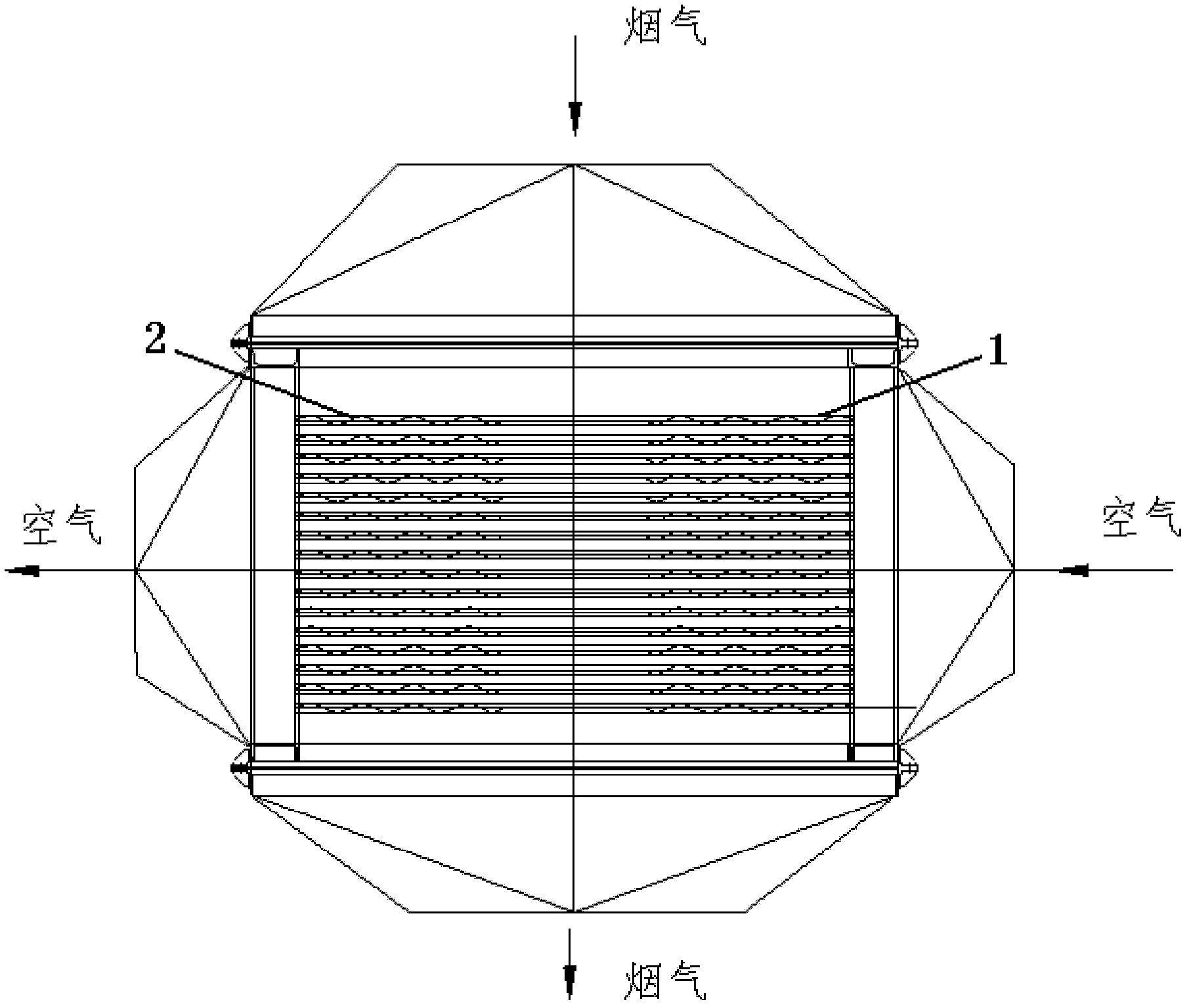

Glass tube air preheater

An air preheater and air preheating tube technology, applied in heat exchange equipment, lighting and heating equipment, combustion methods, etc., can solve the problems of blockage of flue gas channels, inconvenience, and inability to achieve environmental protection, and achieve an increase in heat exchange coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] High temperature flue gas 370°C → spoiler preheater → heat pipe preheater → glass tube preheater → exhaust flue gas 120°C

[0024] Air 290°C ← spoiler preheater ← heat pipe preheater ← glass tube preheater ← outside air 20°C

[0025] It can be seen from the above that the temperature difference of nearly 350°C between the high-temperature flue gas and the low-temperature cold air outside is used as the driving force for heat exchange. The flue gas flows through the spoiler preheater, heat pipe preheater, and glass tube preheater until After being discharged, the temperature of the flue gas drops step by step from 370°C to 120°C; correspondingly, the outside cold air passes through the glass tube preheater, heat pipe preheater, spoiler preheater until it is sent into the combustion system Participating in the combustion process, the temperature continues to rise until 290°C. During the combustion process of the heating furnace, the higher the temperature of the hot air,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com