Porous organic filter and preparation method thereof

A filter and organic technology, applied in the field of porous organic filter and its preparation, can solve the problems of complex process, pollution, large quantity, etc., and achieve the effect of simple process, simplified process and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of Modifier Solution

[0030] According to the mass ratio, deionized water: WD-20 silicone coupling agent = 20:1 for mixing. Stir on a magnetic stirrer for about 1 h. The obtained modifier solution was used for later use.

[0031] 2. Modification of 400 mesh UHMWPE powder

[0032] Mix according to the ratio of 400-mesh UHMWPE powder:modifier solution=5:1, and stir with a mixer for more than 0.5h to ensure that the 400-mesh UHMWPE powder can be completely wrapped by the silicone coupling agent solution. After the stirring is completed, the modified UHMWPE powder is dried in an oven at 70°C for 5 hours. A completely dried modified UHMWPE powder is obtained.

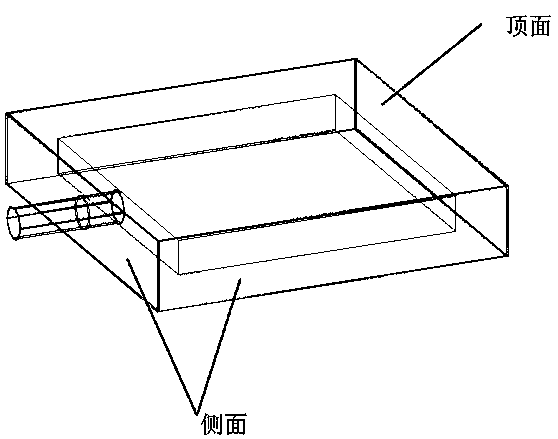

[0033] 3. Mold pretreatment

[0034] Paste a layer of polytetrafluoroethylene film with a thickness of less than 0.3mm inside the Fe mold to act as a release agent and a release agent to avoid the impact of the metal mold on the performance of the UHMWPE powder. After pretreatment, the molds are ...

Embodiment 2

[0042] 1. Preparation of modifier solution

[0043] According to the mass ratio, deionized water: WD-60 silicone coupling agent = 50: 1 for mixing. Stir on a magnetic stirrer for about 1 h. The obtained modifier solution was used for later use.

[0044] 2. Modification of 400 mesh UHMWPE powder

[0045] Mix according to the ratio of 400-mesh UHMWPE powder:modifier solution=4:1, and stir with a mixer for more than 0.5h to ensure that the 400-mesh UHMWPE powder can be completely covered by the silicone coupling agent solution. After the stirring is completed, the modified UHMWPE powder is dried in an oven at 70°C for 5 hours. A completely dried modified UHMWPE powder is obtained.

[0046] 3. Mold pretreatment

[0047] Paste a layer of polytetrafluoroethylene film with a thickness of less than 0.3mm inside the Fe mold to act as a release agent and a release agent to avoid the impact of the metal mold on the performance of the UHMWPE powder. After pretreatment, the molds are...

Embodiment 3

[0055] 1. Preparation of modifier solution

[0056] According to the mass ratio, deionized water: WD-70 silicone coupling agent = 40: 1 for mixing. Stir on a magnetic stirrer for about 1 h. The obtained modifier solution was used for later use.

[0057] 2. Modification of 400 mesh UHMWPE powder

[0058] Mix according to the ratio of 400-mesh UHMWPE powder:modifier solution=6:1, and stir with a mixer for more than 0.5h to ensure that the 400-mesh UHMWPE powder can be completely wrapped by the silicone coupling agent solution. After the stirring is completed, the modified UHMWPE powder is dried in an oven at 70°C for 5 hours. A completely dried modified UHMWPE powder is obtained.

[0059] 3. Mold pretreatment

[0060] Paste a layer of polytetrafluoroethylene film with a thickness of less than 0.3mm inside the Fe mold to act as a release agent and a release agent to avoid the impact of the metal mold on the performance of the UHMWPE powder. After pretreatment, the molds are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

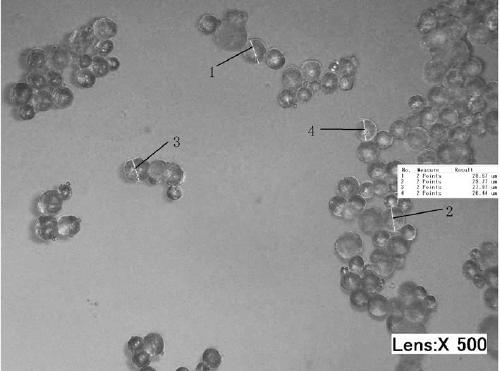

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com