Large scale water-fire tube hot-water boiler with single drum horizontal vertical spirally corrugated tube

A technology for threaded smoke pipes and hot water boilers, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc. The effect of reducing the exhaust gas temperature, prolonging the residence time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

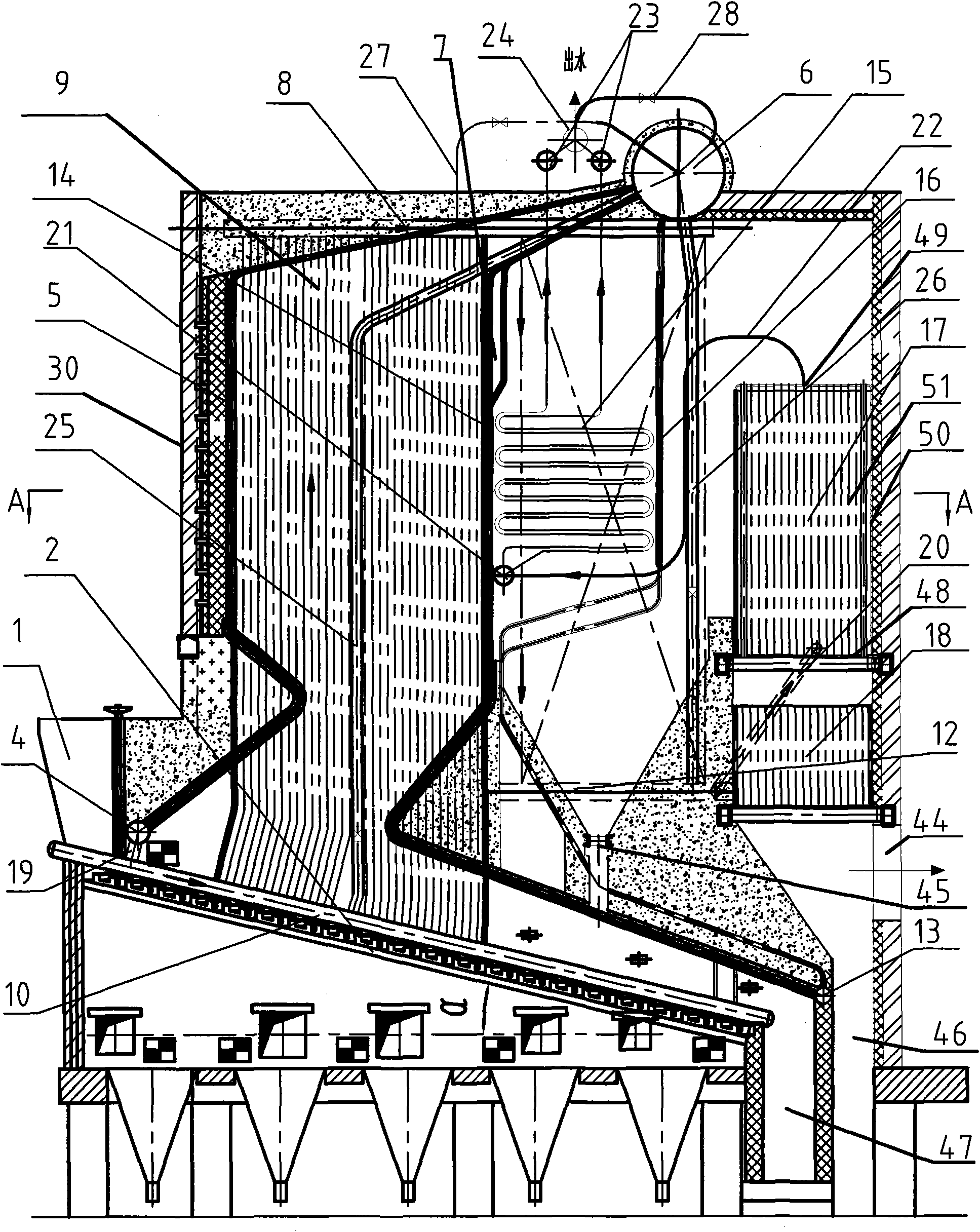

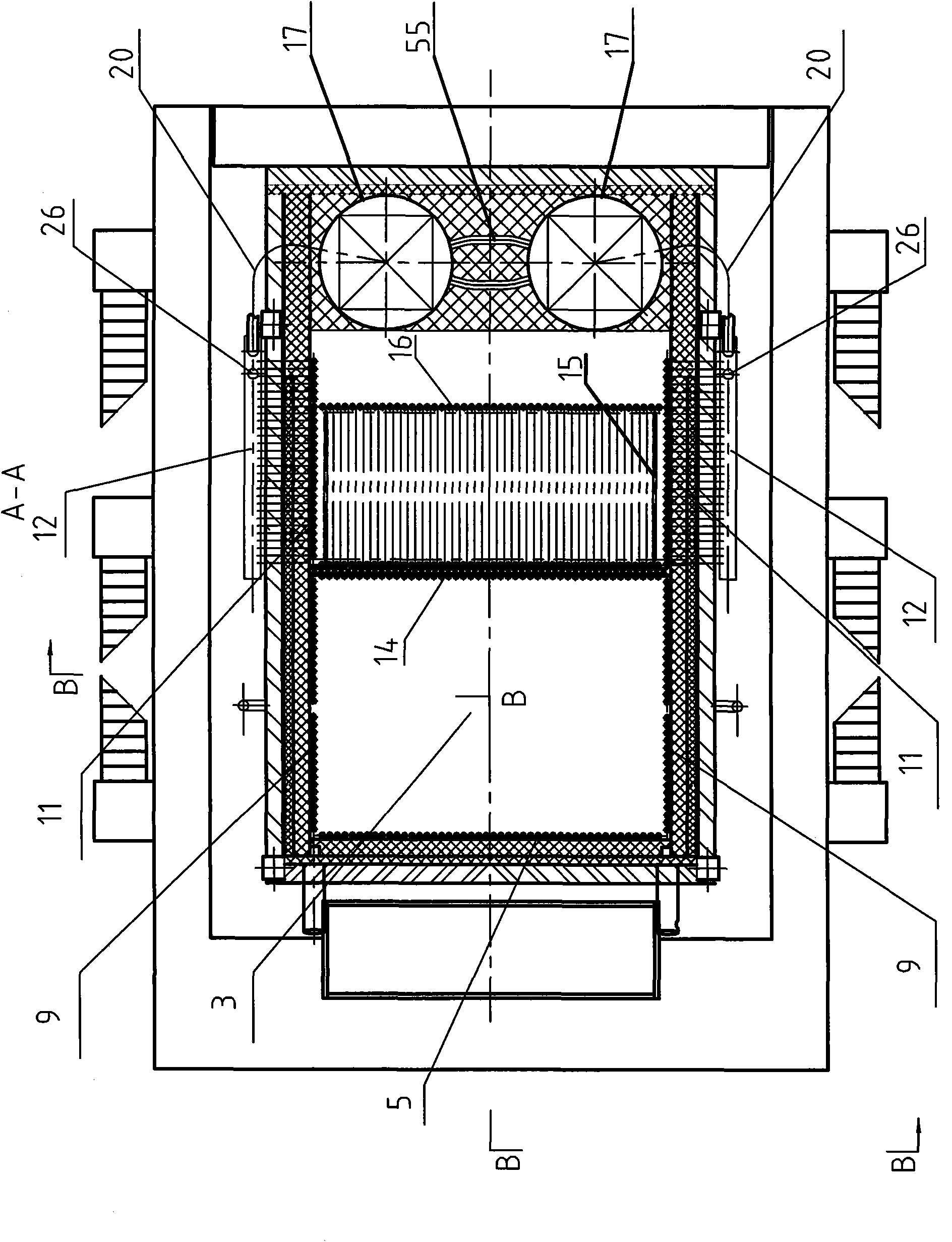

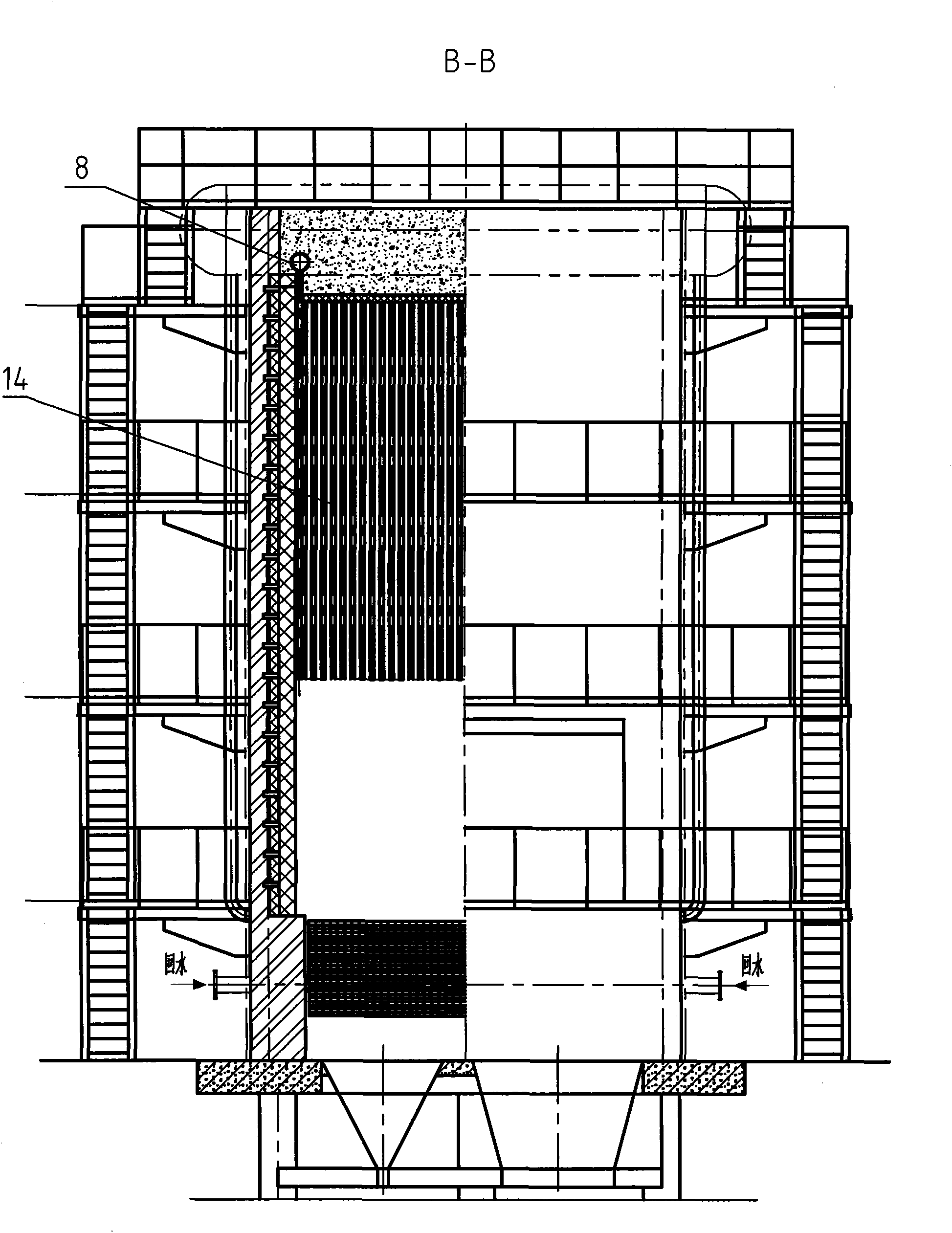

[0009] Specific implementation mode one: combine Figure 1~3 To illustrate this embodiment, the single-drum horizontal vertical threaded smoke tube large-scale water-fire tube hot water boiler in this embodiment includes a furnace body 30, a coal feeding hopper 1, a combustion equipment 2, a front wall water-cooled lower header 4, a front wall Wall water cooling wall 5, upper drum 6, two upper headers of side wall water cooling walls 8, two front side wall water cooling walls 9, two front side water cooling wall lower headers 10, two rear side wall water cooling walls 11 , two water-cooled lower headers of the rear side wall, lower header of the water-cooled wall of the furnace rear wall 13, water-cooled wall of the furnace rear wall 14, the first connecting pipe 19, the second connecting pipe 20 and the third connecting pipe 22, the front wall The water-cooled wall 5, the water-cooled wall 14 of the rear wall of the furnace and the two front side wall water-cooled walls 9 are...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the vertical threaded smoke pipe economizer 17 in this embodiment is composed of a housing 50 and a plurality of threaded smoke pipes 51; the multiple threaded smoke pipes 51 are vertically placed in the housing 50, and Both ends of each vertically placed threaded smoke pipe 51 are respectively inserted into corresponding threaded smoke pipe installation holes on the upper cover plate 49 and the lower bottom plate 48 of the housing 50 . Such an arrangement not only has a simple structure, but also prevents dust accumulation in the threaded smoke pipe 51 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: In this embodiment, the diameter of the threaded smoke pipe 51 is 56.5 mm, 63 mm, 69 mm or 81 mm. Such setting ensures that the vertical threaded smoke pipe will not produce dust accumulation under different loads. Other components and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com