Patents

Literature

101results about How to "Solve dust accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

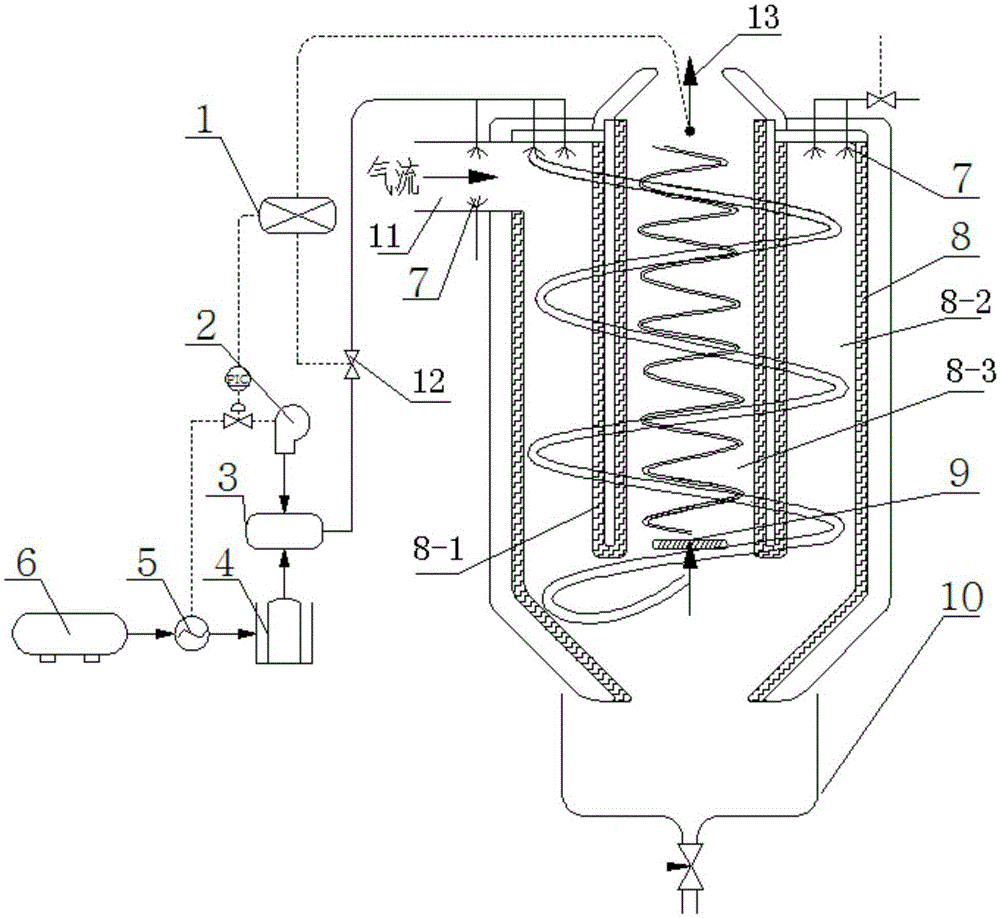

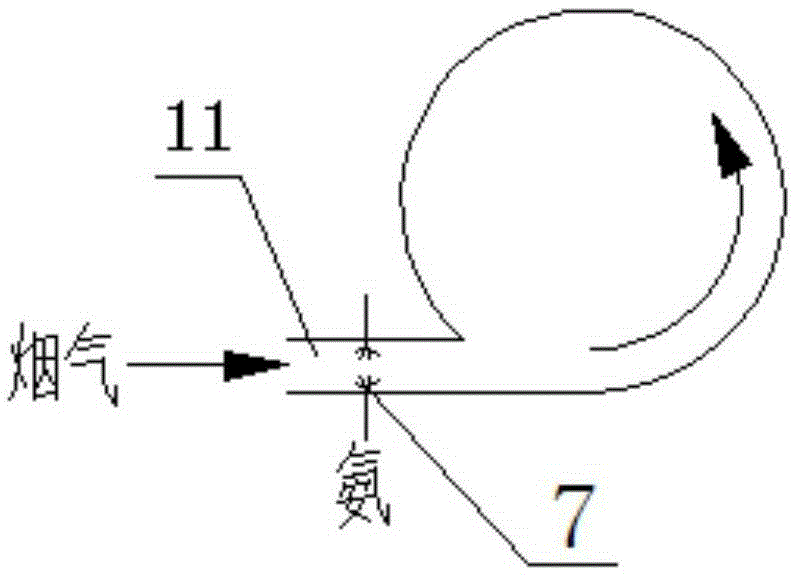

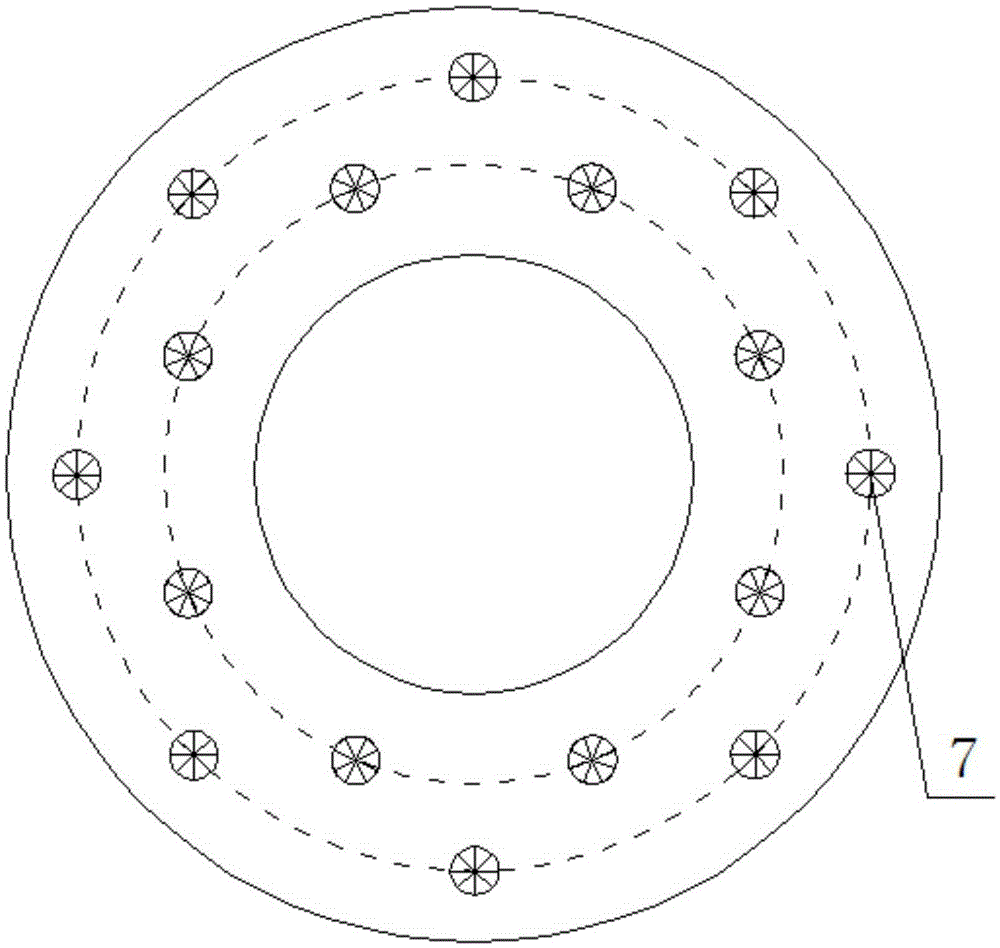

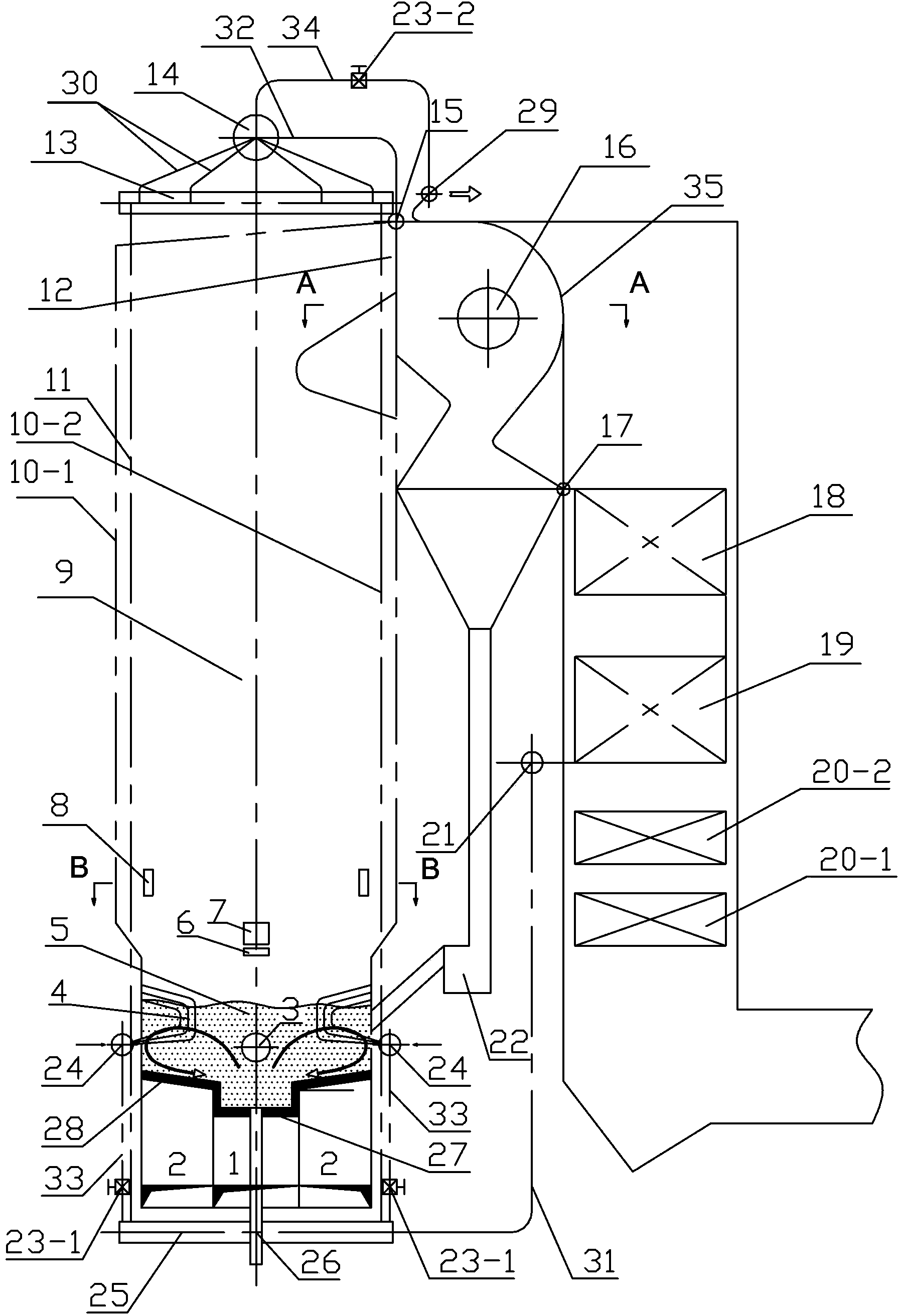

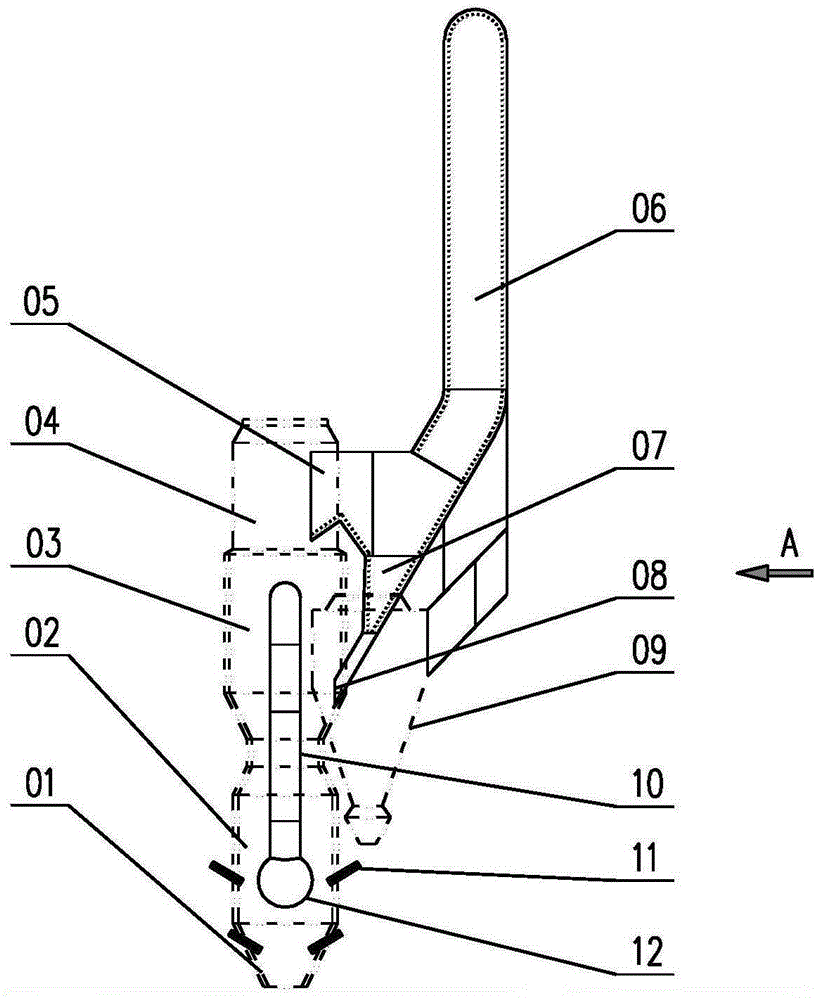

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

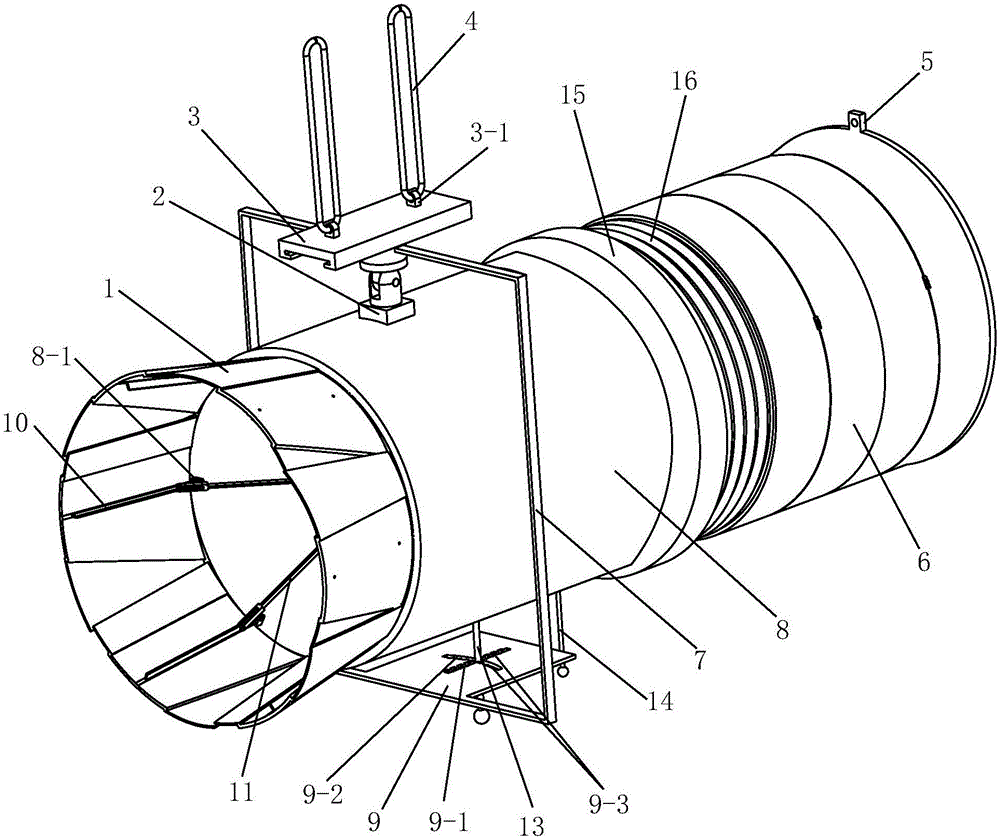

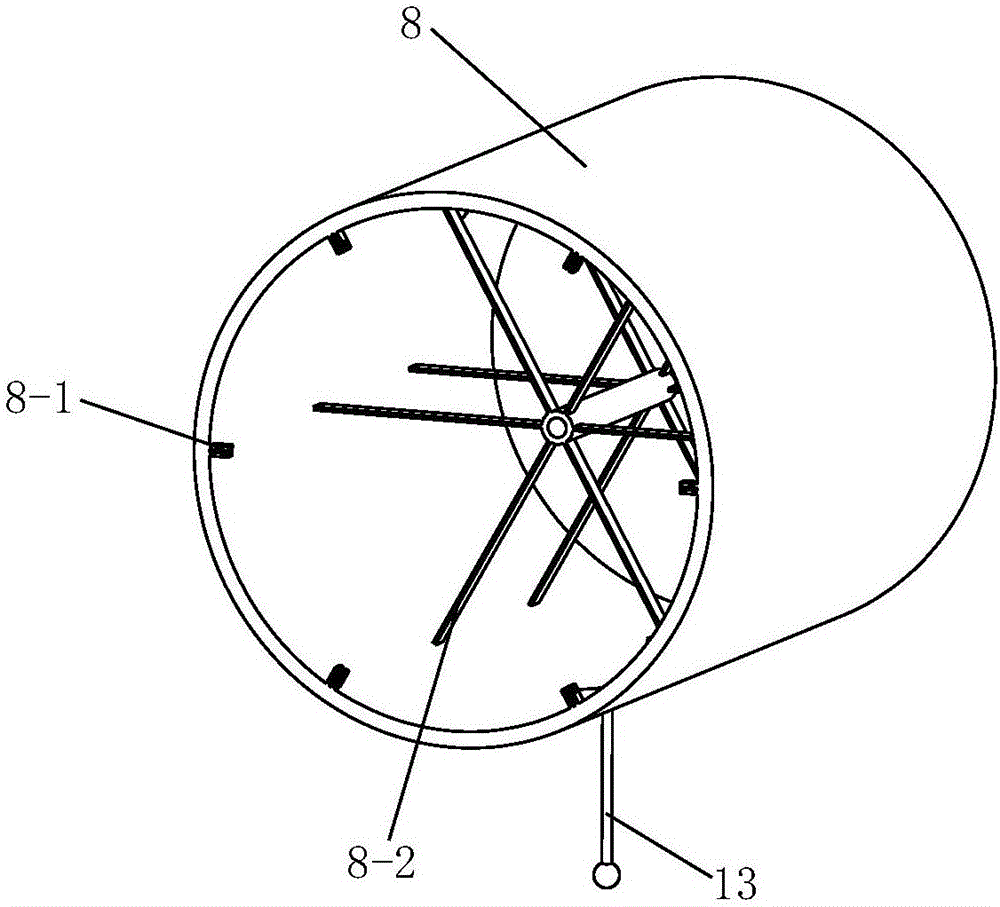

Manual coal-mine-tunneling ventilation-air-cylinder air outlet control device

ActiveCN106194235AImprove safety and reliabilitySimple structureMining devicesTunnel/mines ventillationUniversal jointEngineering

The invention discloses a manual coal-mine-tunneling ventilation-air-cylinder air outlet control device. The manual coal-mine-tunneling ventilation-air-cylinder air outlet control device comprises a support, a hardness air cylinder and a guiding rail. The hardness air cylinder penetrates through the support, the guiding rail is arranged above the support, hanging cables are connected to the top of the guiding rail, a sleeve is fixed to the top of the support, a sliding block is fixed on the sleeve and matched with the guiding rail, a universal joint is arranged between the top of the hardness air cylinder and the support, a rotating piece of the universal joint extends into the sleeve, a swinging piece of the universal joint is fixed to the top of the hardness air cylinder, a plurality of blades are arranged on an outlet in the hardness air cylinder and form a circular-truncated-cone-type structure, the small end of the circular-truncated-cone-type structure is close to the hardness air cylinder, a blade opening-and-closing mechanism is arranged on the hardness air cylinder, and a turning adjusting rod is fixed to the bottom of the hardness air cylinder. The manual coal-mine-tunneling ventilation-air-cylinder air outlet control device is convenient to install and use and high in safe reliability, the problems that as the local ventilator power is continuously improved, and the diameter of the air cylinder is increased, circulation air is caused, the local air speed of a working area is super high, and the working condition is poor are solved, and an air-flowing field in a roadway can be reasonably controlled.

Owner:XIAN UNIV OF SCI & TECH

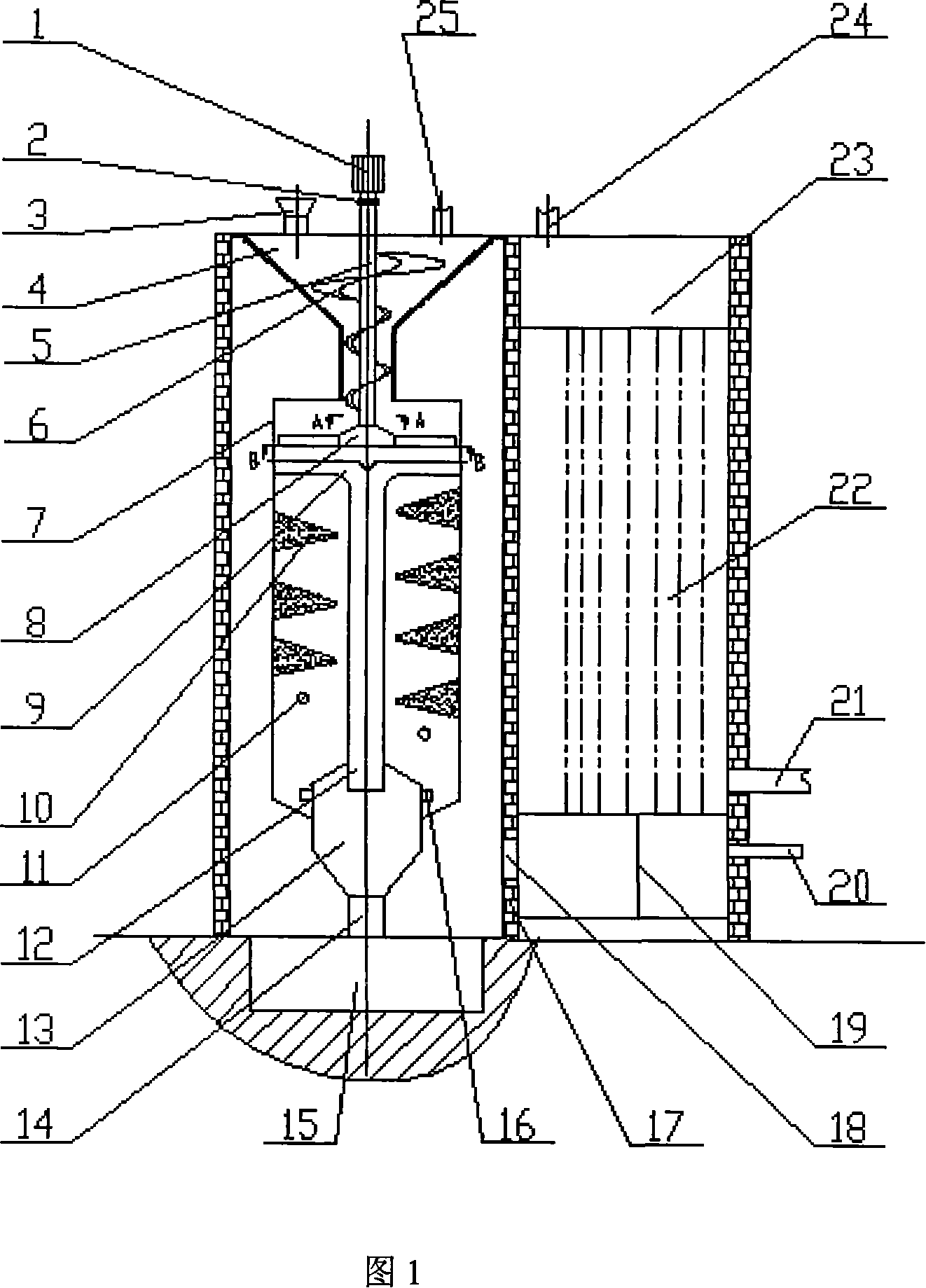

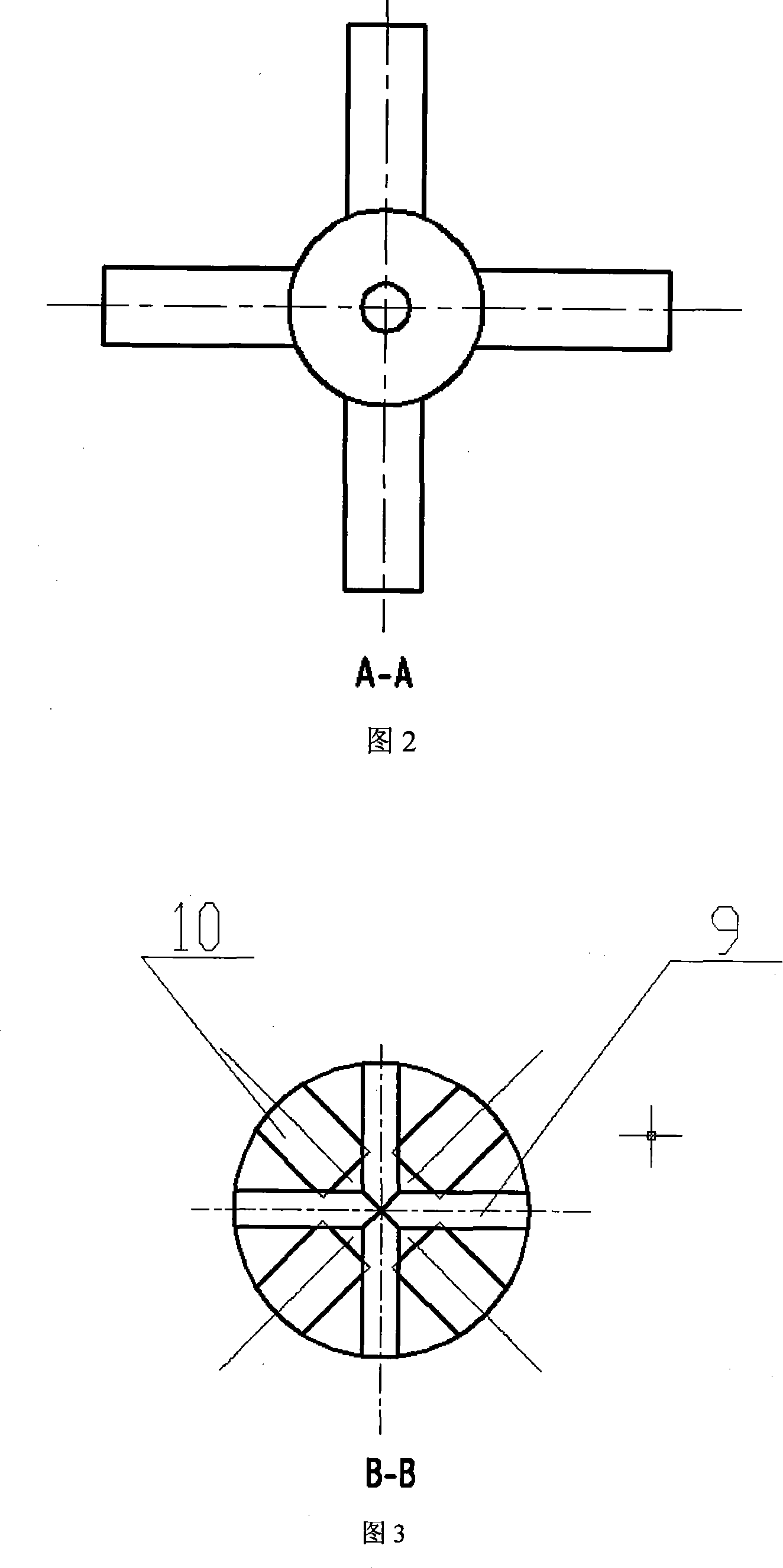

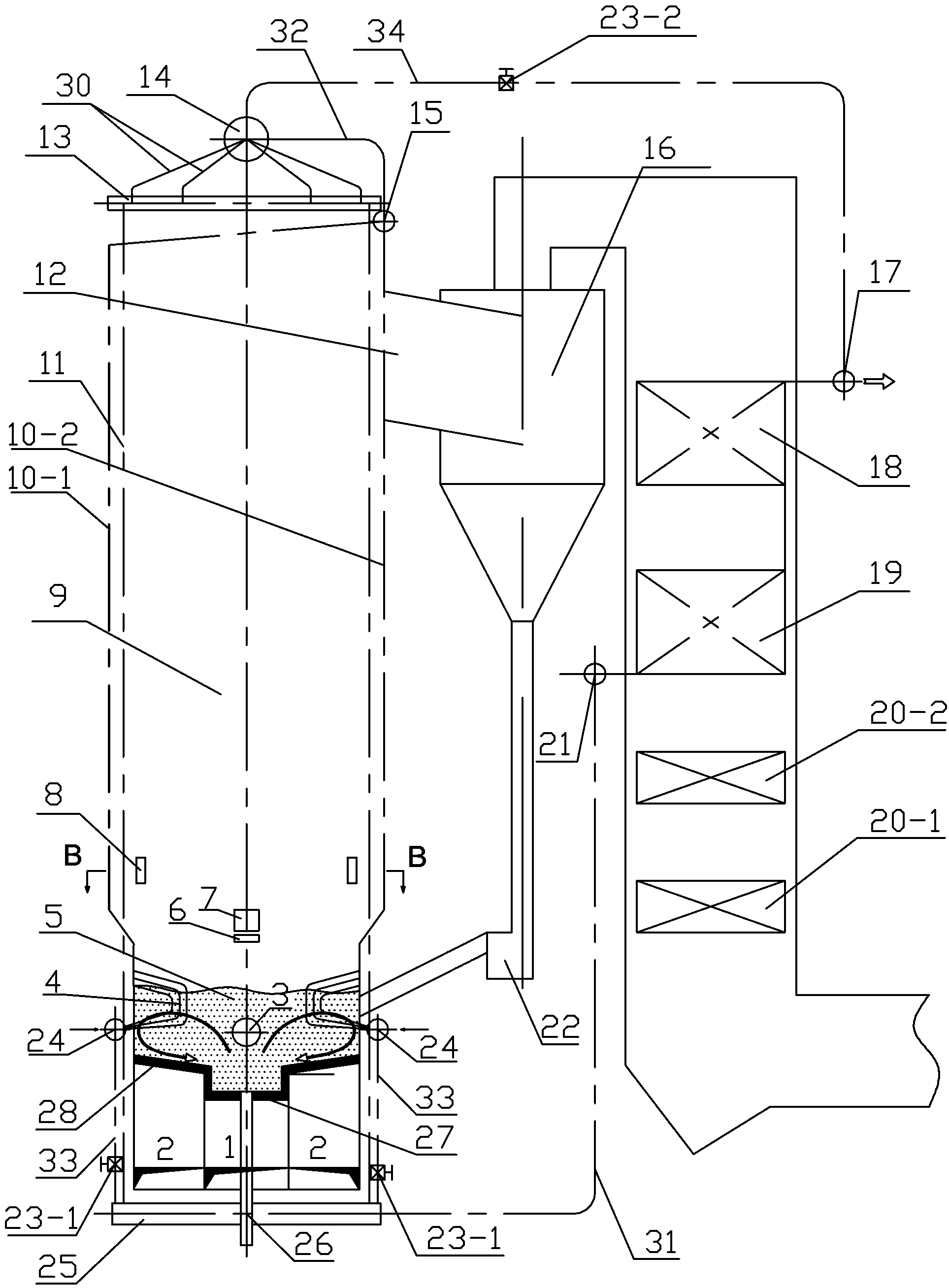

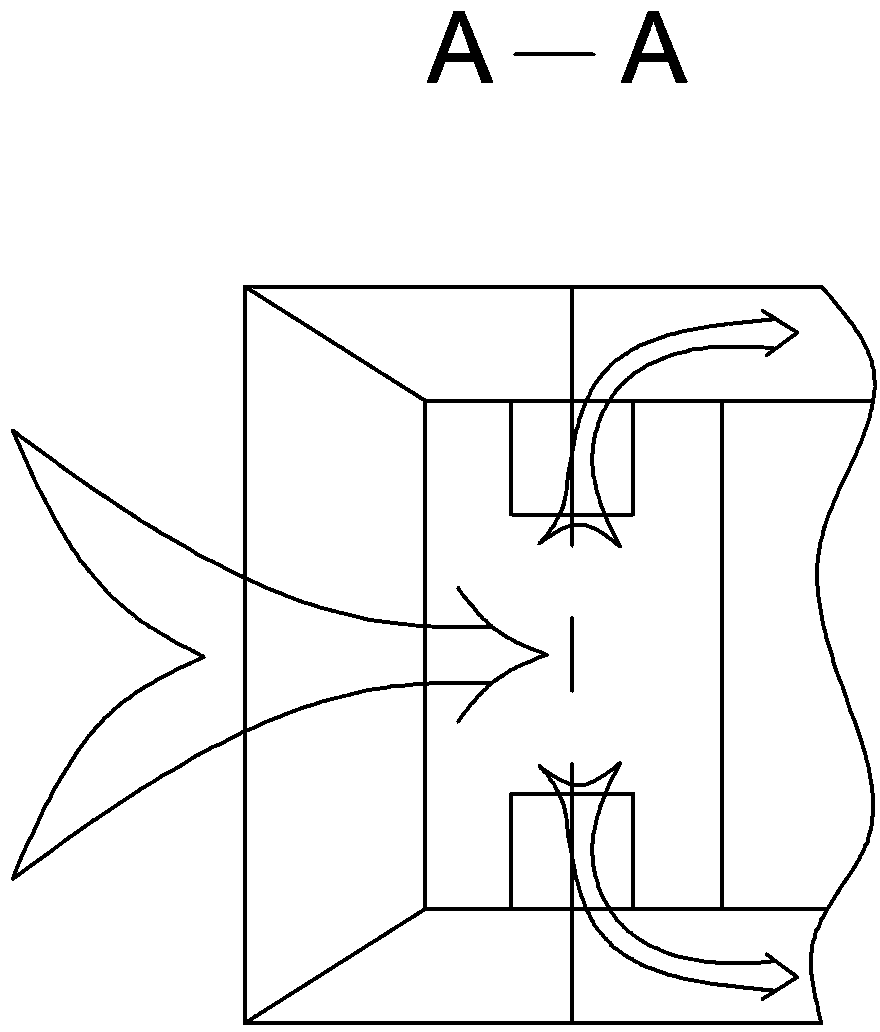

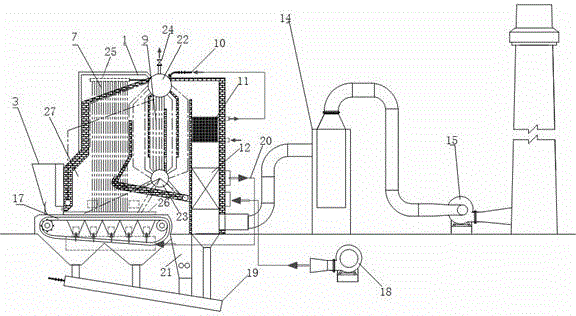

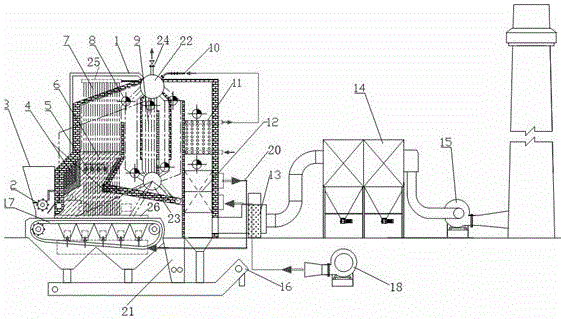

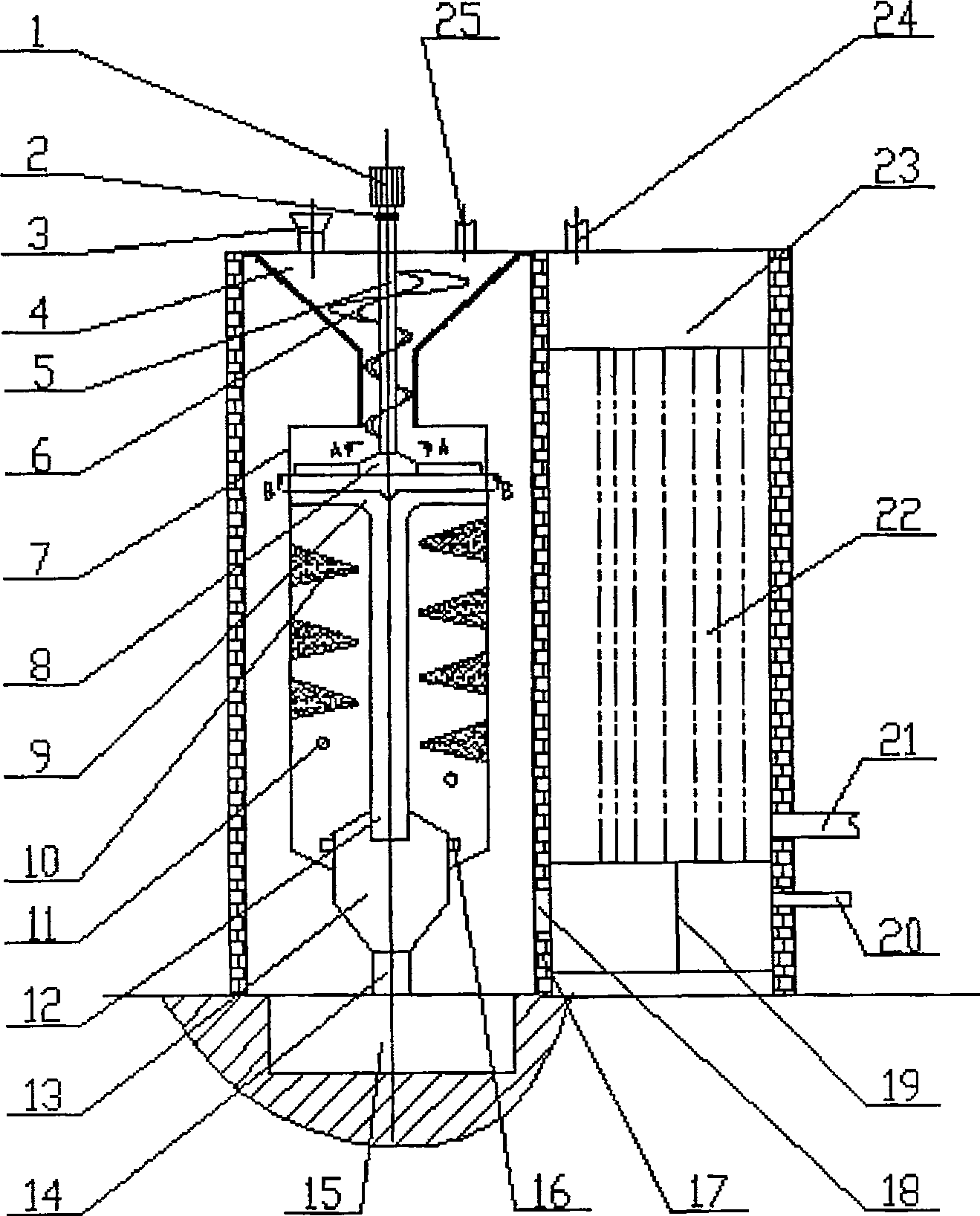

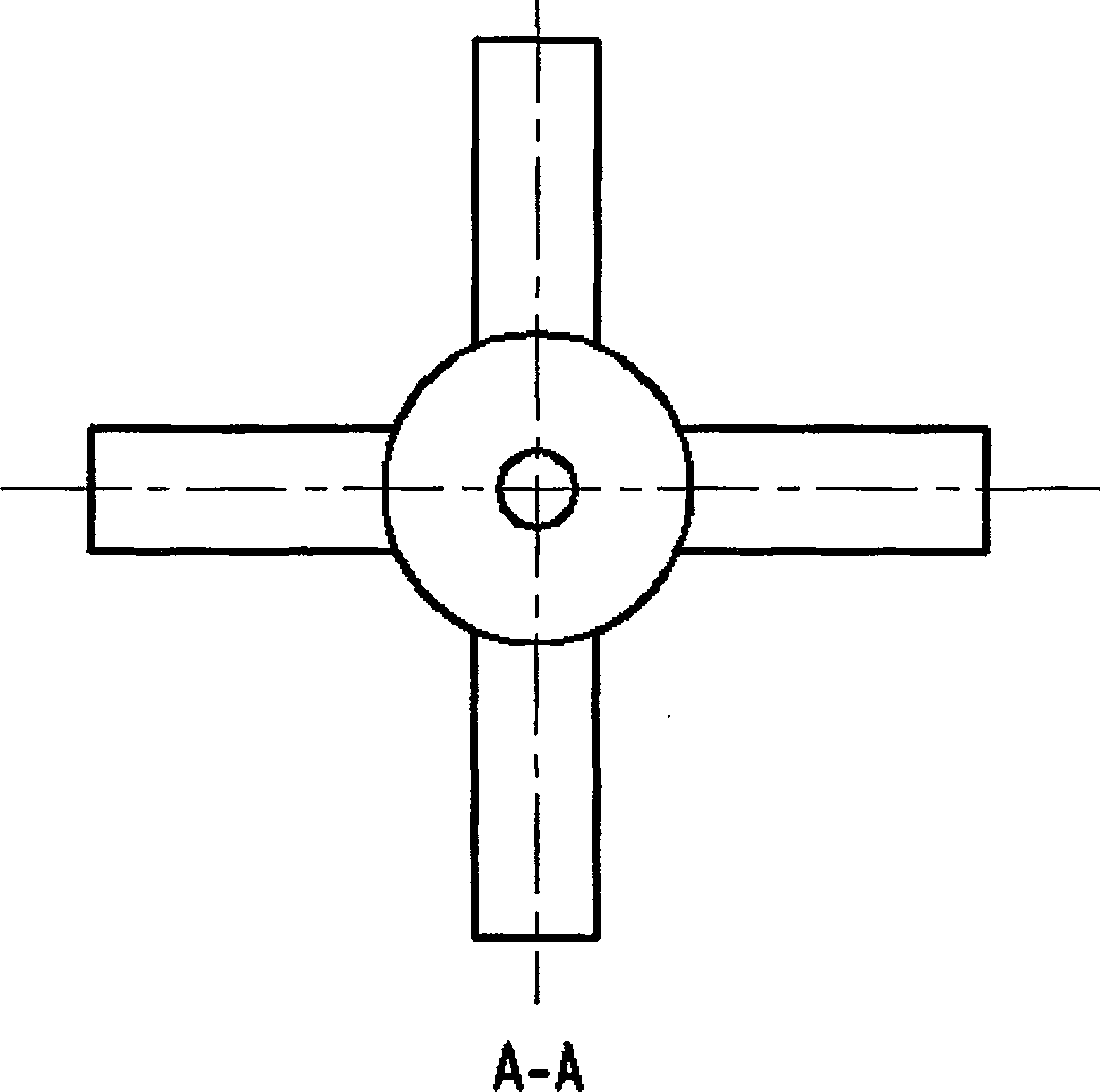

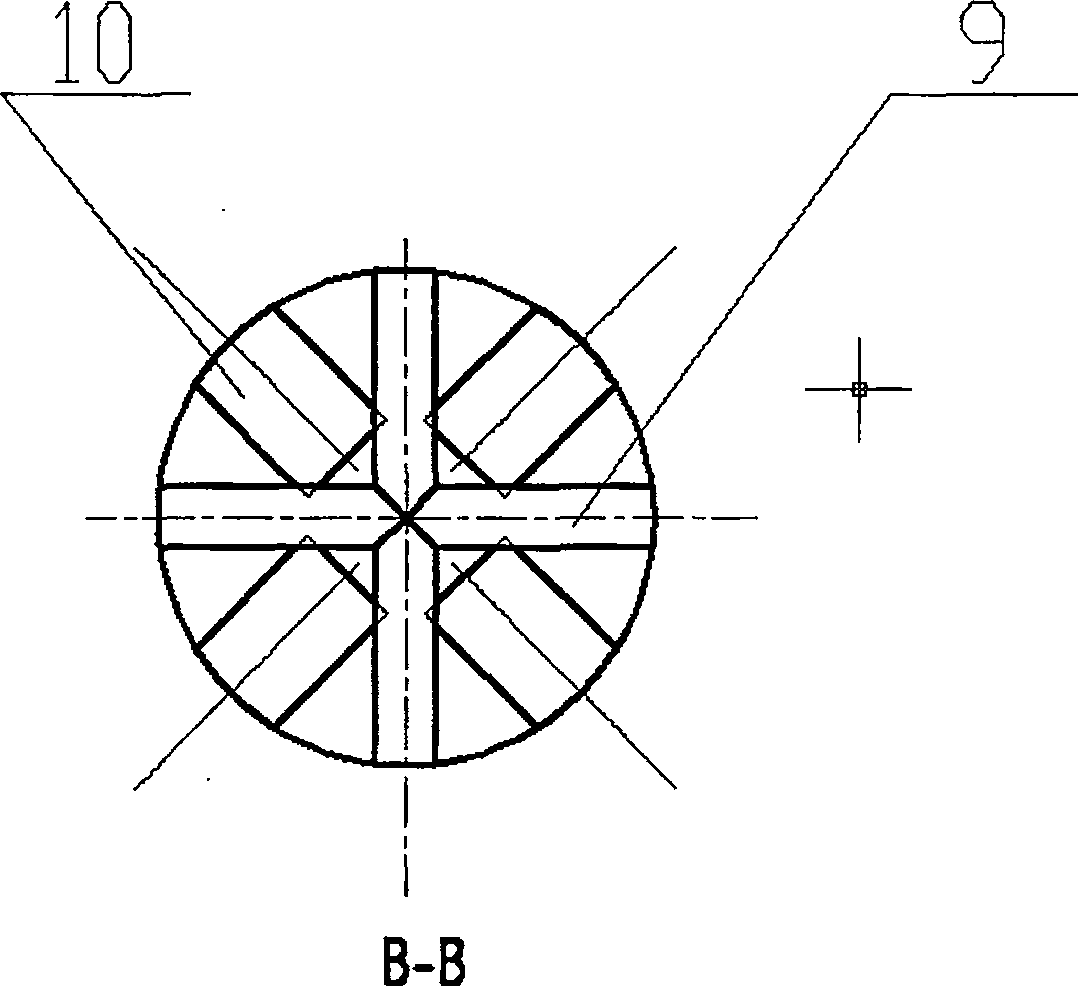

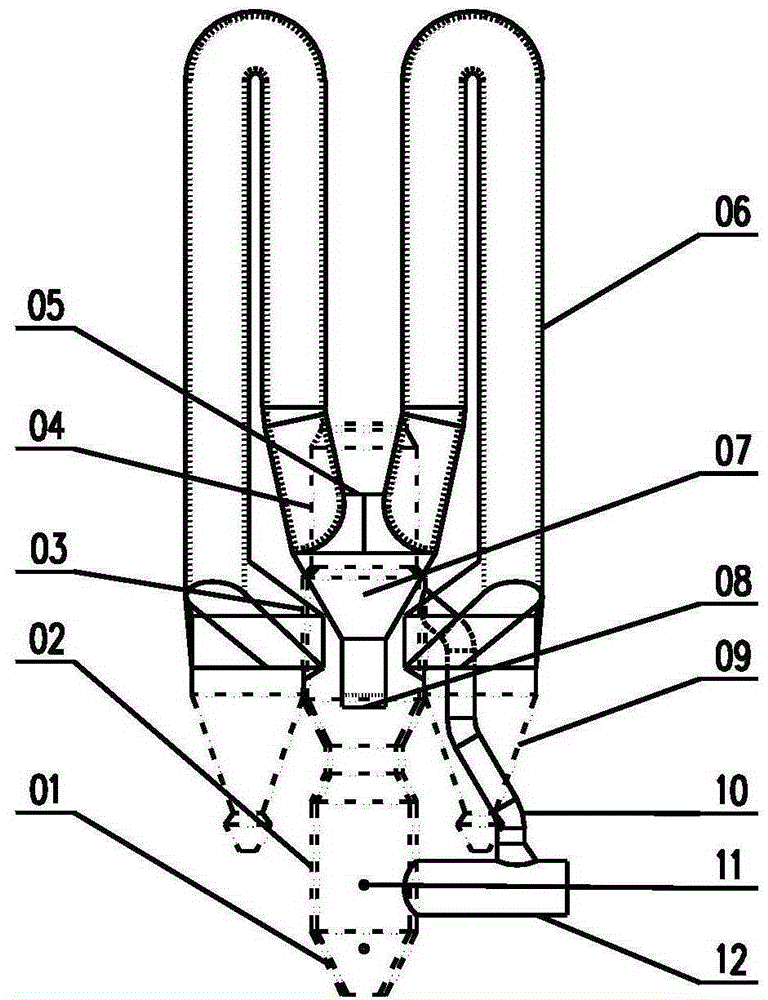

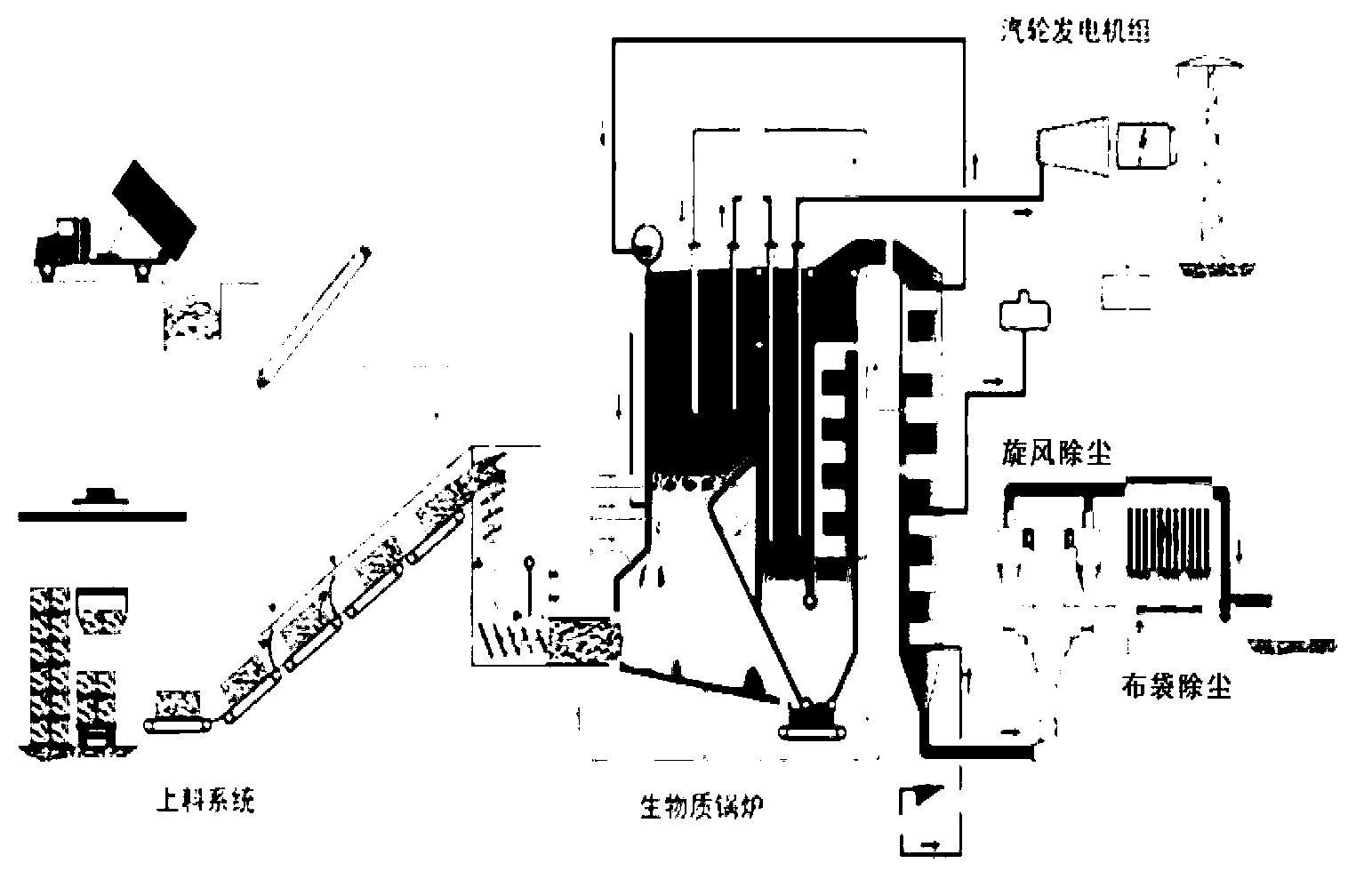

Biomass high temperature combustion boiler

InactiveCN101122384AEven distribution of feedExtended stayBoiler flue tubes/fire tubesSolid fuel combustionSolid phasesFlue gas

The invention is high-efficiency and low-pollution biomass high-temperature combustion boiler and belongs to the boiler technical field. The invention comprises a biomass granule feeding device, a fuel even distribution plate, a cross flue tube, a radiate diversion block, an air nozzle in sections, a cyclone dust collector, a liquid drainage pool, a furnace, and a heat convection chamber. The invention is characterized in that a hopper of the biomass granule feeding device is arranged above the boiler for pre-drying; radiate diversion blocks are arranged in good order in the boiler; the pre-heated high-temperature is injected upwards into a hearth from the nozzle sections in a tangential direction to realize the staged and swirl combustion; the bottom is equipped with a gas, liquid and solid phase high-temperature cyclone segregator; the central high-temperature flue gas flows through a central flue tube to the upper cross flue tube and then enters the annular clearance between the furnace and the boiler wall and the hot convection chamber from below the boiler wall. The invention combines characteristics of biomass fuel and comprehensively absorbs the advantages of high-temperature air combustion, staged combustion, cyclone combustion, cyclone dust collection, liquid drainage, flue gas recirculation and other technologies, so the invention can realize the clean and high-efficiency use of the renewable energy of biomass.

Owner:UNIV OF SCI & TECH OF CHINA

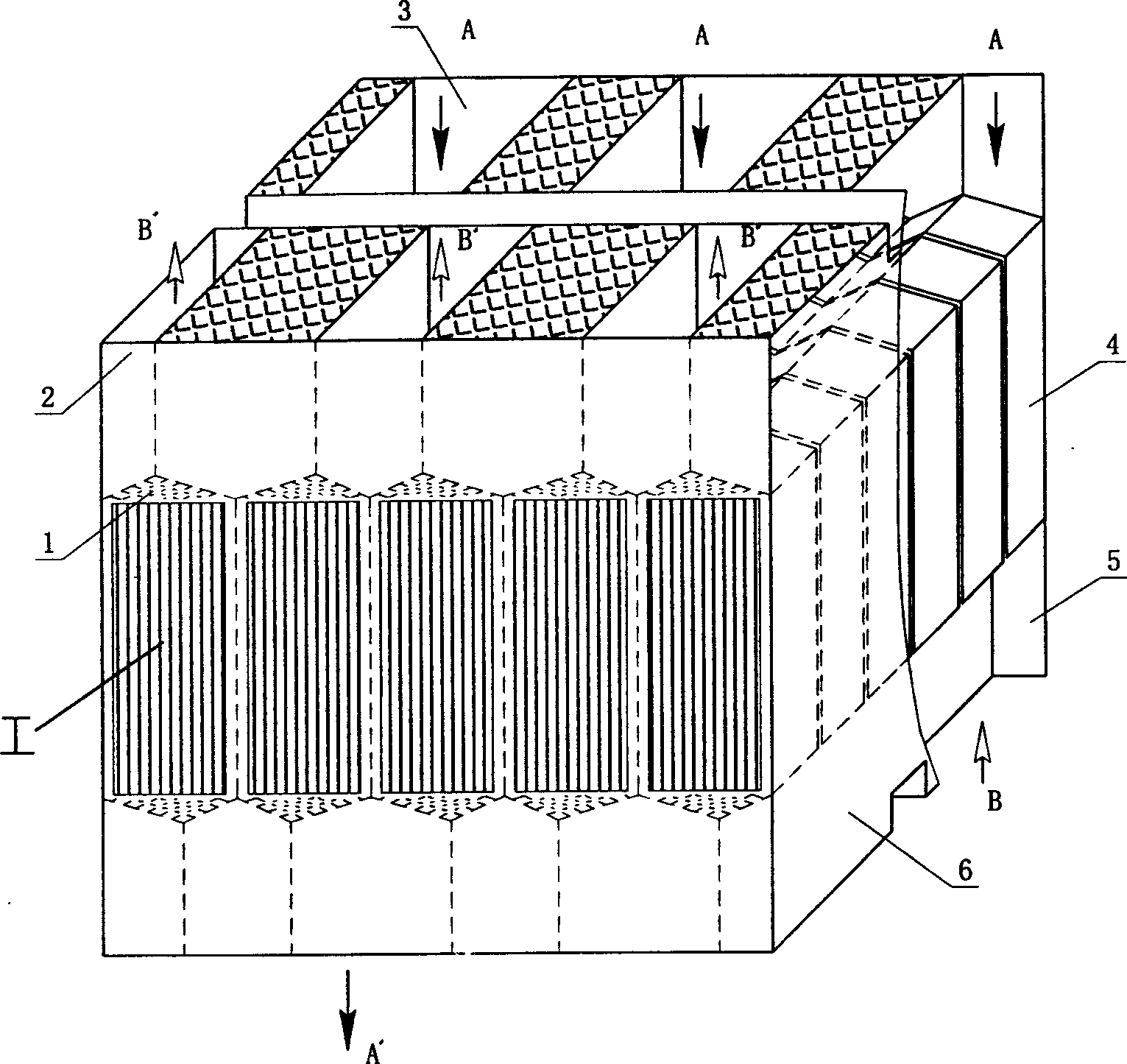

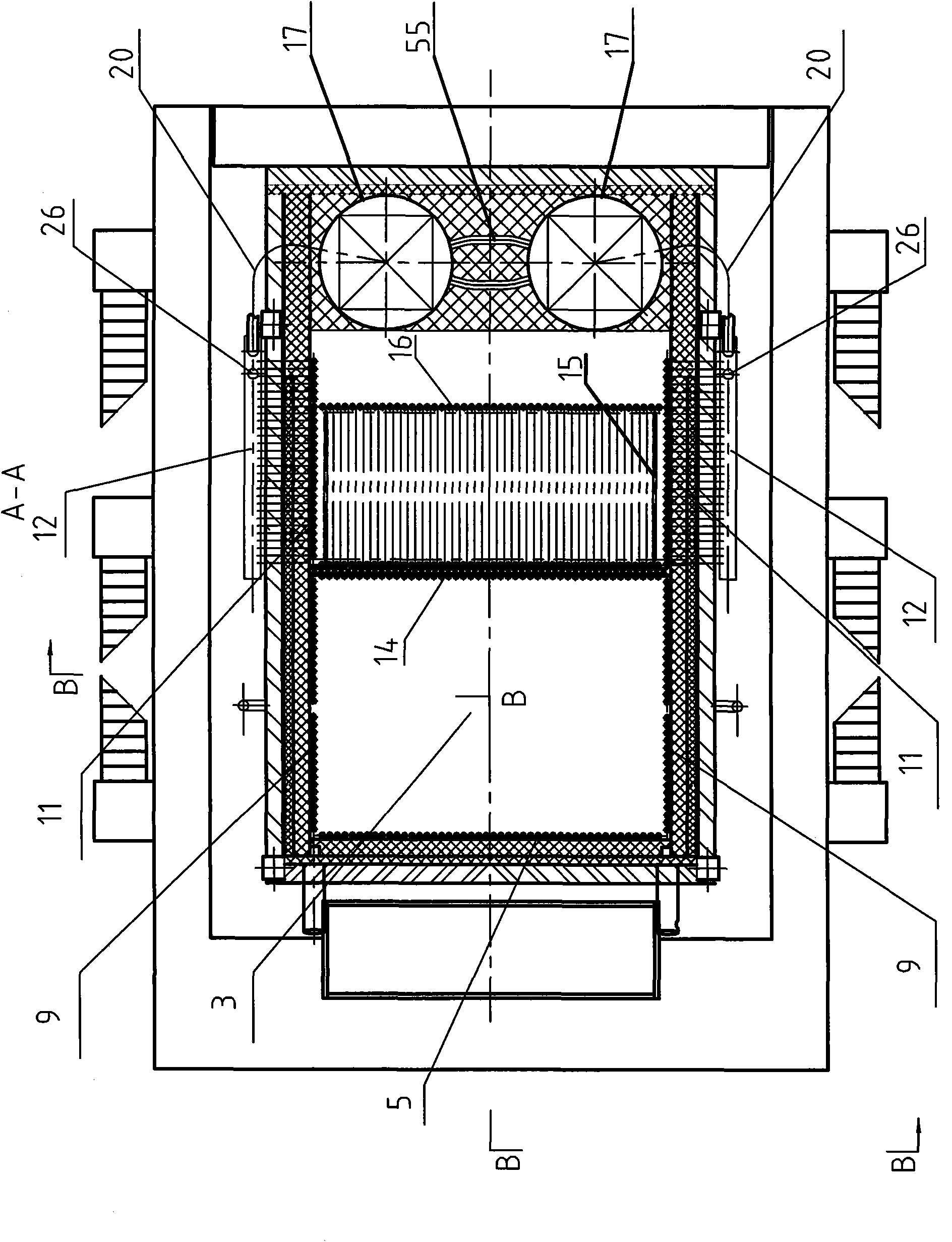

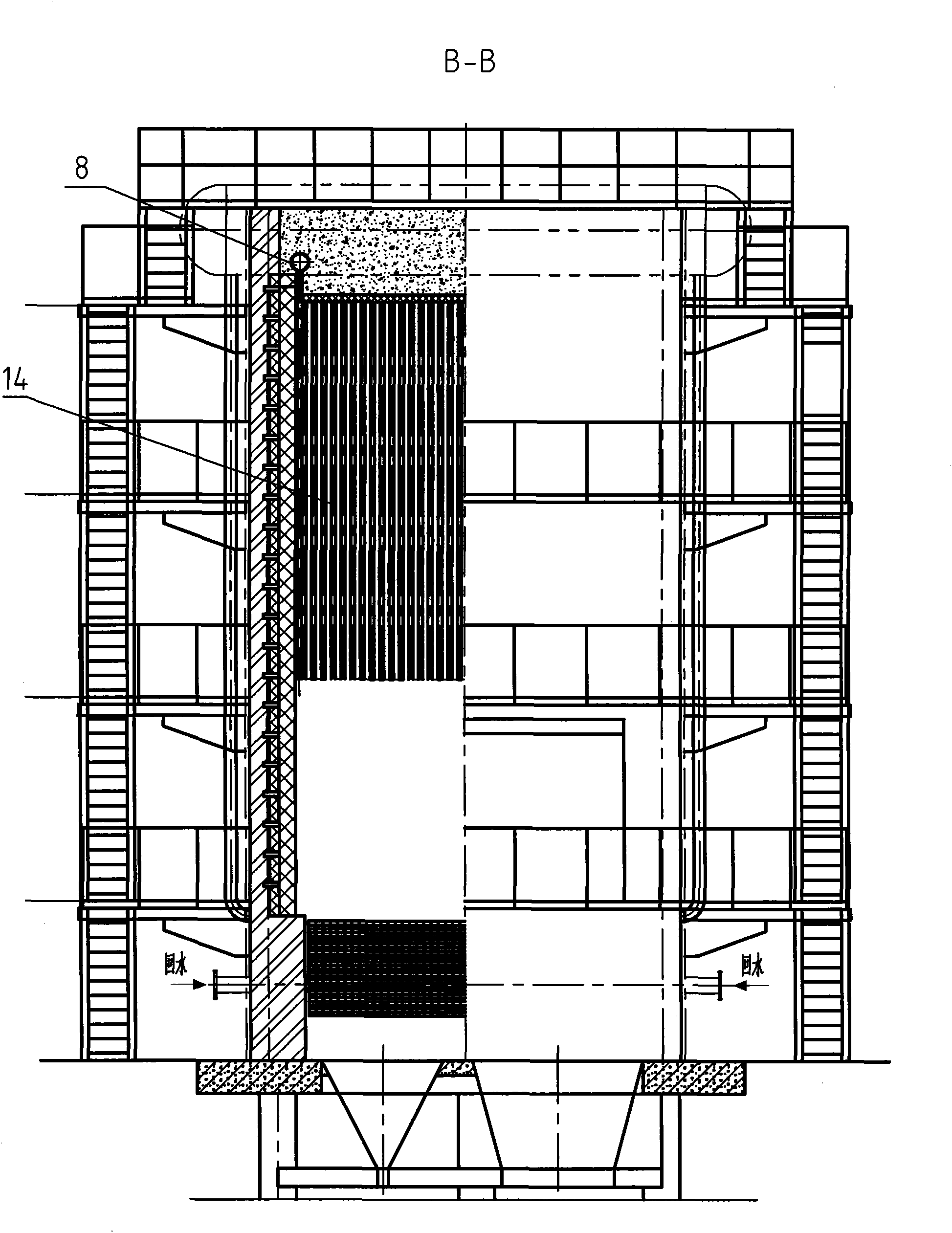

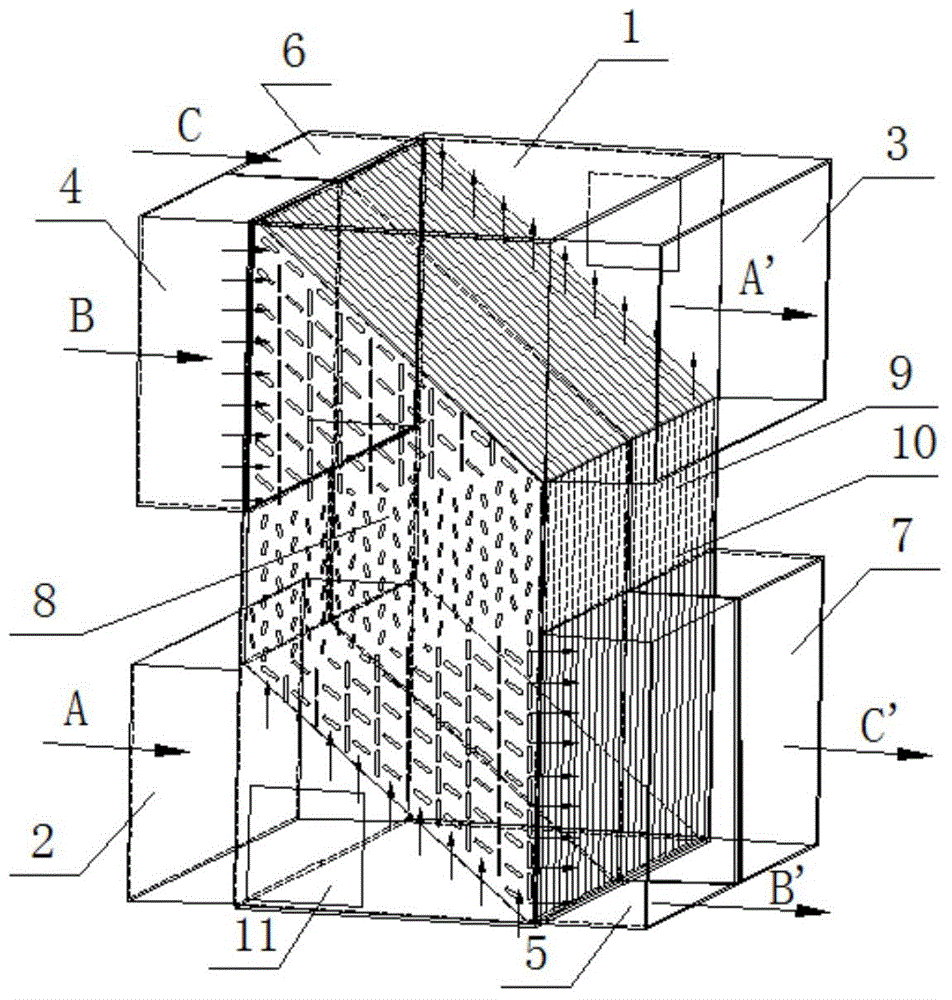

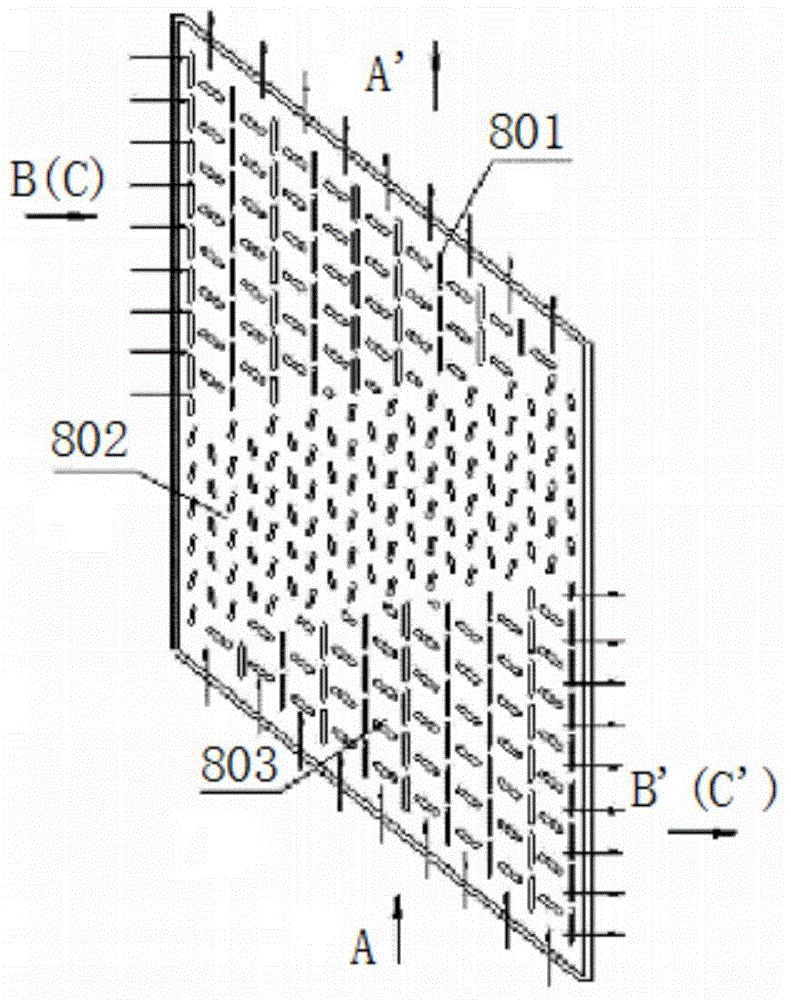

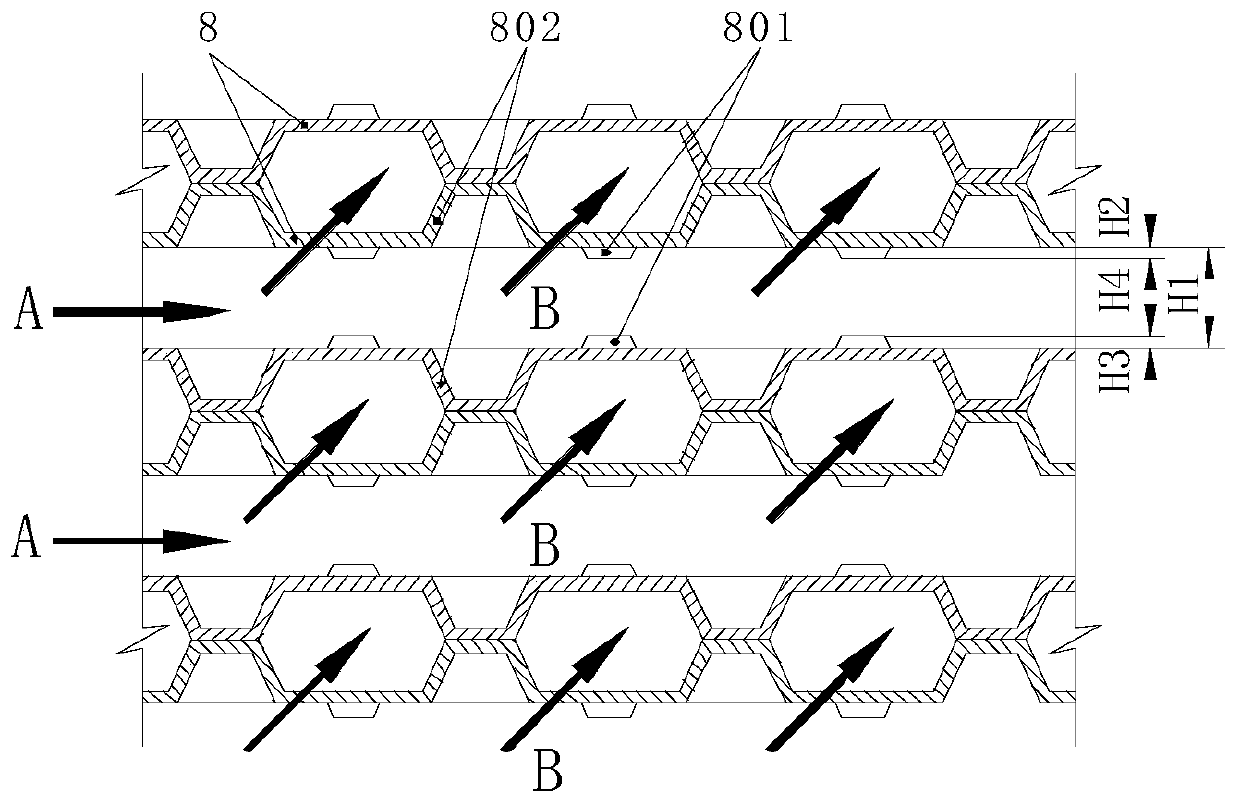

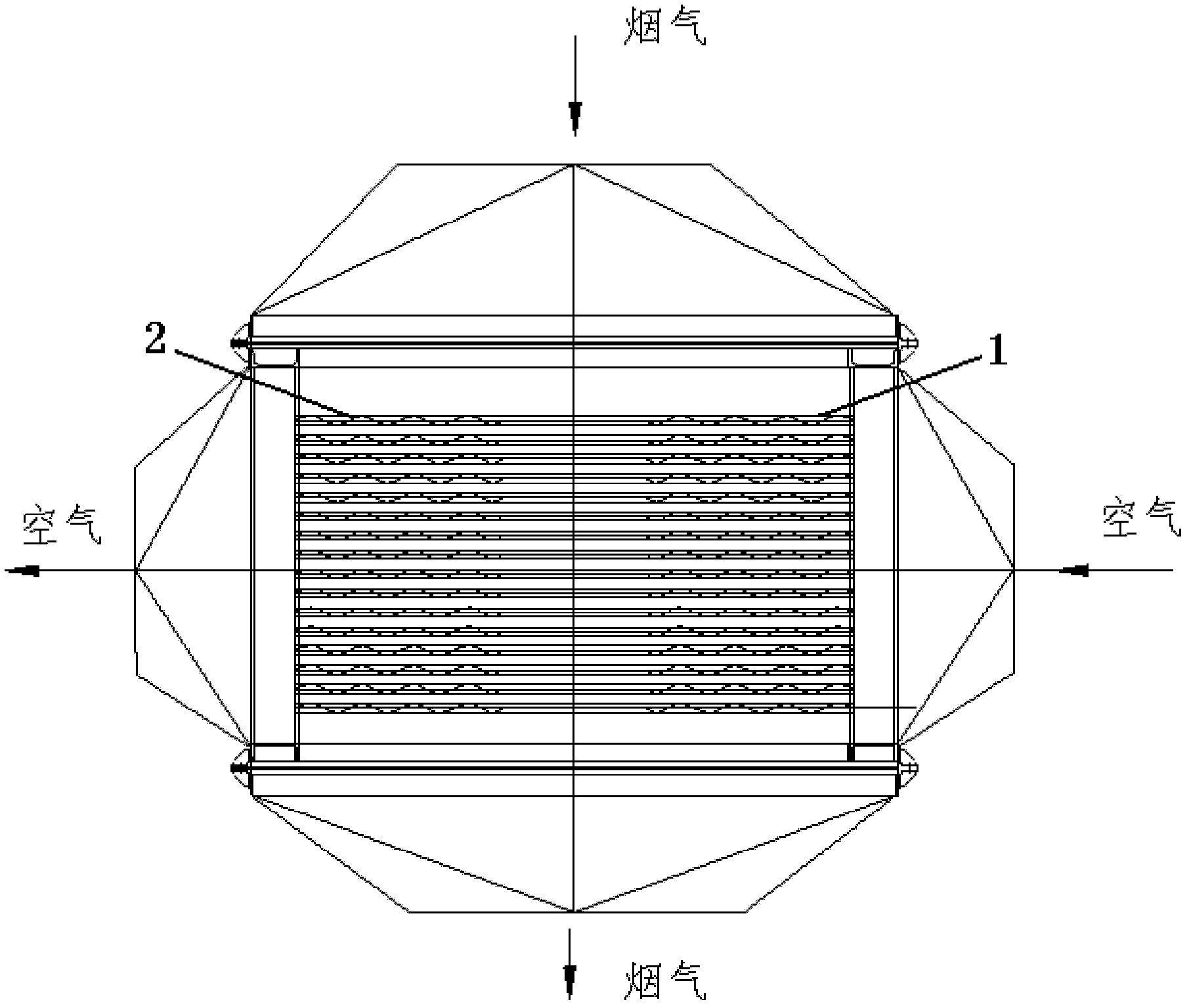

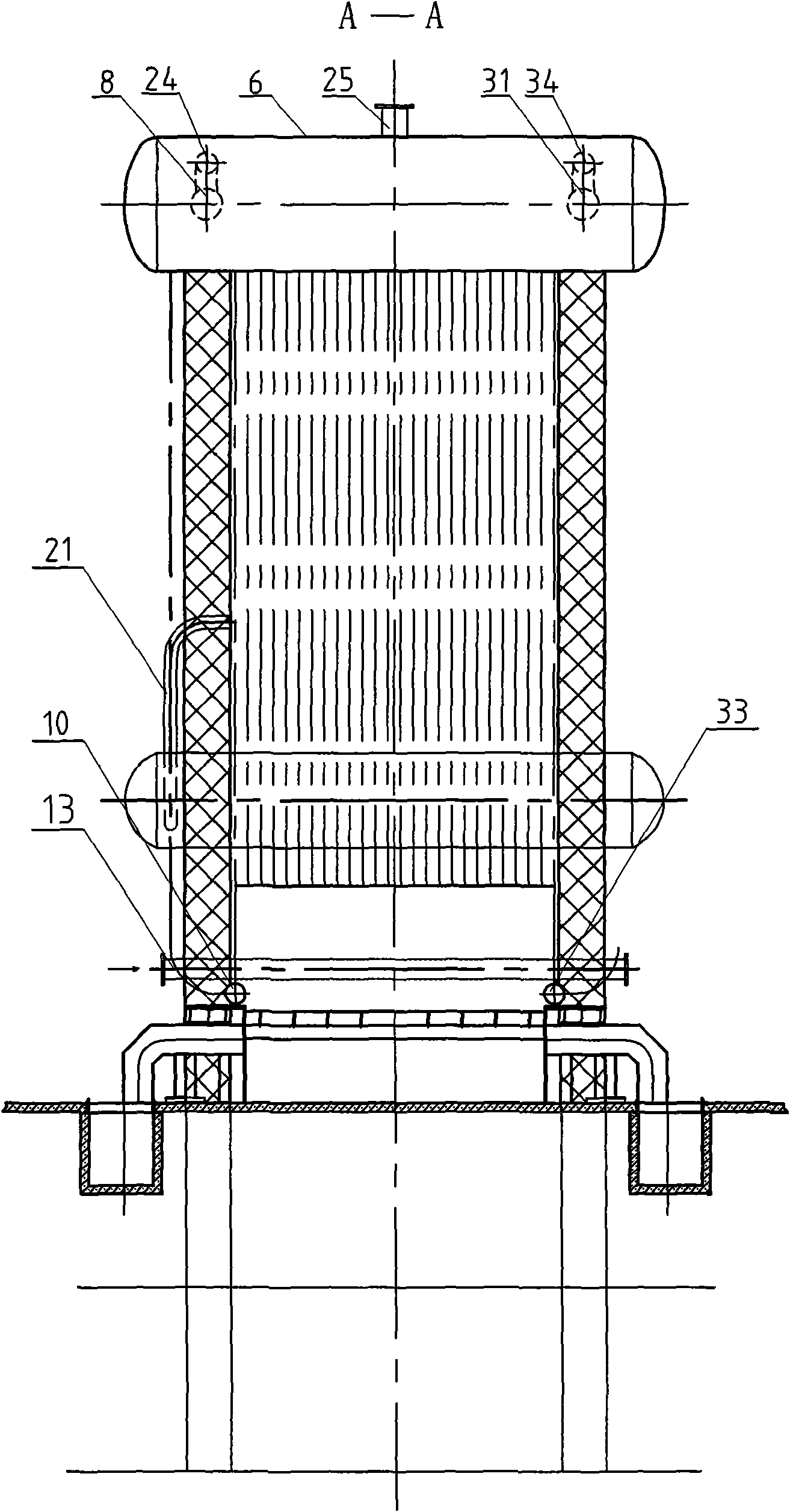

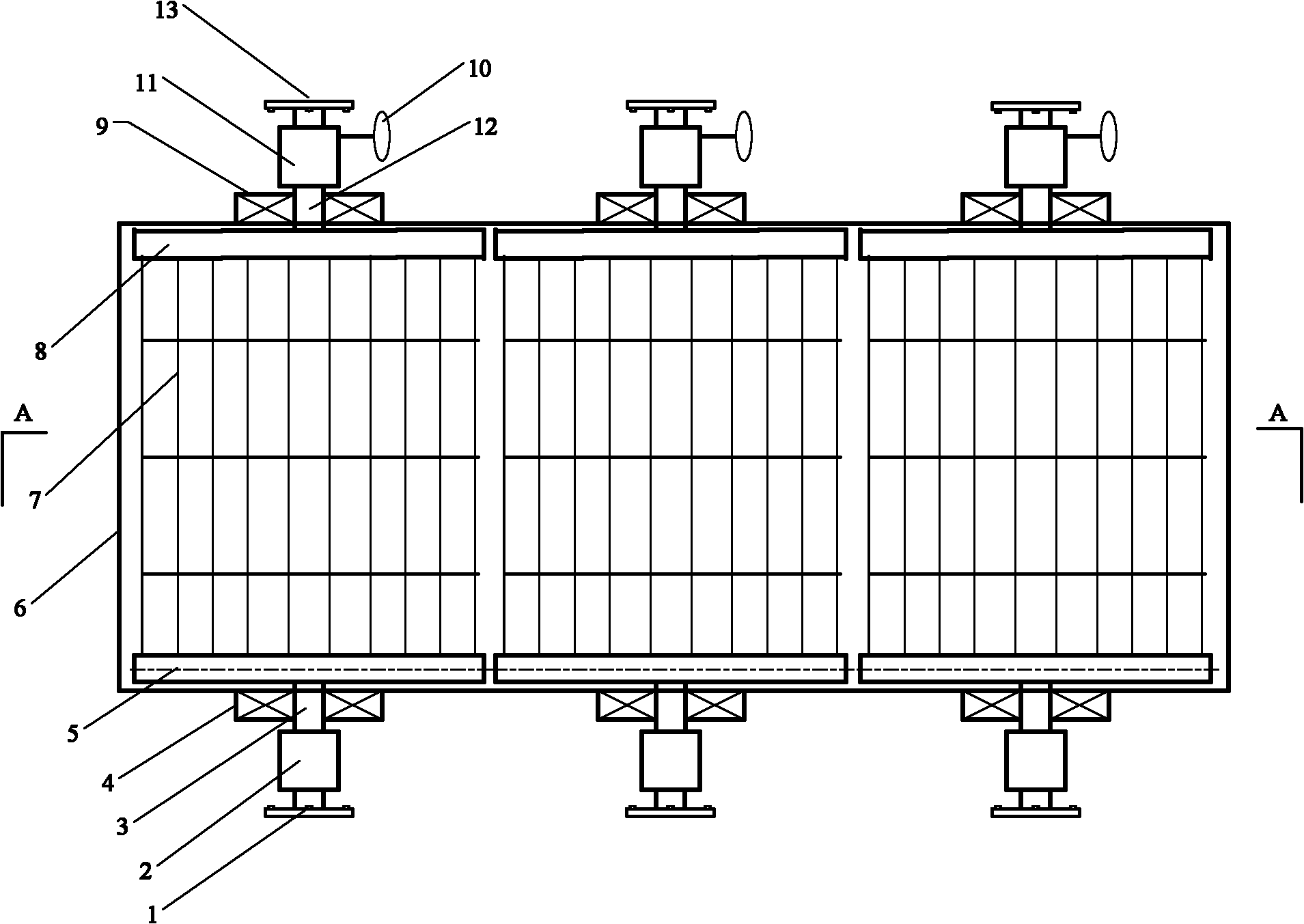

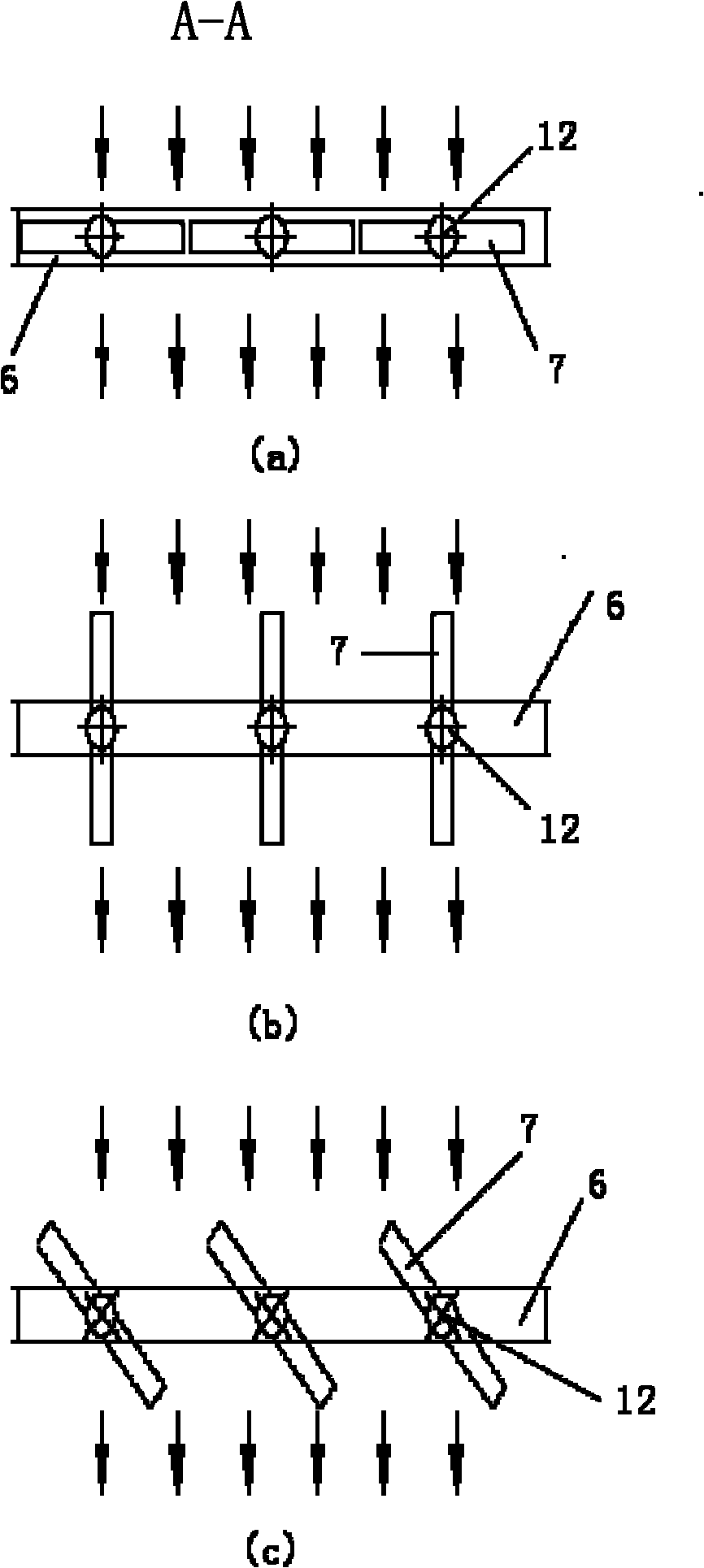

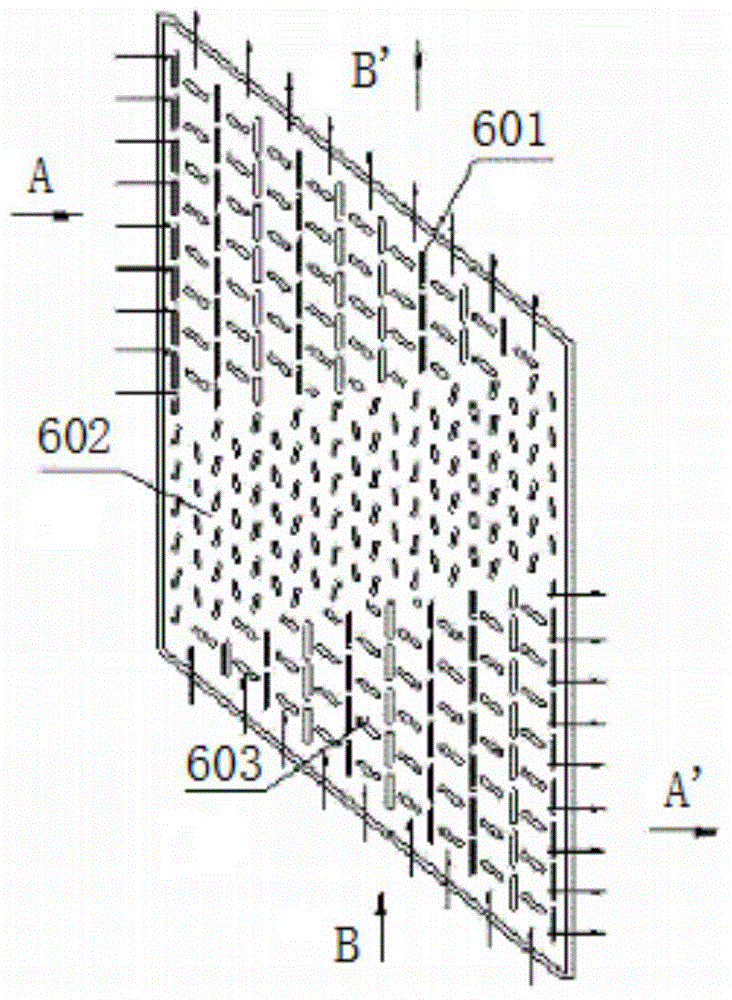

Plate type air preheater

ActiveCN1884915AEasy to blow sootSolve the problem of equipment dust accumulationCombustion processIndirect carbon-dioxide mitigationHeat transfer efficiencyEngineering

The invention relates to a sheet air preheating device, which comprises: a box, a heat exchange element, and an air-smoke entrance tubular box, wherein said box is arranged with sheet heat exchange element formed by sheet beam with at least one layer of one sheet beam module; the upper end of sheet beam is through to the smoke inlet tubular box and the air outlet tubular box, while the lower end is through to the smoke outlet tubular box and the air inlet tubular box; the sheet beam module is formed by layered ripple sheets; the air-smoke channels of sheet beam module are sealed channels with reversed direction. The invention uses reverse flow to exchange heat, with high efficiency, small volume, light weight and low cost.

Owner:GANSU LANPEC TECH +2

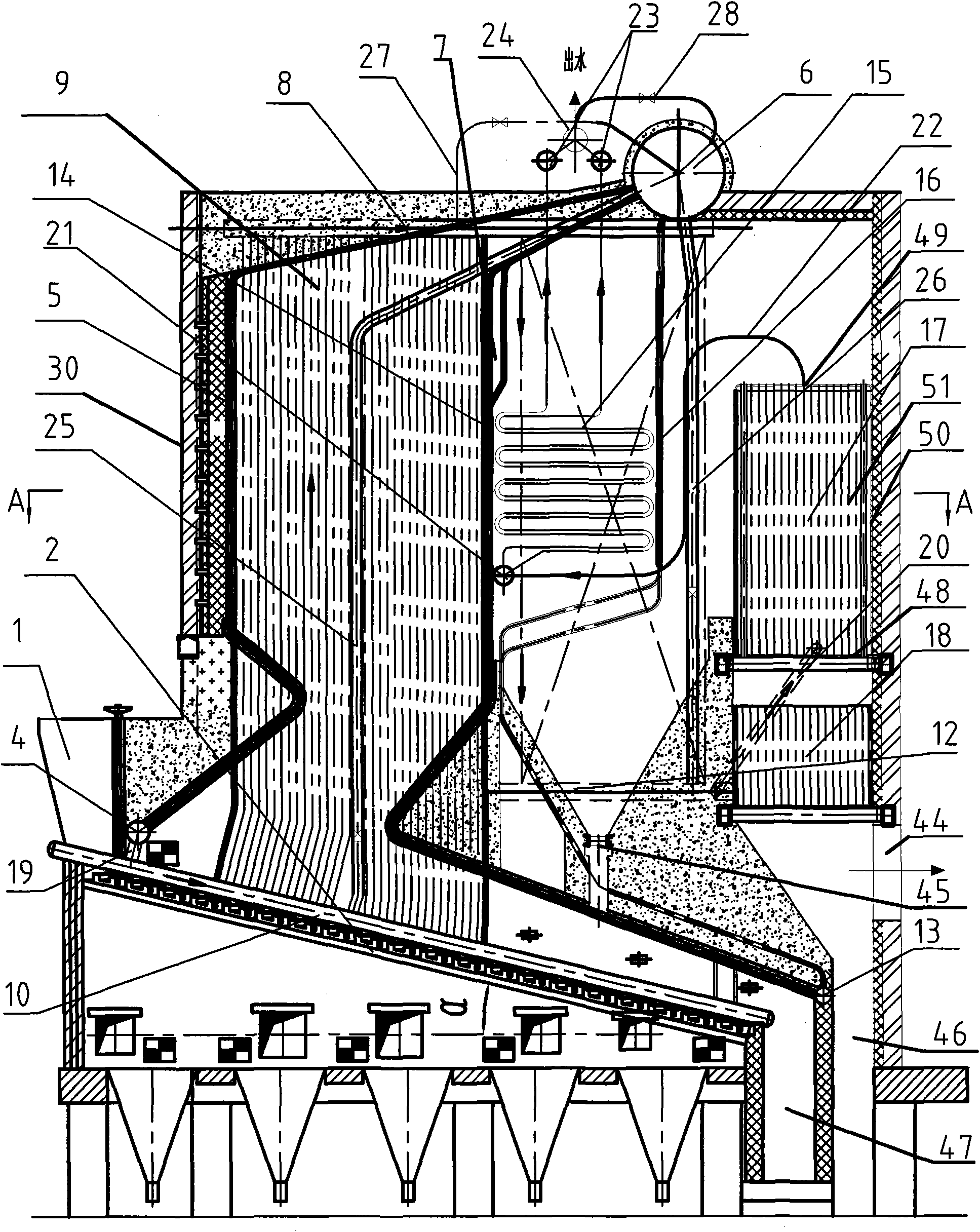

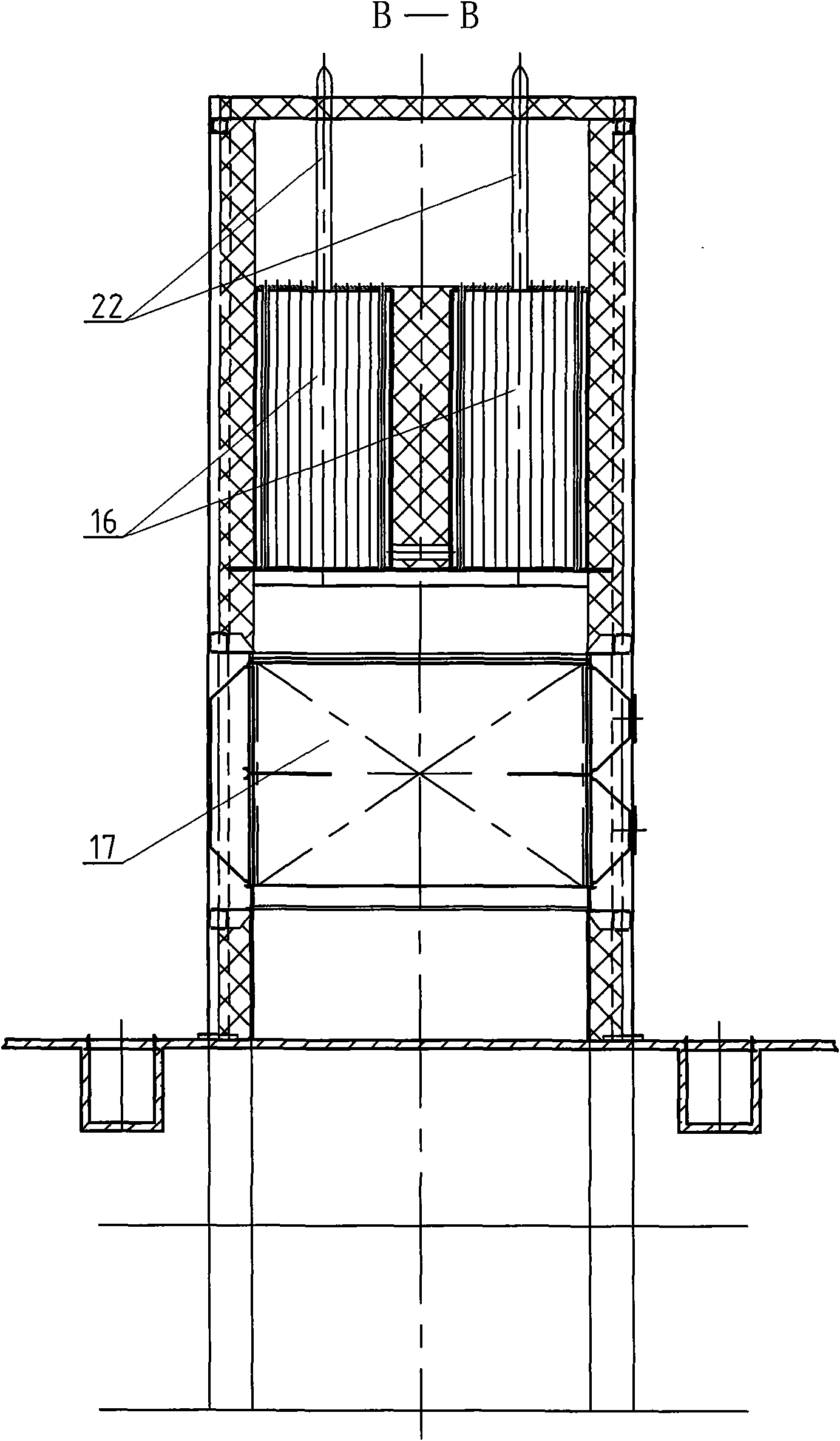

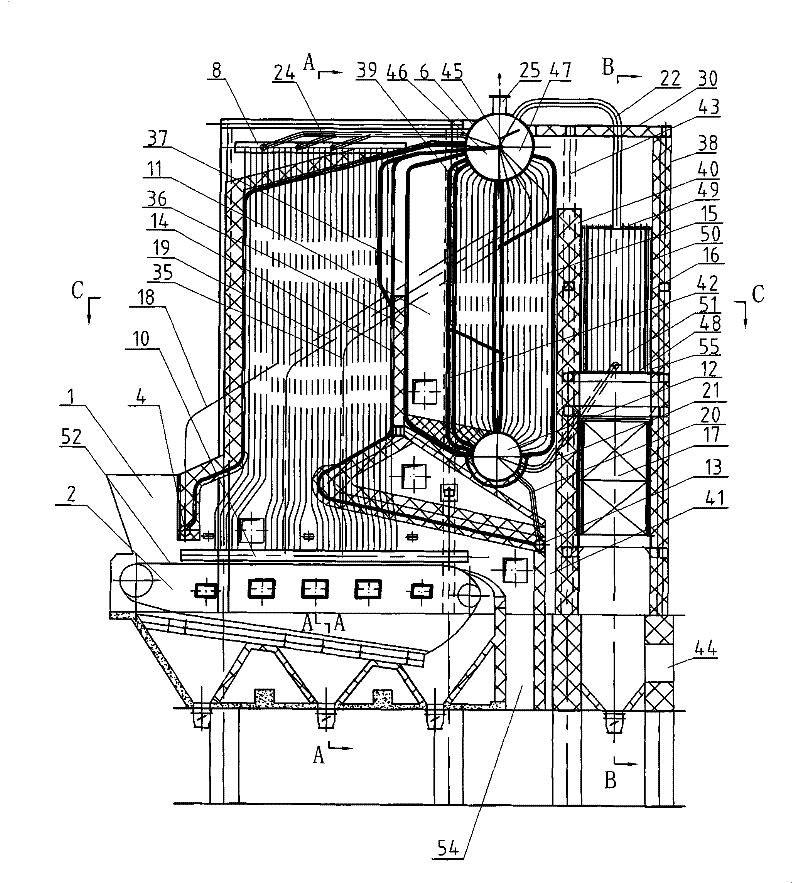

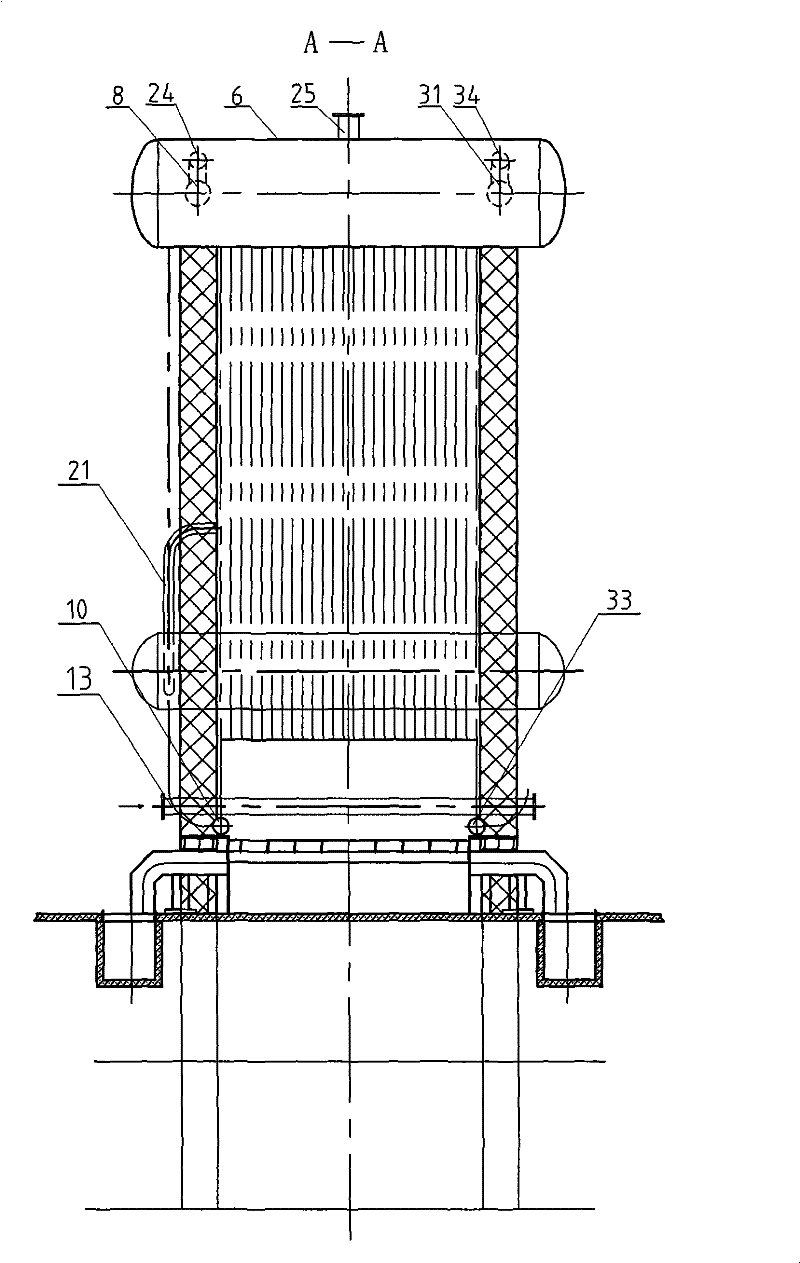

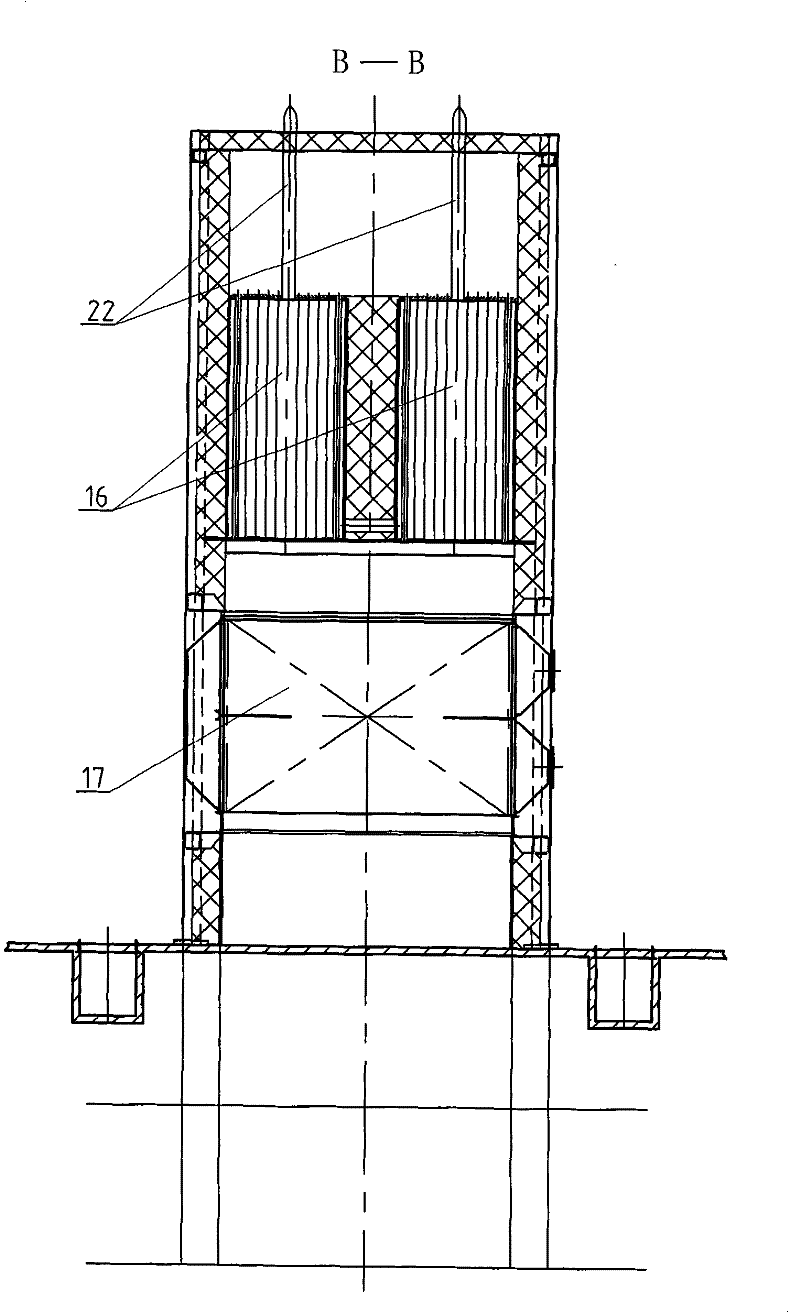

Low-range circulating fluidized bed water boiler for combusting inferior fuel and combustion method thereof

ActiveCN102901212BReduce wearReduce carbon contentFluidized bed combustionIndirect carbon-dioxide mitigationFluidized bedEngineering

The invention relates to a low-range circulating fluidized bed water boiler for combusting inferior fuel and a combustion method of the low-range circulating fluidized bed water boiler, and particularly relates to a circulating fluidized bed water boiler and a combustion method of the low-range circulating fluidized bed water boiler. The invention aims to solve the problem that the conventional grate firing water boiler can only combust high-quality coal and the water wall of the conventional circulating fluidized bed water boiler is seriously abraded when inferior fuel is combusted. Multiple buried pipes are uniformly arranged on both sides in a low-speed bed in a dense-phase area on the lower part of the boiler body; both sides of a high-speed bed air chamber are respectively provided with a low-speed bed air chamber; an intermediate wind-distribution plate is arranged at the upper part of the high-speed bed air chamber; the upper part of each low-speed bed air chamber is respectively provided with a side wind-distribution plate; a two-side wall water-cooling wall upper header is arranged at the upper end of the boiler body; a two-side wall water-cooling wall lower header is arranged at the lower end of the boiler body; a boiler barrel is arranged on the upper part of the two-side wall water-cooling wall upper header; and the two-side wall water-cooling upper header is communicated with the boiler barrel through a first connecting pipe. The low-range circulating fluidized bed water boiler for combusting inferior fuel is applied to the fields of utility boilers, industrial boilers and waste disposal utilization.

Owner:哈尔滨红旗锅炉有限公司

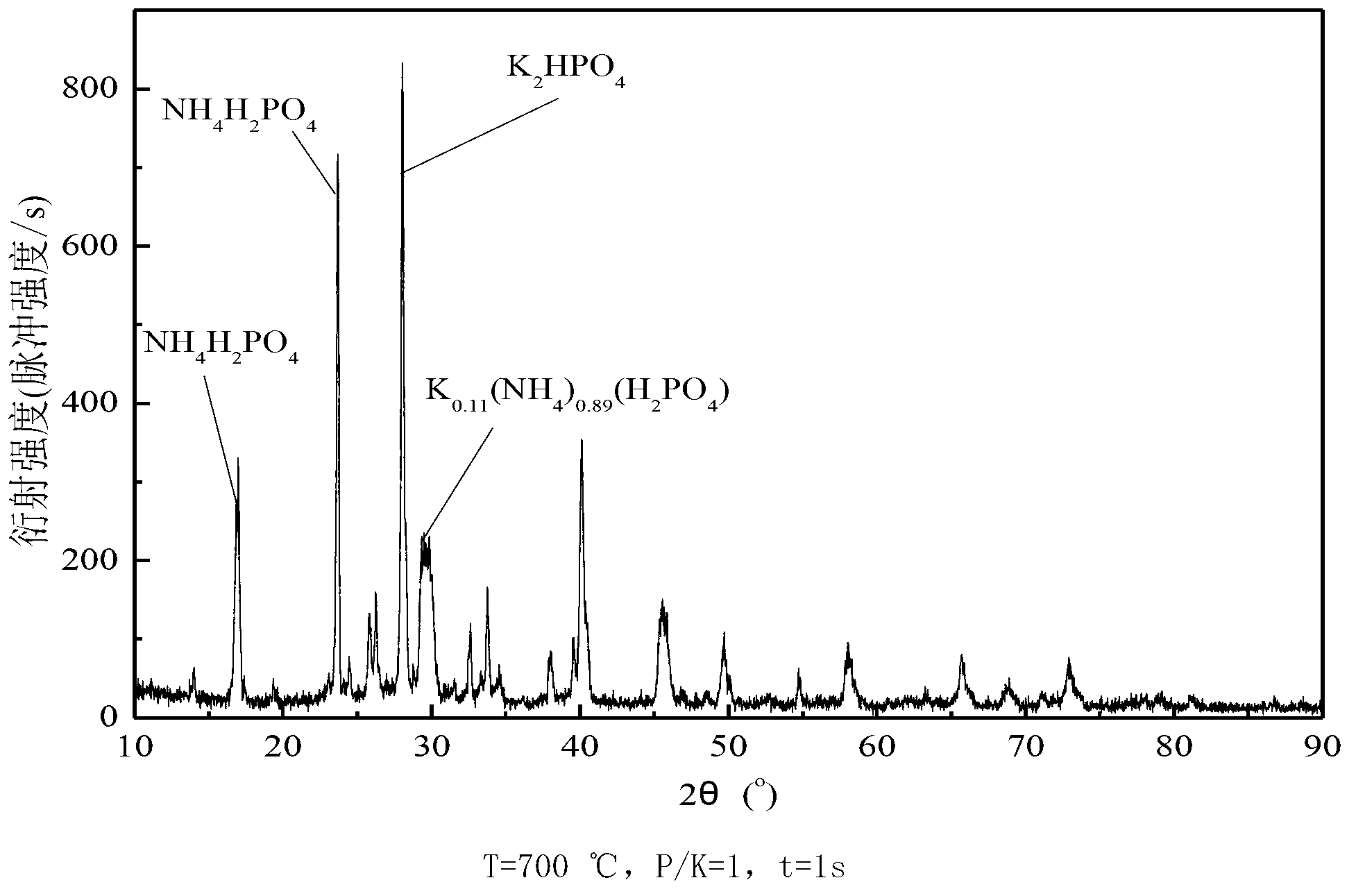

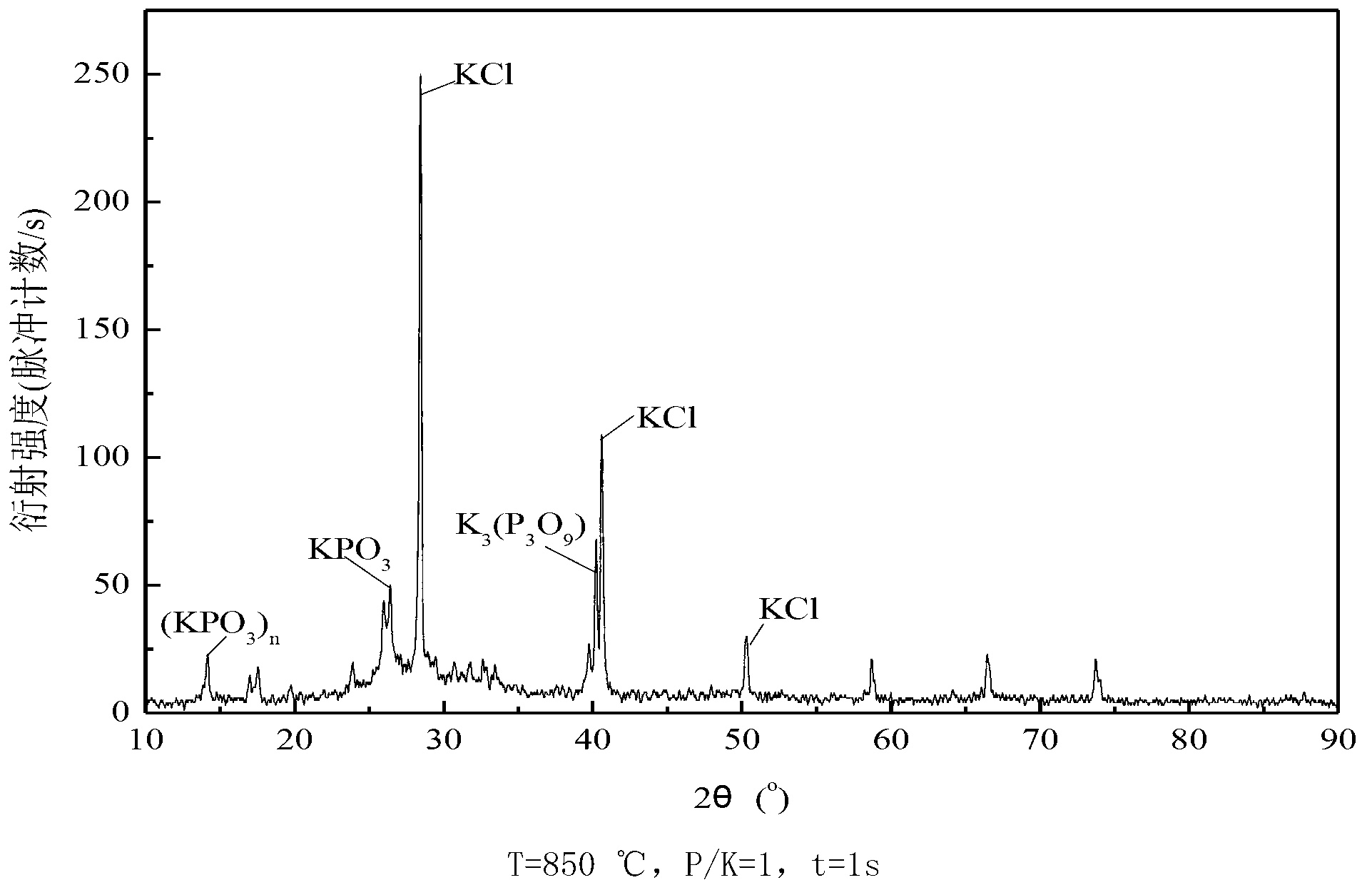

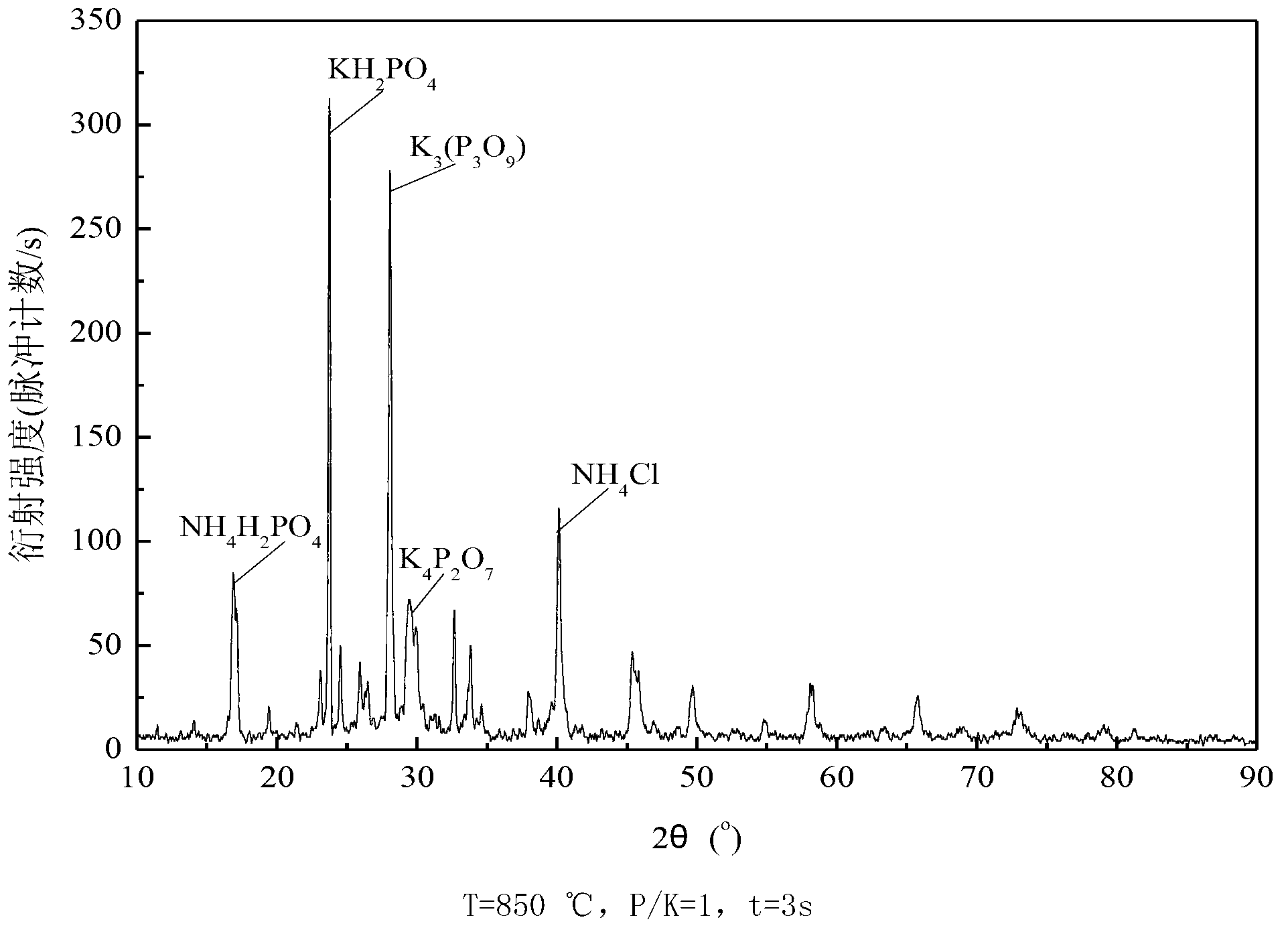

Method for removing gas-phase potassium ions in biomass flue gas by utilizing ammonium phosphate

ActiveCN103252162ASolve dust accumulationAvoid dust and corrosionDispersed particle separationFuel additivesChemistryPotassium ions

The invention discloses a method for removing gas-phase potassium ions in biomass flue gas by utilizing ammonium phosphate. The method comprises the following steps of: adding quantitative ammonium phosphate additive onto a material layer of a fire grate of a boiler or into the hearth of the boiler by virtue of a spraying device in a biomass combustion device, and carrying out a reaction on the ammonium phosphate additive as well as gas-phase potassium chloride and potassium carbonate in the flue gas at a set temperature to generate potassium phosphate, so as to remove the gas-phase potassium ions in the biomass combustion flue gas. By adopting the method for removing gas-phase potassium ions in biomass flue gas by utilizing ammonium phosphate, potassium ions in the flue gas when biomass fuel combusts can be effectively removed, the problems that ash is deposited on a biomass boiler heating surface and the biomass boiler heating surface is slagged and corroded can be avoided, and removal of NOx can be promoted by amino groups produced when ammonium phosphate is heated and decomposed.

Owner:SHANDONG UNIV

Boiler chromium-based decoking and coal saving agent composition and preparation method thereof

The invention relates to a coal additive for coal-fried boilers in industries such as electricity generation, thermoelectricity, petroleum, chemical industry, metallurgy and the like and particularly relates to a boiler chromium-based decoking and coal saving agent composition, which is prepared from the following components in parts by weight: 65-80 parts of chromium oxide, 12-20 parts of copper sulfate, 8-13 parts of cerium oxide, 8-13 parts of vanadium pentoxide, 10-16 parts of manganese dioxide, 12-18 parts of potassium permanganate, 6-11 parts of potassium chlorate, 15-22 parts of zinc oxide, 10-15 parts of potassium molybdate, 8-13 parts of cobalt carbonate, 9-15 parts of barium carbonate, 30-40 parts of sodium carbonate, 6-10 parts of ferric trichloride, 40-55 parts of active white attapulgite clay and 0.1-0.3 part of a penetrant JFC. By using the boiler chromium-based decoking and coal saving agent composition, the problems of boiler coking and dust deposition, which are not solved for a long time, of the coal-fried boilers, are solved, the coal saving rate is larger than 4%, the problem that boiler parts are corroded by acidic substances is solved, the service life of a boiler is prolonged, and the atmospheric environment pollution is reduced. The boiler chromium-based decoking and coal saving agent composition is also suitable for deslagging of the coal-fried boilers.

Owner:LANZHOU XINXING NEUTRAL CLEANING TECH

Large scale water-fire tube hot-water boiler with single drum horizontal vertical spirally corrugated tube

A single drum horizontal vertical spirally corrugated tube large scale water-fire tube hot-water boiler relates to a water-fire tube hot-water boiler. The invention solves the problem that the existing water-fire hot-water boiler is likely to accumulate ash under low load, thus causing rise of flue gas temperature and obvious drop of heat efficiency. A membrane water wall partition is parallelly arranged at the rear of the water wall in a hearth rear wall ; two rear side wall water walls are positioned at the rear of the hearth rear wall water wall as well as at two sides in a furnace body; a coiled pipe is arranged in a cavity formed by the enclosure of the hearth rear wall water wall, the membrane water wall partition and the two rear side wall water walls; the hearth rear wall water wall, the membrane water wall partition, the two rear side wall water walls and the cavity formed by the enclosure of the three are positioned in the middle part of the furnace body; and the hearth rear wall water wall is a membrane water wall; and at least one vertical spirally corrugated tube coal economizer is arranged at the rear end in the furnace body. The invention adopts the vertical spirally corrugated tube coal economizer, and therefore no ash is accumulated in the spirally corrugated tube, ash removal is easy and the heat efficiency of the boiler is improved.

Owner:哈尔滨红旗锅炉有限公司

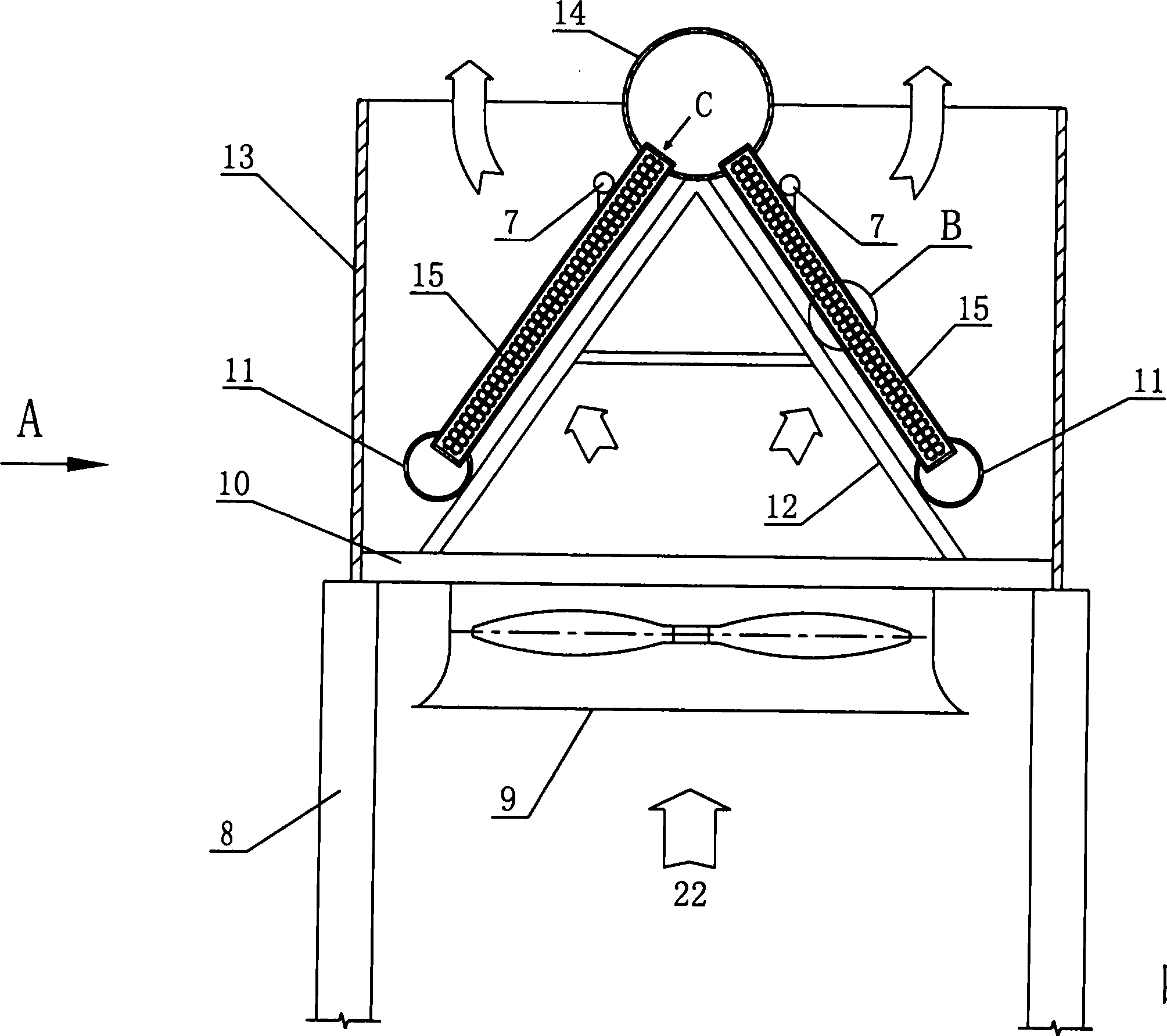

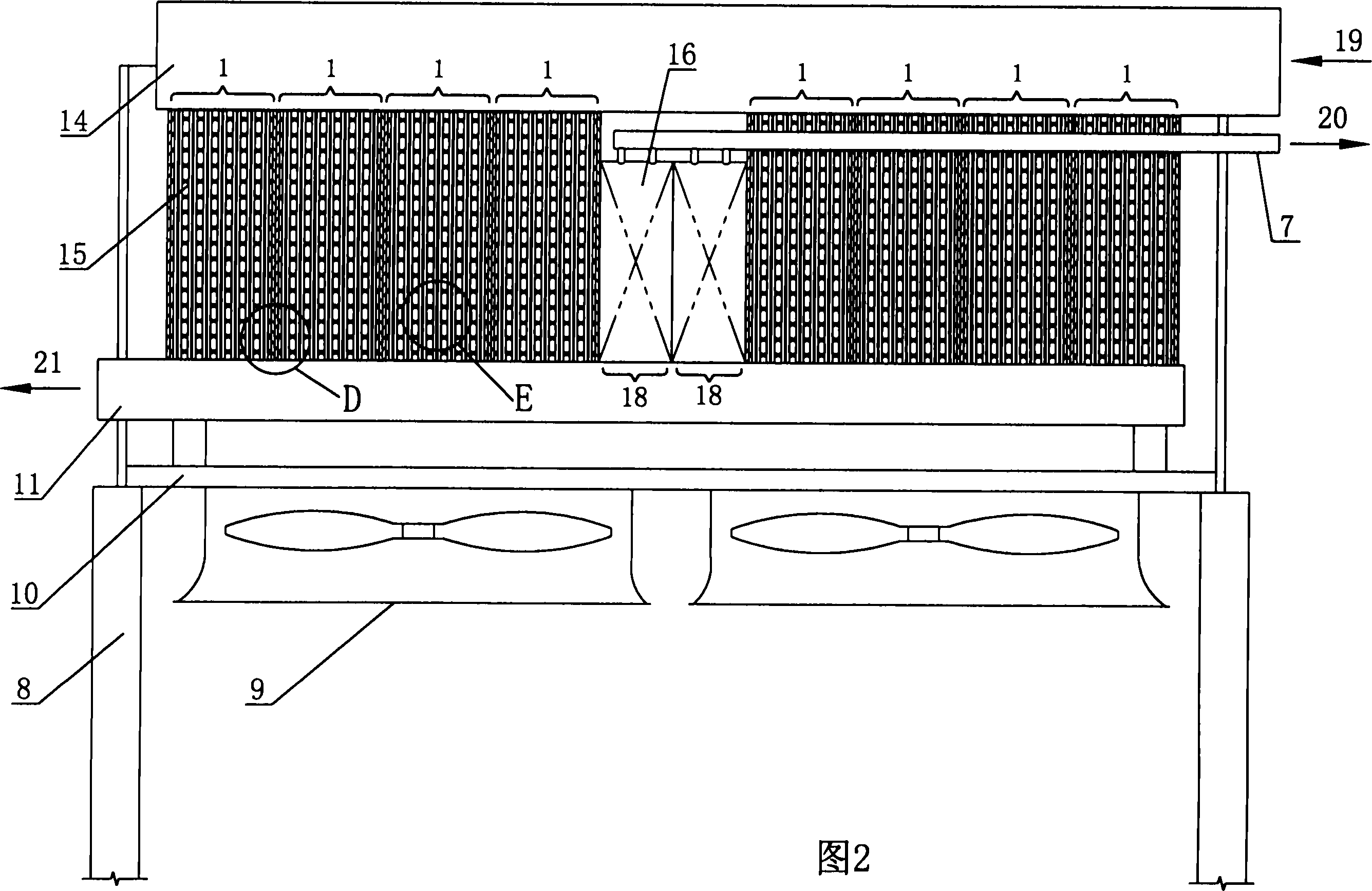

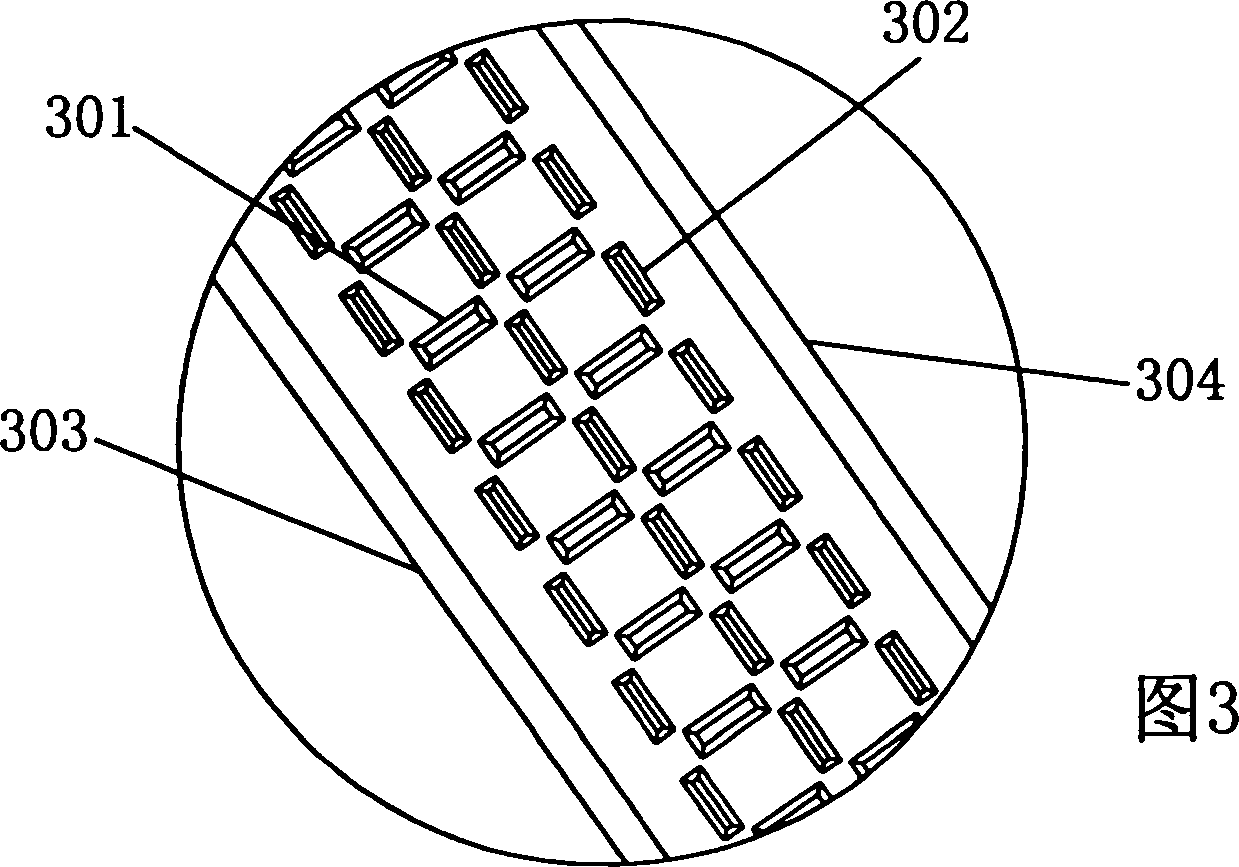

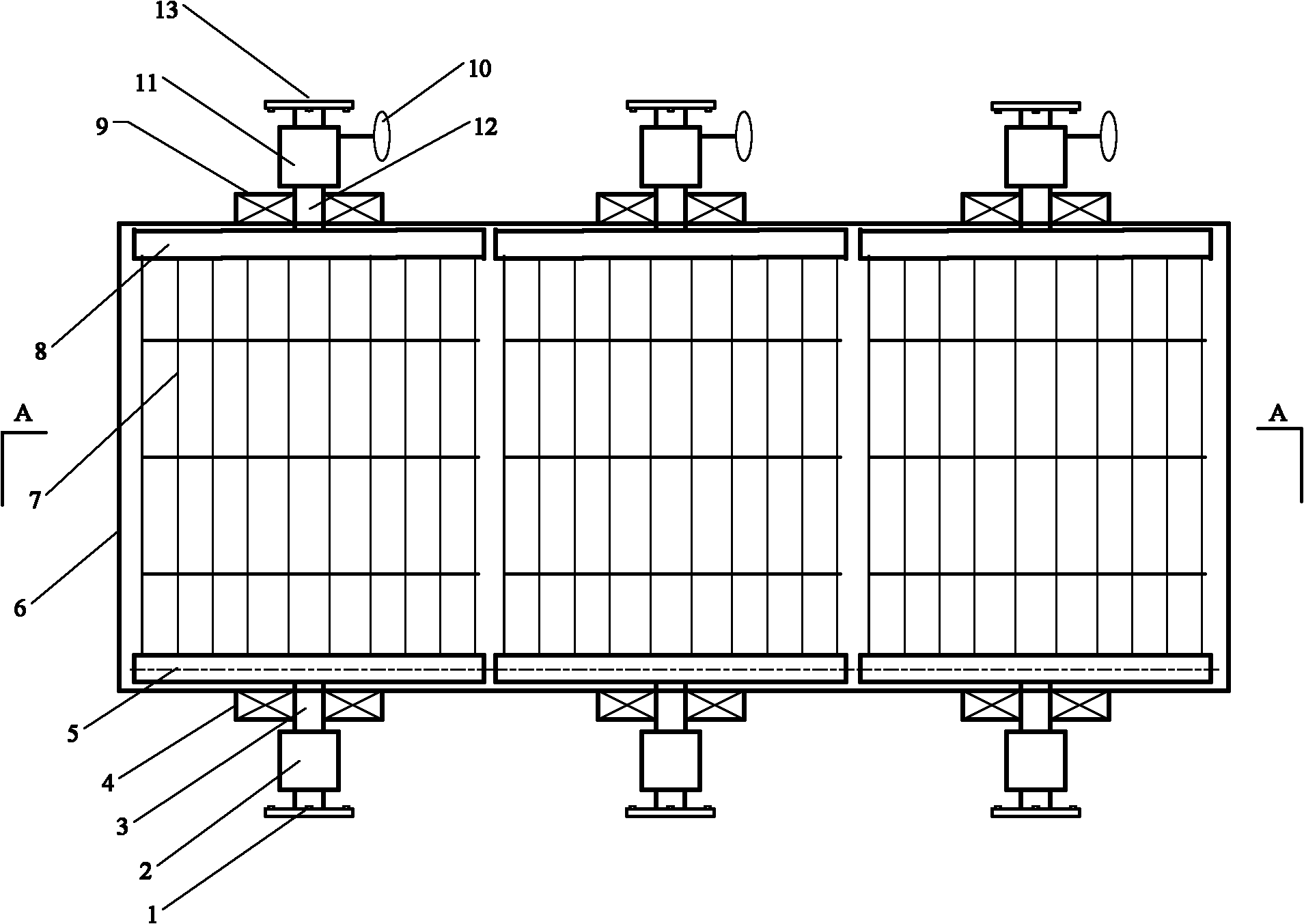

Plate type air condenser

InactiveCN1884949ANot easy to scale and accumulate dustHigh heat transfer efficiencySteam/vapor condensersMachines/enginesHeat transfer efficiencyEngineering

The invention relates to a sheet air condenser, wherein the support has one platform; a fan is mounted under the platform; an A-shaped support is mounted above the platform, while it is mounted with baffle walls around; two side surfaces of A-shaped support are suspended with leeward sheet heat transmission element and reverse sheet heat transmission element; the upper end of A-shaped support is mounted with steam distribute tube while two lower ends are mounted with condensed liquid collecting tubes, and the upper part at two sides is mounted with exhaust tube; the upper end of longitudinal channel of leeward sheet heat transmission element is through to the steam distributing tube, while the lower end is through to two condensed liquid collecting tube; the upper end of longitudinal channel of reverse sheet heat transmission element is through to two exhaust tubes, while the lower end is through to two condensed liquid collecting tubes. The invention has high heat transmission efficiency, better cooling effect, and low energy consumption.

Owner:张延丰 +1

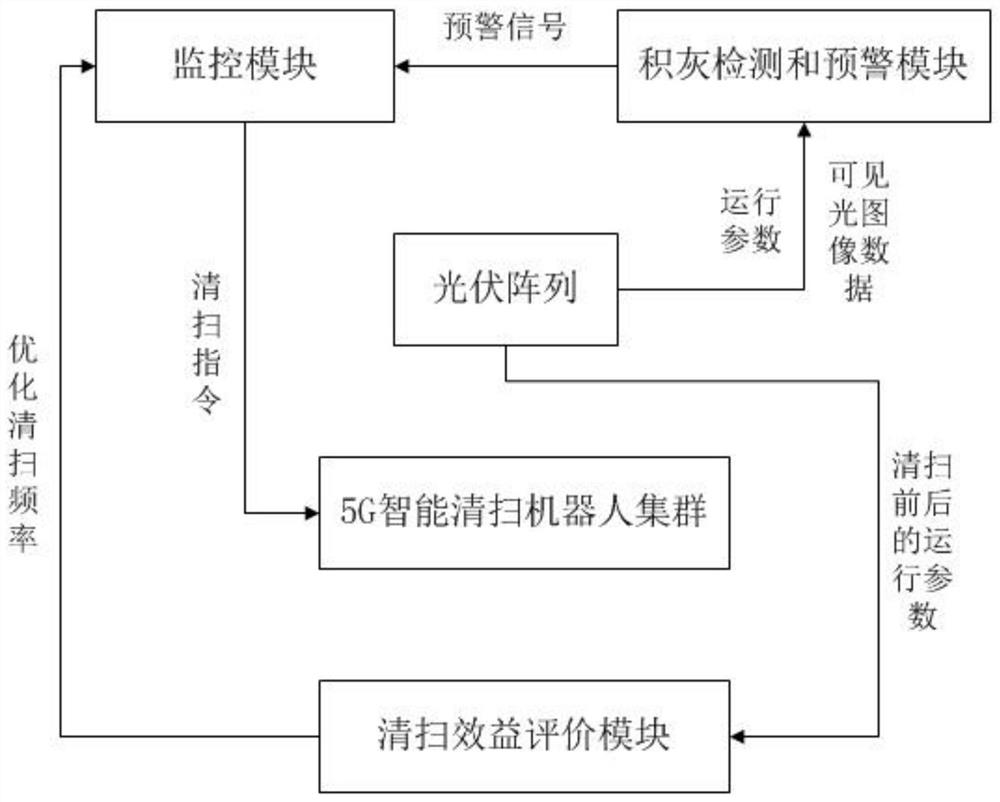

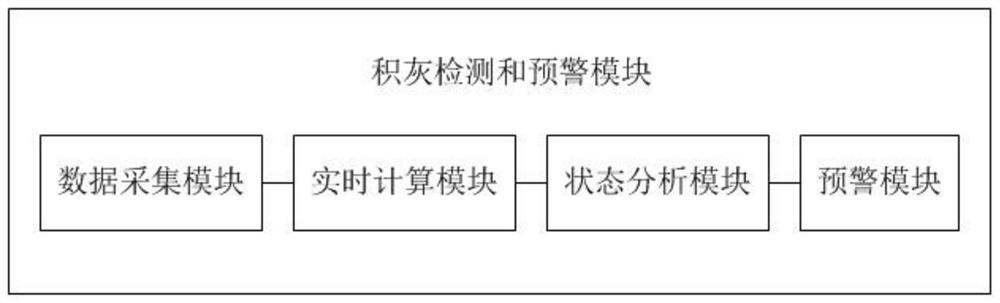

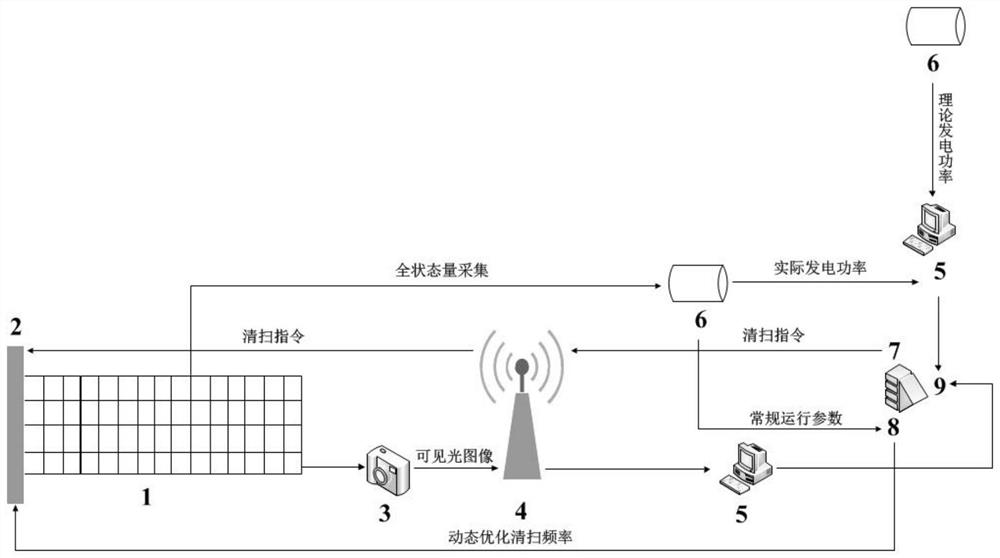

Photovoltaic power station sweeping and monitoring integrated management system

ActiveCN112871938ASolve dust accumulationImprove operation and maintenance levelPhotovoltaicsFlexible article cleaningPhotovoltaic arraysComputer science

The invention belongs to the field of intelligent sweeping, and specifically relates to a photovoltaic power station sweeping and monitoring integrated management system comprising a dust deposition detection and early warning module, a monitoring module, an intelligent sweeping robot cluster and a sweeping benefit evaluation module. The dust deposition detection and early warning module judges the dust deposition state through operation parameters of a photovoltaic array and outputs an early warning signal when the dust deposition state reaches a dust deposition threshold state. The monitoring module sends a sweeping instruction to the intelligent sweeping robot cluster when receiving the early warning signal, and optimizes the sweeping process according to the received operation data of the intelligent sweeping robot. The intelligent sweeping robot cluster controls full-automatic cleaning of the photovoltaic array according to the cleaning instruction and sends operation data to the monitoring module. The sweeping benefit evaluation module judges the sweeping effect according to the change of the operation parameters of the photovoltaic array before and after sweeping, and determines the optimal sweeping frequency in combination with the sweeping benefit data of the photovoltaic array. According to the scheme, deposited dust sweeping is carried out on the photovoltaic array with the advantages of less manpower, low cost and intelligence, and meanwhile the operation and maintenance level of a photovoltaic power station is improved.

Owner:GUODIAN NEW ENERGY TECH INST

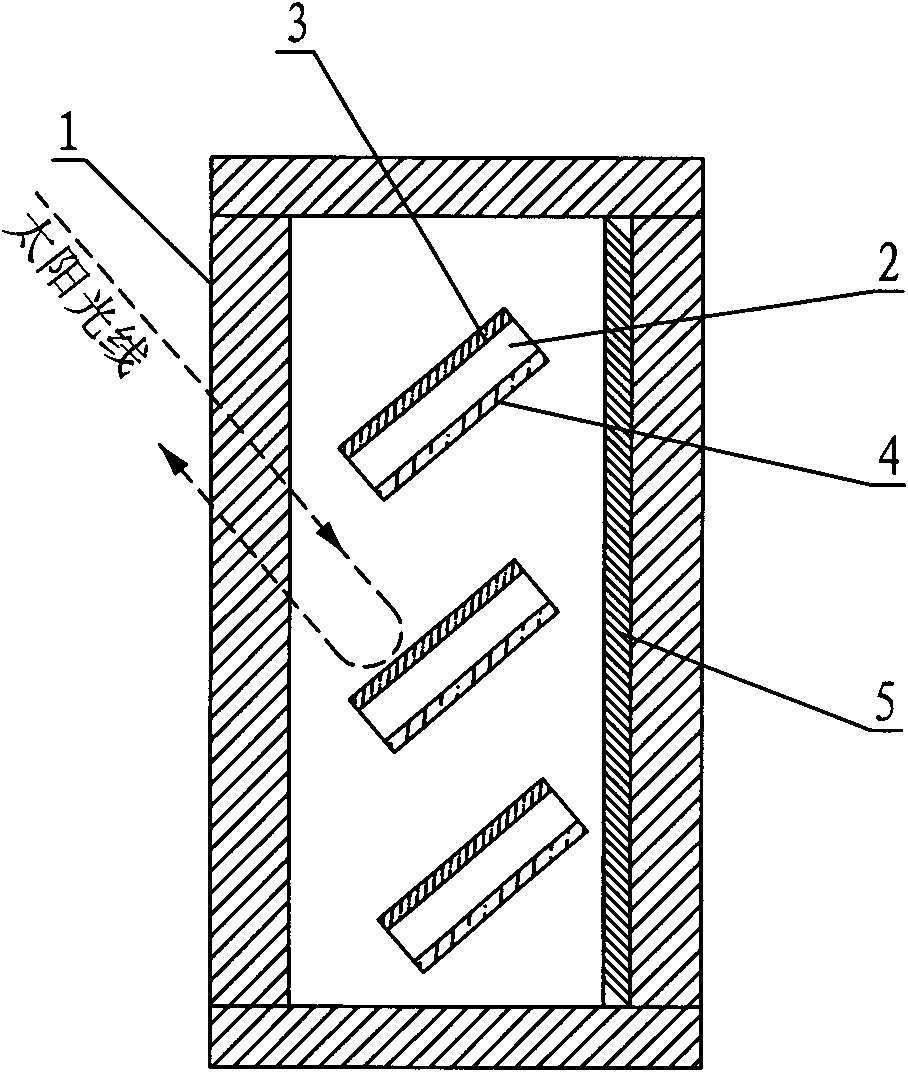

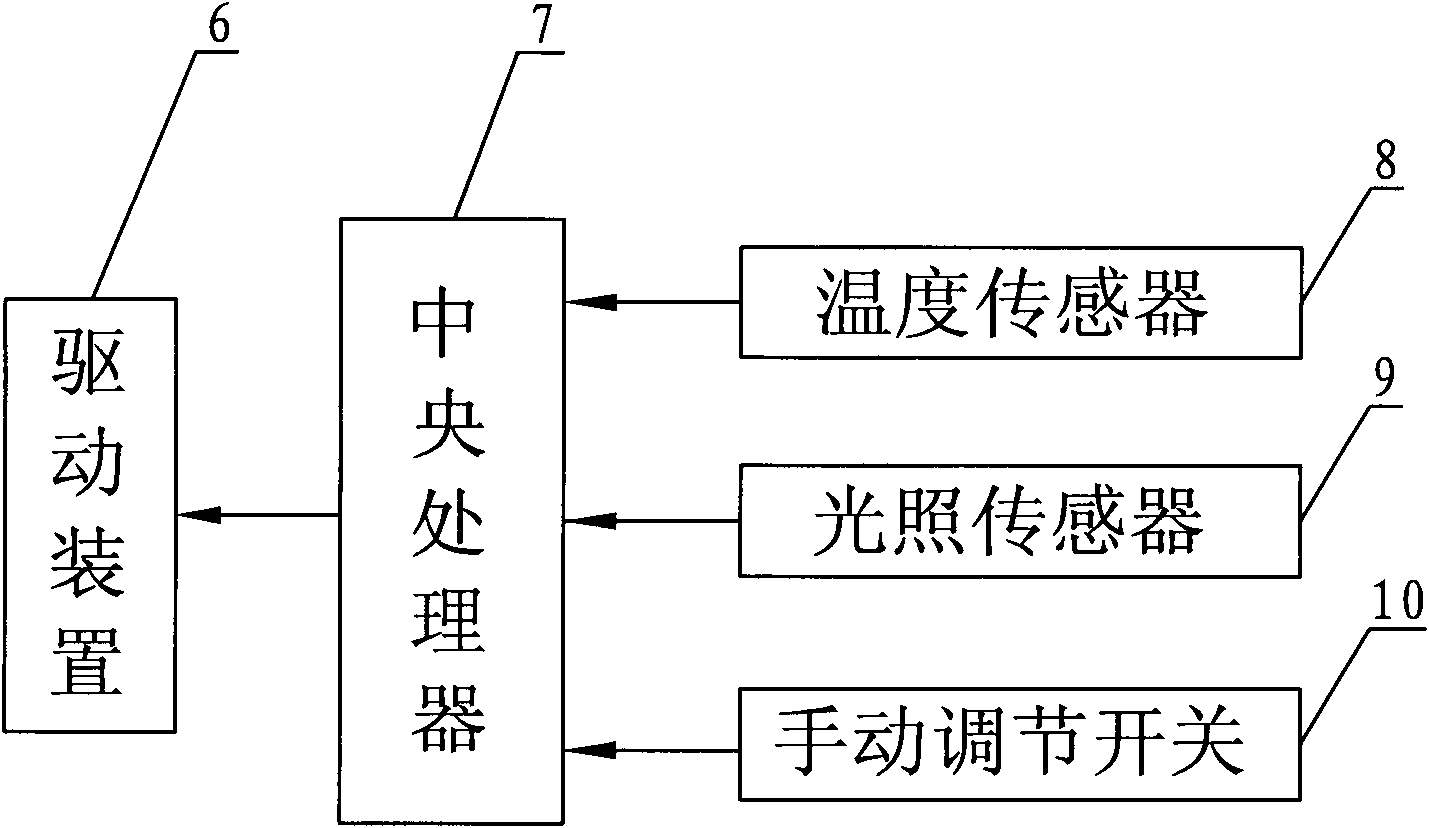

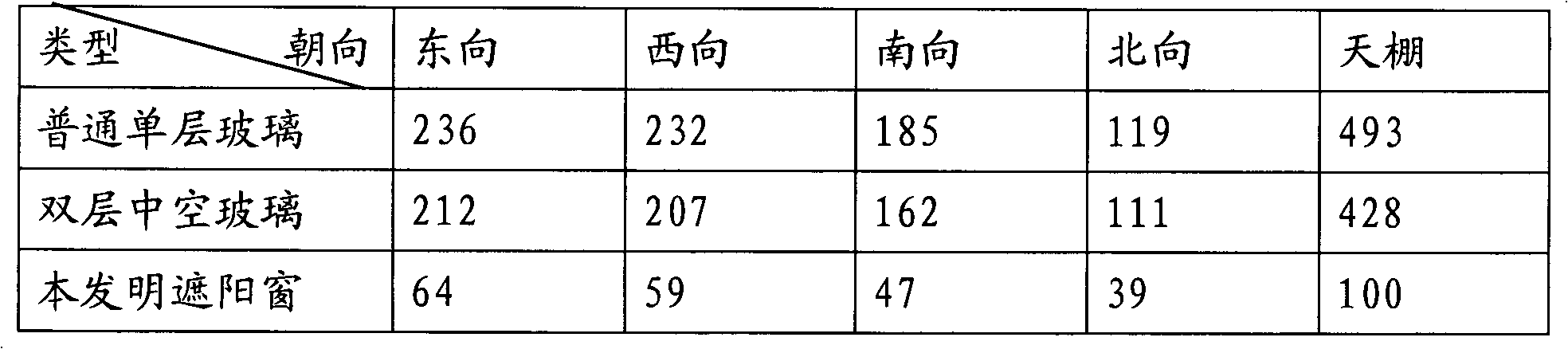

Heat insulating type sun-shading energy saving device

The invention relates to a casement window sun-shading device and particularly discloses a heat insulating type sun-shading energy saving device which comprises a hollow glass body, a plurality of shutters arranged in parallel, and a driving device used to drive the shutters to overturn. The hollow part inside the hollow glass body forms a sealed cavity in which the shutters are installed; high-reflectivity coatings and low-reflectivity coatings are respectively arranged on the front sides and the back sides of the shutters; and a low reflectivity coating film is arranged on the wall of the side of the sealed cavity, which faces the interior of a house. The heat insulating type sun-shading energy saving device not only solves the problem of dust stratification but also solves the problem of secondary heat transmission while shading the sun, so the heat insulation effect of the heat insulating type sun-shading energy saving device is better.

Owner:许鹏

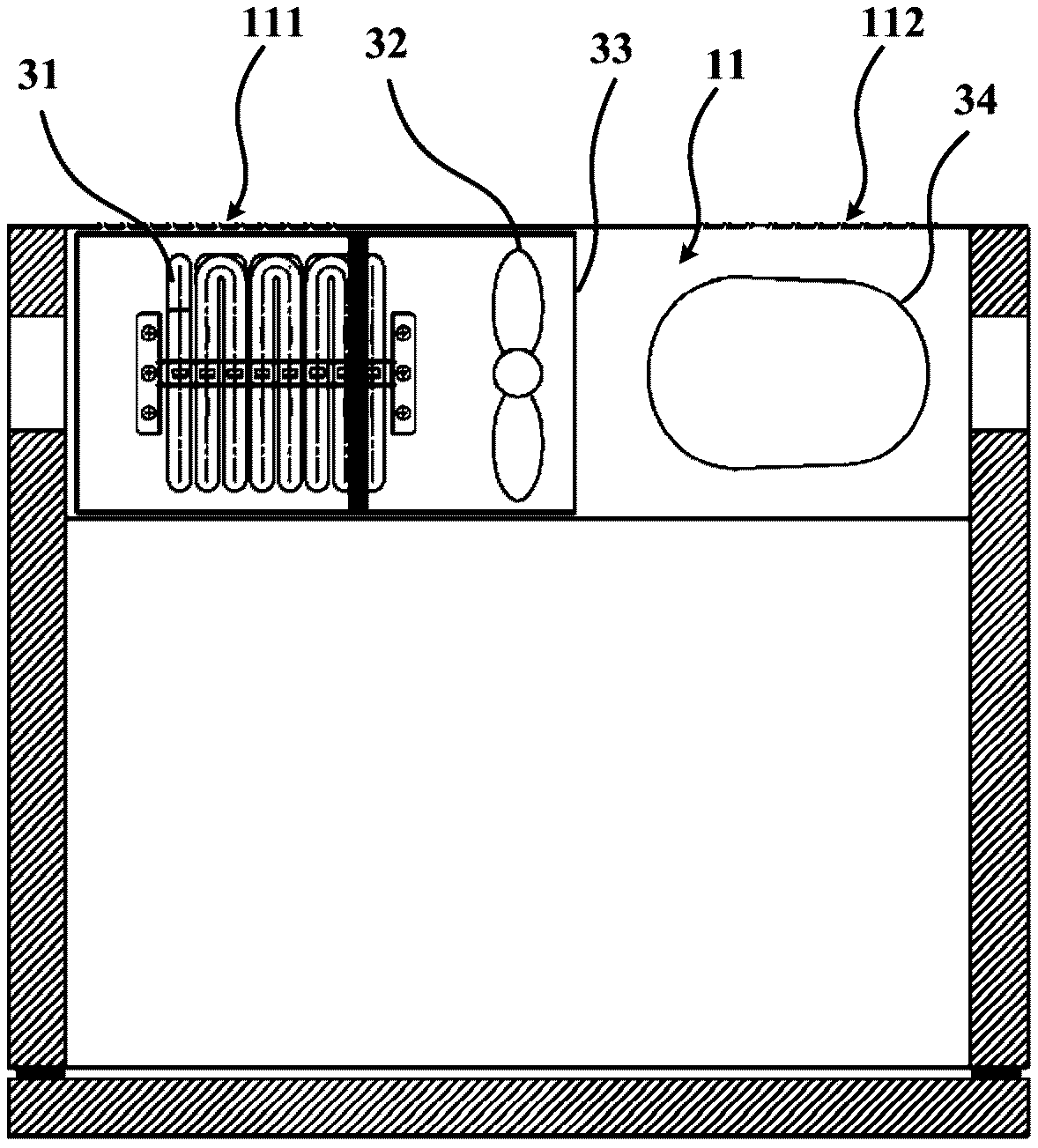

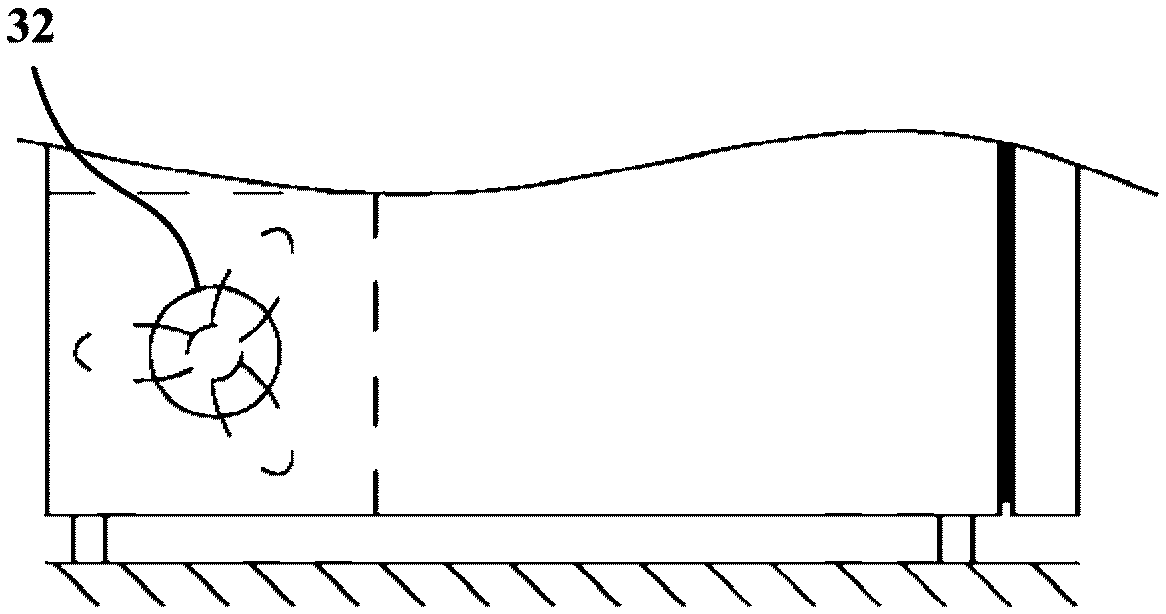

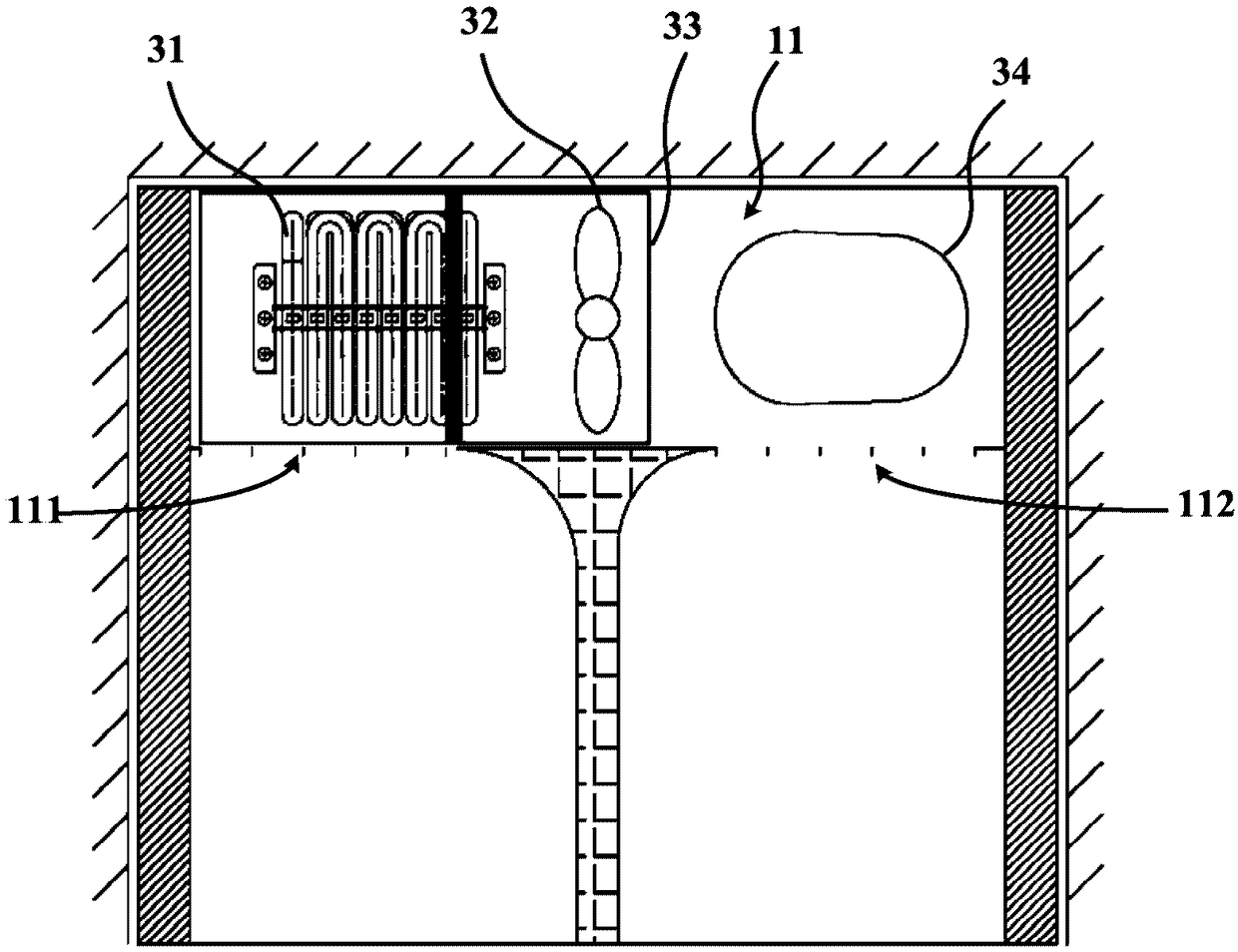

Refrigerator

ActiveCN108413686ASolve dust accumulationReduce energy consumptionLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention provides a refrigerator. The refrigerator comprises a refrigerator body, a door body, a refrigeration system and a dust accumulation disc, wherein an object storage space and a compressor bin are limited in the refrigerator body; the compressor bin is arranged on the back side of the bottom of the refrigerator body; the front side of the compressor bin is an air duct; the compressorbin is provided with an air inlet; the air inlet communicates with the air duct; the door body is pivotally arranged on the front surface of the refrigerator body, and is used for allowing a user to open and close the object storage space; the refrigeration system provides cold energy for the object storage space; and the dust accumulation disc is detachably arranged at the air duct, communicateswith the air inlet of the compressor bin, and blocks dust in air entering the air duct, so that clean air enters the compressor bin. According to the refrigerator, the dust accumulation problem of therefrigeration system in the compressor bin is solved through a simple structure, the refrigeration effect of the refrigeration system is prevented from being affected by accumulated dust, and besides, entire energy consumption of the refrigerator can be further reduced; and the dust accumulation disc is detachably arranged at the air duct, so that the user can regularly pull out and clean the dust accumulation disc conveniently, and utilization convenience of the user is improved.

Owner:大连海尔电冰箱有限公司 +2

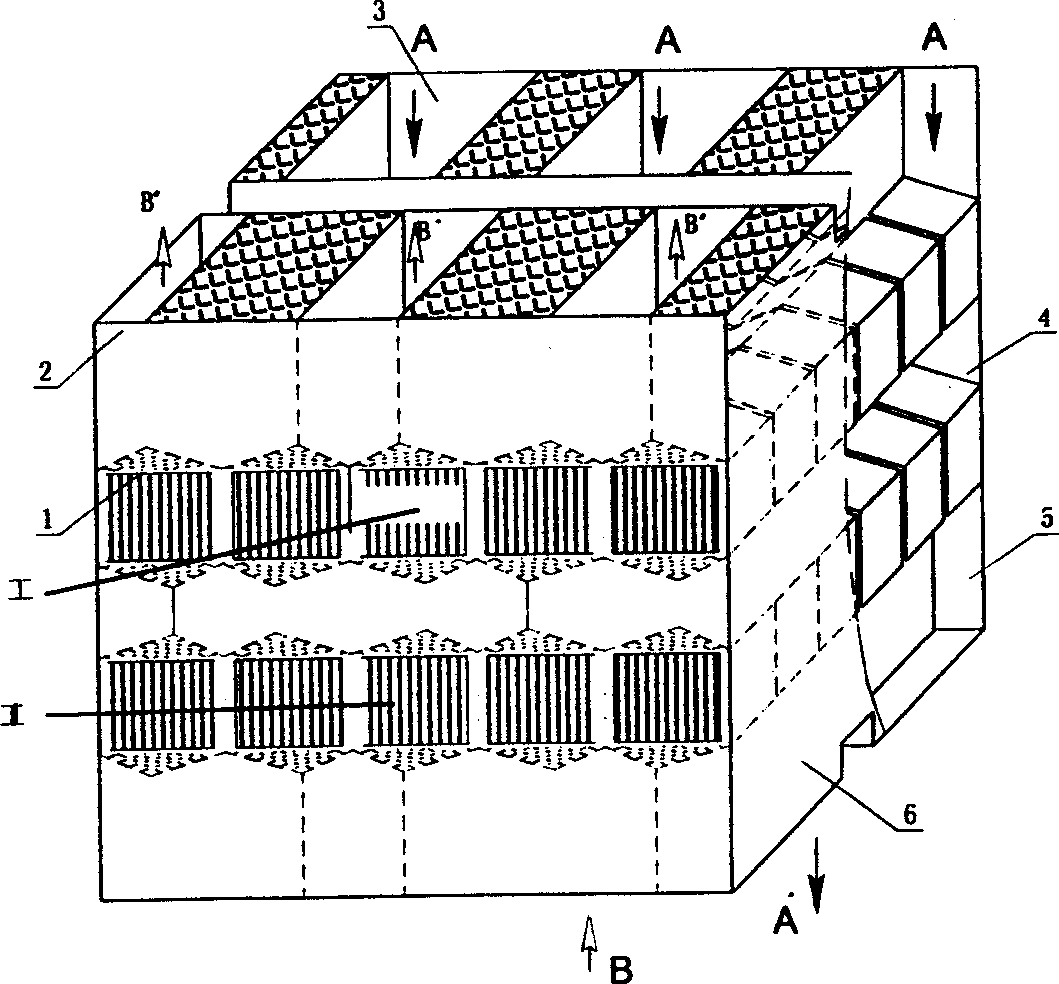

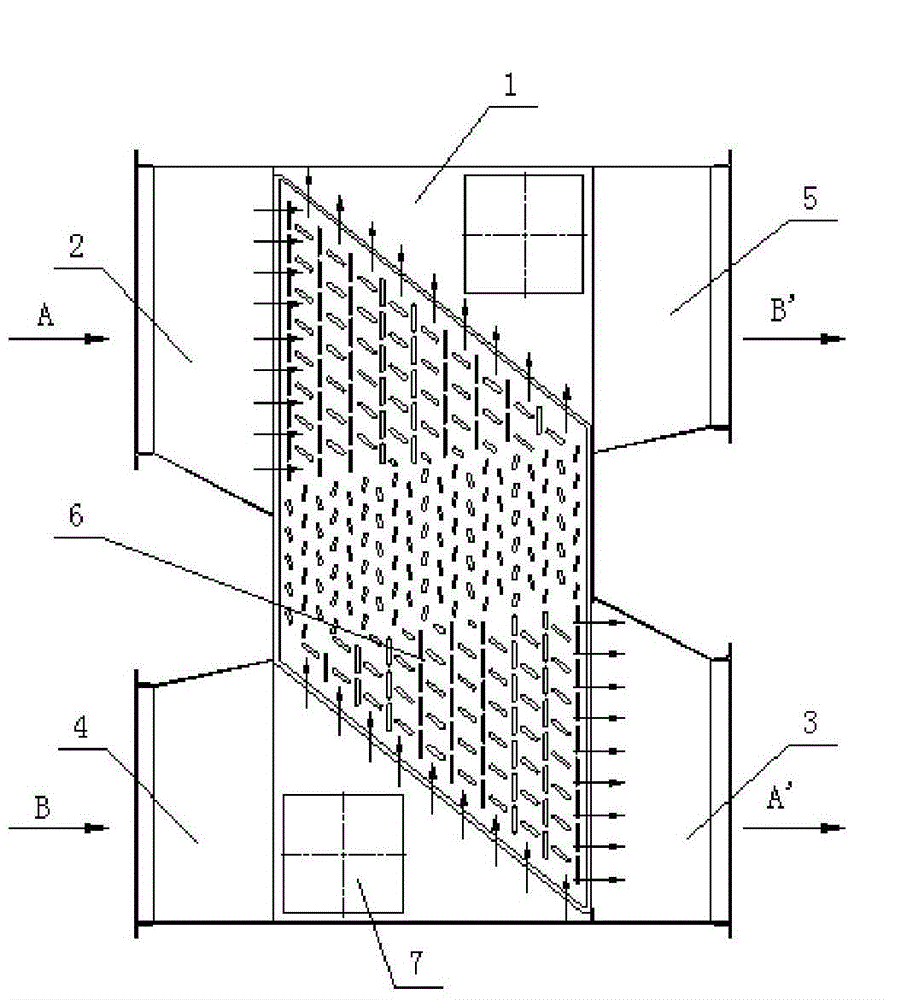

All-welded plate type heat exchanger for multi-stream gas-to-gas heat exchange

InactiveCN104677147AIncrease profitMeet the needs of multi-media heat exchangeLaminated elementsStationary plate conduit assembliesCounter flowComputer module

The invention relates to an all-welded plate type heat exchanger for multi-stream gas-to-gas heat exchange; an upright quadrangular heat transfer plate assembly module is chosen as a heat transfer element; dust impurities of heat exchange mediums attached on plates fall because of the self weight; moreover, the surfaces of the plates are smooth and have no flowing dead zone, so that the dust-blowing is convenient, the daily maintenance and cleaning of equipment are facilitated and the dust deposition of the equipment is solved thoroughly. The quadrangular heat transfer plate assembly module is a pure counter-flowing corrugated plate; and a hot medium and a cold medium are in a pure counter-flowing state at two sides of the plates. The corrugations of the plates are capable of strengthening heat transfer and play guiding and supporting roles. After the plates are overlapped, a hot medium passage and a cold medium passage are respectively formed at two sides of the plates, and the corrugations contact with one another; the mutual supporting structure is capable of strengthening the medium pressure-bearing ability of the plates; meanwhile, the equipment is compact in structure and small in volume; and the manufacturing cost of the equipment is reduced.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

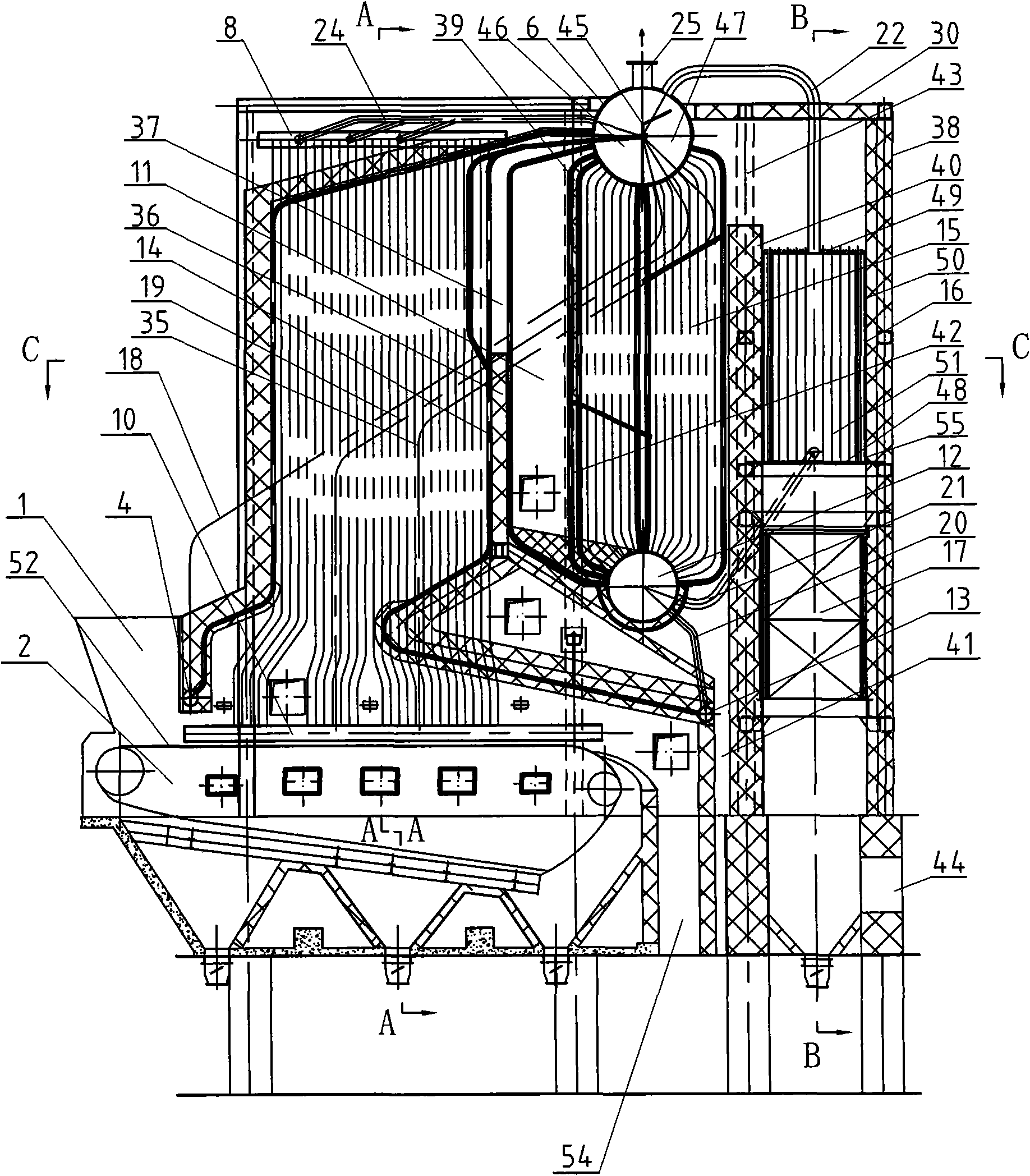

Boiler thermodynamic system with smoke wastes as fuels and method thereof

InactiveCN106224981AAchieve combustionHigh thermal efficiencySolid fuel combustionIndirect carbon-dioxide mitigationAir preheaterShock wave

The invention discloses a boiler thermodynamic system with smoke wastes as fuels and a method thereof. The system comprises a boiler body, a stokehole hopper, a fire grate, a water-cooled wall pipe, a convection pipe, a coal economizer, an air preheater, an air blower, a dust remover and an induced draft fan; a feeding roller is arranged in the stokehole hopper; a front arch and a back arch are arranged in a combustion chamber; a secondary air device is arranged at the middle part of the combustion chamber; and multiple shock wave dust blowers are arranged on heated surfaces of the water-cooled wall pipe, the convection pipe, the coal economizer and the air preheater. The system can effectively use the smoke wastes of redrying enterprises, and realizes energy recovery and resource reuse; when the boiler thermodynamic system uses the smoke wastes as main fuels, the heat efficiency of a boiler is higher than the heat efficiency of a coal-fired boiler; and the smoke NOx and SO2 and dust emission of the boiler reaches the requirements on a gas-fired boiler in the GB13271-2014 boiler atmospheric pollutant discharge standard.

Owner:QILIN REDRYING FACTORY YUNNAN TOBACCO REDRYING +1

Biomass high temperature combustion boiler

InactiveCN100513869CImprove combustion efficiencyEfficient and stable combustion and clean emissionBoiler flue tubes/fire tubesSolid fuel combustionCycloneClean energy

The invention relates to a high-efficiency and low-pollution biomass high-temperature combustion boiler, which belongs to the technical field of boilers. The invention includes a biomass particle feeder, a fuel uniform distribution plate, a cross smoke pipe, a radiation guide block, a sectional air nozzle, a cyclone dust collector, a liquid slag discharge pool, a furnace, and a steam generating chamber. The feature is that the hopper of the biomass particle feeder is set above the boiler, which can realize pre-drying; the furnace is built with well-arranged radiation guide blocks; the preheated high-temperature air enters the furnace chamber tangentially and vertically from the nozzle to realize grading , swirling combustion; the bottom is equipped with a gas-liquid-solid three-phase high-temperature cyclone separator, and the high-temperature flue gas in the center flows through the central flue pipe to the upper cross flue pipe and enters the annular gap between the furnace and the furnace wall, and enters the steam generation chamber from the bottom of the furnace wall . The invention combines the characteristics of biomass fuel and comprehensively absorbs the advantages of high-temperature air combustion, graded combustion, cyclone combustion, cyclone dust removal, liquid slag removal and flue gas recirculation, and can realize clean and efficient utilization of renewable energy biomass.

Owner:UNIV OF SCI & TECH OF CHINA

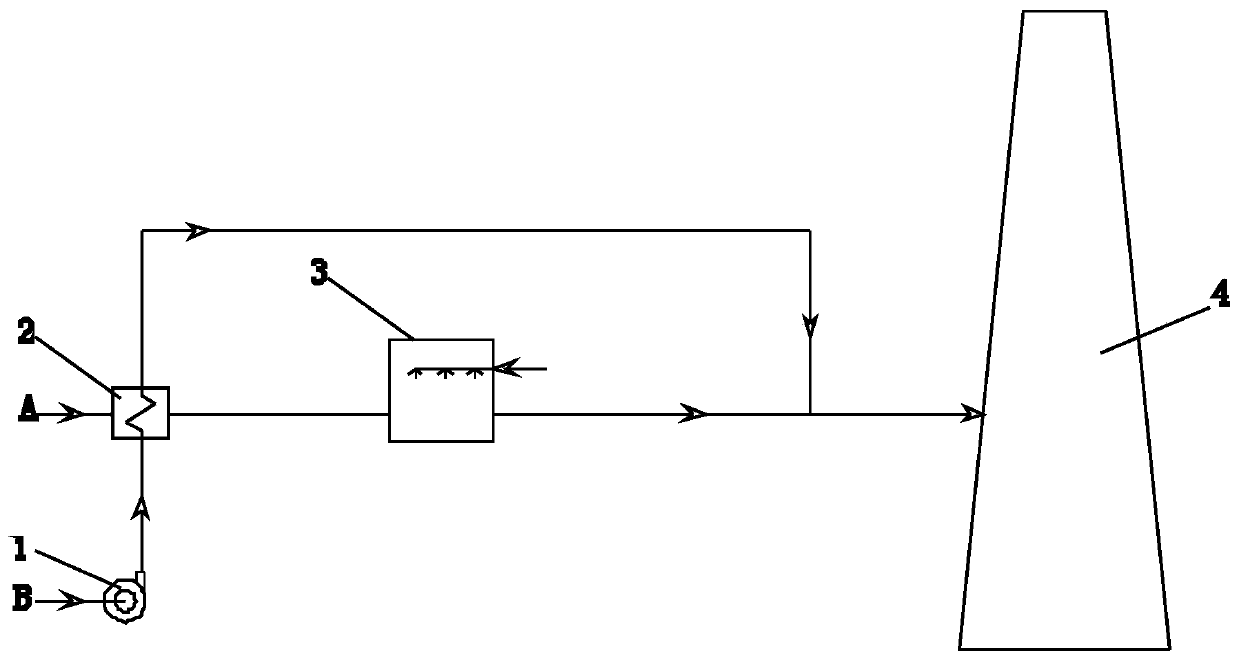

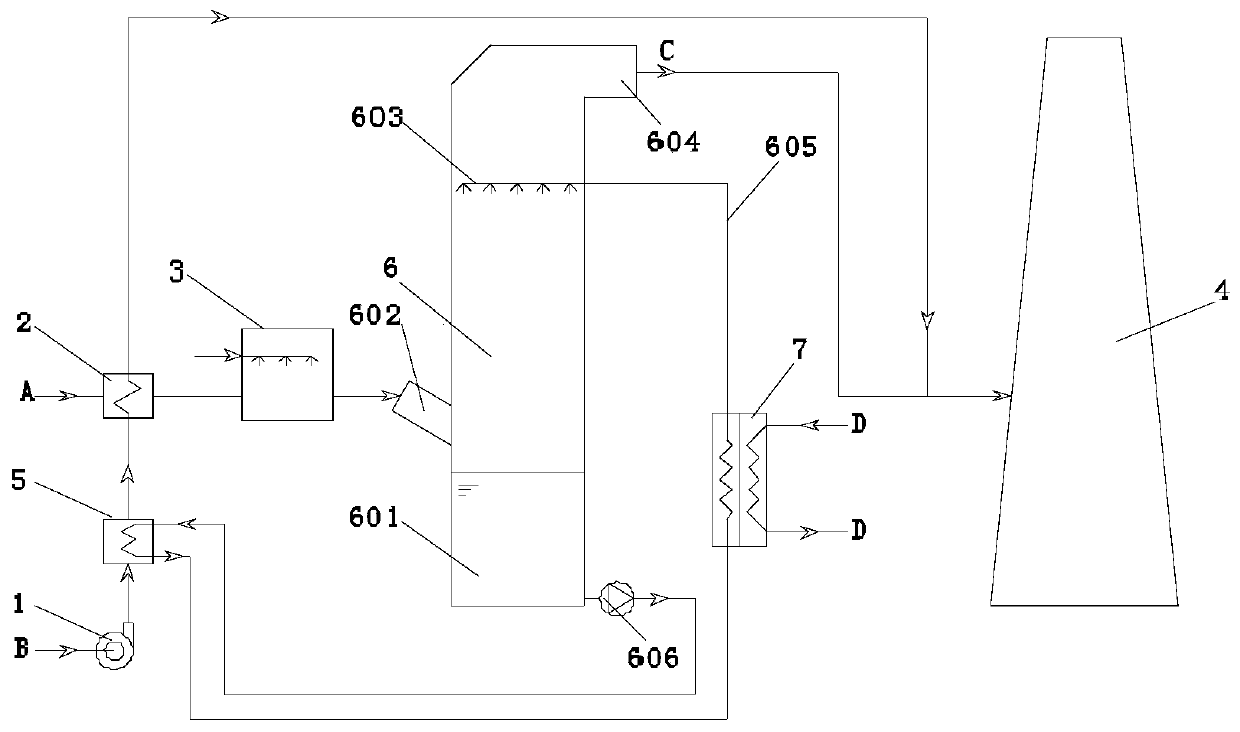

Furnace kiln wet flue gas white-elimination system

PendingCN110180335AReduce the temperatureImprove waste heat recovery efficiencyGas treatmentRecuperative heat exchangersSocial benefitsProcess systems

The invention discloses a furnace kiln wet flue gas white-elimination system, and relates to a white-elimination process of a wet flue gas after spray cooling of furnace kiln flue gas. The system comprises a gas-gas heat exchanger, a flue gas spray cooling apparatus and a fan. A flue gas and air are subjected to heat exchange, the flue gas after cooling enters the flue gas spray cooling apparatus,the wet flue gas after cooling is mixed with hot air to obtain a mixture, the mixture is heated and dehumidified, and then discharging is carried out through a chimney, and thus the white-eliminationrequirement is realized. The process system is simple, emission of air pollution and secondary pollutants is reduced while the consumption of a spray cooling liquid is reduced during a flue gas cooling process, and at the same time, the demand of flue gas white elimination is solved, so that the system has multiple purposes. Moreover, the implementation cost is low, and economic and social benefits are remarkable.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

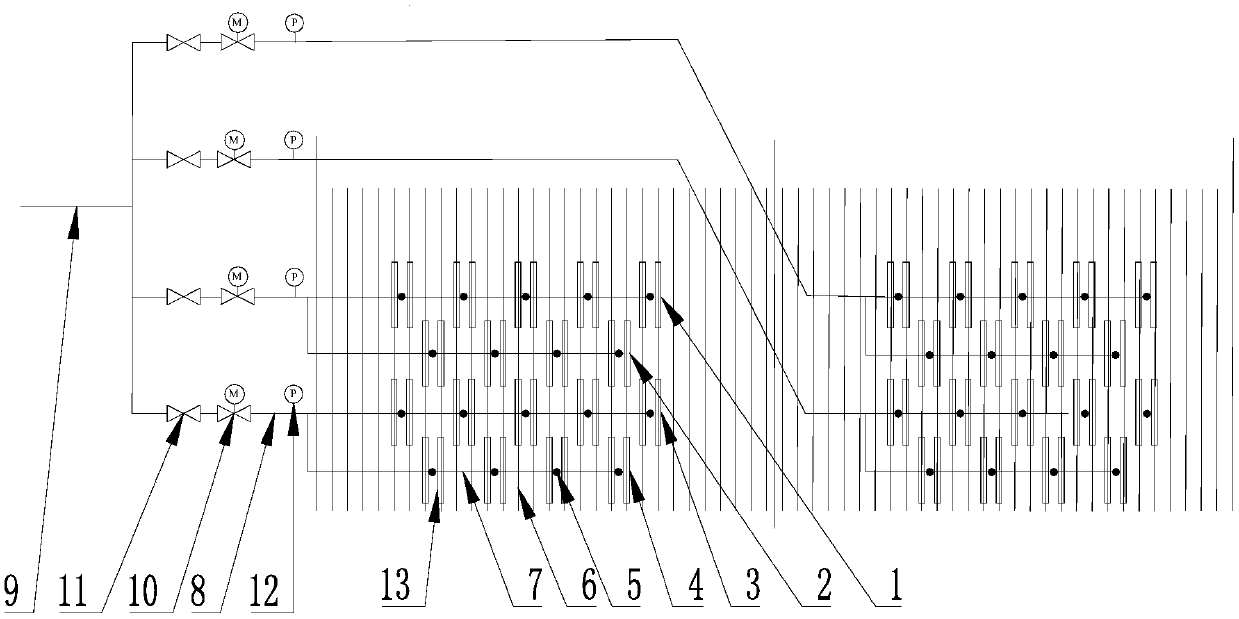

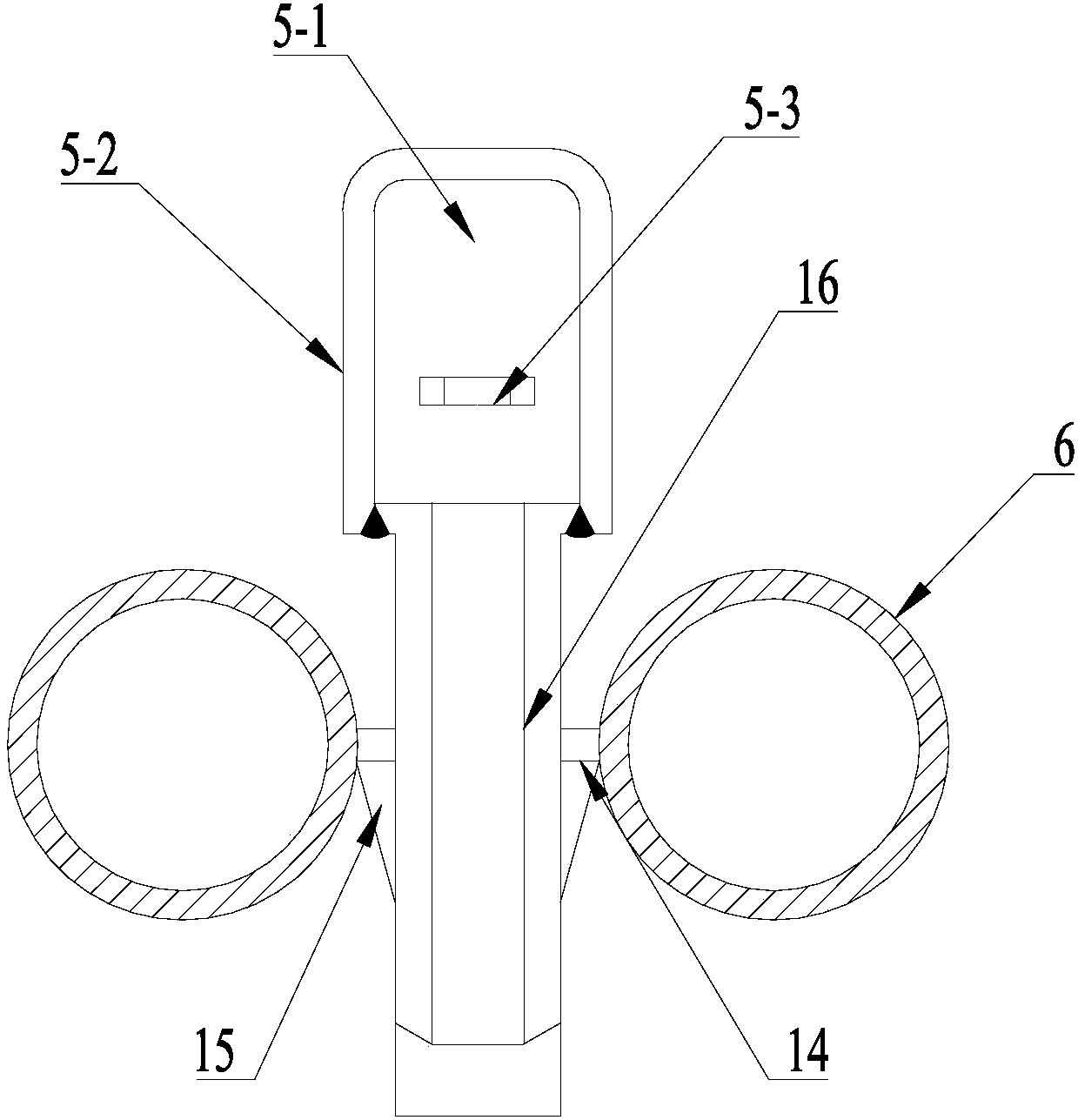

Boiler flue ash blowing system and ash blowing method

The invention discloses a boiler flue ash blowing system and an ash blowing method. The ash blowing device comprises two sets of ash blowing devices symmetrically arranged on the bottom inner wall ofa horizontal flue along a center line of the width direction of the flue; the ash blowing devices comprise multiple sets of ash blowing modules arranged in a smoke flowing direction; the ash blowing modules comprise two rows of ash blowing wind caps (5) arranged in a staggered manner; each row of ash blowing wind caps (5) is arranged in the width direction of the horizontal flue; the two rows of ash blowing wind caps (5) respectively communicate to branch pipes (8) by intake pipes (5); all the branch pipes (8) communicate to a main pipe (9); the main pipe (9) is connected to a compressed gas supply device; electromagnetic valves (10) are arranged on the branch pipes (8); and a control device is connected with the electromagnetic valves (10), and controls opening and closing of the branch pipes (8) through the electromagnetic valves (10). The boiler flue ash blowing system and ash blowing method can solve the problem of ash accumulation in the horizontal flue.

Owner:SHANGHAI HUADIAN ELECTRIC POWER DEV CO LTD

Energy conservation and emission reduction modification method for reducing emission load of nitric oxide of DDF decomposing furnace

ActiveCN105299625AIncrease volumeExtended dwell timeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelDecompositionNitric oxide

The invention discloses an energy conservation and emission reduction modification method for reducing the emission load of nitric oxide of a DDF cement decomposing furnace. By arranging an air gathering bellows and a gooseneck pipe on the DDF decomposing furnace with the small volume, the smoke standing time is prolonged; part of coal powder is distributed to the conical portion of the decomposing furnace, part of tertiary air is distributed to the upper middle portion of the decomposing furnace, the volume of the DDF decomposing furnace is enlarged, the position of part of coal powder entering the furnace is reduced, and the coal powder burn-off rate is improved. The coefficient of excess air in the lower middle portion of the decomposing furnace is smaller than 1.0. Under the condition of insufficient oxygen, CO of a large proportion is generated to become reducing agents for reducing and eliminating nitric oxide. An ash returning channel is arranged inside the air gathering bellows and feeds raw materials and coal powder particles subsided back to the position above a middle nozzle of the decomposing furnace, so that the problem of sintering blockage of accumulated ash is solved, the coarse particle processing capacity of the decomposing furnace is improved, the decomposition rate of raw materials entering the furnace is improved, and through the double effects of reducing emission of nitric oxide and reducing heat loss, the effective energy conservation and emission reduction of a cement calcining system are achieved.

Owner:BEIJING TRIUMPH INT ENG

Glass tube air preheater

InactiveCN103185350ASolve dust accumulationReduce dust accumulationCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to a glass tube preheater, which is characterized in that stainless steel twisted strips are arranged in light tubes of the glass tube, and the heat exchanging coefficient of an inner membrane of each light tube can be increased by reinforcing the turbulent flow of the inner membrane of the light tube. By utilizing the heat exchanging characteristic of the glass tube preheater at a low smoke temperature, the smoke discharging temperature is reduced, the ash accumulation and scaling can be reduced, and the smoke dew point corrosion can be reduced.

Owner:LUOYANG HEZONG PETROCHEM ENG

Large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue

A large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue relates to a water-fire tube hot water boiler. The aim of the invention is to settle the problems of ash accumulation, hard ash elimination, and reduced thermal efficiency of boiler in the prior water-fire tube hot water boiler. A burnout chamber, a convection calandria and a vertical threaded flue coal economizer are provided in the boiler body. The convection calandria is communicated with the upper barrel and the lower barrel. A warm water area and a hot warm water area are installed in the upper barrel. A first connecting pipe is communicated with a lower box of water cooled wall of back wall and the lower drum. A second connecting pipe is communicated with a lower drum and a vertical threaded flue coal economizer. A third connecting pipe is communicated with a hot water area and the vertical threaded flue coal economizer. The down pipe of water cooled wall of front wall is communicated with a lower collection box of water cooled wall of front wall and the cold water area. The down pipe of left wall is communicated with a lower collection box of water cooled wall of left wall. The down pipe of right wall is communicated with a lower collection box of water cooled box of water cooled wall of right wall. The large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue according to the invention adopts the vertical threaded flue coal economizer and has the advantages of no ash accumulation in the threaded flue, easy ash elimination and high thermal efficiency of boiler.

Owner:HARBIN INST OF TECH

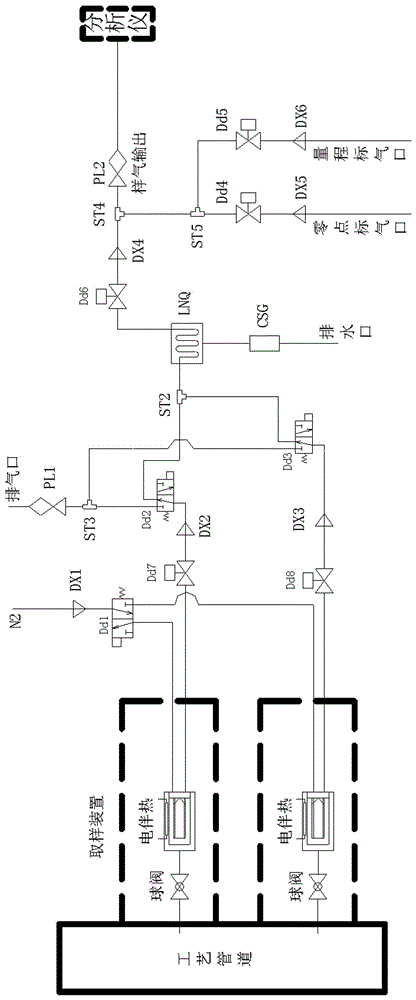

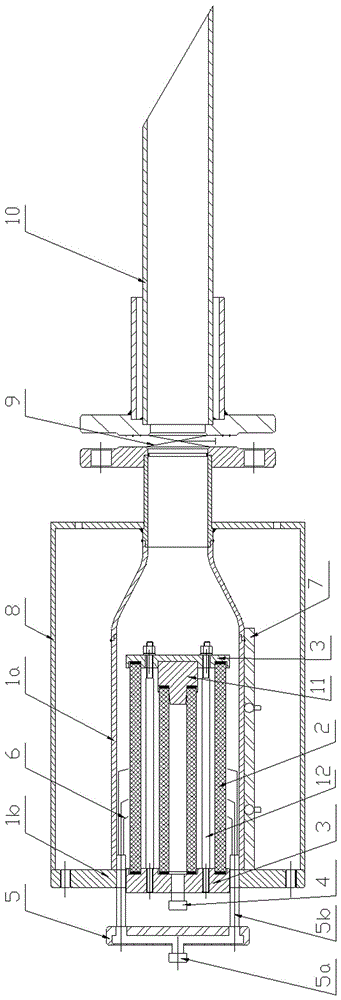

Control method and gas pretreatment system for integrated gas analysis

PendingCN106483003AThe pre-processing process is simpleTroubleshooting Sampling InterruptionsWithdrawing sample devicesPreparing sample for investigationGas analysisProcess engineering

The invention relates to a control method and gas pretreatment system for integrated gas analysis. The gas pretreatment system for integrated gas analysis compromises two sampling device which includes a sampling shell provided with a gas inlet and a filter element inside. The inner cavity of the filter element is communicated with the inner cavity of the sampling shell through the filter holes arranged on the filter element, and also communicated with a gas outlet. A gas distributor is fixed on the sampling shell. An air outlet of the gas distributor is provided with a nozzle. An air jet port of the nozzle is towards the filter element. The air inlets of the gas distributors of a first sampling device and a second sampling device are respectively connected with the air supply through a first sweeping pipeline and a second sweeping pipeline. The gas outlets of the first sampling device are respectively connected with the imports of an exhaust port and a condenser through a first sampling line. The gas outlets of the second sampling device are respectively connected with the imports of the exhaust port and the condenser through a second sampling line. The air outlet of the condenser is connected with an analyzer. The control method and gas pretreatment system for integrated gas analysis has the advantages of simplifying the system and achieving the seamless handover between sweeping and sampling.

Owner:CHONGQING IRON & STEEL GRP ELECTRONIC CO LTD

Frameless detachment-free rotary air heater

InactiveCN102162647ASpeed up the flowAvoid spoilersCombustion processIndirect carbon-dioxide mitigationEngineeringHeat transfer tube

The invention discloses a frameless detachment-free rotary air heater, which consists of 3 to 8 groups of outer fin reinforced heat transfer tube bundles, wherein each group of heat transfer tube bundle has a frameless self-supporting structure consisting of spiral fin heat transfer tube bundles welded on a thin-walled inlet steam collecting tank and a thin-walled drainage collecting tank respectively, and the heat transfer tube bundles are averagely distributed in a primary air flue and a secondary air flue; any heat transfer tube bundle can rotate separately in a full angle of 360 degrees by adopting the self-supporting stable structure of the tube bundle so as to solve the problems that separate rotation of the heating surface of a certain stage cannot be realized, rotation in the full angle of 360 degrees cannot be realized, the heating surface cannot be rotated without cutting off steam, the operation part has complex structure and is not easily detached or maintained and ash blockage, leakage and fin deformation are caused; and the rotary air heater is frameless and detachment-free, can rotate in the full angle of 360 degrees, and is convenient to maintain.

Owner:XI AN JIAOTONG UNIV +1

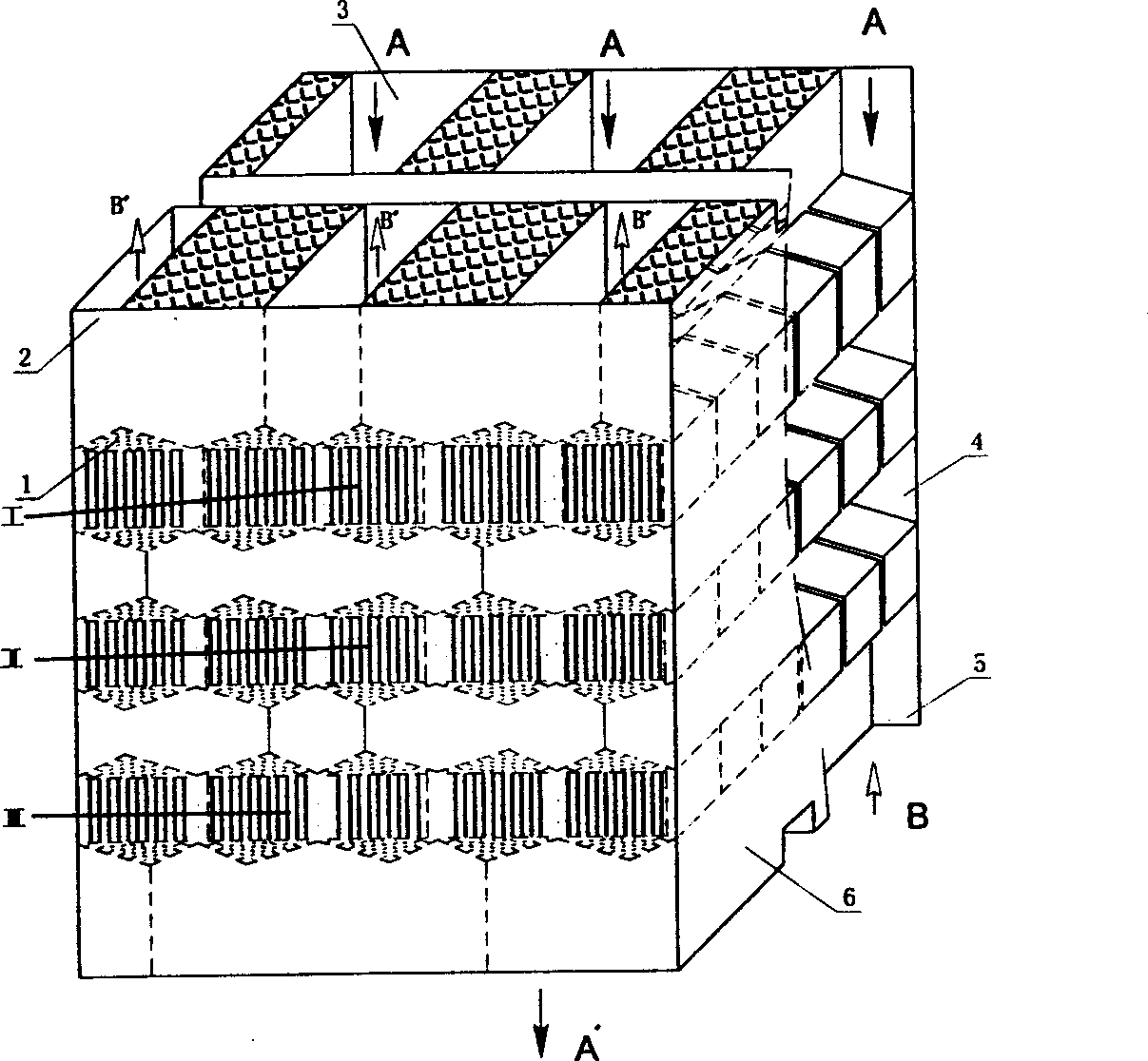

Gas-to-gas full-welding plate type heat exchanger

InactiveCN104677148AEasy to blow sootEasy maintenanceLaminated elementsStationary plate conduit assembliesPlate pressureComputer module

The invention relates to a gas-to-gas full-welding plate type heat exchanger. The gas-to-gas full-welding plate type heat exchanger is that a vertically-positioned quadrate heat transfer plate set module is used as a heat transfer element; dust and impurities of a heat exchange medium, attached on a plate can fall down due to the gravity effect; the surface of the plate is smooth and free of flowing dead area, so that the dust can be conveniently blown away, the daily maintenance and cleaning of the device can be conveniently carried out, and the problem of dust accumulating in the device can be completely solved; the quadrate heat transfer plate set module is pure reversed-flowing corrugated plate; a heat medium and a cold medium purely flows in reversed directions at two sides of the plate; the corrugating part of the plate has the effects of guiding and supporting, besides reinforcing heat transfer; the plate can be overlapped to respectively form a heat medium channel and a cold medium channel at two sides, and the corrugating parts are in contact with each other; the structure of mutual supporting has the effect of improving the plate pressure bearing capacity meanwhile, the device is compact in structure, small in size, and low in manufacturing cost.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

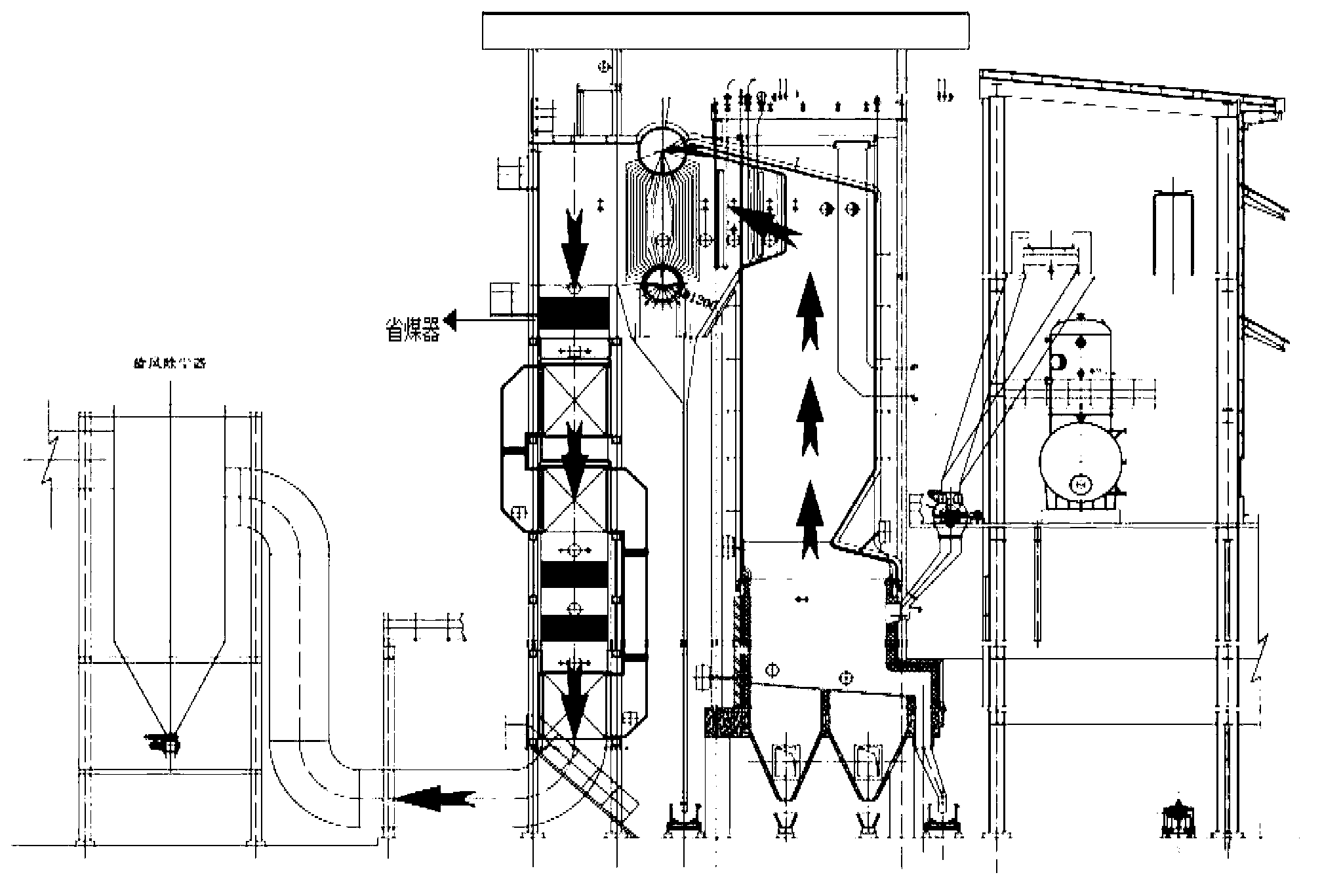

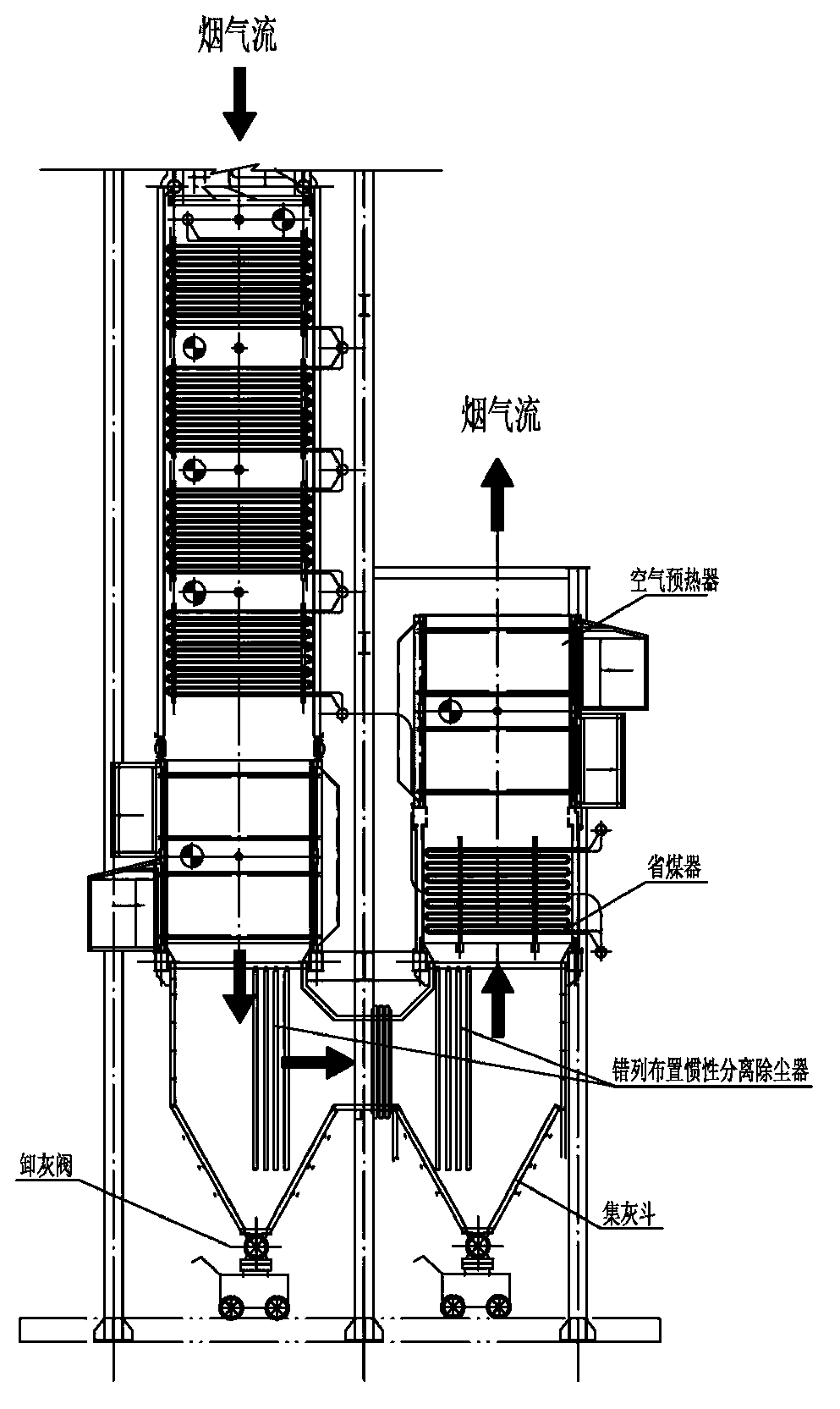

Rear smoke channel of biomass boiler and biomass boiler

ActiveCN103234212ASolve dust accumulationImprove self-cleaning abilityChimneysAir preheaterEngineering

The invention provides a rear smoke channel of a biomass boiler and the biomass boiler. The rear smoke channel of the biomass boiler is arranged in a U shape, and smoke descends from the top of the rear smoke channel to the bottom and then rises from the bottom to the top. The rear smoke channel comprises dust removing devices, an ash bucket, one or more economizers and a first air preheater, wherein dust removing devices are located at positions of two corners of a U-shaped flow line of the smoke, the ash bucket is located under dust removing devices, dust removing baffle plates are arranged inside dust removing devices, when smoke dust in the smoke collides with dust removing baffle plates, the smoke dust changes directions and falls into the ash bucket under the action of gravity, one or more economizers are located at a position where the smoke flows from bottom to top, and the first air preheater is located above one or more economizers which are arranged at the position where the smoke flows from bottom to top. By the aid of the rear smoke channel of the biomass boiler and the biomass boiler, the automatic dust removing capability of the boiler can be improved, the land occupied by the dust removing device of the boiler and the investment cost can be reduced, and various problems caused by ash deposition of the boiler can be solved.

Owner:CHINA CAMC ENG

Low temperature coal economizer with straight channel structure

PendingCN107023817AUniform flow fieldEliminate stagnation zonesLaminated elementsStationary plate conduit assembliesPlate heat exchangerEngineering

The invention relates to the technical field of boiler fuel gas waste heat recovery equipment, and particularly to a low temperature coal economizer with a straight channel structure. The low temperature coal economizer comprises a heat transfer module, a medium channel box arranged at one end of the heat transfer module and flue transition boxes on the upper side and the lower side of the heat transfer module. According to the low temperature coal economizer with the straight channel structure, the problems in the prior art that the conventional plate heat exchanger is liable to flow passage blockage, dirt accumulation and corrosion, and temperature crossover of cold and hot mediums are solved.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

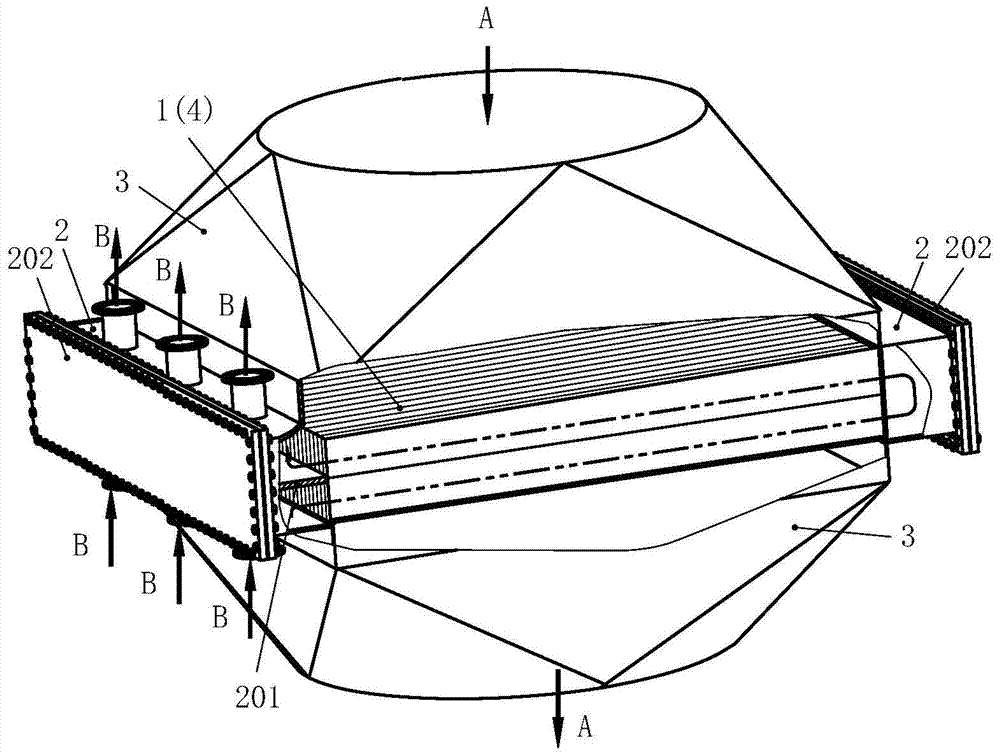

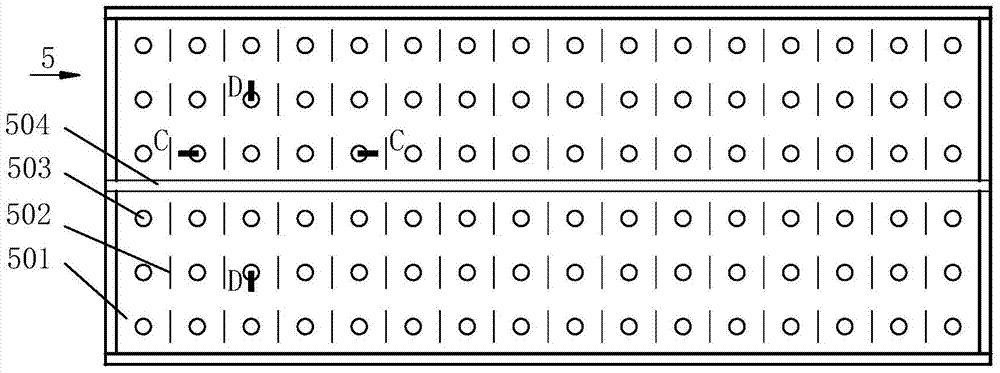

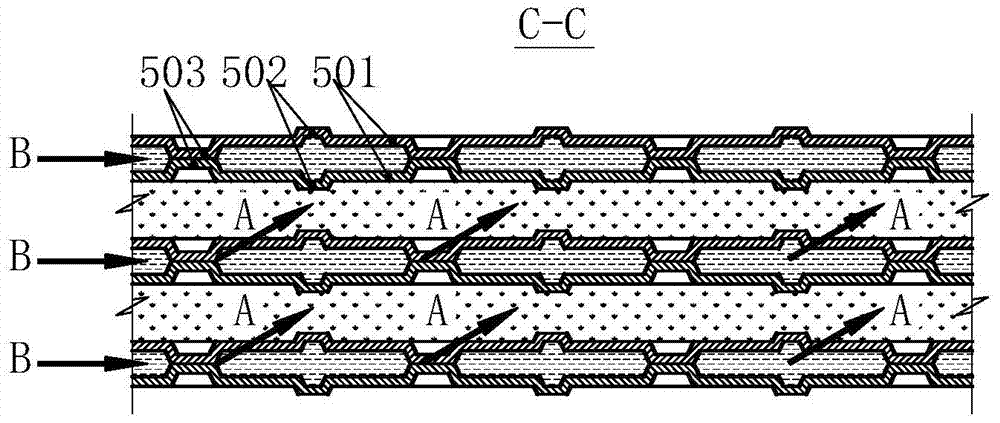

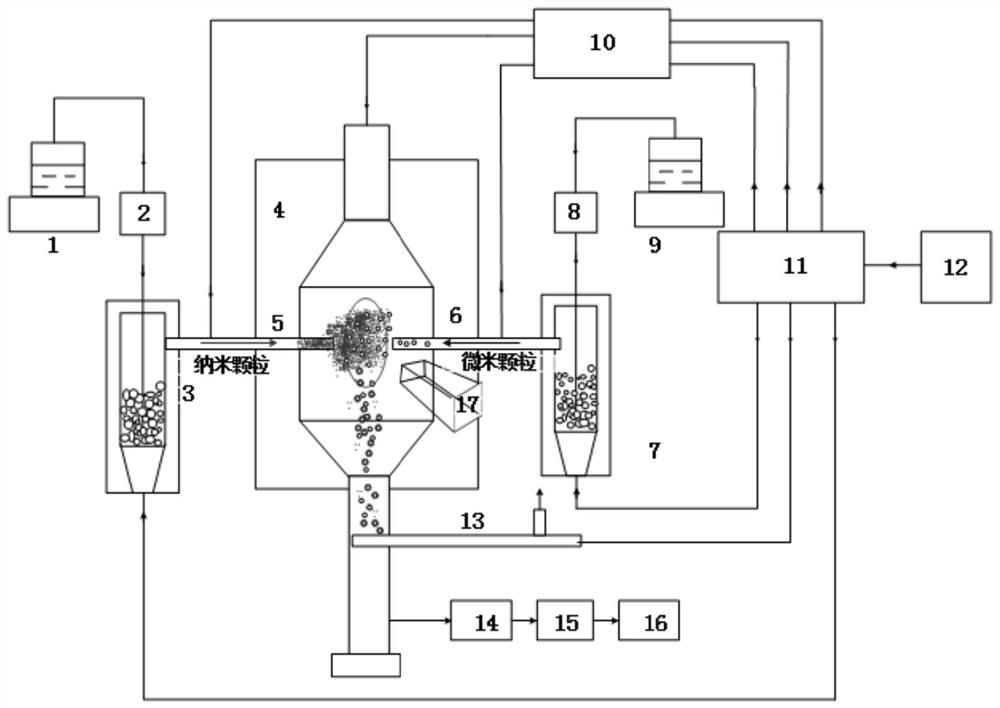

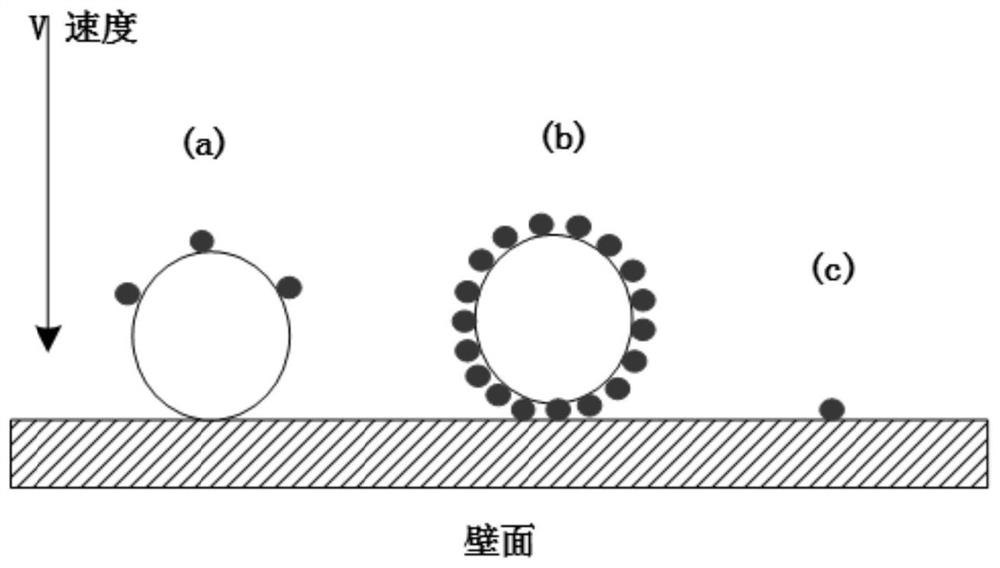

Device and method for regulating and controlling fly ash deposition layer based on impinging stream technology

The invention discloses a device and method for regulating and controlling a fly ash deposition layer based on an impinging stream technology, and belongs to the technical field of ash deposition prevention and control. The device for regulating and controlling the fly ash deposition layer based on the impinging stream technology comprises a high-temperature hearth, a nano-particle spraying systemand a fly ash spraying system, the nano-particle spraying system and the fly ash spraying system are used for spraying nano-particles and micron fly ash into the high-temperature hearth correspondingly, and the spraying directions of the nano-particle spraying system and the fly ash spraying system are oppositely arranged. According to the method for regulating and controlling the fly ash deposition layer, nano-particles are introduced into the high-temperature hearth, so that the surface of coal-fired fly ash is coated with the nano-particles, the surface viscosity of the coal-fired fly ashcan be effectively reduced, the structure and composition of the fly ash deposition layer are regulated and controlled, and finally the purpose of remarkably solving the ash deposition problem is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue

A large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue relates to a water-fire tube hot water boiler. The aim of the invention is to settle the problemsof ash accumulation, hard ash elimination, and reduced thermal efficiency of boiler in the prior water-fire tube hot water boiler. A burnout chamber, a convection calandria and a vertical threaded flue coal economizer are provided in the boiler body. The convection calandria is communicated with the upper barrel and the lower barrel. A warm water area and a hot warm water area are installed in the upper barrel. A first connecting pipe is communicated with a lower box of water cooled wall of back wall and the lower drum. A second connecting pipe is communicated with a lower drum and a verticalthreaded flue coal economizer. A third connecting pipe is communicated with a hot water area and the vertical threaded flue coal economizer. The down pipe of water cooled wall of front wall is communicated with a lower collection box of water cooled wall of front wall and the cold water area. The down pipe of left wall is communicated with a lower collection box of water cooled wall of left wall.The down pipe of right wall is communicated with a lower collection box of water cooled box of water cooled wall of right wall. The large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue according to the invention adopts the vertical threaded flue coal economizer and has the advantages of no ash accumulation in the threaded flue, easy ash eliminationand high thermal efficiency of boiler.

Owner:HARBIN INST OF TECH

Novel accumulated dust blowing device of sector plate of boiler air pre-heater

InactiveCN110455120ASolve dust accumulationEasy to control air volumeCleaning heat-transfer devicesAir preheaterAir volume

The invention discloses a novel accumulated dust blowing device of a sector plate of a boiler air pre-heater. The novel accumulated dust blowing device comprises a pre-heater body, a secondary air side opening, a top cover, a center hole, a flue gas side opening, a primary air side opening, a main pipe, branch pipes, valves, a primary air inlet, a shaft hole, the sector plate, dust blowing spray heads, a rotor, a heat transfer element and a rotor center barrel. The main pipe is mounted to be connected to the upper portion of the sector plate from the lower portion of a primary air bin, carbonsteel pipelines are selected as branches and are directly communicated into the sector plate, connecting parts are all welded, and therefore the blowing device is formed; the corresponding valve is mounted on each branch, the air volume can be controlled conveniently, and labor force is reduced; meanwhile, the problem that the air leakage rate is increased due to accumulated dust in the running process is avoided, and the problem of dust accumulation of the sector plate is thoroughly solved; and modification is extremely simple and convenient, and production requirements are met.

Owner:国家能源集团谏壁发电厂

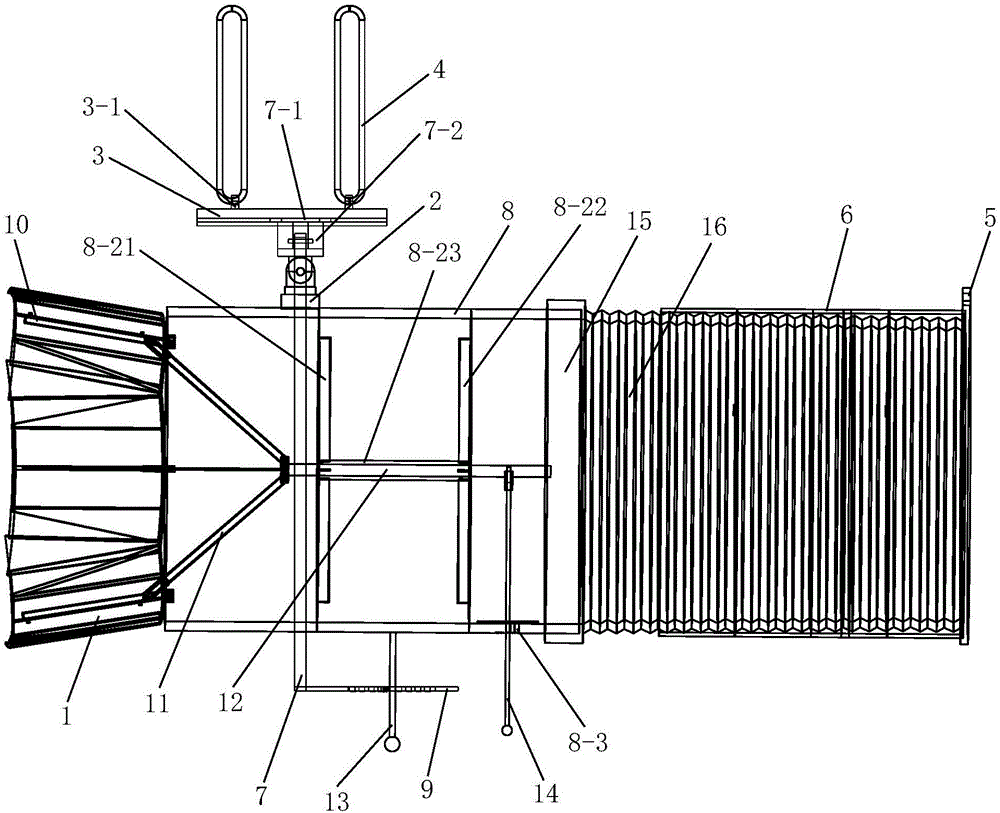

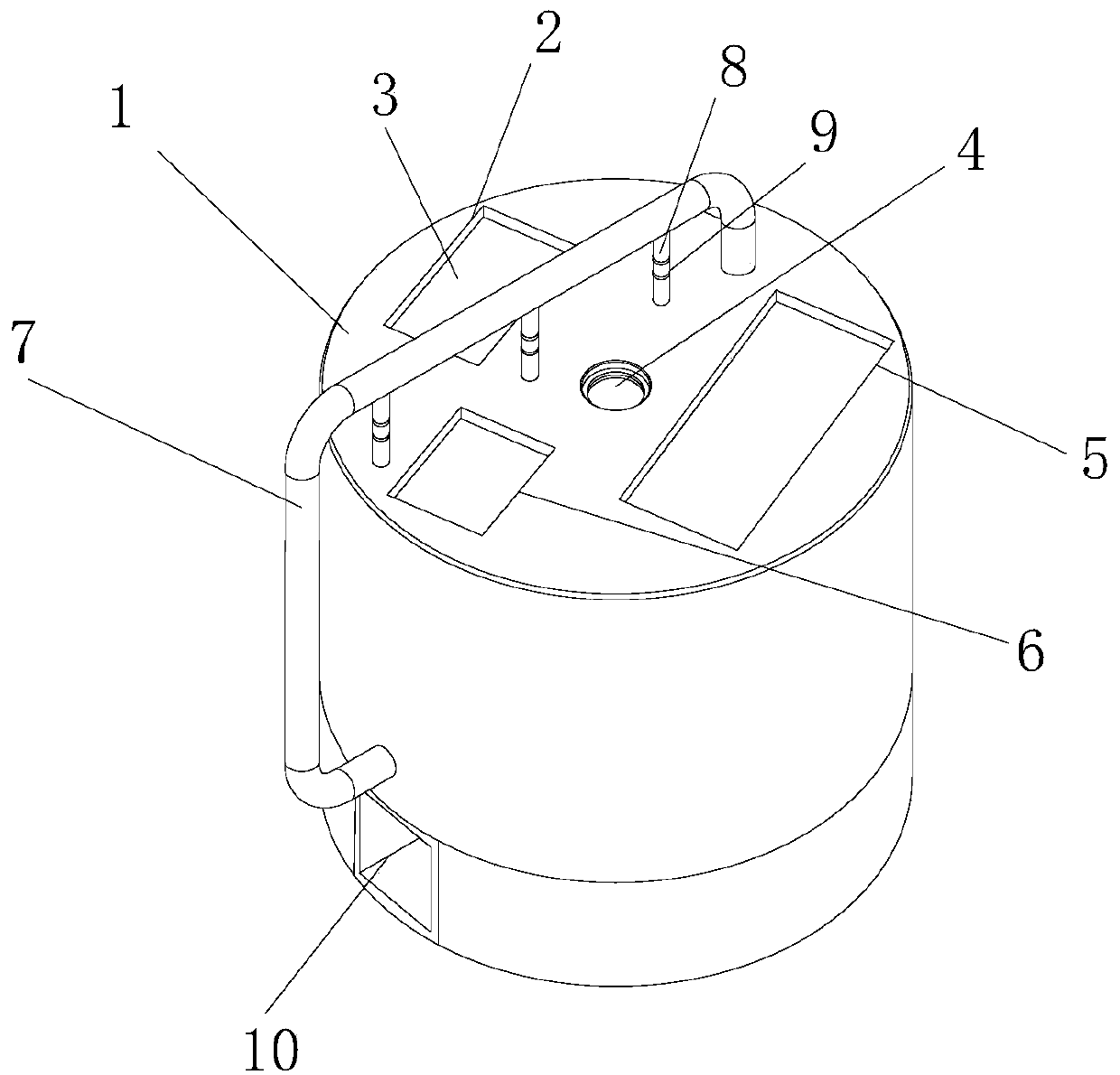

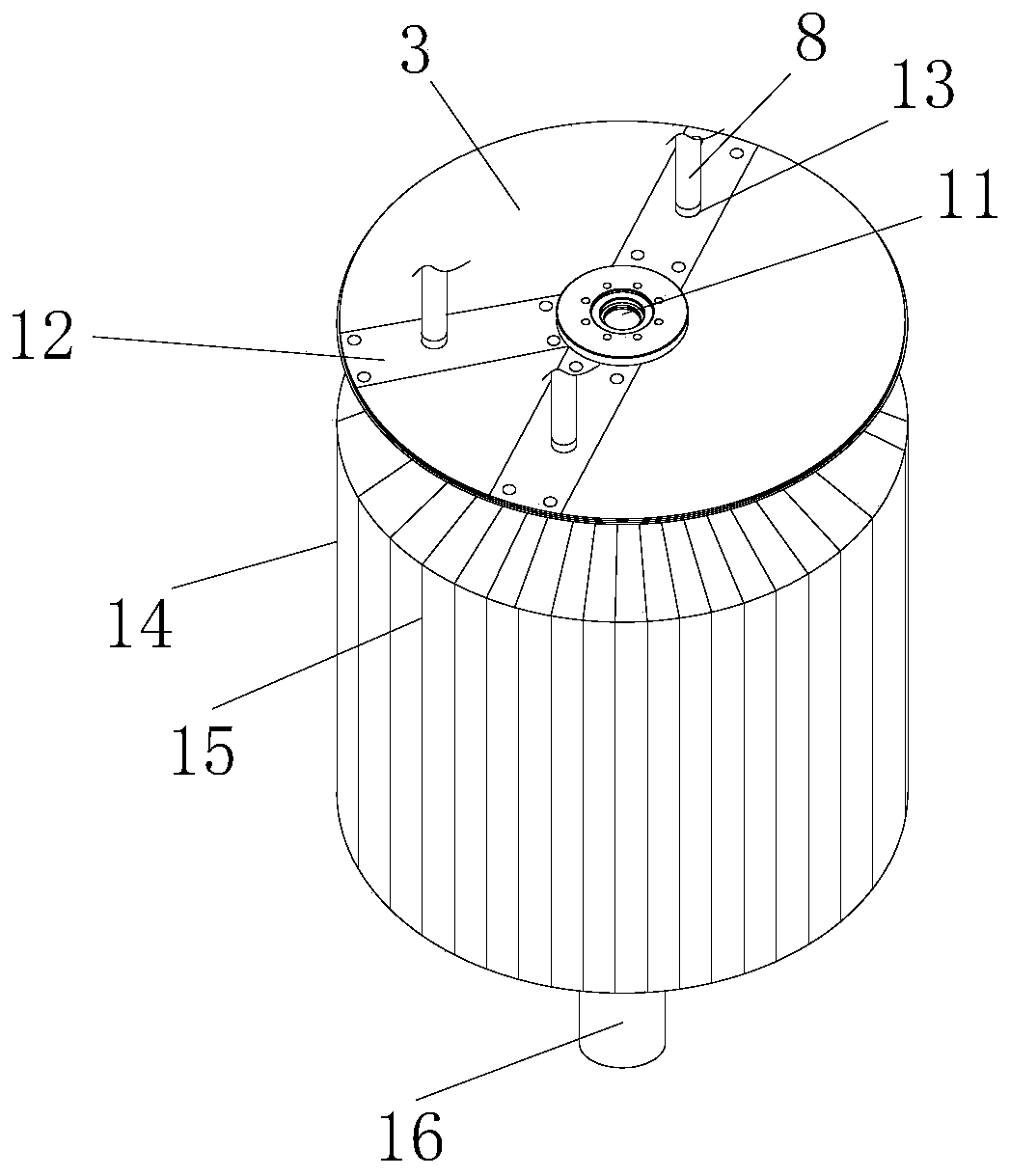

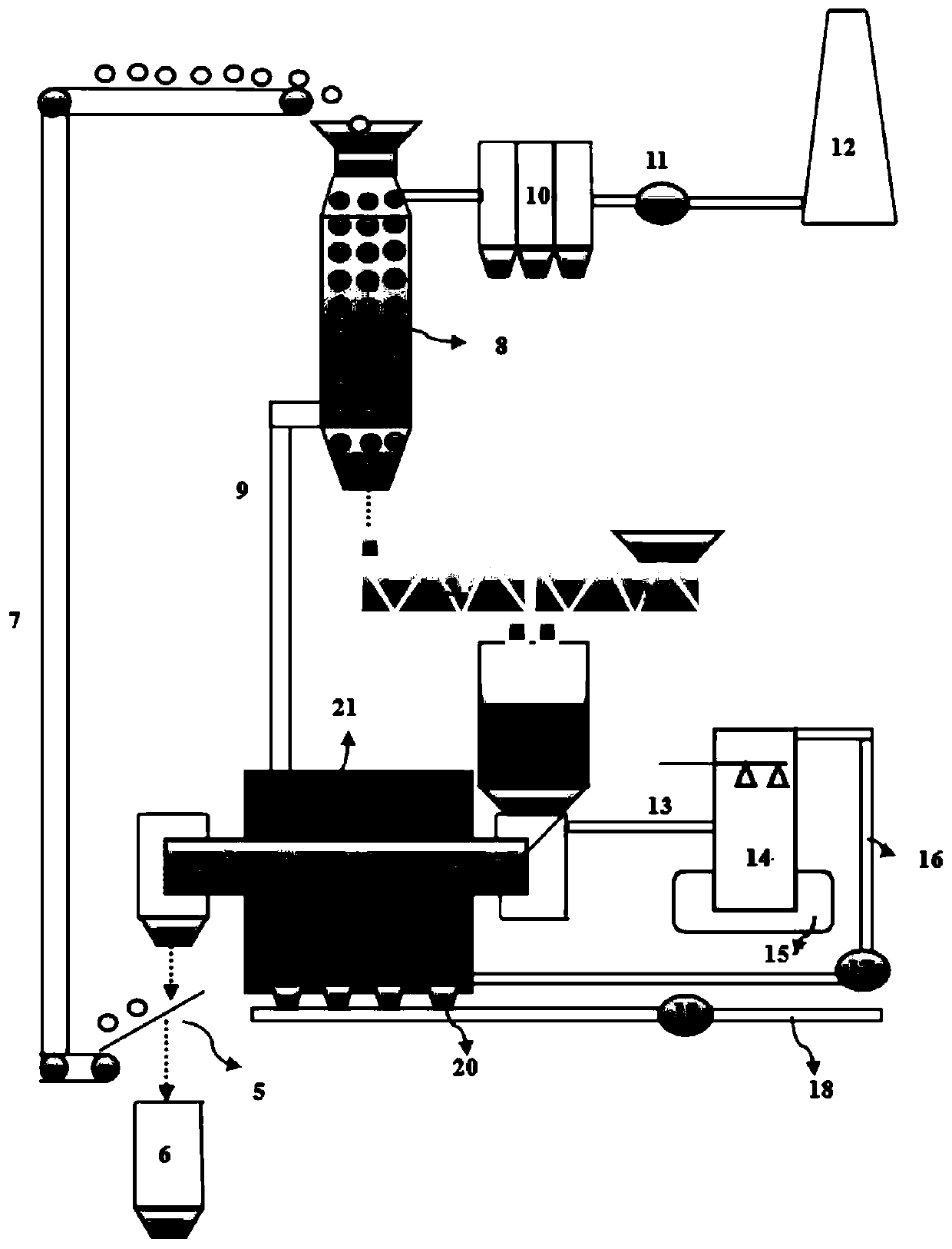

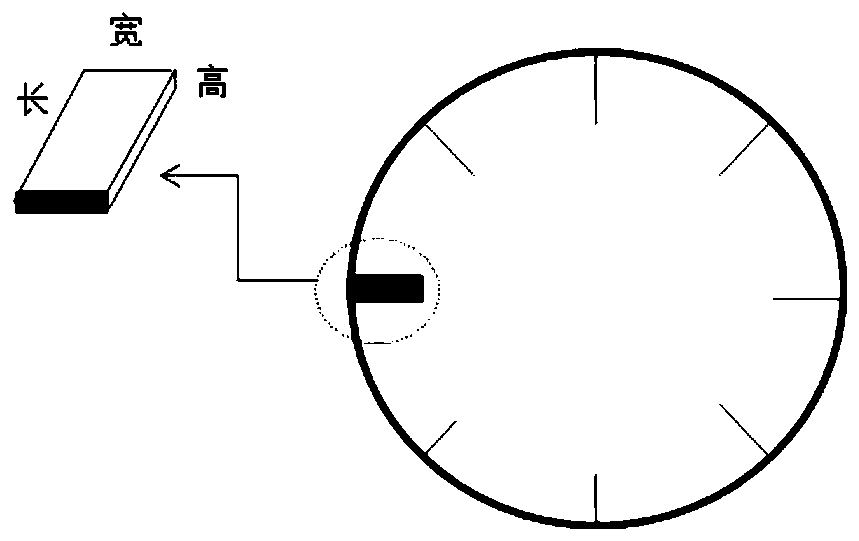

Sludge drying and dewatering equipment and method

PendingCN111533426AEfficient drying and dehydrationImprove drying efficiencySludge treatment by de-watering/drying/thickeningSludgeProcess engineering

The invention belongs to the field of solid waste resource utilization, and relates to sludge drying and dewatering equipment and a sludge drying and dewatering method. The equipment comprises a 1 # conveying device (1), a surge bin (2), a 2 # conveying device (3), a rotary drum indirect drying device (4), a screening device (5), a dry sludge storage device (6), a 3 # conveying device (7) and a waste heat recovery device (8), wherein the 1 # conveying device (1) and the 2 # conveying device (3) are communicated with the surge bin (2); the surge bin (2), the rotary drum indirect drying device (4) and the screening device (5) are sequentially communicated; oversize products of the screening device (5) are conveyed into a waste heat recovery device (8) through the 3 # conveying device (7); materials in the waste heat recovery device (8) are conveyed back to the surge bin (2) through the 2 # conveying device (3). The equipment and the method provided by the invention have the advantages ofhigh dehydration efficiency and low energy consumption, and can effectively avoid the problems of easy hardening and easy wall adhesion in direct drying of sludge.

Owner:余佳萱

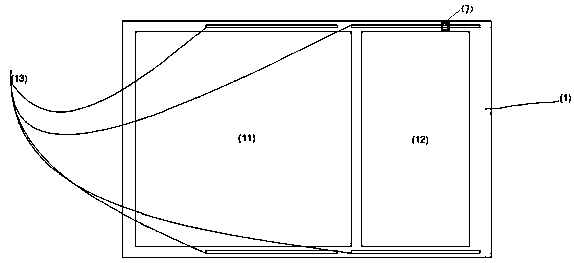

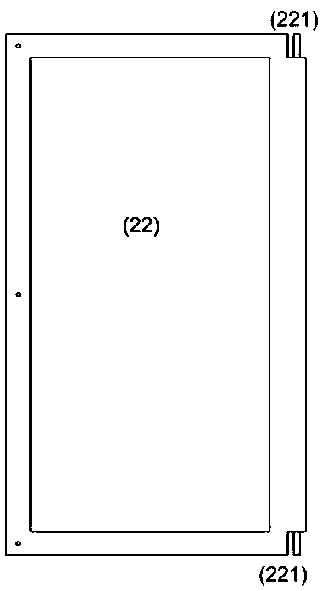

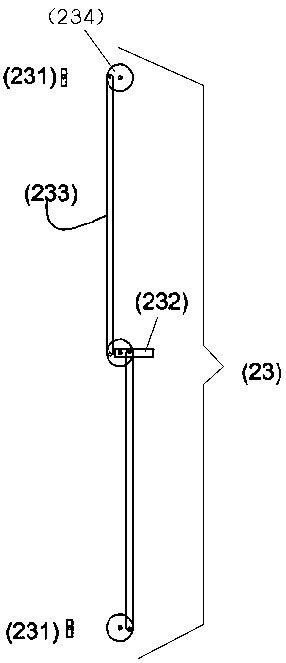

Double-open-close mode window capable of optimizing airtightness

The invention discloses a double-open-close mode window capable of optimizing airtightness. The double-open-close mode window comprises a window frame for fixing with a wall body, and an inner windowbody which is installed in the window frame and relatively parallelly slid and rotatably flatly opened. A contact surface of the inner window body and the window frame is provided with a sealing adhesive tape. One part of the window frame is provided with a fixed glass which cannot be opened and closed, and the other part is a hollow window frame for bearing the inner window body. The double-open-close mode window has the following advantages of a double-open-close mode, space-saving, convenient living, and convenient cleaning, and is capable of effectively solving a problem of sliding chute dust deposition.

Owner:王佳浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com