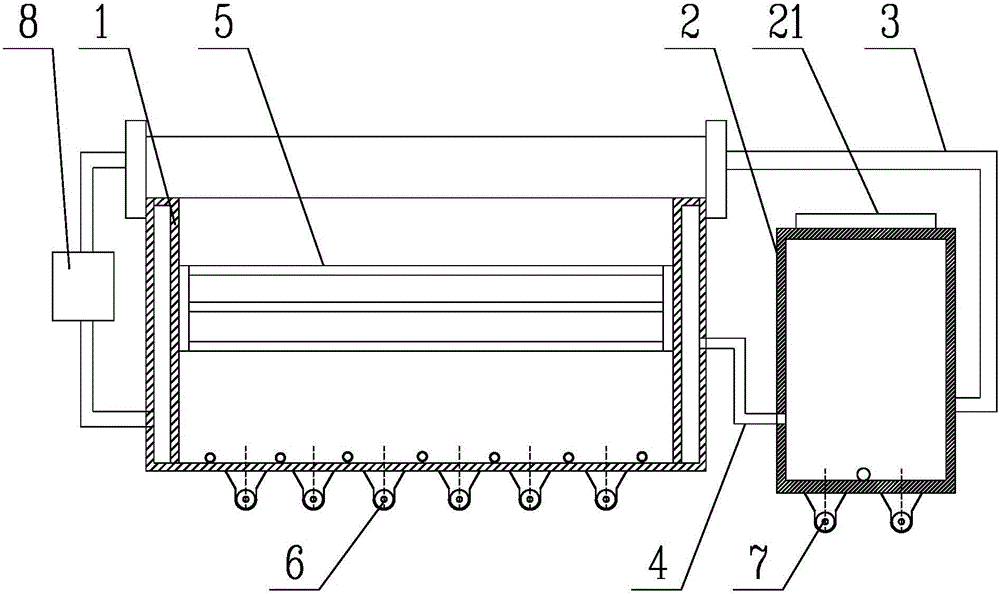

High-efficient and energy-saving aluminum rod mixing heating furnace

ActiveCN104596283AImprove heating efficiencyRetain performanceFurnace typesPreheating chargesHeating timeHeat losses

The invention discloses a high-efficient and energy-saving aluminum rod mixing heating furnace applied to the aluminum extrusion process. The heating furnace comprises a single-rod furnace and a multi-rod furnace which is integrated with the single-rod furnace. The single-rod furnace comprises a first furnace body, a heating zone arranged in the first furnace body, and spray guns which are used for heating the single-rod furnace and are respectively arranged on the upper part and lower part of the first furnace body. The multi-rod furnace comprises a second furnace body which is arranged on one side of the first furnace body and integrated with the first furnace body, and a preheating zone which is in communication with the heating zone and is arranged in the second furnace body. The first furnace body and the second furnace body are provided with a pipe body which is used for communicating the heating zone with the preheating zone, and the pipe body is provided with a pressure sensor. The high-efficient and energy-saving aluminum rod mixing heating furnace has the advantages that the energy is saved, the heat loss is small, the preheating time is short, the heating efficiency of aluminum rods is high, the daily maintenance and repairing are applicable, and the effect that the aluminum rods are in gradient heating is realized.

Owner:佛山市法比澳挤压机械科技有限公司

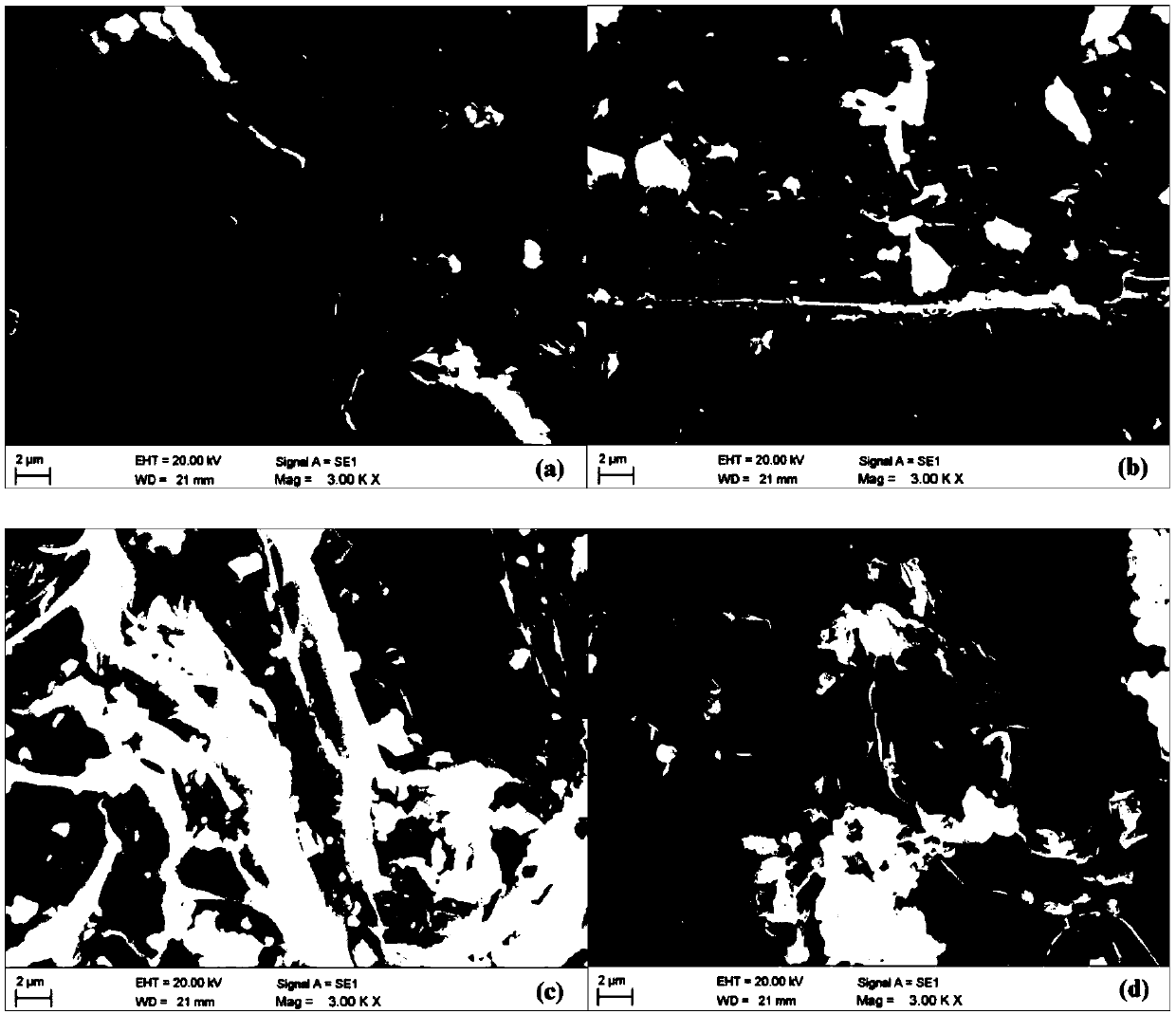

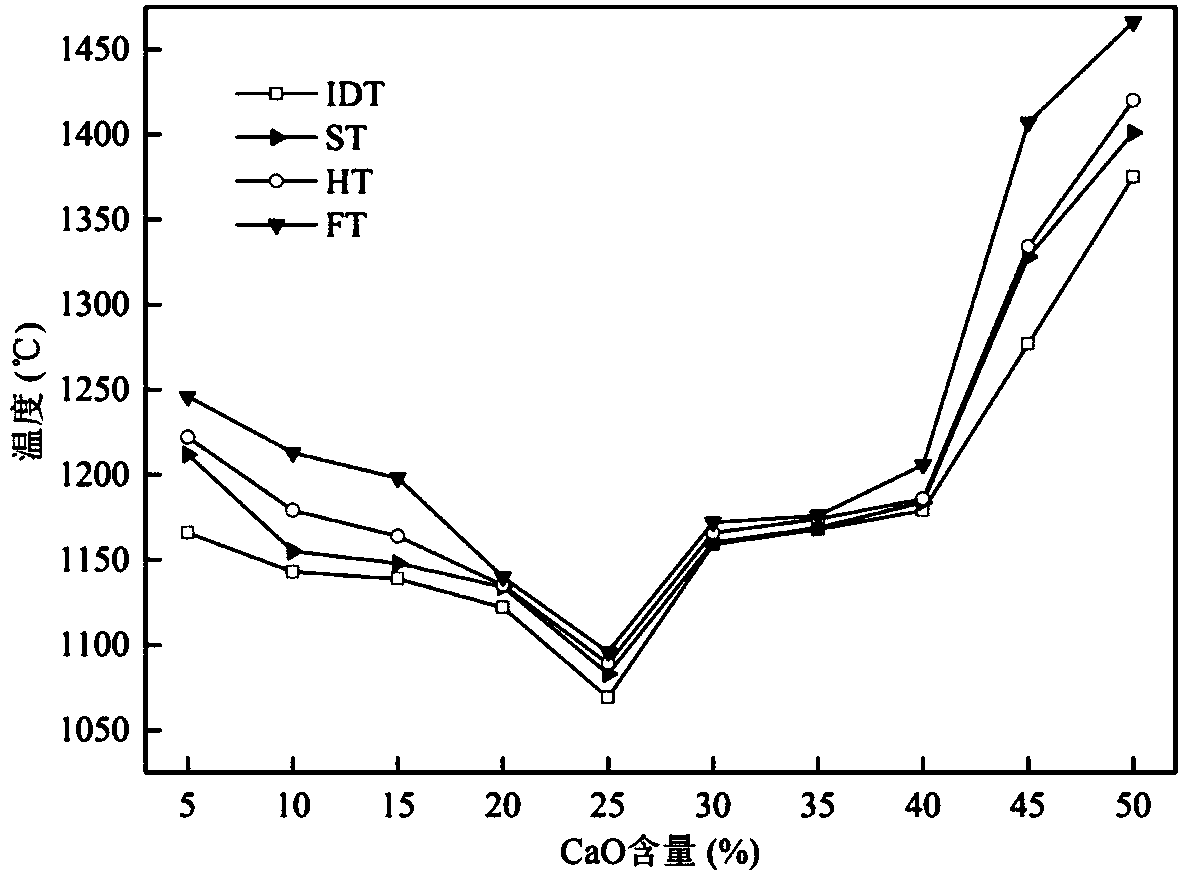

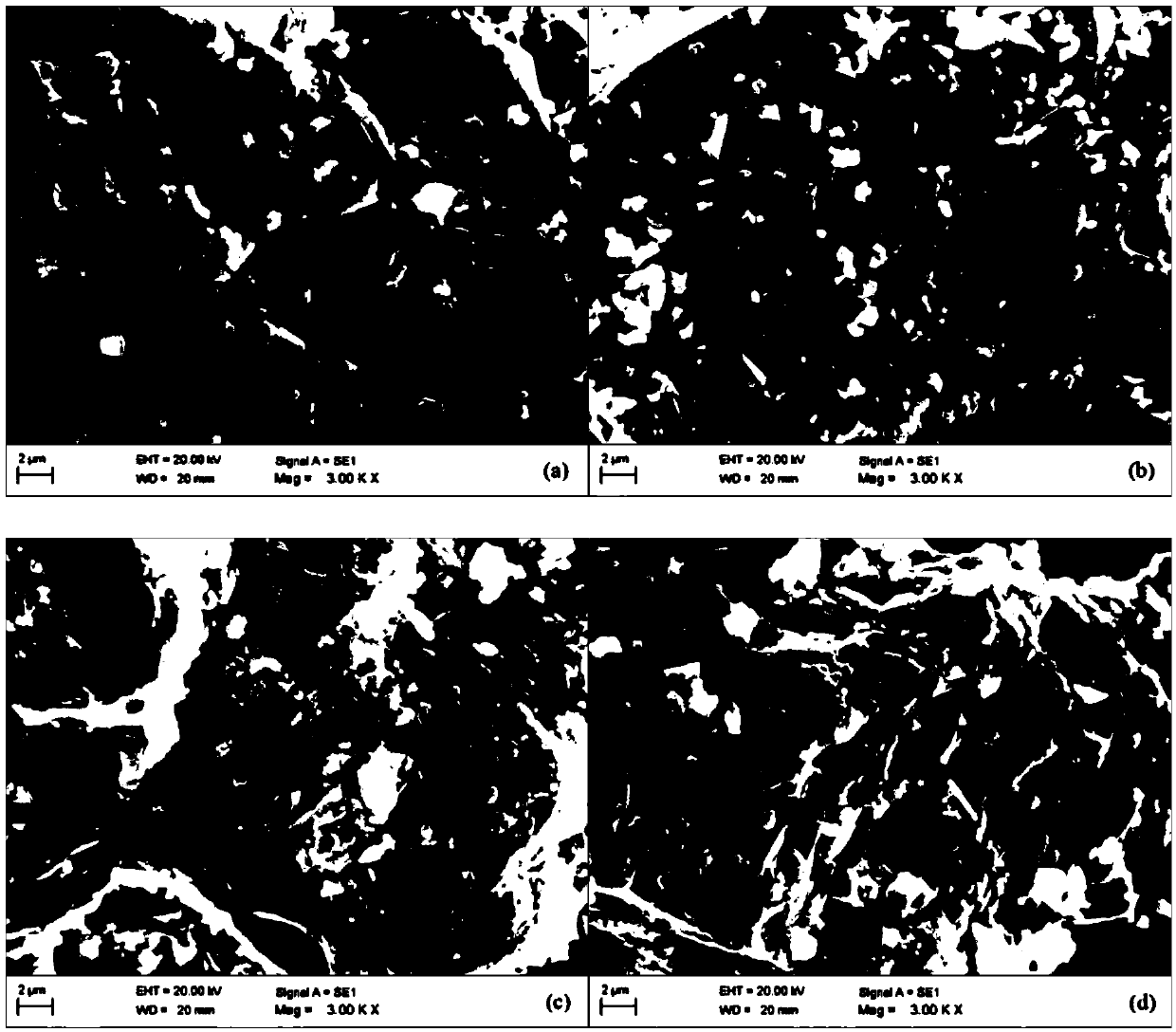

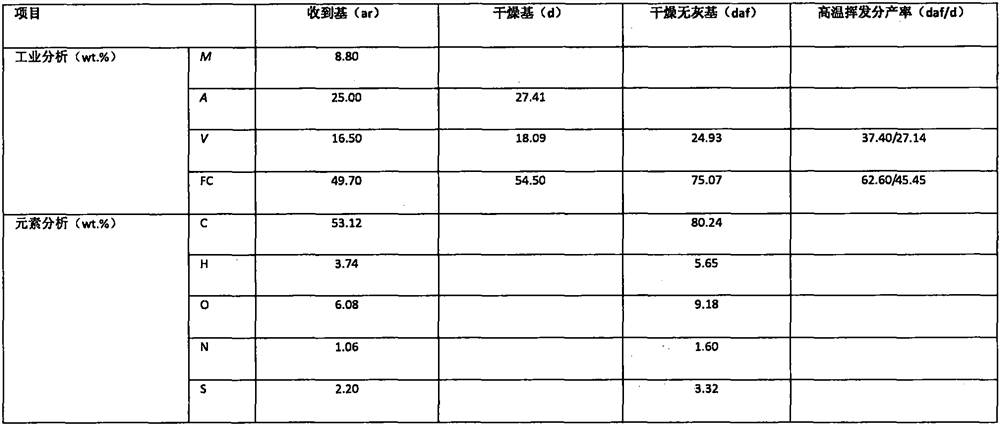

Calcium and magnesium additive for improving coal slagging performance and application

PendingCN108676601AHigh melting pointImprove slagging characteristicsSolid fuelsFuel additivesSlagToxic industrial waste

The invention discloses a calcium and magnesium additive for improving the coal slagging performance and application, and belongs to the technical field of coal chemical industry. The calcium and magnesium additive is a mixture of carbide slag and magnesium-containing waste slag; when the addition amount of the calcium and magnesium additive is within a suitable range, the ash melting point can beincreased by 100-150 DEG C, and calcium oxide in the carbide slag is produced into calcium-containing aluminosilicate having a melting point higher than that of sodium aluminosilicate through a competitive reaction so as to increase the ash melting point and solve the slagging problem; meanwhile, calcium carbide in the carbide slag reacts with water in air to produce acetylene gas, so that a combustion-supporting effect is achieved and flameout of a hearth is avoided; magnesium oxide in the magnesium-containing waste slag reduces the viscosity and avoids large slag formation in a boiler through prevention of aggregation of a polymer; the used carbide slag and the used magnesium-containing waste slag are industrial wastes, and the purchase cost thereof is much lower than that of kaolin, diatomite and bauxite, so that low-cost improvement on the slagging performance can be achieved, and thus the operating cost of a power plant is greatly reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

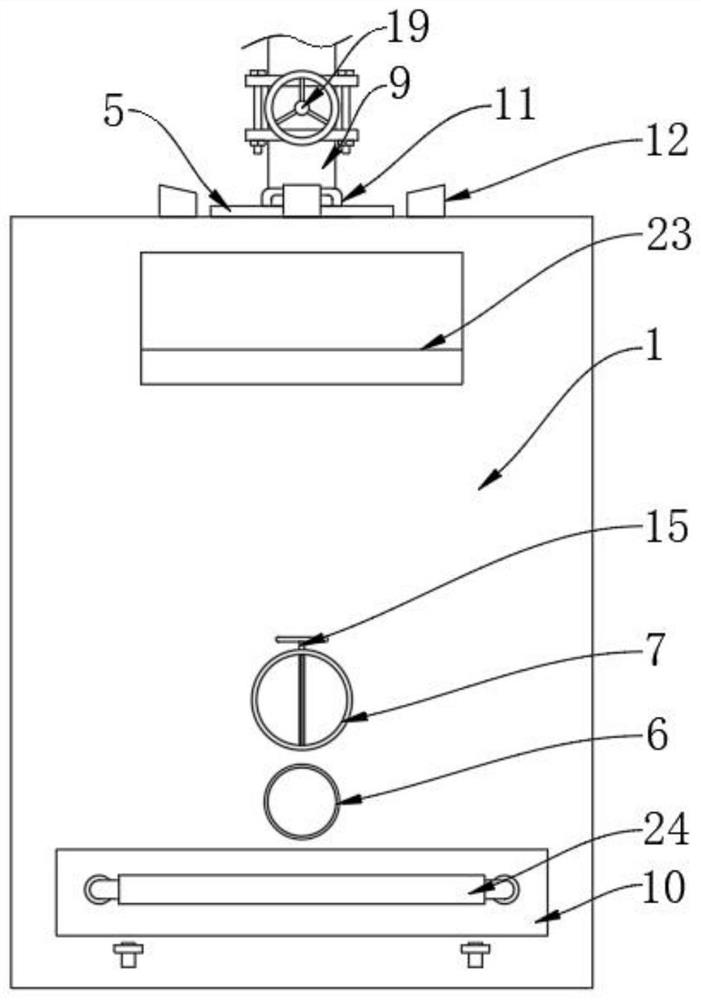

Vibration type furnace chamber garbage incinerator

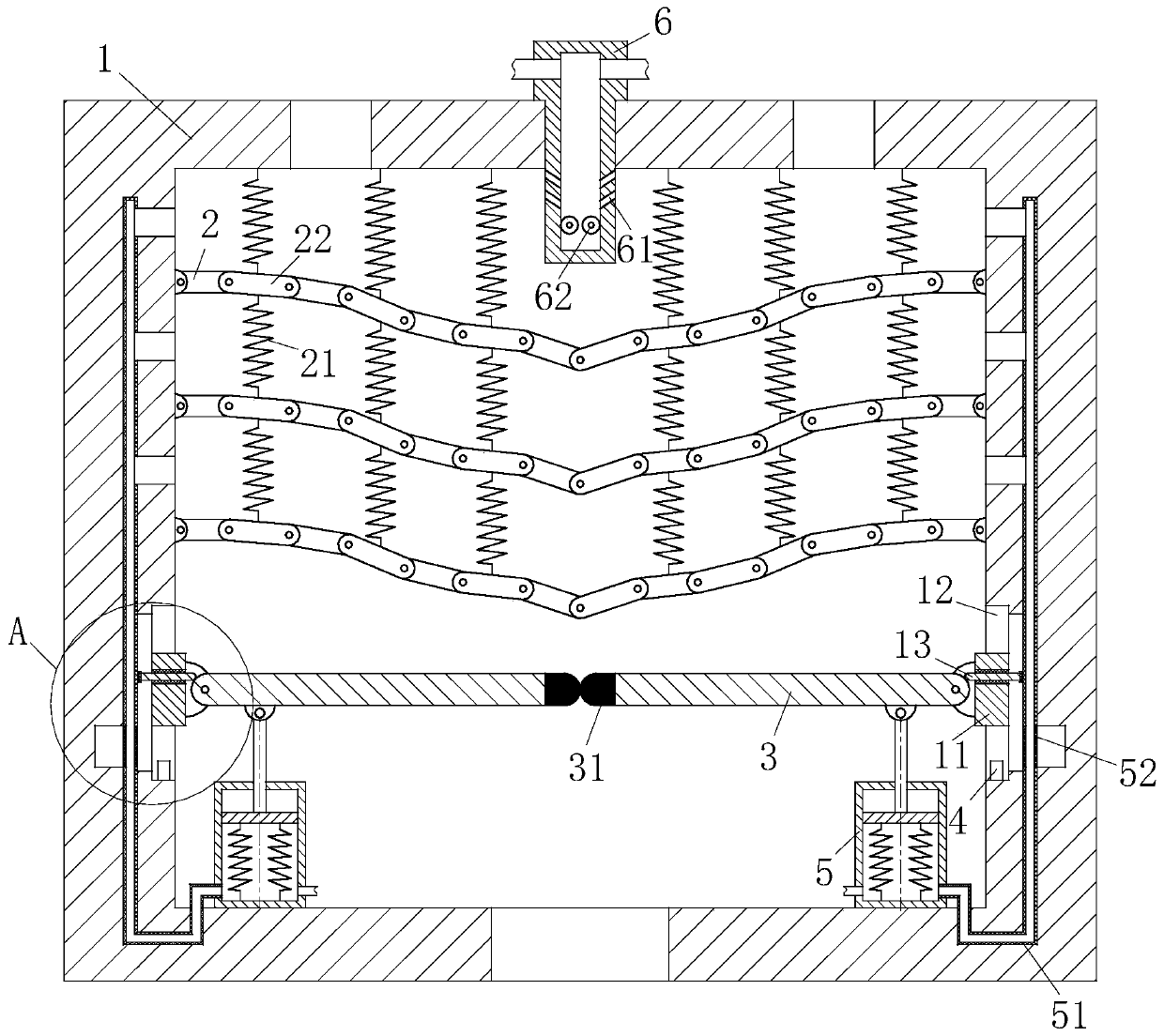

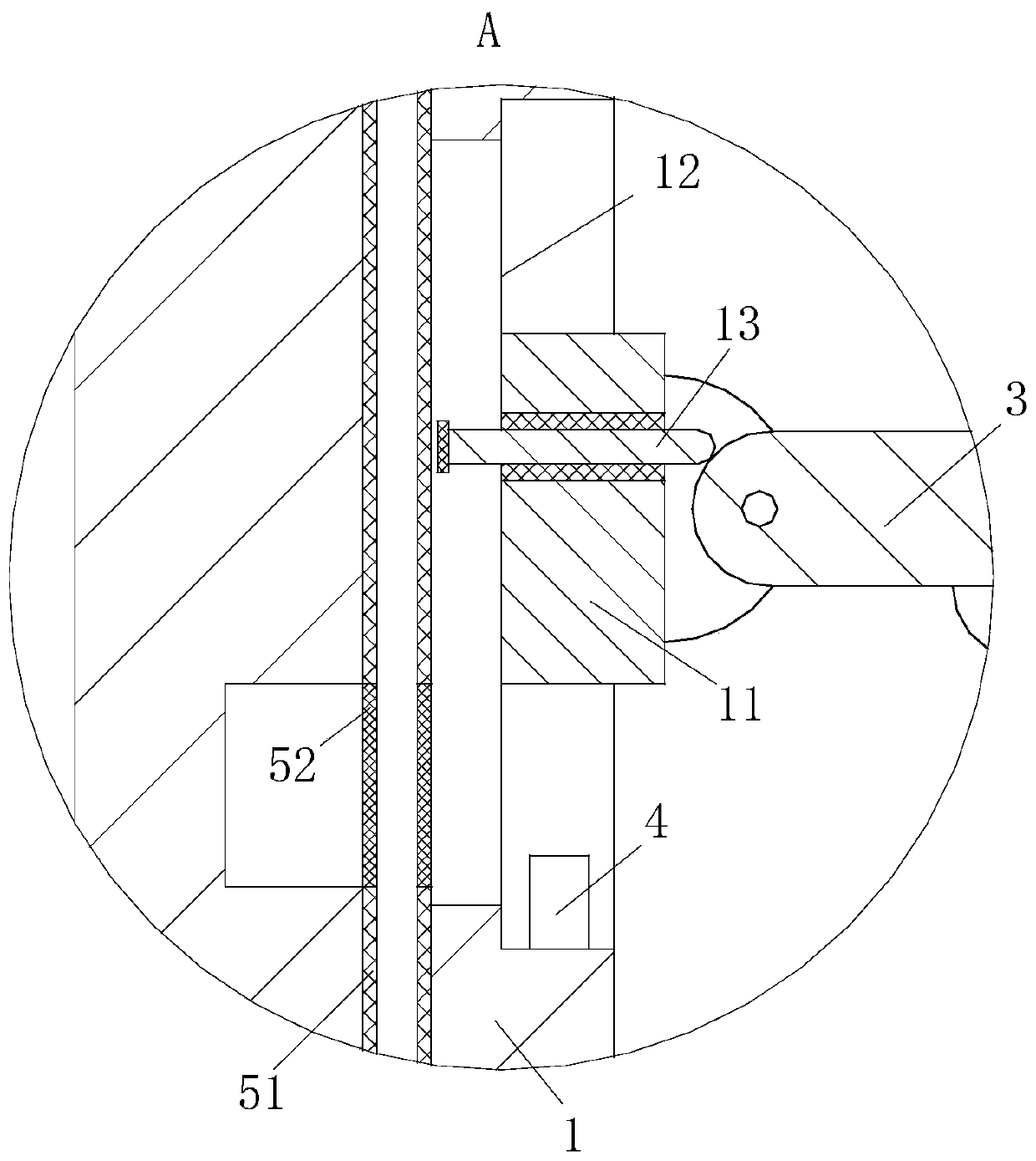

The invention belongs to the technical field of garbage incinerators, and particularly relates to a vibration type furnace chamber garbage incinerator. The vibration type furnace chamber garbage incinerator comprises a furnace body, a plurality of fire grates are arranged above the furnace body, combustion-supporting springs are among the fire grates, and combustion-supporting blocks are arrangedon the combustion-supporting springs; sliding grooves for mounting sliding blocks are symmetrically arranged on the left inner wall and the right inner wall of the furnace body, sealing plates are correspondingly hinged to the opposite ends of the sliding blocks, electromagnets are arranged at the end parts of the sealing plates, and travel switches are arranged at the lower ends of the sliding grooves; and the lower surfaces of the sealing plates are hinged to piston rods of two air cylinders which are symmetrically arranged on a bottom plate of the furnace body left and right, springs are arranged between pistons of the air cylinders and inner bottom plates of the air cylinders, air outlets of the air cylinders are connected with air outlet pipes, the upper ends of the air outlet pipes penetrate into the furnace wall of the furnace body and communicate with cavities formed among the fire grates through a channel formed above the furnace body, the air outlets of the air cylinders areprovided with one-way valves with a one-way air outlet function, air inlets of the air cylinders are provided with one-way valves with a one-way air inlet function, the air inlets of the air cylindersare connected through air inlet pipes, and the other ends of the air inlet pipes are positioned at the top of the furnace body.

Owner:徐海军

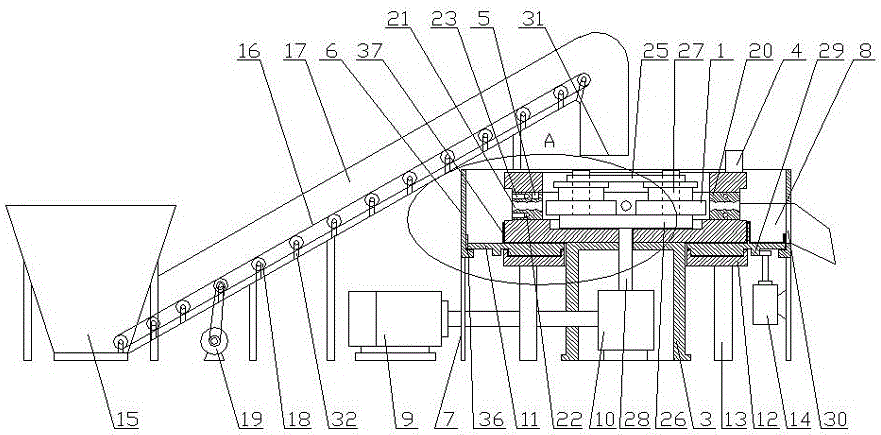

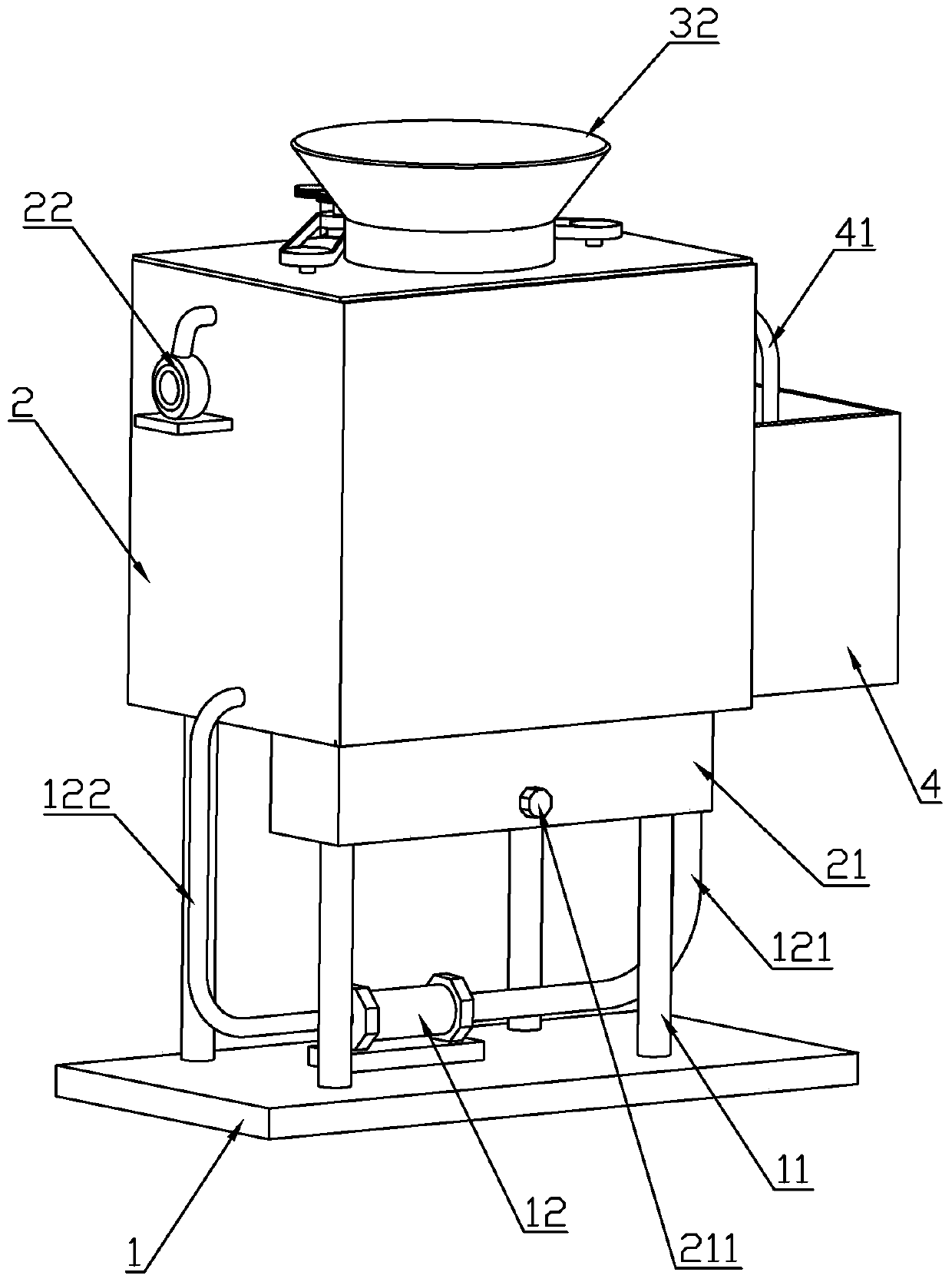

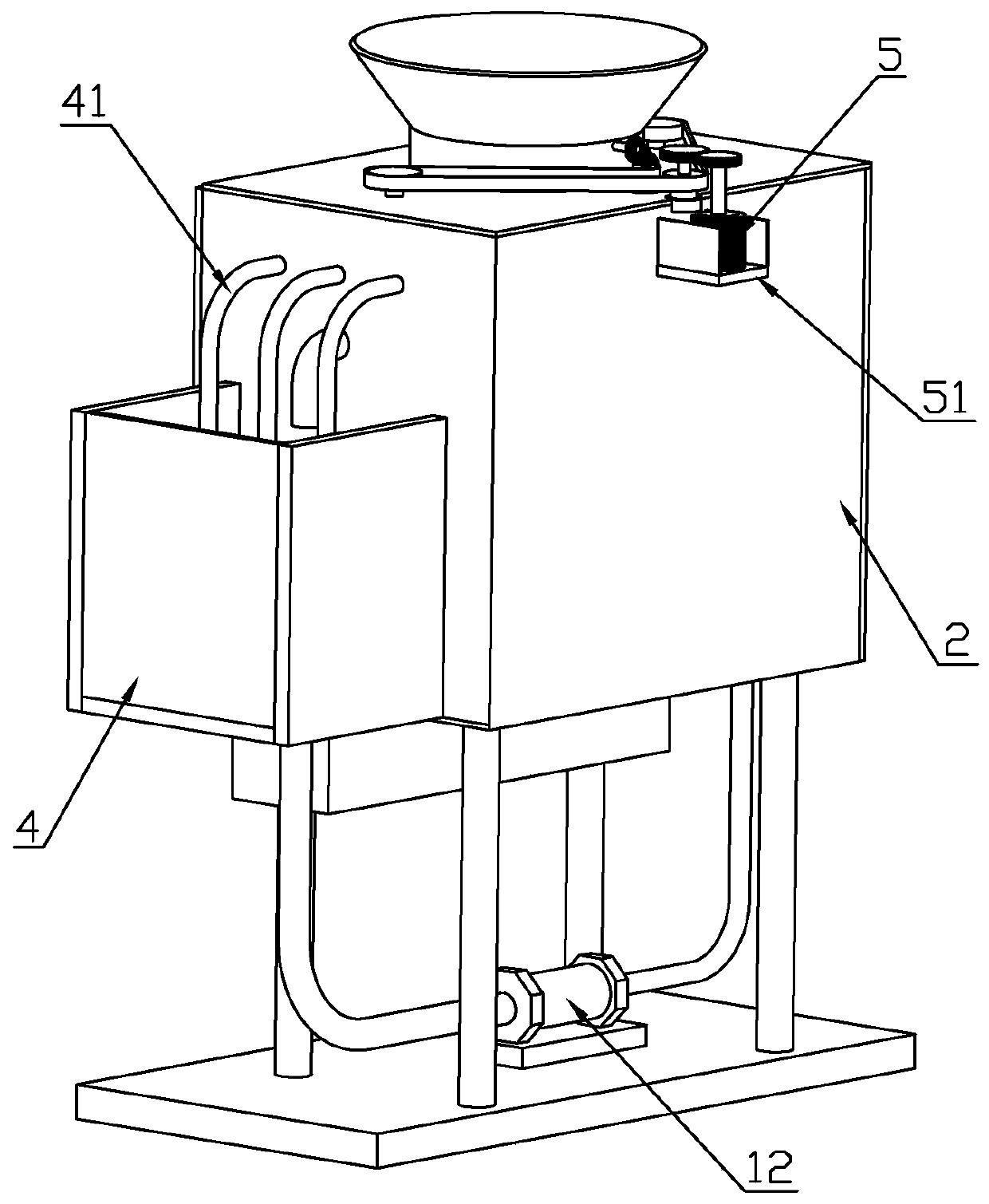

Device and method for preparing rice hull forming and briquetting fuel

InactiveCN106393782AGood molding effectIncrease the calorific value of combustionBiofuelsSolid fuelsCombustionWater channel

The invention discloses a device for preparing rice hull forming and briquetting fuel. An extrusion bin is fixedly mounted on a base. A heater is mounted on the extrusion bin. An annular press mold is arranged in the middle of the extrusion bin and provided with a circle of forming holes in row. The forming holes are in a corrugate shape. Water channels are arranged on the upper portion and the lower portion of the annular press mold correspondingly. A water inlet and a water outlet which communicate with the water channels are formed in the annular press mold. A temperature sensor is mounted in the annular press mold. Paired fixed plates comprise the upper fixed plate and the lower fixed plate. The lower fixed plate is movably mounted in the extrusion bin and provided with paired supporting rods. A method for preparing the rice hull forming and briquetting fuel comprises the following steps of a, raw material treatment, b, feeding, c, extruding forming, d, cooling and e, packaging. The device and method have the beneficial effects that the rice hull forming effect and the production efficiency are improved, rice hull combustion is facilitated, and great environment friendliness is achieved.

Owner:湖北铭鼎节能科技有限公司

Cutting torch for flame cleaning gun

InactiveCN102229016APlay a combustion-supporting effectLarge flame diameterGaseous fuel burnerGas flame welding apparatusEngineeringTorch

Owner:章丘市裕丰气割队

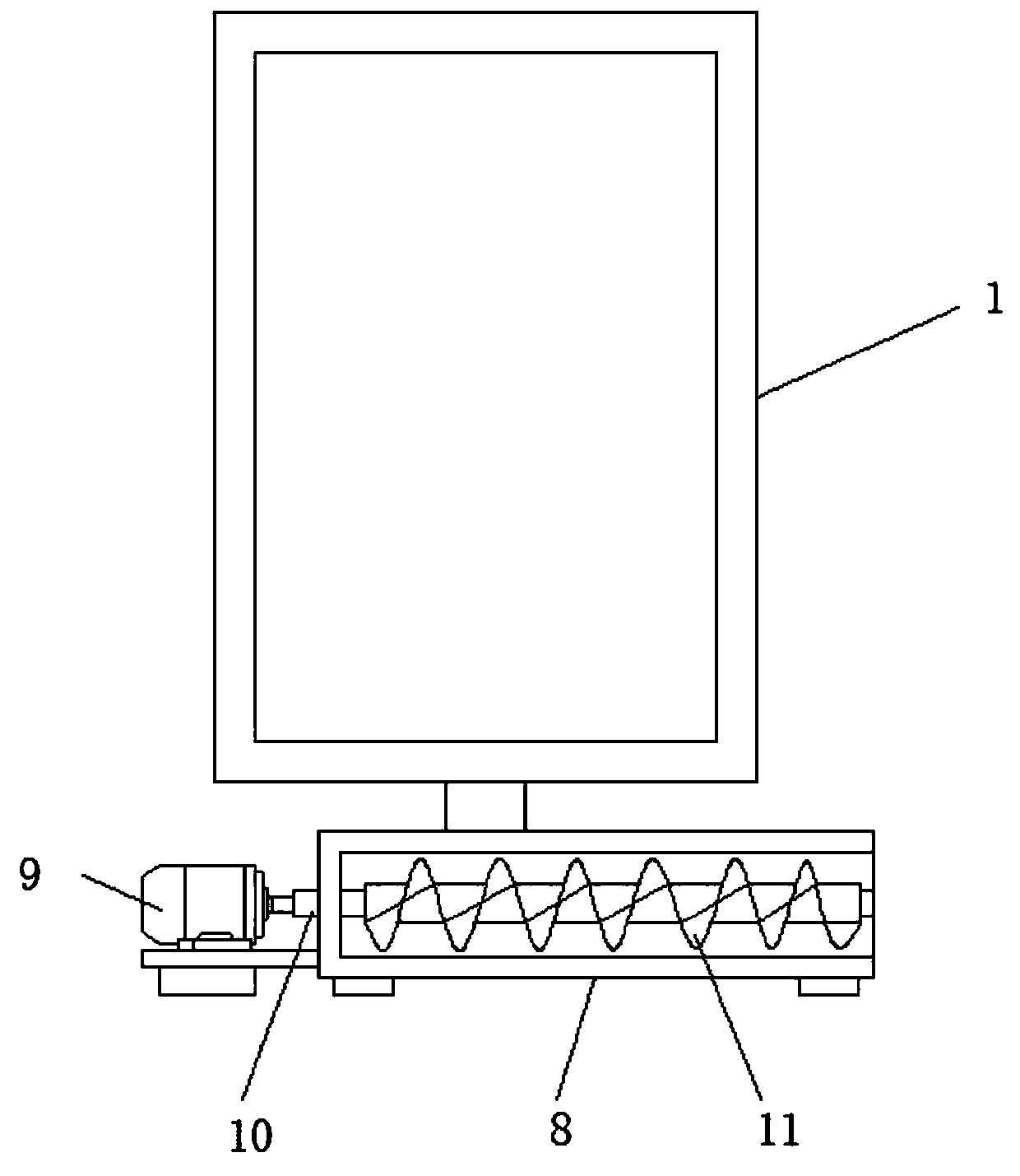

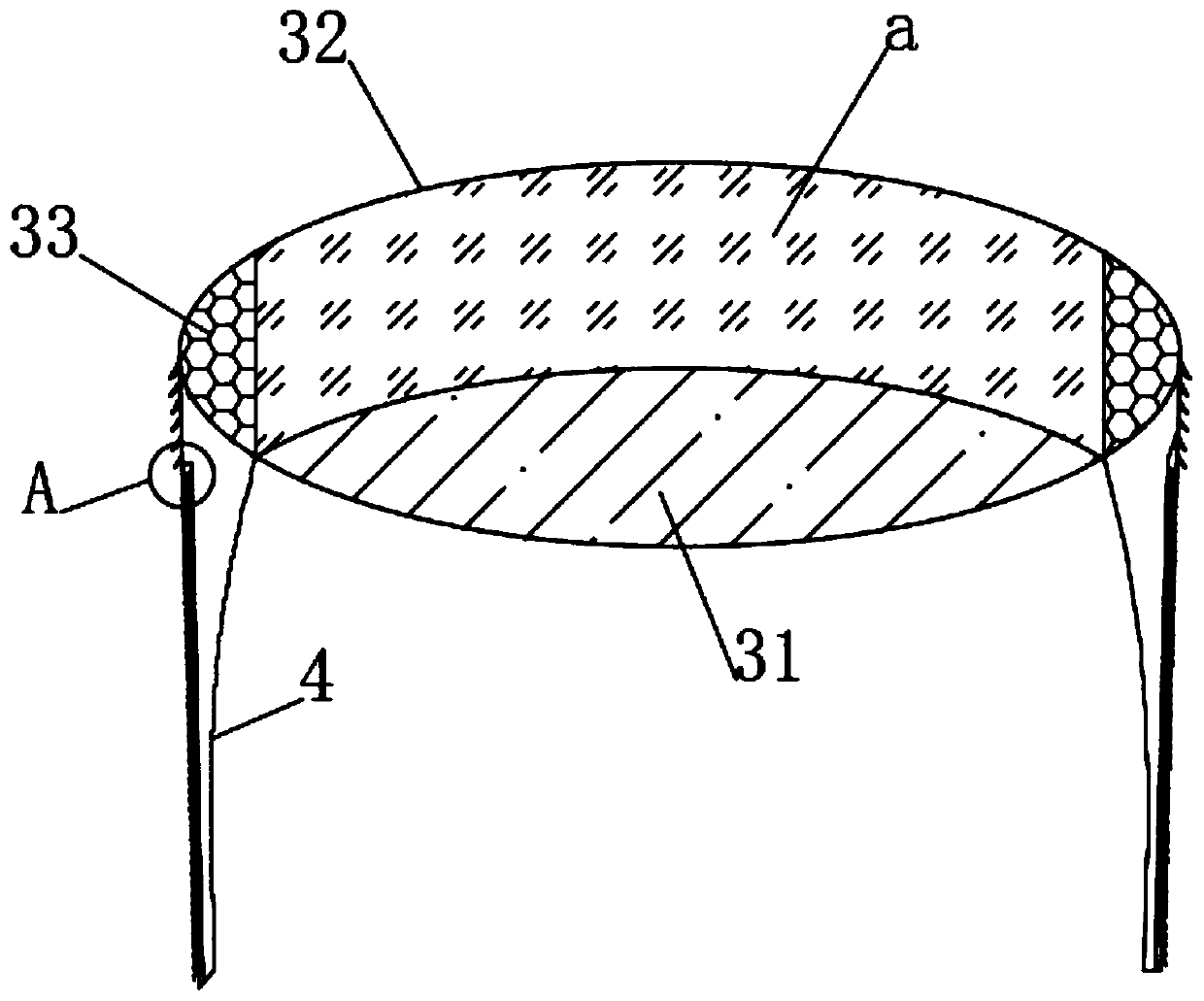

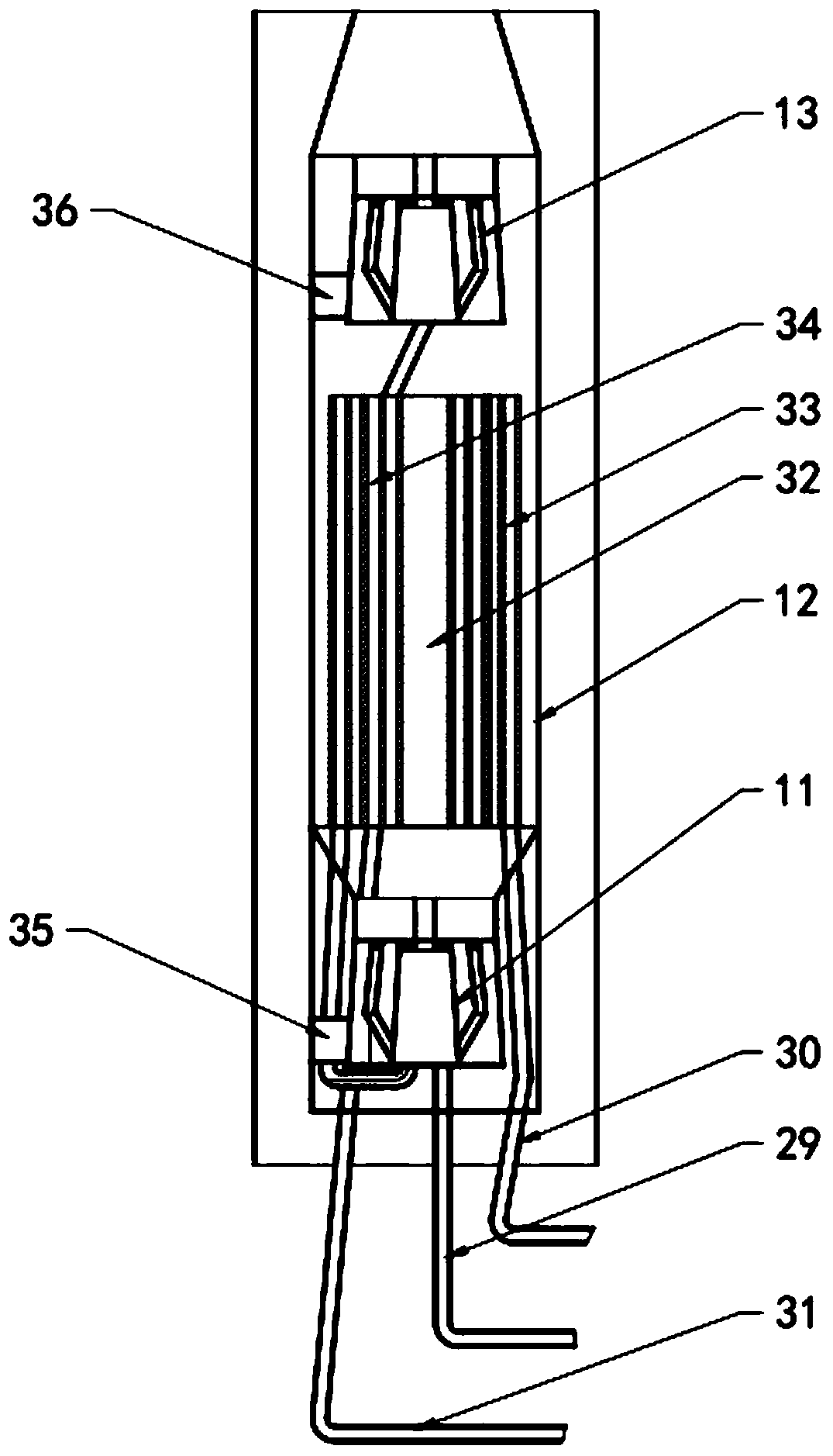

Biomass forming fuel solid phase low temperature and gas phase high temperature combustion method and device

ActiveCN106949460ASolve cokingSolve slaggingSolid fuel combustionCombustion apparatusGas phasePollutant emissions

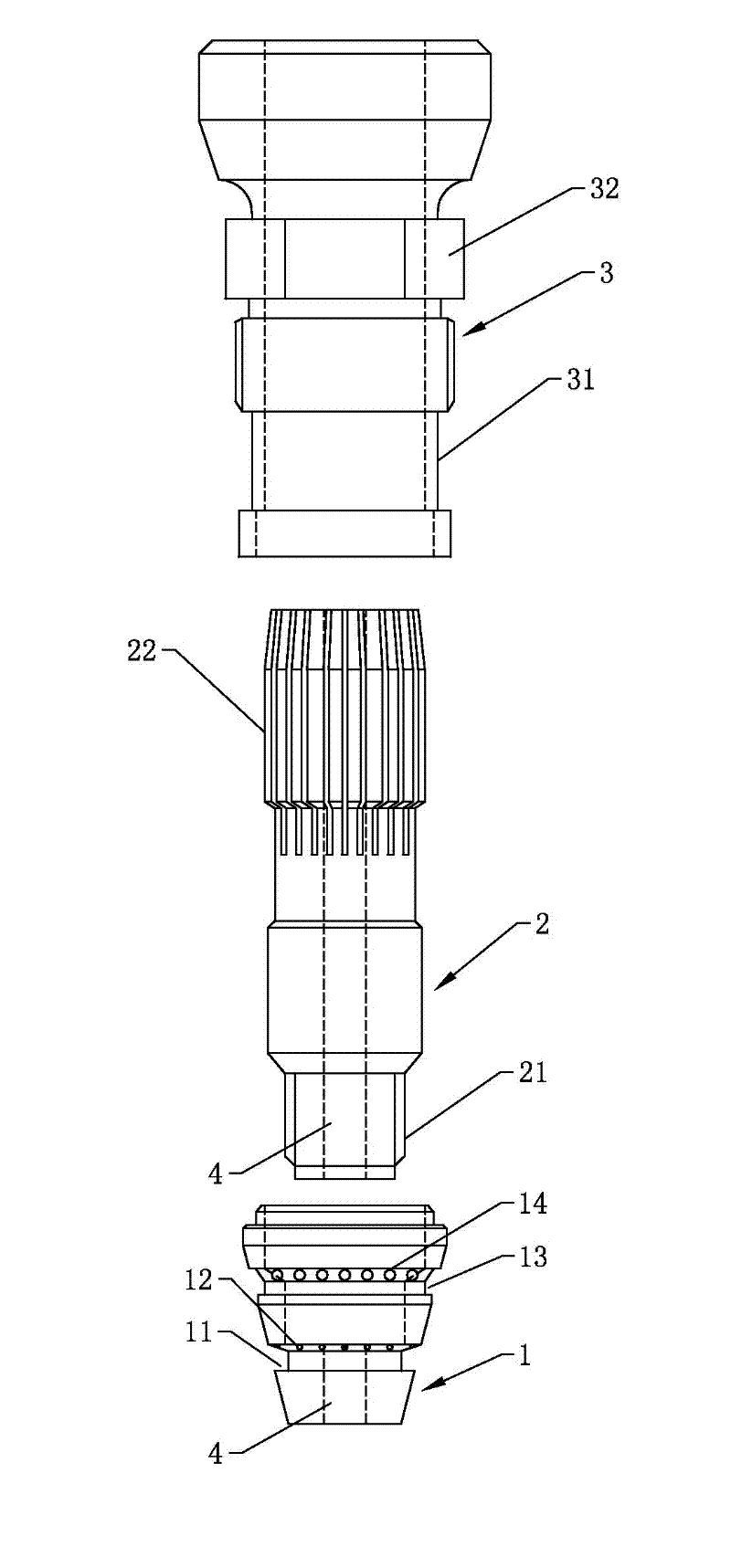

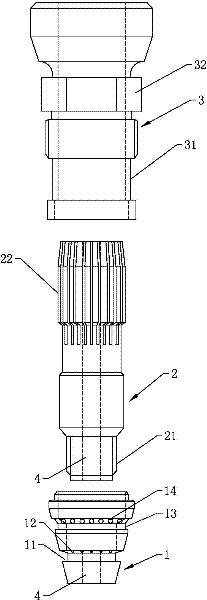

The invention provides a biomass forming fuel solid phase low temperature and gas phase high temperature combustion method and device and belongs to the technical field of biomass combustion. The biomass forming fuel solid phase low temperature and gas phase high temperature combustion method is characterized by comprising the following steps that (1) biomass fuel is dried and pyrolyzed into coal, and gas produced by drying and pyrolyzing is combusted on the upper portion of the biomass fuel; (2) the pyrolyzed biomass fuel is crushed into coal powder with the particle size not larger than 3 mm and is accumulated; (3) the coal powder is smoldered into ash, the smoldering temperature is not higher than 650 DEG C, and incompletely-combusted gas produced by smoldering is transported to the upper portion of the biomass fuel to be combusted; and (4) the ash is discharged after being cooled. The biomass forming fuel solid phase low temperature and gas phase high temperature combustion method solves the problems that for combustion equipment of straw and other agricultural waste, coking and slagging occur, gas and solid pollutant emission is high, and ash fertilizers lose efficacy from the source. The biomass forming fuel solid phase low temperature and gas phase high temperature combustion device adapts to small and medium-sized combustion equipment.

Owner:SHANDONG UNIV OF TECH

Straw biomass combustion device

InactiveCN111550767ABurn fullyNo manual filling requiredGas treatmentDispersed particle filtrationProcess engineeringBiomass combustion

The invention discloses a straw biomass combustion device. The straw biomass combustion device comprises a device body, a flue and a feeding hopper, wherein the inner side wall of the device body is provided with a dust dropping net; the lower end of the device body is provided with a first electric motor; the flue is arranged at the right side of the device body; the flue communicates with a treatment barrel; the lower end of the feeding hopper communicates with a second conveying housing; the inner side wall of the feeding hopper is rotatably connected to a crushing roller; the rear end of the crushing roller is connected to fourth rotary shafts; the fourth rotary shafts penetrate through the inner rear side wall of the feeding hopper; the fourth rotary shafts are in engaged connection through a first gear and a second gear; the first gear is arranged on the fourth rotary shaft at the left side; and the fourth rotary shaft at the right side is connected to a fourth electric motor. According to the straw biomass combustion device disclosed by the invention, the first electric motor drives a stirring rod to stir the straw biomass fuels, so that the straw biomass fuels are combustedsufficiently to achieve combustion-supporting effect; and moreover, generated dust is prevented from being condensed, so that dust drops through the dust dropping net.

Owner:胡立宇

Environment-friendly waste incinerator

InactiveCN109899806AReduce incomplete combustionImprove permeabilityIncinerator apparatusDrive motorAir blower

The invention discloses an environment-friendly waste incinerator. The environment-friendly waste incinerator comprises a base plate, a heat insulated box, an incineration outer barrel, a cooling water tank and a driving motor. The base plate is flatly placed on the ground and used for stably supporting the device. The top side of the base plate is provided with a plurality of supporting columns.The top ends of the supporting columns are connected with the heat insulated box. The heat insulated box is of a double-layer structure and is internally provided with a heat insulation interlayer. One side of the heat insulated box is fixedly connected with the cooling water tank. The cooling water tank is used for containing cooling water. The top end of the incineration outer barrel is connected with a transition barrel. The incineration outer barrel is rotatably connected with the transition barrel. The transition barrel penetrates through the heat insulated box in a sealed mode. The top end of the transition barrel is fixedly connected with a feed port. An air blower I is arranged on one side of the heat insulated box. The air blower I is connected with an air pipe I. The air pipe I extends into the heat insulated box in a sealed mode. The environment-friendly waste incinerator is reasonable in structure, facilitates thorough incineration on waste and can filter waste gas.

Owner:刘妍

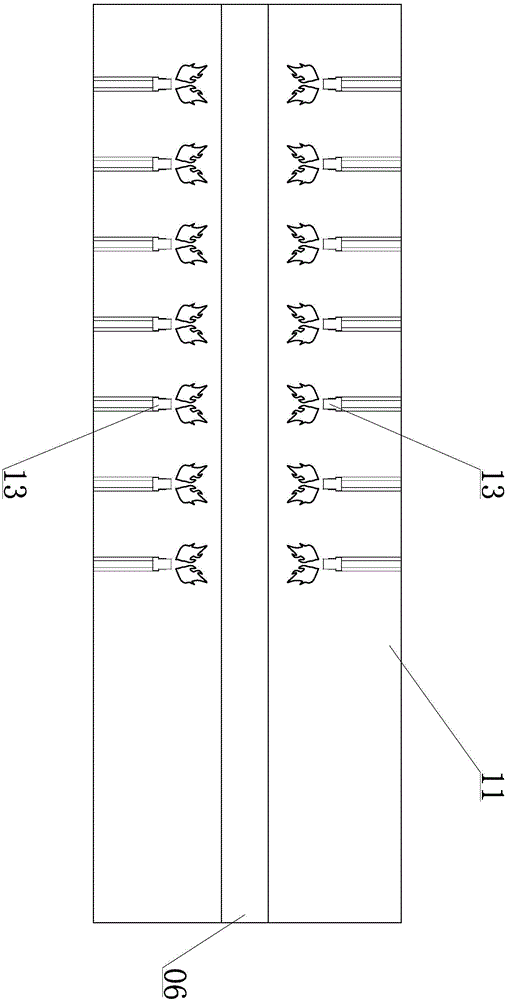

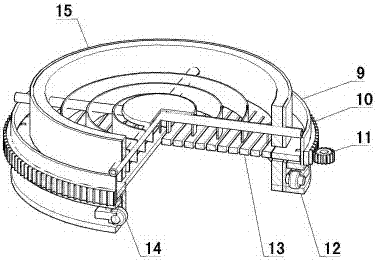

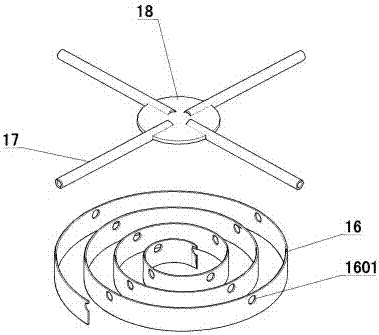

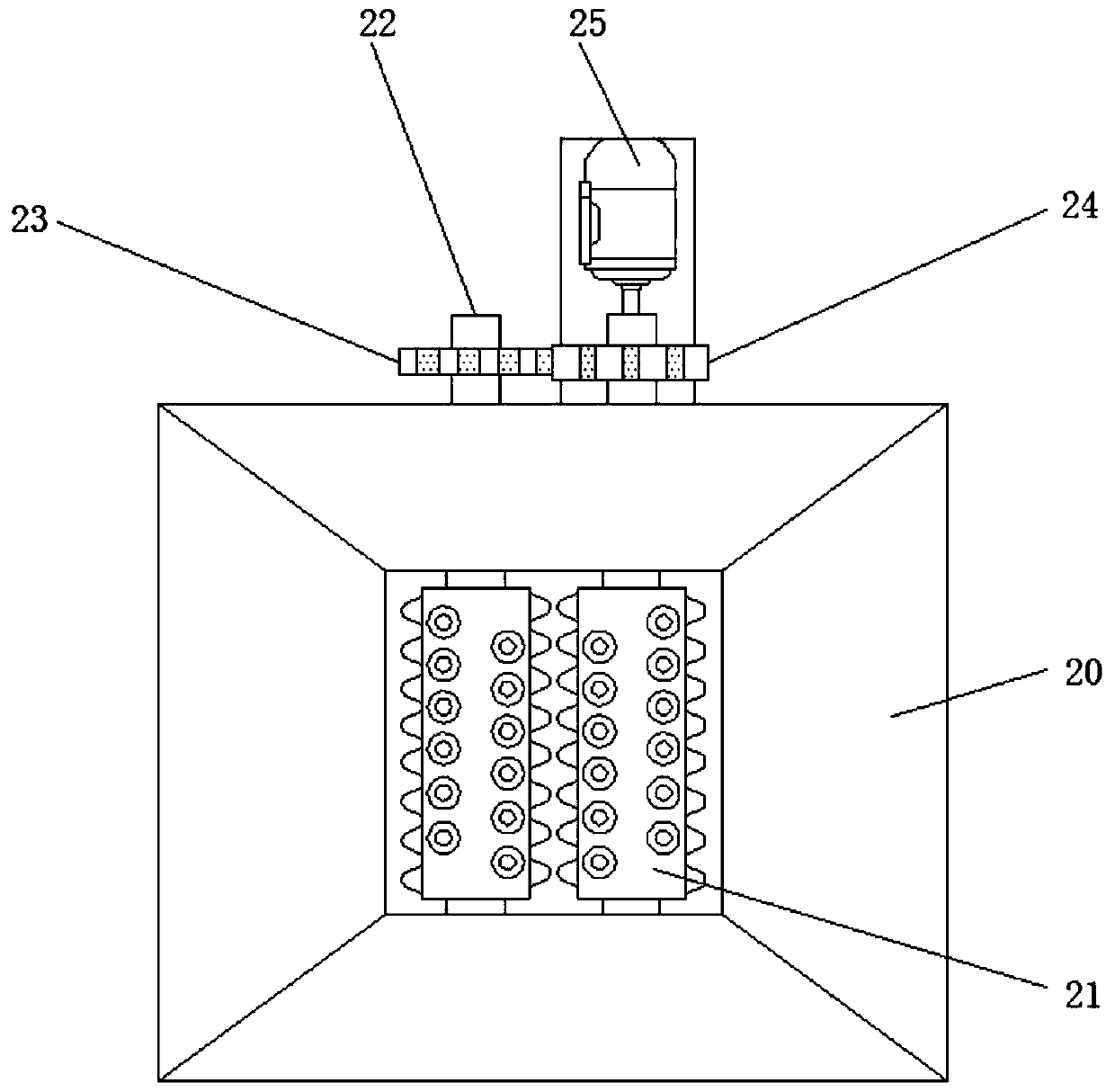

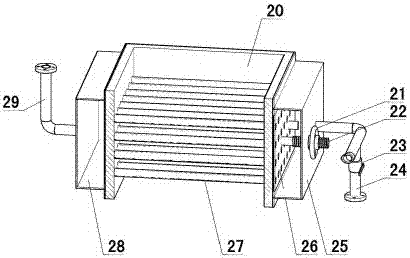

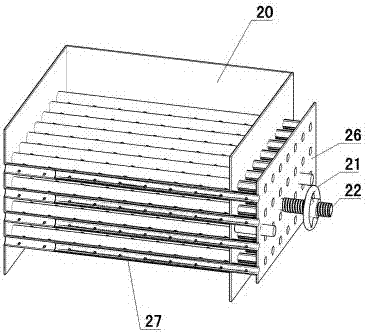

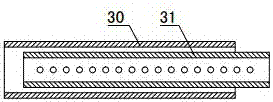

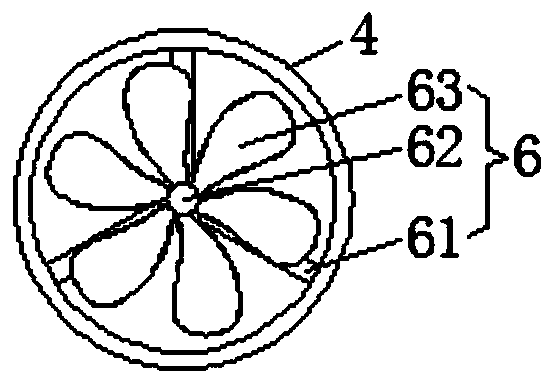

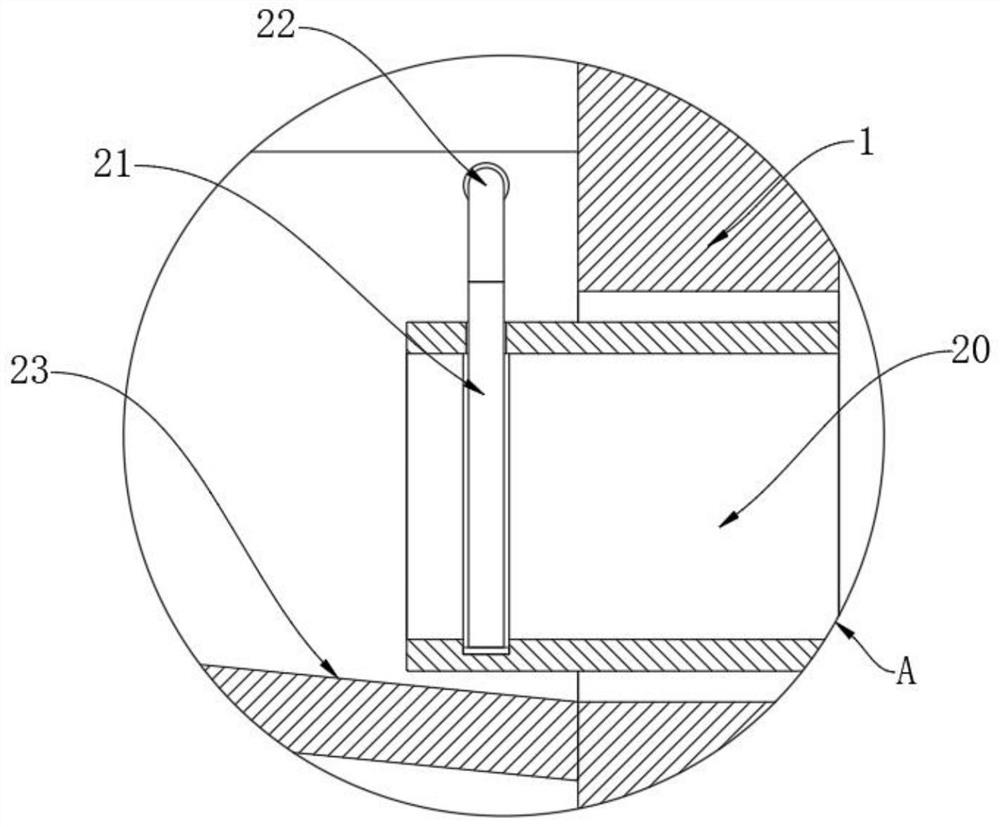

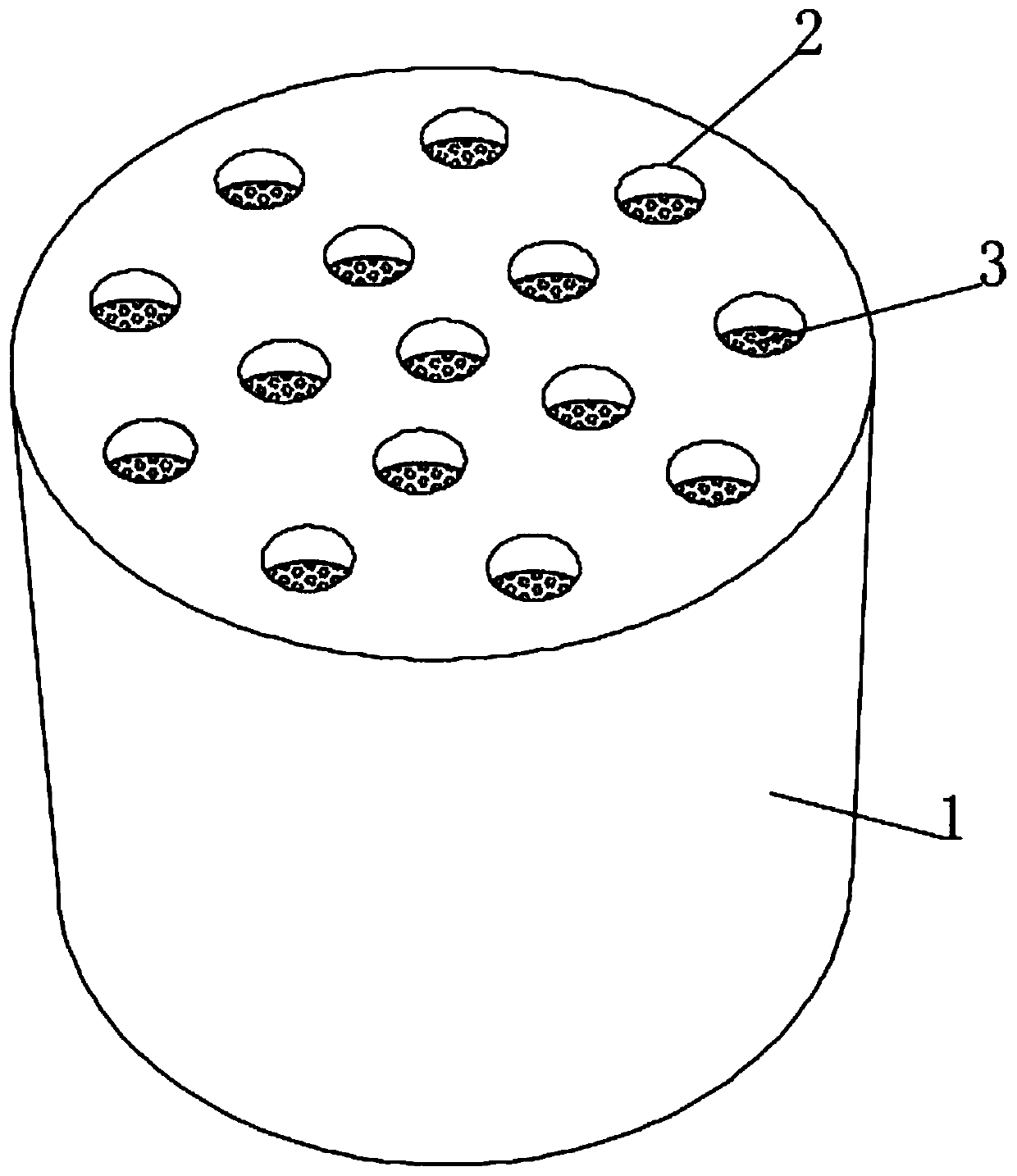

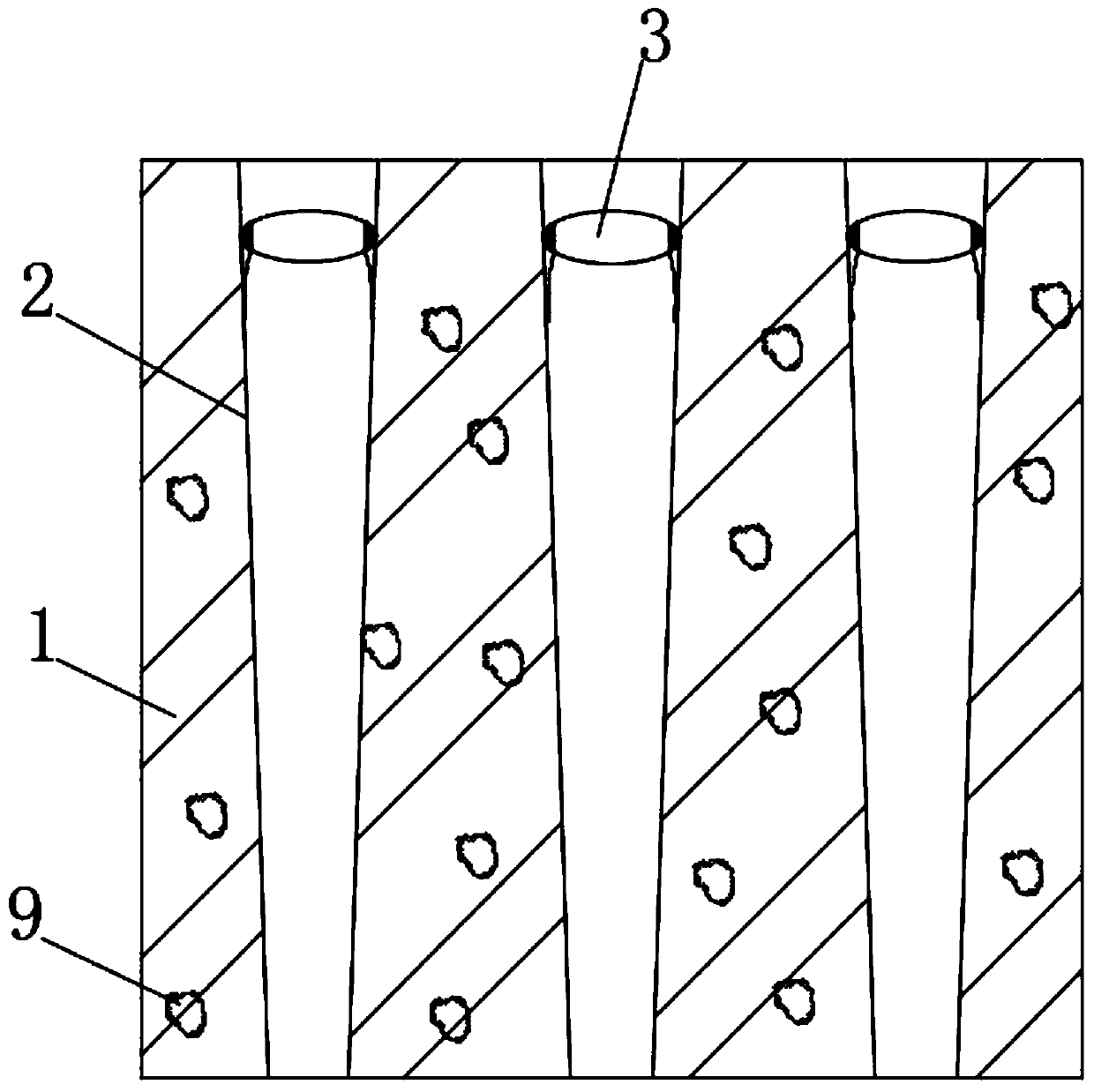

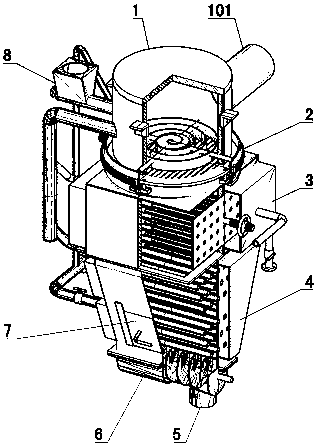

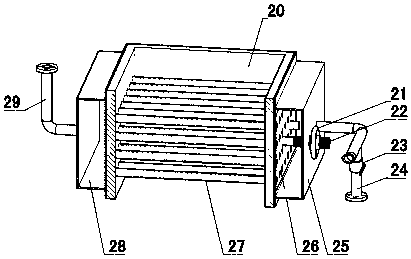

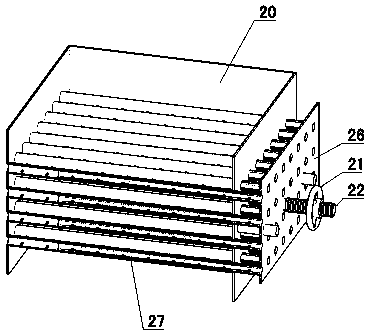

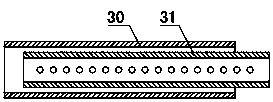

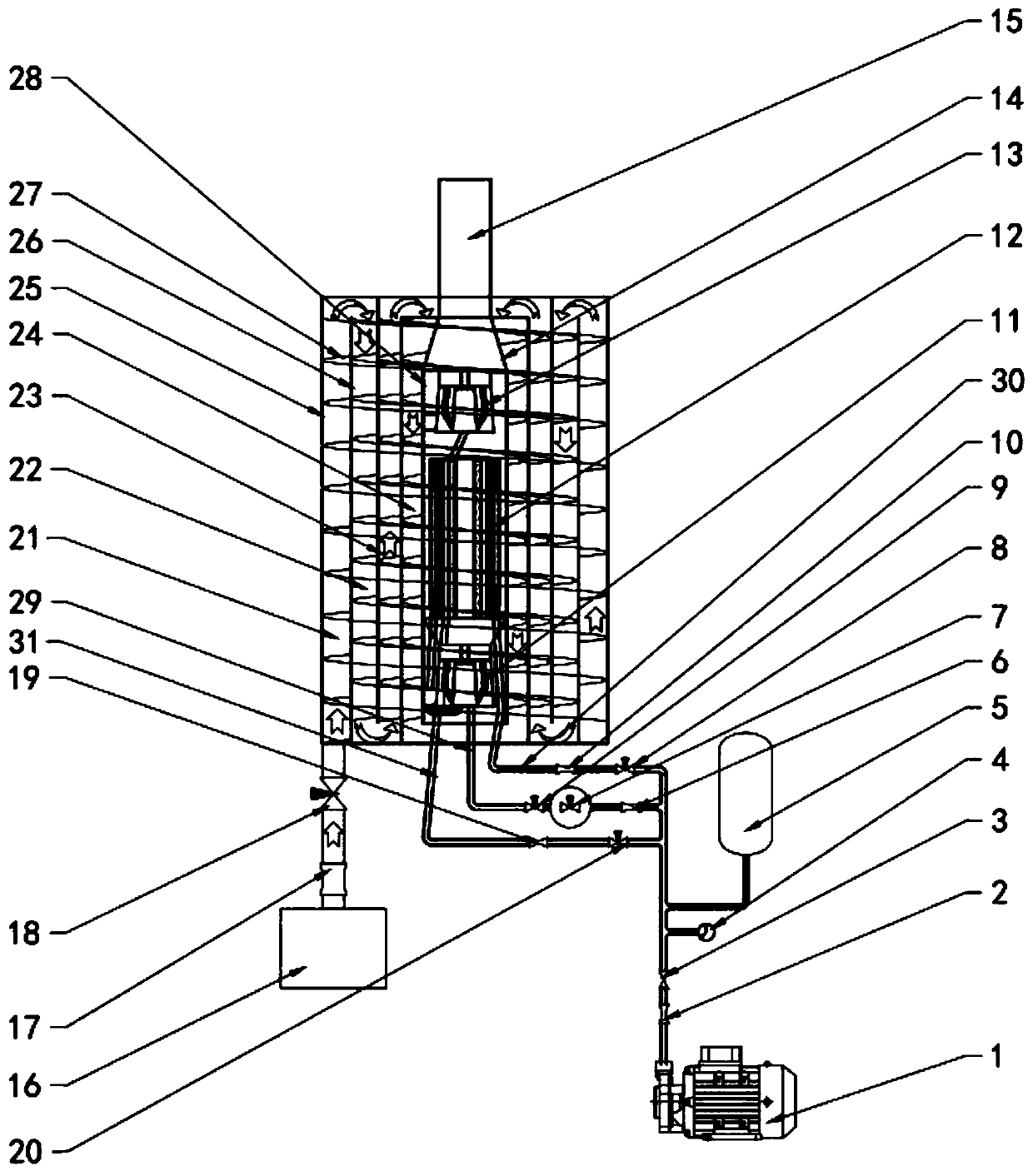

Powdered carbon quick low-temperature combustion smoldering device of biomass briquette combustion device

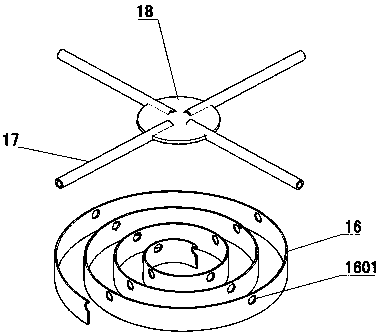

ActiveCN106895436AReduce the temperatureAvoid cokingAir supply regulationFuel feeding arrangementsAir volumePotassium

The invention discloses a powdered carbon quick low-temperature combustion smoldering device of a biomass briquette combustion device, and belongs to the technical field of biomass combustion. The powdered carbon quick low-temperature combustion smoldering device is characterized in that the two ends of air inlet pipes (27) communicate with the outer side of a smoldering pool (20); air outlets are formed in the pipe walls of the air inlet pipes (27); flowing air is introduced into the air inlet pipes (27) to cool the smoldering pool (20); a part of air in the air inlet pipes (27) enters the smoldering pool (20) to assist combustion; the air inlet pipes (27) are further connected with an air volume adjusting unit used for adjusting the flow velocity of cooling air; a combustion assistance adjusting mechanism is connected with the air inlet pipes (27); and the combustion assistance adjusting mechanism cooperates with the air volume adjusting unit to adjust the volume of combustion-supporting air entering the smoldering pool (20). According to the powdered carbon quick low-temperature combustion smoldering device of the biomass briquette combustion device, coking and slagging of fuel and volatilization of potassium, sodium and chloride elements are avoided, problems of gas and solid pollutant emission and equipment sticky dirt due to straw combustion are radically reduced, and ash can be directly utilized in farmland fertilizers.

Owner:SHANDONG UNIV OF TECH

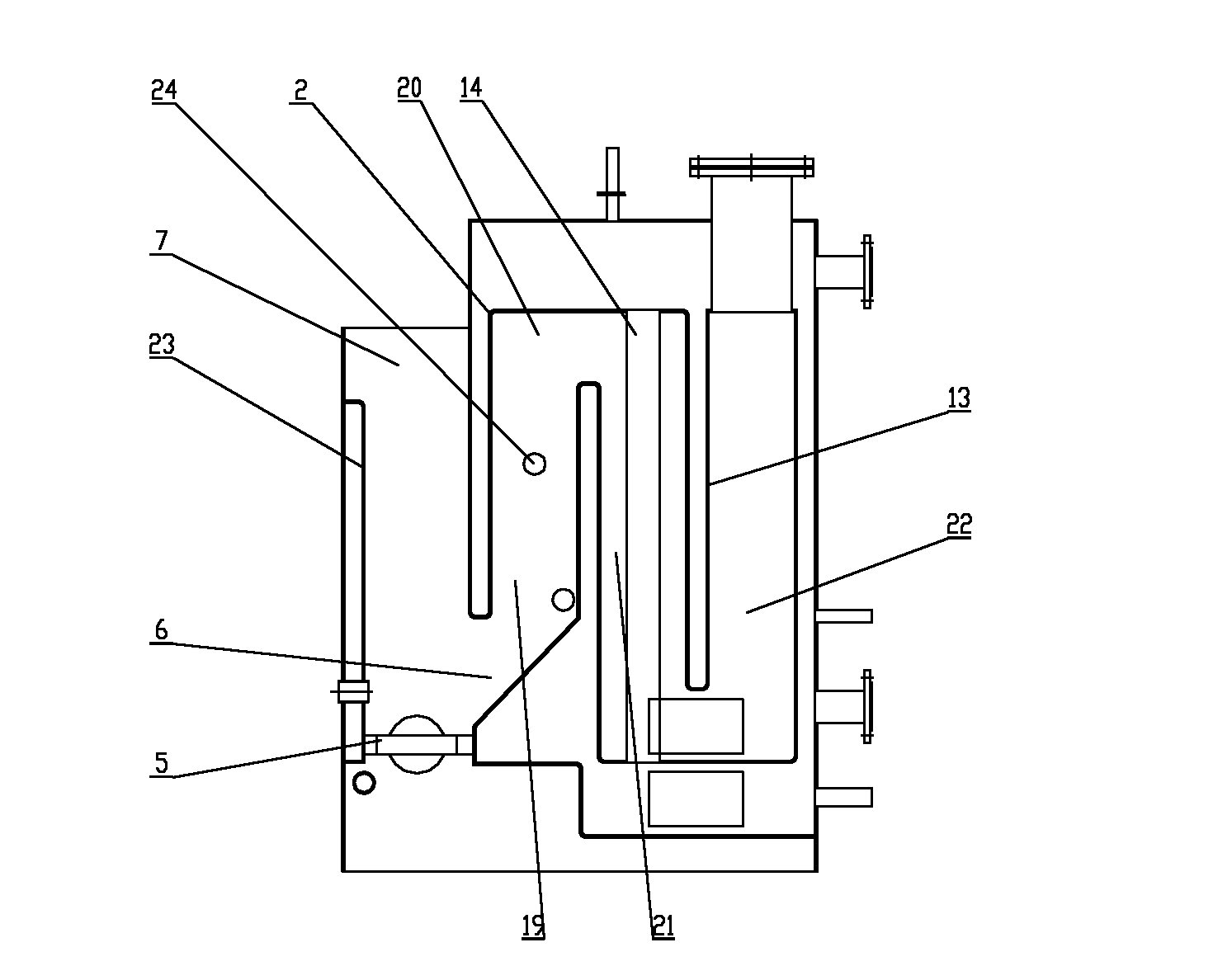

Oil atomization nozzle capable of improving combustion efficiency and fire burning furnace utilizing oil atomization nozzle

InactiveCN109974022APrecise supply controlImprove combustion efficiencyFuel supply regulationLiquid fuel feeder/distributionCombustionFuel efficiency

The invention discloses an oil atomization nozzle capable of improving the combustion efficiency and a fire burning furnace. An oil conveying mechanism is arranged on the top of an oil atomizer body,an inner cavity is formed in the oil atomizer body, and the right side of the inner cavity is fixedly provided with an isolation block. The isolation block isolates the left side of the inner cavity,so that an oil chamber is formed, and the oil conveying mechanism communicates with the oil chamber. A bearing structure is arranged in the inner cavity, a needle valve is arranged in the oil chamber,the needle valve penetrates through the isolation block and is connected with the bearing structure, and the needle valve and the isolation block are in sliding connection. The position, located on the right side of the bearing structure, in the inner cavity is fixedly provided with an armature. The right side in the oil atomizer body and the armature are concentrically provided with an electromagnetic coil, and an electromagnet is formed through cooperation of the electromagnetic coil and the armature. The bottom of the inner side of the fire burning furnace is connected with the oil atomizer body through a columnar cover and a connecting structure. According to the purpose, the oil atomization nozzle capable of improving the combustion efficiency and the fire burning furnace utilizing the oil atomization nozzle are provided, and the advantages that supply control is accurate, and the fuel efficiency is high are achieved.

Owner:景德镇朝蓬生物能源技术股份有限公司

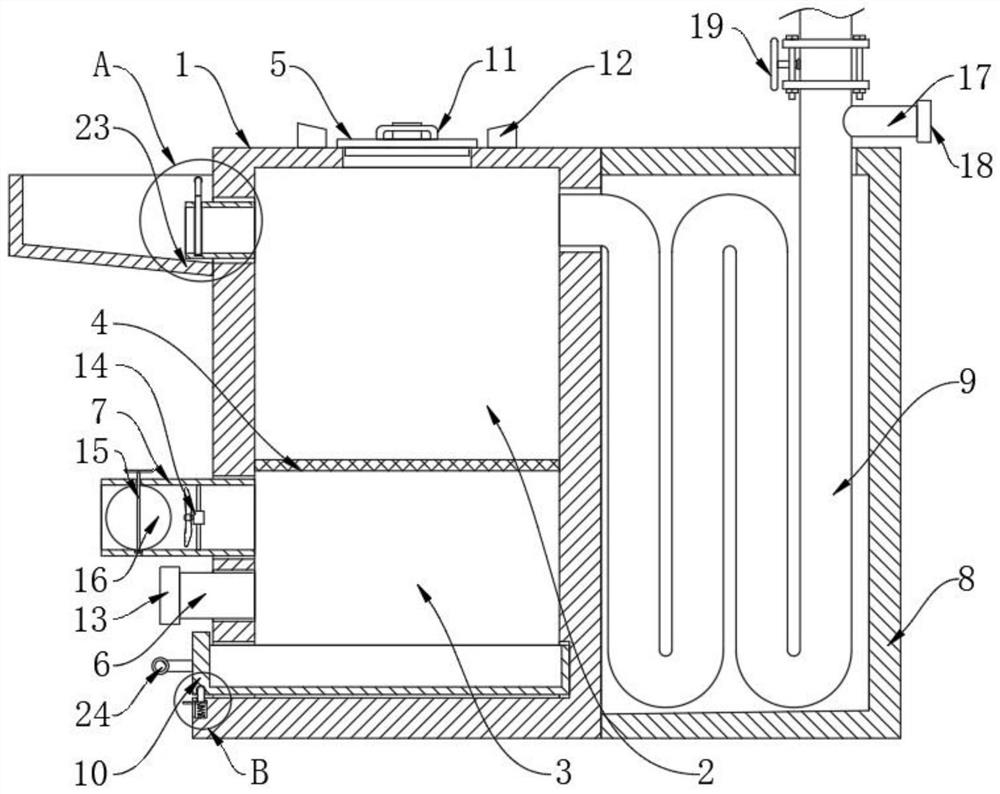

Electronic temperature-control constant temperature boiler for biomass fuel and coal

InactiveCN102384585AFire does not affectIf it catches fire, it will not be affected by feedingWater heatersCombustion chamberElectronic temperature

The invention relates to a boiler, in particular to an electronic temperature-control constant temperature boiler for biomass fuel and coal. The constant temperature boiler comprises a boiler housing, an inner tank, a furnace hearth and a smoke outlet, and is characterized in that a furnace grate, a combustion chamber and a material feeding bin are arranged on one side in the inner tank in sequence from the bottom up; the transversal S-shaped furnace hearth formed through vertical up-down-staggered inner tank clapboard water jackets is arranged on the other side of the inner tank; a water outlet, a water return opening, a water inlet and a sewage outlet are formed at the back part of the boiler housing in sequence from the top down; a safe gas outlet is formed at the top of the boiler housing; a furnace door is arranged at the upper part of a furnace grate; and primary air matching holes traversing the inner part of the furnace hearth are formed above the furnace grate and at the lower part of the front wall of the material feeding bin. The constant temperature boiler has a unique structure, can solve the problem that only the coal can be burnt in the traditional boiler and the biomass fuel cannot be burnt in the traditional boiler, and runs at a constant temperature.

Owner:余生明

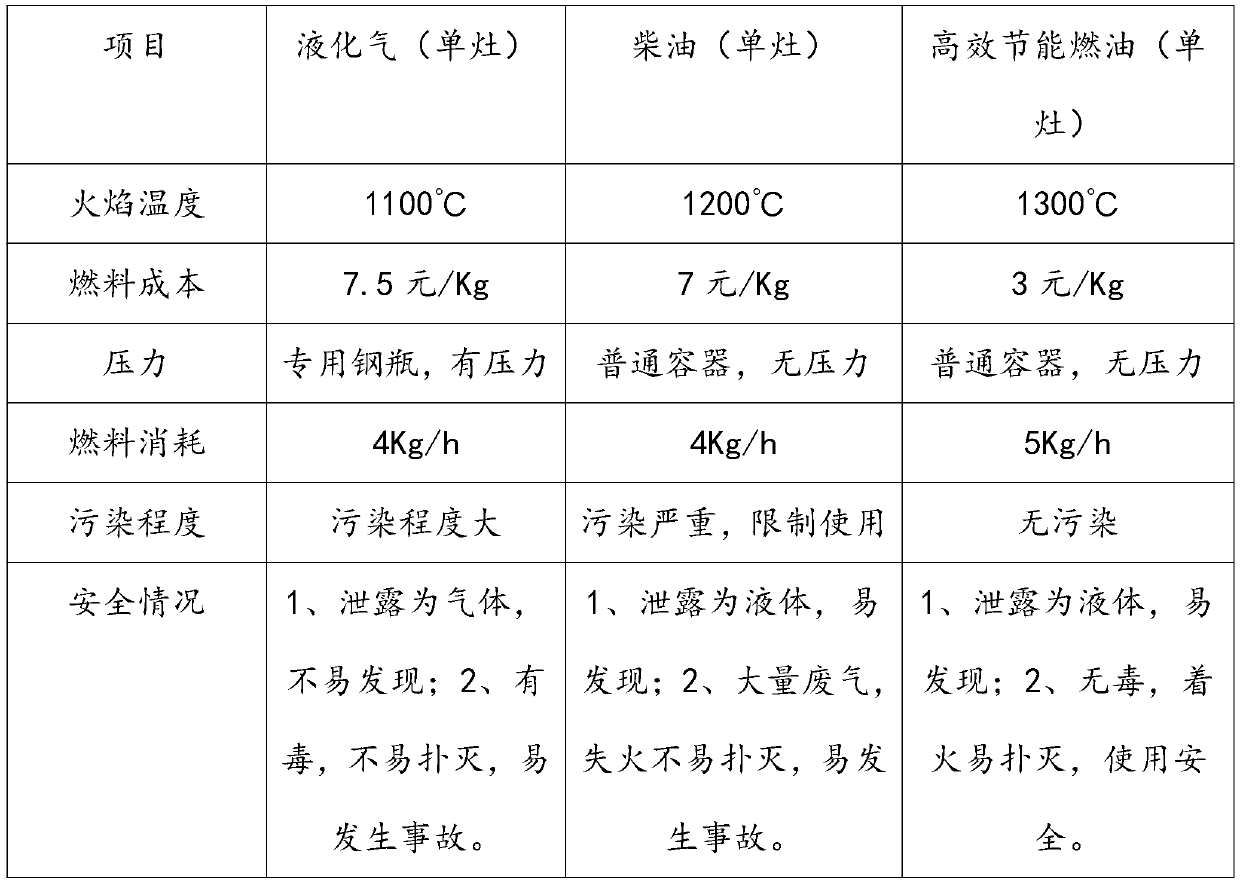

Efficient energy-saving fuel oil and preparation method thereof

InactiveCN109593569AMake up for deficienciesHigh calorific valueLiquid carbonaceous fuelsFuel oilTert butyl

The invention discloses efficient energy-saving fuel oil. The efficient energy-saving fuel oil comprises the following raw materials in parts by weight: 30 parts of petroleum alcohol, 15 parts of C5,15 parts of 2-methyltetrahydrofuran, 10 parts of dimethyl ether, 15 parts of gasoline, 1.5 parts of tert-butyl ferrocene, 1.5 parts of methylcyclopentadienyl tricarbonyl manganese, 3 parts of hydrogenperoxide, 4 parts of xylol, 28 parts of absolute ethyl alcohol, 0.5 parts of sodium dodecylbenzene sulfonate, 0.5 part of potassium chlorate, 1 part of an antioxidant and 1 part of N,N'-salicylidenepropylene diamine. The efficient energy-saving fuel oil disclosed by the invention has the advantages of high oxygen content, high combustion efficiency, no black smoke, no deposited carbon, no residual liquid and residues, low waste gas emission, cleanness and sanitation, environmental friendliness and high safety.

Owner:余龙超

Hot-blast stove secondary air inlet system

InactiveCN112432363AGuaranteed to burnBurn fullyAir heatersCentral heating systemThermodynamicsHot air oven

The invention discloses a hot-blast stove secondary air inlet system which comprises a hot-blast stove body. A combustion cavity and an ash collecting cavity are formed in the hot-blast stove body, and a perforated plate is fixedly connected to the inner wall of the combustion cavity. A through hole is formed in the upper surface of the hot-blast stove body, and the inner wall of the through holeis provided with a sealing cover matched with the through hole in a sleeving manner. A fuel feeding port, a first air inlet and a second air inlet are formed in the side face of the hot-blast stove body, and a first air inlet pipe is fixedly connected to the inner wall of the first air inlet. By arranging the first air inlet pipe, normal combustion of fuel in the hot-blast stove body can be guaranteed. When the fuel amount needs to be increased, an adjusting shaft is rotated to enable an adjusting valve to control the air inlet amount of a second air inlet pipe, induced draft fan blades are pushed by airflow to rotate, and external air is guided to flow into the combustion cavity to achieve a combustion supporting effect. Thus, the whole system has the effect of enabling the fuel to be sufficiently combusted, and also can adjust heat generated by the fuel.

Owner:铜陵美天新能源科技有限公司

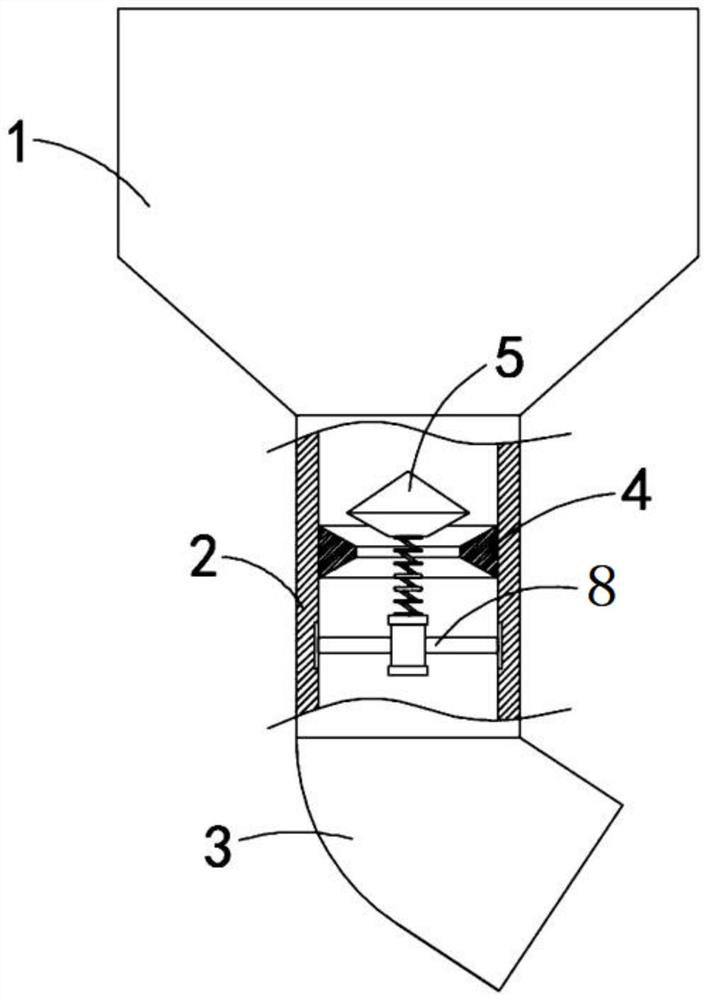

A feed mechanism for a biomass fuel furnace

ActiveCN109911565BSave human effortPlay a combustion-supporting effectSolid fuel combustionConveyor partsRound tableEngineering

The invention belongs to the field of biomass energy conversion, and particularly relates to a biomass fuel furnace feeding mechanism comprising a feeding hopper. The lower end of the feeding hopper is fixedly connected with a vertical pipe, the lower end of the vertical pipe is fixedly connected with a diagonal pipe, a sealing ring is fixedly connected into the vertical pipe, the upper end of thesealing ring is recessed downwards to be arranged in a bowl shape, a sealing block matched with the sealing ring is arranged over the sealing ring, and the lower end of the sealing block is in a round table shape protruding downwards; and the lower end of the sealing block is fixedly connected with a memory spring, the lower end of the memory spring is fixedly connected with a connecting seat, and the connecting seat is fixedly connected to the inner side wall of the vertical pipe through a plurality of connecting rods. According to the biomass fuel furnace feeding mechanism, it can determinethat there is not much fuel remaining in a fuel furnace through the change of the temperature of the position, close to the feeding mechanism, in the fuel furnace, the sealing block is automaticallyjacked upwards, fuel in the feeding hopper can be replenished into the fuel furnace in time, the whole process does not require manual supervision, simpleness and convenience are achieved, and human resources are saved.

Owner:浏阳市三工环保科技有限公司

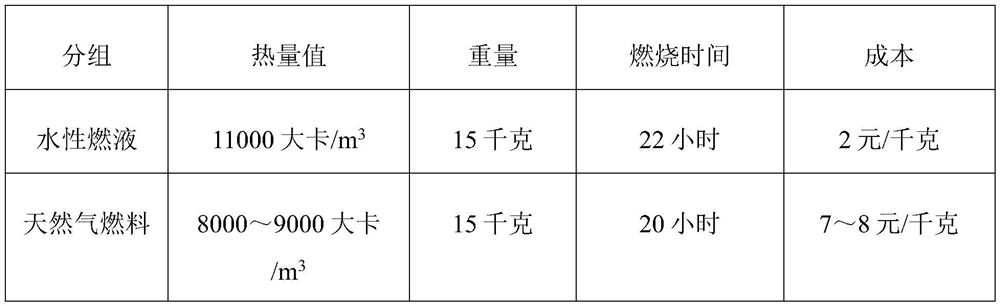

Water-based fuel liquid as well as preparation method and application thereof

PendingCN114806658AReduce nitrite alkaliImprove water qualityLiquid carbonaceous fuelsFuel additivesNitrocelluloseCombustion

The invention provides water-based fuel liquid as well as a preparation method and application thereof, and relates to the technical field of fuel preparation. The water-based fuel liquid is prepared from the following raw materials in parts by weight: 700 to 800 parts of water, 0.8 to 1.2 parts of nitrocellulose, 0.8 to 1.2 parts of glycerol, 0.6 to 1.5 parts of propylene glycol and 800 to 1100 parts of glycol. The preparation method comprises the following steps: filtering water, adding nitrocellulose while stirring, uniformly mixing glycerol and propylene glycol, pouring into water, stirring to a homogeneous phase, then adding glycol, uniformly stirring, standing and emulsifying to obtain the water-based fuel liquid. The water, the nitrocellulose, the glycerol, the propylene glycol and the ethylene glycol are adopted as raw materials to prepare the water-based fuel liquid, and the water-based fuel liquid is low in cost, low in carbon, environmentally friendly, high in flash point and incapable of being ignited with open fire, so that the water-based fuel liquid has the advantages of being safe, non-explosive, convenient to transport and high in fuel heat value which can reach 11000 kilocalories and is higher than natural gas, and therefore the water-based fuel liquid has more excellent combustion performance.

Owner:赵玉庆

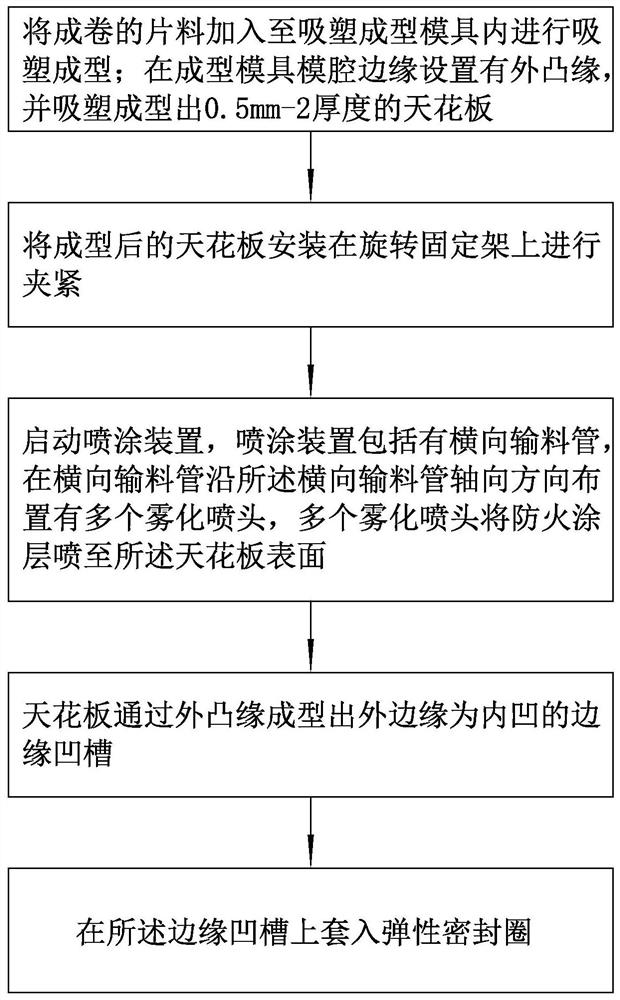

Ceiling material blister manufacturing method

The invention discloses a ceiling material blister manufacturing method. The method comprises the following steps that S1, a coiled sheet material is added into a blister forming mold for blister forming; an outer flange is arranged on the edge of a mold cavity of the forming mold, and a ceiling with the thickness being 0.5 mm<-2> is formed through blister forming; and S2, the formed ceiling is installed on a rotary fixing frame to be clamped. The blister ceiling has the following advantages that the situation that part of positions are not sprayed due to traditional manual spraying is avoided, the spraying effect of a fireproof coating is better, a certain combustion-supporting effect is achieved, fire disasters are avoided, a sealing structure is arranged, the attaching degree between a ceiling outer wall and a ceiling support can be effectively improved, and the sealing structure has the advantages that the overall installation stability is improved, falling is prevented, the upper space and the lower space of the ceiling are isolated, the conditions of dust accumulation, mosquito breeding and water leakage are prevented, and the quality of the ceiling is greatly improved.

Owner:中山市吉万包装制品有限公司

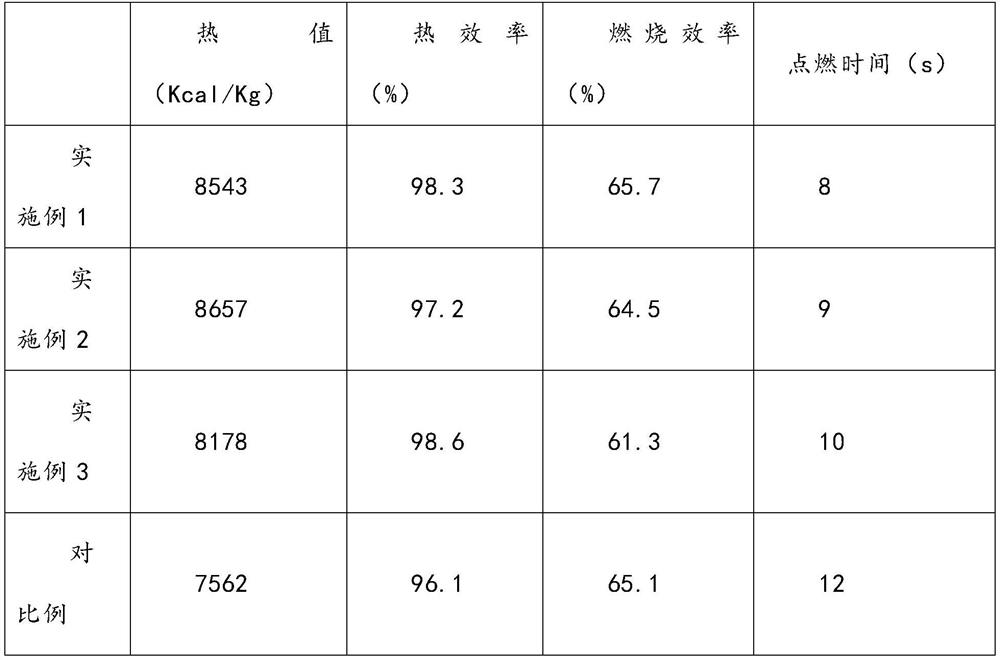

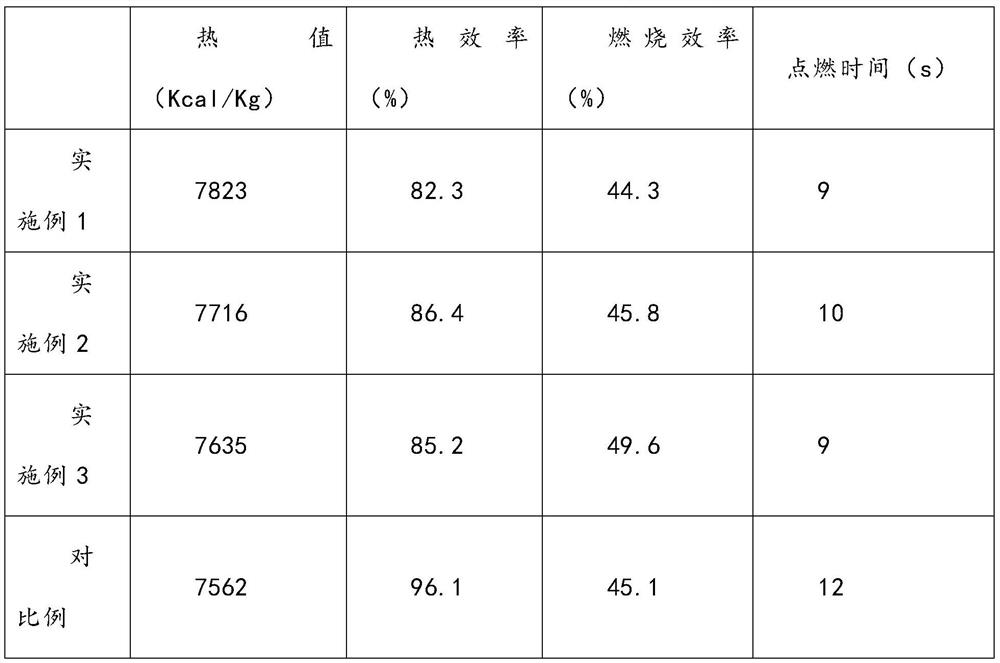

A kind of sawdust biomass fuel and preparation method thereof

ActiveCN108517235BLow ignition temperatureImprove stabilityBiofuelsSolid fuelsCellulosePulp and paper industry

The invention discloses a sawdust biomass fuel, which comprises the following raw materials in parts by weight: 60 parts of wood chips, 14 parts of additives, 6 parts of attapulgite powder, 4 parts of rare earth minerals, 2 parts of oxygen enhancer, and 0.3 parts of oxygen increase synergist , 8 parts of biological asphalt, 3.5 parts of blue-green algae mud, 1.5 parts of ammonium sulfate, and the auxiliary agent is polyanionic cellulose. The wood chip biomass fuel prepared by the present invention has high combustion efficiency, good stability, is not easy to be oxidized, can be fully burned, and can reduce the generation of harmful gases. The optimal ratio is obtained, and then the wood chip biomass fuel has the best performance, high use value and good application prospect.

Owner:深圳市泓丰科技有限公司

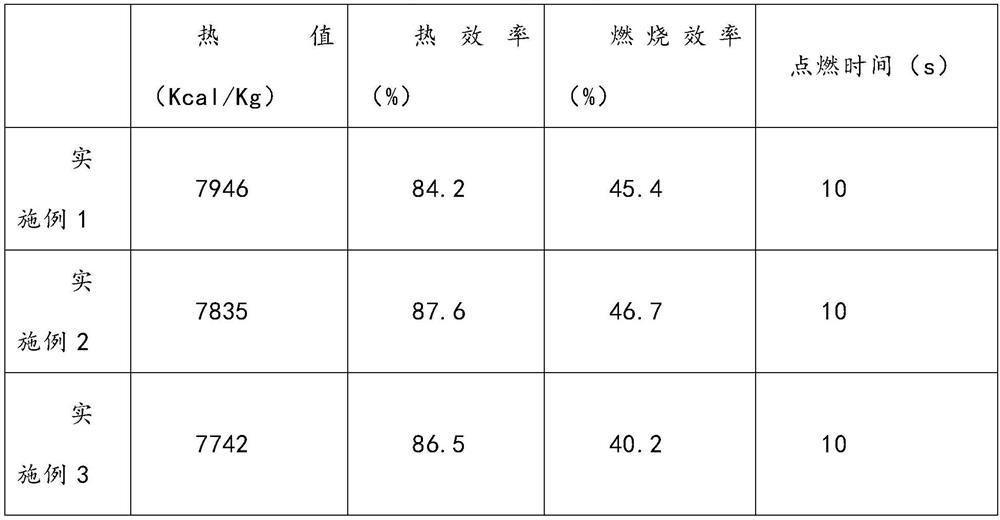

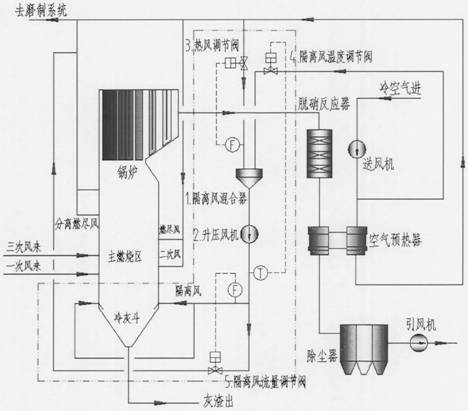

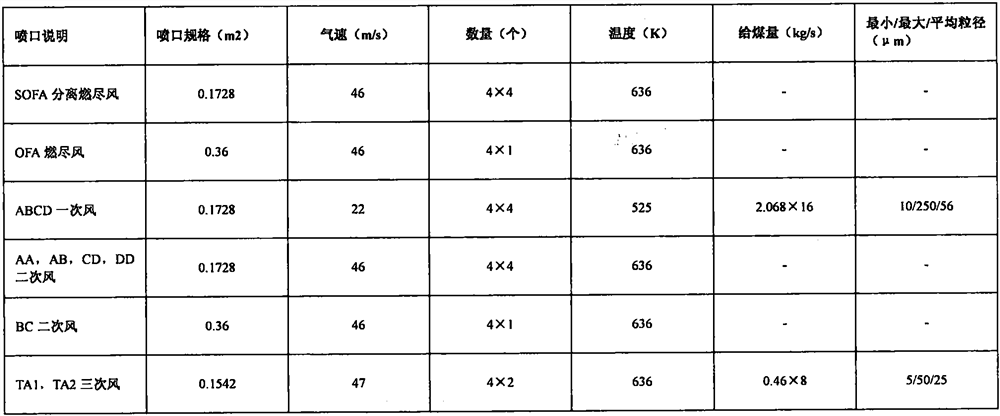

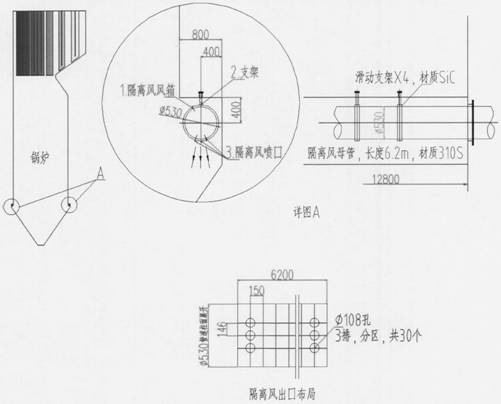

Boiler system capable of improving burn-off rate of pulverized coal and reducing NOx generation amount

PendingCN112393231AIncrease oxygen concentrationReduce oxygen concentrationFuel supply regulationIndirect carbon-dioxide mitigationThermodynamicsProcess engineering

The invention discloses a boiler system capable of improving the burn-off rate of pulverized coal and reducing the NOx generation amount. According to the boiler system, on the basis of a four-cornertangential combustion type industrial coal-fired boiler system, an air isolation system is additionally arranged, namely air with set temperature and flow is introduced from a proper position betweena main combustion area and an ash cooling hopper area, and is injected into the ash cooling hopper of a hearth at an optimal angle by designing an optimized injection speed, and therefore, the purposes of improving the burn-off rate of the pulverized coal and reducing the NOx generation amount are achieved. The isolated air system is not only suitable for newly-built boilers, but also has the advantages of being short in transformation period, small in investment and high in economic return when used for old boiler transformation.

Owner:付烜

High-combustion-rate coal briquette with coal cinder not easy to break

The invention discloses a high-combustion-rate coal briquette with coal cinder not easy to break, and belongs to the field of coal combustion; the invention discloses a high-combustion-rate coal briquette with coal cinder not easy to break. Combustion-supporting particles are arranged in the coal briquette body; oxygen can be supplied to the coal briquette body for supporting combustion during combustion; therefore, the combustion rate of the coal briquette body is improved, the resource waste is effectively reduced, meanwhile, the molten internal combustion-supporting particles can continuously permeate into gaps in the coal briquette body; in combination with the arrangement of the breakage-reducing rubber ring and under the guide action of the wall-attached guide hairs and the deep-layer liquid guide thorns, hot melt adhesive can continuously flow out of the breakage-reducing rubber ring and can seep into the inner wall of the vent hole and cracks of the deeper part of the inner wall of the vent hole; and after combustion is finished, the hot melt adhesive is cured, a certain bonding effect can be achieved on the surface and the interior of the coal cinder at the same time, andtherefore the situation that the coal cinder is broken is effectively avoided, the integrity of the coal cinder is effectively guaranteed, and the cleaning and replacing difficulty of the coal cinderis effectively reduced.

Owner:张宏

Combustion-supporting device of furnace

InactiveCN101776278BBurn fullyGood for hydrogen and oxygen separationNon-combustible gases/liquids supplyCombustion chamberEngineering

The invention discloses a combustion-supporting device of a furnace, which comprises a furnace body and a chimney, wherein the chimney is arranged on the furnace body; a combustion chamber is arranged in the furnace body; one side of the combustion chamber is provided with a furnace door; and the lower end of the combustion chamber is provided with an air intake. The combustion-supporting device is characterized in that a water storage layer is arranged around the combustion chamber; a steam chamber is arranged above the water storage layer; the steam chamber is connected with a steam pipe; afurnace bar made of hollow pipes is arranged between the air intake and the combustion chamber; the furnace bar is communicated with the steam chamber by the steam pipe; and an injector head is arranged above the furnace bar. The invention has the advantages that the furnace bar made of the hollow pipes is arranged between the air intake and the combustion chamber, and the injector head is arranged above the furnace bar, and therefore, steam can be sprayed into the combustion chamber to agitate air in the combustion chamber, thereby taking the combustion-supporting effect and greatly saving fuels.

Owner:NINGBO ZHENHAI JIEDENG APPL TECH INST

Production process of microcrystalline foam fireproof and thermal insulation materials by using aeolian sand and peat

ActiveCN104446596BPlay a combustion-supporting effectSolve pollutionSolid waste disposalCeramicwareThermal insulationPeat

The invention relates to a manufacturing process for producing a microcrystal foaming fireproof thermal insulation material by utilizing aeolian sand and peat, and in particular to a manufacturing process of a fireproof thermal insulation material by reutilizing Mu Us aeolian sand in Ningxia region. The manufacturing process is characterized by comprising the following steps: processing aeolian sand, peat and limestone into tiny fine powder, uniformly mixing the fine powder according to a specified proportion, flattening and ramming the fine powder mixture in a firing mould, integrally firing the mixture in a high-temperature firing kiln once and cooling molding. The manufacturing process for producing the microcrystal foaming fireproof thermal insulation material by utilizing the aeolian sand and the peat has the beneficial effects that, by utilizing the aeolian sand as a main raw material, the environment pollution problem caused by the aeolian sand is solved, the production cost is reduced, the resource utilization rate is increased, the waste is changed into the wealth, and the environment is optimized; by utilizing the peat as a production raw material, a combustion supporting effect of raw material self combustion in a firing procedure is realized, the firing speed can be increased, and the fuel cost and the energy consumption are reduced.

Owner:NINGXIA BLACK GOLD TECH CO LTD

Efficient garbage incineration system

InactiveCN106765177AImprove combustion efficiencyPlay a combustion-supporting effectIncinerator apparatusFurnace temperatureCombustion

The invention discloses an efficient garbage incineration system. An auxiliary fine incineration furnace is arranged, circulating gas in a main incineration furnace is sent into the auxiliary fine incineration furnace for assisting in combustion, and tail gas in the auxiliary fine incineration furnace returns into auxiliary heating pipes of the main incineration furnace to assist in heating. In the reaction process, fine material closed incineration is performed in the auxiliary fine incineration furnace, so that the furnace temperature of the auxiliary fine incineration furnace is greatly higher than that of the main incineration furnace; on one hand, the gas which is not fully combusted and generated by the main incineration furnace enters an auxiliary furnace body for further combustion, and the effect of assisting in combustion in the auxiliary furnace body is effectively achieved; and on the other hand, the high-temperature tail gas finally generated by the auxiliary fine incineration furnace performs auxiliary heating on garbage above a combustion layer in the main incineration furnace, before the garbage is combusted, the drying and reduction processes are accelerated, and thus combustion efficiency of the main incineration furnace is further improved.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

A biomass briquette fuel solid-phase low-temperature, gas-phase high-temperature combustion device

ActiveCN106918039BEmission reductionReduce pollutionSolid fuel combustionLump/pulverulent fuel feeder/distributionGas solidSlag

The utility model relates to a solid-phase low-temperature and gas-phase high-temperature combustion device for biomass briquette fuel, which belongs to the technical field of biomass combustion. It is characterized in that: the feed port of the smoldering zone (3) communicates with the discharge port of the furnace (1), the discharge port of the smoldering zone (3) communicates with the cooling zone (4), and the lower part of the furnace (1) is equipped with There is a grate (13), the grate (13) is equipped with a crushing mechanism (2) for crushing materials, and the grate (13) is connected with a rotating mechanism to disturb the biomass fuel and make the carbon powder fall into the The smoldering area (3) is smoldering, and at the same time, the block biomass fuel is moved to the middle of the grate (13), and the crushing mechanism (2) breaks the block biomass fuel into carbon powder and falls into the smoldering area (3). burn. The solid-phase low-temperature and gas-phase high-temperature combustion device for biomass briquette fuel solves the problems of coking, slagging, high emission of gas-solid pollutants and failure of ash fertilizers from the root causes of agricultural waste burning equipment such as straw.

Owner:SHANDONG UNIV OF TECH

Boiler equipment capable of improving burn-off rate of pulverized coal and reducing NOx generation amount

PendingCN112393230AImprove the combustion processImprove burnout rateIndirect carbon-dioxide mitigationCasings/liningsProcess engineeringInjection air

The invention discloses boiler equipment capable of improving the burn-off rate of pulverized coal and reducing the NOx generation amount. On the basis of a four-corner tangential combustion type industrial coal-fired boiler, the structure of a water cooling wall is improved by selecting the position between a cold ash hopper and a main combustion area, an air injection component is additionally arranged and used for injecting air with the proper temperature and flow into a hearth at the optimized injection speed and the optimal angle, the burn-off rate of the pulverized coal can be improved,and the NOx generation amount can be reduced. The newly-added air injection component is not only suitable for a newly-built boiler, but also has the advantages of being short in transformation period, small in investment and high in economic return when used for transformation of an old boiler.

Owner:付烜

Smoldering device for fast and low-temperature combustion of carbon powder in biomass briquette fuel combustion device

ActiveCN106895436BReduce the temperaturePlay a combustion-supporting effectAir supply regulationFuel feeding arrangementsAir volumePotassium

The utility model relates to a smoldering device for fast and low-temperature combustion of carbon powder in a biomass briquette fuel combustion device, which belongs to the technical field of biomass combustion. It is characterized in that: the two ends of the air inlet pipe (27) communicate with the outside of the smoldering pool (20) respectively, the wall of the air inlet pipe (27) is provided with air outlet holes, and the air inlet pipe (27) is filled with flowing air , so as to cool the smoldering pool (20), part of the air in the air inlet pipe (27) enters the smoldering pool (20) to support combustion, and the air inlet pipe (27) is also connected to an air volume adjustment unit that adjusts the cooling air flow rate, and the combustion-supporting adjustment The mechanism is connected with the air inlet pipe (27), and cooperates with the air volume adjustment unit to adjust the amount of combustion-supporting air entering the smoldering pool (20). The smoldering device for rapid and low-temperature combustion of carbon powder in the biomass briquette fuel combustion device avoids coking and slagging of the fuel, reduces the volatilization of potassium, sodium and chloride elements, and reduces the problem of gas-solid pollutant emission and equipment sticking from the root cause of straw combustion. The ash can be used directly as farm fertilizer.

Owner:SHANDONG UNIV OF TECH

Backflow incense and preparation method thereof

PendingCN114831970AImproves drying performance and moisture resistanceImprove adhesive performanceInorganic non-active ingredientsPharmaceutical delivery mechanismChinese herbsSandalwood

The invention relates to the technical field of incense, and particularly discloses backflow incense and a preparation method thereof. The backflow incense is formed by polymerizing the following raw materials in parts by weight: 55-60 parts of moxa; 5 to 10 parts of sandalwood; 30-40 parts of Chinese herbal medicine powder; 10 to 15 parts of an adhesive; 5-10 parts of a drying agent; the adhesive is a composition of coconut powder, starch and lotus root starch; the drying agent is green bristlegrass carbon powder; the preparation method comprises the following steps: drying sandalwood and moxa at 50-60 DEG C, grinding the sandalwood, sieving with a 100-mesh sieve, stirring and mixing sandalwood powder and Chinese herbal medicine powder, adding an adhesive and a drying agent, stirring and mixing, adding the moxa, adding deionized water according to the volume ratio of a fixture to the deionized water of 1: 3, kneading and hammering until medicine mud is agglomerated, and drying to obtain the traditional Chinese medicine paste. And after shading and fermenting for 30-60 minutes, taking a proper amount of medicine mud, putting the medicine mud into a mold for molding, taking out and drying in the shade to obtain the backflow incense. The backflow incense can be used for indoor aromatherapy and fragrance tasting, and has the advantages of moisture resistance and moisture resistance.

Owner:泉州永春达盛香业股份有限公司

Liquid vaporization combustor and combustion method thereof

PendingCN110925752AHigh pure calorific valueIncrease temperatureDomestic stoves or rangesLiquid heating fuelThermodynamicsCombustor

The embodiment of the invention discloses a liquid vaporization combustor and a combustion method thereof and relates to the technical field of combustors. A liquid supply device is connected with a first stove through a first combustion pipeline; a vaporization device comprises a combusting and heating chamber and a vaporization chamber; the first stove is arranged on the lower side of the combusting and heating chamber; a second stove is arranged on the upper side of the combusting and heating chamber; the vaporization chamber and the combusting and heating chamber are mutually sealed with each other; the first stove and the second stove are communicated with the vaporization chamber; and the liquid supply device is communicated with the vaporization chamber through a vaporization and combustion pipe; a pre-vaporization mechanism is used for converting liquid fuel into combustible gas; the combustible gas passing through the first combustion pipeline is used for igniting the first stove; the flame of the first stove is used for heating the vaporization device and is combusted through the second stove; the combustion of the second stove is more sufficient; the temperature and theheat are improved along the combustion of the second stove; combustible materials which are not combusted by the first stove and pollutants are subjected to secondary combustion during combustion of the second stove; and low emission or zero emission is achieved.

Owner:廊坊市万福容器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com