Method for deeply removing copper from cobalt salt solution

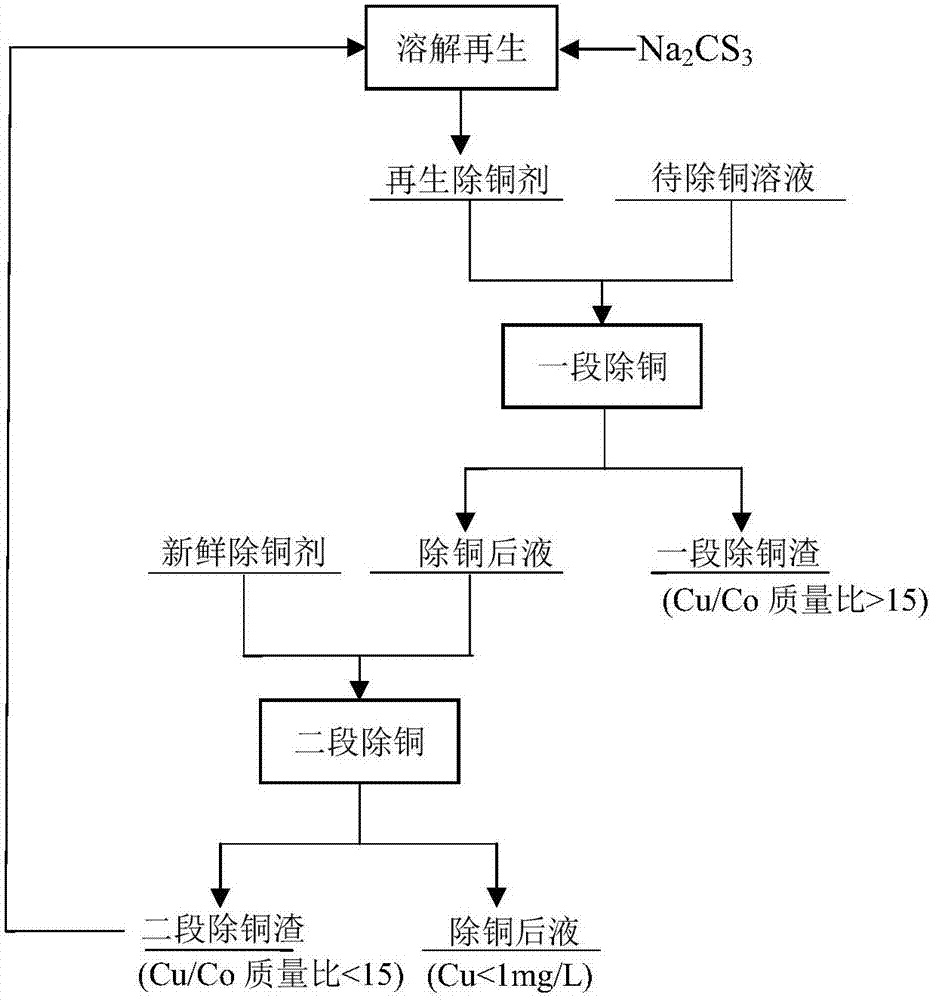

A solution and cobalt salt technology, applied in chemical instruments and methods, cobalt halides, cobalt compounds, etc., can solve the problem of copper removal slag being difficult to deal with, and achieve the effects of improving treatment effect, convenient operation and improving recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare 0.01mol / L Na 2 CS 3 solution, according to the formula: Na 2 CS 3 Added molar weight=n×total copper molar weight in the copper removal liquid-the remaining Co molar weight in the slag, by the amount that n is 1.4, add Na 2 CS 3 Add the solution into the container containing the second-stage copper removal slag. The molar amount of Co remaining in the copper slag is 0.0003mol. After dissolving at 25°C for 5 minutes, press Na 2 CS 3 Add CoCl to 1.2 times the molar amount 2 , stirred and reacted for 15 minutes, the stirring speed was 500r / min, and a regenerated copper removing agent was obtained.

[0039] Select 60mL of copper removal solution (60g / LCo, 0.5g / LCu), the total molar amount of copper in the copper removal solution is 0.00047mol, add the above-mentioned regenerated copper removal agent to carry out a stage of copper removal, and carry out solid-liquid separation to obtain One stage of copper removal slag and one stage of copper removal liquid, the ...

Embodiment 2

[0044] Prepare 0.1mol / L Na 2 CS 3 solution, according to the formula: Na 2 CS 3 Added molar weight=n×total copper molar weight in the copper removal liquid-remaining Co molar weight in the slag, by the amount that n is 1.5, add Na 2 CS 3 Add the solution into the container containing the second-stage copper removal slag. The molar amount of Co remaining in the copper slag is 0.0003mol. After dissolving at 28°C for 30 minutes, press Na 2 CS 3 Add CoCl to 1.4 times the molar amount 2 , stirred and reacted for 20 minutes, the stirring speed was 700r / min, and a regenerated copper removing agent was obtained.

[0045] Select 60mL of copper removal solution (60g / LCo, 0.5g / LCu), the total molar amount of copper in the copper removal solution is 0.00047mol, add the above-mentioned regenerated copper removal agent to carry out a stage of copper removal, and carry out solid-liquid separation to obtain One stage of copper removal slag and one stage of copper removal solution, the ...

Embodiment 3

[0050] Prepare 1.5mol / L Na 2 CS 3 solution, according to the formula: Na 2 CS 3 Added molar weight=n×total copper molar weight in the copper removal liquid-remaining Co molar weight in the slag, by n being 1.6 times the amount of Na 2 CS 3 Add the solution into the container containing the second-stage copper removal slag, the molar amount of Co remaining in the copper slag is 0.0003mol, after dissolving at 30°C for 60min, press Na 2 CS 3 Add CoCl to 1.6 times the molar amount 2 , stirred and reacted for 30 minutes, the stirring speed was 800r / min, and a regenerated copper removing agent was obtained.

[0051] Select 60mg / L of copper removal solution (60g / LCo, 0.5g / LCu), the total molar amount of copper in the copper removal solution is 0.00047mol, add the above-mentioned regenerated copper removal agent to carry out a stage of copper removal and solid-liquid separation , obtain a section of copper removal slag and a section of copper removal solution, and the copper co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com