Patents

Literature

37results about How to "Not effectively" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Confrontation migration learning method and system for cross-border big data analysis

InactiveCN107958287AReduced distribution shiftReduce the amount of data calculationNeural learning methodsData vectorMachine learning

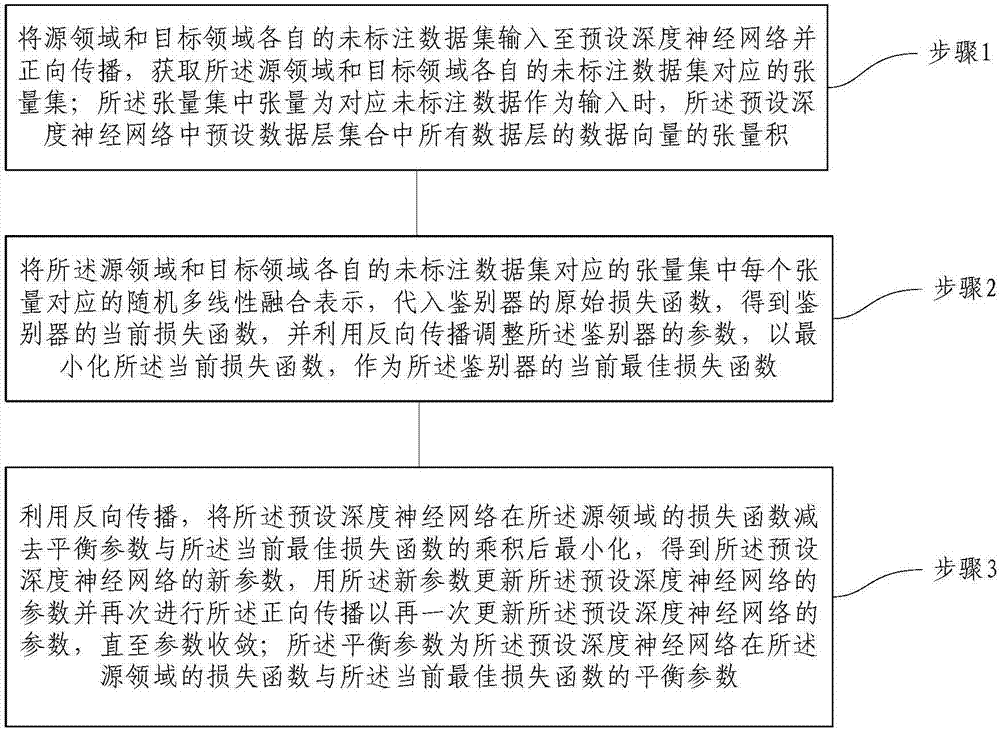

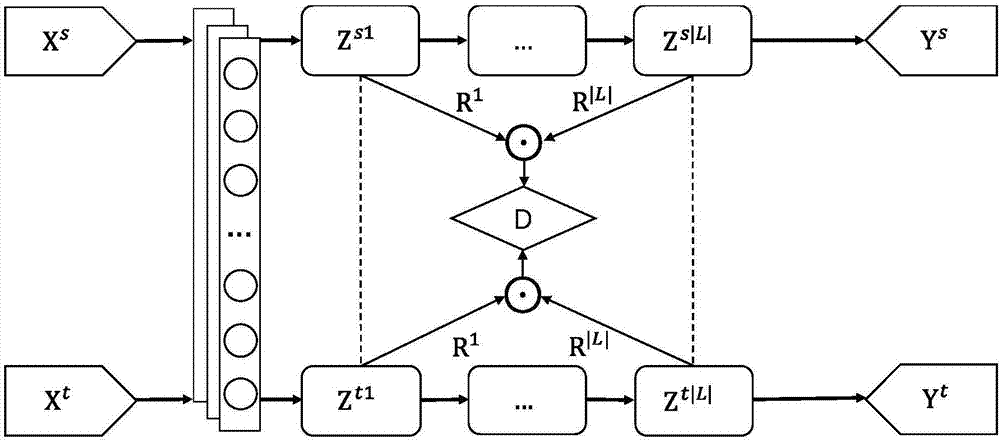

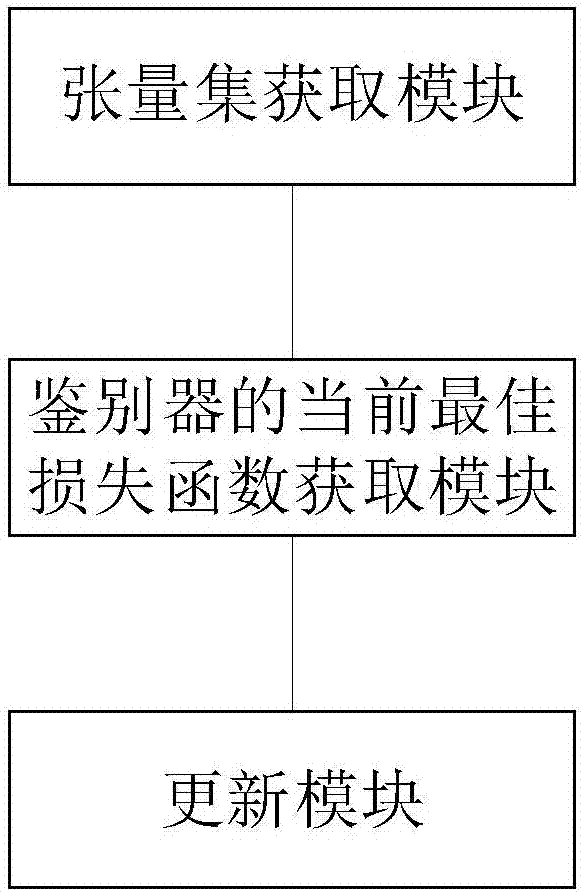

The present invention provides an adversarial transfer learning method and system for cross-border big data analysis. The method includes: substituting the random multi-linear fusion representation corresponding to each tensor in the tensor set corresponding to the unlabeled data set in the source domain and the target domain into the original loss function of the discriminator to obtain the current loss function of the discriminator, and Using backpropagation, adjust the parameters of the discriminator to minimize the current loss function as the current best loss function of the discriminator; the tensor in the tensor set is in the preset deep neural network The tensor product of the data vectors of all data layers in the preset data layer set; update the preset deep neural network parameters based on the current best loss function and enter the next update of the preset deep neural network parameters until the parameters converge . The joint distribution offset of multiple data layers in the preset deep neural network preset data layer set obtained by the present invention is reduced, and the application effect is better in the target field.

Owner:TSINGHUA UNIV

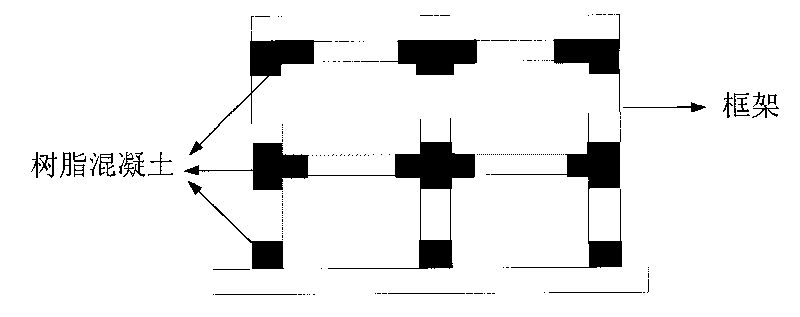

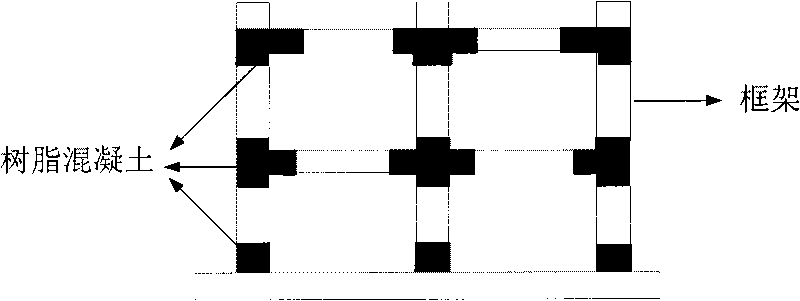

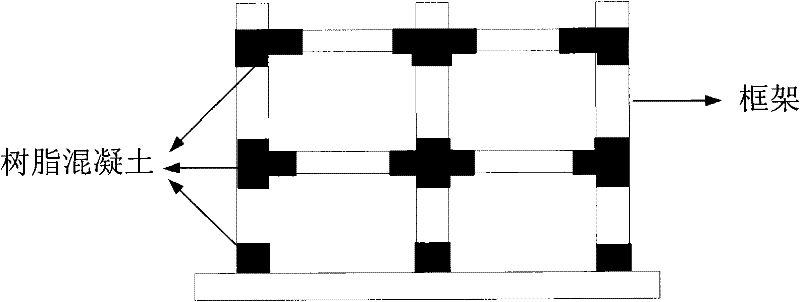

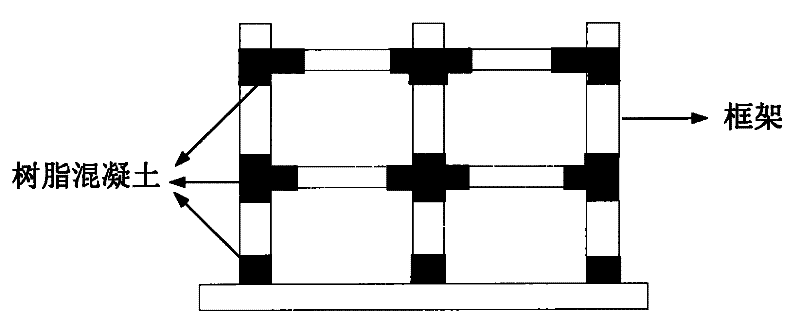

Method for making shock-resistant and energy-dissipating framework by mixing resin concrete and reinforced concrete

InactiveCN101718113AEffective seismic response reductionLow initial construction costShock proofingRebarPlastic hinge

The invention relates to a method for making a shock-resistant and energy-dissipating framework by mixing resin concrete and reinforced concrete, which comprises the following six steps of: (1) reserving a position of the framework, at which a plastic hinge is possible to emerge, and pouring other parts of the framework according to an original construction design; (2) conserving the concrete poured in the framework for 14 days, carving burrs from the concrete around the reserved position, clearing gravels and dust off and cleaning the surface by acetone; (3) priming a layer with a thickness of 3 to 5mm by resin cement; (4) supporting a template at the reserved position; (5) preparing and pouring the resin concrete; and (6) standing and conserving the resin concrete framework over 10 DEG C for 72 hours and stripping a mold. Because the ultimate compression strain of the resin concrete is far greater than that of the ordinary concrete, the resin concrete is filled at an appropriate position in an ordinary reinforced concrete framework to form a mixed framework structure. Therefore, the framework can consume earthquake energy on the premise of not being damaged entirely. The method has a practical value in the technical field of civil engineering.

Owner:BEIHANG UNIV

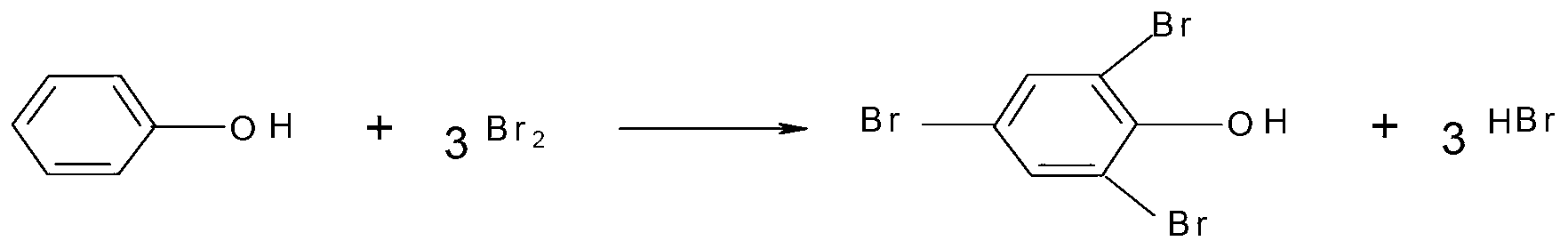

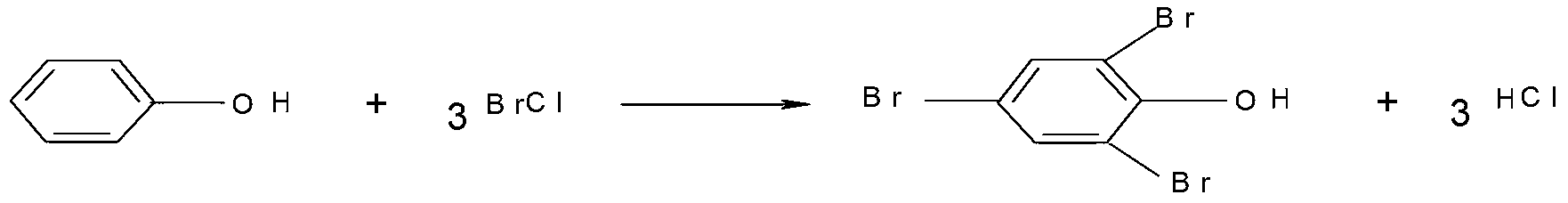

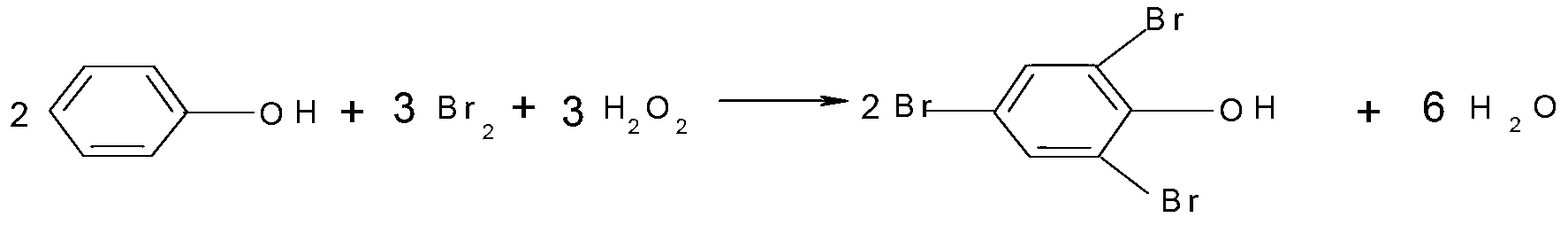

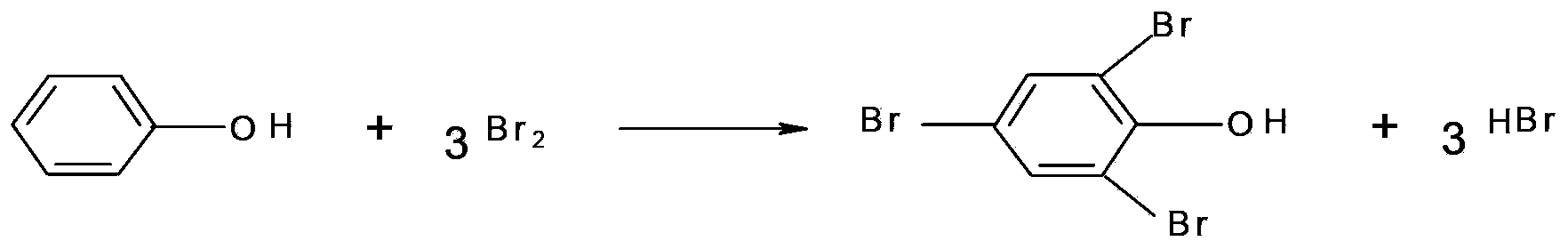

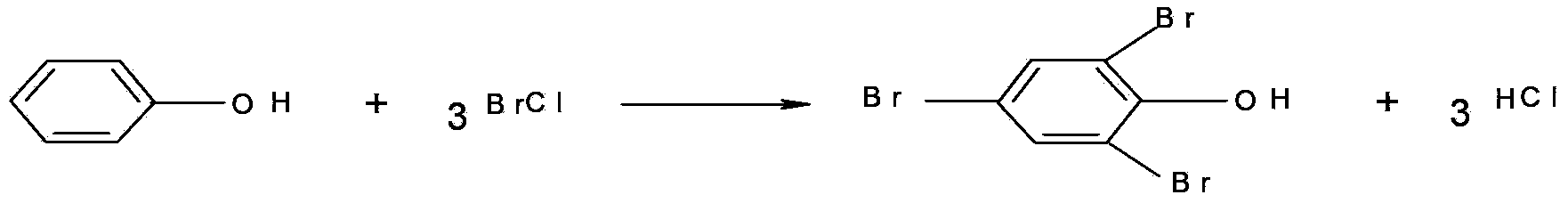

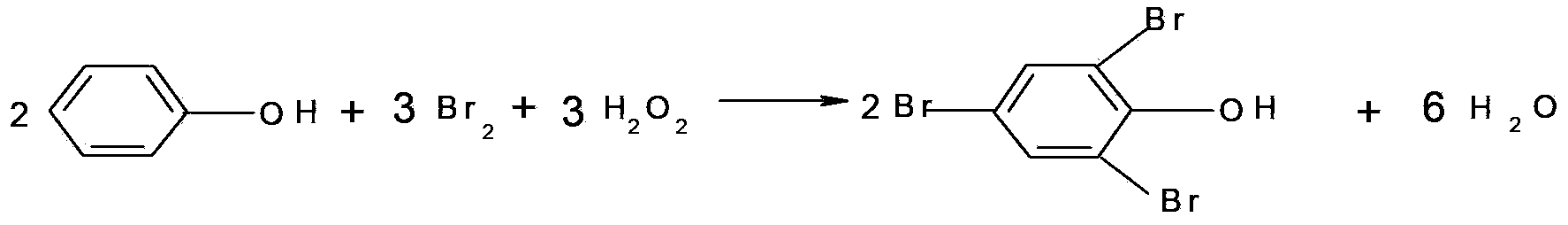

Optimized production method of Tri (tribromophenyl) cyanurate

ActiveCN103275025AAvoid introducingStable melting pointOrganic chemistryOrganic compound preparationChlorobenzeneFiltration

The invention relates to an optimized production method of Tri (tribromophenyl) cyanurate. Chlorobenzene is added into a reactor, phenol is added, hydrogen peroxide and bromine are dropwise added into the reactor in a staggering manner, extraction is performed by the aid of the chlorobenzene, a tribromophenol and chlorobenzene mixed liquid is obtained, cyanuric chloride is added into the mixed liquid, an initiating agent CTAB (cetyl trimethyl ammonium bromide), anhydrous sodium carbonate and methylbenzene are added for reaction, and a crude product is transferred to a heating kettle, the product is subjected to pressure reduction and suction filtration in a heating and dissolving state and is finally transferred to a distillation kettle and stirred and crystallized, edulcoration is realized before unit cell arrangement, and the product is obtained. According to the optimized production method of Tri (tribromophenyl) cyanurate, the produced by-products are reduced, the yield is improved, and the product quality is higher.

Owner:山东寿光神润发海洋化工有限公司

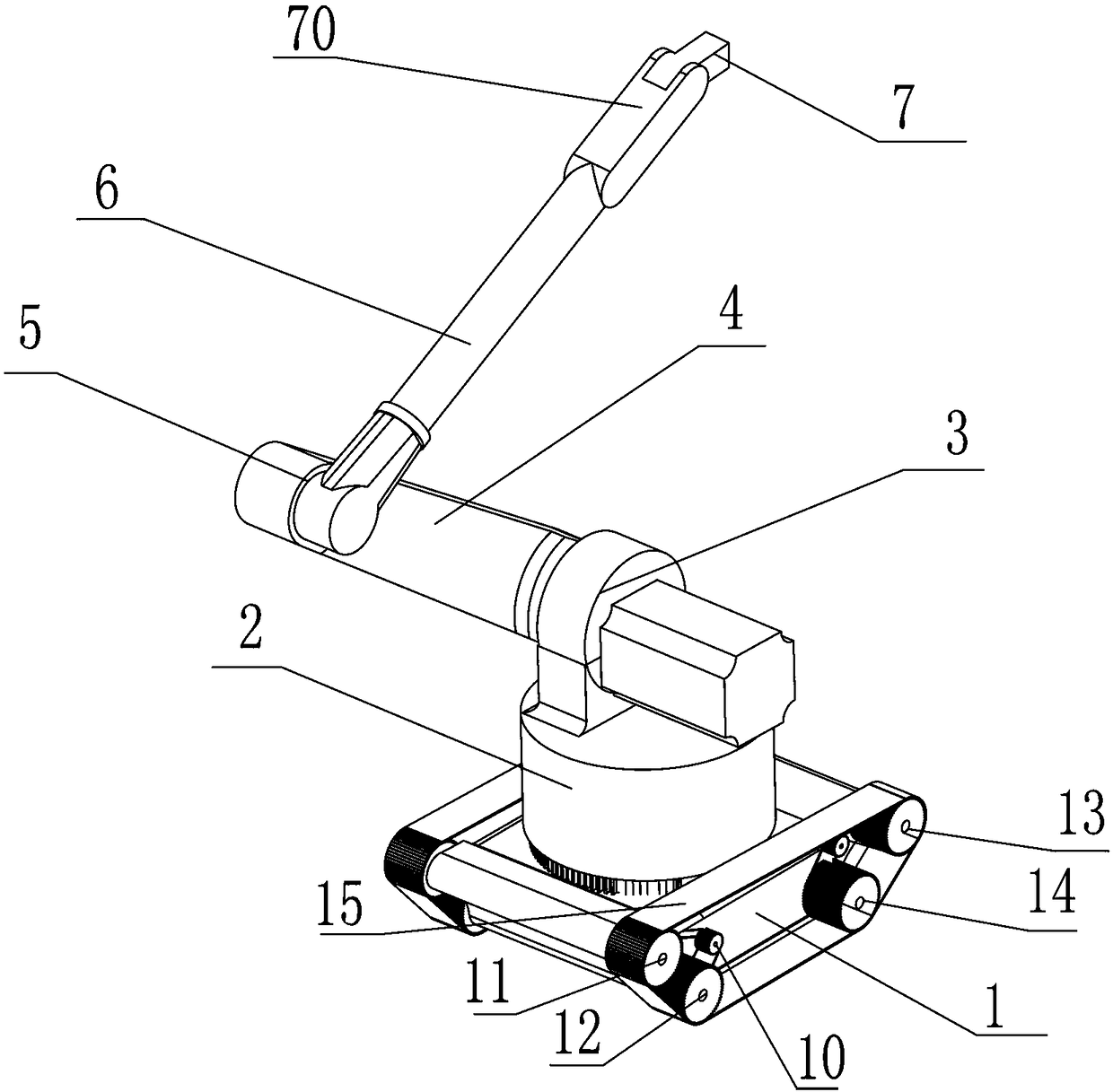

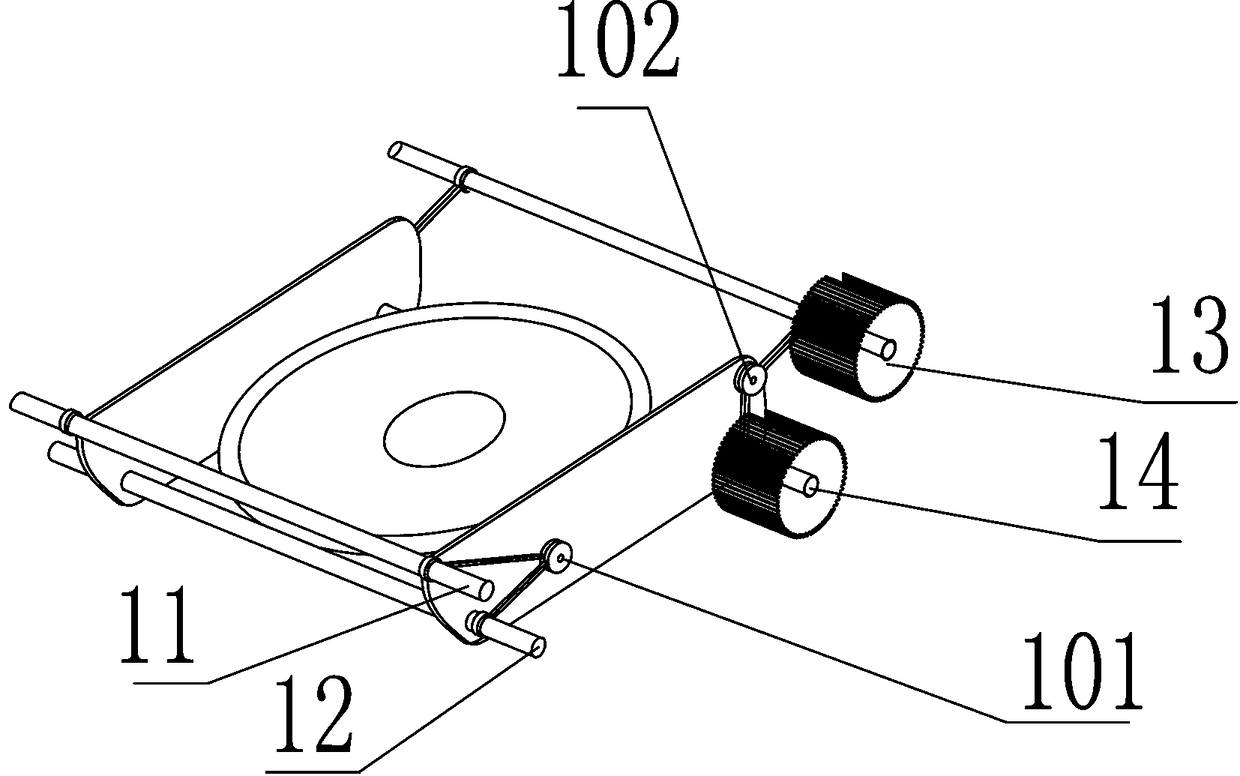

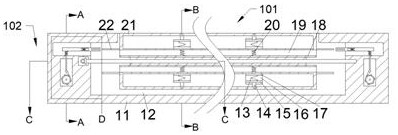

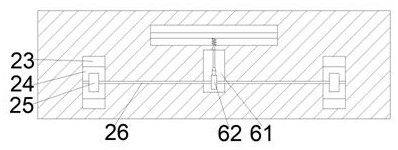

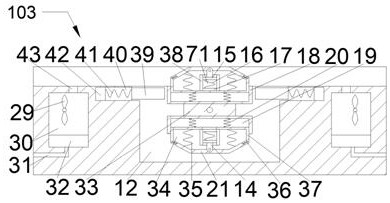

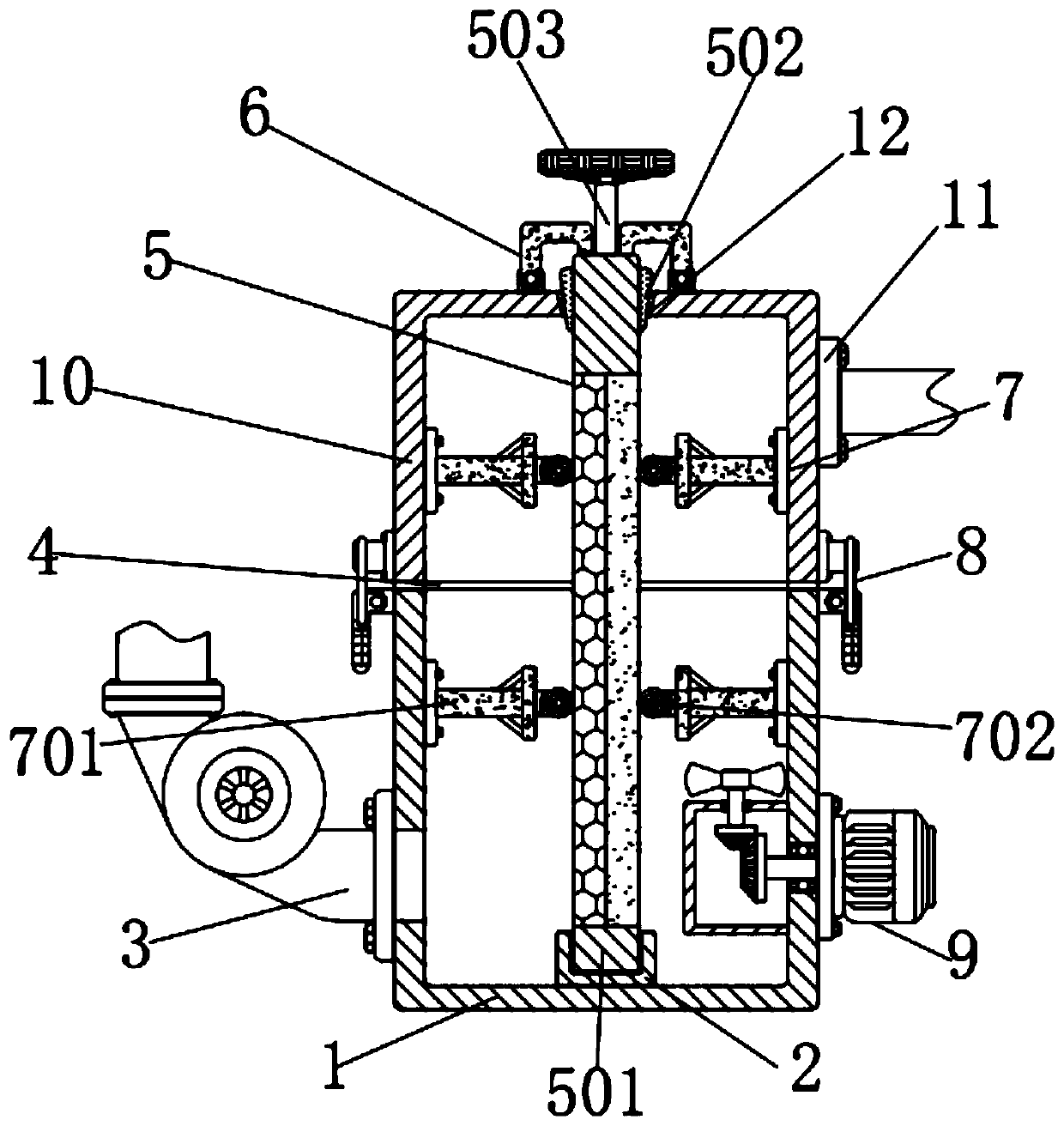

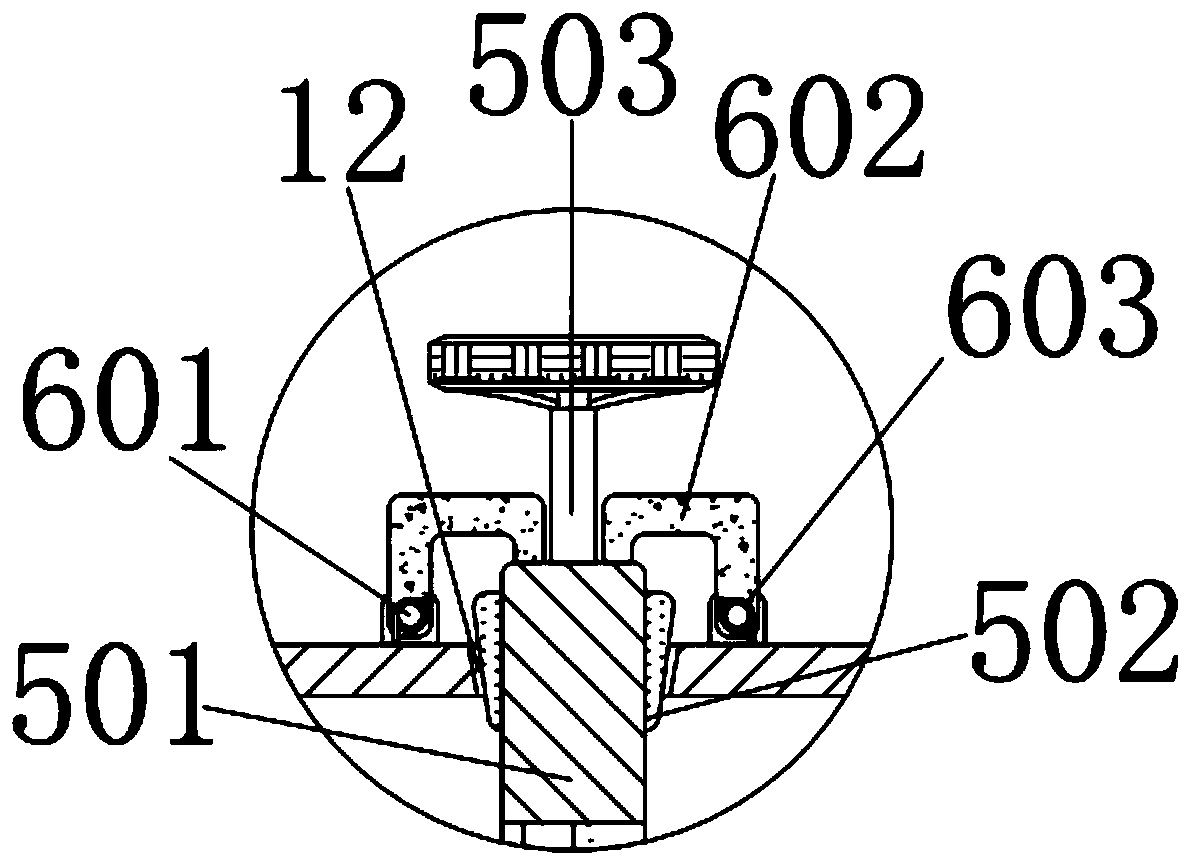

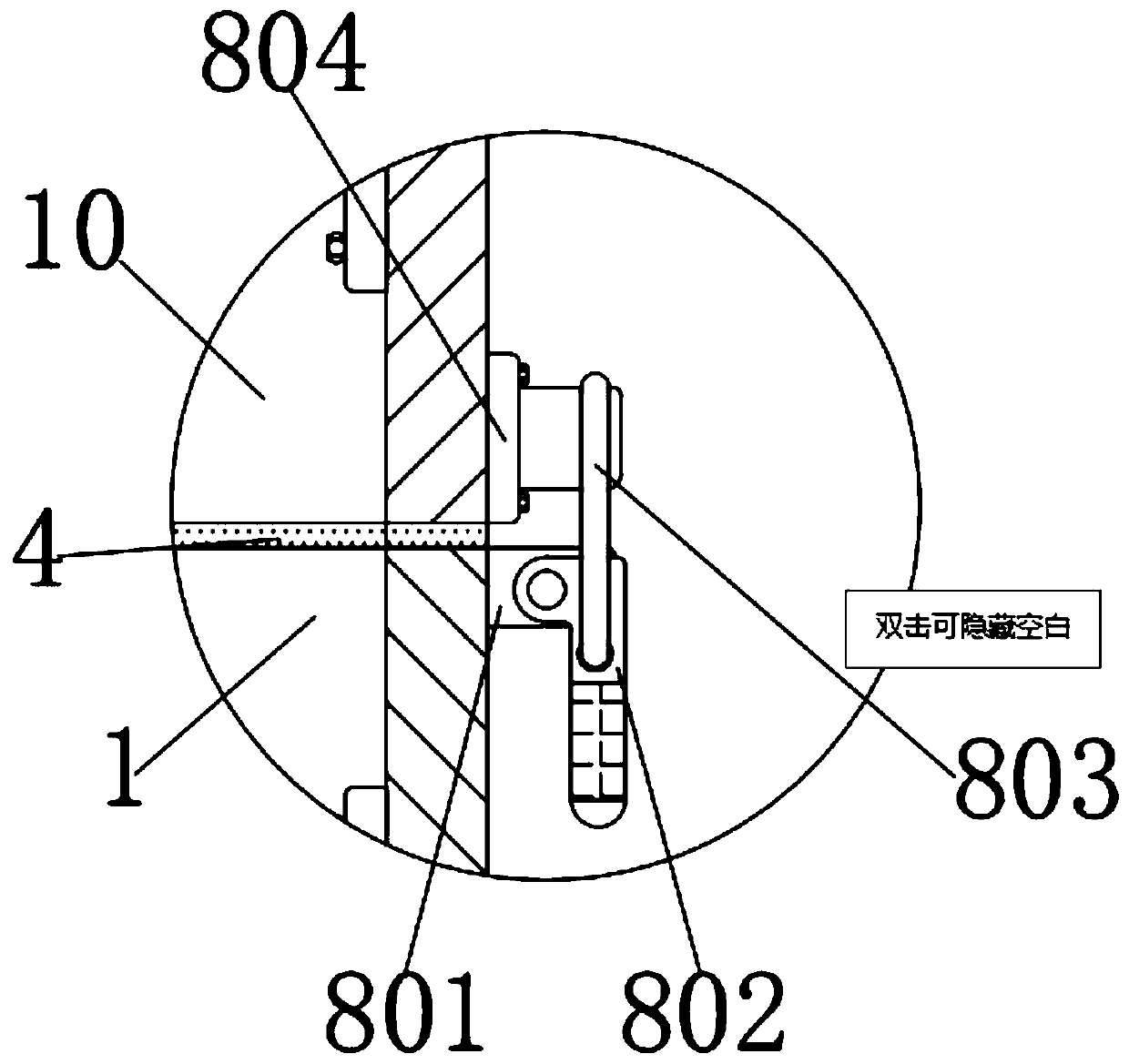

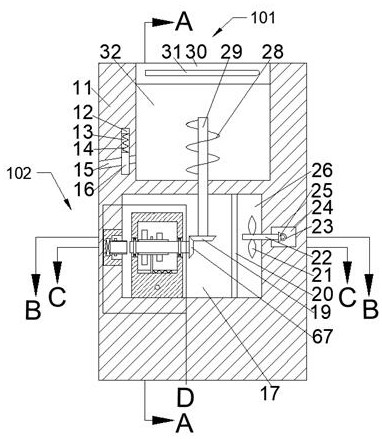

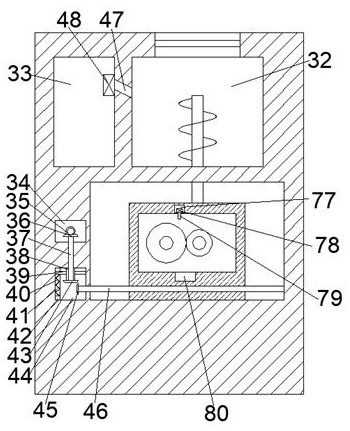

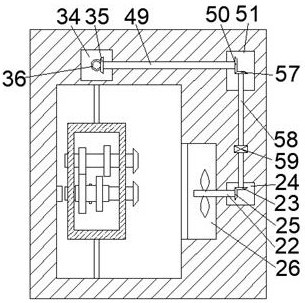

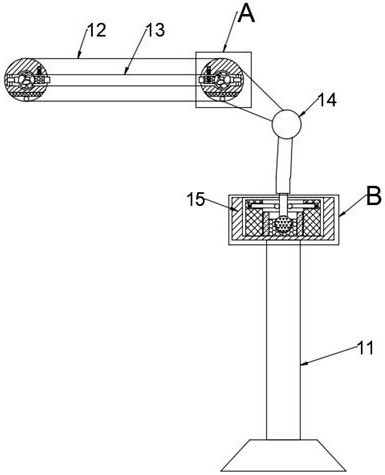

Track robot spraying device

InactiveCN108748072ASelf-regulation of tensionImprove tightnessSpraying apparatusManipulatorDrive wheelSprayer

The invention discloses a track robot spraying device, and belongs to the technical field of machines. The spraying device comprises a track driving device; the track driving device comprises drivingwheels, thrust wheels, guide wheels, towing wheels, tracks and flexible control elements; the positions between the driving wheels and the thrust wheels as well as between the guide wheels and the towing wheels are each provided with one set of flexible control elements; the top part of the track driving device is provided with a rotary chassis; a master control module used for controlling the spraying device to run is arranged in the rotary chassis; and the rotary chassis is provided with a first arm joint, a first arm, a second arm joint, a second arm and a sprayer. The invention aims to provide a track robot spraying device capable of avoiding a poor effect brought by manual construction and avoiding the phenomenon that the human body of a constructor is harmed by directly making contact with harmful gas released from coating.

Owner:深圳市绿恩贝智能科技有限公司

Foaming agent for mineral flotation and preparation method thereof

The invention belongs to the technical field of mineral flotation preparation, in particular to a foaming agent for mineral flotation and a preparation method thereof. The preparation method comprises the following steps of: adopting monohydric alcohol and polyatomic alcohol as raw materials, reaction for 1-3 hours at the temperature of 70-90 DEG C in an insert environment under the action of a catalyst, reducing the temperature to the room temperature, and adjusting pH of a product to be neutral to obtain the foaming agent for mineral flotation. The foaming agent has good performance, and the preparation method is simple and easy to control, and is low in energy consumption and cost.

Owner:河南省核力科技发展有限公司

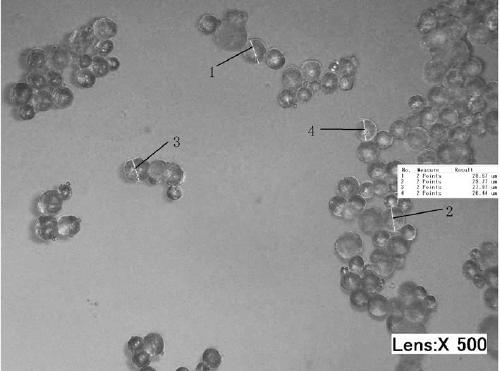

Method for quickly separating mites acarids from feed

The invention provides a method for quickly separating mites from feed. The method comprises the following steps: taking a proper quantity of samples from which the mites need to be collected, and adopting a sample screen of different apertures according to the sizes of the mites to carry out preliminary screening; evenly spreading the samples which are subjected to the preliminary screening on a plastic plate, overturning the plastic plate after standby, and enabling a great quantity of mites and a small quantity of feed fragments to be adsorbed on the plastic plate; reversely buckling the plastic plate attached to the samples subjected to preliminary processing on a thinner sample screen, beating with hands or a small stick to cause all samples to fall into the sample screen, inverting the sample screen after the standby, so that residual feed falls and the required mites are left in the screen almost without the feed fragments.

Owner:NANCHANG UNIV

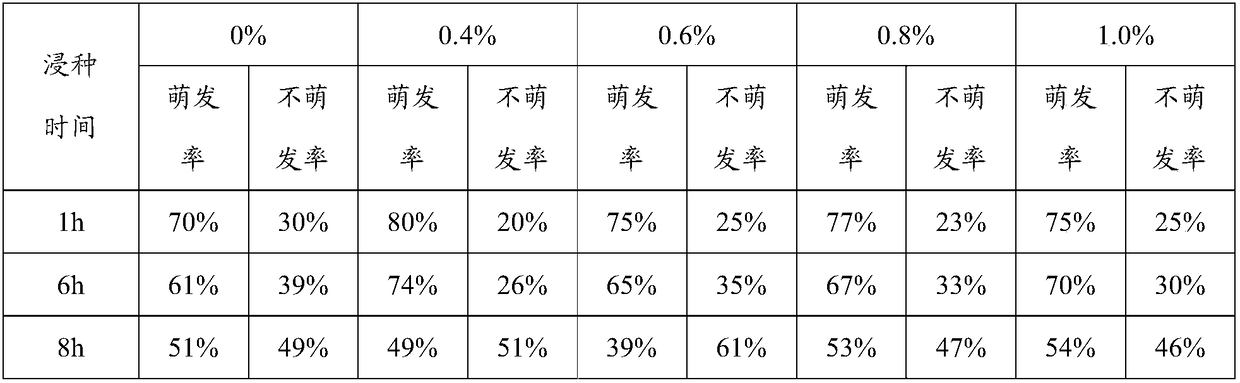

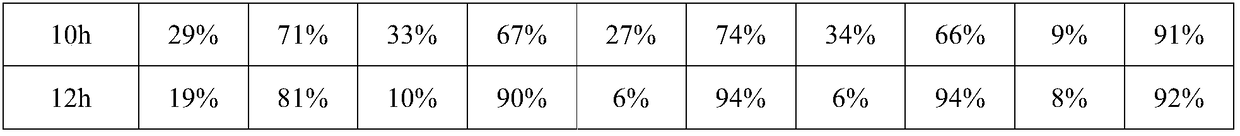

Method for creating red kidney bean mutant by using EMS (Ethy Methan Sulfonate) mutagenic agent and application thereof

InactiveCN108450325AEfficient creationReduce dosagePlant genotype modificationGrowth plantPre treatment

The invention belongs to the technical field of kidney bean breeding and particularly relates to a method for creating a red kidney bean mutant by using an EMS (Ethy Methan Sulfonate) mutagenic agentand the application thereof. The method comprises steps of seed pretreatment, mutagenesis treatment and seeding culture, wherein the step of mutagenesis treatment comprises steps of alternatively soaking sterile seeds into a plant growth regulator and a 0.01-0.05% EMS solution, wherein the soaking time of the plant growth regulator is 5-10minutes, the soaking time of the EMS solution is two timesof that of the plant growth regulator, and alternative soaking is carried out for 2-5 times; and sucking off moisture on the surfaces of the seeds so as to obtain primary mutagenesis seeds; radiatingthe primary mutagenesis seeds with rays so as to obtain secondary mutagenesis seeds; sowing and culturing the seeds, and screening the red kidney bean mutant. The method provided by the invention is aspecial efficient mutagenesis method, the mutagenesis efficiency can be improved, the amount of cancerogen such as EMS can be reduced, and the health threatening upon seed breeding operators can be reduced.

Owner:CORN RES INST SHANXI ACAD OF AGRI SCI

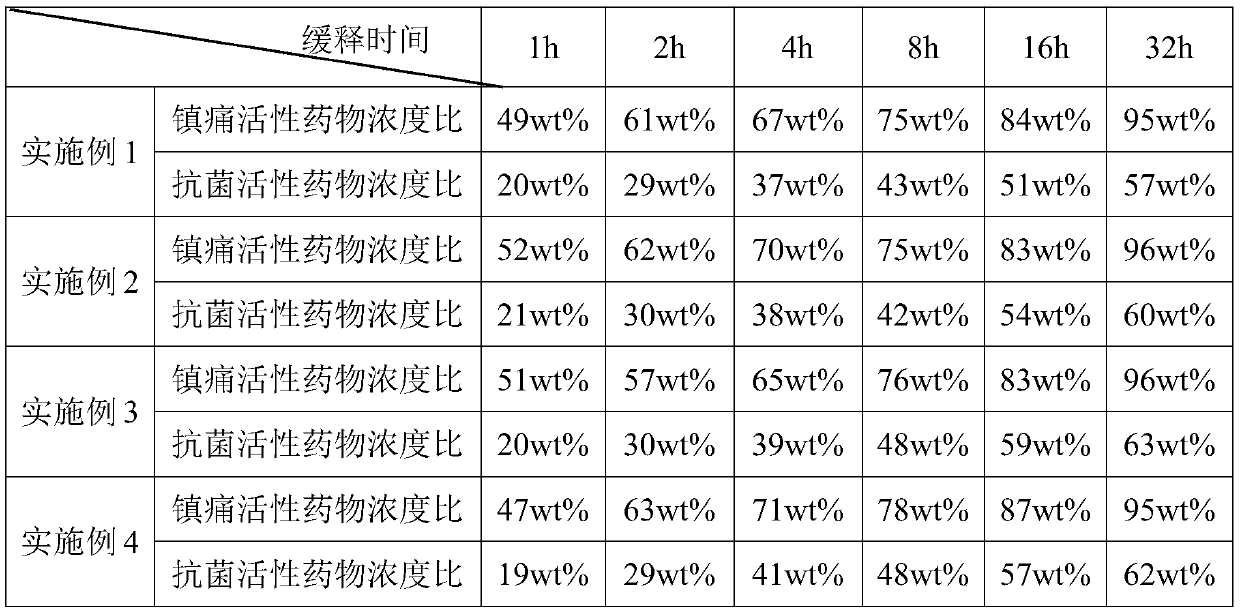

Slow-release pain-easing antibacterial absorbable dressing and preparation method thereof

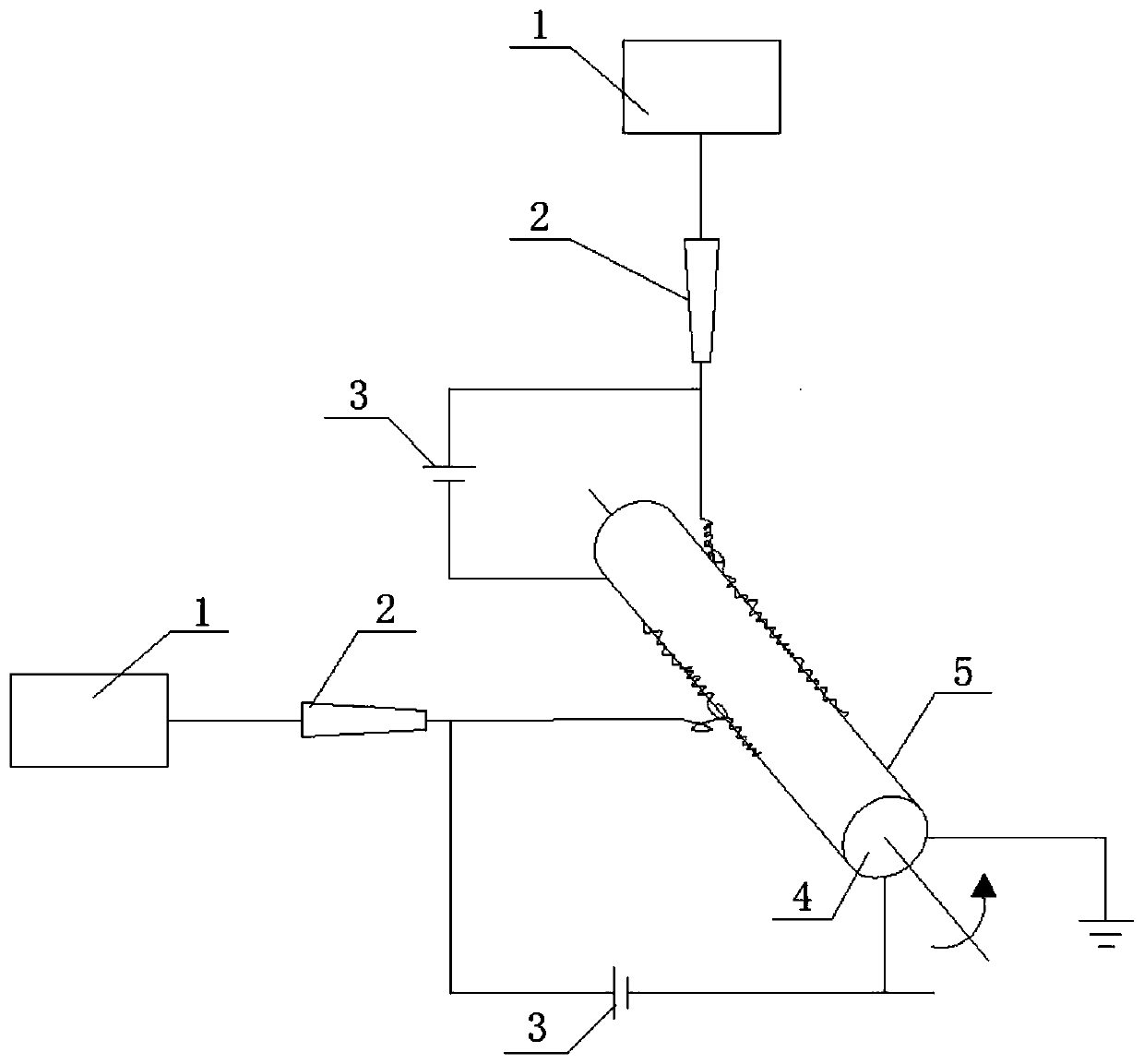

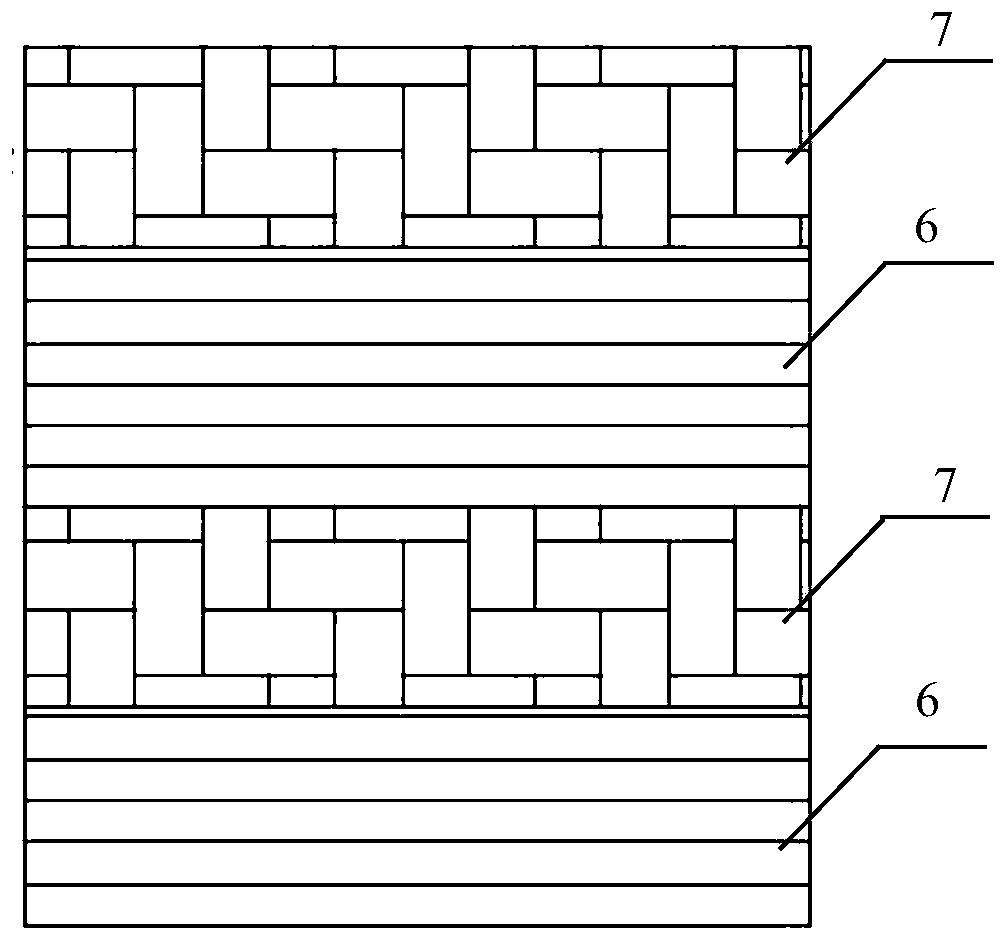

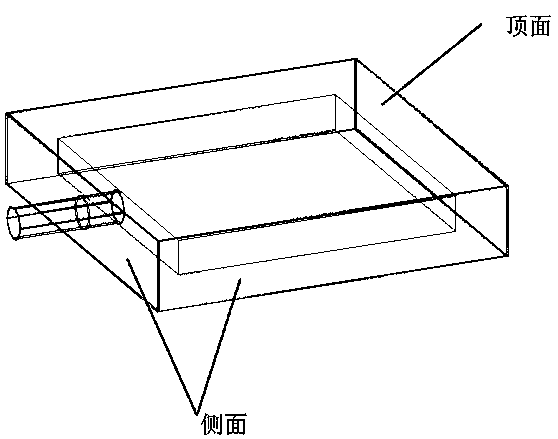

InactiveCN109745576ASlow down the spreadExtended release timeAbsorbent padsConjugated synthetic polymer artificial filamentsFiberElectrospinning

The invention provides a preparation method of a slow-release pain-easing antibacterial absorbable dressing. The preparation method includes the following steps that a, a spinning solution A is prepared; b, a spinning solution B is prepared; c, electrostatic spinning is conducted, wherein the spinning solution A in the step a and the spinning solution B in the second b are added into an electrostatic spinning device comprising two single-channel injection pumps and subjected to electrostatic spinning, so that electrostatic spinning fiber membranes are obtained, wherein the included angle formed by single-axis spray nozzles (2) of the two single-channel injection pumps (1) is 60-180 degrees; d, the electrostatic spinning fiber membranes are crosslinked fixedly. Through the preparation method of the slow-release pain-easing antibacterial absorbable dressing, the speed of diffusing medicine in a carrier is decreased, release time is prolonged, the medicine is released gradually on the wounded part, and the effective medicine concentration of the wounded part can be kept for a long term. The invention further provides the slow-release pain-easing antibacterial absorbable dressing.

Owner:HUAINAN UNITED UNIVERSITY

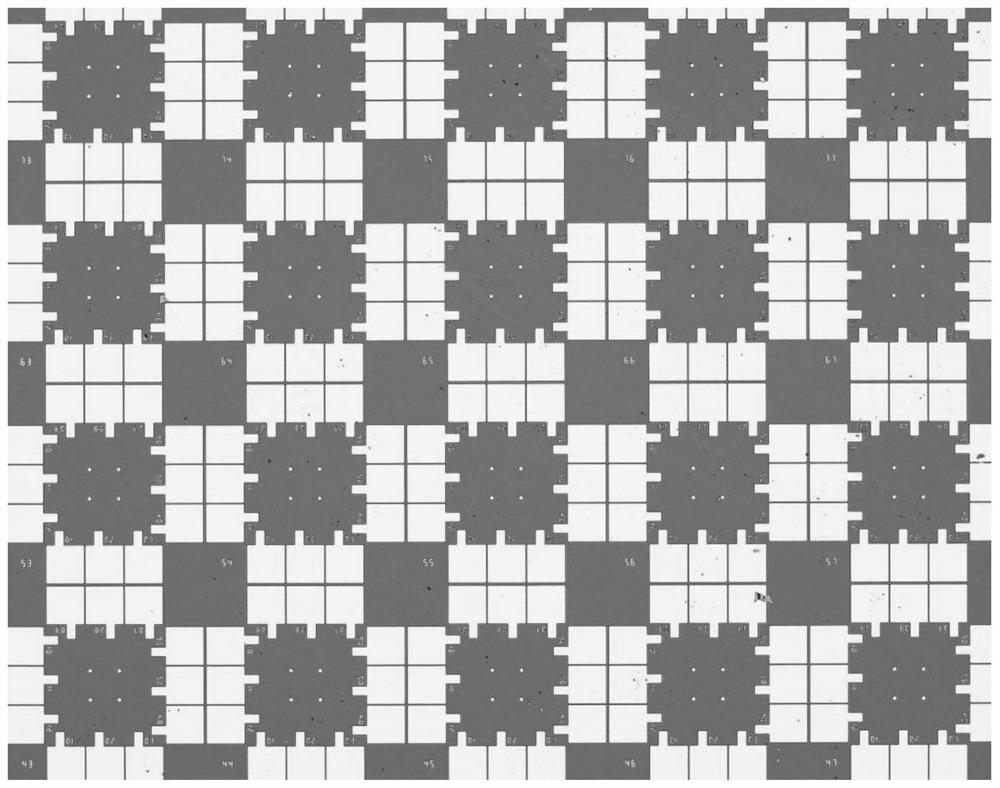

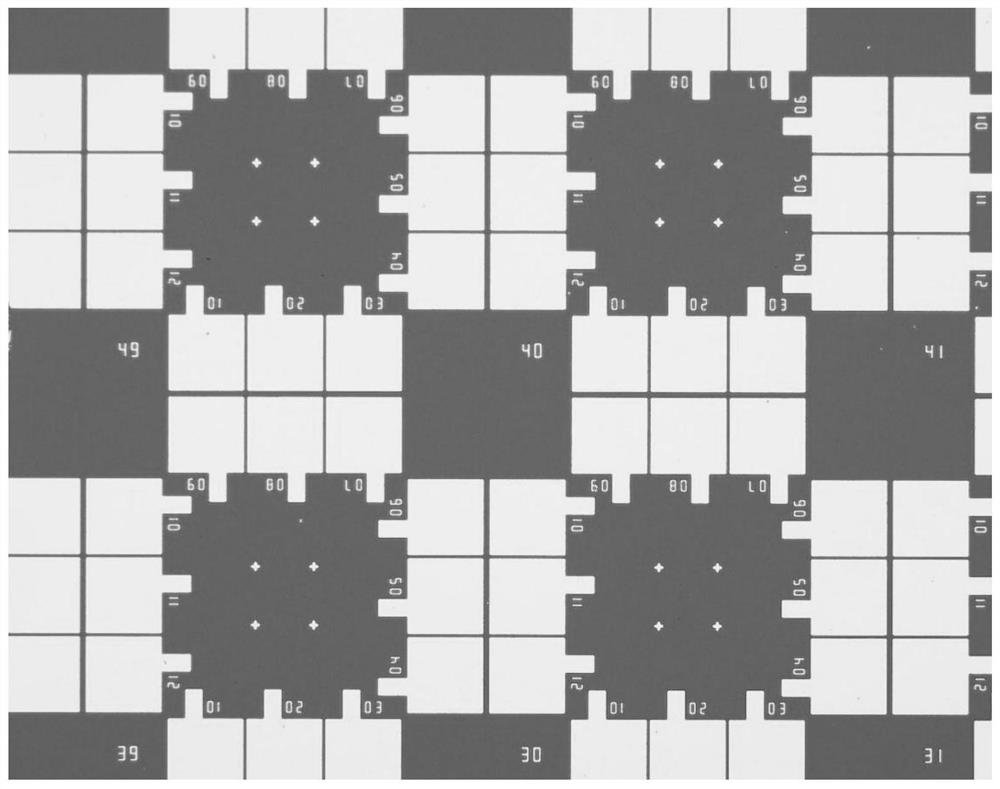

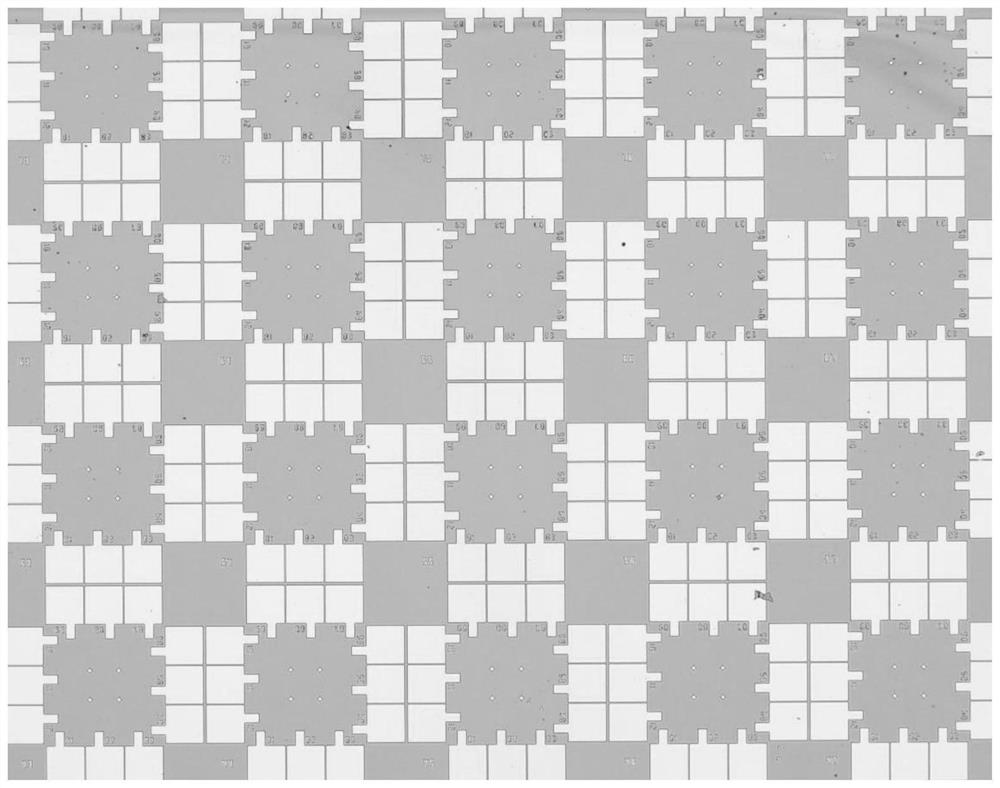

Method for patterning transfer of graphdiyne film

ActiveCN112859514AIncreased process complexityNot effectivelyOriginals for photomechanical treatmentThin membraneGraphite

The invention discloses a method for patterning transfer of a graphdiyne film, and belongs to the field of processing of two-dimensional materials. The method comprises the following steps of: uniformly coating photoresist on a target substrate, carrying out patterning exposure and development, and exposing a place where the pattern of the graphdiyne film is expected to be transferred; transferring the graphdiyne film to the developed target substrate through a wet transfer method; and removing photoresist from the target substrate on which the graphdiyne film is transferred, so as to obtain the patterned graphdiyne film. The invention aims to overcome the defects of the prior art, and provides the method for patterned transfer of the graphdiyne thin film in the laboratory; the method is simple to operate; the precision and success rate of patterned transfer of the graphdiyne film are high; the obtained graphdiyne film is relatively clean; and the process problem that the transfer position, shape and size of the graphdiyne film are uncontrollable is solved.

Owner:UNIV OF SCI & TECH BEIJING

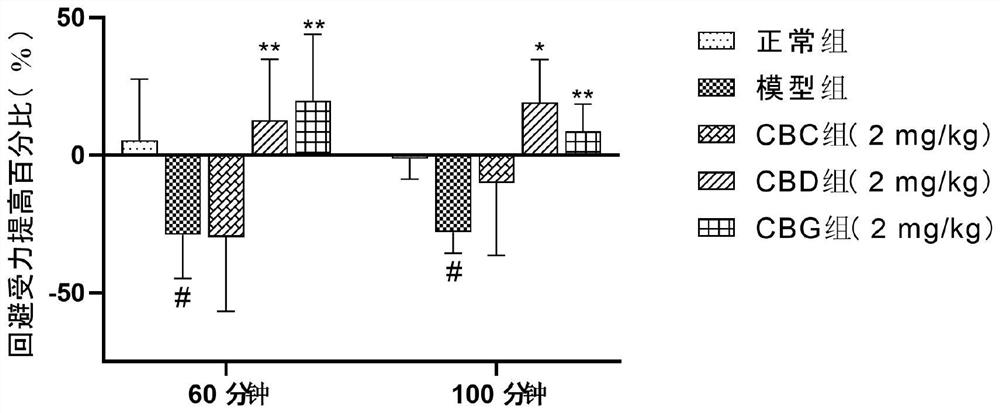

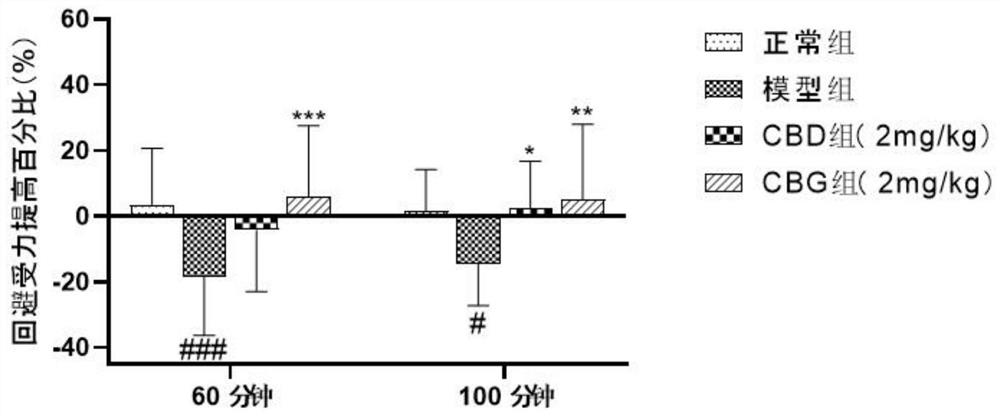

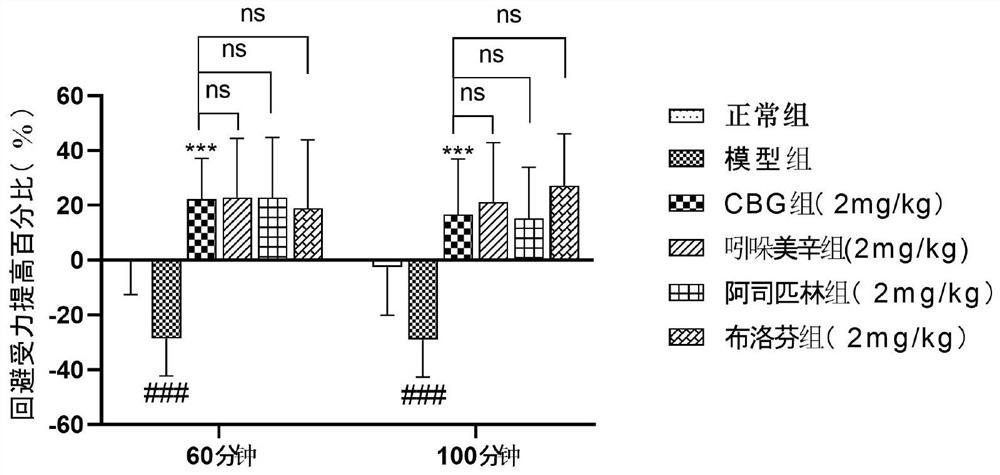

Application of cannabinoid molecules CBG in preparation of inflammatory pain drugs and medicinal preparation

PendingCN113491681AReduce patient painImprove compliance and safetyHydroxy compound active ingredientsAntipyreticCannabinoidergicArthritis

The invention discloses application of cannabinoid molecules CBG in preparation of inflammatory pain drugs and a medicinal preparation. Local administration experiments find that different cannabinoid molecules have different effects on inflammatory pain, and further find that the CBG effect is optimal and is stronger than the effect on SNI pain. Furthermore, the effective dose (0.25-3mg / kg) and the action time (60-140min) of the CBG are screened, and the effective dose (1-3mg / kg) and the action time (60-100min) of the CBG are optimized. Finally, animal arthritis model verification finds that the CBG can treat arthritis pain. The result shows that the cannabinoid molecules CBG are more suitable for treating inflammatory pain and can be developed into an external preparation.

Owner:无锡诺平医药科技有限公司 +1

Traffic equipment capable of intelligently adjusting gradient of deceleration strip

InactiveCN112301905AKeep healthyNot effectivelyPump componentsDispersed particle filtrationSpeed bumpControl theory

The invention discloses traffic equipment capable of intelligently adjusting gradient of a deceleration strip which comprises a deceleration strip body, a deceleration cavity is formed in the deceleration strip body, a deceleration device is arranged in the deceleration cavity, and the deceleration device comprises a rotating block rotationally arranged in the deceleration cavity. Deceleration andreplacement are carried out in a deceleration strip adjusting mode, then automobile tail gas treatment is carried out, the deceleration gradient of the deceleration strip is adjusted in a deceleration strip gradient adjusting mode, accordingly, the automobile deceleration speed is adjusted, power generation is carried out by a deceleration strip power generation device, and an automobile exhausttreatment device filters exhaust emitted by an automobile. The aisle environment is protected, the body health of pedestrians is guaranteed, meanwhile, the deceleration strip can be replaced, a commondeceleration strip cannot be replaced in time after being damaged, passing vehicles are difficult to decelerate effectively, and the effect is poor.

Owner:绍兴铭庭电子科技有限公司

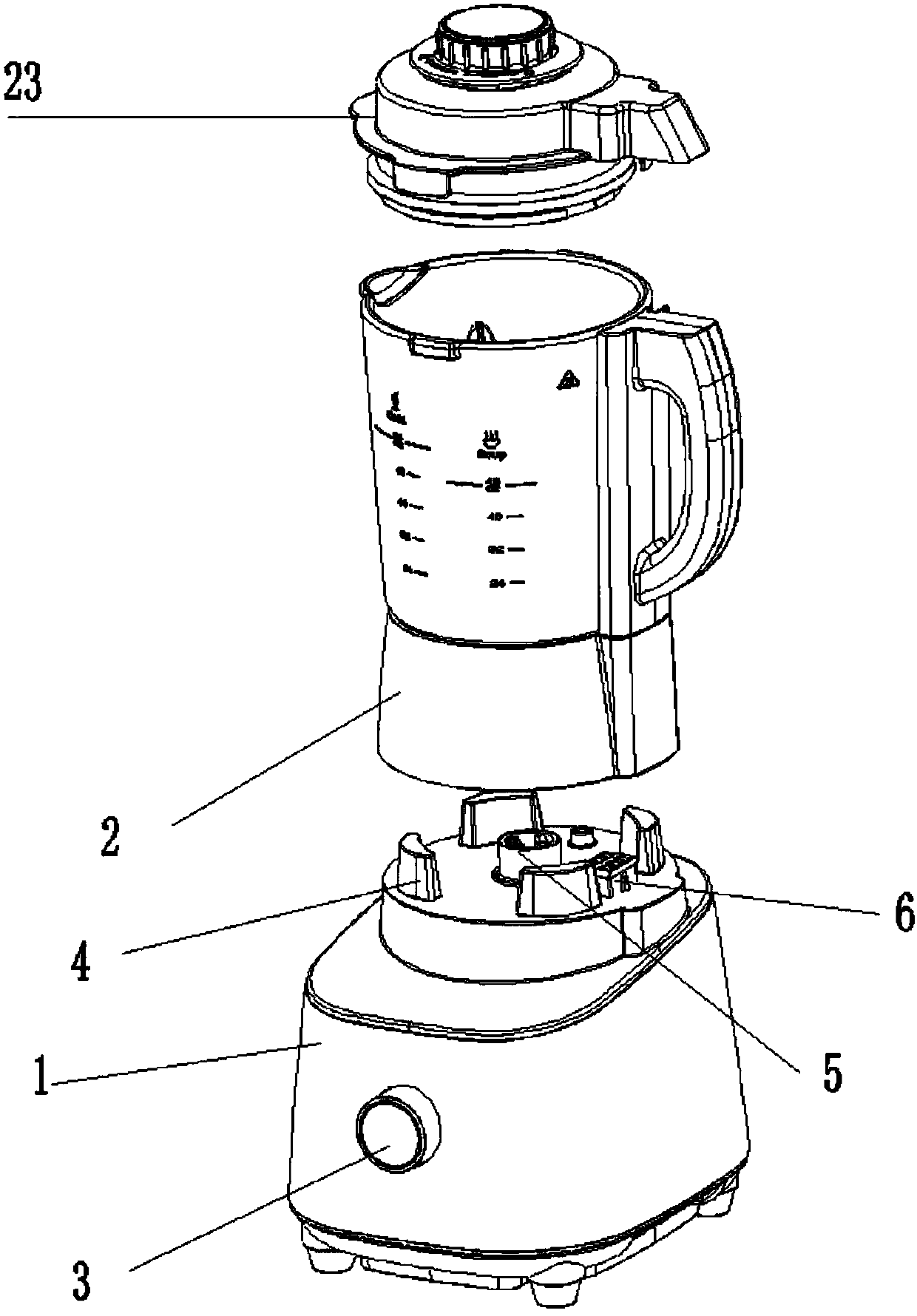

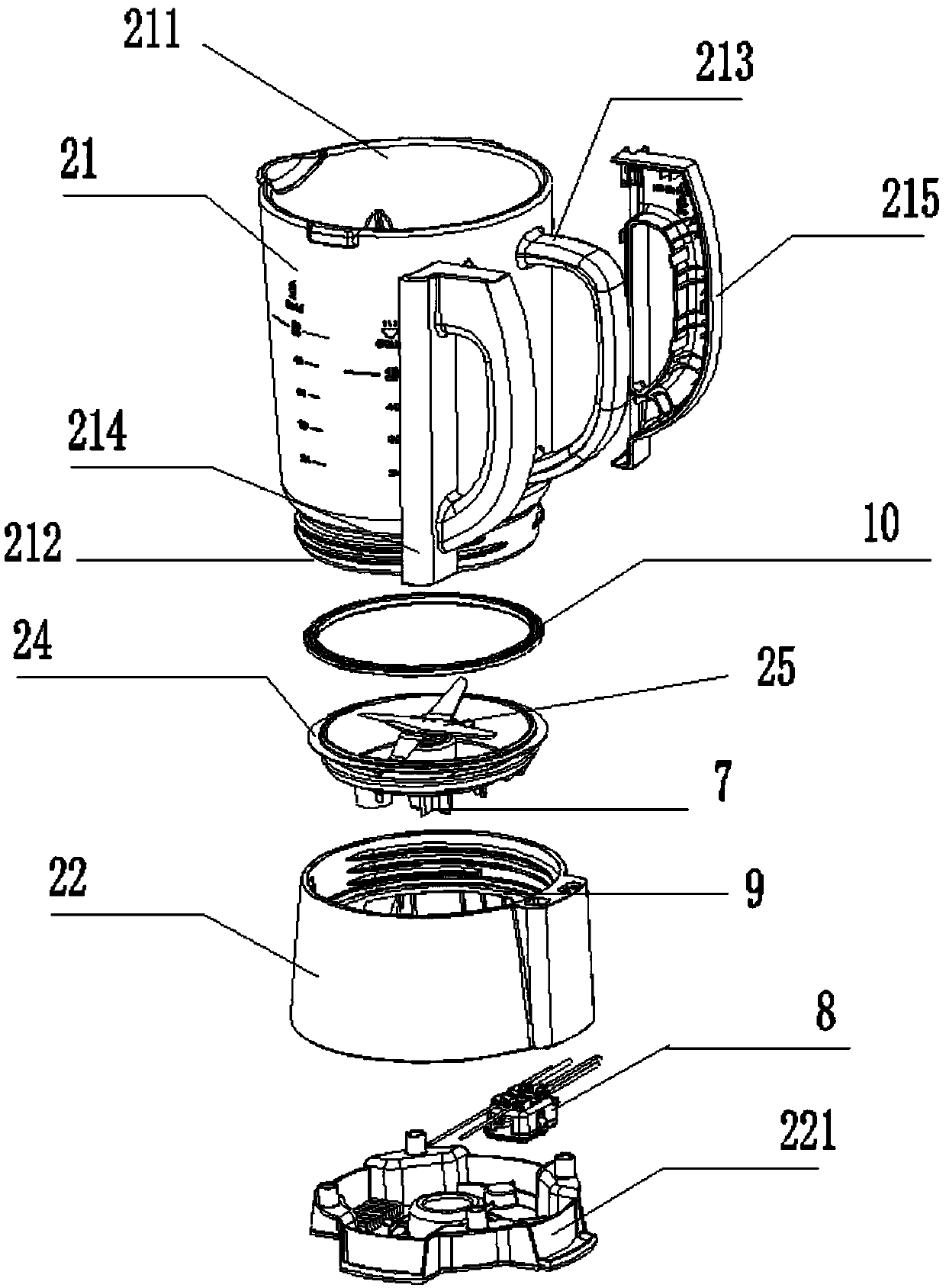

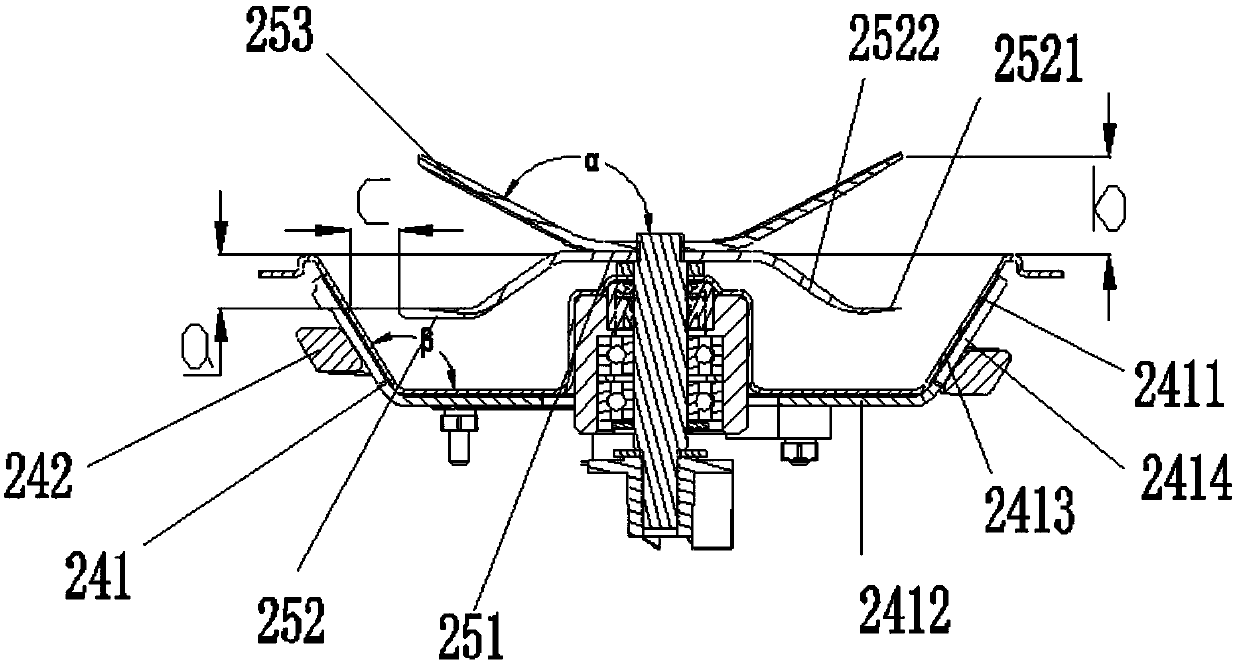

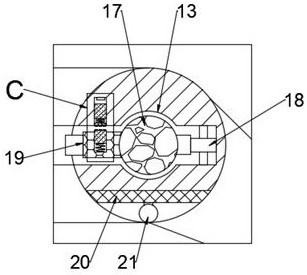

Food processor with high smashing efficiency

The invention discloses a food processor with high smashing efficiency. The food processor comprises a motor base with a motor and a stirring cup arranged on the motor base, the stirring cup comprisesa glass cup, a cup base, a cup lid, a heating disc and a smashing blade, and the glass cup is arranged on the cup base, wherein the heating disc comprises a heating disc body and a heating tube, theheating disc body is in a bowl shape, and comprises a side wall and a bottom wall, the side wall is in an inverted cone shape, the heating tube is arranged on the outer side of the side wall, the peripheral side of the smashing blade forms a dynamic smashing space, the smashing blade comprises a first wing root and first blade wings, the outermost ends of the first blade wings are located in the heating disc body, and the first blade wings rotate at high speed to drive materials to impact the side wall and are heated through the side wall to rebound upwards and inwards to enter the dynamic smashing space again to participate in smashing. Through the technical scheme, the smashing efficiency of the food processor is high.

Owner:JOYOUNG CO LTD

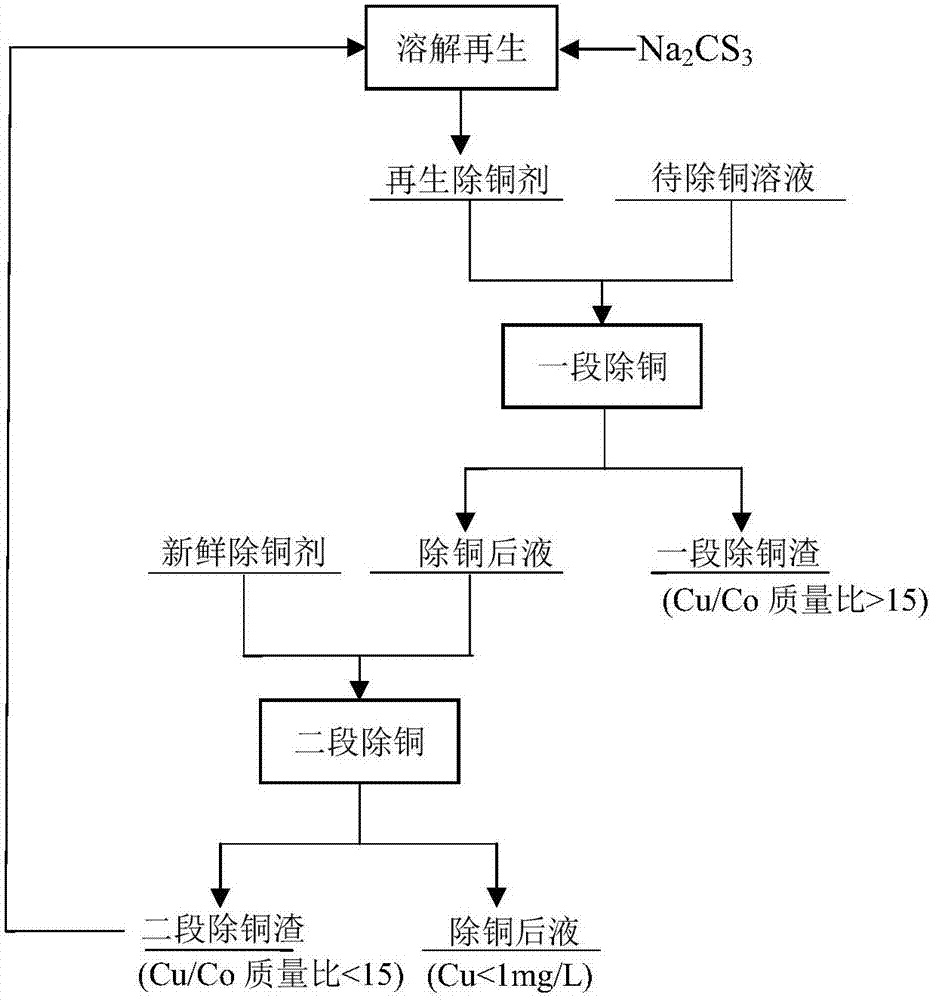

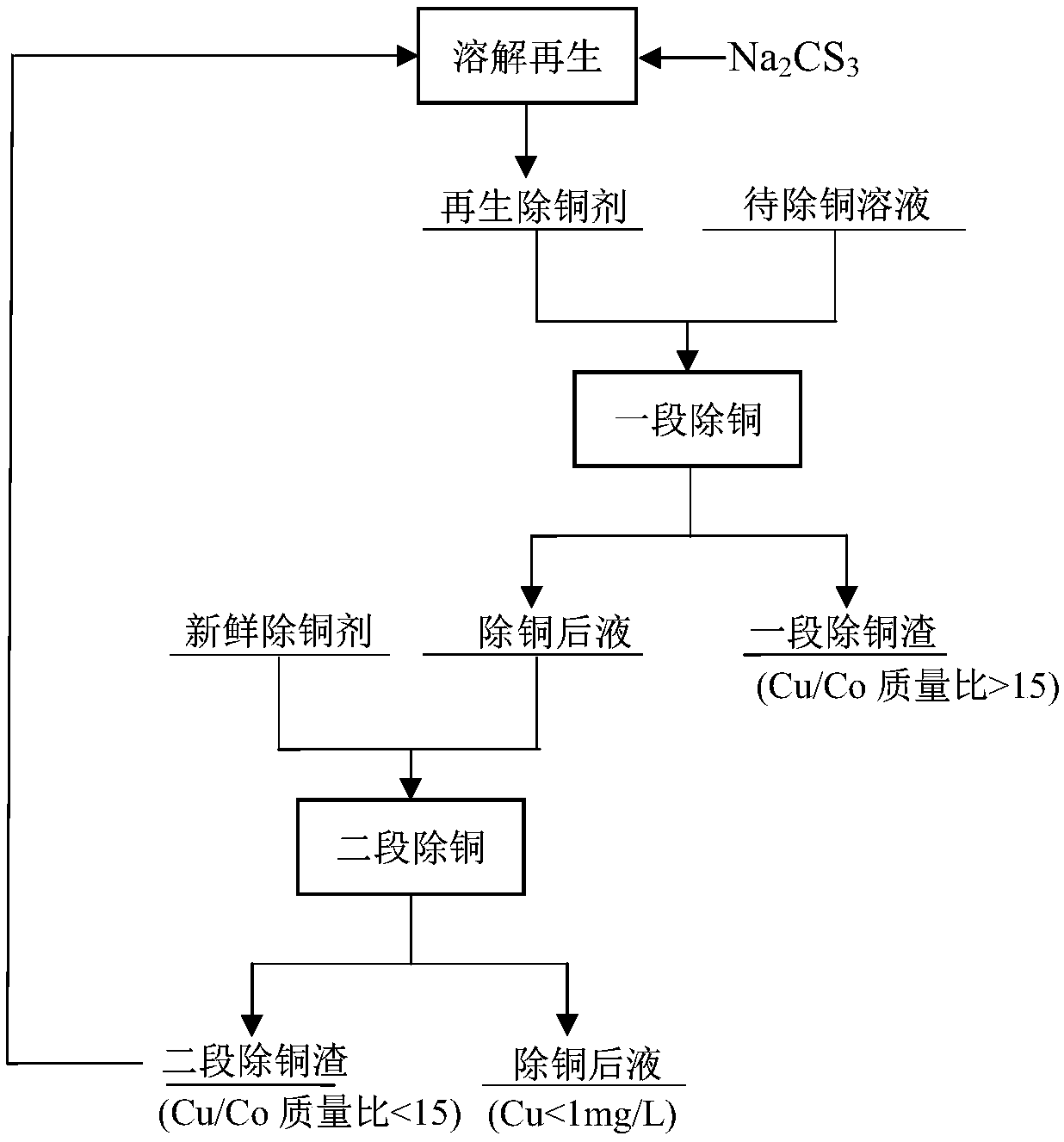

Method for deeply removing copper from cobalt salt solution

The invention relates to a method for deeply removing copper from a cobalt salt solution. A two-stage copper removal technology is adopted for removing copper from a cobalt chloride solution. A regenerated copper removal agent used in a first stage of copper removal is sourced from copper removal slag produced by a second stage of the copper removal, and finally qualified copper slag is discharged; and cobalt thiocarbonate is added in the second stage of the copper removal, so that a qualified copper-removed liquid is produced. The method provided by the invention has the advantages that the characteristic that the copper removal slag can be regenerated into the copper removal agent is fully utilized, copper concentration can be reduced to below 1mg / L, and copper removal slag with the copper-cobalt ratio higher than 15 / 1 is obtained.

Owner:CENT SOUTH UNIV

Automatic packaging method for flour

InactiveCN105883110AIntelligent, efficient and fast packagingNot effectivelyWrapper twisting/gatheringSolid materialEngineeringPressure sensor

The invention discloses an automatic packaging method for flour. The automatic packaging method for flour comprises the steps of S1, loading: flour required to be packaged is poured into a loading device, a switch of the loading device is switched on, a stirring drying device in the loading device operates to stir the flour for 5 to 10 min and dry and heat the flour for 5 to 10 min to prevent the flour from caking, and a sealing plate of the loading device is opened to enable the flour to enter a feeding device; and S2, feeding: the flour to be packaged is poured into a loading groove in the feeding device, a pressure sensor in the loading groove senses the mass of the entering flour, when the mass pressure of the flour is larger than the bearing strength of a baffle plate, the baffle plate at the bottom of the loading groove is opened, a feeding sealing plate is tightly closed, the flour drops into packaging bags, and the packaging bags containing flour are pushed into a bag clamping device. According to the automatic packaging method for flour, the pressure sensor controls the mass of the flour packaged in the packaging bags, so that the mass of the flour in all the packaging bags is the same, and the intelligent, efficient and fast flour packaging is achieved.

Owner:安徽蓝盈食品股份公司

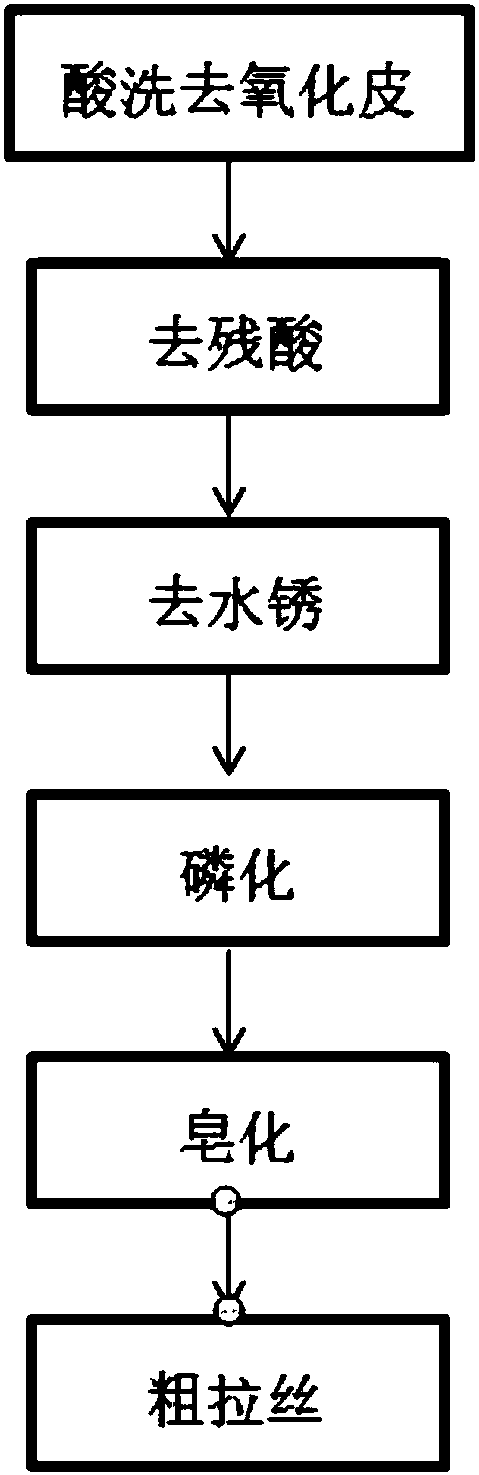

Pretreatment technology of hydraulic plunger workpiece

InactiveCN108531920APickling doesn't work wellNot effectivelyMetallic material coating processesProcess efficiency improvementEngineeringTherapeutic effect

The invention discloses a pretreatment technology of a hydraulic plunger workpiece. The pretreatment technology of the hydraulic plunger workpiece comprises the following steps of step 1.1, pickling for descaling; step 1.2, residual acid removal; step 1.3, scale removal; step 1.4, phosphorization; step 1.5, saponification; and step 1.6, coarse wire drawing. The pretreatment technology of the hydraulic plunger workpiece is accurate in control and good in treatment effect.

Owner:SANMEN TONGSHUN RIVET

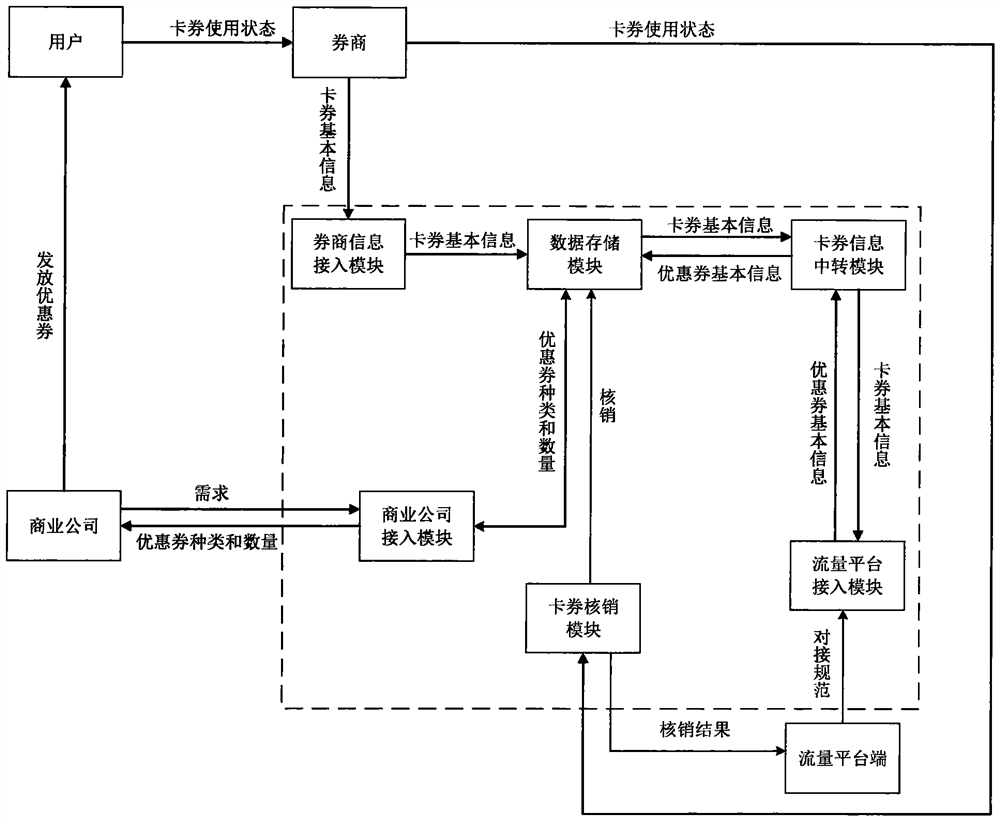

Multi-brokerage and multi-platform-oriented coupon sharing and verification system and method

PendingCN114331541ASingle transmission pathHigh dissemination costsMarketingComputer networkEngineering

The invention relates to a card and coupon sharing and cancel-after-verification system and method, in particular to a card and coupon sharing and cancel-after-verification system and method oriented to multiple securities traders and multiple platforms. Existing broker cards and coupons are single in propagation path, high in propagation cost and poor in effect, and only cards and coupons subordinate to the broker can be propagated, the broker access module in the application can integrate different types of cards and coupons subordinate to a plurality of brokers, and different brokers only need to access basic information of the cards and coupons; according to the method, the basic information of the cards and coupons of different securities traders is integrated to generate the uniquely identified coupons in the flow platform end for different commercial companies to use, the propagation effect is good, the number of buyers is large, and audiences are wide.

Owner:深圳微应科技有限公司

Setting machine flue gas treatment device

InactiveCN110694367AScientific and reasonable structureEasy to useGas treatmentDispersed particle filtrationActivated carbonInterference fit

The invention discloses a setting machine flue gas treatment device. The setting machine flue gas treatment device comprises a lower box body and an upper box body, a groove block is fixedly connectedto the bottom of the inner wall of the lower box body; a filter plate is in clearance fit with the inner wall of a box body opening, the outer wall of the top of the filter plate is sleeved with a rubber plug, the outer wall of the rubber plug is in interference fit with the inner wall of the box body opening, the bottom of the filter plate is in clearance fit with the inner wall of a groove of the groove block, and the top of the filter plate is fixedly connected with a handle. According to the setting machine flue gas treatment device, the filter plate, the rubber plug and the box body opening are matched; activated carbon plates should be replaced; through cooperation between a support and rolling wheels, when the filter plate is installed, rapid positioning can be conducted, and the problems that the filter plate cannot be vertically and fixedly installed, and consequently the effect is poor when the filter plate is used for filtering flue gas is solved.

Owner:湖州荣大环境科技有限公司

A method for deep copper removal in cobalt salt solution

Owner:CENT SOUTH UNIV

Porous organic filter and preparation method thereof

ActiveCN109224882ASinterability meetsProper adjustment of sintering characteristicsWaste water treatment from ceramic industriesUltrafiltrationFiltrationEngineering

The invention discloses a porous organic filter and a preparation method thereof. The porous organic filter comprises two flat plates of which upper parts are provided with grooves, wherein the two flat plates are oppositely spliced; a spliced groove is positioned between the two flat plates; four sides of the two flat plates are packaged; a groove part is embedded into an exhaust pipe; when the grooves of the flat plate are placed upward, ultra-high molecular weight polyethylene with different particle sizes is sequentially distributed with powder to form a microporous filtration layer, a mesoporous filter layer and a macroporous filter layer; the grooves are positioned in the maicroporous filtration layer. The preparation method comprises the following steps: carrying out modifying treatment on the ultra-high molecular weight polyethylene of the microporous filtration layer in advance; then distributing powder in a die by using the ultra-high molecular weight polyethylene with the different particle sizes according to the needs; carrying out heat treatment and then demolding to obtain organic plates with grooves; finally, packaging the two plates with the grooves to form a wholeand embedding the whole into the exhaust pipe to obtain a suction filtration type filter. The filter disclosed by the invention can intercept particles with the sizes of 5 mum or above and has a greater flux.

Owner:XIANNING NANBO PHOTOELECTRIC GLASS CO LTD

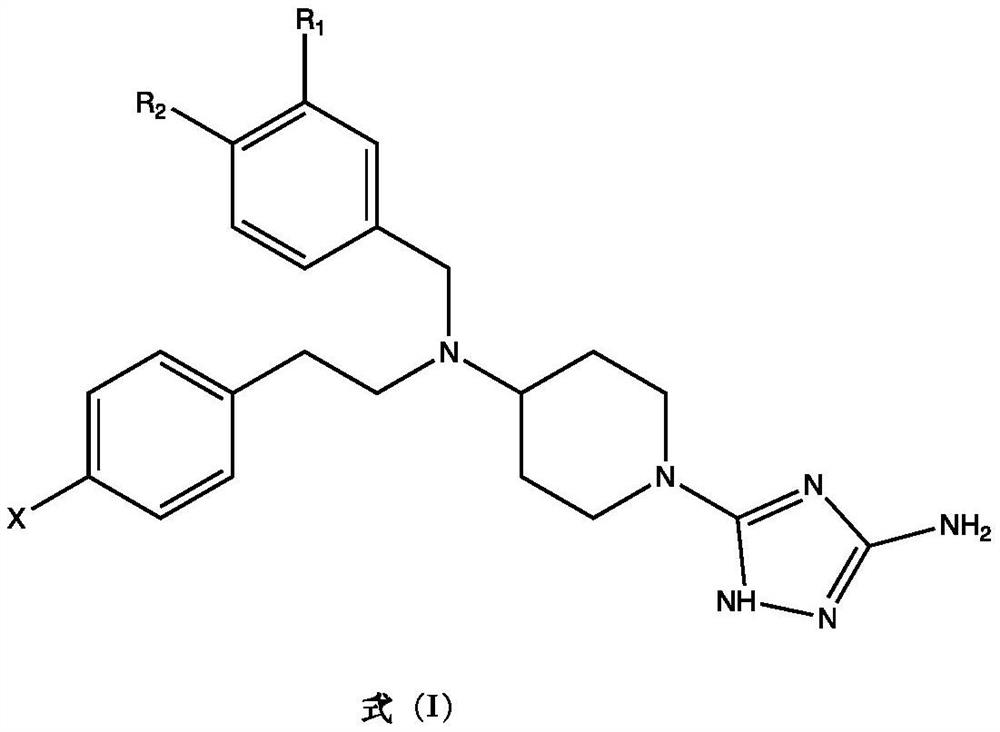

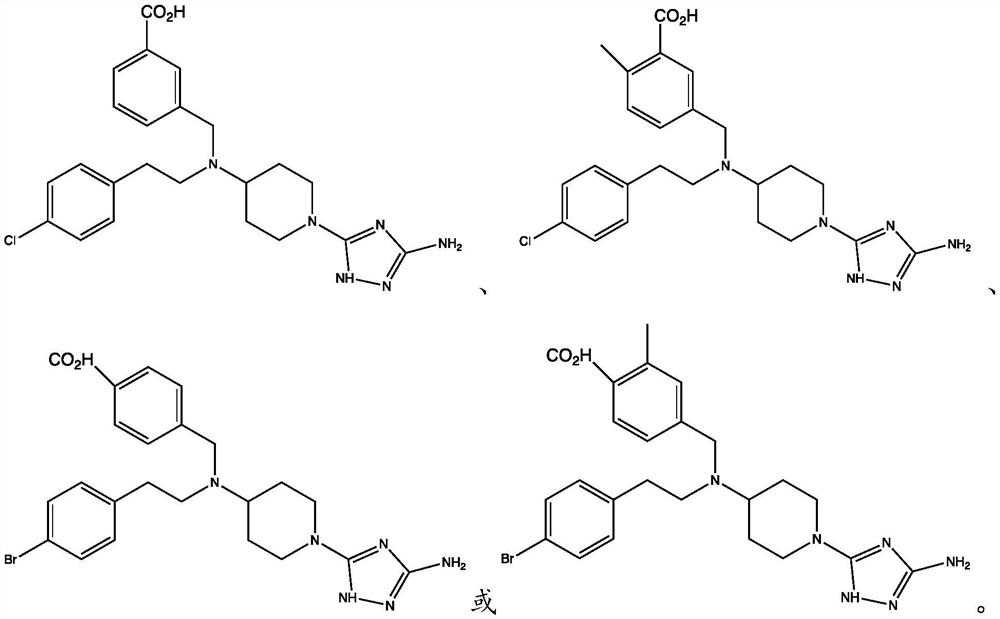

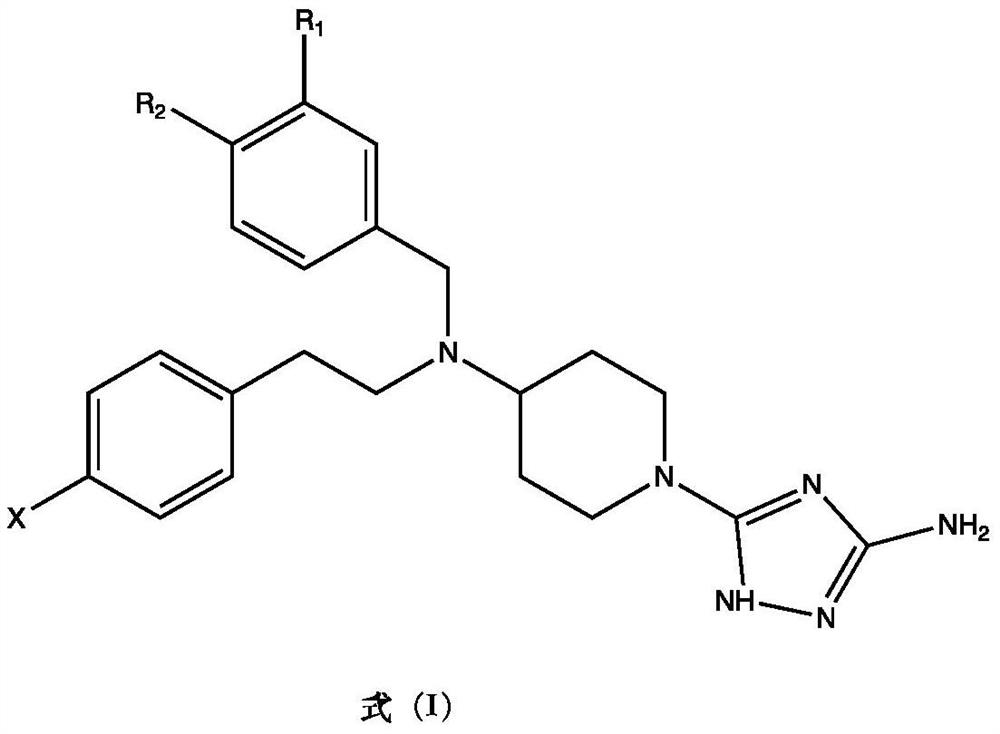

Plant fungicide for preventing and treating banana wilt

ActiveCN111732571AImprove qualityGreat potential for research and market applicationsBiocideOrganic chemistryPlant fungiBacilli

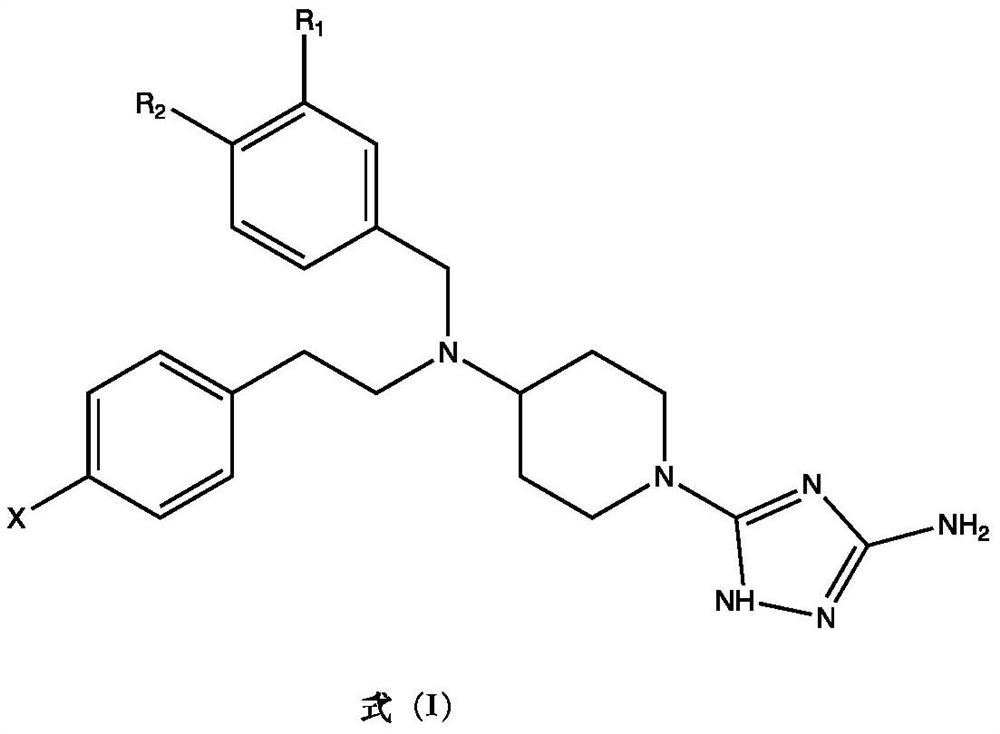

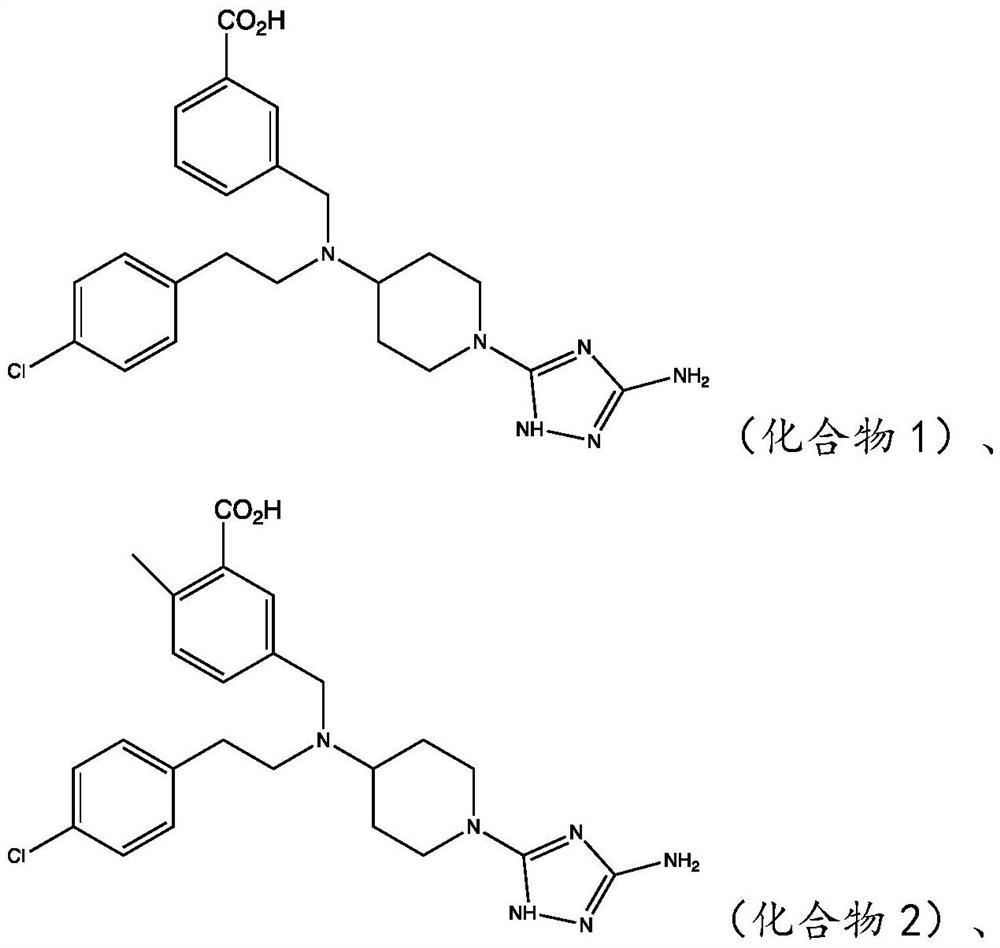

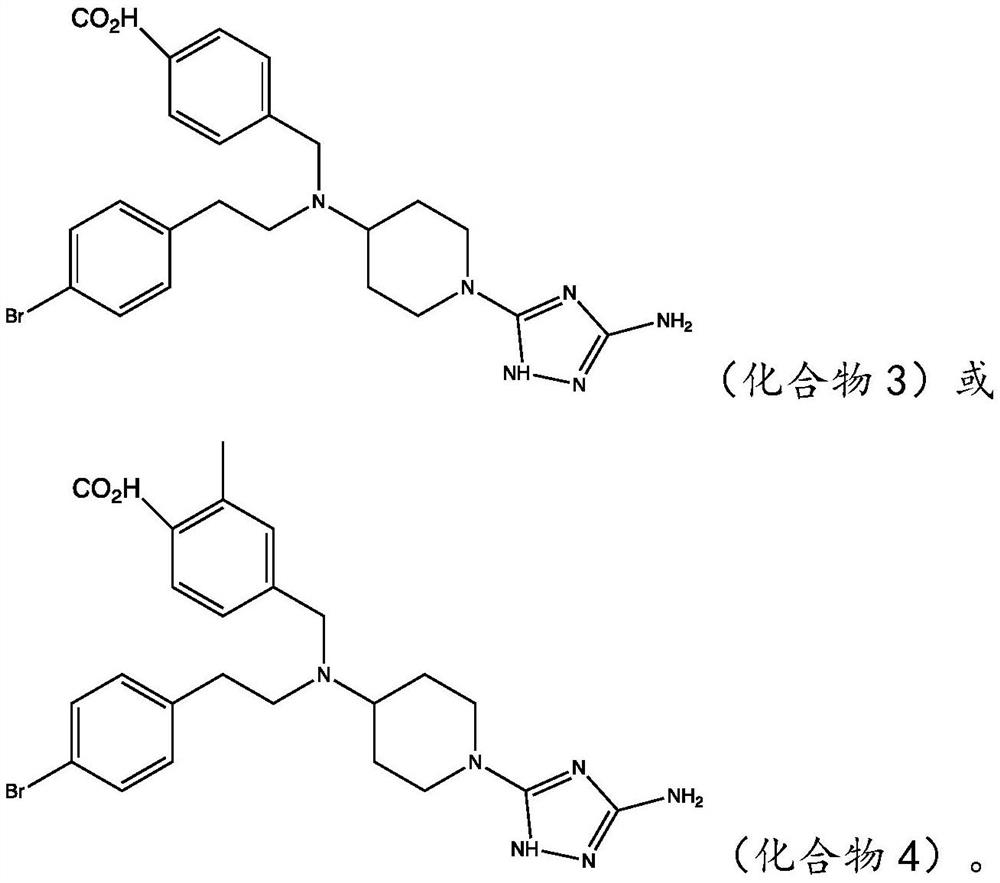

The invention provides a plant fungicide which is used for preventing and treating banana wilt and contains an amino triazole compound. The amino triazole compound provided by the invention has the effect of inhibiting a plant pathogenic fungus fusarium oxysporum f.sp. cubense, and has a certain potential in the aspect of preventing and treating banana wilt caused by the fusarium oxysporum f.sp. cubense. The formula (I) is shown in the specification. In addition, the invention further provides a plant fungicide containing the amino triazole compound and bacillus amyloliquefaciens, and the plant fungicide has a synergistic effect in the aspect of preventing and treating banana wilt caused by fusarium oxysporum f.sp.cubense.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Traditional Chinese medicine composition for preventing and treating gout and preparation method of traditional Chinese medicine composition

InactiveCN107898948ASave raw materialsReduce purchasesSkeletal disorderFood scienceSugarOral solutions

The invention relates to a traditional Chinese medicine composition for preventing and treating gout. The traditional Chinese medicine composition is prepared from the following components in parts byweight: 1-60 parts of basil, 18 parts of lotus leaves, 1-20 parts of pseudobulb of appendiculate cremastra, 1-30 parts of ramie flower and 1-40 parts of crotalaria sessiiflora. Pharmaceutical preparations are as follows: dosage forms such as capsules, pills, oral solutions, tablets, decoctions and powder prepared by virtue of production processes in traditional Chinese medicine production in theprior art. White granulated sugar, sorbitol and ascorbic acid are added into the formula and are prepared into a beverage by virtue of a processing method in the prior art.

Owner:邹松涛

Optimized production method of Tri (tribromophenyl) cyanurate

ActiveCN103275025BInhibitionSuppress generationOrganic chemistryOrganic compound preparationChlorobenzeneDistillation

Owner:山东寿光神润发海洋化工有限公司

A method for rapidly separating mites and feed

The invention provides a method for quickly separating mites and feed. The steps are to take an appropriate amount of samples that need to be collected from the mites, and use sampling sieves with different apertures according to the size of the mites to perform preliminary screening; the samples after the preliminary screening are evenly spread on the Turn over the plastic plate after standing still, a large number of mites and a small part of feed debris will be adsorbed on the plastic plate; put the plastic plate with the sample after preliminary treatment upside down on the finer sampling sieve, Gently tap with your hand or a small wooden stick to make all the samples fall into the sampling sieve. After standing still, invert the sampling sieve, the residual feed will fall off, and the rest in the sieve is all the required mites, basically no feed debris.

Owner:NANCHANG UNIV

Preparation process of antioxidant 1425

PendingCN112645980AReduce cumbersome processLow costOrganic compound preparationGroup 5/15 element organic compoundsDistillationProcess engineering

The invention relates to the technical field of antioxidants, and discloses a preparation process of an antioxidant 1425. According to the preparation process of the antioxidant 1425, mixed raw material mixed liquid is conveyed into a distillation tower to be distilled after being filtered, the raw material mixed liquid in the distillation tower is heated through high temperature, sublimated fog water is conveyed into a condensation pipe for cooling through a pipeline, and the cooled water is processed and stored through a low-boiling-point component storage tank; a raw material pump machine and a special conveying pump machine are added in the steps, conveying of the pump machines is utilized, and a valve is arranged in a pipeline of a final finished product, so that it is guaranteed that internal antioxidant is isolated from a human body, and the situation that the effect of the antioxidant is poor due to the fact that external factors influence components of the internal antioxidant is avoided; and by means of process distillation, traditional process complexity is reduced, the cost is reduced, the application range is widened, and the production efficiency is improved.

Owner:SUQIAN RUIXING CHEM CO LTD

A plant fungicide for preventing and treating banana wilt

ActiveCN111732571BImprove qualityNot effectivelyBiocideOrganic chemistryBiotechnologyBacillus amyloliquefaciens

The invention provides a plant fungicide containing aminotriazole compounds for preventing and treating banana wilt. The aminotriazole compounds provided by the invention have the effect of inhibiting the plant pathogenic fungus Fusarium oxysporum f.sp. cubic (Fusarium oxysporum f.sp.cubense), and are used in the prevention and treatment of banana wilt caused by Fusarium oxysporum f.sp.cubense. has some potential. In addition, the present invention also provides a plant fungicide comprising an aminotriazole compound and Bacillus amyloliquefaciens, which has a synergistic effect in preventing and treating banana wilt caused by Fusarium oxysporum cuba-specific.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

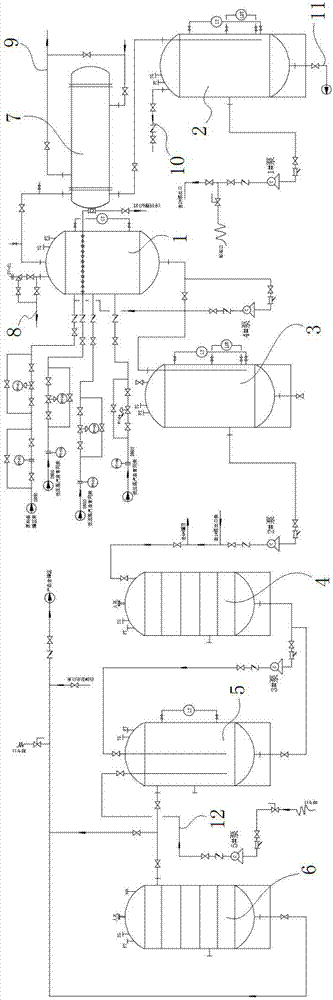

Deodorization cleaning treatment system for lightweight coal tar

InactiveCN107541246ANot effectivelyTreatment with plural serial refining stagesAfter treatmentNitrogen

The invention provides a deodorization and cleaning treatment system for light coal tar. The technology uses multiple tanks with different treatment functions as modules, and a corresponding pipeline system is designed according to the material flow route. Specifically, the light coal tar first enters the steam stripping tank to remove ammonia and 1.5t / h aromatic compounds in the light coal tar, and then enters the static separation tank to separate the aromatic compounds and Water, used for the finishing of aromatics; at the same time, the 6.5t / h light coal tar discharged from the bottom of the steam stripping tank is dehydrated in the static dehydration tank, and then passes through the desulfurization resin tank, desulfurization catalyst tank, and solid treatment agent tank in sequence , which can effectively remove hydrogen sulfide, mercaptan and some colloid components, so that the color and smell of the oil are significantly improved. After purification, the Saybolt color number is greater than 30, and the sulfur and nitrogen are less than 50ppm. The treated light coal tar can be used as the raw material of the reforming unit, and the whole unit operates under normal temperature and pressure, and the catalyst can be regenerated.

Owner:SHANDONG BAOTA NEW ENERGY CO LTD

Deceleration processing equipment based on material stirring

InactiveCN112473432ANot effectivelyTransportation and packagingRotary stirring mixersProcess engineeringMaterials processing

The invention discloses a deceleration processing equipment based on material stirring. The deceleration processing equipment comprises a material processing machine, a stirring cavity is formed in the upper side in the material processing machine, a material processing device is arranged in the stirring cavity, processing materials are firstly stored and then stirred at different speeds, the processing materials are firstly put into the stirring cavity, and then mixed through the stirring device, products with different viscosities are obtained by controlling the stirring speed through the stirring device, a common stirring device lacks a speed controller and is difficult to control the stirring speed, common material products are stirred manually, and the viscosity requirements of the products are difficult to control accurately. in addition, large-batch products are difficult to process, certain defects exist in manual management, and the effect is poor.

Owner:绍兴欢歌智能科技有限公司

Hair perming device capable of controlling temperature and preventing local overheating

The invention discloses a hair perming device capable of controlling temperature and preventing local overheating. The device comprises a machine body, a machine box is fixedly arranged at the upper end of the machine body, a fixing block is fixedly arranged in a cavity in the machine box, a spherical groove is formed in the fixing block, a rotating ball is rotationally arranged in the spherical groove in the fixing block, a cylindrical cavity is formed in the rotating ball, the temperature of the head of a customer in all directions can be monitored in the using process, when the temperature of a certain direction is too high, the distance between a heat source and the head in the direction is increased, the situation that the customer feels uncomfortable or even hurt due to local overheating is avoided, meanwhile when the temperature of a certain direction is continuously low, the distance between the heat source and the head is properly reduced, and the poor effect of the perm liquid medicine caused by too low temperature is avoided.

Owner:义乌市萧成化妆品有限公司

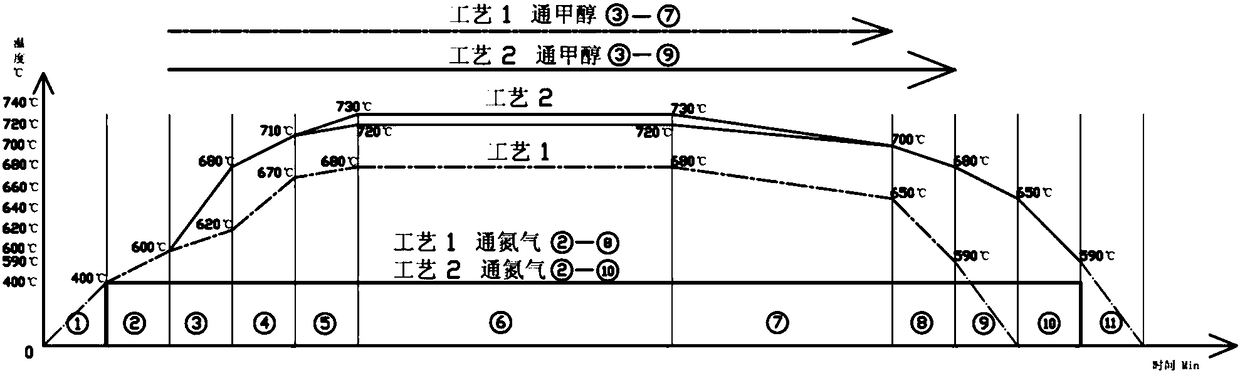

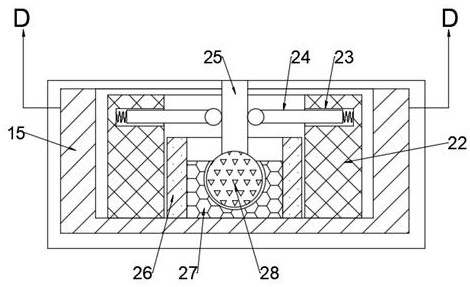

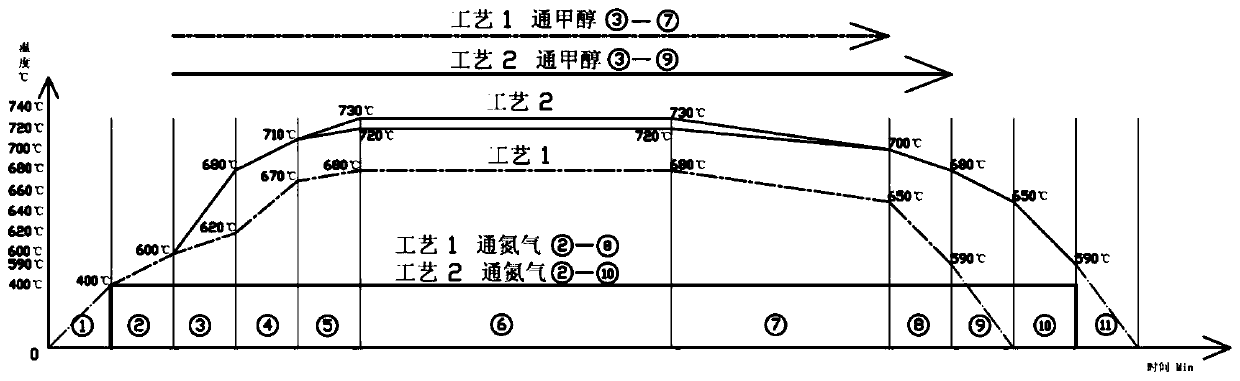

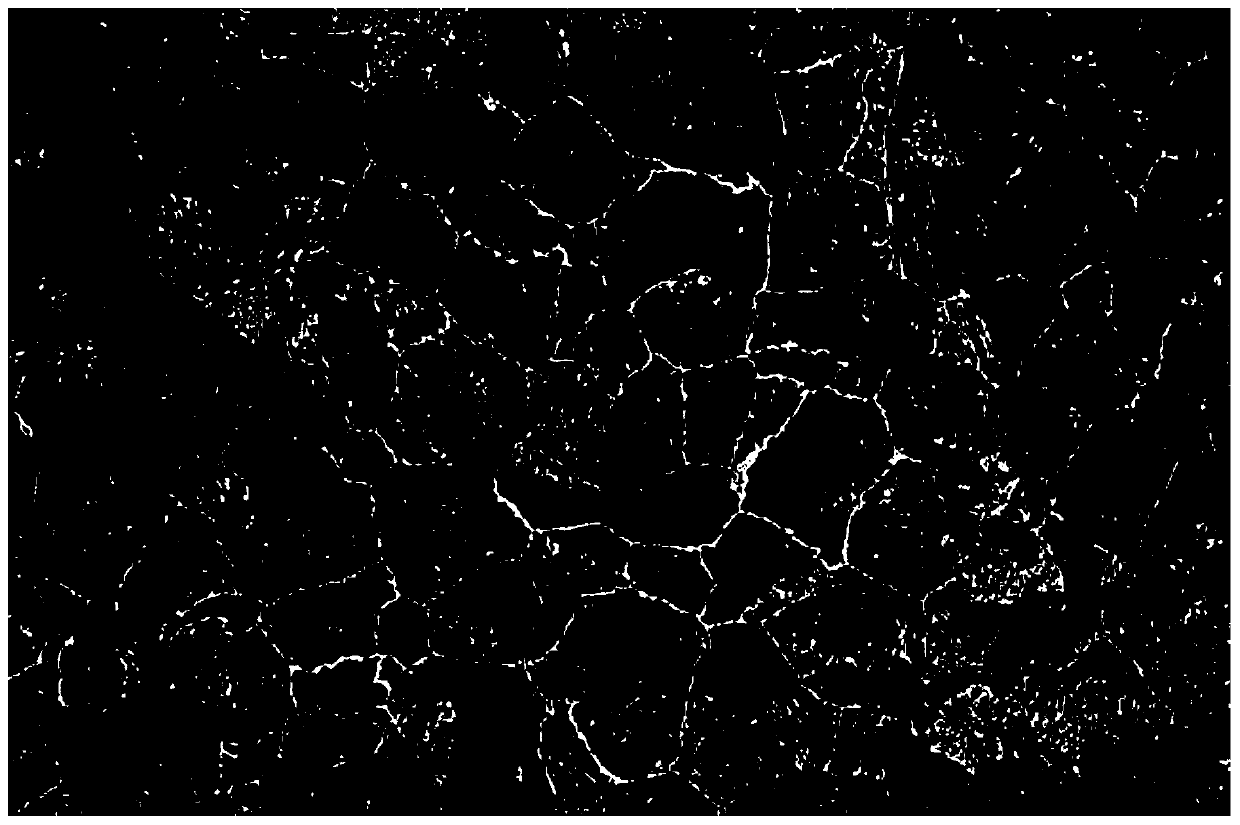

A system for heat treatment of hydraulic plunger workpiece

ActiveCN108559830BPickling doesn't work wellNot effectivelyEdge grinding machinesPolishing machinesThermodynamicsEngineering

The invention discloses a system for performing thermal treatment on a hydraulic plunger piston workpiece. The system comprises the following steps of: 1.1) removing oxide skin by pickling; 1.2) removing residual acid; 1.3) removing scale incrustation; 1.4) phosphating; 1.5) saponifying; 1.6) performing rough wire drawing; 1.7) nodulizing and thermally circulating; 1.8) cleaning materials; 1.9) performing fine wire drawing; 1.10) performing cold upsetting; 1.11) reshaping products; 1.12) quenching; 1.13) vibrating and grinding; 1.14) demagnetizing; 1.15) performing surface treatment; and 1.16)screening. The invention provides a system for efficiently performing thermal treatment on the hydraulic plunger piston workpiece.

Owner:SANMEN TONGSHUN RIVET

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com