Biomass forming fuel solid phase low temperature and gas phase high temperature combustion method and device

A biomass fuel and briquette fuel technology, which is applied in the direction of solid fuel combustion, combustion equipment, lighting and heating equipment, etc., can solve the problems of high emissions, gray fertilizer failure, etc., to reduce pollution, increase combustion temperature, and improve equipment reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

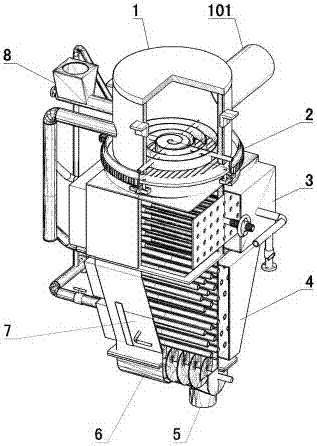

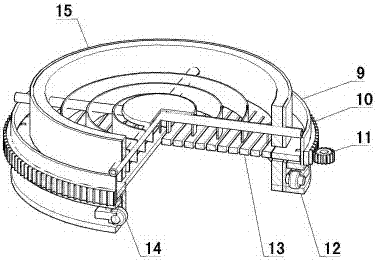

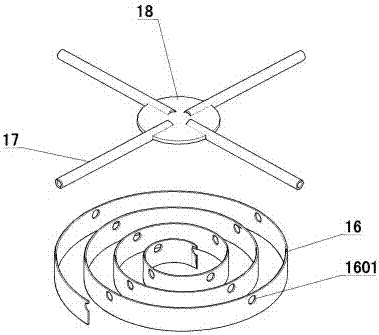

[0045] Such as figure 1 Shown: a biomass briquette fuel solid-phase low-temperature, gas-phase high-temperature combustion device, including a furnace 1, a smoldering area 3 and a cooling area 4 arranged in sequence from top to bottom, the feed port of the smoldering area 3 and the furnace 1 The discharge port is connected, the discharge port of the smoldering zone 3 is connected with the cooling zone 4, the bottom of the furnace 1 is provided with a grate 13, and the grate 13 is provided with a crushing mechanism 2 for crushing materials, and the materials are in the lower part of the furnace 1 Drying and pyrolysis, the grate 13 is connected with a rotating mechanism to disturb the biomass fuel, and make the carbon powder fall into the smoldering area 3 for smoldering, and at the same time move the block biomass fuel to the middle of the grate 13, and the crushing mechanism 2 The blocky biomass fuel is broken into carbon powder and then falls into the smoldering zone 3 for sm...

Embodiment 2

[0081] Such as Figure 12 Shown: the difference between embodiment 2 and embodiment 1 is: the smoldering pool air intake box 25 includes the smoldering pool combustion-supporting box and the smoldering pool cooling box, and the smoldering pool cooling box and the smoldering pool combustion-supporting box are set independently. Air inlet pipe 27 comprises combustion-supporting air inlet pipe 41 and cooling air inlet pipe 42, and combustion-supporting air inlet pipe 41 and cooling air inlet pipe 42 are all arranged in the smoldering pool 20, and the right end of combustion-supporting air inlet pipe 41 and the smoldering pool combustion-supporting The box is communicated, and the right end of the cooling air inlet pipe 42 is communicated with the cooling tank of the smoldering pool. The left ends of the combustion-supporting air inlet pipe 41 and the cooling air inlet pipe 42 are all communicated with the gas outlet box 28 of the smoldering pool. The combustion-supporting air in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com