Porous organic filter and preparation method thereof

A filter and organic technology, applied in the field of porous organic filters and their preparation, can solve a large number of problems, complicated processes, pollution, etc., and achieve the effects of simple process, simplified process, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of Modifier Solution

[0030] According to the mass ratio, deionized water: WD-20 silicone coupling agent = 20:1 for mixing. Stir on a magnetic stirrer for about 1 h. The obtained modifier solution was used for later use.

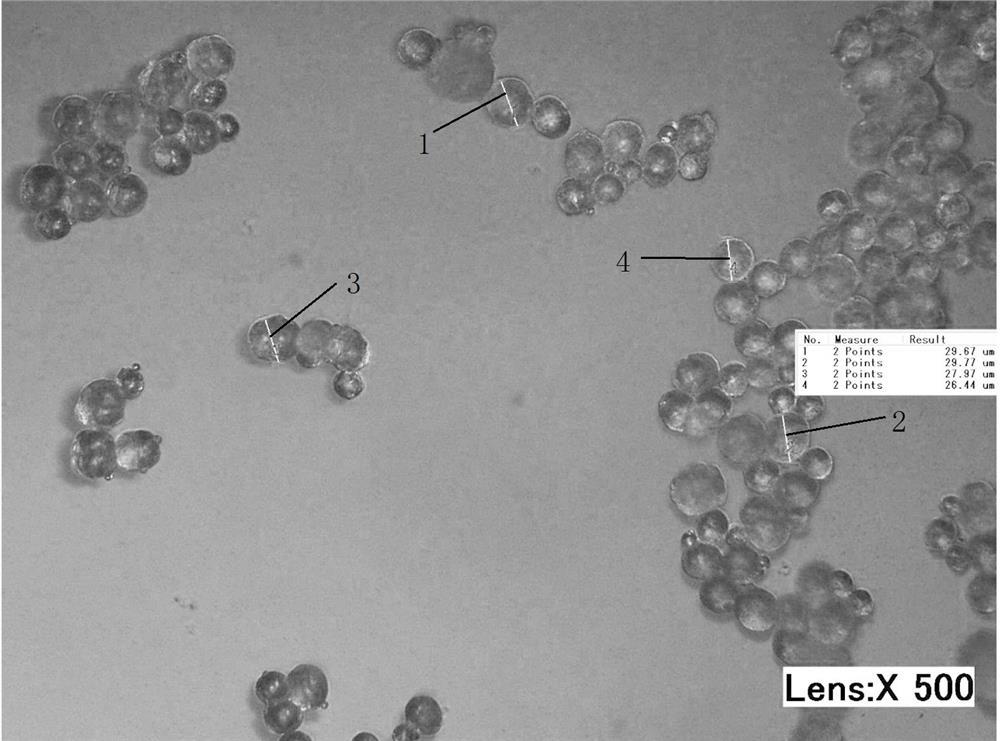

[0031] 2. Modification of 400 mesh UHMWPE powder

[0032] Mix according to the ratio of 400-mesh UHMWPE powder:modifier solution=5:1, and stir with a mixer for more than 0.5h to ensure that the 400-mesh UHMWPE powder can be completely wrapped by the silicone coupling agent solution. After the stirring is completed, the modified UHMWPE powder is dried in an oven at 70°C for 5 hours. A completely dried modified UHMWPE powder is obtained.

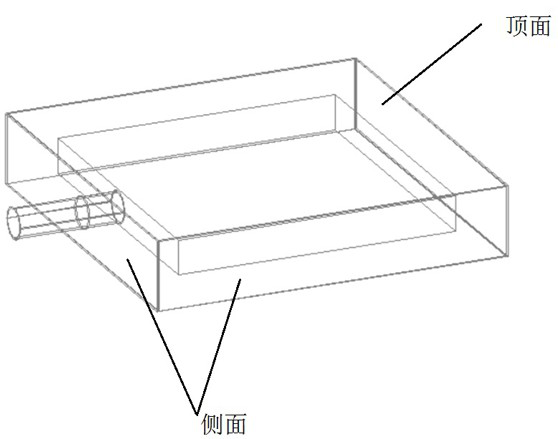

[0033] 3. Mold pretreatment

[0034] Paste a layer of polytetrafluoroethylene film with a thickness of less than 0.3mm inside the Fe mold to act as a release agent and a release agent to avoid the impact of the metal mold on the performance of the UHMWPE powder. After pretreatment, the molds are ...

Embodiment 2

[0042] 1. Preparation of Modifier Solution

[0043] According to the mass ratio, deionized water: WD-60 silicone coupling agent = 50: 1 for mixing. Stir on a magnetic stirrer for about 1 h. The obtained modifier solution was used for later use.

[0044] 2. Modification of 400 mesh UHMWPE powder

[0045] Mix according to the ratio of 400-mesh UHMWPE powder:modifier solution=4:1, and stir with a mixer for more than 0.5h to ensure that the 400-mesh UHMWPE powder can be completely covered by the silicone coupling agent solution. After the stirring is completed, the modified UHMWPE powder is dried in an oven at 70°C for 5 hours. A completely dried modified UHMWPE powder is obtained.

[0046] 3. Mold pretreatment

[0047] Paste a layer of polytetrafluoroethylene film with a thickness of less than 0.3mm inside the Fe mold to act as a release agent and a release agent to avoid the impact of the metal mold on the performance of the UHMWPE powder. After pretreatment, the molds are...

Embodiment 3

[0055] 1. Preparation of Modifier Solution

[0056] According to the mass ratio, deionized water: WD-70 silicone coupling agent = 40: 1 for mixing. Stir on a magnetic stirrer for about 1 h. The obtained modifier solution was used for later use.

[0057] 2. Modification of 400 mesh UHMWPE powder

[0058] Mix according to the ratio of 400-mesh UHMWPE powder:modifier solution=6:1, and stir with a mixer for more than 0.5h to ensure that the 400-mesh UHMWPE powder can be completely wrapped by the silicone coupling agent solution. After the stirring is completed, the modified UHMWPE powder is dried in an oven at 70°C for 5 hours. A completely dried modified UHMWPE powder is obtained.

[0059] 3. Mold pretreatment

[0060] Paste a layer of polytetrafluoroethylene film with a thickness of less than 0.3mm inside the Fe mold to act as a release agent and a release agent to avoid the impact of the metal mold on the performance of the UHMWPE powder. After pretreatment, the molds are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com