Crusher

A pulverizer and crushing device technology, which is applied in the direction of grain processing, etc., can solve the problems of fusible soft agglomeration of materials, low efficiency of material crushing, affecting product quality, etc., and achieve the effect of long service life, simple structure and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

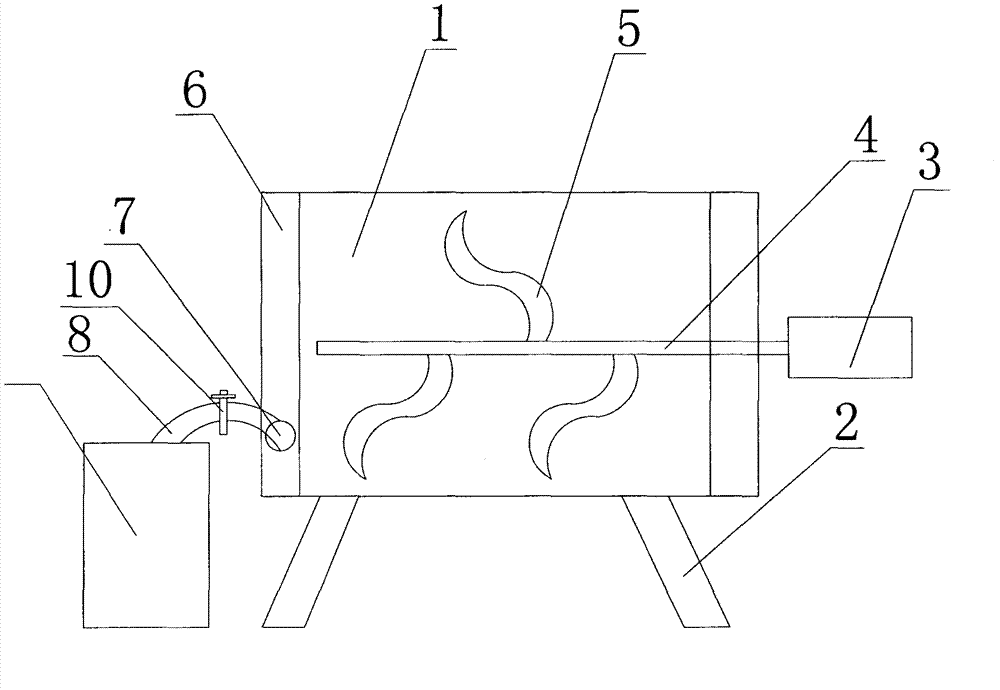

[0012] Such as figure 1 As shown, the pulverizer of the present invention includes a pulverizer housing 1, a frame 2, and a pulverizing device. It is an anti-vibration motor, the main shaft 4 is fixed with a blade 5, the number of the blade 5 is at least two, the blade 5 is S-shaped, and a cavity 6 is provided in the pulverizer housing 1, and an air inlet 7 is opened on the cavity 6. The air inlet 7 is connected to the external cooling device through the pipeline 8, the cooling device is a liquid nitrogen generator 9, and the pipeline 8 is provided with a control valve 10, the material is stirred evenly, the crushing rate of the mixer is high, the quality of the product is provided, and the structure is simple. Easy to use and long service life, the liquid nitrogen generator can reduce the temperature of the processed material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com