Food processor with high smashing efficiency

A technology for food processing machines and pulverization efficiency, which is applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of longer pulverization time, difficult to clean, and increased noise, so as to achieve the improvement of pulverization efficiency and heating efficiency, and heating efficiency. The effect of improving and improving the crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

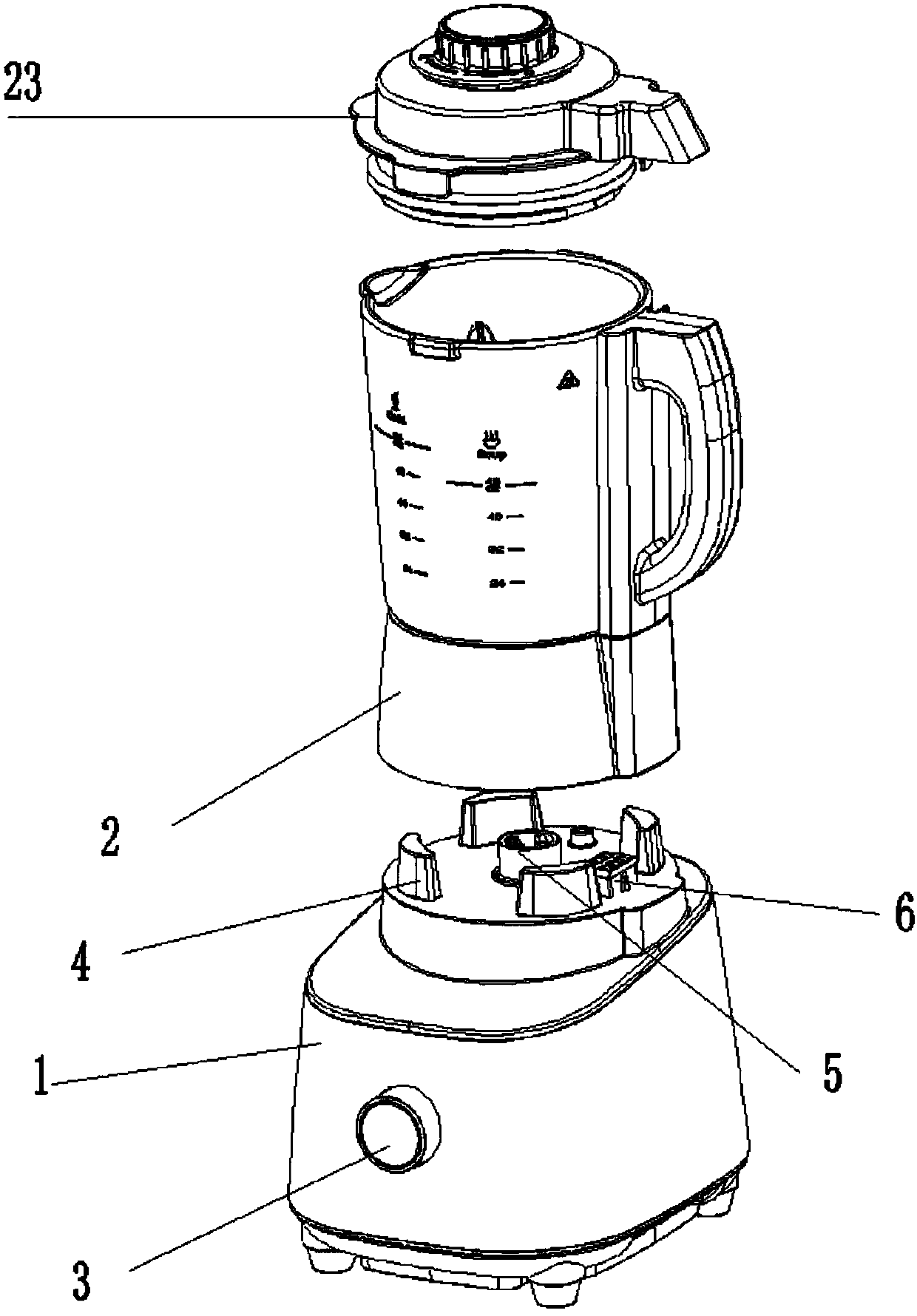

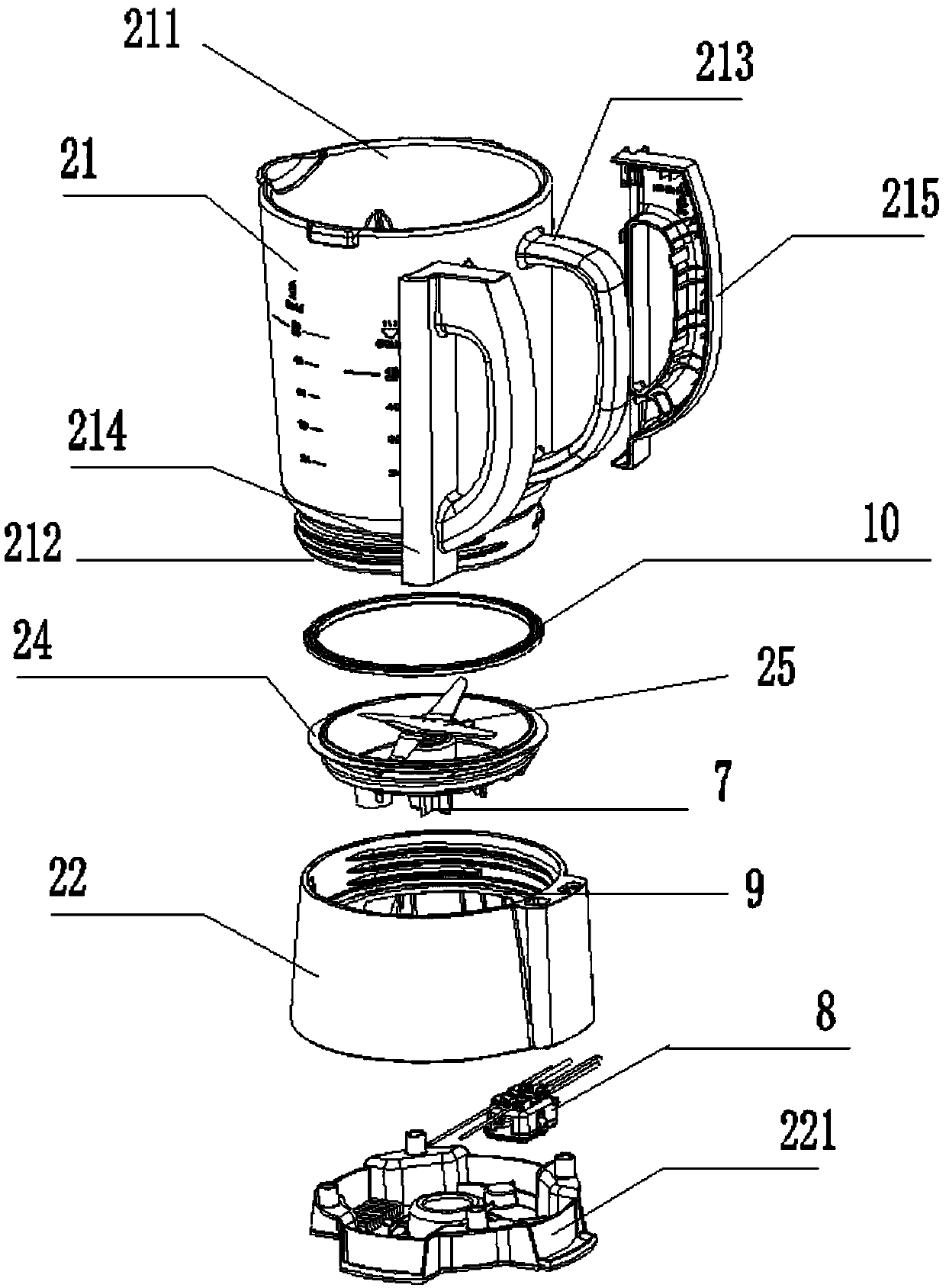

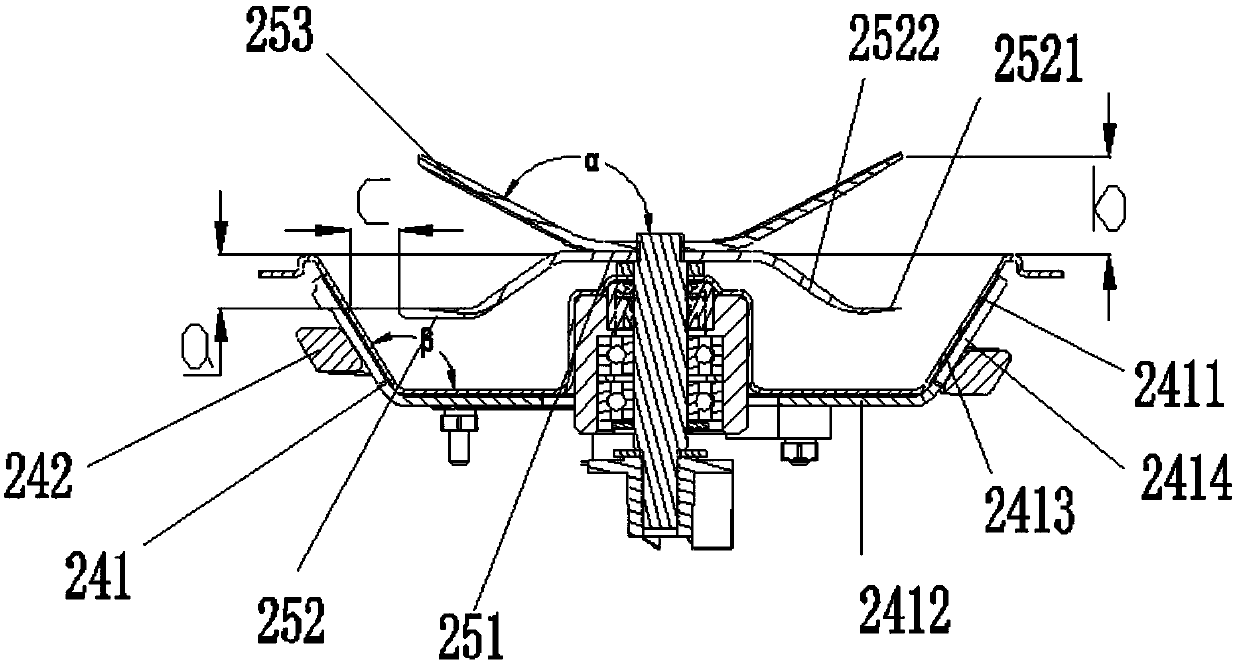

[0036] like figure 1 , figure 2 As shown, the present invention provides a food processor with high crushing efficiency, including a machine base 1 with a motor (not shown in the figure), a stirring cup 2 arranged on the machine base 1, and an operation button is arranged on the machine base 1 3. A shock absorber 4, a lower coupling 5 and a lower coupler 8 are arranged on the top of the base 1. The stirring cup 2 includes a glass body 21, a cup holder 22, a cup cover 23, a heating plate 24 and a crushing knife 25. The cup An upper coupling and an upper coupling are arranged at the bottom of the seat 22. The crushing knife 25 passes through the upper coupling and cooperates with the lower coupling 5 to realize the transmission connection with the motor. The cup holder 22 also includes a heat shield 221 at the bottom. The heat shield 221 fastens the upper coupler under the cup holder 22, the glass cup body 21 is arranged on the cup holder 22, the cup cover 23 is covered on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com