Biomass high temperature combustion boiler

A high-temperature combustion, biomass technology, applied in the field of boilers, can solve the problems of low utilization rate of combustion heat, large moisture content of biomass, low combustion temperature, etc., to increase residence time, increase convective heat transfer, and uniform feed distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

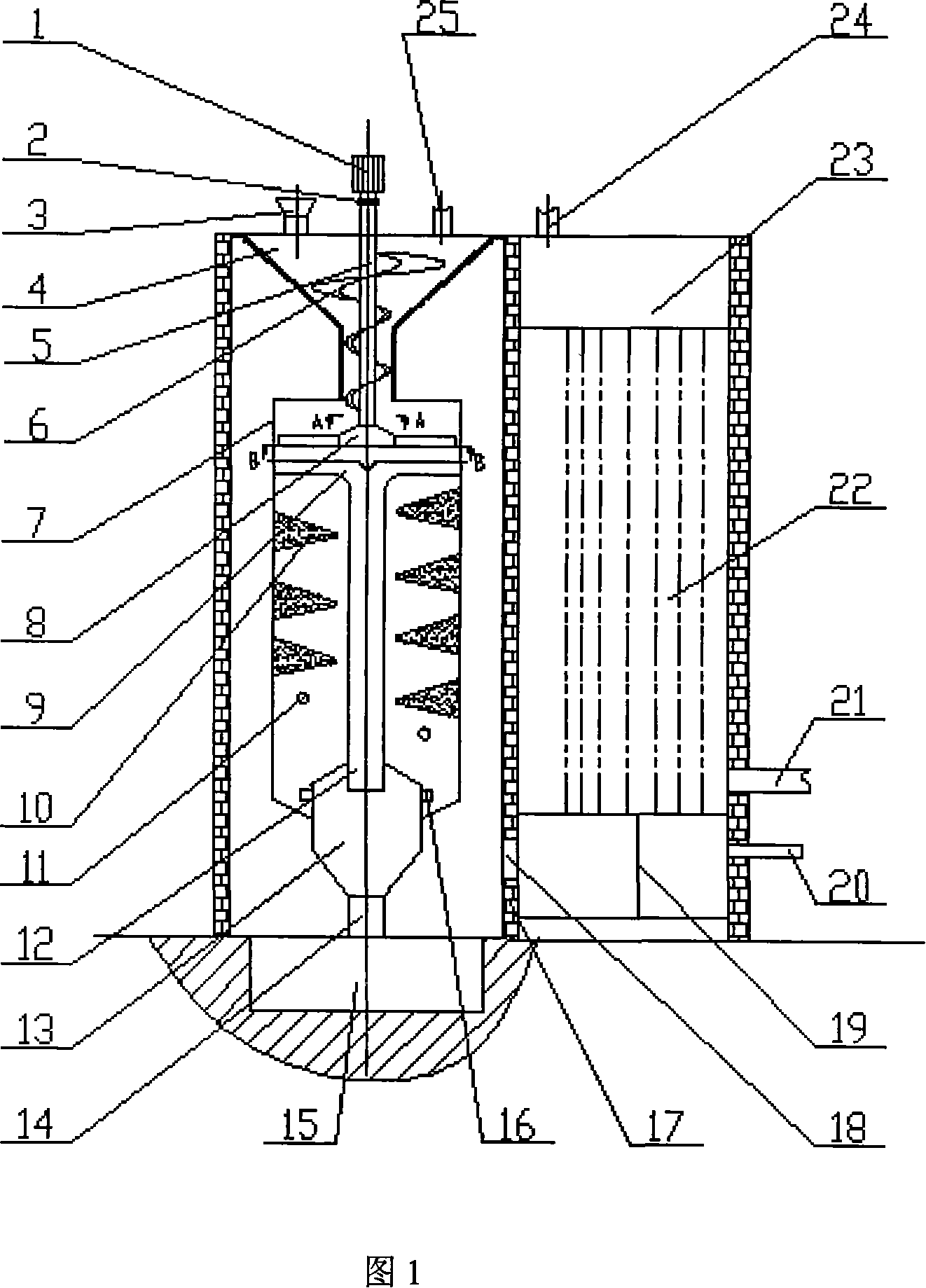

[0013] The specific implementation of the biomass high-temperature combustion boiler of the present invention will be further described below in conjunction with the accompanying drawings.

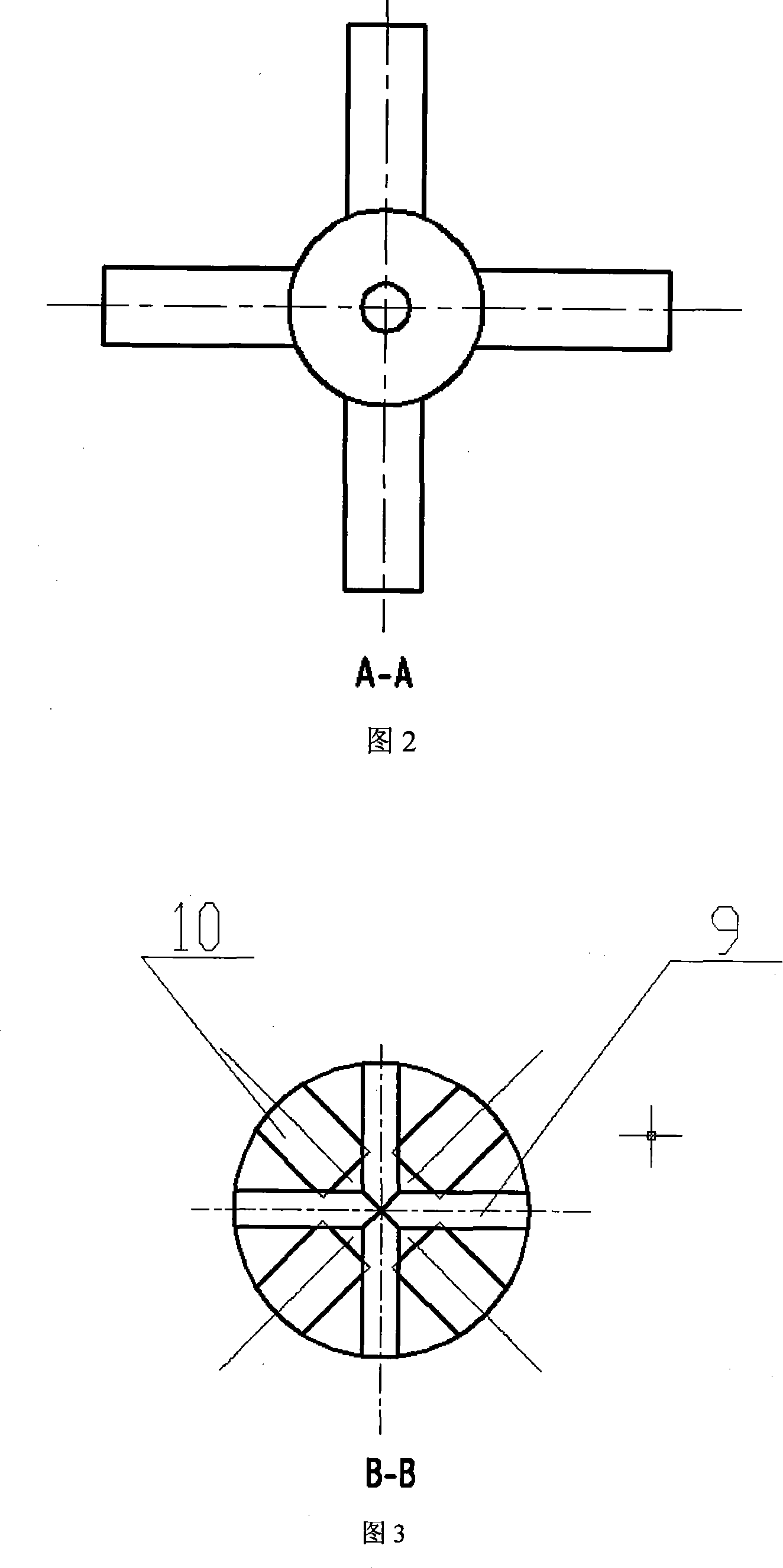

[0014] The structure of the biomass high-temperature combustion boiler of the present invention is shown in Figure 1, which mainly includes a motor 1, a coupling 2, a feed port 3, a hopper 4, a rotating shaft 5, a spiral blade 6, and a fuel uniform distribution plate 8. Biomass particle feeding device, furnace 7, radiation guide block 10, preheating chamber and combustion chamber composed of sectional air nozzle 11, cyclone separator 13, central smoke pipe 12, cross smoke pipe 9, liquid slag discharge tank The flue gas ash discharge device that is formed by 15, the steam generation chamber that divider 19, smoke pipe 22, 2 baffle chambers 23 are formed.

[0015] The hopper 4 of the biomass particle feeding device is made of materials with excellent thermal conductivity and heat resistance,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com