Sludge drying and dewatering equipment and method

A technology of sludge drying and dewatering equipment, applied in the field of solid waste resource utilization, can solve the problems of easy hardening in the drying cavity, low dewatering efficiency, and difficulty in dewatering, and achieves the improvement of drying efficiency, reduction of dewatering costs, and reduction of equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

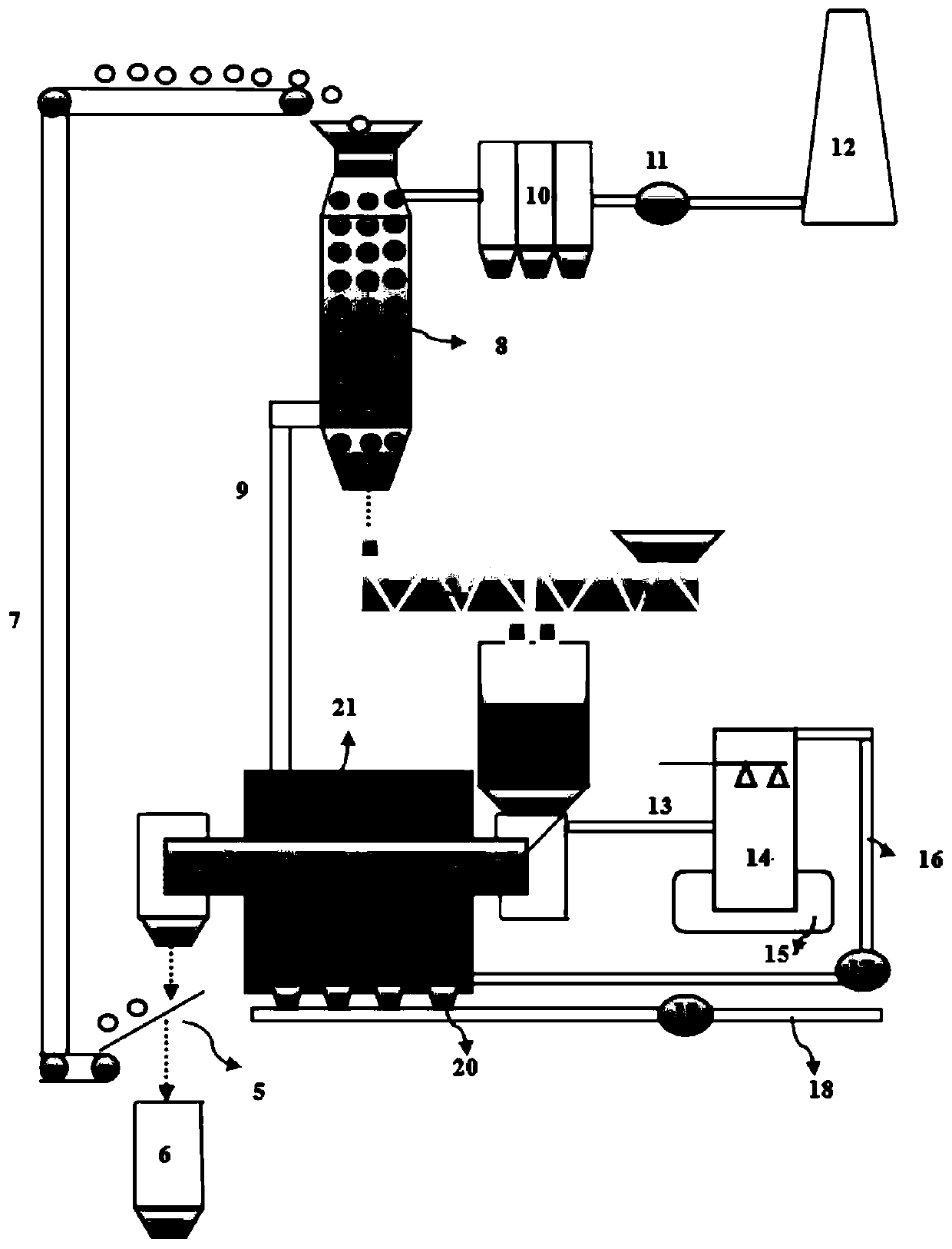

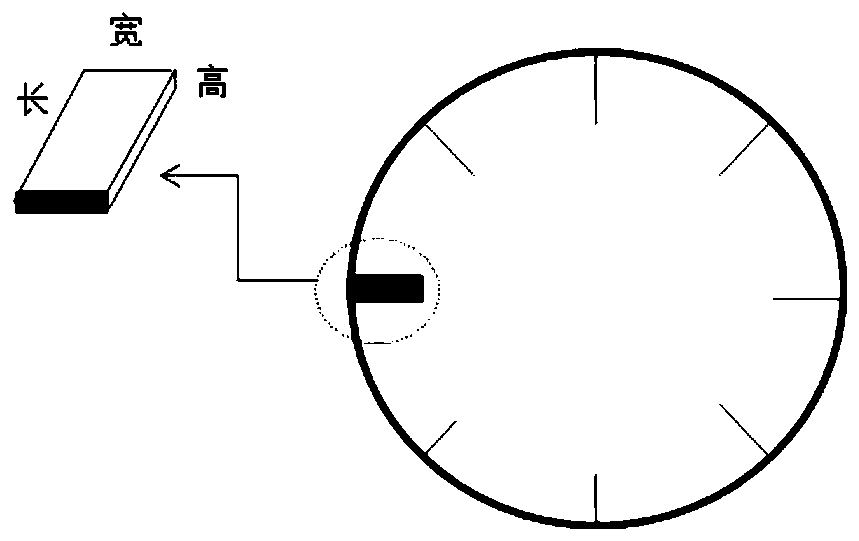

[0068] Such as figure 1 Shown, wet sludge and heat storage ball (the addition amount of heat storage ball is 10% of wet sludge volume; The moisture content of wet sludge is 85%; Heat storage ball is the spherical shape with smooth surface, and diameter is 0.5cm and The density is 5t / m 3 ) into the buffer bin 2 via 1# conveying device 1 and 2# conveying device 3 respectively, and then jointly enter the rotary drum indirect drying device 4 with a heating furnace temperature of 300°C (wet sludge and heat storage balls are indirectly dried on the rotary drum The filling rate in the device is 20%) to carry out internal and external synergistic drying and dehydration, and the dried material is screened by the screening device 5, and the undersize is dried sludge, which is directly sent to the dry sludge storage device 6, and the oversize It is a heat storage ball, which is transported to the waste heat recovery device 8 through the 3# conveying device 7, and is heated by the waste ...

Embodiment 2

[0070] Such as figure 1 As shown, the wet sludge and heat storage balls (the addition of heat storage balls is 20% of the wet sludge volume; the moisture content of wet sludge is 60%; the heat storage balls are spherical with a smooth surface, a diameter of 2cm and a density of 7.8t / m 3 ) into the buffer bin 2 via 1# conveying device 1 and 2# conveying device 3 respectively, and then jointly enter the rotary drum indirect drying device 4 with a heating furnace temperature of 400°C (wet sludge and heat storage balls are indirectly dried on the rotary drum The filling rate in the device is 20%) to carry out internal and external synergistic drying and dehydration, and the dried material is screened by the screening device 5, and the undersize is dried sludge, which is directly sent to the dry sludge storage device 6, and the oversize It is a heat storage ball, which is transported to the waste heat recovery device 8 through the 3# conveying device 7, and is heated by the waste ...

Embodiment 3

[0072] Such as figure 1 As shown, wet sludge and heat storage balls (the addition of heat storage balls is 30% of the volume of wet sludge; the moisture content of wet sludge is 40%; heat storage balls are spherical with smooth surface, diameter is 1cm and density 3t / m 3 ) into the buffer bin 2 via 1# conveying device 1 and 2# conveying device 3 respectively, and then jointly enter the rotary drum indirect drying device 4 with a heating furnace temperature of 200°C (wet sludge and heat storage balls are indirectly dried on the rotary drum The filling rate in the device is 10%) to carry out internal and external synergistic drying and dehydration, and the dried material is screened by the screening device 5, and the undersize is dried sludge, which is directly sent to the dry sludge storage device 6, and the oversize It is a heat storage ball, which is transported to the waste heat recovery device 8 through the 3# conveying device 7, and is heated by the waste heat of the flue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com