Sugarcane leaf crushing and returning machine

A sugarcane leaf and frame technology, applied in the field of sugarcane leaf crushing and returning machines, can solve problems such as fire hazards, environmental pollution, waste of resources, etc., and achieve the effects of convenient operation, high picking and crushing rates, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

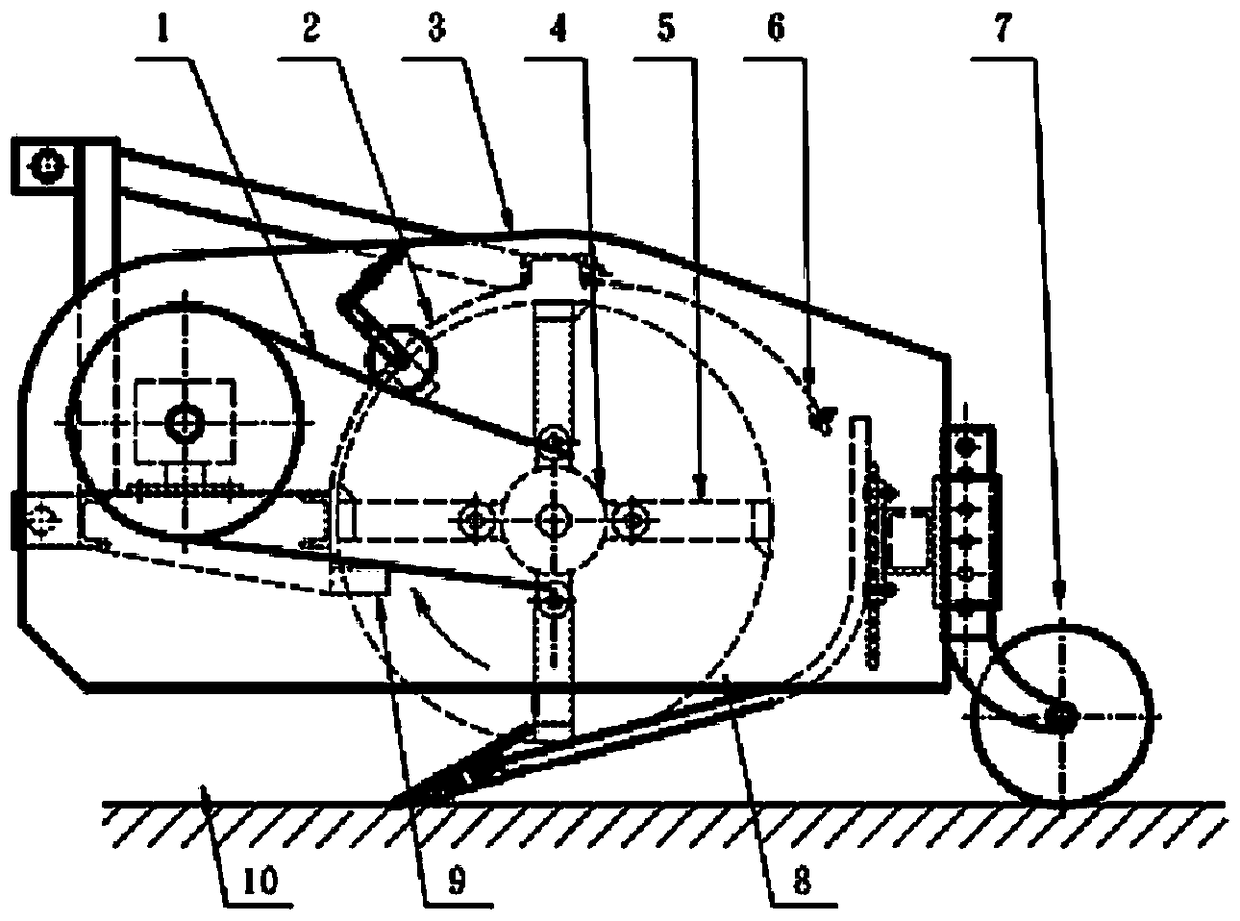

[0017] exist figure 1 Among them, the sugarcane leaf crushing and returning machine is mainly composed of a transmission system, a frame, a front baffle, a swing knife, a fixed knife, a knife roller, a rear baffle, a limit wheel and a profiling leaf collector; the transmission system It includes a gearbox and a V-shaped conveyor belt; the frame is hung on the wheeled tractor after three points; the flail knife and the fixed knife are the main working parts for crushing; the limit wheel is used as a profiling wheel; The profiling leaf collector described above is mainly composed of oblique rods and connecting plates; the oblique rods are composed of curved rods and bottom shovels connected by bolts; on the same plane.

[0018] The working method of the sugarcane leaf crushing and returning machine is as follows: the power output shaft of the tractor transmits the power to the gearbox, and then drives the crushing mechanism to swing the knife at high speed through the V-belt va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com