Patents

Literature

94results about How to "Improve crushing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Freeze-drying technology of bletilla striata vacuum freeze-drying

PendingCN109520213AAvoid the loss of active ingredientsImprove crushing rateDrying solid materials without heatRefrigeration temperatureFreeze dry

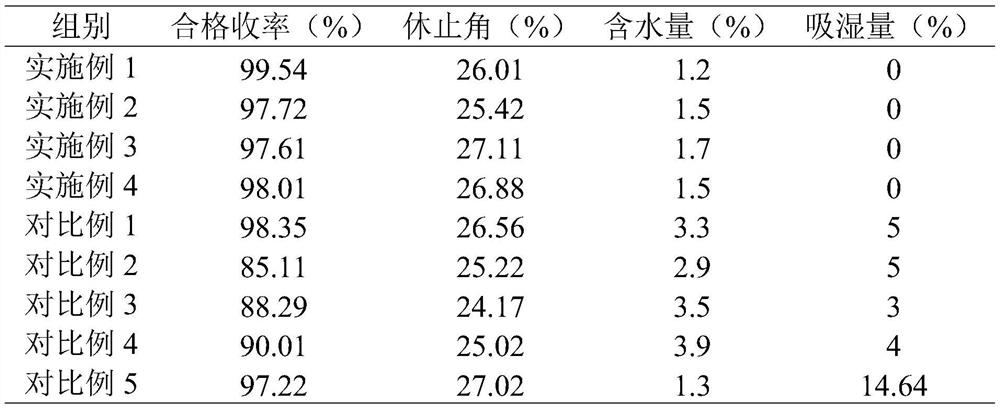

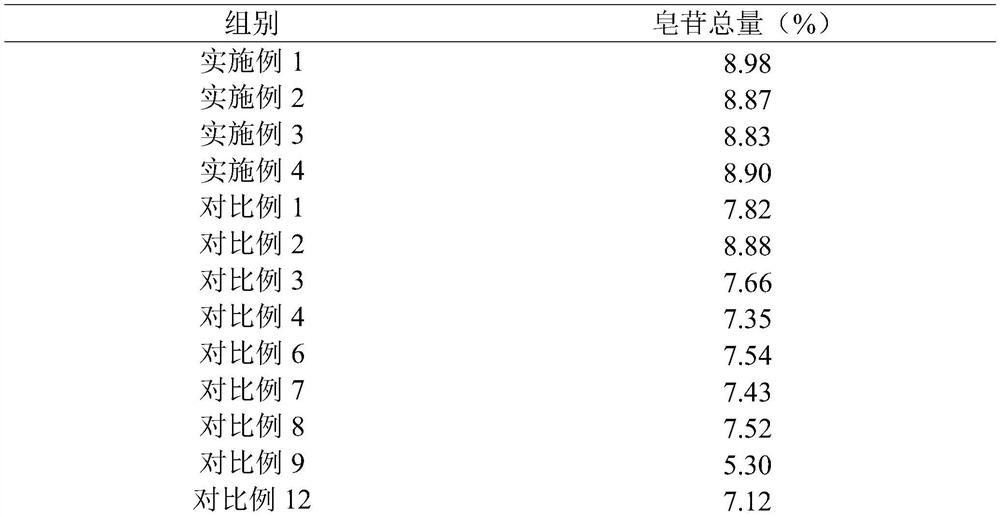

The invention provides a freeze-drying technology of bletilla striata vacuum freeze-drying, and relates to the field of bletilla striata processing. The freeze-drying technology comprises the following steps of pre-freezing: putting bletilla striata in a vacuum freeze-drying machine, cooling bletilla striata to be minus 30 DEG C or below, and maintaining the temperature for 3 h to 4 h; and vacuumdrying: starting a cold trap refrigeration mode, controlling refrigeration temperature of a cold trap device to be minus 60 DEG C or below, maintaining the vacuum degree to be 30 Pa or below, and carrying out drying treatment. According to the freeze-drying technology of bletilla striata vacuum freeze-drying provided by the invention, effective components of fresh bletilla striata can be remainedto the greatest extent, freeze-dried bletilla striata are beautiful in section and loose in structure, and can be directly smashed, the smashing rate is high, the dissolution rate is high during decoction, storage time of freeze-dried bletilla striata is prolonged, and mass is light.

Owner:九信(武汉)中药研究院有限公司

Pseudo-ginseng vacuum freeze-drying method and application thereof

InactiveCN112229148APrevent local melting and disintegrationAvoid affecting product qualityDrying solid materials without heatDaily livingFreeze-drying

The invention relates to a pseudo-ginseng vacuum freeze-drying method and application thereof, and relates to the technical field of traditional Chinese medicine processing. According to the vacuum freeze-drying method, pseudo-ginseng homogenate is subjected to pre-freezing and vacuum drying treatment, in the pre-freezing step, pre-freezing is carried out in stages at the temperature of minus 20-minus 75 DEG C, and in the vacuum drying treatment step, vacuum drying is carried out at the temperature of minus 20-30 DEG C. The vacuum freeze-drying method is applied to preparation of pseudo-ginseng processed products, and the obtained pseudo-ginseng processed products are high in cleanliness, fine and smooth in taste, stable in quality, accurate in dosage, convenient to apply and carry, high in dissolution and absorption speed, higher in product standardization, higher in production efficiency and suitable for daily life of normal people.

Owner:湖北金贵中药饮片有限公司

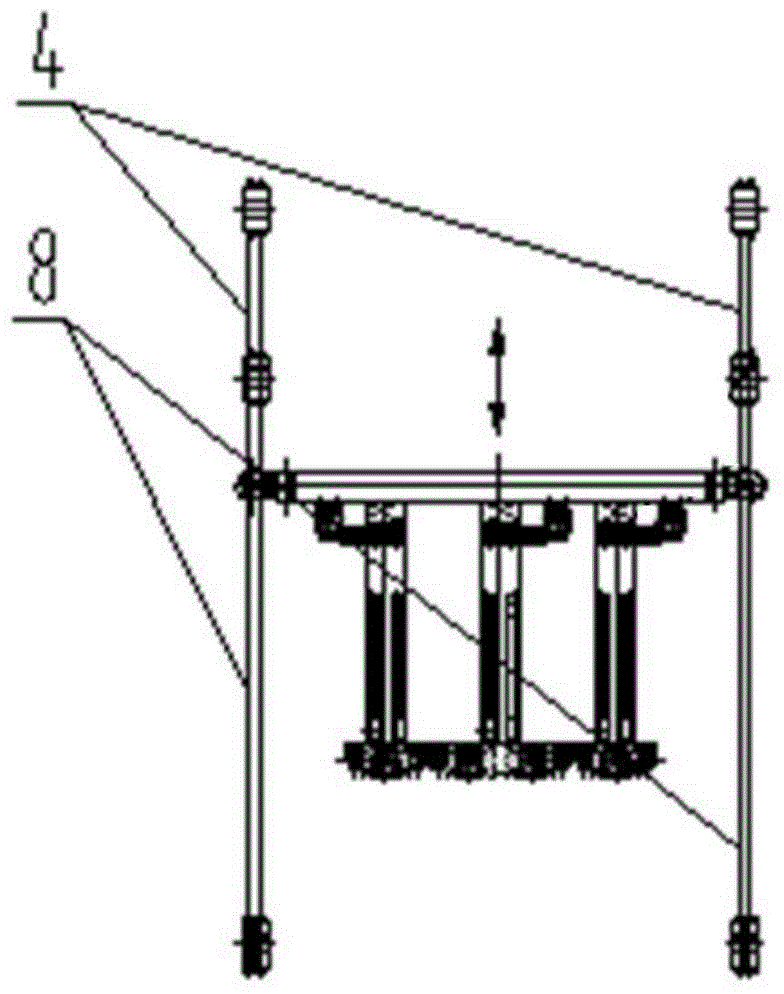

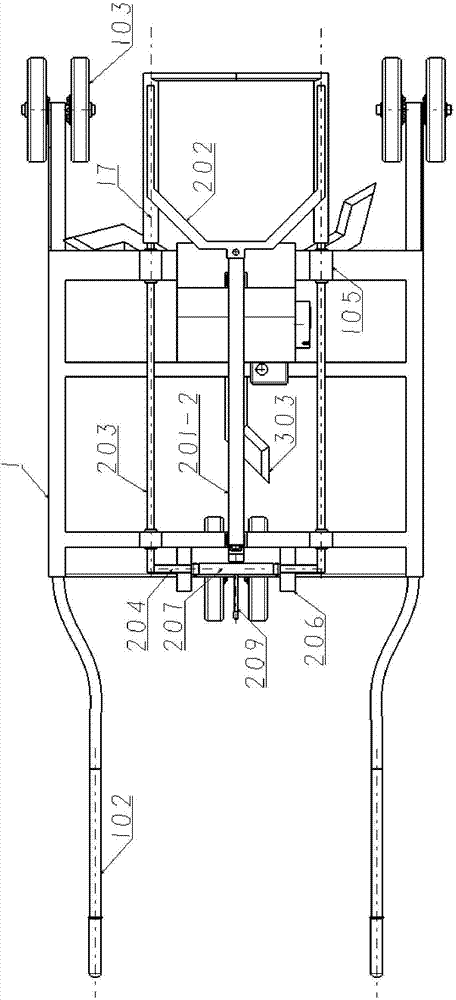

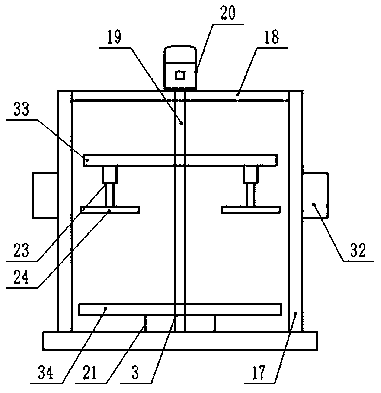

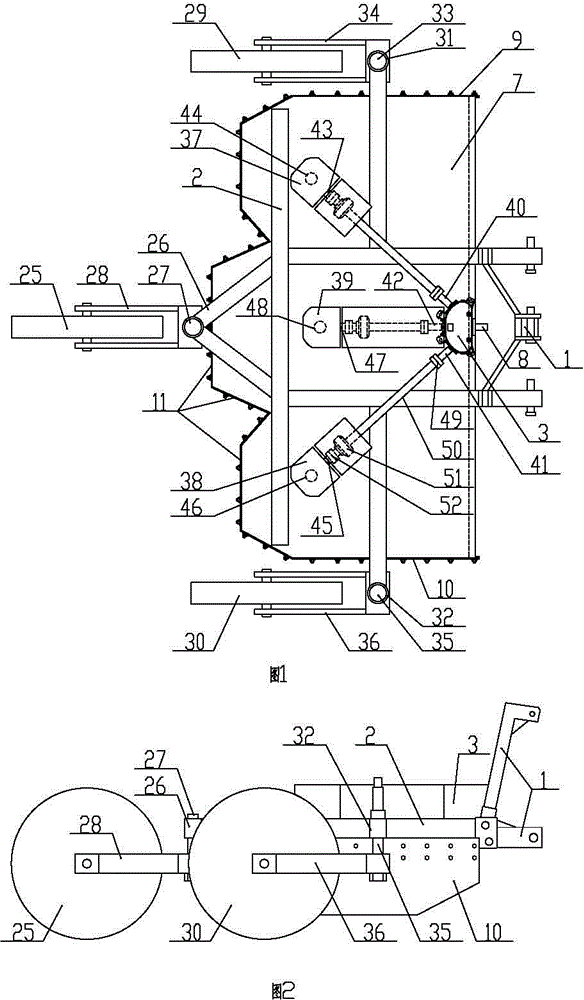

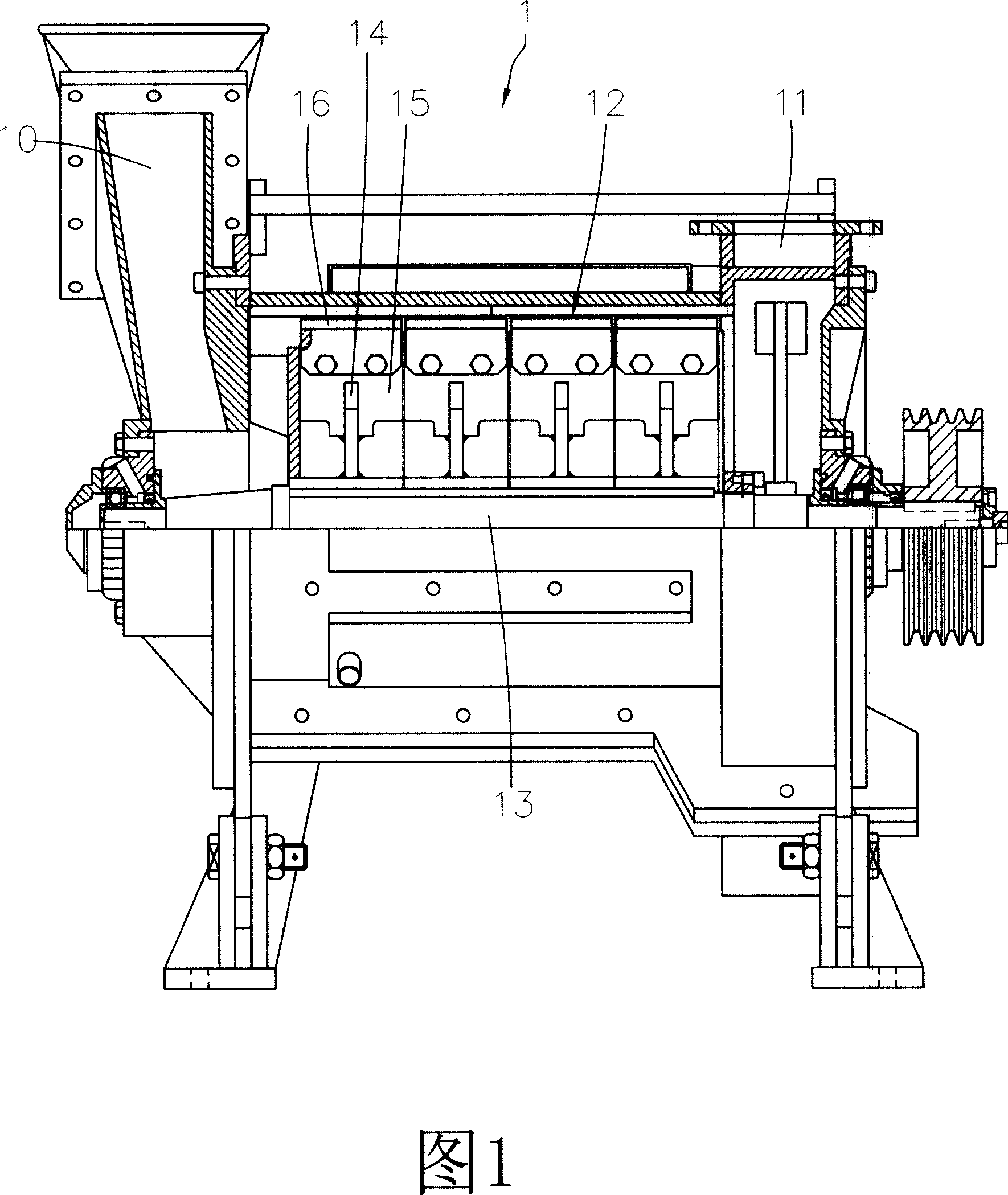

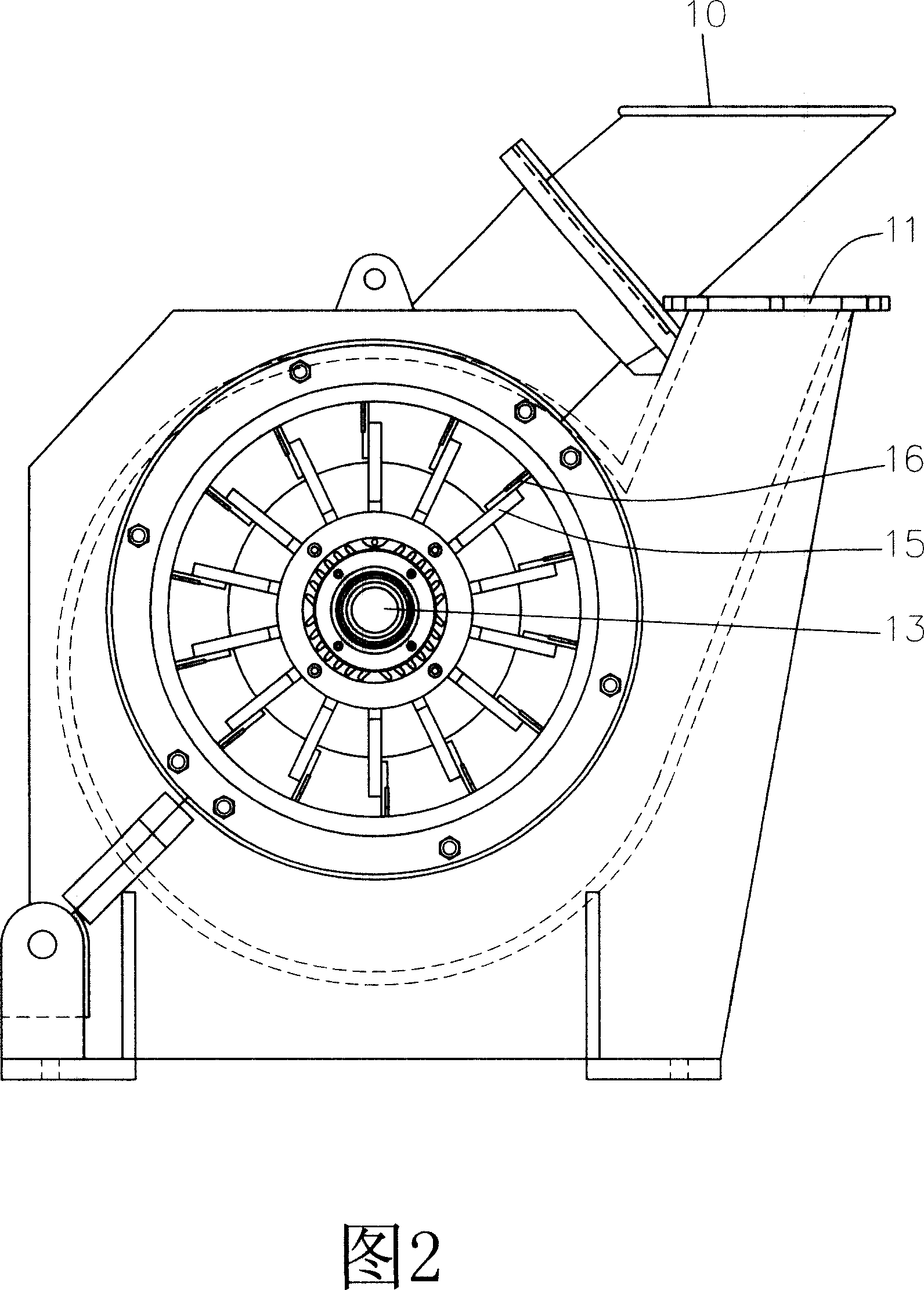

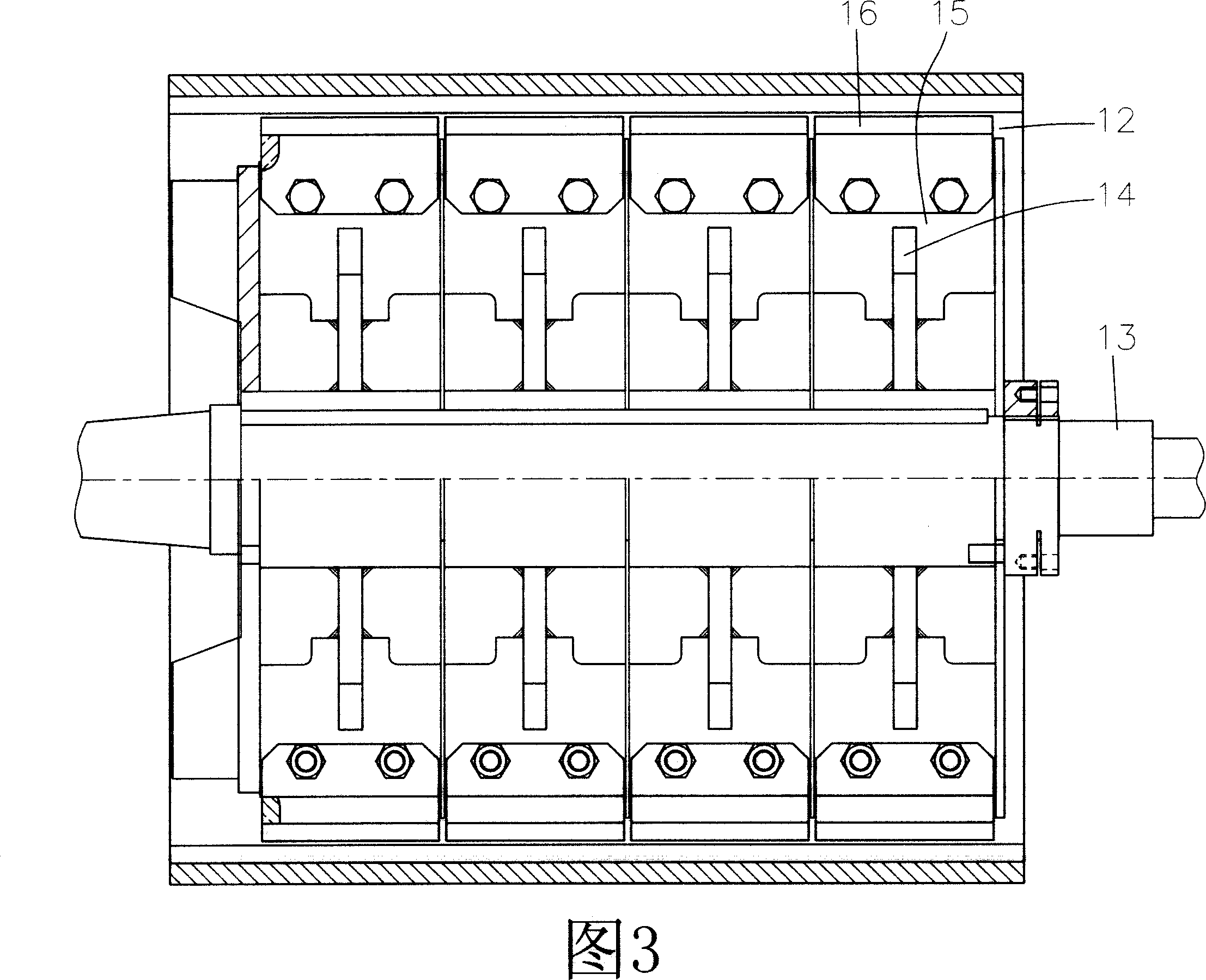

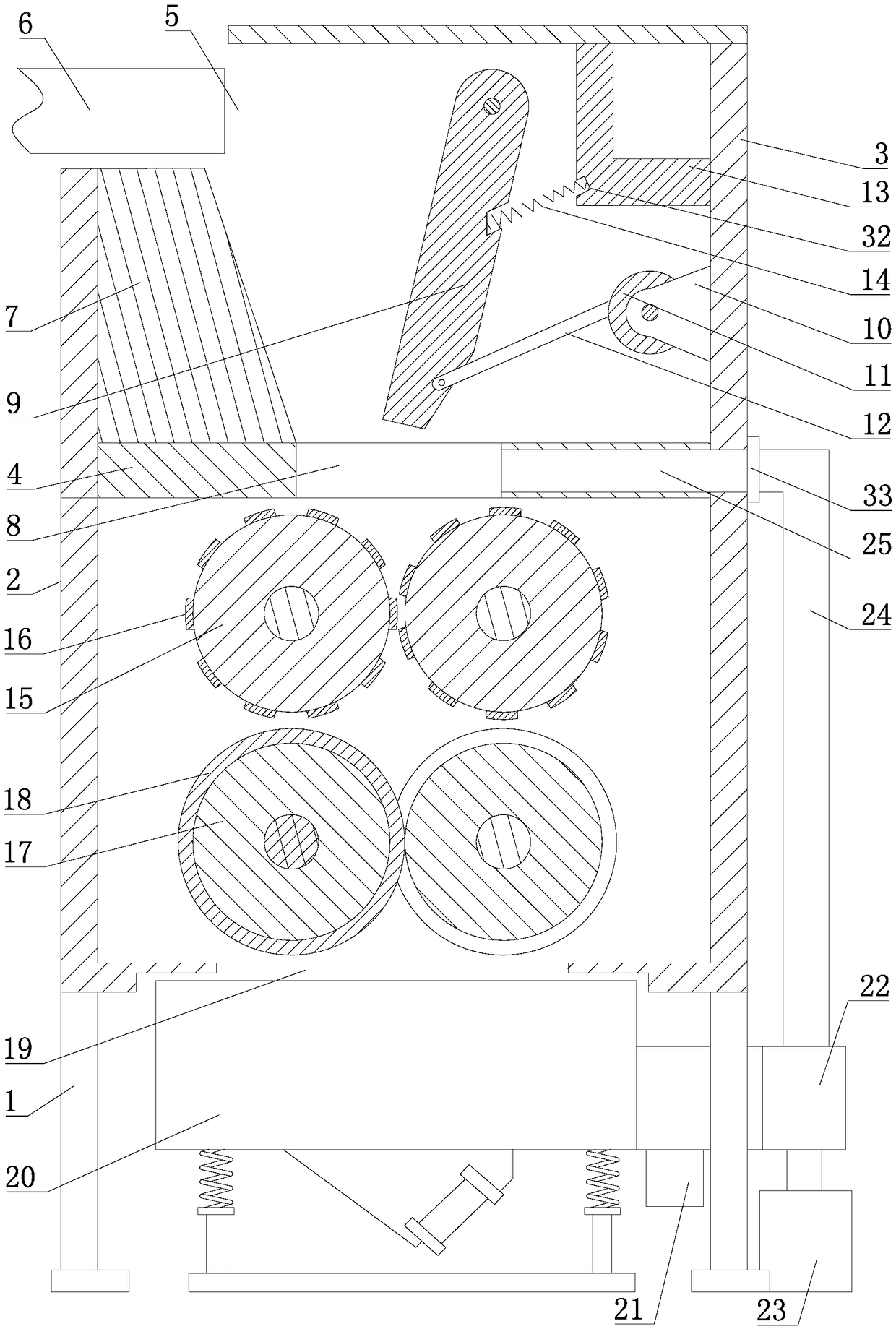

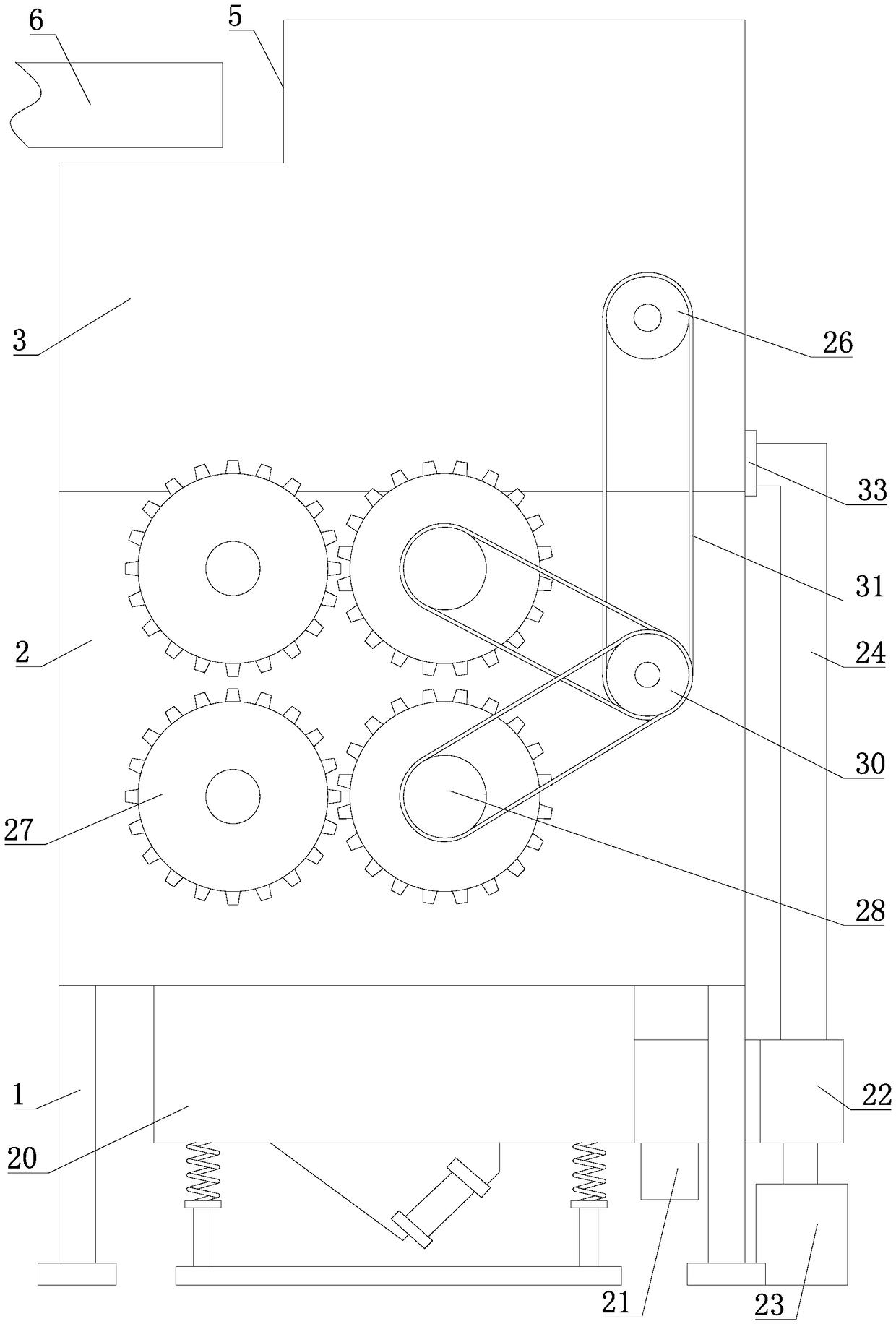

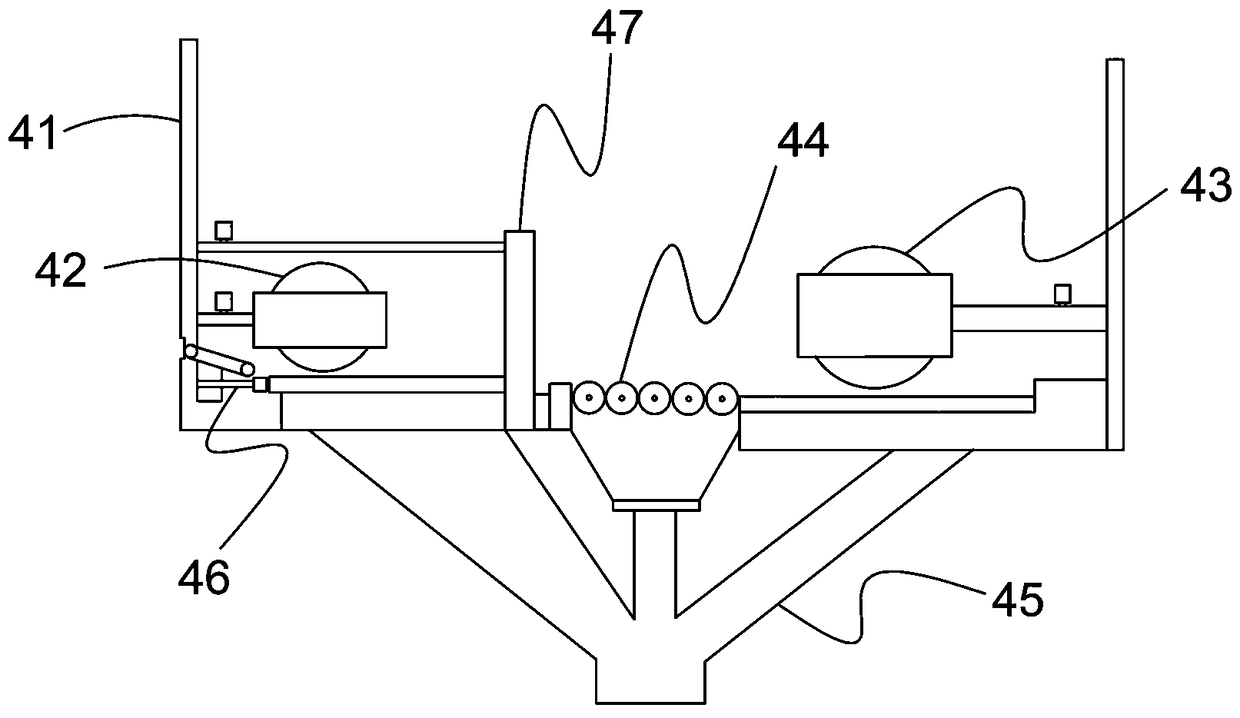

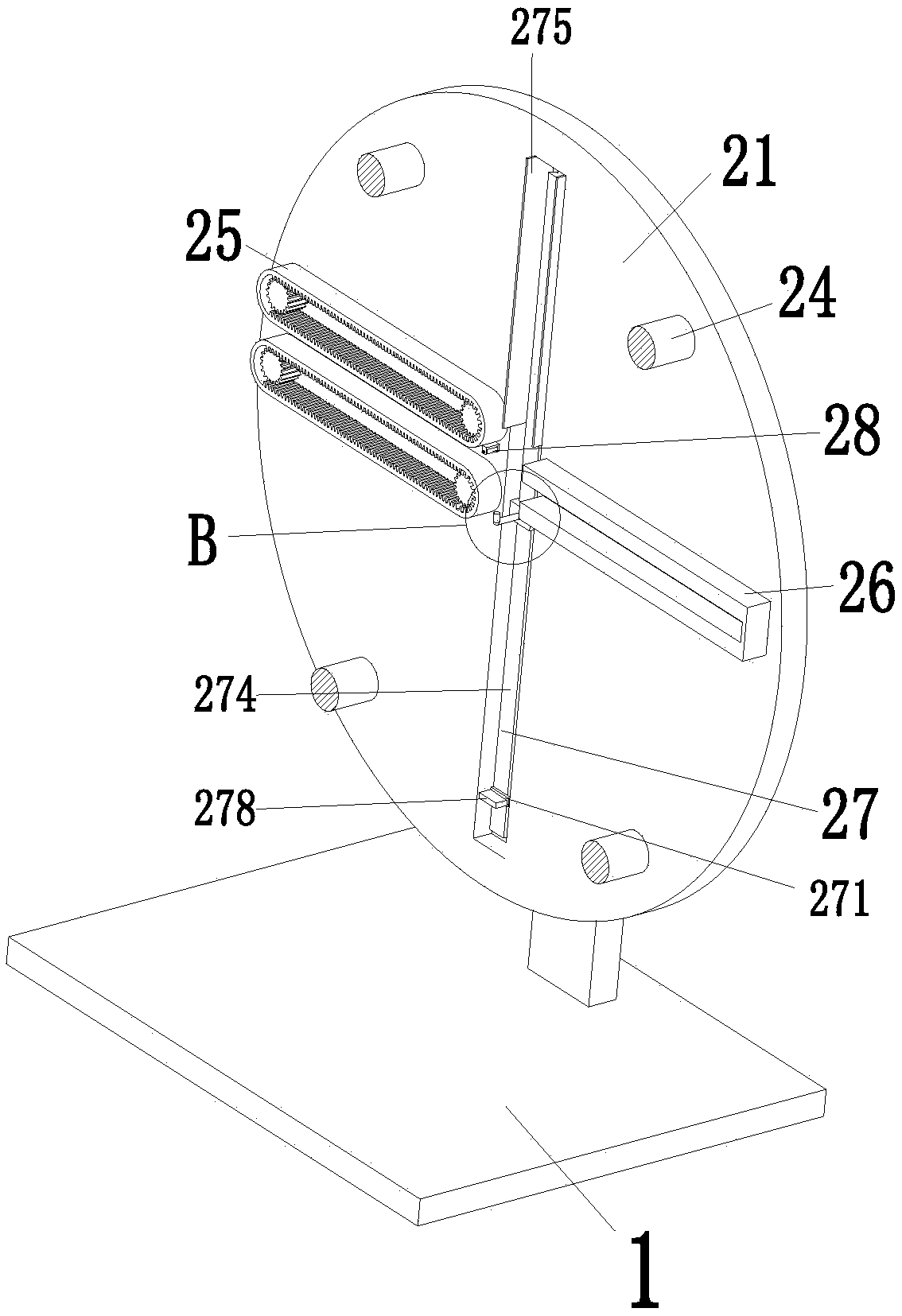

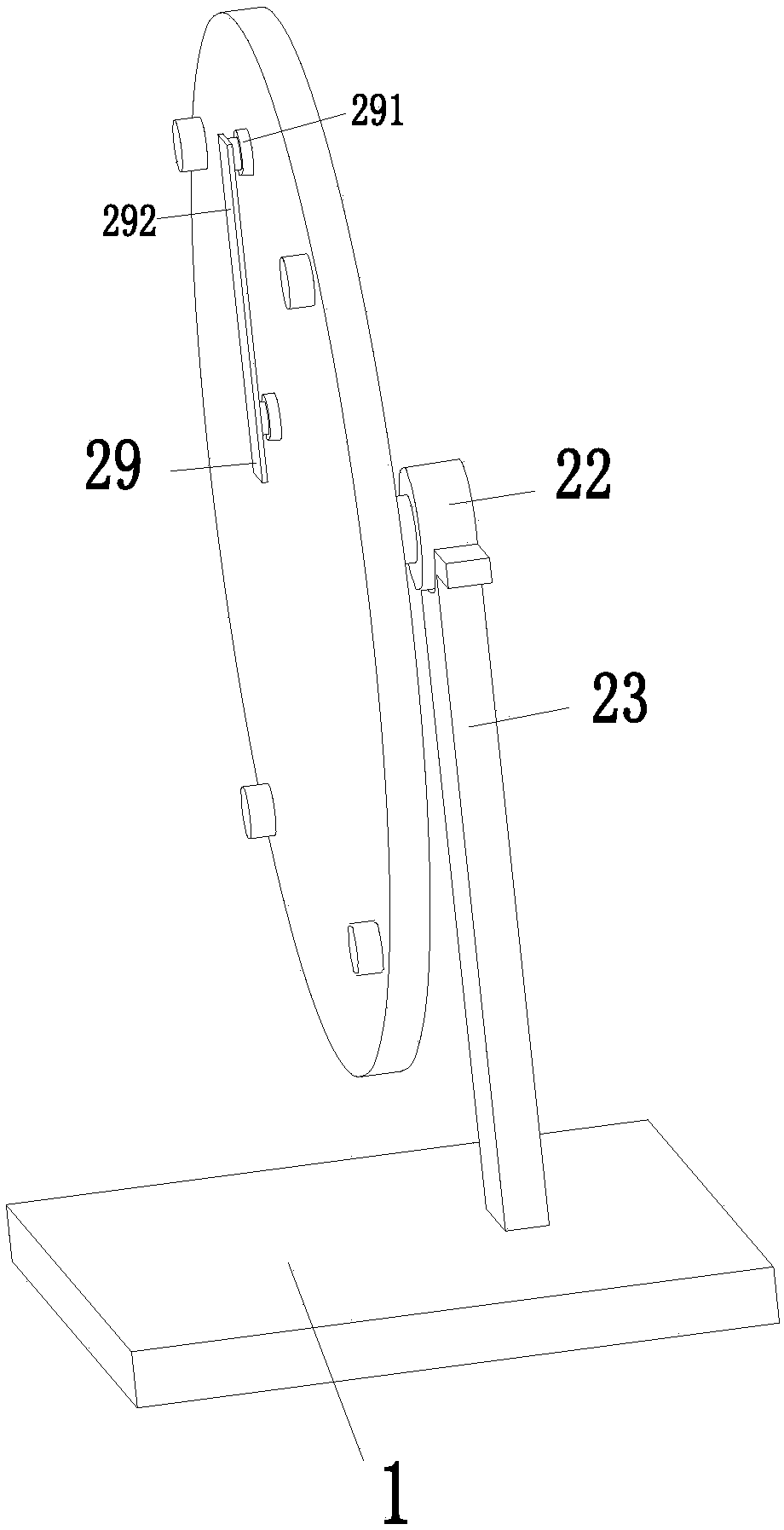

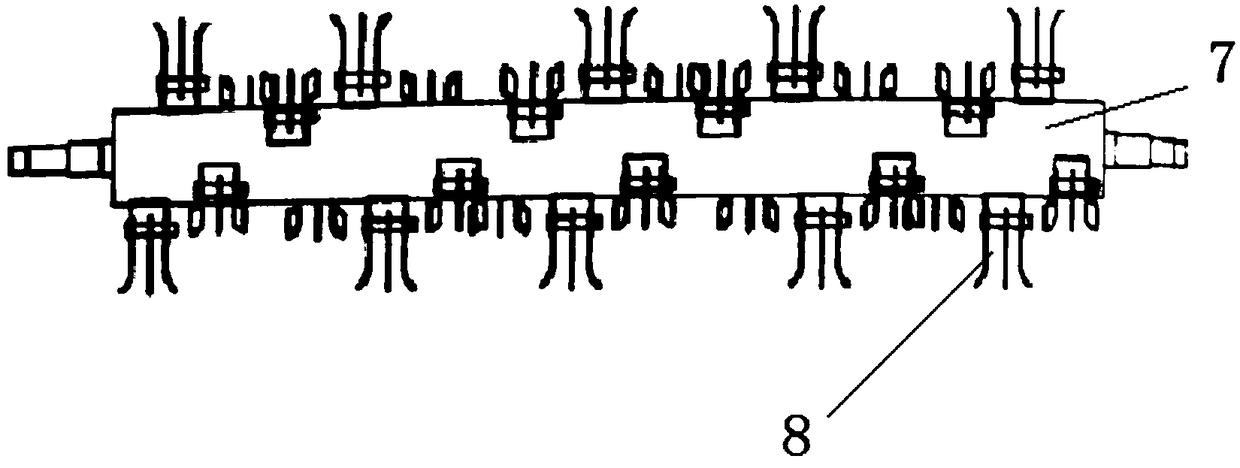

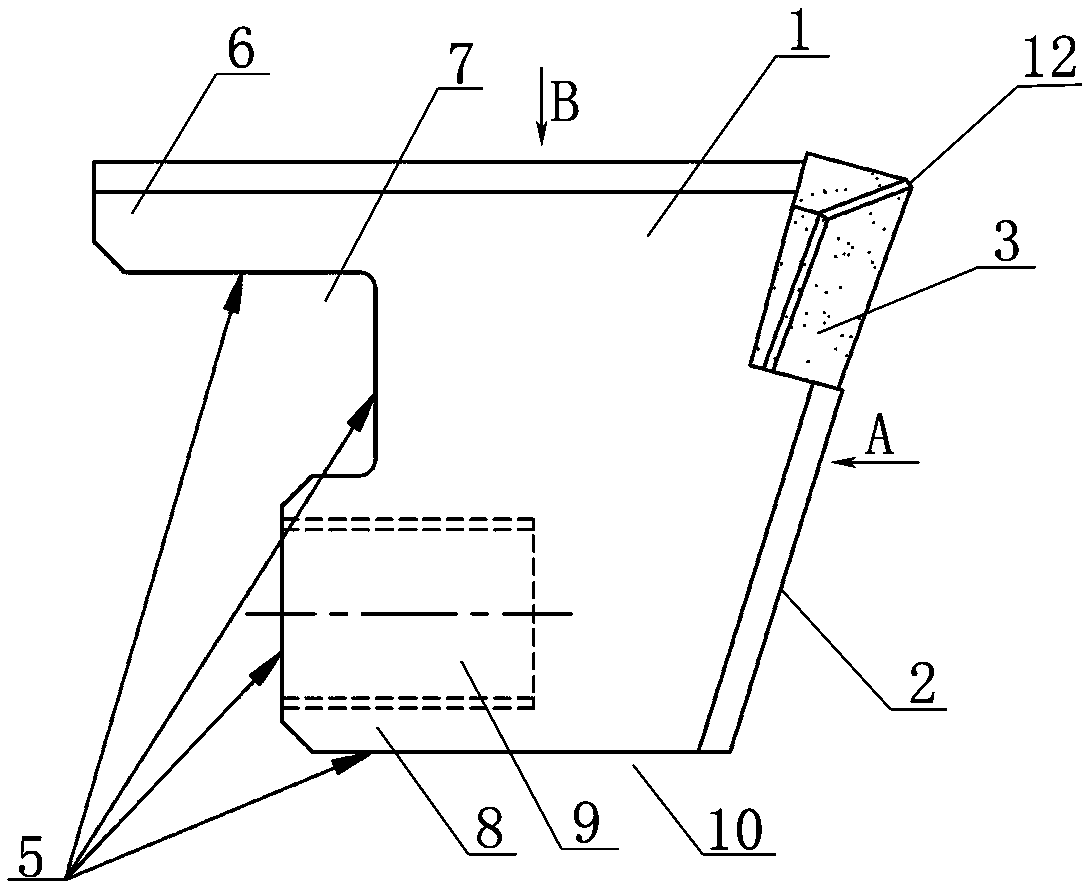

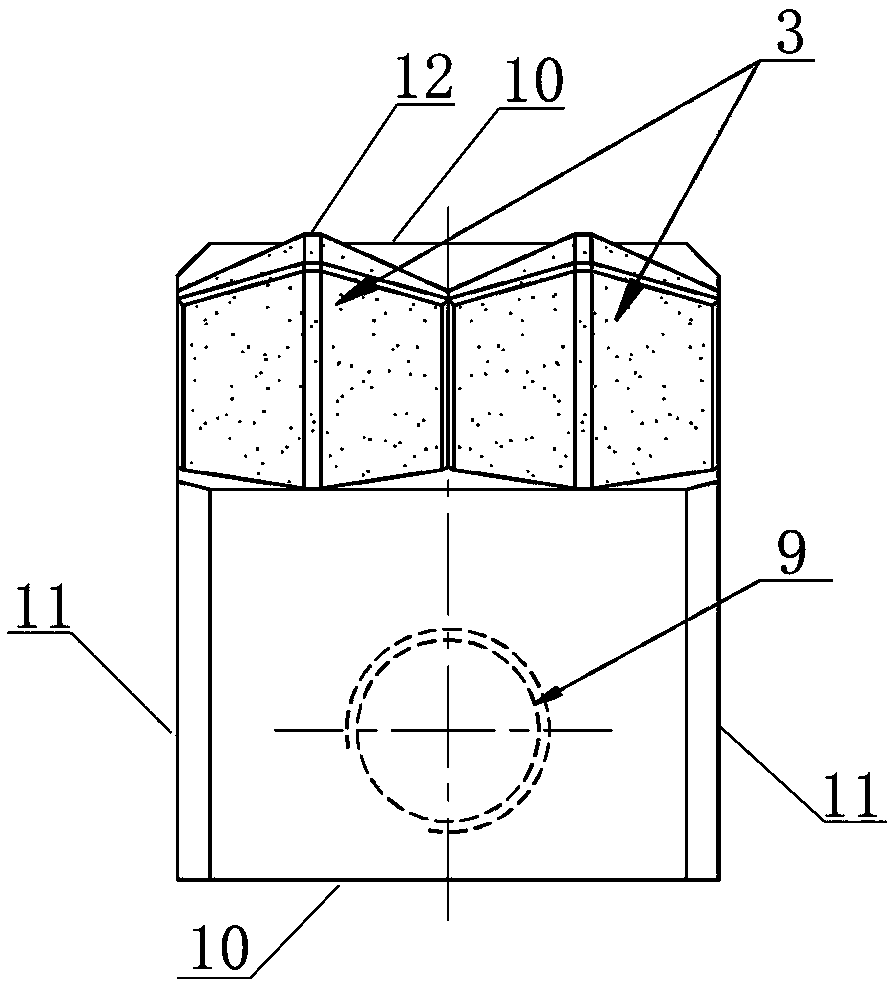

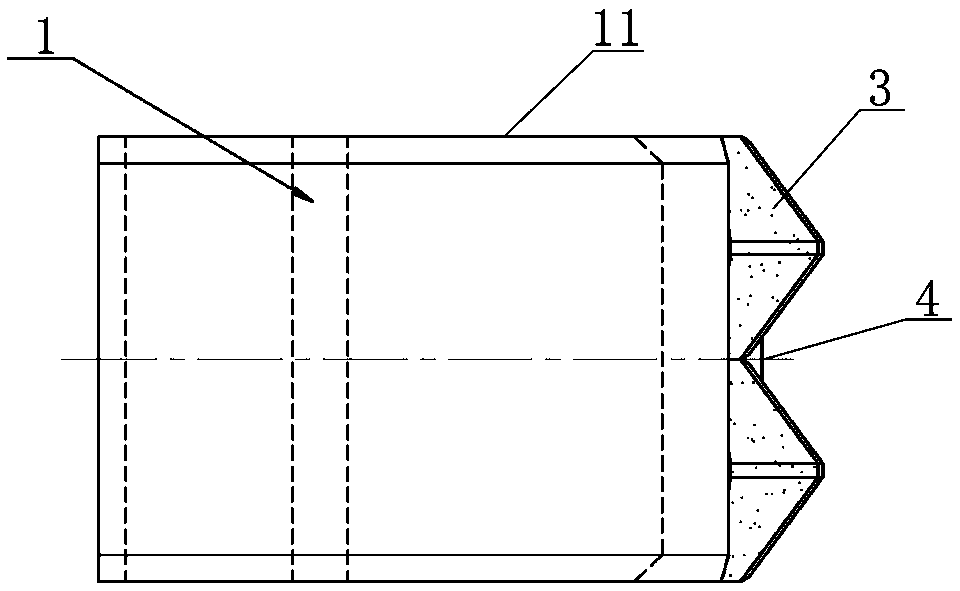

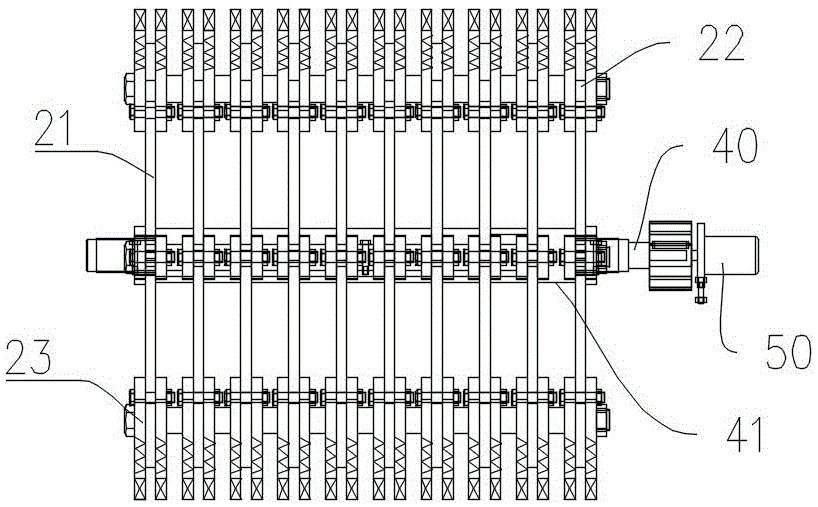

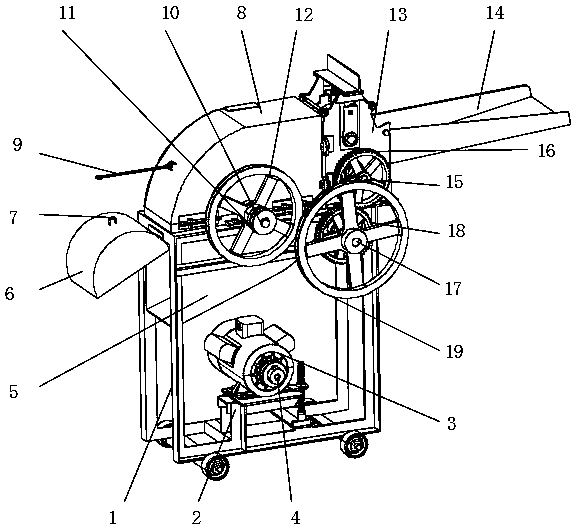

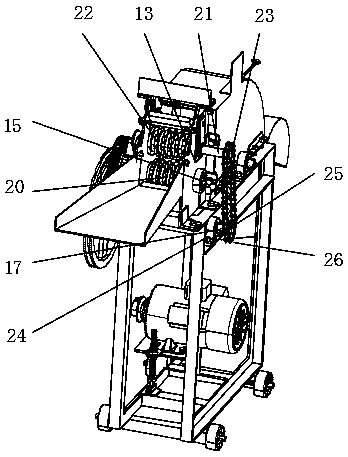

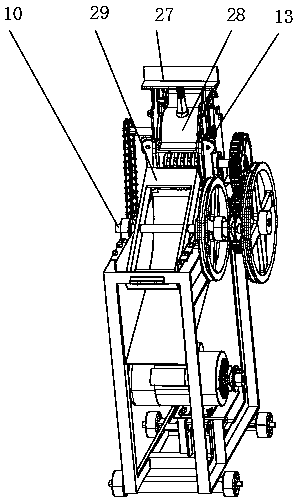

Automatic horizontal flue-cured tobacco bale loosing device of tobacco slice making line in cigarette factory

ActiveCN103948160AImprove crushing rateHigh penetration rateTobacco preparationMechanical engineeringFlue

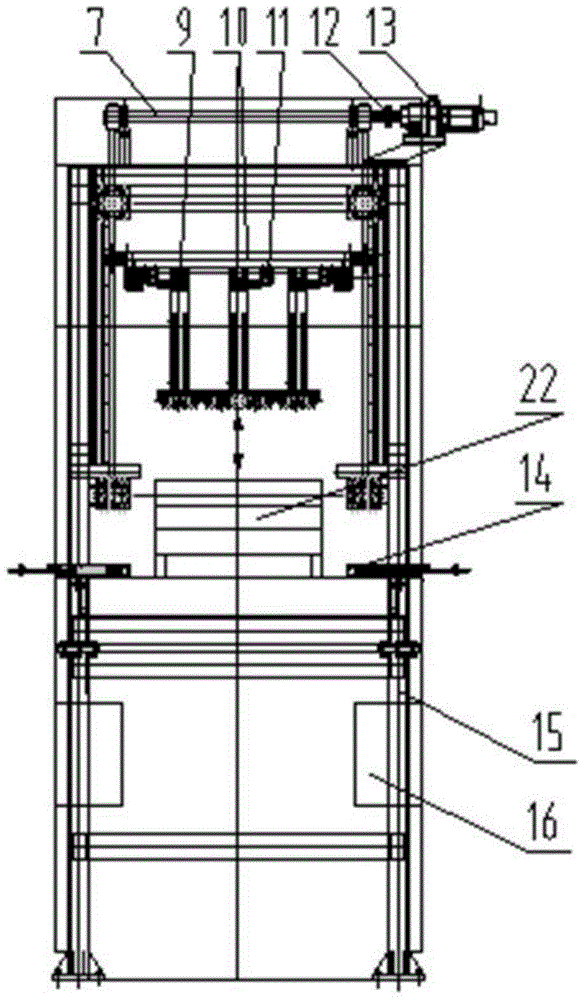

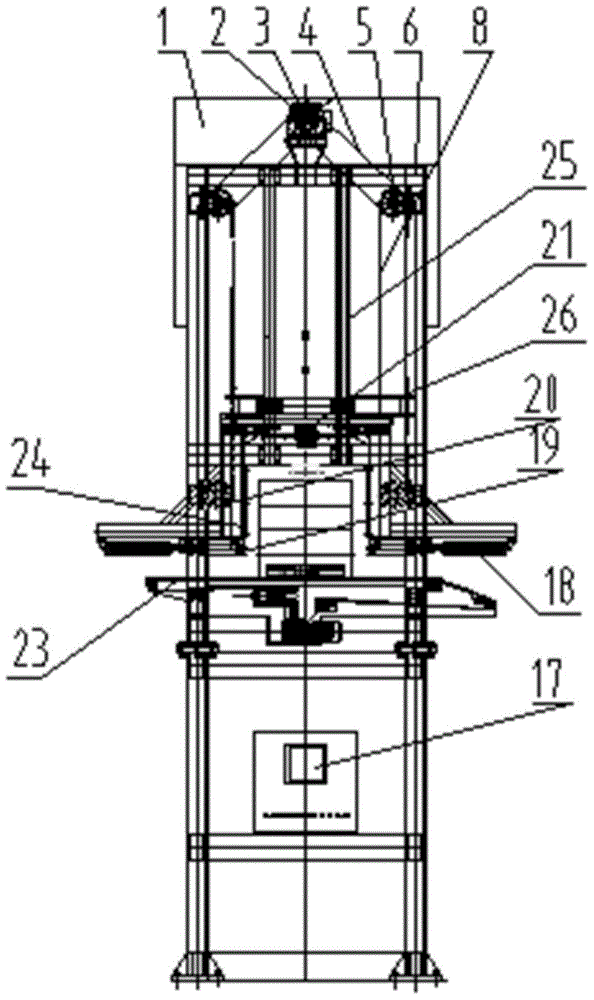

The invention discloses an automatic horizontal flue-cured tobacco bale loosing device of a tobacco slice making line in a cigarette factory. The automatic horizontal flue-cured tobacco bale loosing device consists of an upper stander (6) and a lower stander (15), wherein a conveyer (23) is arranged at the lower end of the upper stander (6); a clamping cylinder and a push plate (14) are arranged above the conveyer (23); the upper part of the upper stander (6) is connected with mounting bases (10) through a chain and chain connection pins (26); the mounting bases (10) are connected with clamping legs (9); the clamping legs (9) are connected with a clamping leg driving cylinder (11) through connection blocks; the inner sides of the clamping legs (9) are connected with an insertion cutter driving cylinder (18) with an insertion cutter (19); the clamping legs (9) on two sides are connected through a crank sliding block mechanism (21). The automatic horizontal flue-cured tobacco bale loosing device is easier to manufacture, high in production efficiency, low in cost, easy to mount, safer, more stable and more humanized; the smashing rate is lower, and the tobacco back-permeation rate is higher.

Owner:云南紫金科贸有限公司 +1

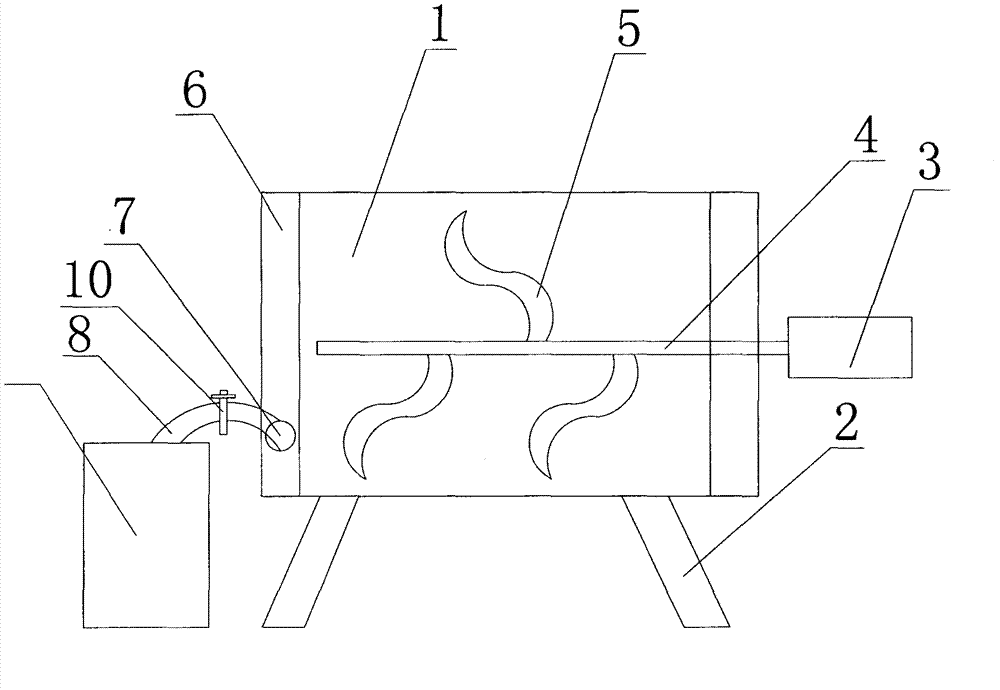

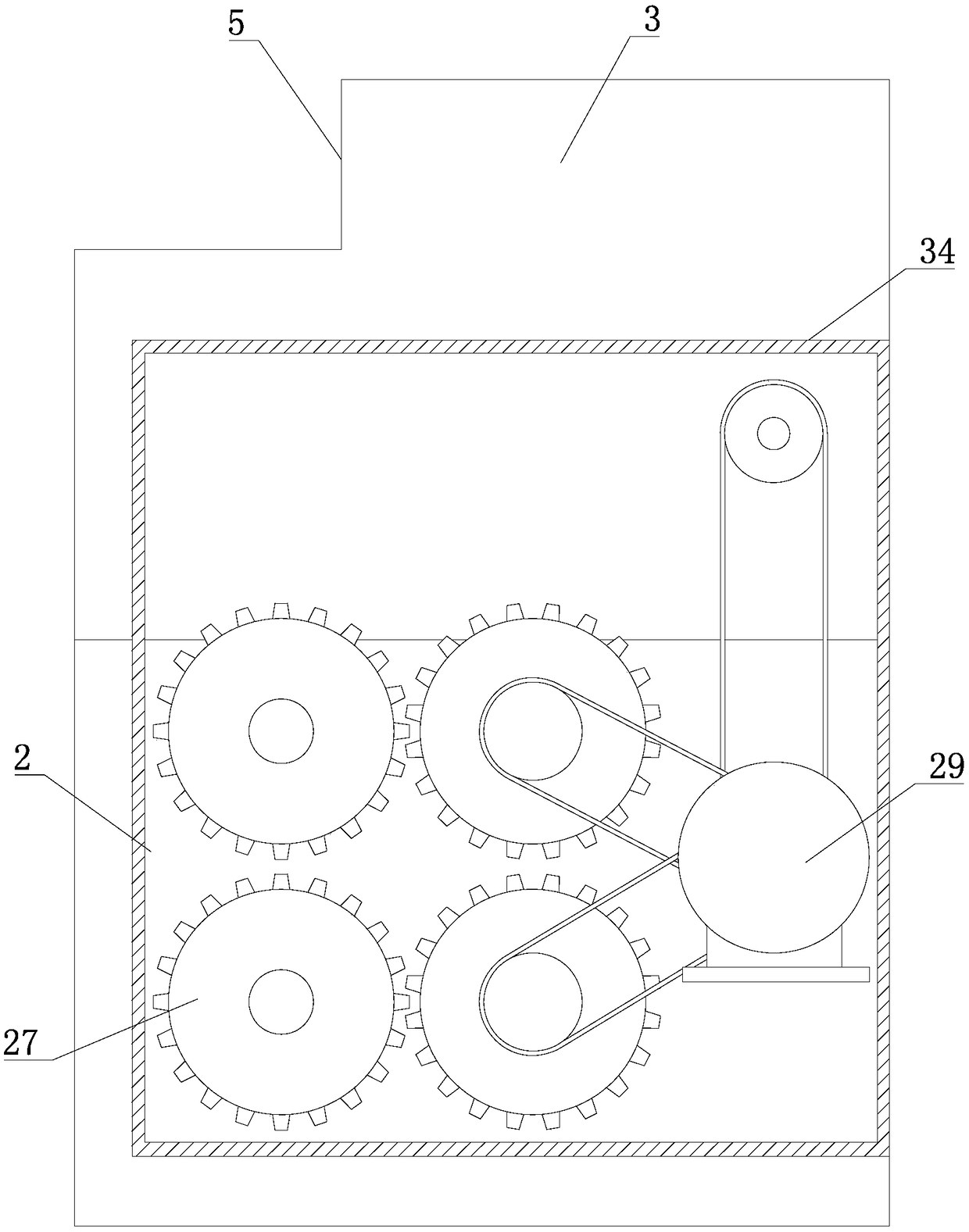

Crusher

The invention relates to a crusher, comprising a crusher shell, a frame, and a crushing unit. The crusher is characterized in that the crusher shell is fixed on the frame, the crushing unit comprises a motor, a main shaft and blades, the blades are fixed on the main shaft, the number of the blades is no less than 2, the blades are S-shaped, the crusher shell is provided with a cavity inside, the cavity is provided with an air intake, the air intake is connected with an external cooling device through a pipeline, and the pipeline is provided with a control valve. According to the invention, materials are stirred uniformly, the stirrer has high crushing rate, the product quality is raised, the structure is simple, the usage is convenient, the service life is long, and a liquid nitrogen generator can reduce the temperature of processing materials.

Owner:任仲斌

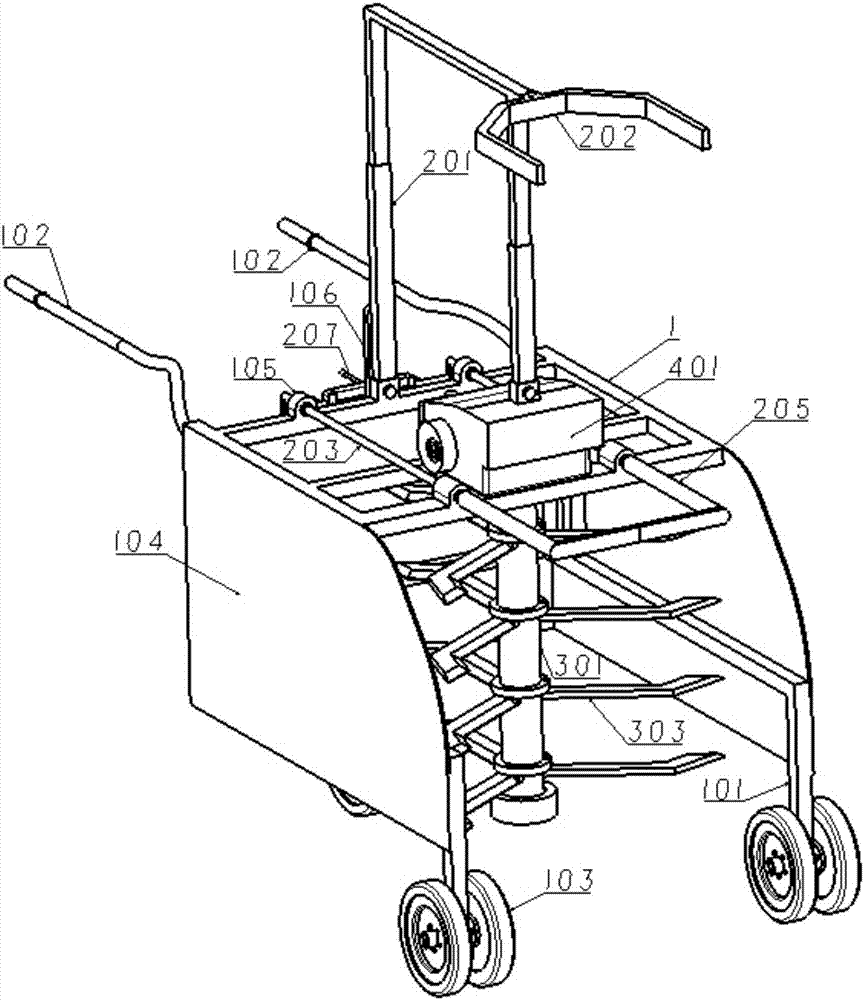

Light and simple vertical banana stem crushing and returning machine

ActiveCN106941861AEffective one-time crushing and returning to the fieldEasy maintenanceMowersReduction driveEngineering

The invention discloses a light and simple vertical banana stem crushing and returning machine, comprising a light and simple rack, a spacing mechanism, a vertical smashing blade, and a transmission device. The spacing mechanism comprises an upper spacing unit, a lower spacing unit, and a limit switch. The light and simple rack is connected with the upper spacing unit and the lower spacing unit through bolts. A U-shaped arm of the upper spacing unit and an L-shaped arm of the lower spacing unit realize spacing effect on banana stems. Torsion of an engine of the transmission device is transmitted to the vertical smashing blade after deceleration of a reducer, to realize to cut and smash banana stems, and then stems on the upper part are cut and smashed in sequence by cutters of the vertical smashing blade in a process of falling down with gravity. The upper spacing unit and the lower spacing unit are used to limit banana stems from two points on a radial direction. The vertical smashing blade realizes to cut and smash banana stems. The machine can efficiently complete crushing and field-returning of the banana stems in low energy consumption in one time, so as to improve effective utilization rate of banana stem resources. The machine is light and simple in structure, and flexible in moving.

Owner:SOUTH CHINA AGRI UNIV

Simple and efficient hydraulic oil extraction equipment

InactiveCN108263010AImprove crushing rateImprove the efficiency of oil extractionGrain treatmentsPressesCircular discTemperature control

The invention discloses simple and efficient hydraulic oil extraction equipment, which comprises a basic base, wherein a feeding device is arranged at the front side of the upper end of the basic base; a hydraulic oil extraction device is arranged at the back side of the upper end of the basic base; the feeding device consists of an inclination angle conveyor, a feeding funnel, a feeding tube, a reverse L-shaped quantity control plate, a crushing box body, a roller device, a heat extraction temperature control box, a cold extraction temperature control box and a vertical support frame; the hydraulic oil extraction device consists of a vertical fixing frame, a horizontal connecting frame, a lead screw, a second rotating motor, a crossed rotating frame, a tubular support frame, a circular disc-shaped rotating frame, an oil extraction barrel, a compression air cylinder, a press plate, a third rotating motor and a driving gear; the oil extraction barrel is separated into an inner barrel body and an outer tube body; an oil storage cavity is formed between the inner barrel body and the outer tube body. The simple and efficient hydraulic oil extraction equipment has the beneficial effectsthat the structure is simple; the practicability is high.

Owner:湖北双明粮棉油有限公司

Multifunctional copper wire separator

PendingCN105251597ASeparation helpsEasy to get wetUsing liquid separation agentGrain treatmentsCopper wireWater storage tank

The invention relates to the technical field of environment protection, in particular to a multifunctional copper wire separator. The multifunctional copper wire separator comprises a machine frame. The machine frame is sequentially provided with a crushing machine and a separating machine from top to bottom, a feed port is formed in the upper end of the crushing machine, and a discharge port communicated with a feed port of the separating machine is formed in the lower end of the crushing machine. The multifunctional copper wire separator is characterized in that a spraying mechanism is arranged in the crushing machine, a plastic discharge port and a metal discharge port are formed in the left end and the right end of the separating machine respectively, a plastic screening mechanism is arranged below the plastic discharge port, and a metal screening mechanism is arranged below the plastic discharge port; the plastic screening mechanism comprises a water storage tank and a sieve, one end of the water storage tank is communicated with the metal screening mechanism through a water guide pipe, the other end of the water storage tank is connected with the spraying mechanism through a water inlet pipe, and the water inlet pipe is provided with a water pump. The multifunctional copper wire separator has the advantages that the crushing rate and the separating rate are high, secondary pollution is avoided, the cost is low and the size is small.

Owner:威海市奥陆达环保设备科技有限公司

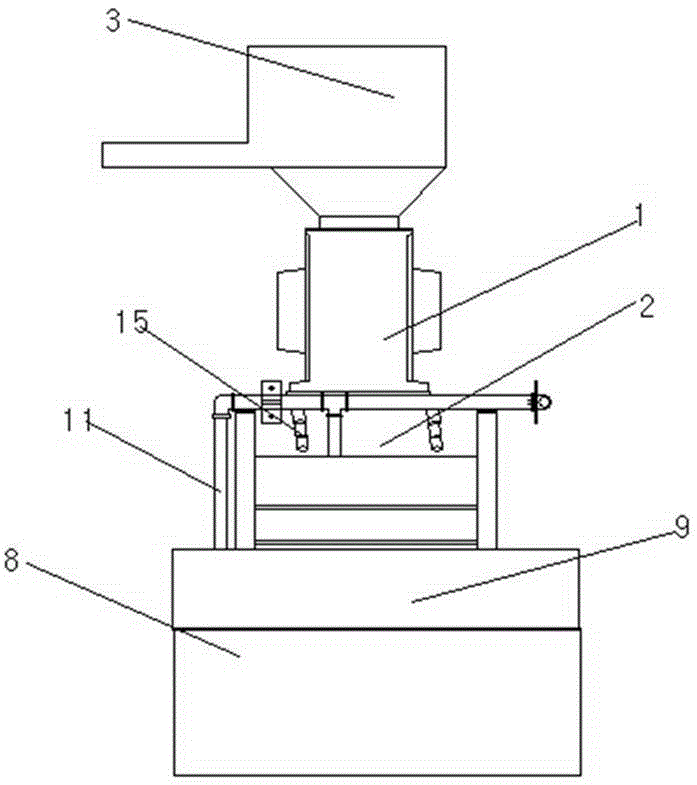

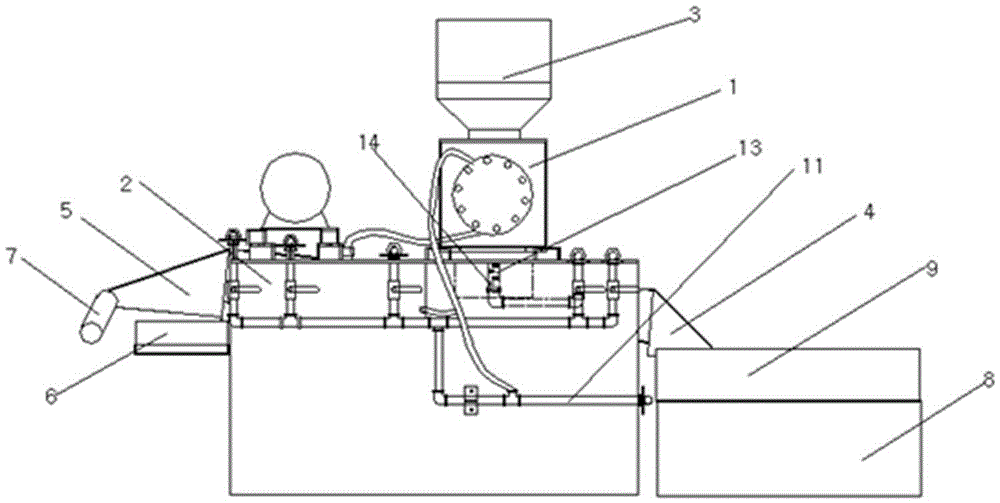

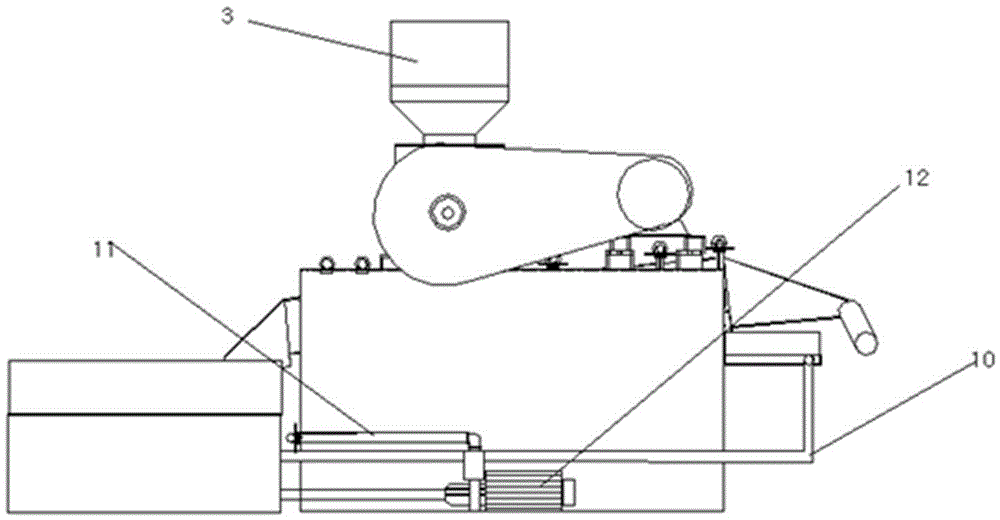

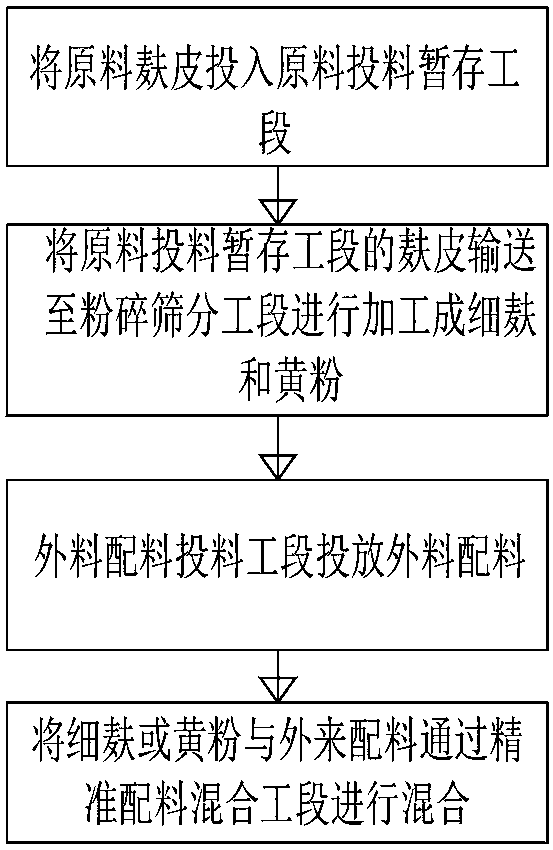

Bran processing technology

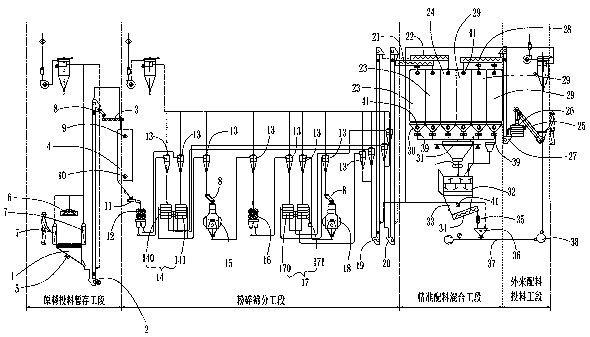

ActiveCN110449248AImprove crushing rateImprove crushing efficiencyMixing methodsMixersBranMechanical engineering

The invention provides a bran processing technology. The technology comprises the following steps of 1, placing raw bran onto a raw material feeding temporary storage section; 2, convey bran in a rawmaterial cabin to a crushing screening workshop section for processing; 3, placing foreign material batch onto a foreign material batch feeding workshop section; and 4, mixing fine bran or yellow powder with foreign batch through an accurate batch mixing workshop section. The bran processing technology has the advantages of being high in production efficiency, high in crushing rate and low in energy consumption.

Owner:广州穗粮实业有限公司

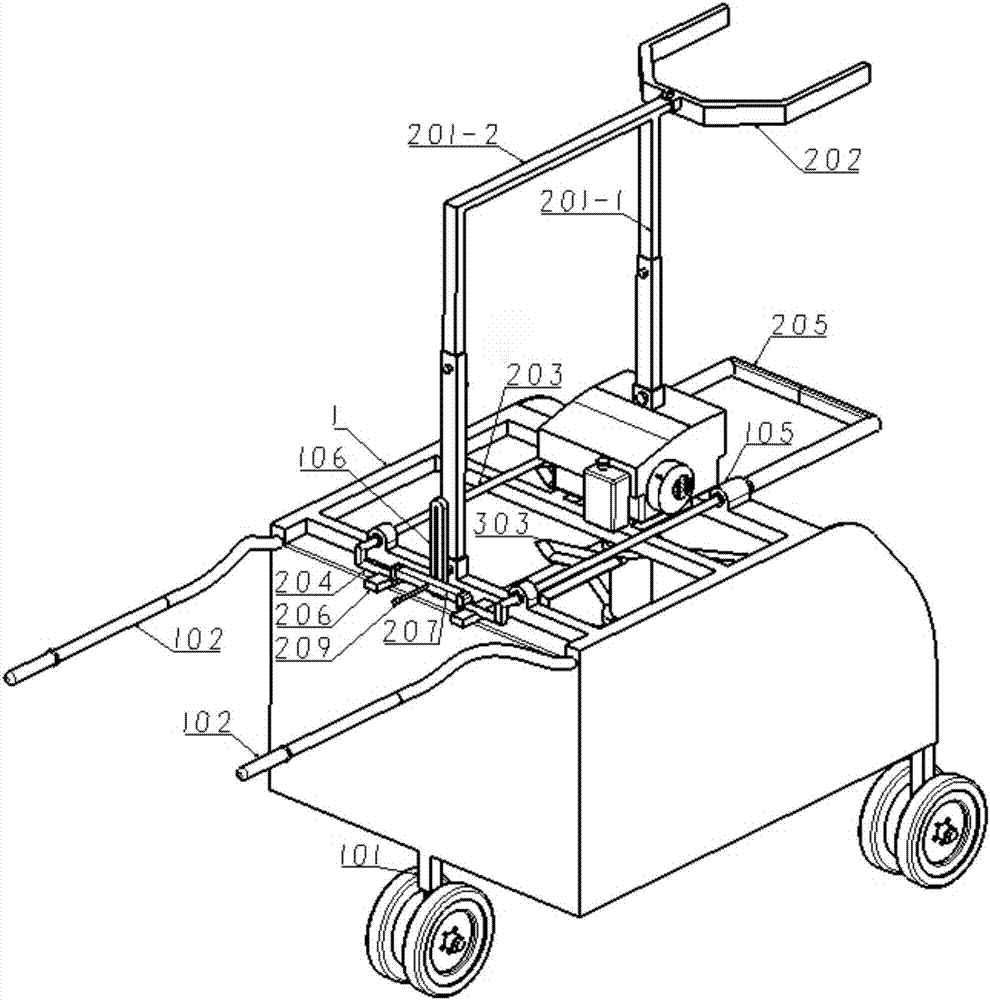

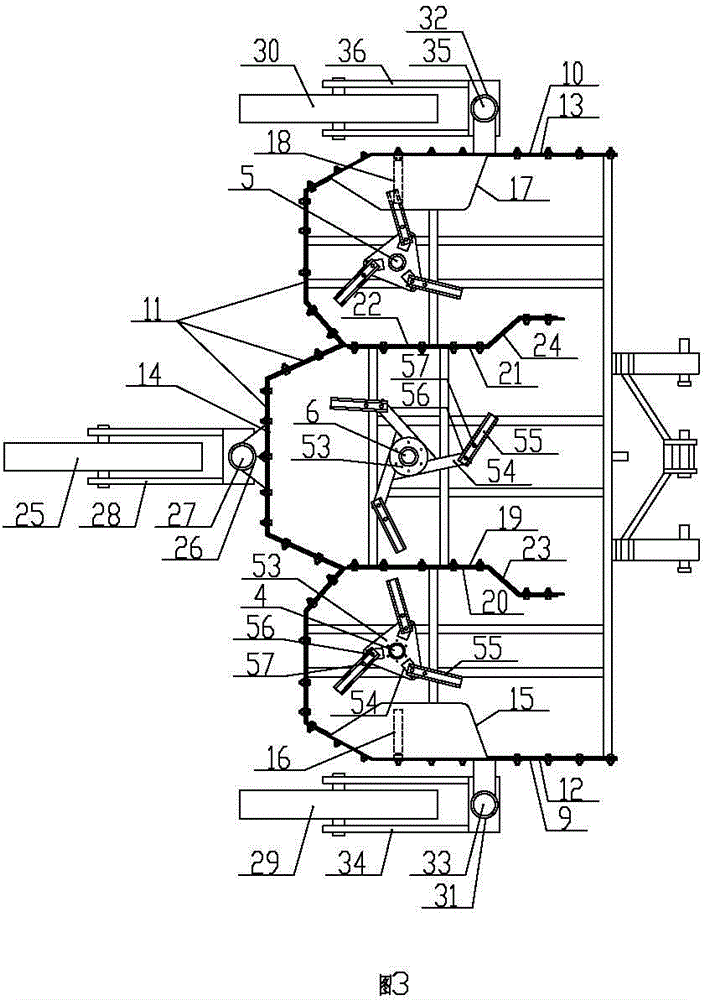

Multi-shaft straw crushing and returning machine

InactiveCN103947383AReasonable structureEasy to useCrop conditionersMowersAgricultural engineeringAgriculture

The invention relates to the technical field of agricultural straw returning machinery, and relates to a multi-shaft straw crushing and returning machine. The multi-shaft straw crushing and returning machine comprises a traction frame, a rack, traveling wheels, a main gear box, a transmission gear, a left cutter shaft, a right cutter shaft and a middle cutter shaft, wherein the traction frame is fixed at the front end of the rack; no less than one traveling wheel is mounted at the back of the rack; a frame plate is fixed at the lower part of the rack; the main gear box is fixedly mounted at the upper end of the frame plate; the left cutter shaft, the right cutter shaft and the middle cutter shaft along the vertical direction are respectively mounted below the frame plate. The multi-shaft straw crushing and returning machine is reasonable and compact in structure and convenient to use, the tractor load is alleviated through the traveling wheels, and three cutter discs are driven to work cooperatively through the main gear box, so that the working width is increased, the straw crushing efficiency is high, the crushing effect is better, and the working efficiency is also improved; the dispersion direction of broken straws can be limited and guided through a baffle plate mounted at the lower end of the frame plate, so that the straws are unlikely to be stacked and are uniform in dispersion, and the machine has the characteristics of safety, simple, convenience and high efficiency.

Owner:玛纳斯县祥和农机有限责任公司

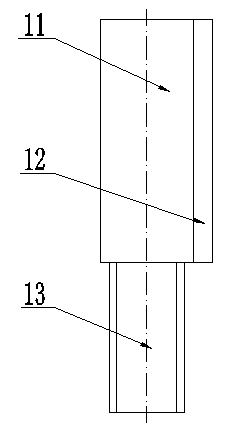

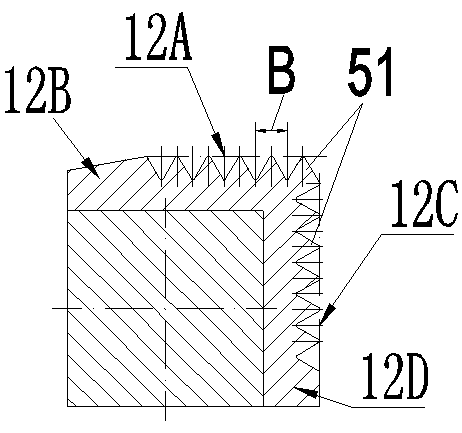

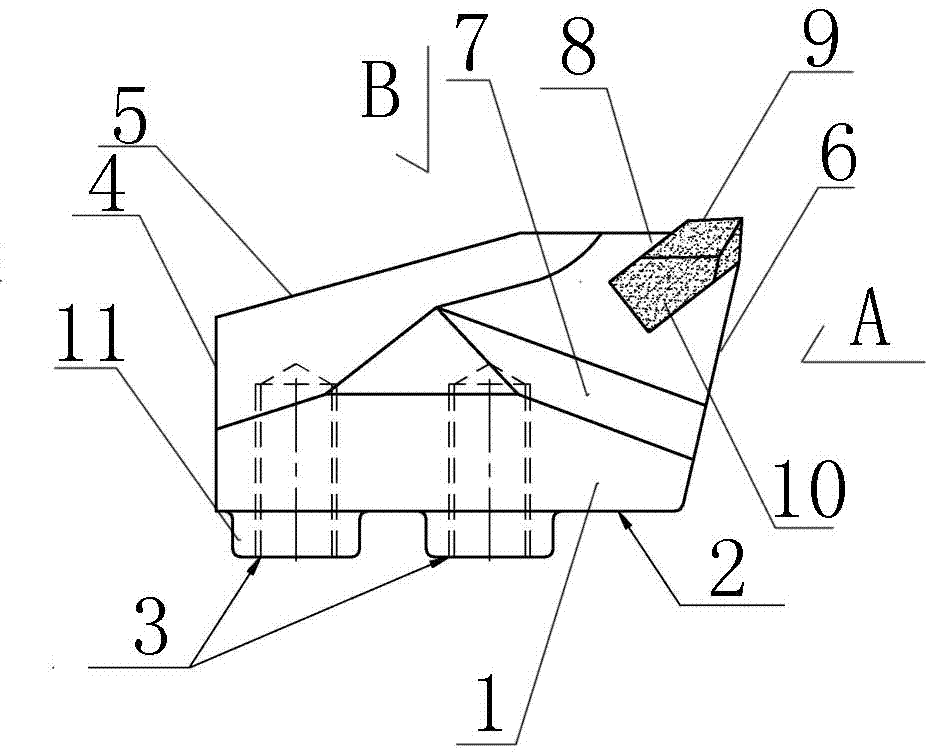

Symmetrical mechanical tooth of crusher and for waste product disposing

InactiveCN107837892AImprove wear resistanceExtended service lifeGrain treatmentsWaste processingParticulates

A symmetrical mechanical tooth of a crusher and for waste product disposing comprises a strip-shaped block body, point parts symmetrically protrude upwards from the upper portions of the two long endsides of the strip-shaped block body, granular hard alloy weld layers are subjected to build up welding from the point parts to the surfaces of the lower portions, and the interiors of the point partson the two sides transit downwards in arc shapes to a middle surface plane; a square block protruding downwards is arranged in the middle of the lower portion of the strip-shaped block body, assemblybottom faces of the strip-shaped block body are arranged on the two sides of the square block, and assembly through holes communicating with the middle surface plane are formed in the middle of the square block upwards; and the middles of the outer surfaces of the two long end sides of the strip-shaped block body protrude outwards, the upper portions and the lower portions of the outer surfaces of the two long end sides of the strip-shaped block body form inclined faces shrinking outwards correspondingly, and the granular hard alloy weld layers on the outer surfaces of the two long end sidesform the side faces with the middles of the lower portions being provided with n-shaped openings. The symmetrical mechanical tooth has the characteristics that the structure is simple, using and installing are convenient, the wear resistance of a tooth head can be greatly improved, the service life of the tooth head can be greatly prolonged, the using cost can be reduced, the working efficiency isimproved, and the material crushing rate is increased.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

Crushing machine

The invention discloses a crushing machine, which relates to the field of machinery equipment. The crushing machine comprises a shell and a crushing device, wherein a rack is arranged below the shell; the crushing device comprises a first crushing layer and a second crushing layer; each of the first crushing layer and the second crushing layer comprises a motor, a rotating shaft and blades; the S-shaped blades are arranged on the rotating shafts. When the crushing machine works, the rotating shafts of the first and the second crushing layer rotate in different directions, thus achieving a double crushing effect and stirring uniformly. The crushing machine can fully crush materials and improve a crushing rate, and is simple in structure and convenient to use.

Owner:常熟市新晨机械厂

Sugarcane leaf crushing and returning machine

InactiveCN108076838ASimple structureEasy to operateLoadersCrop conditionersTransmission systemEngineering

Provided is a sugarcane leaf crushing and returning machine comprising a transmission system, a frame, a front baffle plate, a flail chopper knife, a stationary knife, a knife roll, a rear baffle plate, a spacing wheel and a profiling leaf collector; the transmission system comprises a gearbox and a V-shaped conveyor belt; three points of the frame suspend on a wheel tractor; the flail chopper knife and the stationary knife are main work parts for crushing; the spacing wheel is a profiling wheel; the profiling leaf collector is mainly composed of a diagonal rod and a connecting board; the diagonal rod is composed of a bending rod and a bottom shovel by connecting though bolts; the diagonal rod is rigidly connected with the spacing wheel and is located on a same surface of the tractor wheels. The gap between the flail chopper knife and trenches can exceed the height of ridges, which well solves the problem that common flail chopper knife cannot pick sugarcane leaves; the machine has theadvantages of simple structure, convenient operation, small turning radius, avoiding being entangled and blocked by sugar cane leaves, high pickup rate and crushing rate, and low power consumption.

Owner:周宝东

Turbine grinder

A turbine crusher comprises an inlet at one side, an opposite outlet, crushing chamber inside with ladder slots and at least two crushing knife plates, which connect with shaft rod and driven by it, with the outside radius of the crushing knife plate tapered in arrangement to the outlet direction and corresponding to the ladder slots, material distributing plates and knives on the plate, with raw material sent into the crushing chamber for chopping, crushing along the crusher chamber toward the ladder slot, the crushed material falling into next step for secondary crushing to improve the crushing ratio.

Owner:凌渊明

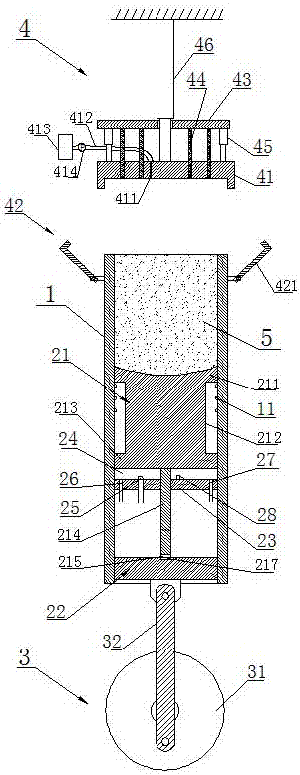

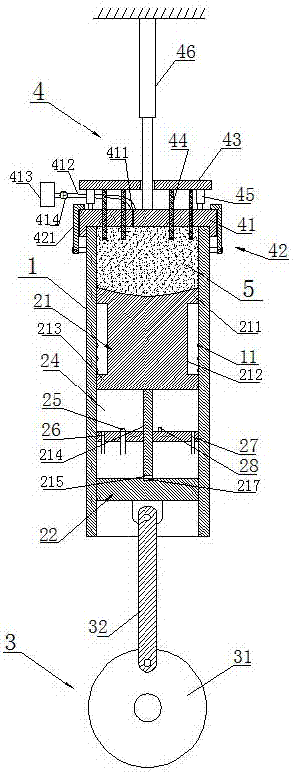

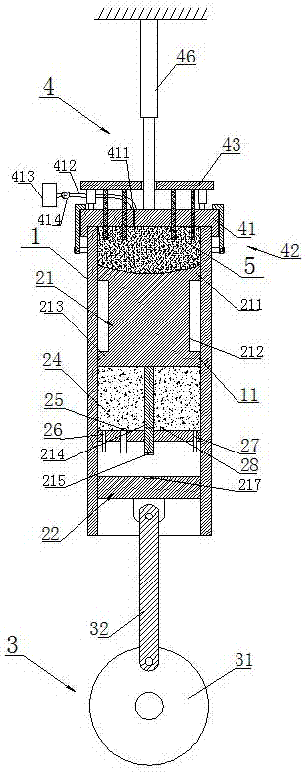

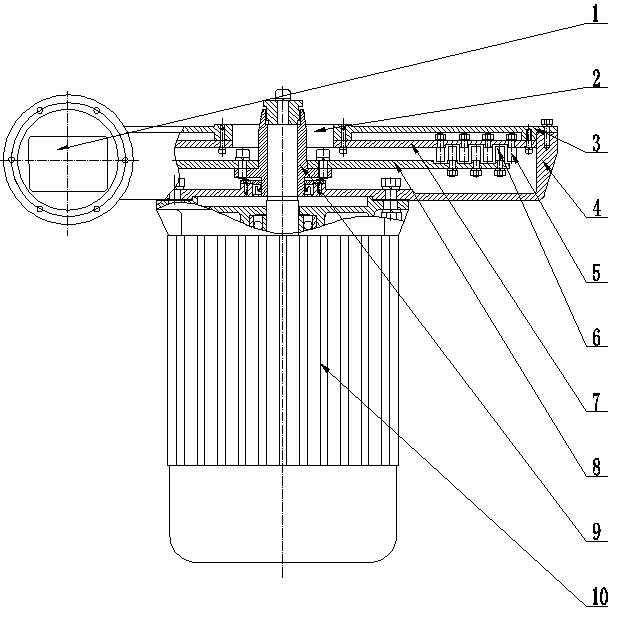

Low-temperature squeezer for tea oil

ActiveCN107216944AImprove crushing rateSqueeze fullyFatty-oils/fats productionFatty substance recoveryEngineeringExpansion chamber

The invention relates to a low-temperature squeezer for tea oil. The low-temperature squeezer comprises a barrel body, a piston assembly, an eccentric gear assembly and a slag discharging assembly, wherein the barrel body is vertically and fixedly arranged, the piston assembly is sleeved by the barrel body in a sealing and sliding mode, the eccentric gear assembly is arranged under the barrel body, and the slag discharging assembly is arranged above the barrel body; the piston assembly comprises an upper piston and a lower piston which are arranged in parallel and at interval; a sealing partition plate is fixed in the barrel body which is between the upper piston and the lower piston; an upper rod which is vertically fixed to the center of the lower end of the upper piston downwards slides in a sealing mode to penetrate through the sealing partition plate; a first magnet is arranged at the lower end of the upper rod; a second magnet attracting the first magnet is arranged at the upper end of the lower piston; the upper piston, the sealing partition plate and an inner wall of the barrel body enclose a combustion and expansion chamber; a fuel spray nozzle, an air inlet capable of being opened and closed, an air outlet capable of being opened and closed and an ignition device are arranged in the combustion and expansion chamber.

Owner:FUJIAN SHENGHUA AGRI SCI & TECH DEV

Efficient waste paper pulverizing device

InactiveCN109013019ASuppress dustEasy maintenance and operationSievingScreeningCartonWorking environment

The invention relates to the field of paper making and particularly provides an efficient waste paper pulverizing device. The pulverizing device comprises a horizontally arranged support frame, wherein a pulverizing box is arranged at the top of the support frame, a paper feeding box is arranged at the top of the pulverizing box, a partition board is horizontally arranged at the connecting part ofthe pulverizing box and the paper feeding box, a feeding opening is arranged in the top of the paper feeding box, and a conveyer belt for conveying waste paper is correspondingly arranged at the position of the feeding opening; and a material guide frame is arranged on the bottom partition board of the paper feeding box below the feeding opening, and a through hole is correspondingly arranged inthe partition board at the bottom outer side of the material guide frame. The structural design is reasonable, the waste paper can be rapidly swallowed after being filled, the pulverizing efficiency is high, and the part of the pulverized waste paper of which the size is unqualified can be effectively secondarily or repeatedly pulverized, so that high waste paper pulverizing rate is ensured. At the same time, fly dust in the pulverizing process of the waste paper can be effectively inhibited, a great working environment is ensured, the structure is reliable and durable, manual operation and maintenance are facilitated, the practicability is high, and actual use conditions are met.

Owner:李京泽

Crusher with functions of impact crushing and extrusion shearing crushing

InactiveCN103223365AReduce consumptionSimple structureCocoaGrain treatmentsElectric machineMaterial consumption

The invention discloses a crusher with functions of impact crushing and extrusion shearing crushing. The crusher comprises a motor, a housing, a rotor assembly and a stator assembly, wherein the rotor assembly comprises a rotor disc and a rotor pin, the stator assembly comprises a stator disc and a stator pin, the rotor pin and the stator pin comprise quadrangular prism-shaped steel billets, the front portions of tangential direction work surfaces of the rotor pin and the stator pin are standard zigzag surfaces, the end of the tangential direction work surface is provided with a first special-shaped zigzag, a width of the top portion of the first special-shaped zigzag is at least two times the width of the tooth bottom of an ordinary zigzag on the front portion of the tangential direction work surface, and an included angle formed by the tangential direction work surface of the stator pin / the rotor pin and a tangent surface of the prism surface A passing through the axis line of the stator pin / the rotor pin is more than or equal to 5 DEG and is less than or equal to 20 DEG. The crusher has characteristics of simple structure, high crushing rate, high crushing efficiency, low cost, small size, wide application range, simple operation, good sealing, less wearing parts, low auxiliary material consumption, high efficiency, and energy saving.

Owner:王洪福

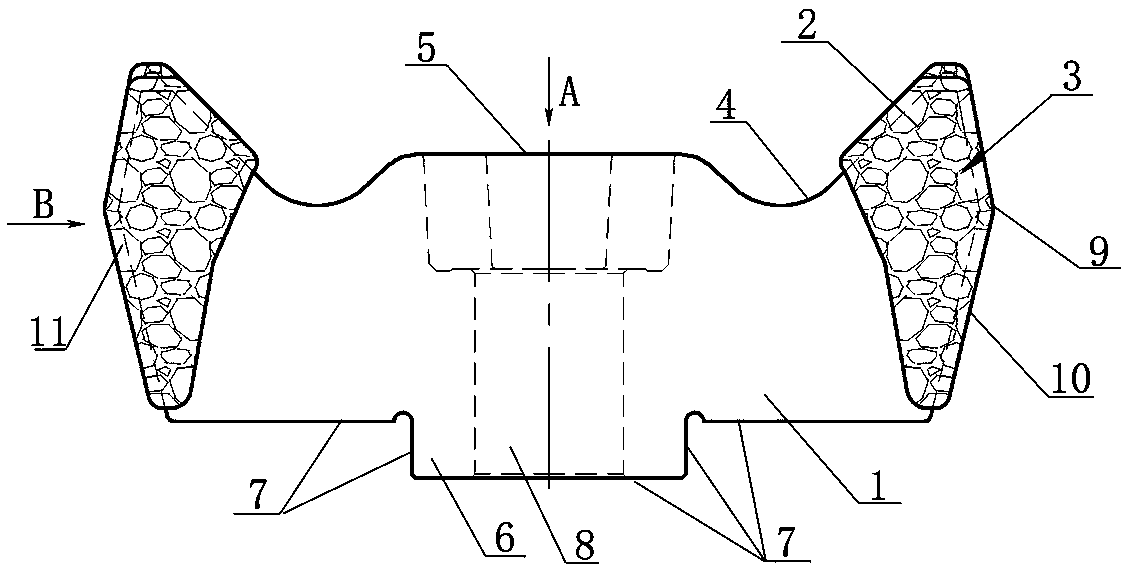

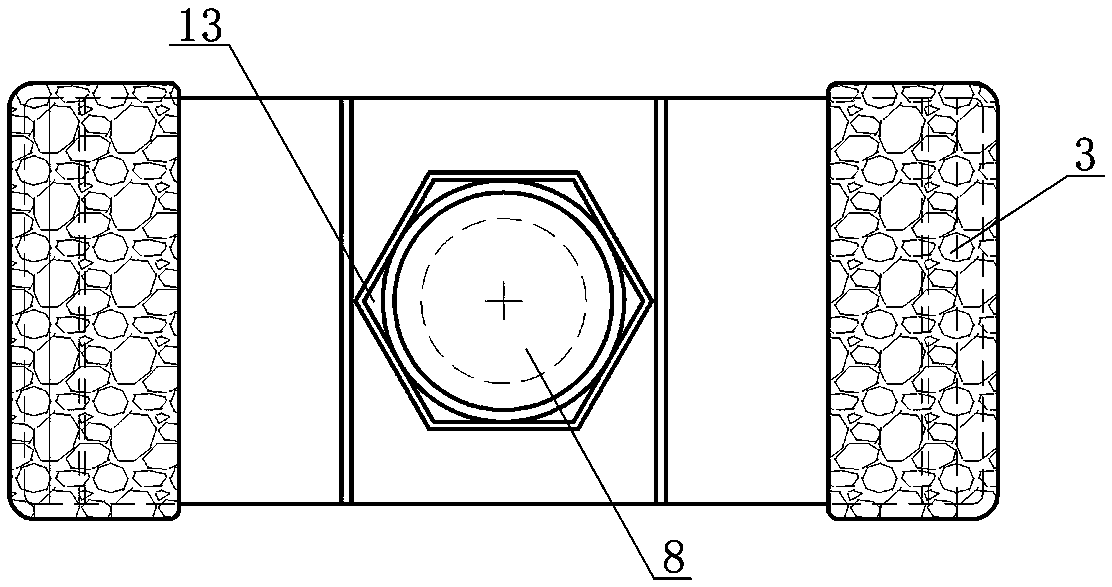

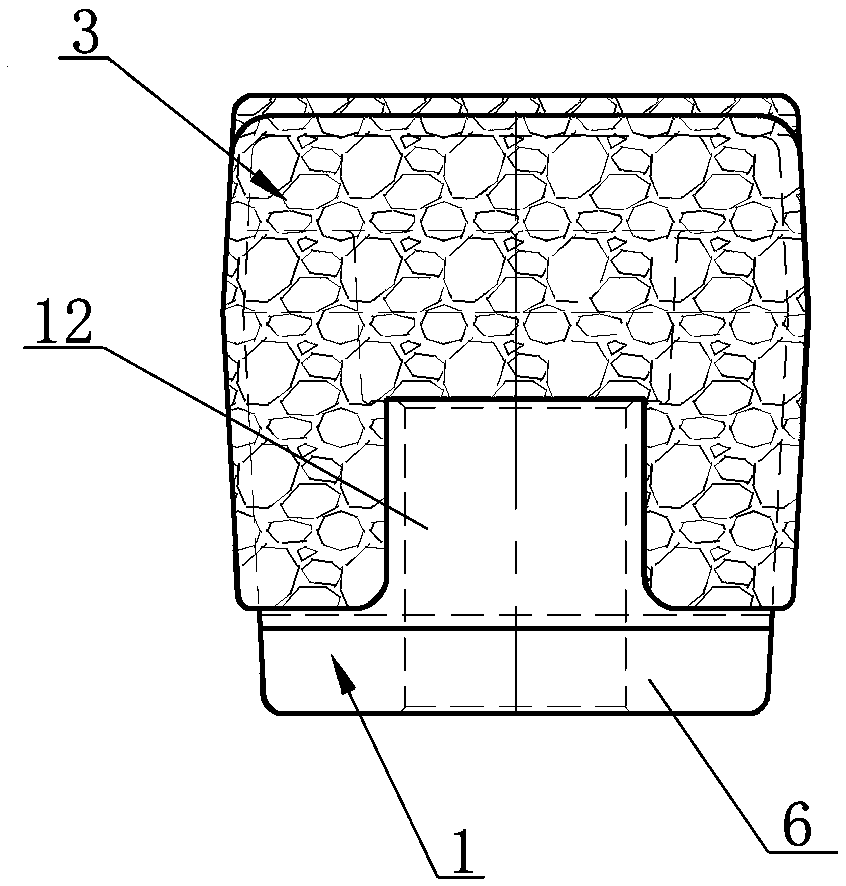

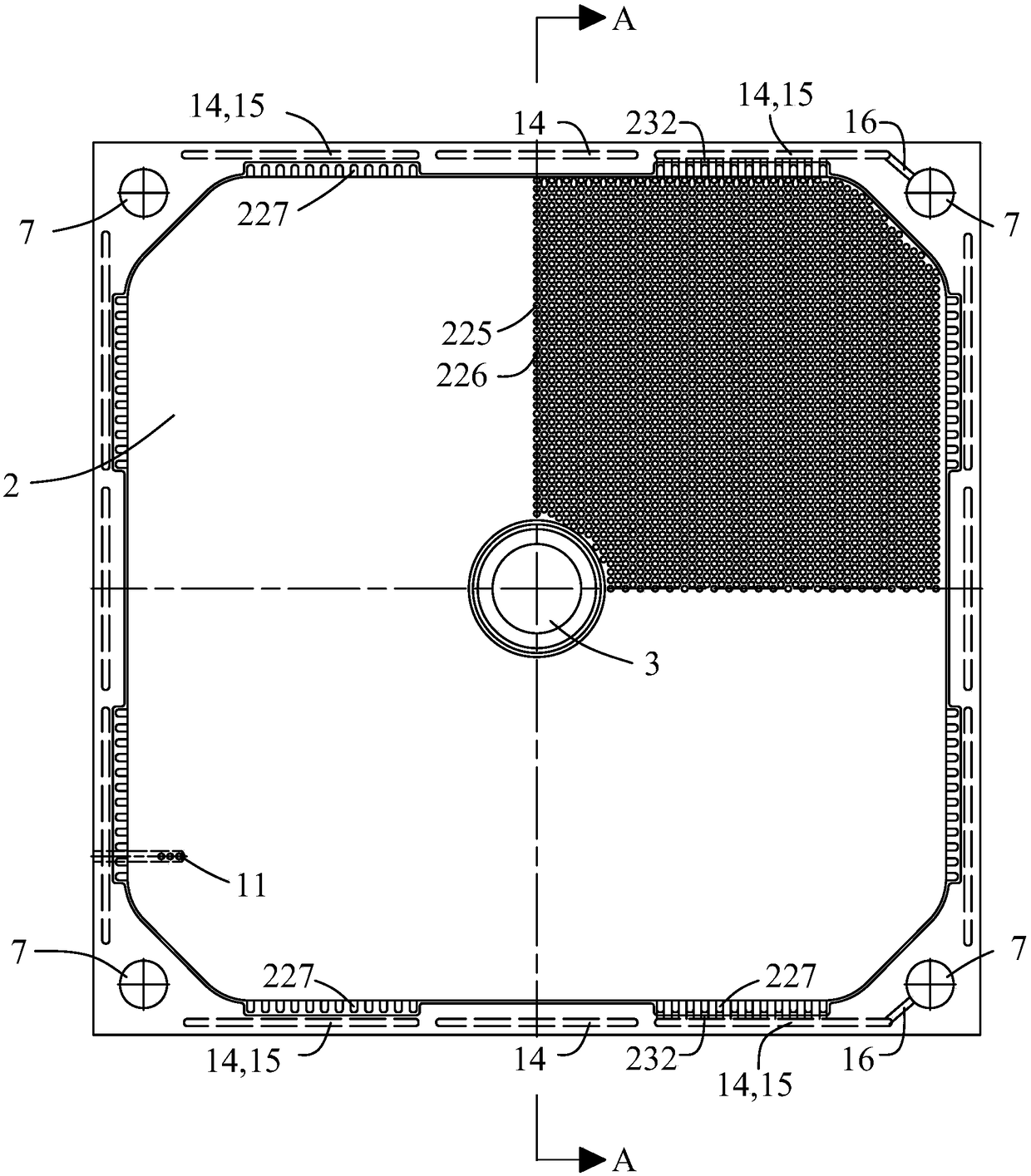

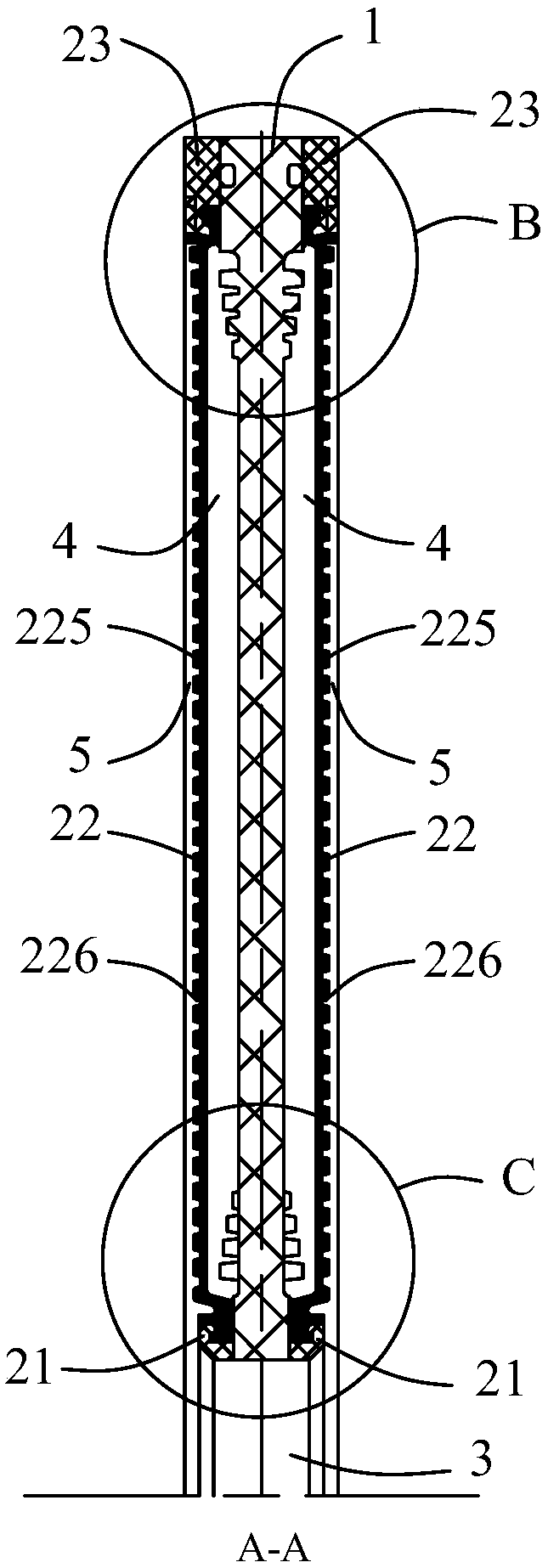

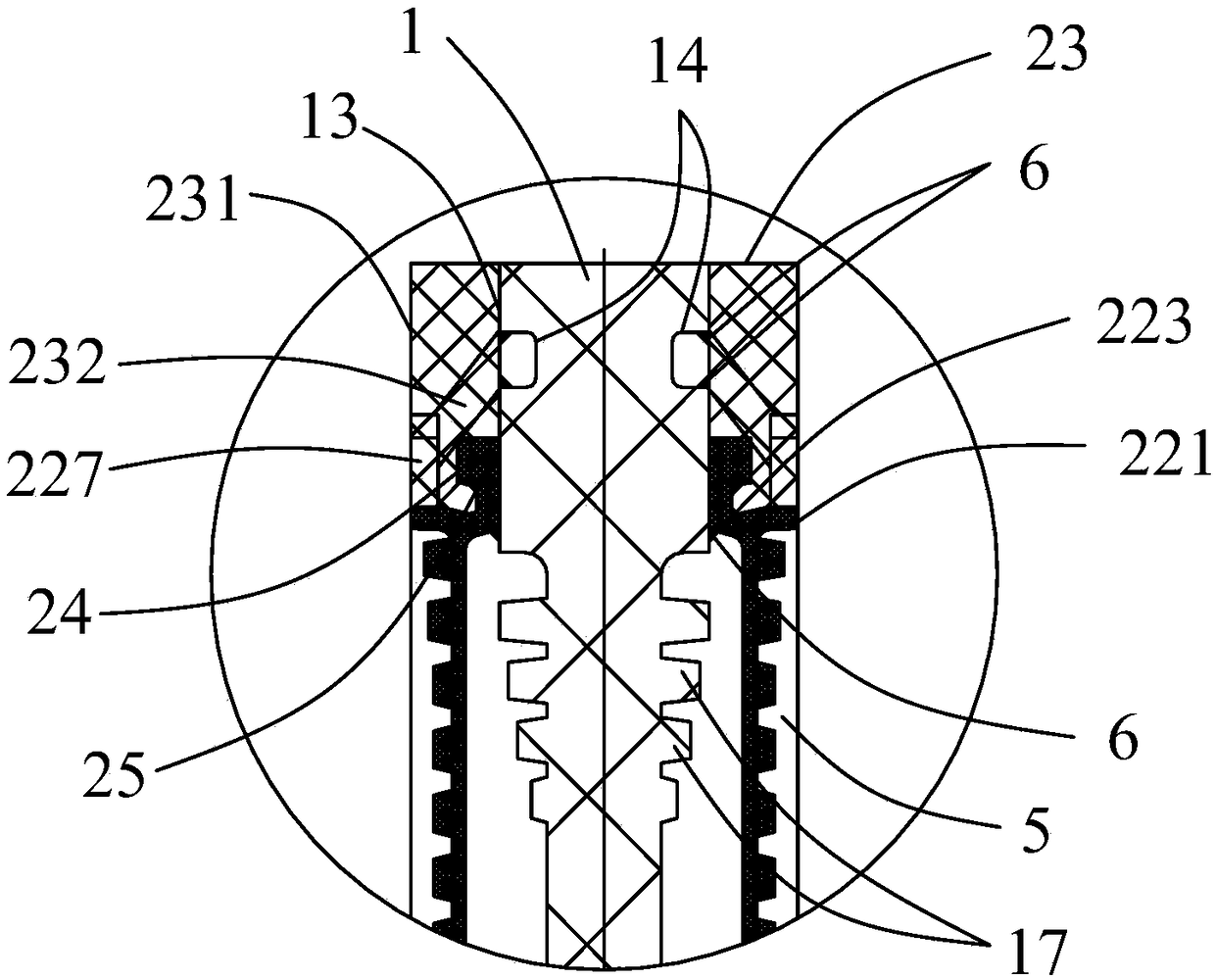

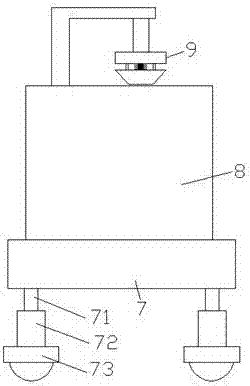

High-elastic diaphragm filter plate and preparation method thereof

PendingCN109126231AStrong resistance to compression deformationImprove deformation abilityFiltration separationEngineeringDiaphragm seal

The invention provides a high-elastic diaphragm filter plate and a preparation method thereof. The diaphragm filter plate comprises a core plate, a diaphragm, a feed hole, a sealed squeezing medium cavity, and a squeezing medium hole formed in the core plate and communicated with the squeezing medium cavity. The diaphragm comprises a hard ring made of hard plastic, a diaphragm main part made of high elastic materials, and a diaphragm frame part made of hard plastic. The squeezing medium cavity is located between the diaphragm main part and the core plate, the outer surface, in the backward direction of the core plate, of the diaphragm frame part is a diaphragm sealing surface, and a filter chamber is formed in the side of the outer surface of the diaphragm main part. The compressive deformation resistance of the hard plastic is high and thus can ensure the sealing performance of the sealing surface of the diaphragm, and the service life of a diaphragm filter plate is greatly prolonged;while the high elastic material has strong deformation ability, the diaphragm main part thus has a larger pressing stroke, the high squeezing rate of the diaphragm filter plate is thus ensured, a filter cake with low water content can be obtained, and ultimately energy consumption for dewatering is greatly reduced.

Owner:ZHEJIANG FUJIE ENVIRONMENTAL PROTECTION EQUIP CO LTD

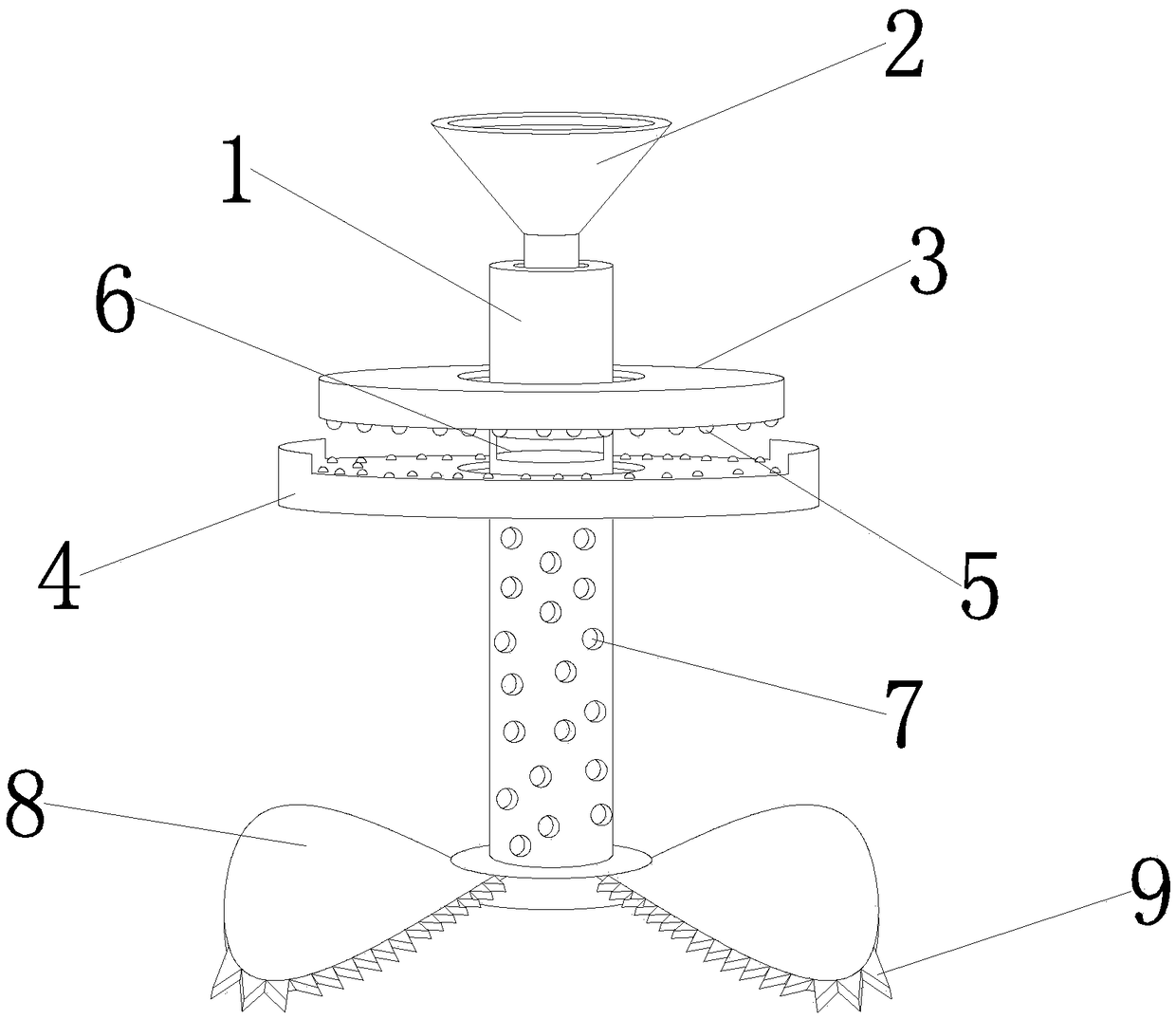

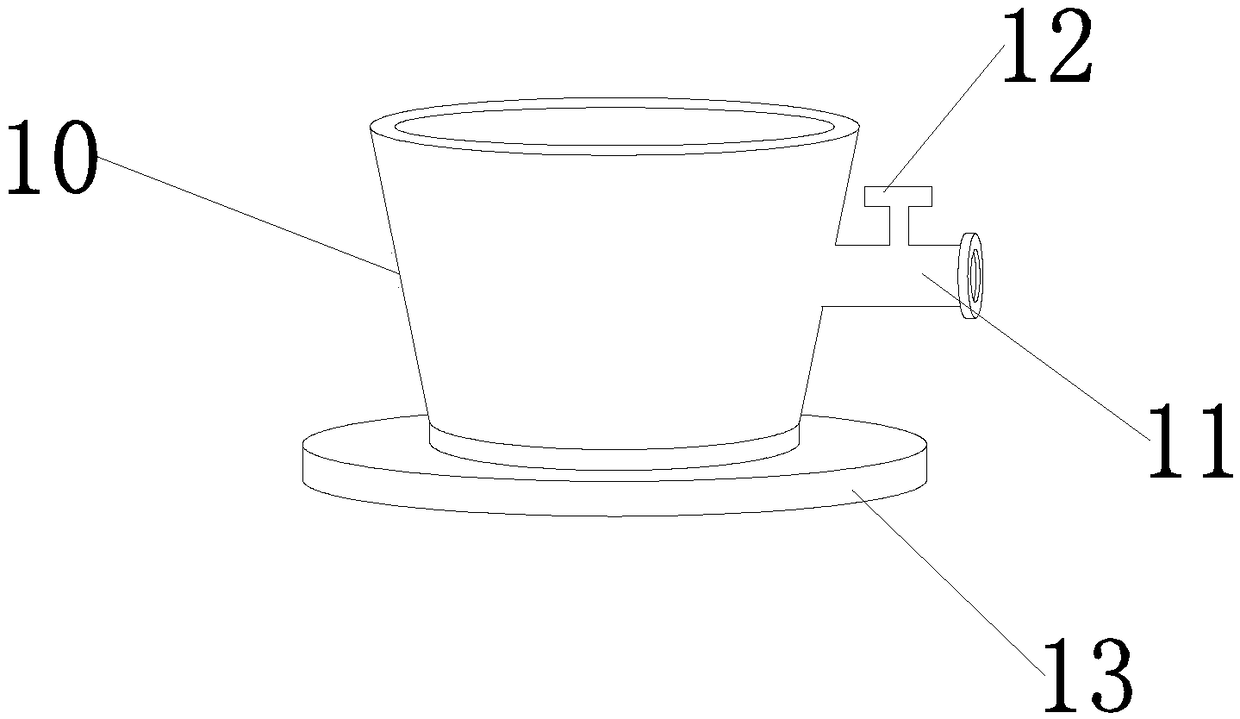

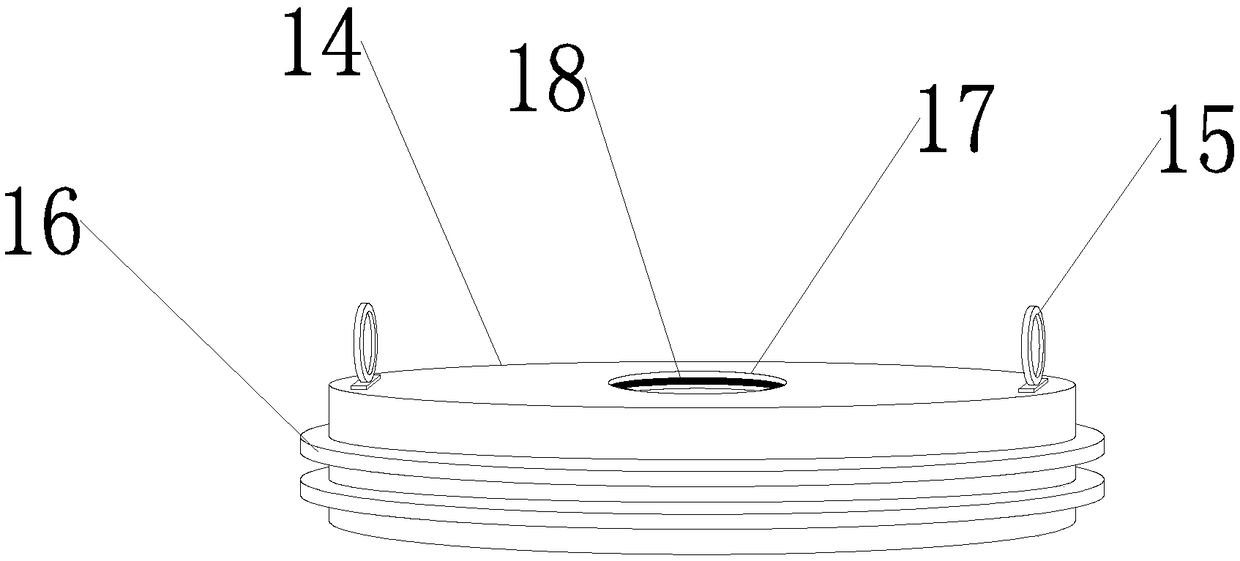

Sewage treating device

ActiveCN107324440AImprove crushing rateAutomatically controlled pulverizationWater/sewage treatment by sorptionSewageEngineering

The invention discloses a sewage treating device. The sewage treating device comprises a base body and an alums putting machine installed at the top of the base body; a putting-in cavity is formed in the top face of the alums putting machine, a funnel groove is formed in the putting-in cavity and is communicated with the bottom of the putting-in cavity, a bevel edge groove is formed in the top of the inner wall at the right side of the putting-in cavity, a smashing chamber is formed and communicated with the bottom of the funnel groove, an adaptor smashing device is arranged in the smashing chamber, a connecting opening is formed and communicated with the smashing chamber, an alums putting cavity extending rightwards is formed in the mode of being communicated with the connecting opening, an alums putting device is arranged in the alums putting cavity, a second slip groove extending horizontally penetrates through the connecting opening, a first guiding and connecting groove extending downwards is formed in the extending tail of the left side of the second slip groove in a communicated mode, a first slip groove extending upwards is formed in the tail of the left side of the first guiding and connecting groove in a communicated mode, and a slip partition plate extending horizontally is connected in the second slip groove in a slip mode. The sewage treating device is simple in structure and convenient to operate, and improves alums smashing uniformity.

Owner:广东华正建设工程有限公司

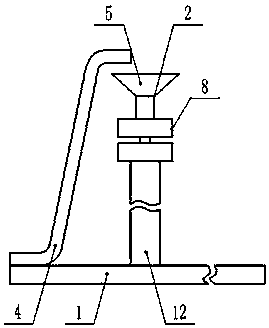

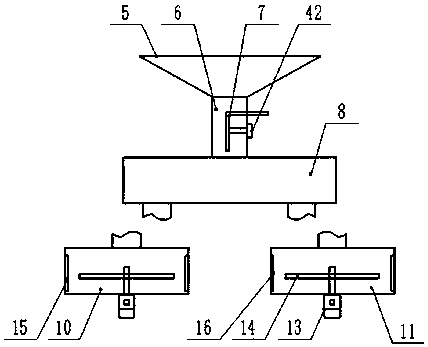

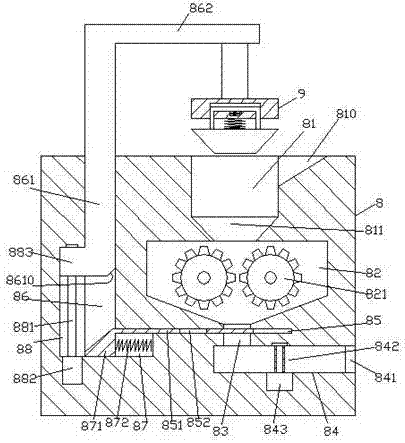

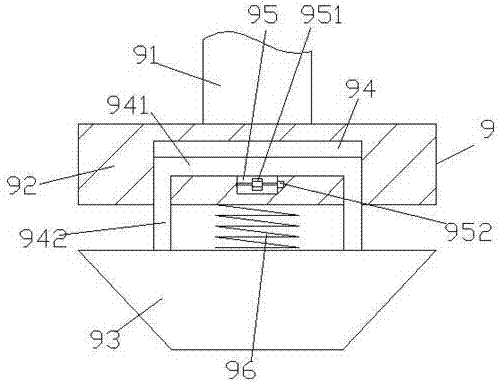

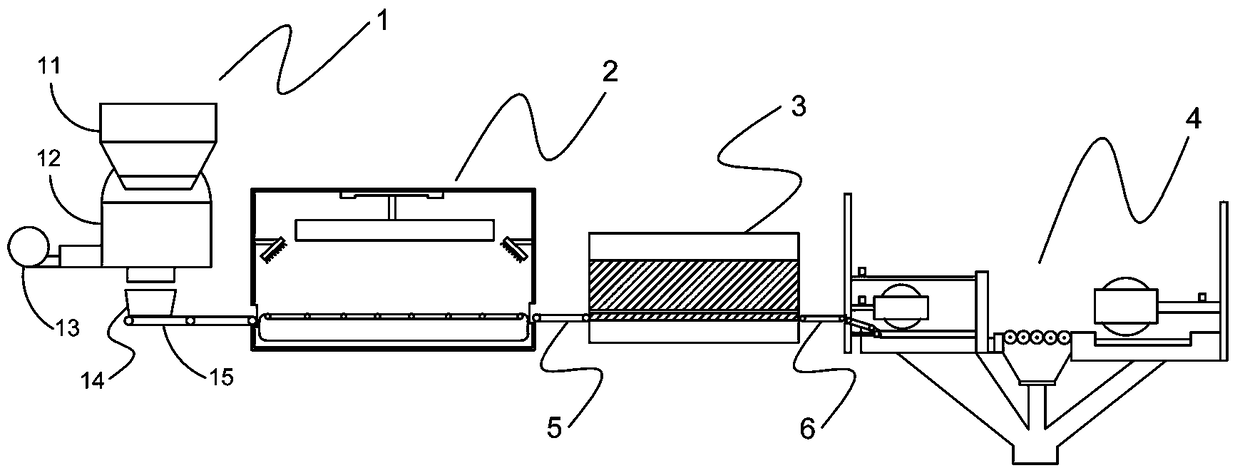

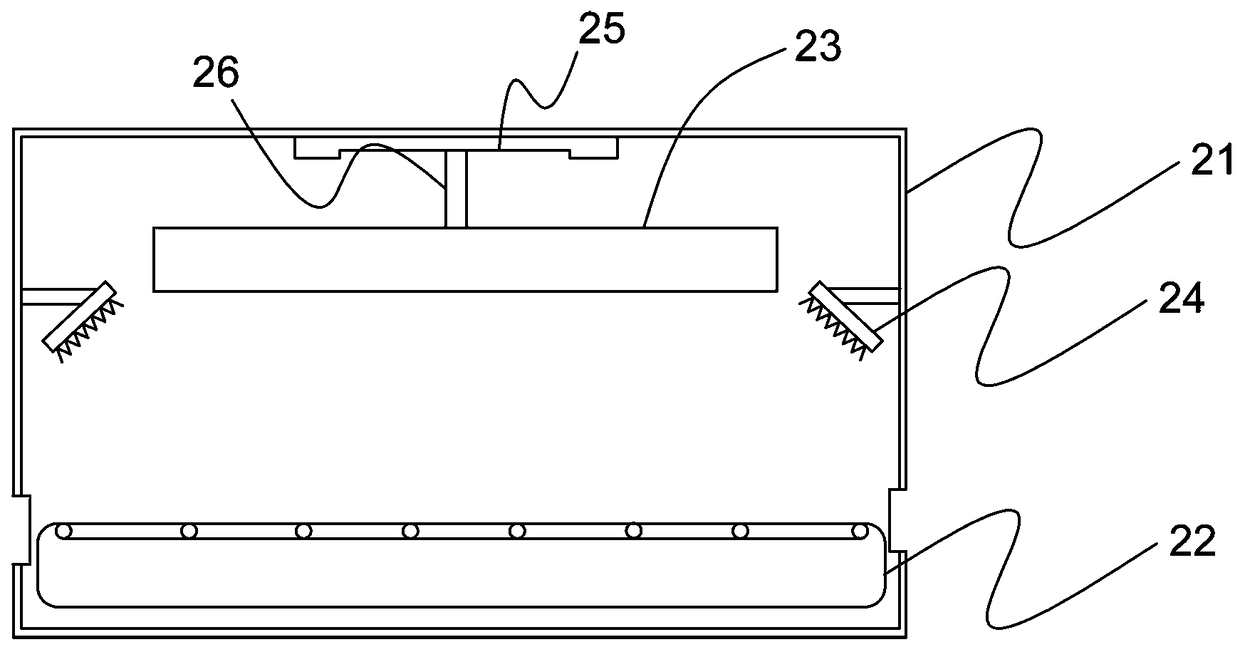

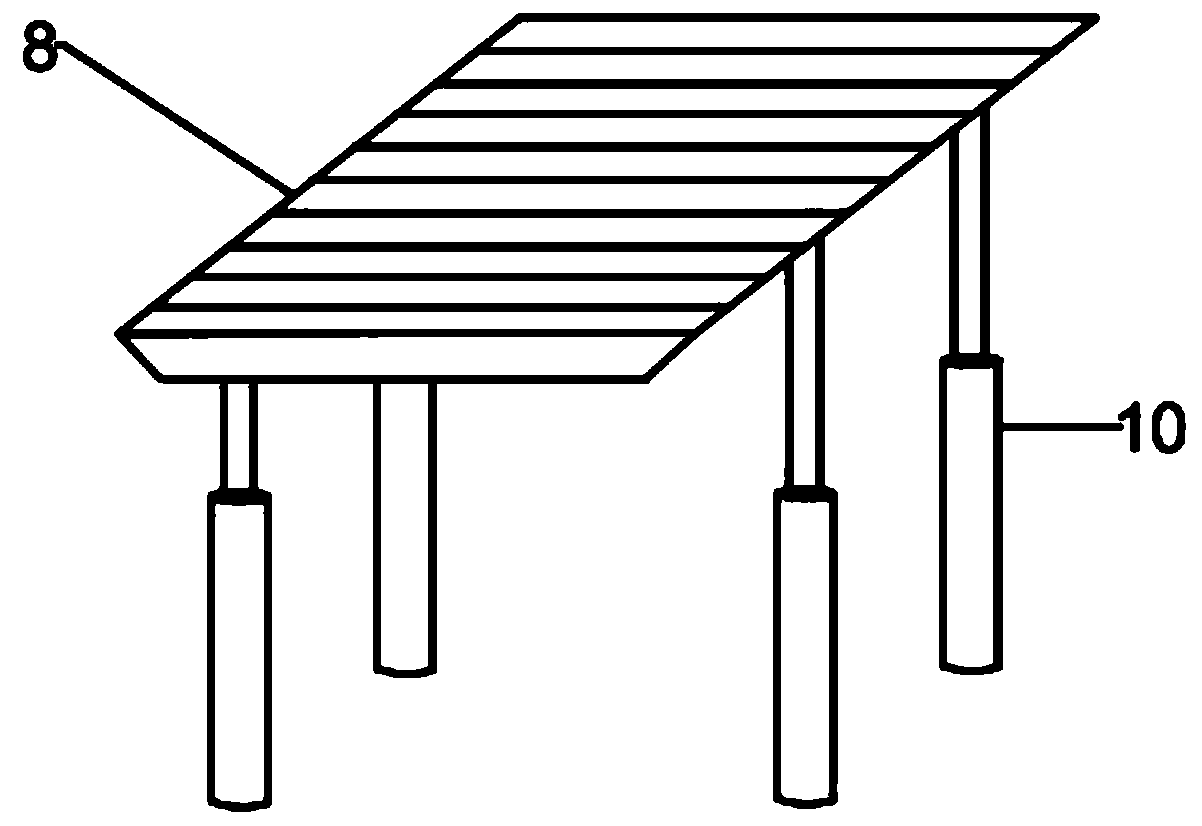

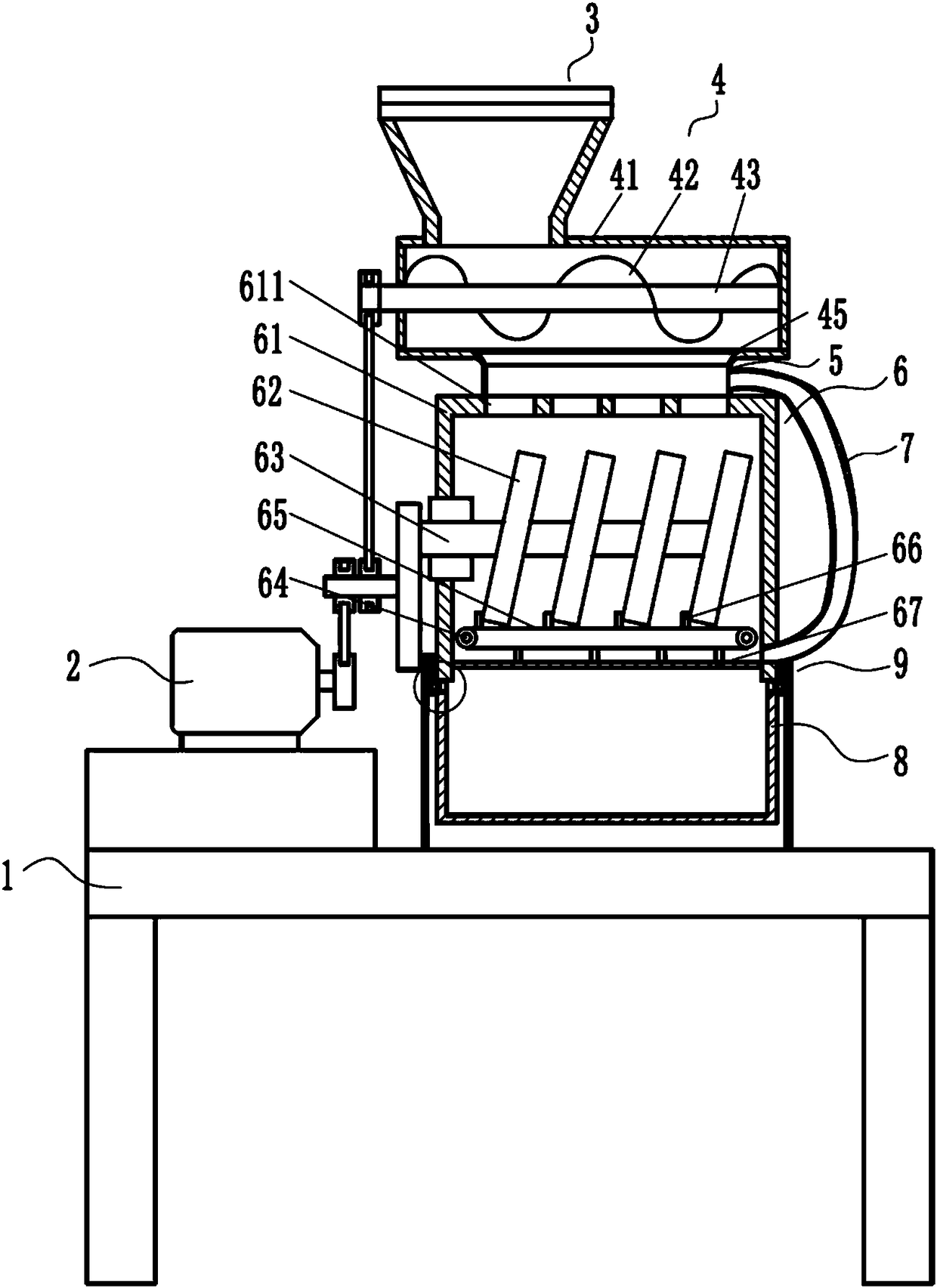

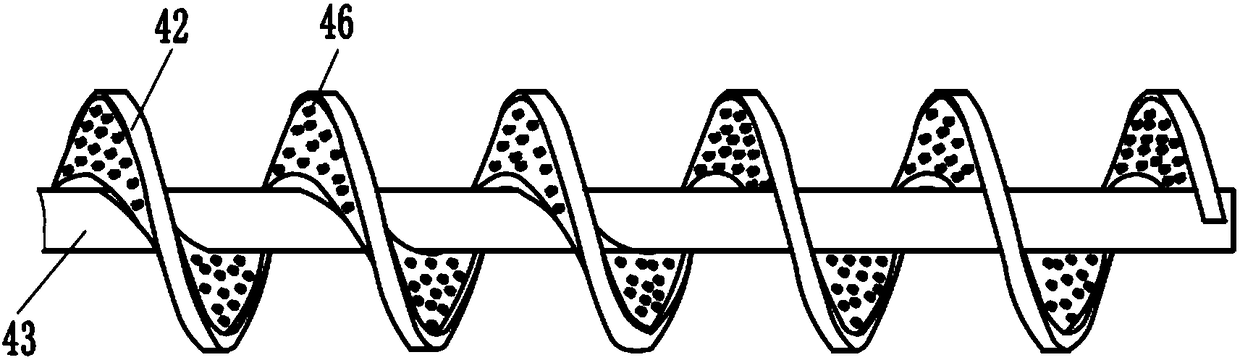

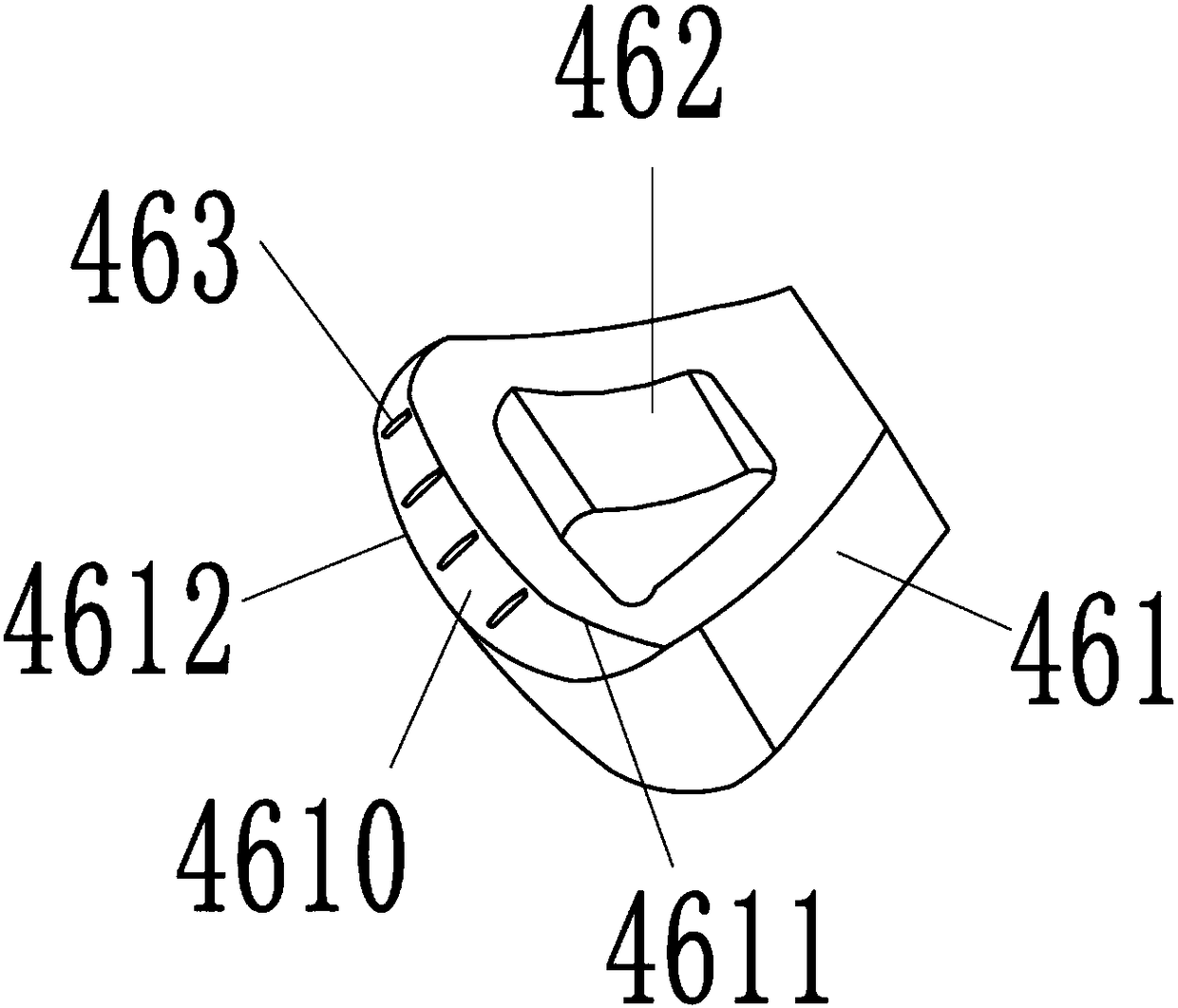

Step-by-step pressing production line equipment for camellia oil

PendingCN109468165AImprove cleanlinessImprove crushing rateFatty-oils/fats productionEngineeringFood processing

The invention belongs to the technical field of food processing, and discloses step-by-step pressing production line equipment for camellia oil. The equipment comprises a screening device, a cleaningdevice, a heating device and a step-by-step pressing device, wherein an outlet of the screening device communicates with an inlet of the cleaning device; an outlet of the cleaning device communicateswith the heating device through a first conveying device; and an outlet of the heating device communicates with the step-by-step pressing device through a second conveying device. Through additional arrangement of the cleaning device and the heating device, the cleanness of camellia seeds are guaranteed and the pressing rate of the camellia seeds is improved; the step-by-step pressing device in the production line is fully automated, and secondary pressing on the camellia seeds is performed, so that the pressing rate of the camellia seeds is further improved, and both time and labor are savedwhile the loss is reduced.

Owner:福清老农民农产品贸易有限公司

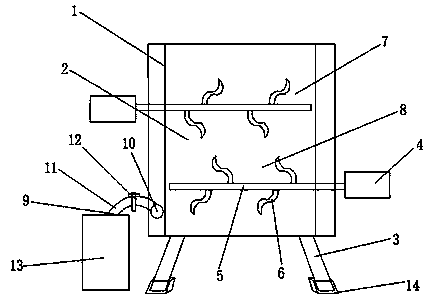

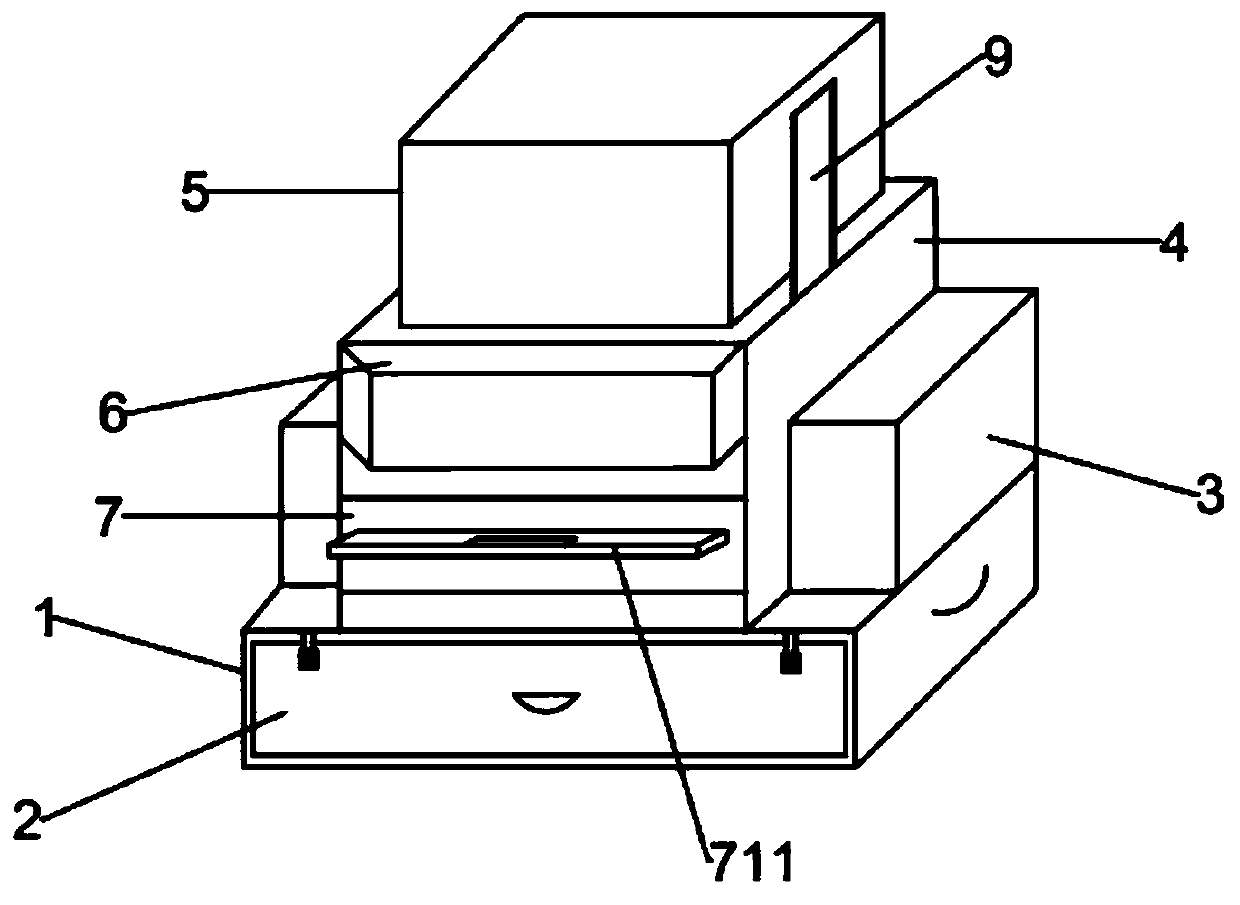

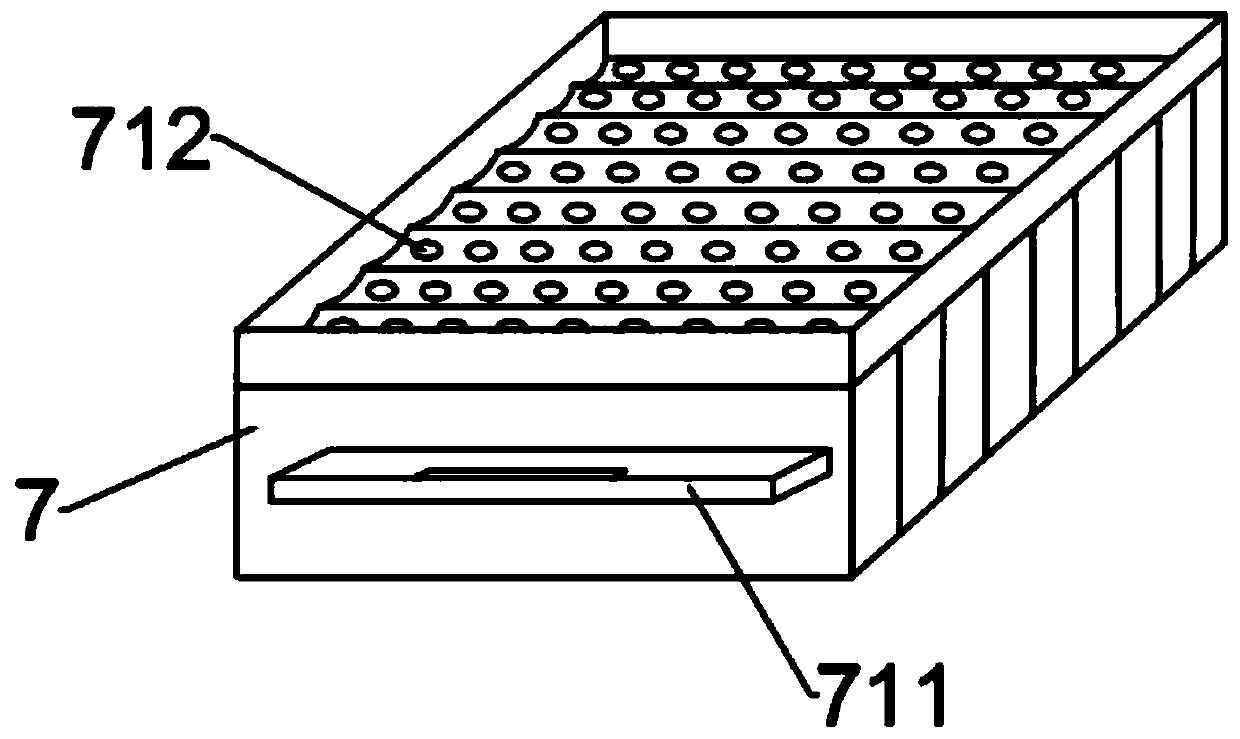

Squeezing device suitable for sugarcane wild germplasm and hybrid offspring thereof

The invention relates to the technical field of squeezing devices, and particularly relates to a squeezing device suitable for sugarcane wild germplasm and hybrid offspring thereof. The squeezing device includes a body; the body comprises a work box, a hollow box, a collecting box and electromechanical boxes. An opening is formed in the top of the work box, the bottom of the hollow box is in buttjoint with the opening of the work box in an adaptive mode, an operation device is arranged in the work box, the collecting box is arranged at the bottom in the work box in a drawer mode, and the electromechanical boxes are arranged on the two outer sides of the work box respectively. The operation device comprises a supporting body, a pressing plate and a hydraulic push rod. A plurality of transversely-arranged supporting blocks are arranged in the supporting body. The upper end of the hydraulic push rod is connected to the edge bottom side of the pressing plate, and the lower end of the hydraulic push rod is connected to the outer side of the supporting body. The problem that a large amount of wild sugarcane juice cannot be extracted at a time is solved, a juice extracting device can rapidly squeeze the wild sugarcane juice, and the wild sugarcane juice is convenient to collect.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

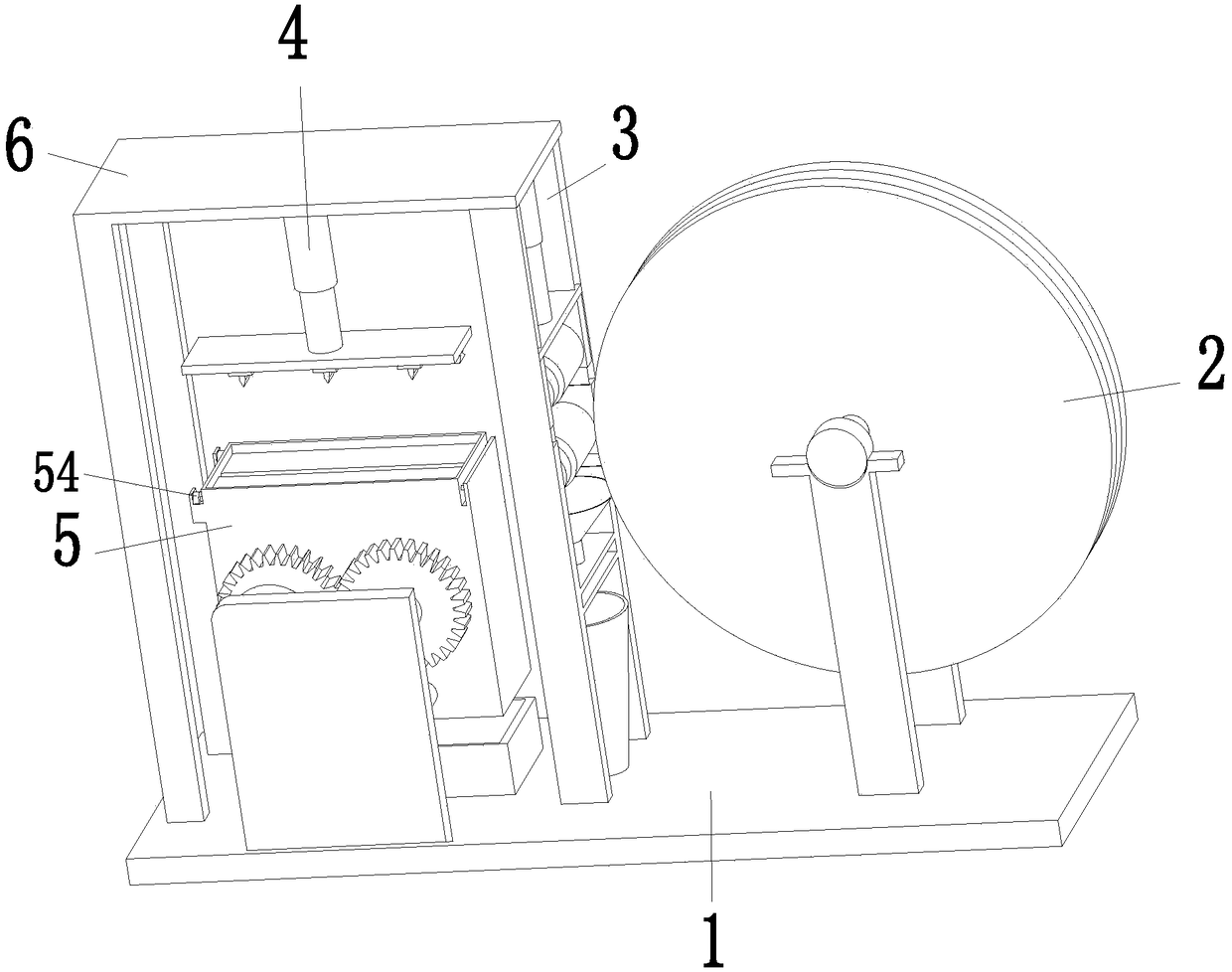

Grinding machine for thin film production ingredients

PendingCN108722627AImprove crushing rateEasy to clean and maintainCocoaGrain treatmentsPistonAdditive ingredient

The invention relates to the technical field of thin films, in particular to a grinding machine for thin film production ingredients. The grinding machine comprises a vertical column, a stirring barrel and a piston. The stirring barrel is arranged at the bottom end of the vertical column and movably connected with the vertical column, and the piston is arranged at the upper end of the stirring barrel and rotatably connected with the stirring barrel; the left side and the right side of the lower end of the vertical column are rotatably connected with two stirring blades, and three or more sharpteeth are closely welded to the front end of each stirring blade; and the front end of the vertical column is movably connected with a movable disc. According to the grinding machine for the thin film production ingredients, a user puts raw materials into the vertical column from the hopper arranged at the upper end of the vertical column, and the raw materials fall onto the upper end of a fixeddisc along with a through groove formed in the front end of the vertical column; then, grinding is conducted through grinding particles arranged on the fixed disc and the movable disc correspondingly,and meanwhile, the movable disc also rotates leftwards and rightwards, so that the grinding effect is achieved; and the ground raw materials flow into the stirring barrel through through holes and then are stirred through the two stirring blades rotatably connected to the bottom end of the vertical column.

Owner:嘉兴市博荣新材料有限公司

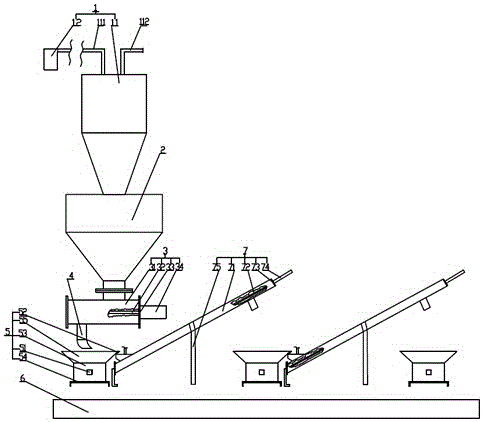

Biomass fuel raw material processing production line and biomass fuel production method

ActiveCN109022088AEasy to operate manuallyGood removal effectBiofuelsSolid fuelsProduction linePulp and paper industry

The invention relates to a biomass fuel raw material processing production line and a biomass fuel production method. The production line comprises a bottom plate, a bending device, a juicing device,a cutting device, a crushing device and a support frame, the bending device is mounted on the upper end surface of the right side of the bottom plate, the juicing device is mounted on the upper end surface of the middle part of the bottom plate, the juicing device is located at the lower side of the right end of the support frame, the cutting device is mounted on the lower end surface of the middle part of the support frame, the crushing device is located just below the cutting device, and the crushing device is mounted on the upper end surface of the left side of the bottom plate. The production line and the production method can realize the integration of bending, sugarcane juicing, sugarcane crushing and direct processing of sugarcane into a biomass fuel, and has the advantages of simplicity in manual operation, thorough pressing of water in sugarcane, secondary pressing of the mechanically bent sugarcane, and thoroughness in crushing of the raw material.

Owner:泰州港润投资发展有限公司

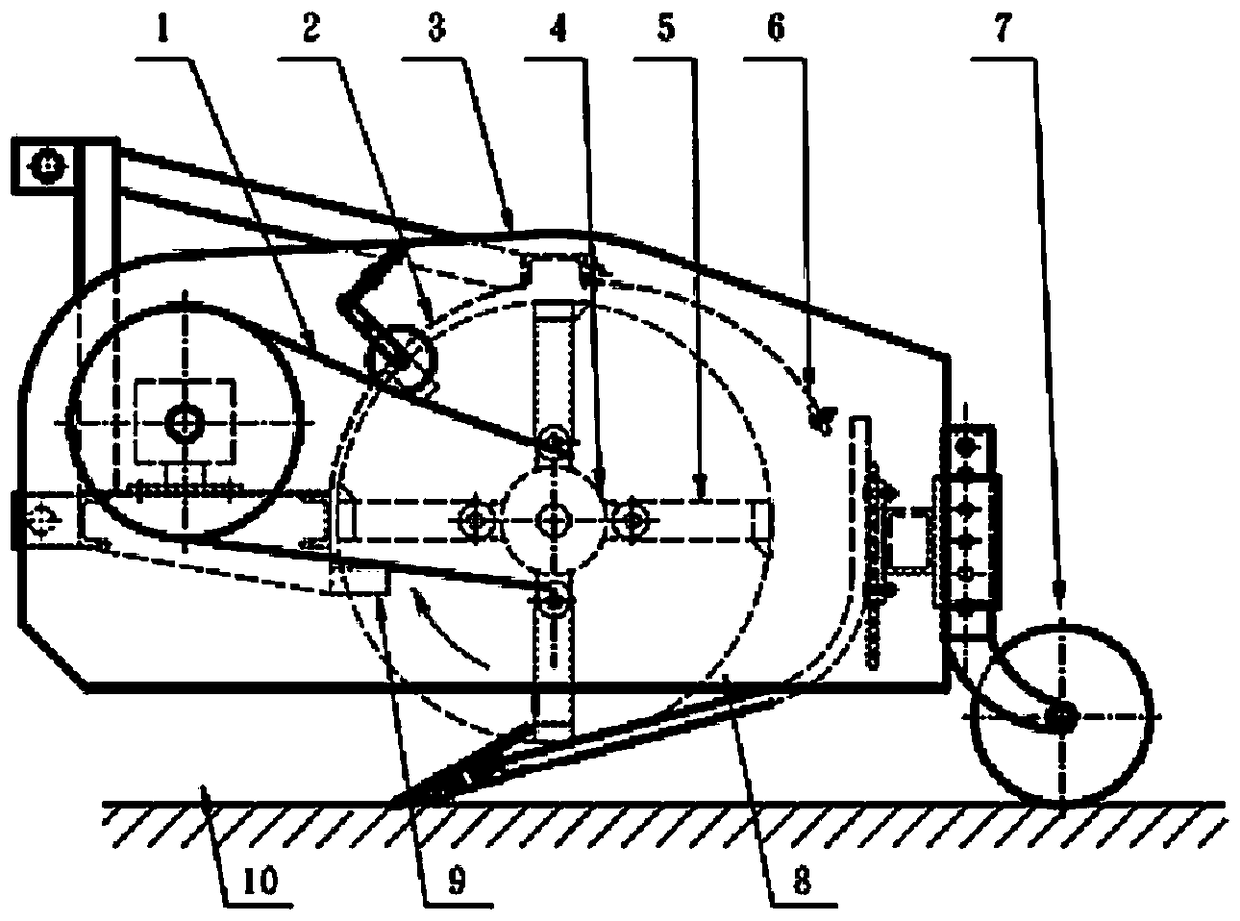

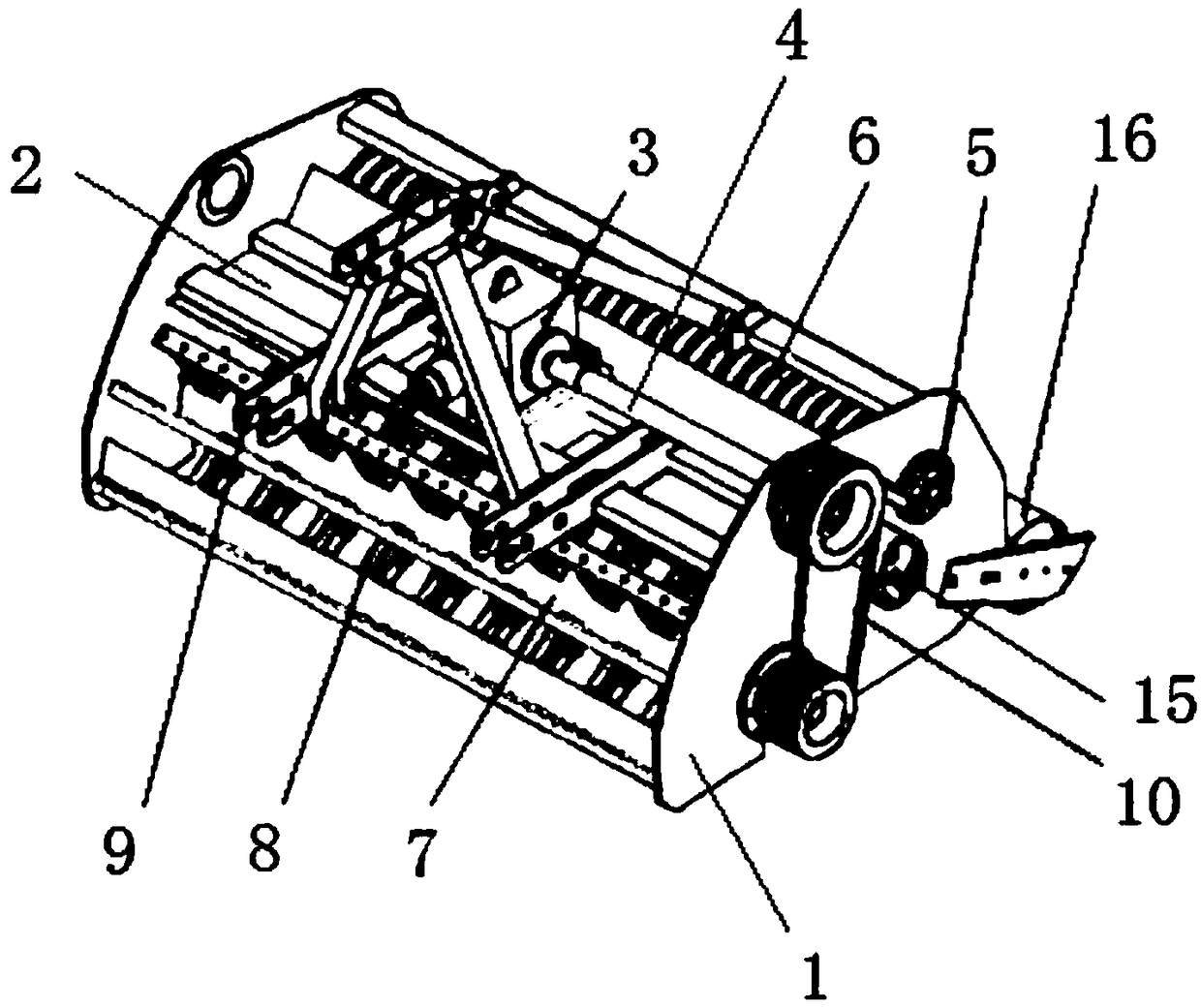

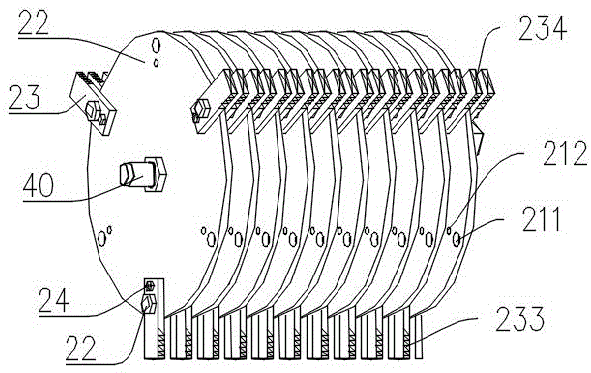

Straw pulverizer

InactiveCN108521986AImprove crushing rateGood stubble removal rateMowersPulverizerAgricultural engineering

The invention discloses a straw pulverizer, and belongs to the technical field of agricultural machinery. The technical scheme of the invention is that the straw pulverizer comprises a frame, an engine, a gearbox, a main shaft, a saw disc cutter shaft, saw blades, a swinging cutter shaft, swinging cutters and a suspension device. The straw pulverizer has the beneficial effects that the crushing rate is high, and the scattering unevenness and the stubble cleaning rate are good.

Owner:赵文兵

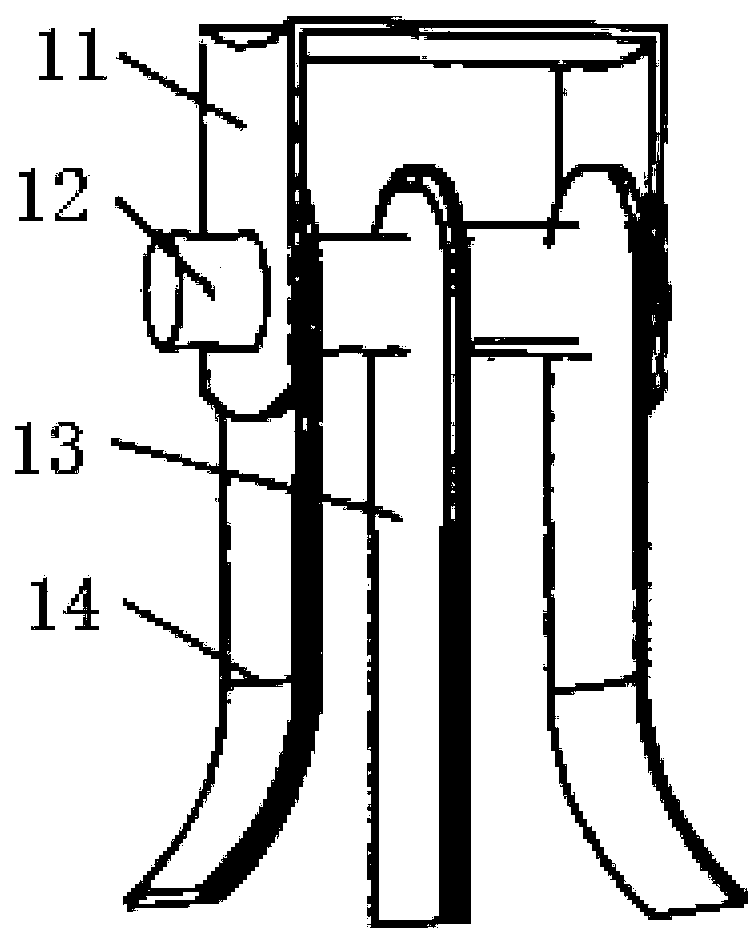

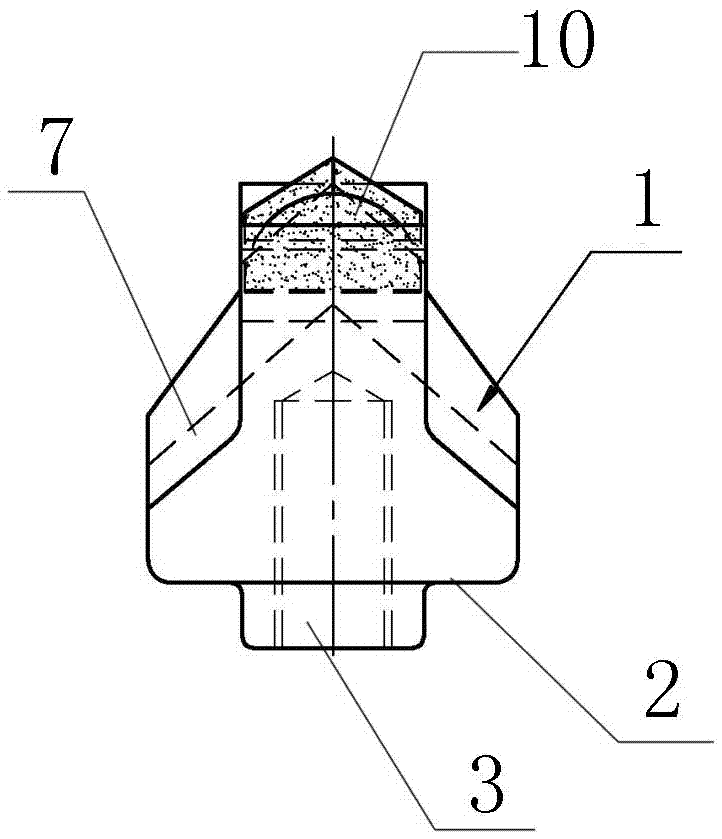

Mechanical bit for crusher and waste disposal

InactiveCN107552160AImprove wear resistanceExtended service lifeGrain treatmentsCemented carbideCrusher

A mechanical tooth head for shredders and waste disposal, which includes a block body. The front of the block body is a working slope, and the sharp corners of the working slope are embedded and welded firmly so that they are arranged left and right. There are two large hard alloy blocks with sharp corners, and an indented triangular gap is formed between the two large hard alloy blocks; the back of the block body is a concave-convex assembly surface, in which The upper part is provided with a protruding column extending backward, and the lower part of the protruding column is provided with an inward recessed groove. A threaded hole at the bottom; the upper surface and the lower surface of the block body are parallel surface planes, and the left and right sides are also parallel side planes; it has a simple structure, easy to use and install, and can greatly improve the gear The wear resistance and service life of the head can reduce the cost of use, improve work efficiency, and improve the crushing rate of materials.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

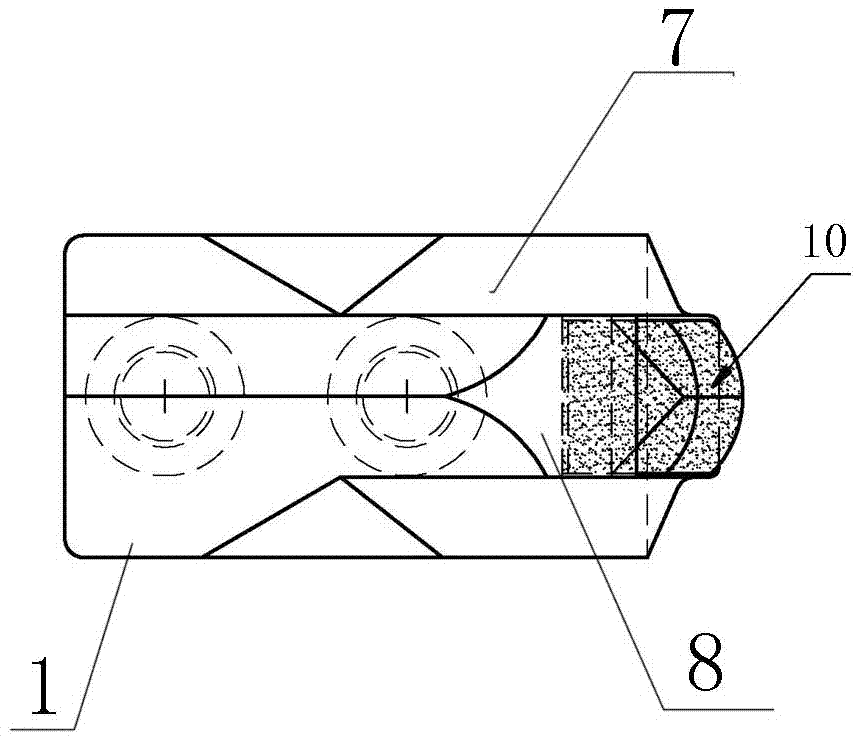

Mechanical tooth of waste disposal smashing machine

A mechanical tooth of a pulverizer for waste treatment, which includes a cuboid block body, the bottom plane of the block body is an assembly surface, and an impermeable threaded hole is vertically opened in the middle of the assembly surface, and the threaded hole Another same non-transparent threaded hole is vertically opened on the assembly surface between the side of the tail end; the middle of the upper end surface of the block body forms an outwardly inclined slope toward the tail end, and the middle and the front side The upper end surface of the center is respectively provided with oblique slots on both sides to form a convex-shaped working narrow block on the middle side, and at least one piece is embedded and welded firmly on the outer upper corner of the convex-shaped narrow working block. Carbide block with pointed head; it has the characteristics of simple structure, convenient use and installation, improved work efficiency, improved material crushing rate and service life, and enhanced wear resistance.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

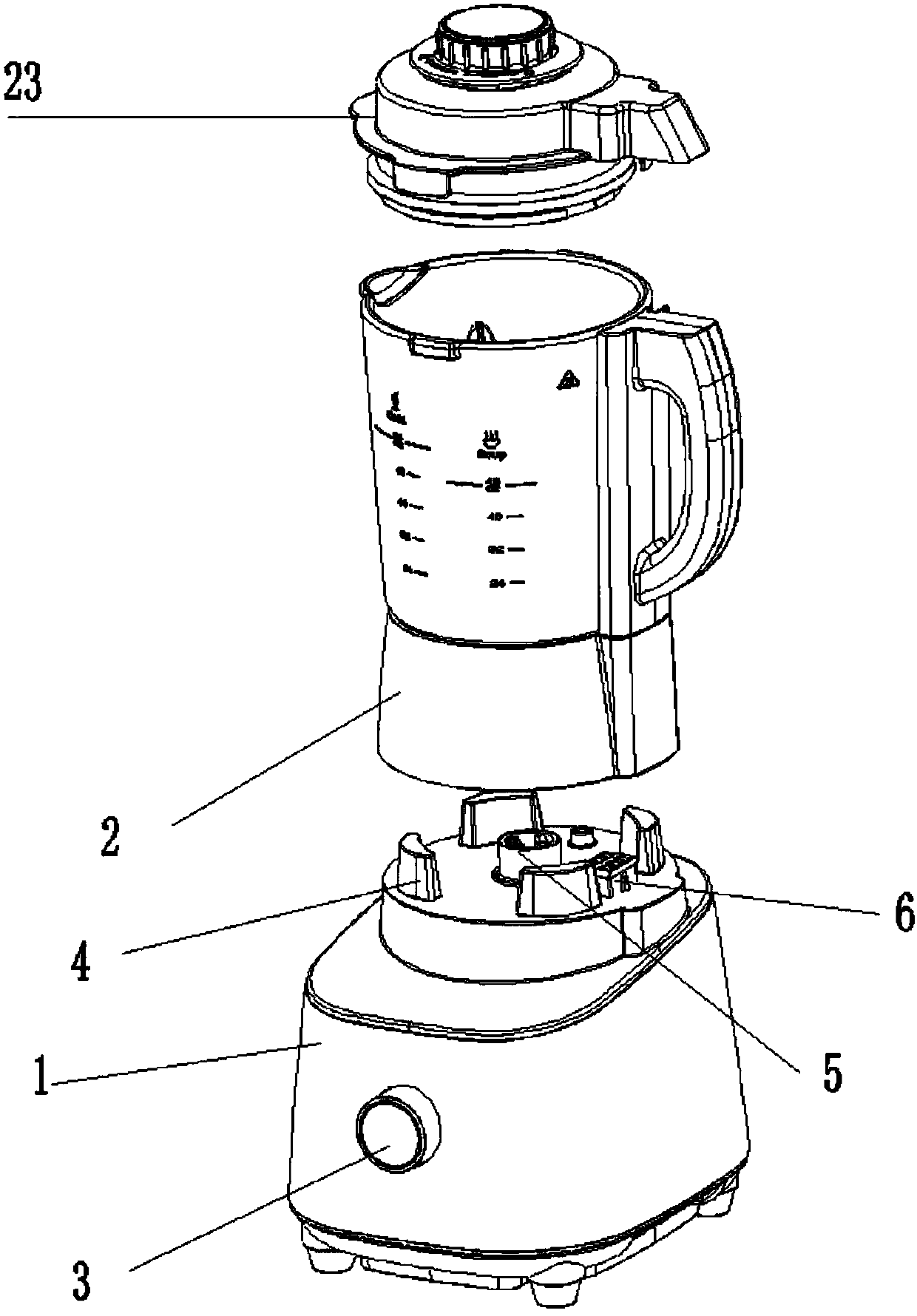

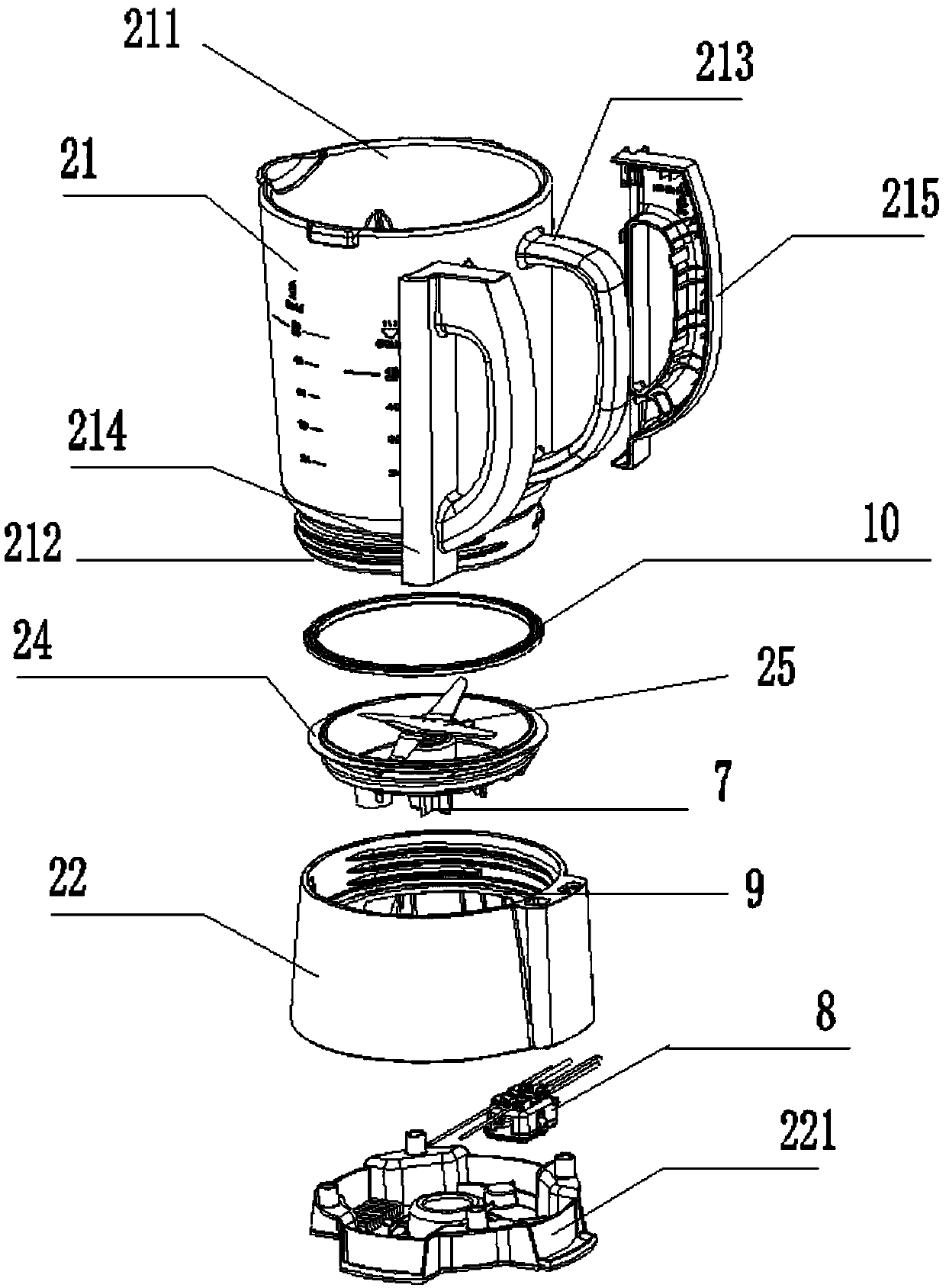

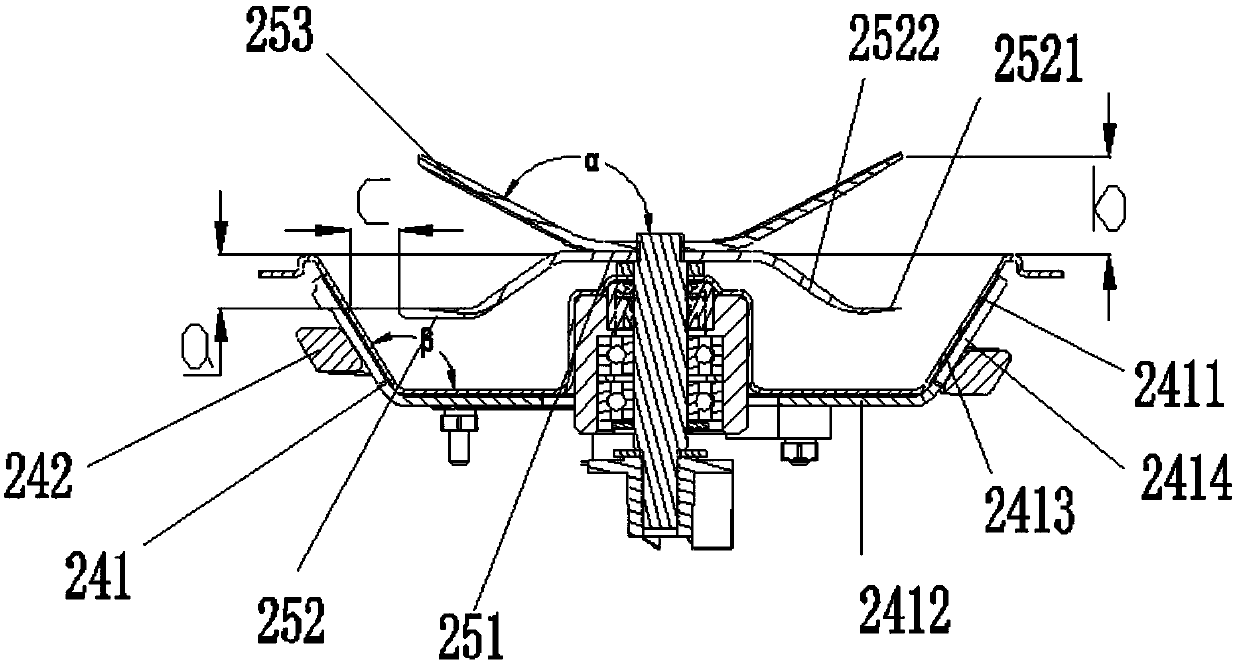

Food processor with high smashing efficiency

The invention discloses a food processor with high smashing efficiency. The food processor comprises a motor base with a motor and a stirring cup arranged on the motor base, the stirring cup comprisesa glass cup, a cup base, a cup lid, a heating disc and a smashing blade, and the glass cup is arranged on the cup base, wherein the heating disc comprises a heating disc body and a heating tube, theheating disc body is in a bowl shape, and comprises a side wall and a bottom wall, the side wall is in an inverted cone shape, the heating tube is arranged on the outer side of the side wall, the peripheral side of the smashing blade forms a dynamic smashing space, the smashing blade comprises a first wing root and first blade wings, the outermost ends of the first blade wings are located in the heating disc body, and the first blade wings rotate at high speed to drive materials to impact the side wall and are heated through the side wall to rebound upwards and inwards to enter the dynamic smashing space again to participate in smashing. Through the technical scheme, the smashing efficiency of the food processor is high.

Owner:JOYOUNG CO LTD

Shell pulverizer

The invention discloses a shell pulverizer. The shell pulverizer comprises a box, a hammer plate component, a sieve plate, a spindle and a motor, wherein the box comprises an upper box and a lower box matched with the upper box, the upper portion of the upper box is provided with a feed inlet, and a concave part is arranged at the connection of the upper box and the lower box and used for placing the sieve plate; the hammer plate component is rotatably arranged between the sieve plate and the feed inlet through the spindle and comprises a plurality of hammer plates, hammer plate bolts, hammer pieces and hammer piece bolts, the positions, close to the circumferential edge, of each hammer plate are provided with a plurality of first through holes and second through holes in one-to-one correspondence to the first through holes, each hammer piece is provided with a third through hole and a fourth through hole, the hammer plate bolts sequentially penetrate the first through holes and the third through holes to fix the hammer plates with the hammer pieces, and the hammer piece bolts sequentially penetrate the second through holes and the fourth through holes to fix the hammer pieces to two sides of the hammer plates so as to form at least one group of hammer pieces on the hammer plates; the motor is used for driving the spindle to rotate. The shell pulverizer is high in shell pulverizing rate, simple in structure, and convenient to mount, demount and maintain.

Owner:XIAMEN UNIV OF TECH

Agricultural environment-friendly organic fertilizer and preparation method thereof

InactiveCN111499464ANutritional diversityImprove crushing rateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersNutritionAgricultural engineering

The invention discloses an agricultural environment-friendly organic fertilizer comprising the following raw materials, by weight: 25-35 parts of chicken manure, 12-20 parts of dry sheep manure, 2-4 parts of bittern, 10-12 parts of blue algae powder, 8-10 parts of sweet wormwood herb, 11-13 parts of kudzu vine, 3-6 parts of EM bacteria stock solution, 15-20 parts of sludge fertilizer, 10-13 partsof sesbania, 9-11 parts of chitin, 6-8 parts of monopotassium phosphate, 5-7 parts of bamboo vinegar, 15-17 parts of silica fume, 8-10 parts of magnesian lime, 12-14 parts of bentonite, 8-10 parts ofammonium nitrate and 6-8 parts of gelatin. The invention also discloses a preparation method of the agricultural environment-friendly organic fertilizer. The organic fertilizer provided by the invention can provide comprehensive nutrition for crops, does not destroy the environment and land properties, and is very environment-friendly to use in agriculture; materials can be crushed and mixed through a mixing device to improve the crushing rate and mixing rate of the materials; the materials are relatively sufficient during later fermentation; and material distribution is uniform.

Owner:傅海燕

Crushing and recovery system for waste television shell

The invention discloses a crushing and recovery system for a waste television shell. The crushing and recovery system for the waste television shell comprises a rack; the rack is provided with a lowercrushing mechanism and a drive mechanism; the upper part of the lower crushing mechanism is fixedly provided with a transition cavity; a discharge hole of the transition cavity communicates with a lower crushing barrel of the lower crushing mechanism; the upper part of the transition cavity is fixedly provided with an upper crushing mechanism; an unloading hole of an upper crushing barrel of theupper crushing mechanism communicates with the transition cavity; a feed hopper is arranged at a feeding hole of the upper crushing barrel; a material return channel is arranged between the transitioncavity and the lower crushing barrel; a detachable recovery tank is arranged at the discharge hole of the lower crushing barrel; the lower crushing mechanism also comprises a pair of transmission chain wheels, a chain and a plurality of baffle plates; the transmission chain wheels are pivoted to the interior of the lower part of the lower crushing barrel; the chain sleeves a pair of transmissionchain wheels; and the baffle plates are sequentially fixedly arranged on the periphery of the chain vertically. By adopting the structure, the crushing and recovery system for the waste television shell can thoroughly crush the waste television shell and then recovery the crushed waste television shell.

Owner:梁山县聚兴再生资源回收有限公司

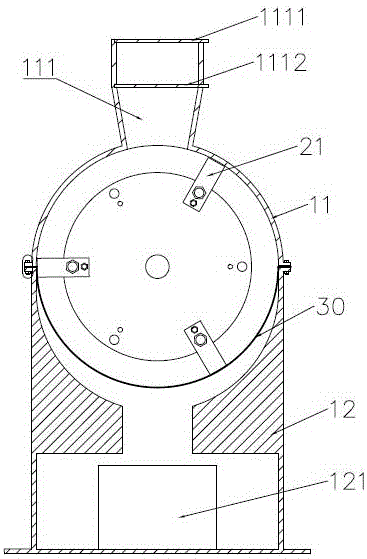

Soybean milk grinding machine

InactiveCN106140428AIncrease productionIncrease productivityGrain treatmentsMilk substitutesEngineeringSoybean oil

The invention relates to the field of processing of bean products and in particular to a soybean milk grinding machine. The soybean milk grinding machine comprises an air exhausting device; a discharging funnel is arranged at the lower end of the air exhausting device; a grinding and pushing device is arranged at the lower end of the discharging funnel; the bottom of the grinding and pushing device is connected with a discharging pipe; a soybean milk squeezing device is arranged just below the discharging pipe; the soybean milk squeezing device comprises a soybean milk outlet and a dreg discharging hole; the soybean milk outlet of the soybean milk squeezing device is connected with a material accepting groove; the dreg discharging hole of the soybean milk squeezing device is connected with a conveying device; the air exhausting device is arranged and soybeans are sucked into a feeding barrel; the soybeans are crushed through the grinding and pushing device and are pushed to the discharging pipe; soybean milk and soybean dreg are separated through the grinding of the soybean milk squeezing device; the soybeans enter the soybean milk squeezing device through the lifting transportation of the conveying device; when the soybeans enter the feeding barrel and the soybeans are repeatedly ground, manual operation is not needed in the whole process, so that the production efficiency is high; the aim of grinding the soybeans in a large batch and the aim of continuous and automatical producing are realized.

Owner:四川来金燕食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com