Turbine grinder

A pulverizer, turbine technology, used in grain processing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

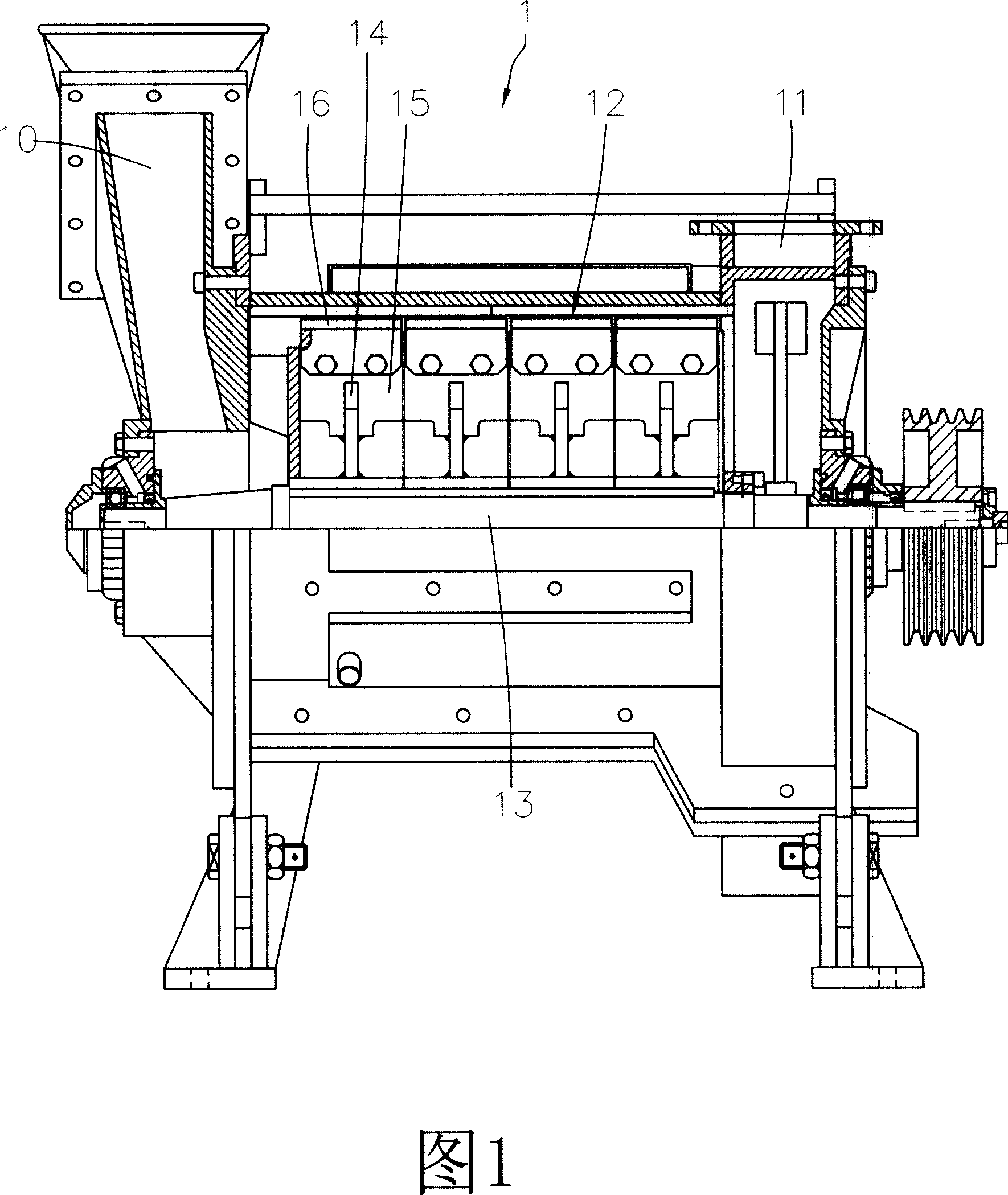

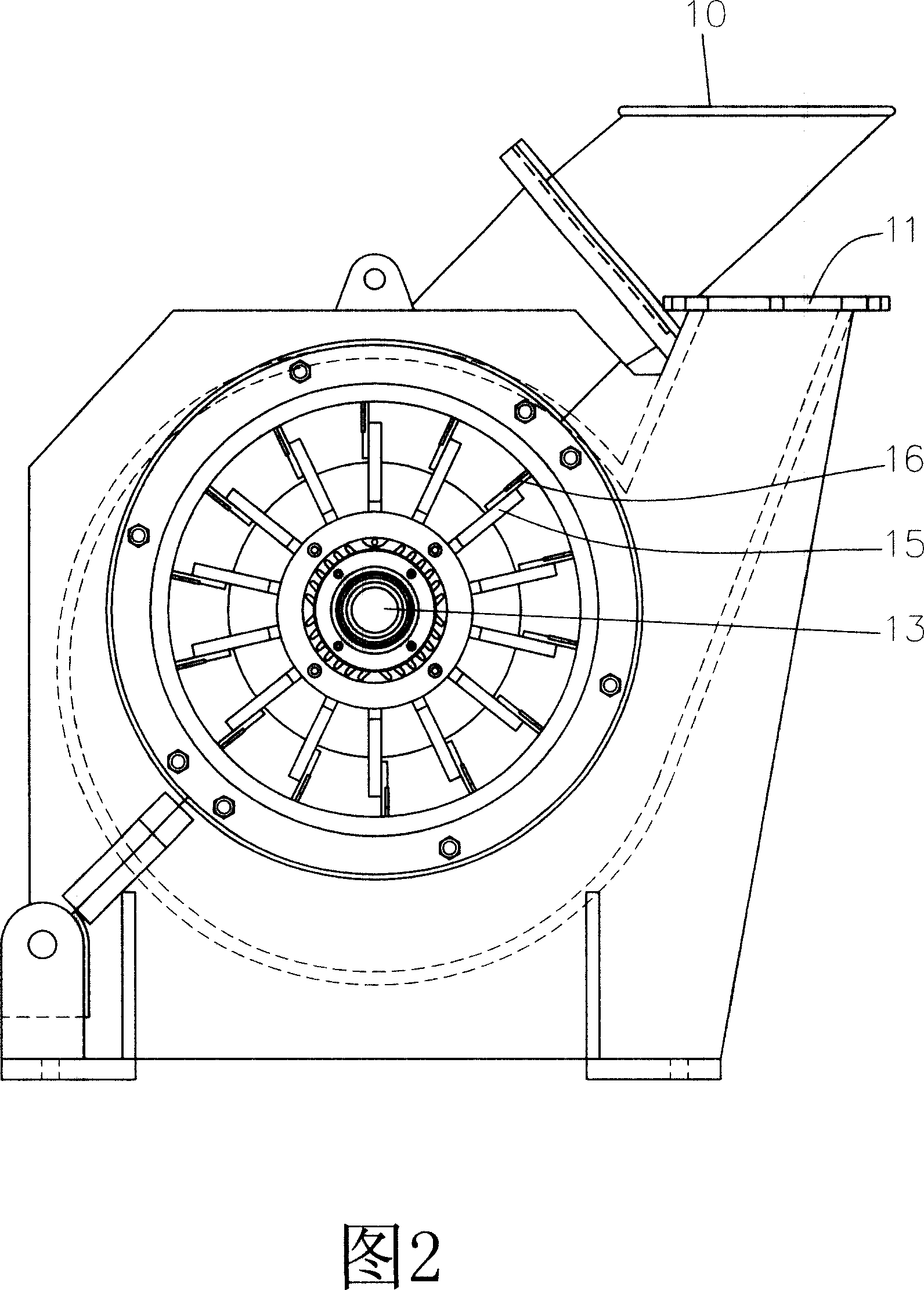

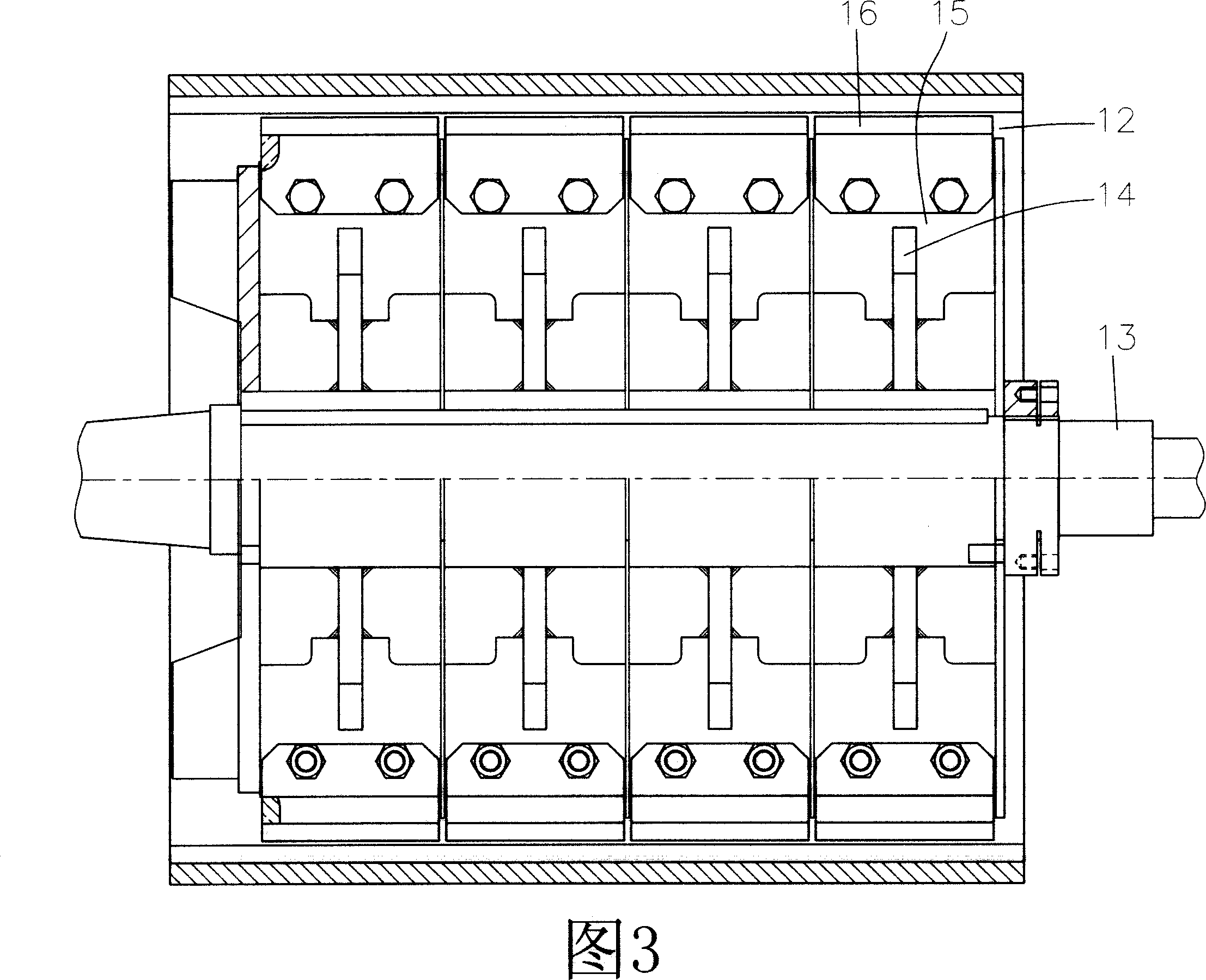

[0013] Relevant present invention is for reaching above-mentioned purpose of use and effect, the technical means that adopts, presents preferred feasible embodiment, and cooperates as shown in the drawing, is described in detail as follows:

[0014] At first, please refer to Fig. 4, shown in Fig. 5, the present invention mainly is that one side of pulverizer 2 is provided with inlet 20, and opposite side is provided with outlet 21, pulverizer 2 is provided with pulverizing chamber 22, and pulverizing chamber 22 is provided with steps. shaped step groove 220, the crushing chamber 22 is provided with at least two or more crushing cutter heads 24, the powder cutting cutters 24 are assembled on the shaft 23 and driven by the shaft 23, and the crushing cutters 24 The tapering arrangement of outer diameters from large to small toward the outlet 21 corresponds to the step grooves 220 . The crushing cutter head 24 is provided with many distribution plates 25 and blades 26 .

[0015] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com