Patents

Literature

41results about How to "Stable melting point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

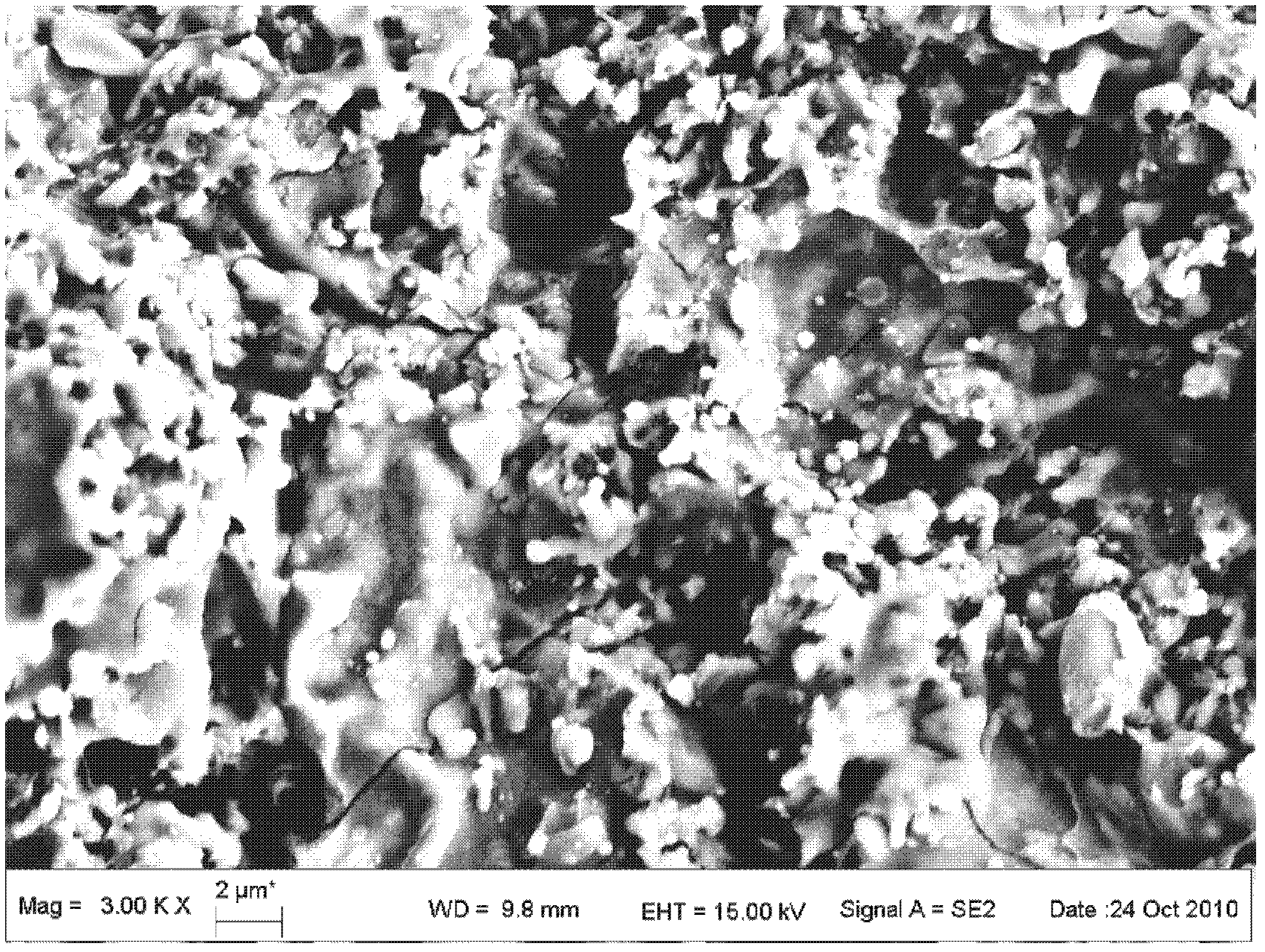

Carbon/carbon composite material ultrahigh temperature oxidation resistant coating and preparation method thereof

The invention discloses a carbon / carbon composite material ultrahigh temperature oxidation resistant coating. The coating comprises the following components, by volume, 40-60% of ZrB2, 15-25% of SiC, 15-20% of TaB2 and 10-15% of Sc2O3. In addition, the invention also provides a preparation method of the coating. According to the invention, TaB2 and Sc2O3 are added to make the melting point of an external layer oxidation product borosilicate glass be risen, the viscosity of the borosilicate glass be risen, the evaporation rate of the borosilicate glass be reduced, the oxygen dispersion coefficient of the borosilicate glass be reduced, an internal layer oxidation product ZrO2 phase be stable, the melting point of ZrO2 be risen, and the oxygen diffusion coefficient of ZrO2 be reduced, so thecoating can satisfy requirements of the ultrahigh temperature oxidation resistance of a carbon / carbon composite material, the coating can be sintered without applying a pressure through adding TaB2 and Sc2O3, the coating has the advantages of high combination strength, compactness, and good ultrahigh temperature mechanical property, and the preparation process has no damages to matrixes.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High-plasticity five-element refractory high-entropy alloy and preparation method thereof

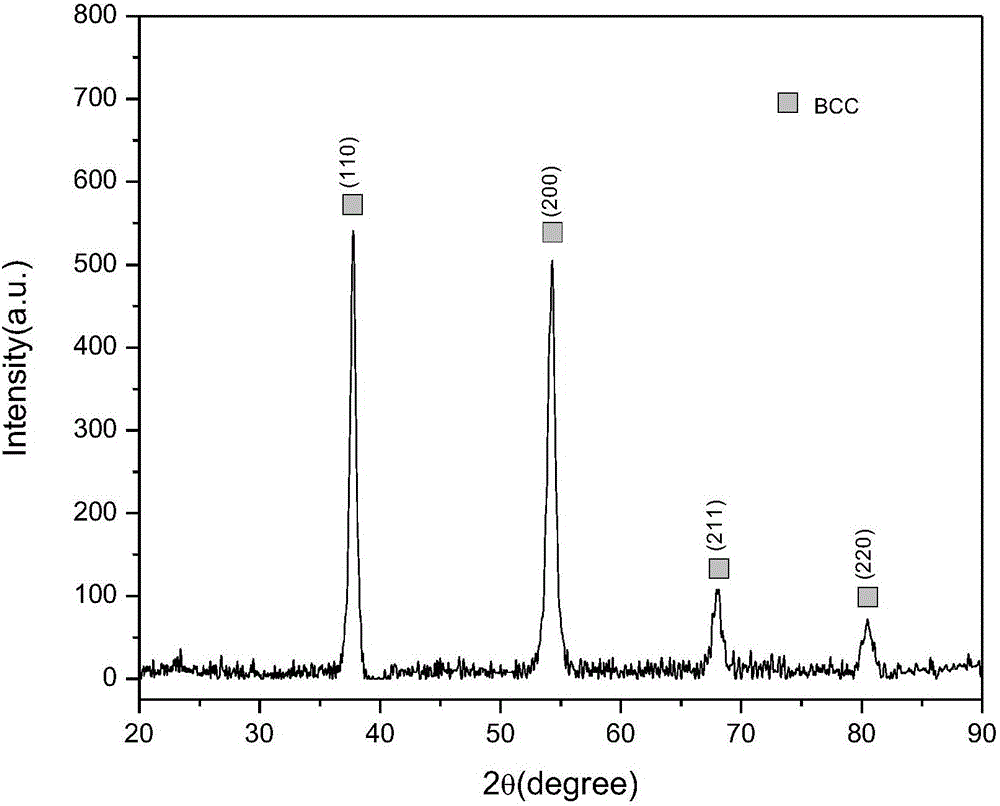

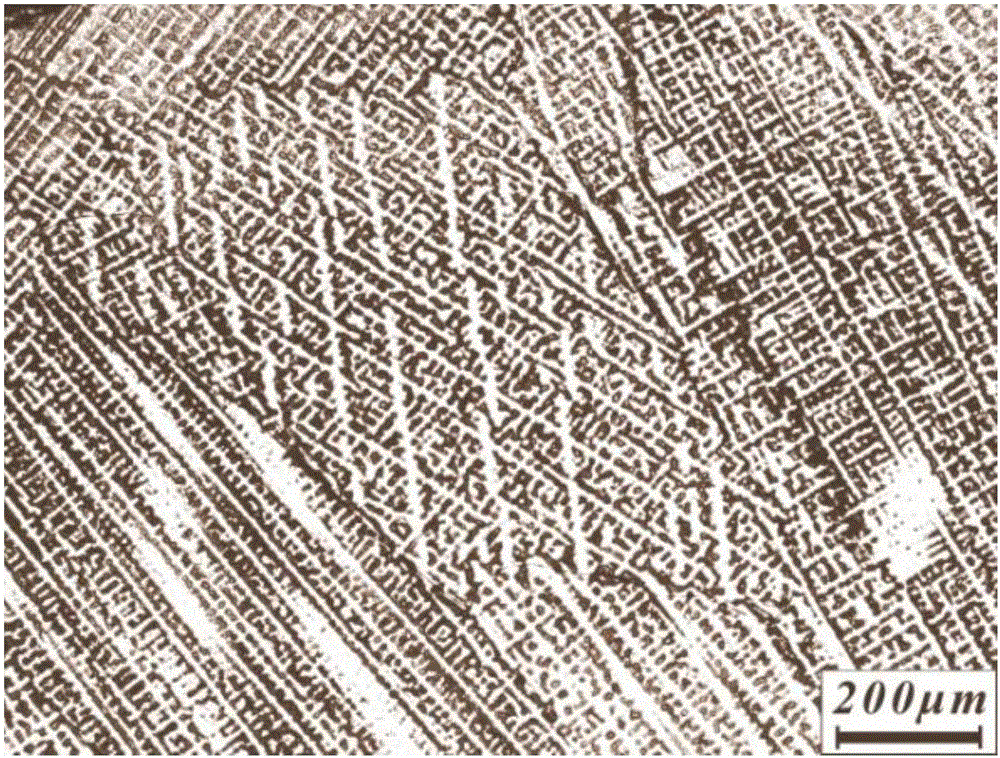

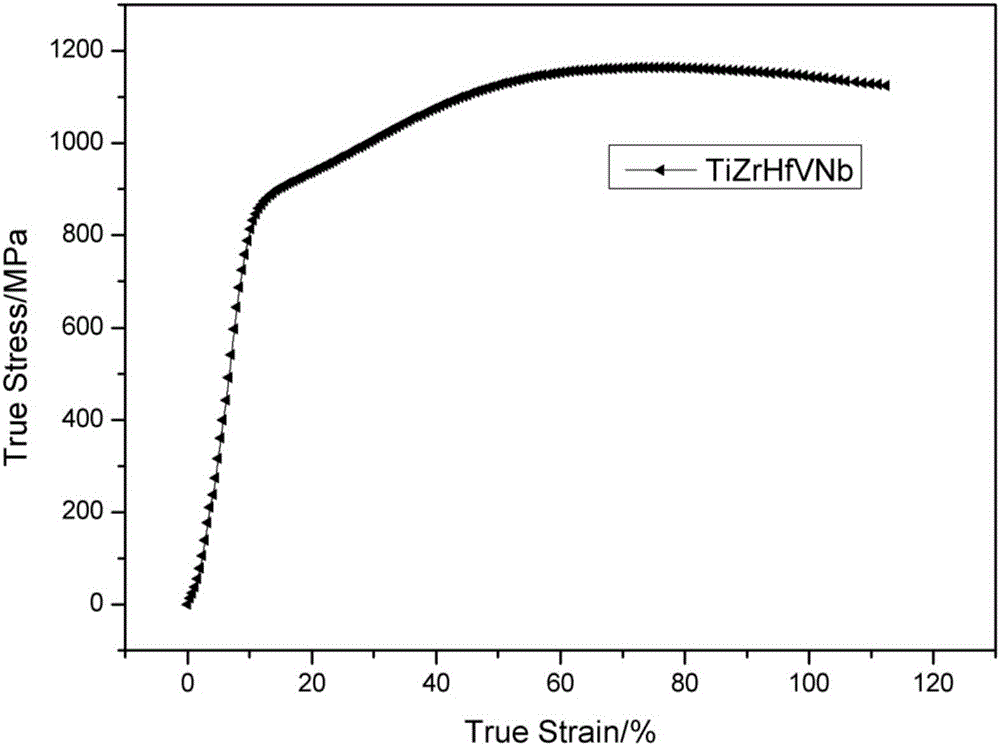

The invention relates to high-plasticity five-element refractory high-entropy alloy and a preparation method thereof and belongs to the field of metal materials. The high-entropy alloy is prepared from zirconium, titanium, hafnium, vanadium and niobium, wherein the molar weights of the zirconium, the titanium, the hafnium, the vanadium and the niobium are equal. The preparation method of the high-plasticity five-element refractory high-entropy alloy comprises the steps that the zirconium, the titanium, the hafnium, the vanadium and the niobium are placed in a water-cooling metal crucible in a melting point progressively-decreasing sequence, the element with the lowest melting point is placed at the bottom, and the element with the highest melting point is placed at the top; and arc striking smelting is conducted in an oxygen-free environment till the five elements are fully mixed, and the high-entropy alloy is obtained. The high-entropy alloy is of a single body-centered cubic structure, the yield strength of the high-entropy alloy is higher than 800 MPa, the tensile strength is over 1100 MPa, and the plastic strain is larger than 55%; and the large solid solubility between the elements is obtained, and a simple solid-solution phase is formed. The preparation method has the advantages that the power is high, the performance is table, operation is convenient, the melting point is high, the vacuum degree is high, and the quantity of impurities is small.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

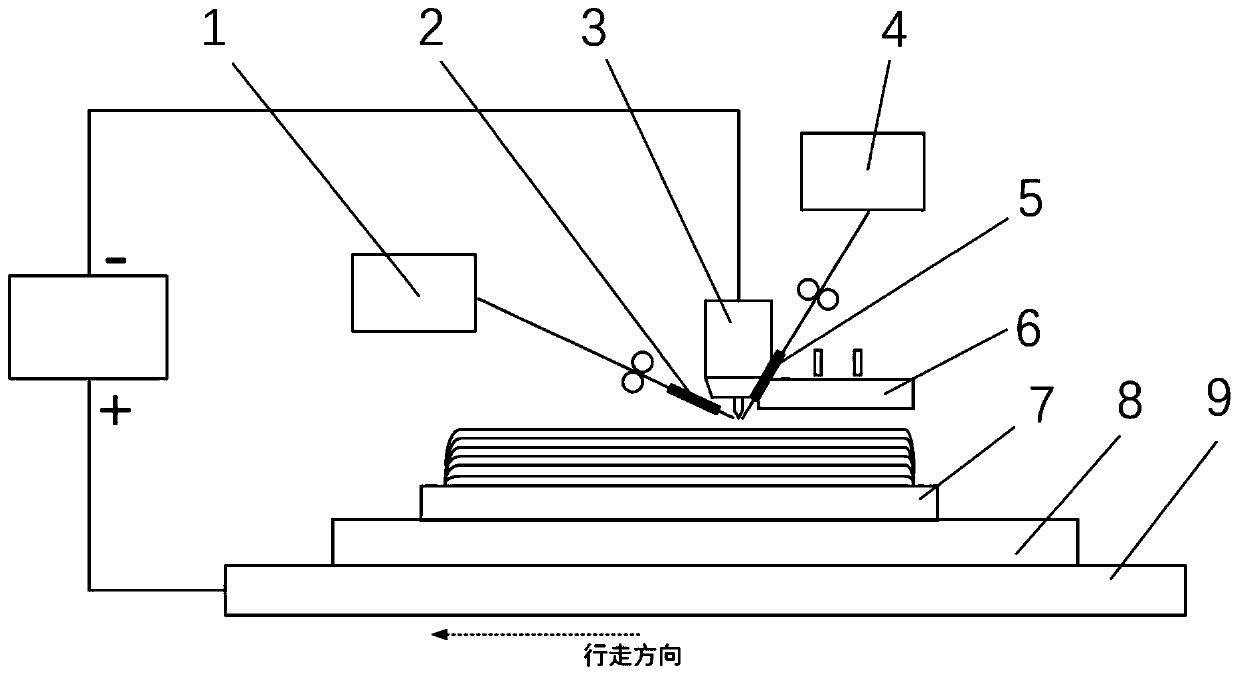

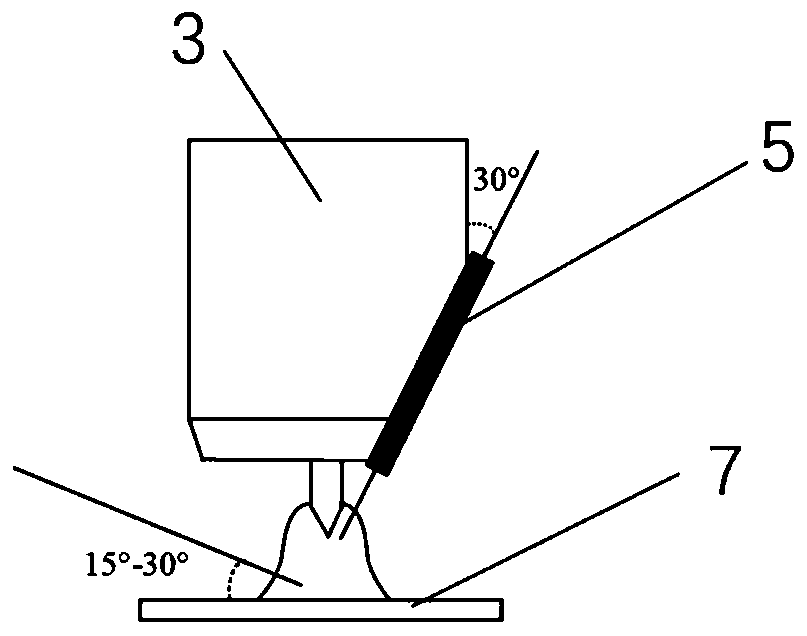

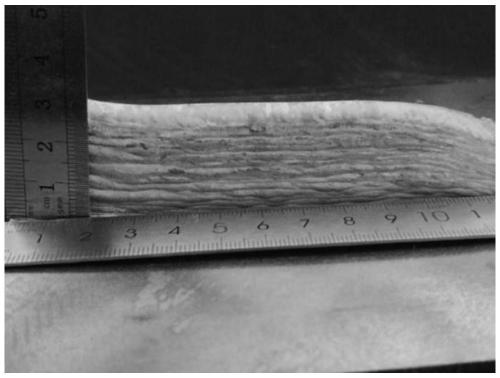

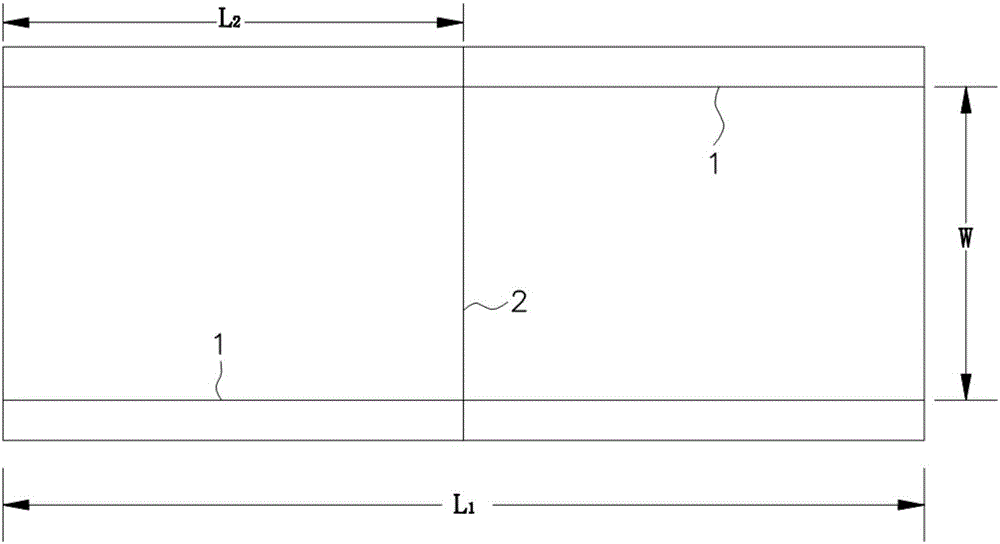

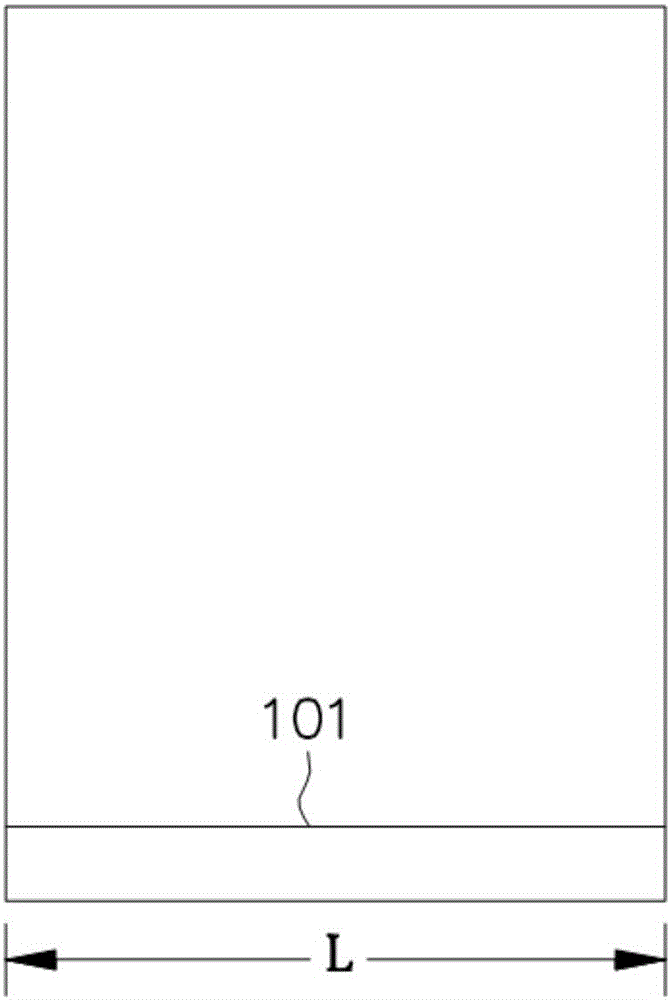

Method for manufacturing TiAl intermetallic compound through heterogeneous double-wire TOP-TIG electric arc additive manufacturing

ActiveCN111390338AStable melting pointSolve the problem of melting out of syncAdditive manufacturing apparatusArc welding apparatusTitanium alloyAdditive layer manufacturing

The invention discloses a method for manufacturing a TiAl intermetallic compound through heterogeneous double-wire TOP-TIG electric arc additive manufacturing, and belongs to the technical field of additive manufacturing. The method solves the problem that when the TiAl intermetallic compound is prepared through an existing electric arc additive manufacturing process, due to the fact that meltingcharacteristic differences of a titanium alloy welding wire and an aluminum welding wire are large, melting of the two wires is not synchronous under heating of the same electric arc, and the obtainedintermetallic compound is not uniform in component structure. According to the method, by regulating the angles and the positions of the welding wires and the extension length of a tungsten electrode, it is ensured that the heat absorbed by the two heterogeneous welding wires is different under heating of the same electric arc, the welding wires can be under the reasonable heating conditions correspondingly, synchronous continuous melting of the two welding wires is achieved, and a TiAl intermetallic compound component uniform in component structure is obtained. By means of the method, the problem that melting of the heterogeneous double wires is not synchronous when the intermetallic compound is manufactured through existing TIG electric arc additive manufacturing is effectively solved,the intermetallic compound manufacture process interval is widened, and stability of the manufacturing process is improved.

Owner:HARBIN INST OF TECH

Automobile clutch pressure plate vertical turning special-purpose water-based milling liquid and production method

The invention discloses a water-based cutting fluid specialized for merry-go-round machine in automobile clutch platen which can reduces cutting temperature and force to maximum extent, improves cutting process efficiency, ensures cutting precision and surface quality, prolongs life of cutting tool, reduces cost, satisfies environmental protection requirements, and method for making the same. Raw materials of specialized water-based fluid and corresponding weight percentage are phytic acid 2.8-3.2%, sodium benzoate 9-11%, triethanolamine 9-11%, sodium carbonate 2.5-3.5%, hyposulfite of soda 0.8-1.2%, polyethyleneglycol 5.5-6.5%, glycyl alcohol 5.5-6.5%, 2-methyl-3(2H)-Isothiazolone 0.4-0.6%, de-ionize water 58-63%. The production process is synthesis with stirring under condition of normal temperature - medium temperature - normal temperature.

Owner:DALIAN SANDAAOKE CHEM

Separator and electrical/electronic components using the same

InactiveUS20090029262A1Shape stableFunction increaseHybrid capacitor separatorsProtecting/adjusting hybrid/EDL capacitorPorous sheetElectronic component

The invention provides a separator characterized by a constitution wherein a porous sheet formed of a thermoplastic polymer having a melting point of 200° C. or lower is incorporating a thin sheet material comprising an organic compound substantially having no stable melting point, which is useful for secondary batteries or capacitors having both the shutting-down function and the high temperature shape stability.

Owner:DUPONT TEIJIN ADVANCED PAPERS JAPAN

Polylol compound phase-change material and preparation method thereof

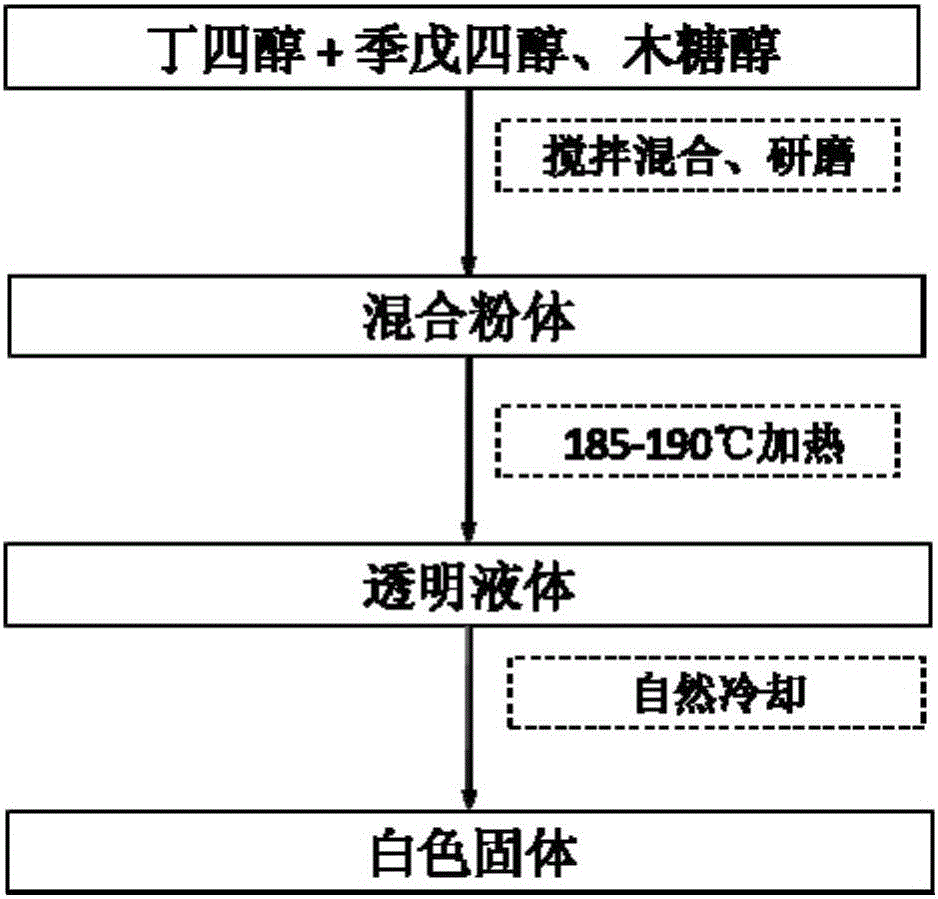

ActiveCN106281235AIncrease enthalpyHigh phase change enthalpyHeat-exchange elementsThermal energyPhase change enthalpy

The invention relates to a polylol compound phase-change material and a preparation method thereof. The compound phase-change material takes butantetraol, pentaerythrotol and xylitol powder as raw materials and is prepared through the following steps: carrying out manual grinding, ball milling or sand milling on a mixture of the butantetraol, the pentaerythrotol and the xylitol for 1h to 3h; then heating the mixture at 185 DEG C to 190 DEG C for 3h to 6h until all the powder is completely melted to form transparent liquid; finally, naturally cooling the transparent liquid to form the white and solid polylol compound phase-change material, wherein the mass percent content of the butantetraol is 60 percent to 75 percent, the mass percent content of the pentaerythrotol is 24 percent to 35 percent and the mass percent content of the xylitol is 1 percent to 5 percent. The polylol compound phase-change material has the advantages of high phase-change enthalpy value, small super-cooling degree, stable melting point and the like, and can be used in the fields of solar heat energy storage, industrial residual heat recycling and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

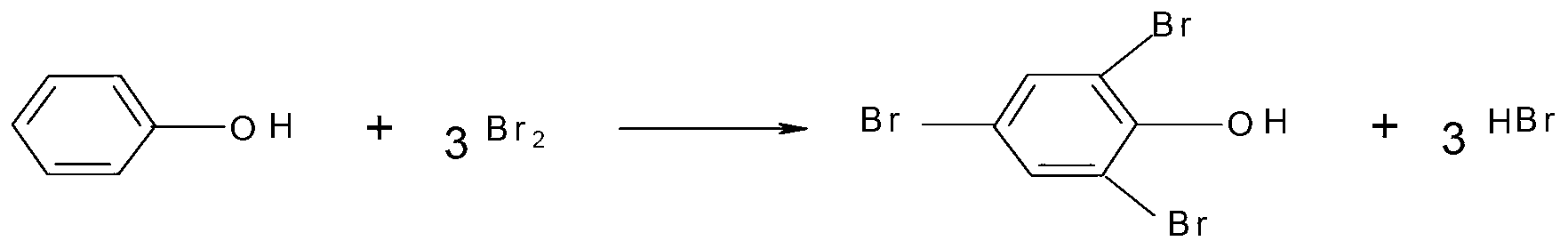

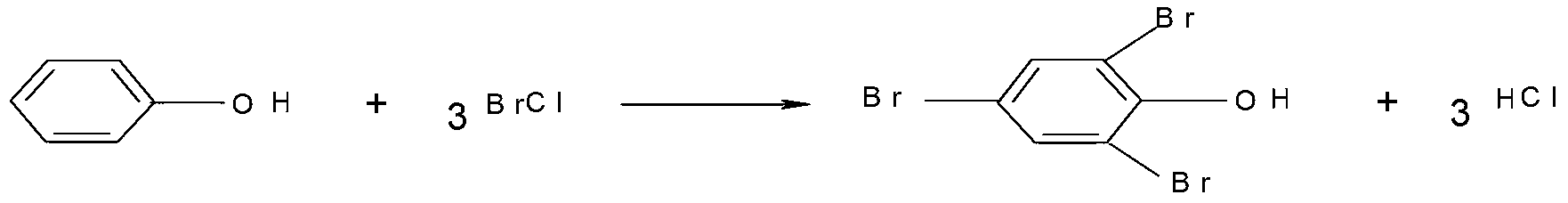

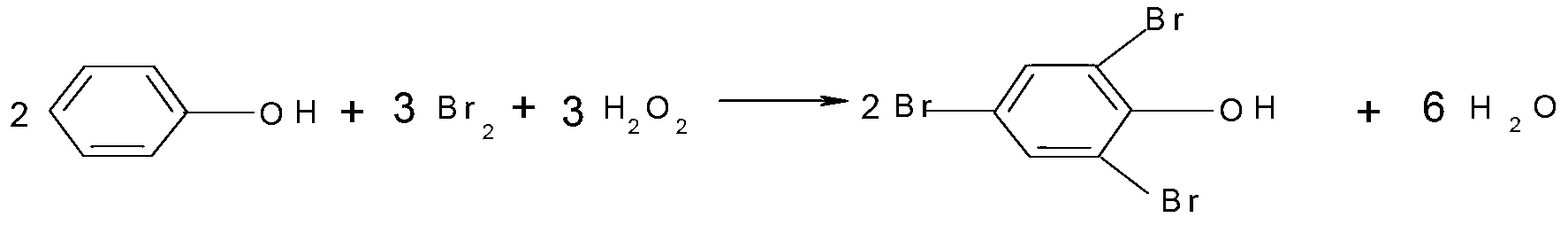

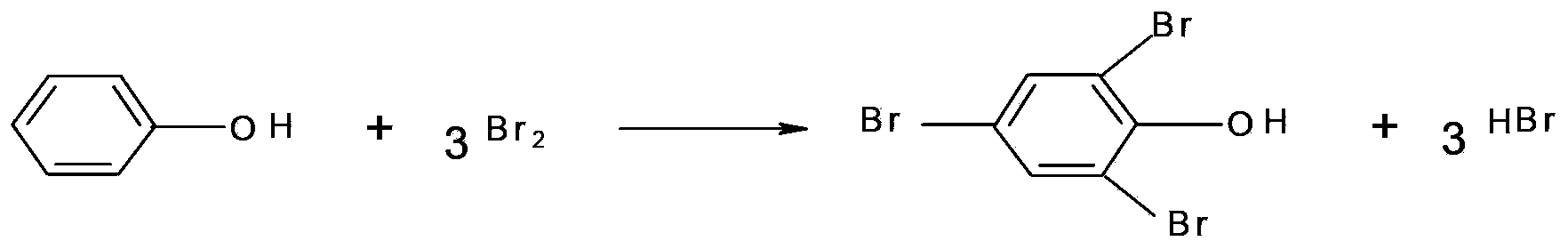

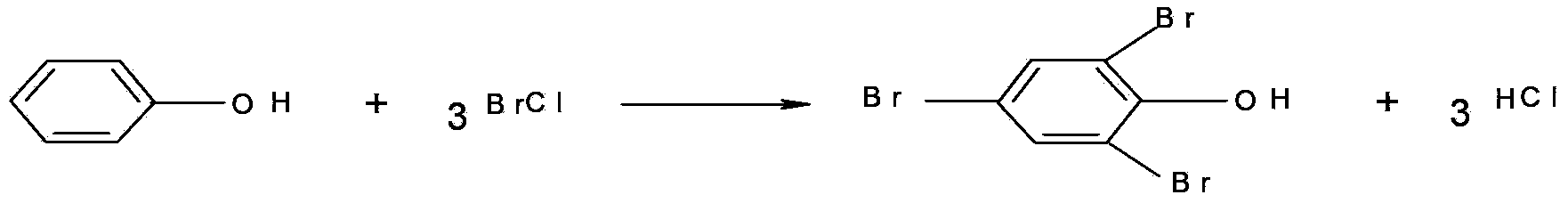

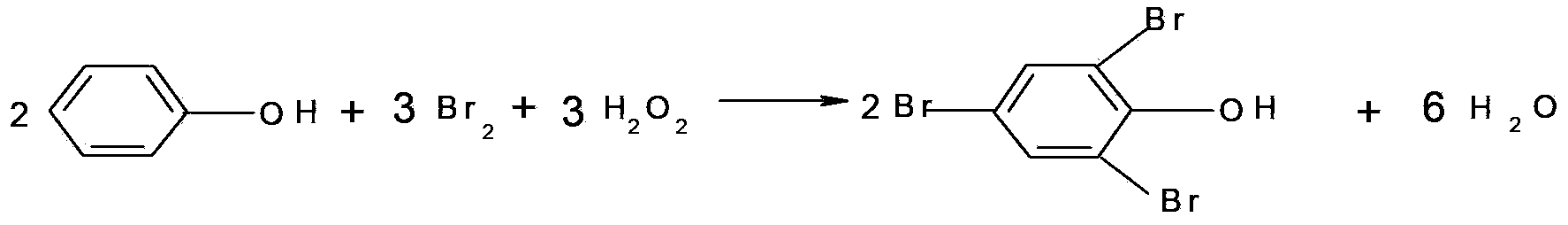

Optimized production method of Tri (tribromophenyl) cyanurate

ActiveCN103275025AAvoid introducingStable melting pointOrganic chemistryOrganic compound preparationChlorobenzeneFiltration

The invention relates to an optimized production method of Tri (tribromophenyl) cyanurate. Chlorobenzene is added into a reactor, phenol is added, hydrogen peroxide and bromine are dropwise added into the reactor in a staggering manner, extraction is performed by the aid of the chlorobenzene, a tribromophenol and chlorobenzene mixed liquid is obtained, cyanuric chloride is added into the mixed liquid, an initiating agent CTAB (cetyl trimethyl ammonium bromide), anhydrous sodium carbonate and methylbenzene are added for reaction, and a crude product is transferred to a heating kettle, the product is subjected to pressure reduction and suction filtration in a heating and dissolving state and is finally transferred to a distillation kettle and stirred and crystallized, edulcoration is realized before unit cell arrangement, and the product is obtained. According to the optimized production method of Tri (tribromophenyl) cyanurate, the produced by-products are reduced, the yield is improved, and the product quality is higher.

Owner:山东寿光神润发海洋化工有限公司

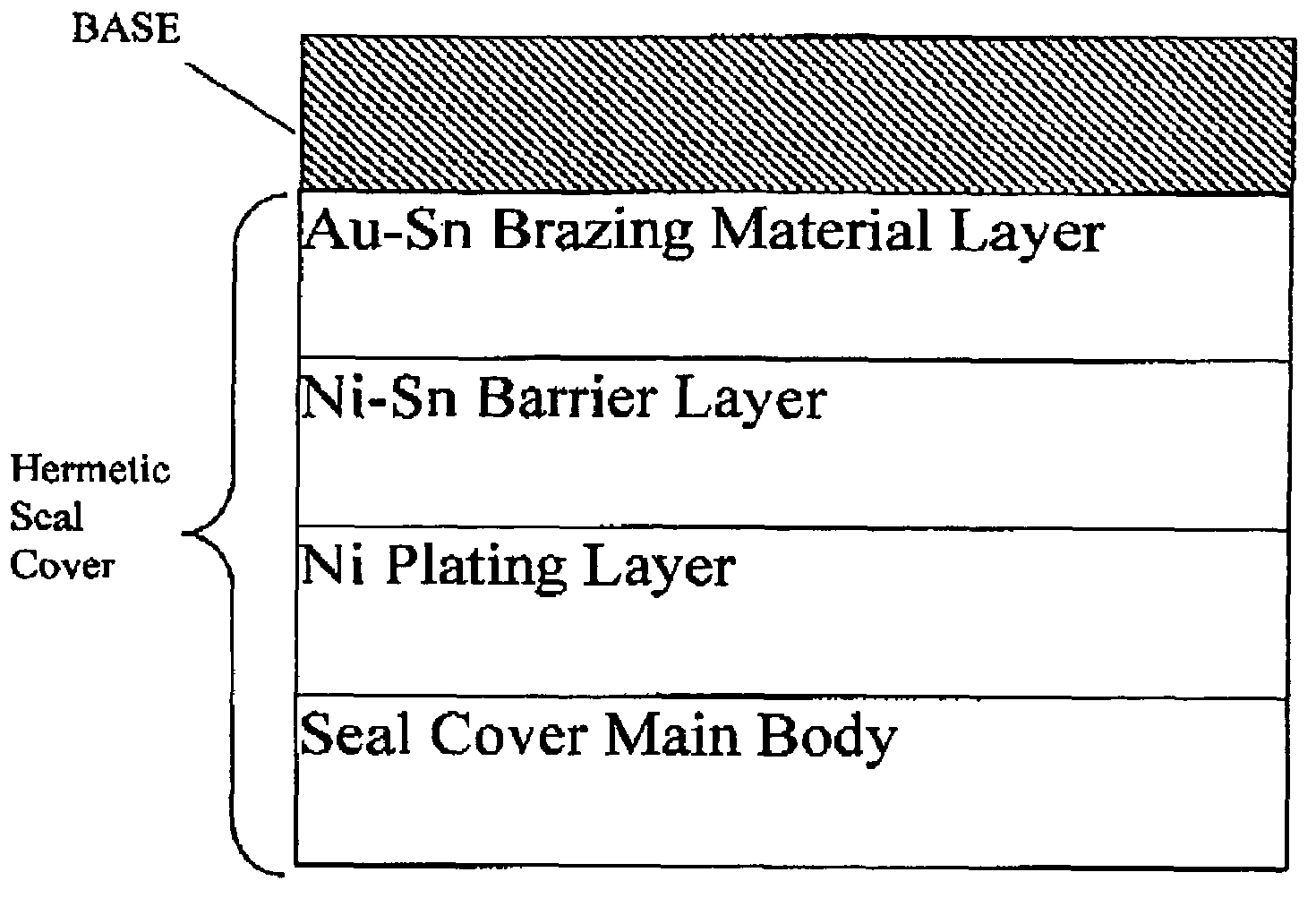

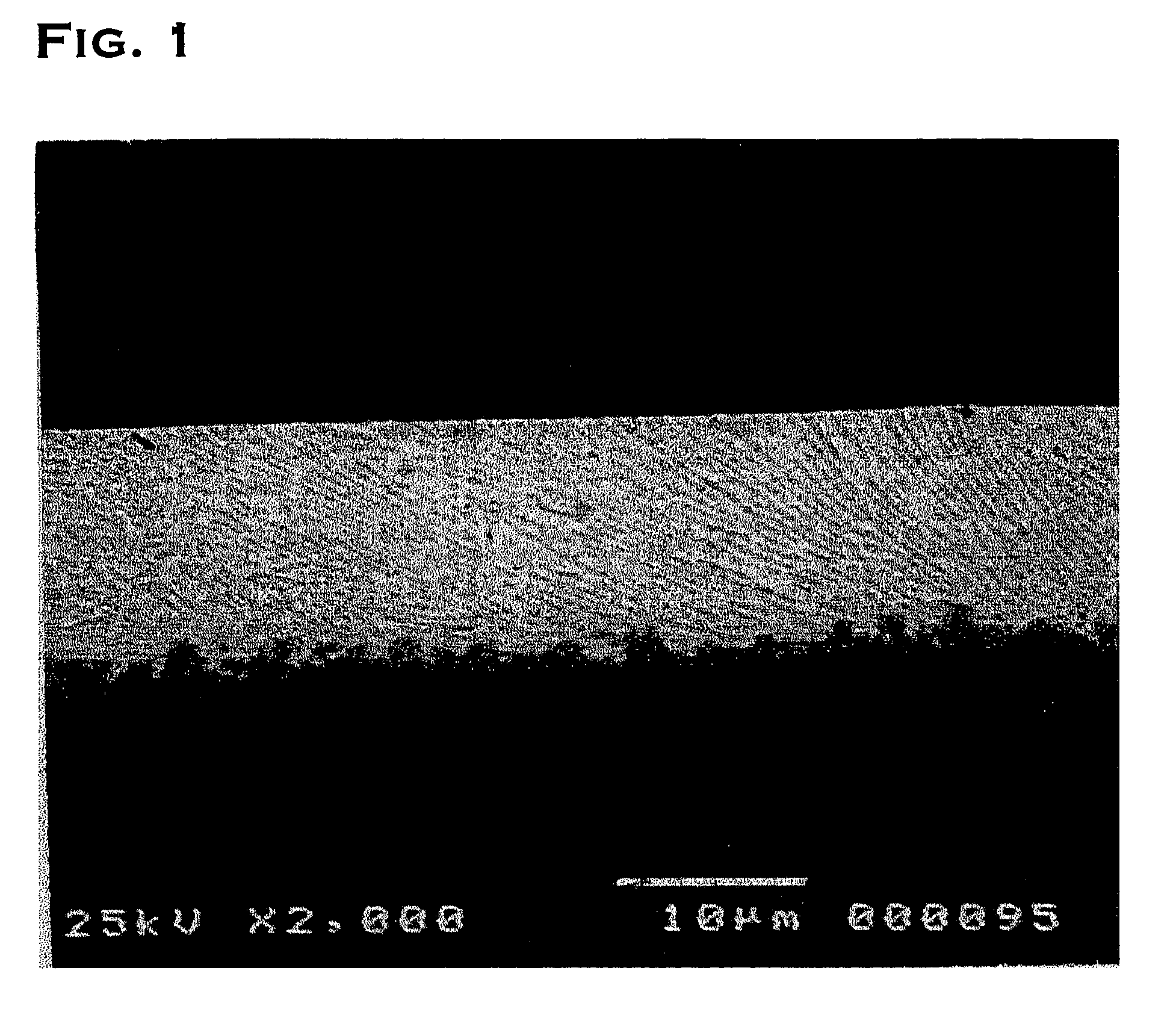

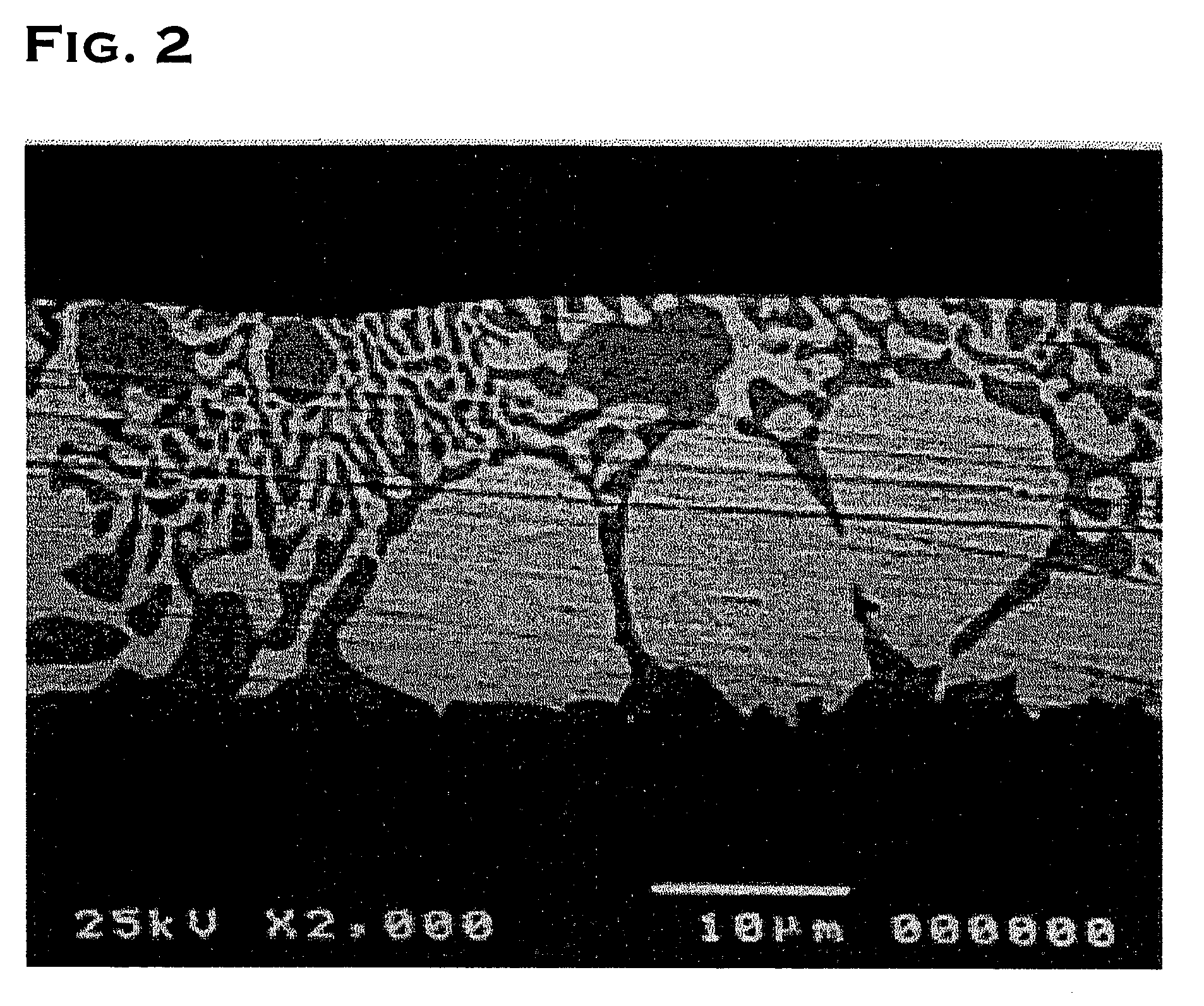

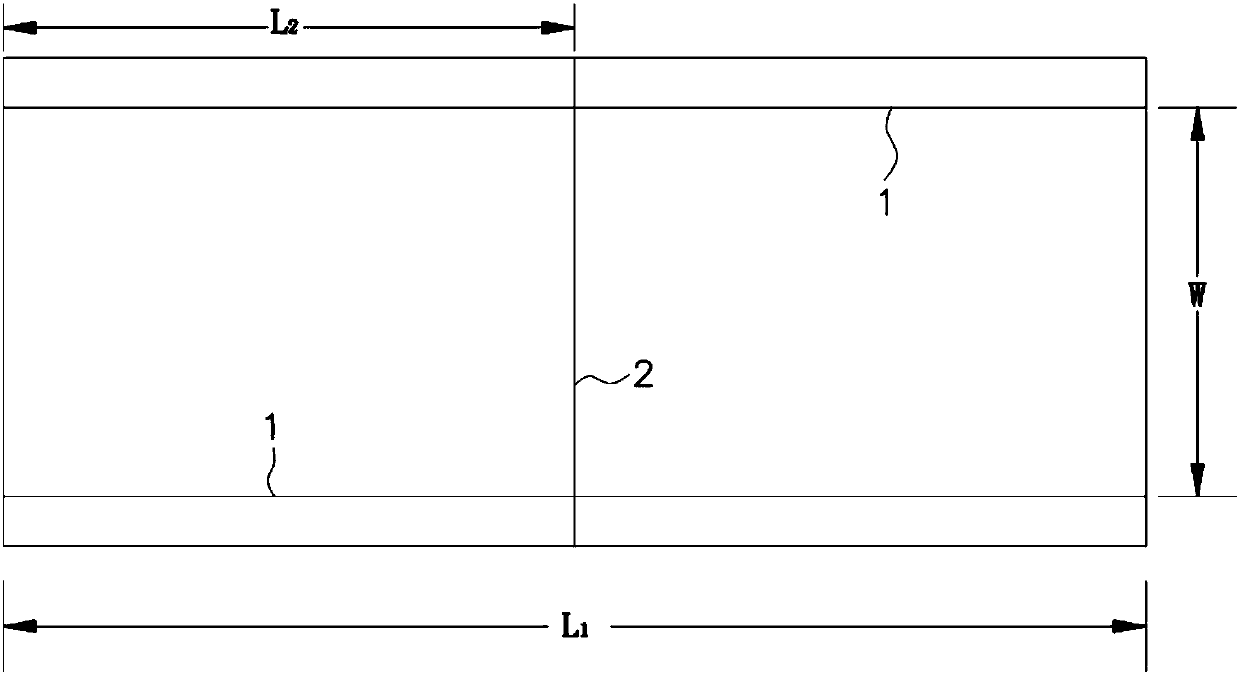

Seal cover structure comprising a nickel-tin (Ni—Sn) alloy barrier layer formed between a nickel (Ni) plating layer and a gold-tin (Au—Sn) brazing layer having Sn content of 20.65 to 25 WT % formed on the seal cover main body

ActiveUS7495333B2Avoid reactionEasily fluctuateSemiconductor/solid-state device detailsSoldering apparatusHermetic sealAlloy

A hermetic seal cover capable of inhibiting defects such as voids from generating in sealing a package, and a method of manufacturing the seal cover are provided. The hermetic seal cover comprises: a seal cover main body; a Ni plating layer applied onto a surface of the seal cover main body; and a Au—Sn brazing material layer fusion bonded to a surface of the Ni plating layer, and is characterized by a Ni—Sn ally layer disposed between the Ni plating layer and the Au—Sn brazing material layer. It is preferable if the Ni—Sn alloy layer has a thickness of 0.6-5.0 μm. It is also preferable if Au—Sn brazing material layer has a Sn content of 20.65-23.5 wt %.

Owner:TANAKA PRECIOUS METAL IND

Preparation method of low-zirconium mullite cast steel brick

The invention relates to a preparation method of a low-zirconium mullite cast steel brick, and belongs to the field of preparation of refractory materials. The raw material formula of the low-zirconium mullite cast steel brick provided by the invention comprises electrically smelted mullite, zirconium oxide, Guangxi white clay, andalusite, kyanite and lignin. According to the method provided by the invention, type and grain size of the raw materials are selected to be matched with the sintering temperature and time provided by the invention, so that the prepared low-zirconium mullite cast steel brick has the characteristics of excellent scouring resistance, high temperature resistance, small creep deformation, high compression strength, good thermal stability and the like, and is suitable for being used in large steel ingot casting in nuclear power products.

Owner:四川锦圆耐材有限公司

Amalgam for electrodeless lamp

The invention relates to the field of mercury-based alloys, in particular to amalgam for an electrodeless lamp. The amalgam for the electrodeless lamp comprises 40 to 60 mass percent of Hg and is characterized by also comprising 40 to 60 mass percent of Zn. The amalgam is used for the electrodeless lamp, and has a favorable relation between mercury air pressure and temperature characteristics, high luminous flux and quick and sensitive response when the lamp is started.

Owner:上海宝临防爆电器有限公司

Naftopidil suppository and preparation method thereof

ActiveCN102018660AEfficient releaseStable melting pointOrganic active ingredientsMetabolism disorderSuppositoryDissolution

The invention relates to naftopidil suppository and a preparation method thereof. The naftopidil suppository comprises the following components in part by weight: 10 to 25 parts of naftopidil, 10 to 60 parts of oleaginous substrate, 10 to 60 parts of water-soluble substrate, 1 to 10 parts of surfactant, 10 to 30 parts of hardening agent and 5 to 15 parts of absorbefacient. The suppository is uniformly dispersed, has high dissolution rate and improves the bioavailability and the effectiveness of medicaments.

Owner:蚌埠丰原涂山制药有限公司

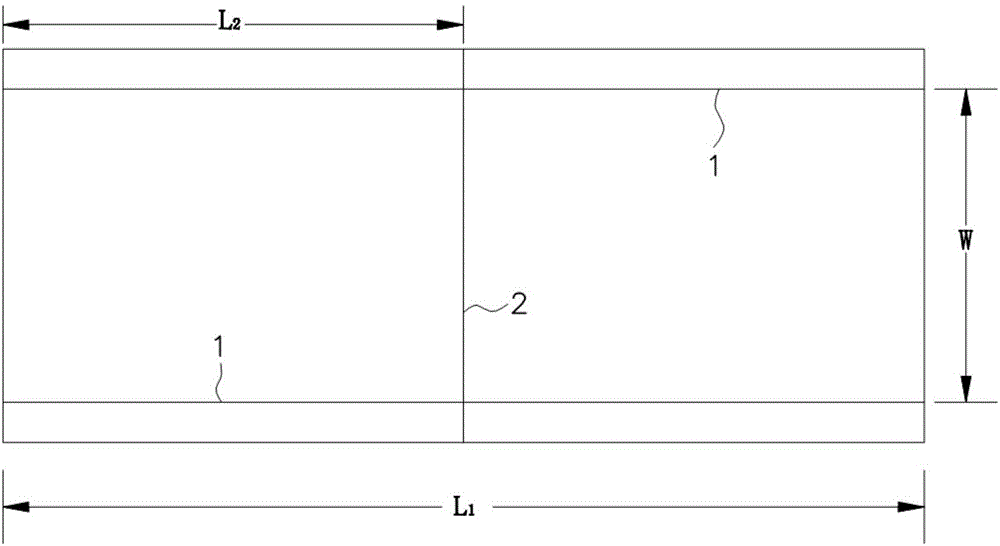

Low-melting-point packaging film and low-melting-point packaging bag

InactiveCN106700215AHigh transparencyStable melting pointFlexible coversWrappersEngineeringEthylene-vinyl acetate

The invention discloses a low-melting-point packaging film and a low-melting-point packaging bag. The low-melting-point packaging film consists of the following formula in percentage by mass: 90% of ethylene vinyl acetate copolymer, 2% of silicon dioxide and 8% of composite open master batch. According to the low-melting-point packaging film disclosed by the invention, a nucleating agent silicon dioxide is added into the formula, so that a packaging film has very good transparency; moreover, a smelting point is controlled to be 73 + / - 1 DEG C, and is stable and the packaging film is not liable to break. The low-melting-point packaging film is especially suitable for producing the low-melting-point packaging bag with bag width smaller than or equal to 400 mm; and the obtained packaging bag is stable in dimension, is consistent in vertical and horizontal physical property, is high in sealing strength, is not liable to generate deformation, is not liable to damage, is high in transparency, is free of crease, and is excellent in appearance.

Owner:仲铂新材料有限公司

Composite Sheet, Manufacturing Method Thereof, And Electric And Electronic Component Using The Same

InactiveUS20080107959A1Good functional stabilityImproved shape stabilityElectrolytic capacitorsLayered productsSimple Organic CompoundsHigh energy

A composite sheet having a layer structure of at least two or more layers in which a porous sheet layer of a thermoplastic polymer having at least a melting point of not higher than 200° C. and a nonwoven fabric-like sheet layer containing at least one component of a fibrid, a short fiber or a fibrillated pulp of an organic compound not substantially having a stable melting point are stacked, the composite sheet being able to be used for condensers, capacitors and batteries, exhibiting a sufficient effect against high energy and large outputs and being suitable as a separator for secondary batteries or capacitors having both shutdown function and high-temperature shape stability.

Owner:DUPONT TEIJIN ADVANCED PAPERS JAPAN

Formaldehyde-free rubber film for synthesizing multilayer solid wood base material

The invention discloses zero-formaldehyde glue film used for synthesizing multilayered solid wood base material, which has the technical proposal that the zero-formaldehyde glue film is prepared by the materials with the following weight parts: 80-90 parts of polyethylene, 5-19 parts of EVA260 resin, 0.1-0.5 parts of low molecular weighted PE wax and 0.1-0.5 parts of titanium dioxide. The glue film has the advantages that as the zero-formaldehyde glue film used for synthesizing multilayered solid wood base material is characterized by stable melting point, the qualification rate of the finished products of multilayered solid wood base material is greatly improved, thus laying the foundation for the development of mass industrialization; as the glue layer is characterized by low water content, the stability of the shapes and sizes of the multilayered solid wood base material is greatly strengthened; as the glue film is characterized by strong adhesion and zero formaldehyde, the multilayered solid wood base material is firmer and more environment-friendly.

Owner:牛桂祥 +1

Hermetic seal cover and manufacturing method thereof

ActiveUS20060001172A1Eliminate damageCurb deterioration of production yieldSemiconductor/solid-state device detailsSolid-state devicesHermetic sealAlloy

A hermetic seal cover capable of inhibiting defects such as voids from generating in sealing a package, and a method of manufacturing the seal cover are provided. The hermetic seal cover comprises: a seal cover main body; a Ni plating layer applied onto a surface of the seal cover main body; and a Au—Sn brazing material layer fusion bonded to a surface of the Ni plating layer, and is characterized by a Ni—Sn ally layer disposed between the Ni plating layer and the Au—Sn brazing material layer. It is preferable if the Ni—Sn alloy layer has a thickness of 0.6-5.0 μm. It is also preferable if Au—Sn brazing material layer has a Sn content of 20.65-23.5 wt %.

Owner:TANAKA PRECIOUS METAL IND

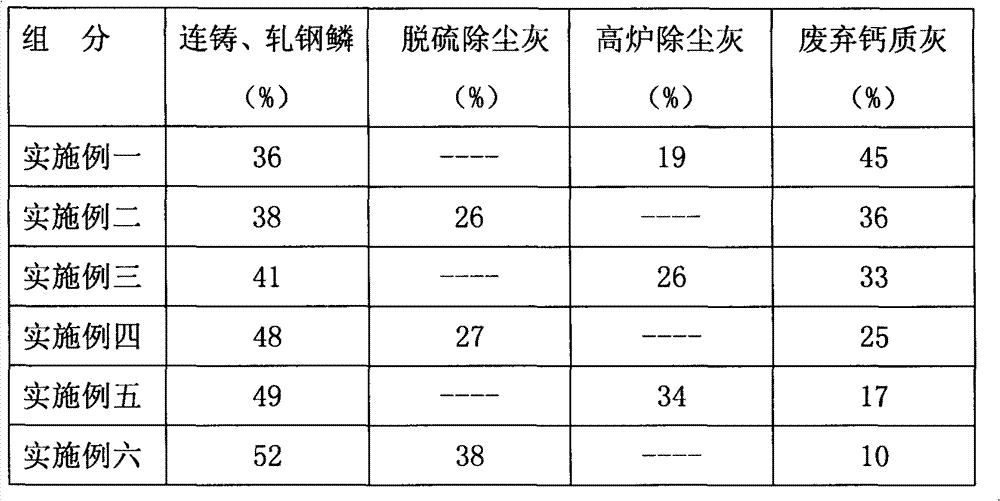

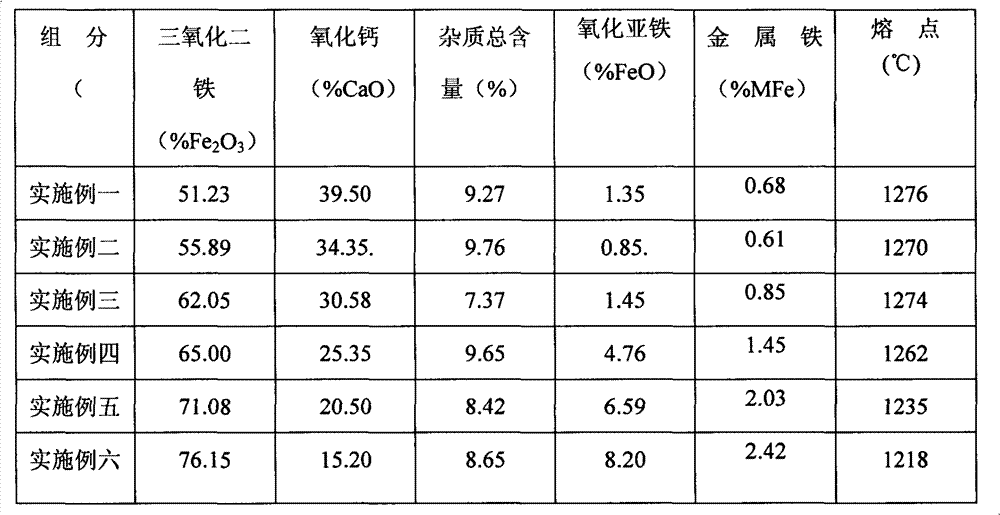

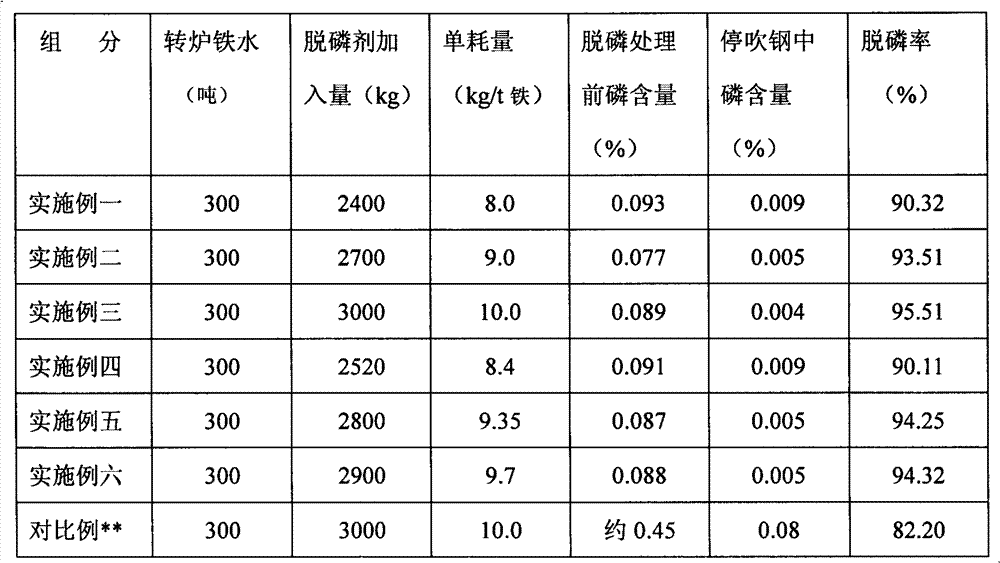

High-efficiency slagging and dephosphorization agent and preparation method thereof

The invention proposes a high-efficiency slagging and dephosphorization agent and a preparation method thereof. The preparation method of the slagging and dephosphorization agent comprises preparing raw materials, crushing, mixing with stirring, distributing materials in a batch-wise way, smelting at a high temperature of 1500 to 1550 DEG C, smelting and tapping, cooling crystallization, breaking to mold, and obtaining the slagging and dephosphorization agent for steel-making, wherein the agent is rich in CaO and Fe2O3, has a particle size of 3 to 40 mm, uses 2CaO.Fe2O3 as a main phase and has a melting point of less than or equal to 1280 DEG C. The dephosphorization agent has increased ferric oxide content due to reduced ferrous oxide, thereby enhancing oxidizability and further improving the slagging and dephosphorization effect of the agent. The agent facilitates reducing dosage of the dephosphorization agent, shortening processing time and improving working efficiency.

Owner:LIAONING TIANHE TECH

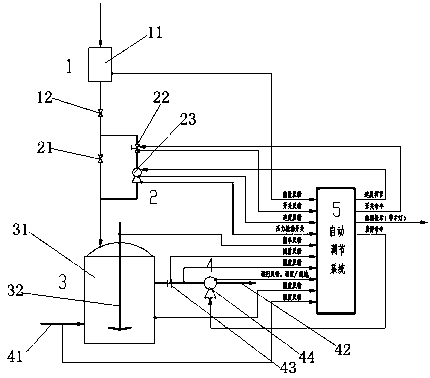

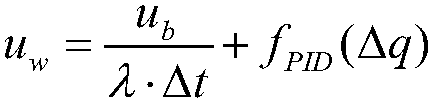

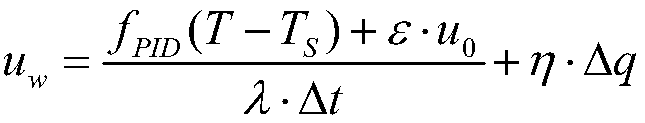

Automatic bromine adding device for synthesizing tetrabromobisphenol A and control method thereof

ActiveCN108786662AReduce labor intensityHigh purityProcess control/regulationOrganic chemistryChemical synthesisTetrabromobisphenol A

The invention discloses an automatic bromine adding device for synthesizing tetrabromobisphenol A and a control method thereof, relating to the field of chemical synthesis equipment. The automatic bromine adding device comprises a bromine discharge device, a control metering device connected with the bromine discharge device through a pipeline to feed materials into a reaction device, and an automatic adjusting device, wherein the reaction device is externally provided with a cooling device. The automatic bromine adding device realizes segmentation control, can automatically adjust the amountof bromine added according to the temperature of a reaction still, and can control the flow rate of brine, the weight of bromine added and other data as well as a feeding sequence to ensure a more stable synthesis reaction, thereby improving product purity, lowering labor intensity of workers and improving a safety factor of production.

Owner:山东金宜善新材料有限公司

Carbonized floor manufacturing method

InactiveCN101579875AMoth-eaten performance is goodStable melting pointWood compressionWood charring/burningParaffin waxManufacturing engineering

The invention relates to a floor manufacturing method, in particular to a carbonized floor manufacturing method. The carbonized floor manufacturing method comprises the following steps: (1) prior period processing: carbonizing a floor to form a carbonized floor and keeping the temperature of the carbonized floor between 70-120 DEG C; (2) immersing a wax: immersing the carbonized floor into melting paraffin liquid and taking out the carbonized floor after 5-30 seconds; (3) finished product: cooling the carbonized floor naturally after being immersed in the wax. In the invention, the carbonized floor with higher temperature is immersed in the wax directly, the paraffin is absorbed completely through a slit on the surface of the carbonized floor, and sanding and archaizing the obtained carbonized floor by the method, painting and adding other industrial chemical on the carbonized floor are not needed, therefore, the carbonized floor has the characteristics of crack resistance, good performance of damaged by worm, environmental protection and long-term maintenance of brightness of the floor.

Owner:南通科华玻璃仪器有限公司

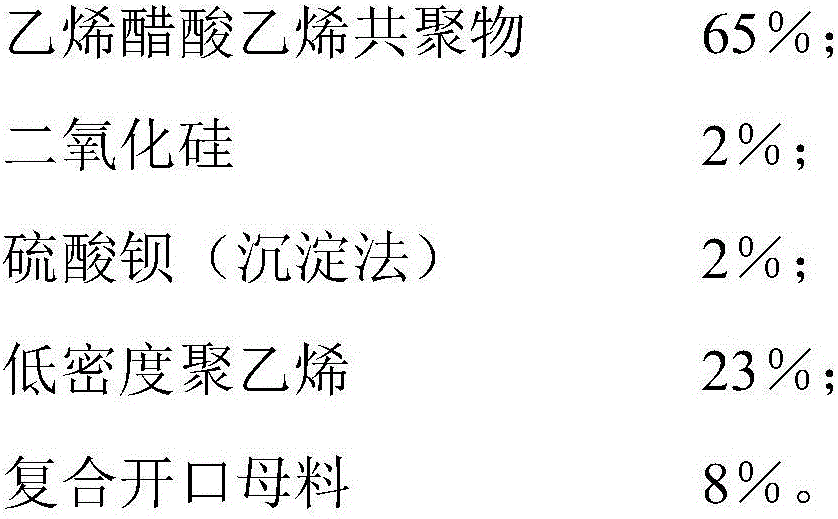

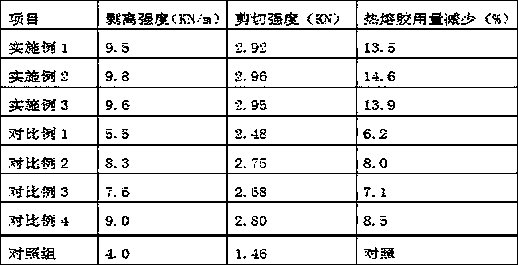

Low-melting-point packing film

The invention discloses a low-melting-point packing film. The low-melting-point packing film is prepared from, by mass, 65% of vinyl acetate copolymer, 2% of silicon dioxide, 2% of barium sulphate (precipitating method), 23% of low-density polyethylene and 8% of compound open master batch. The nucleating agent silicon dioxide is added in the formula, so that the packing film has good transparency. In addition, a melting point is controlled to be 90 + / -1 DEG C and is stable, and the packing film does not easily break. The low-melting-point packing film is especially suitable for a low-melting-point packing bag with the production bag width smaller than or equal to 400 mm, the obtained packing bag is stable in size, convenient in vertical and horizontal physical property and high in sealing strength, does not easily deform, does not easily break and is high in transparency, free of wrinkles and excellent in appearance.

Owner:仲铂新材料有限公司

Special-purpose water-base cutting liquid for cannonball cartridge finish turning and producing method thereof

InactiveCN101260342AHigh affinityImprove adsorption capacityLubricant compositionWater basedPhytic acid

The invention discloses water-based cutting fluid special for fine turning cannonball cartridges and a production method, wherein, the water-based cutting fluid special for the fine turning cannonball cartridges can maximally decrease the cutting temperature and the cutting force, improve the efficiency of cutting machining, assure the cutting accuracy and the surface quality of the workpiece, prolong the service life of the cutting tool, decrease the cost, and meet the requirement of environmental protection. The raw materials of the special water-based cutting fluid and the weight percentage are as follows: phytic acid 1.5-2.5 percent, sodium benzoate 7-9 percent, trolamine 5-7 percent, trisodium phosphate 1.5-2.5 percent, sodium thiosulfate 0.5-1.5 percent, benzotriazole 0.05-0.15 percent, industrial alcohol 2.5-3.5 percent, polyethyleneglycol 3.5-4.5 percent, glycerin 2.5-3.5 percent, isothiazolone 0.4- 0.6 percent, and deionized water 68-72 percent. The production method is that: the synthetic condition of normal temperature, middle temperature and normal temperature is adopted for stirring synthesis.

Owner:DALIAN SANDAAOKE CHEM

Tackifier capable of improving gluing property of EVA hot melt adhesive

InactiveCN108977122AImprove bonding performanceImprove glue abilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceHot melt

The invention relates to the technical field of chemical materials and discloses a tackifier capable of improving the gluing property of an EVA hot melt adhesive. The special main chain structure andspatial structure of silicone resin are utilized to tightly combine inorganic nano particles with macromolecular layers through chemical bonds, thereby endowing resin with favorable performance; the prepared tackifier has good compatibility with EVA resin, can achieve a synchronous softening effect, and is capable of improving the fluidity and diffusibility of the melt adhesive; the adhesive interface wetting property and initial viscosity are good, and the melt adhesive can spread on an adherend; even if in an repeated changed outside environment, stable fusing point of the hot melt adhesivecan be maintained; the EVA hot melt adhesive prepared by adding the tackifier is good in gluing property and good in thermostability; and the tackifier amount is 30-40% of common tackifiers, so that the cost is saved. The tackifier is capable of obviously improving the gluing property of the EVA hot melt adhesive, and realizing practical significance of high-quality and low-cost production of hotmelt adhesives, thereby being a technical scheme worthy of popularizaiton and use.

Owner:ANHUI SOYA DECORATIVE MATERIALS

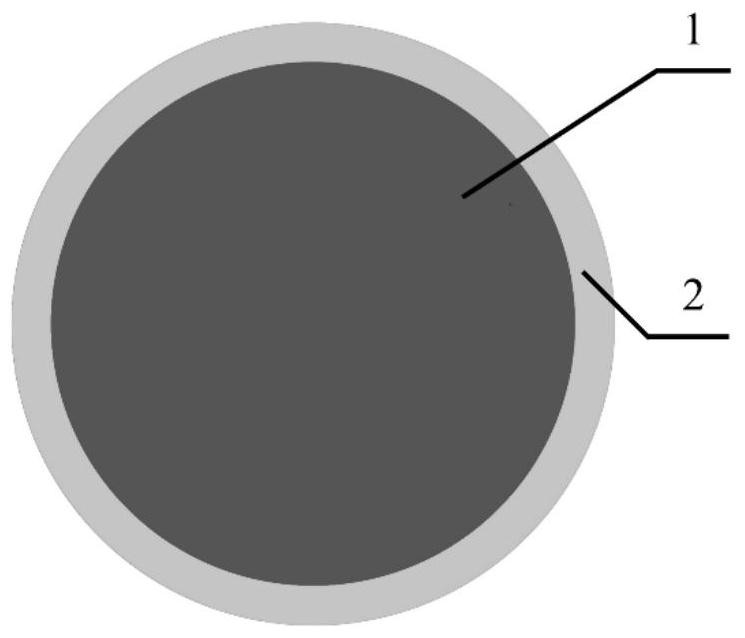

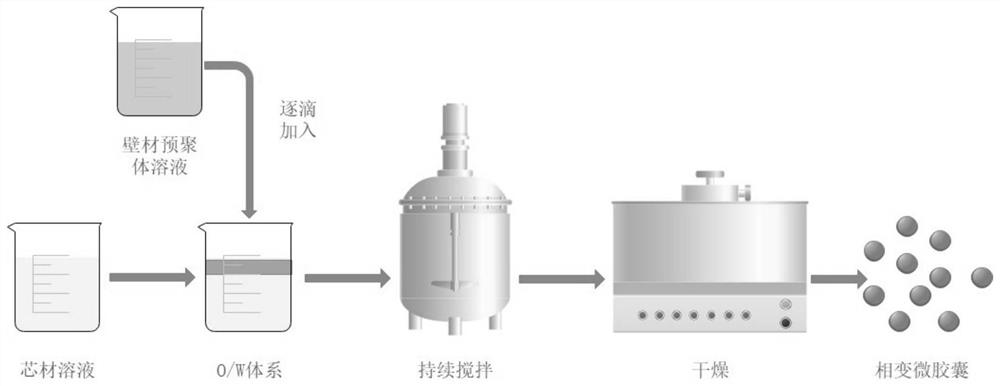

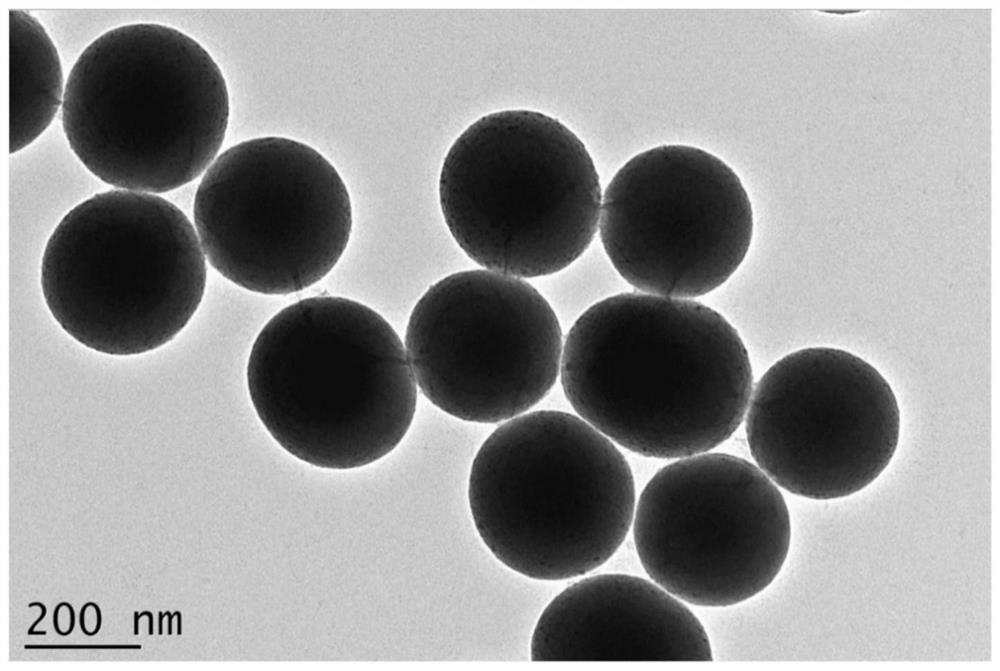

Liquid metal phase change microcapsule and preparation method thereof

PendingCN114656935AImprove heat resistanceHigh thermal conductivityHeat-exchange elementsMicroballoon preparationIndiumHeat stability

The invention provides a liquid metal phase change microcapsule which is of a structure prepared by adopting a sol-gel method and using liquid metal as a core material and non-metal oxide as a wall material and comprises a phase change core and a shell surrounding the phase change core, the phase change core is a liquid metal core, and the shell is a non-metal oxide layer; the liquid metal is bismuth-indium-tin alloy, bismuth-indium alloy or gallium-indium-tin alloy; and the non-metal oxide is silicon dioxide or titanium dioxide. The invention further provides a preparation method of the liquid metal phase change microcapsule. The liquid metal phase change microcapsule of a single-layer inorganic wall material is prepared by adopting a sol-gel method, so that the erosion of the liquid metal phase change material to some metal surfaces is effectively prevented, and the microcapsule has a relatively high heat conductivity coefficient and good heat stability.

Owner:DALIAN MARITIME UNIVERSITY

Low-melting-point packaging film and application thereof to preparation of packaging bag

InactiveCN106750846AStable melting pointNot easy to breakBag making operationsPaper-makingWrinkleEthylene-vinyl acetate

The invention discloses a low-melting-point packaging film and application thereof to preparation of a packaging bag. A formula of the low-melting-point packaging film comprises the following raw materials in percentage by mass: 90 percent of ethylene vinyl acetate copolymer, 2 percent of silicon dioxide and 8 percent of compound openability master batch. In the formula, the silicon dioxide serving as a nucleating agent is added, so that the packaging film has high transparency; moreover, the melting point is controlled at 73+ / -1 DEG C, so that the low-melting-point packaging film is stable in melting point, and is prevented from being damaged. The low-melting-point packaging film is particularly suitable for producing a low-melting-point packaging bag which is less than or equal to 400mm in bag width; the obtained packaging bag is stable in size, is consistent in longitudinal and horizontal physical properties, has high sealing strength, high transparency and superior appearance, is prevented from being deformed or damaged easily, and is free from wrinkles.

Owner:仲铂新材料有限公司

Multifunctional composite modificator for cast steel

InactiveCN109182651AInhibit grain growthRefining microstructureProcess efficiency improvementPhosphorusWear resistance

The invention discloses a multifunctional composite modificator for cast steel. The modificator is prepared from the following components in percentage by mass: 17-23 percent of Si3N4, 15-25 percent of AlN, 5-9 percent of Fe-SiRE, 14-18 percent of Al, 5-7 percent of Mg, 6-10 percent of Nb, 6-10 percent of V and 14-20 percent of CaO. The multifunctional composite modificator can solve the problemsof thick crystal grain, high content of phosphor, low toughness and low abrasion resistance in the cast steel producing process, so that the material performance is improved, and the material utilization can be improved.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

Non-reactive casting powder for fluoride-free high-aluminum steel continuous casting crystallizer

The invention discloses non-reactive casting powder for a fluoride-free high-aluminum steel continuous casting crystallizer, and belongs to the technical field of metallurgical engineering. The fluoride-free high-aluminum steel continuous casting crystallizer non-reactive casting powder comprises the following components in percentage by mass: 20 to 35 percent of CaO, 15 to 35 percent of Al2O3, 1 to 10 percent of SiO2, 7 to 15 percent of BaO, 7 to 15 percent of B2O3, 10 to 17 percent of Na2O + Li2O, 2 to 10 percent of C, 1 to 7 percent of MnO, 1 to 7 percent of MgO and the balance of inevitable impurities. Compared with the traditional casting powder, the casting powder disclosed by the invention is not added with CaF2, so that the problem of large fluctuation of components caused by components in the aluminum reduction casting powder in the continuous casting process of high-aluminum steel, especially the performance of the casting powder, and the pollution to air, the harm to human bodies and the damage to continuous casting equipment caused by volatilization of F-containing gas in the continuous casting process are avoided.

Owner:SHANGHAI INST OF TECH

Composite modifier, prepared through mixed loading of aluminum-antimony-copper-ferrosilicon alloy and nanometer magnesium oxide-boron nitride, for gray pig iron and preparation method of composite modifier

The invention relates to a composite modifier, prepared through mixed loading of aluminum-antimony-copper-ferrosilicon alloy and nanometer magnesium oxide-boron nitride, for gray pig iron and a preparation method of the composite modifier. The modifier is prepared from the following raw materials in parts by weight: 1-2 parts of nanometer magnesium oxide, 2-3 parts of nanometer boron nitride, 1-3 parts of aluminum powder, 0.8-1 parts of antimony powder, 3-5 parts of expansible graphite powder, 3-4 parts of copper powder, 4-6 parts of silicon iron powder with 45% of silicon content, 0.2-0.3 part of aluminum-magnesium silicate, 20-25 parts of ethanol water at the concentration of 5-8%, and 0.4-0.5 part of an additive. The nano-powder and the manganese-molybdenum-copper-ferrosilicon alloy powder loaded on the expansible graphite powder are mutually bonded and loaded to prepare the composite modifier with stable properties, the effect of promoting generation of crystal nucleus and refining the crystal nucleus is achieved, the composite alloyed powder optimizes the matrix structure, refines the graphite body and improves the strength, the modifier is rapidly melted after being added into the molten iron, the graphitization process is promoted, the comprehensive mechanical property of the gray pig iron is effectively improved, and compared with the traditional modifier, the composite modifier is more convenient to use, and the production cost is also reduced.

Owner:徐世云

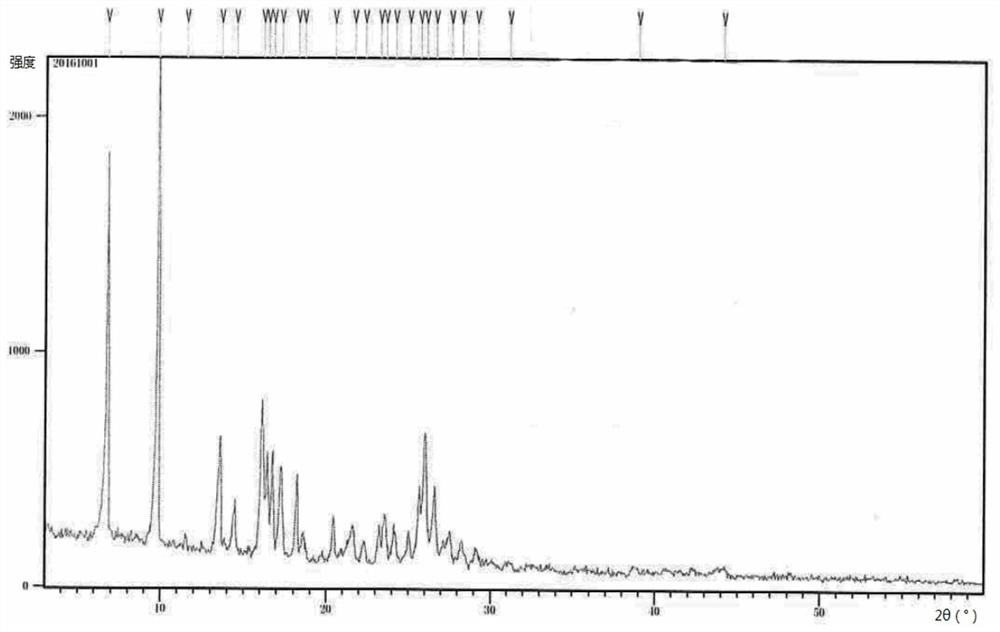

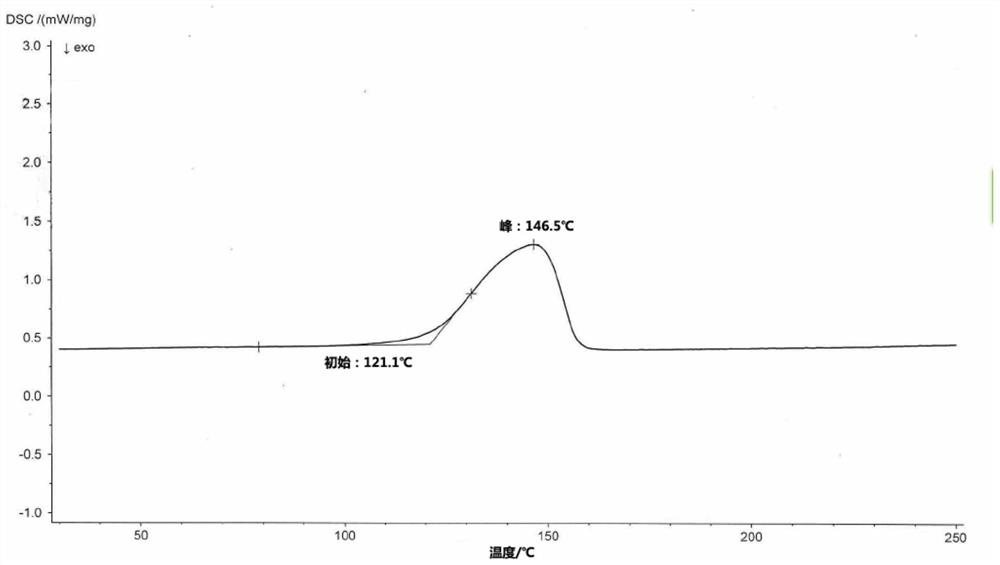

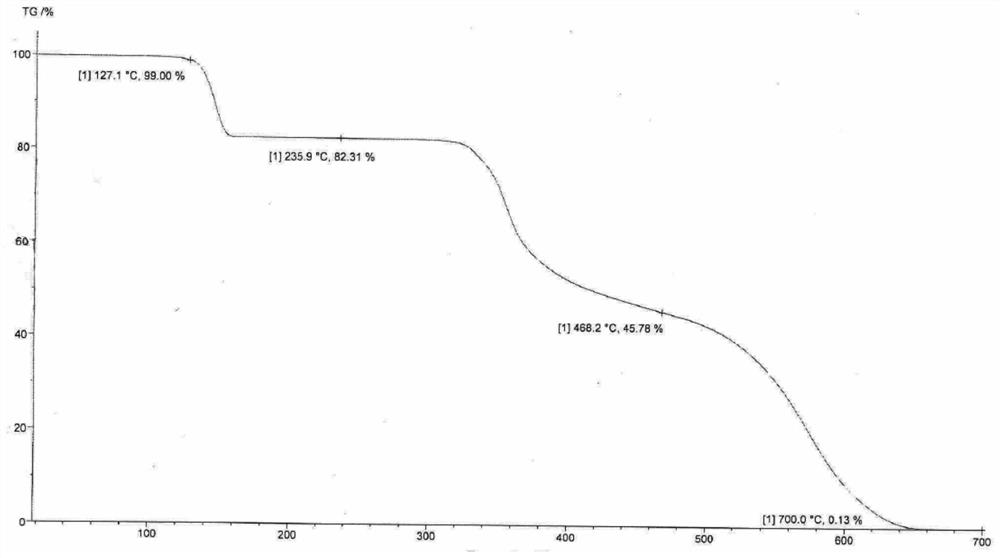

A crystal form of a tubulin inhibitor (vda-1)

ActiveCN108658945BStable formStable melting pointOrganic active ingredientsOrganic chemistry methodsDiseaseDepressant

The present invention provides an A crystal form of (3Z,6Z)-3-[((E)-3-(5-tert-butyl)-1H-imidazol-4-yl)methylene]-6-((E)-3-(3-fluorophenyl)-2-propenylidene)piperazine-2,5-dione (VDA-1). The A crystal form has a stable morphology, a definite melting point, and good chemical stability and is high-temperature resistant and suitable for pharmaceutical uses. The A crystal form can be used to treat a hyperproliferative disease.

Owner:SHENZHEN NEPTUNUS PHARMA RES INST CO LTD

Preparation method of low-zirconium mullite cast steel brick

The invention relates to a preparation method of a low-zirconium mullite cast steel brick, and belongs to the field of preparation of refractory materials. The raw material formula of the low-zirconium mullite cast steel brick provided by the invention comprises electrically smelted mullite, zirconium oxide, Guangxi white clay, andalusite, kyanite and lignin. According to the method provided by the invention, type and grain size of the raw materials are selected to be matched with the sintering temperature and time provided by the invention, so that the prepared low-zirconium mullite cast steel brick has the characteristics of excellent scouring resistance, high temperature resistance, small creep deformation, high compression strength, good thermal stability and the like, and is suitable for being used in large steel ingot casting in nuclear power products.

Owner:四川锦圆耐材有限公司

Optimized production method of Tri (tribromophenyl) cyanurate

ActiveCN103275025BInhibitionSuppress generationOrganic chemistryOrganic compound preparationChlorobenzeneDistillation

Owner:山东寿光神润发海洋化工有限公司

Carbon/carbon composite material ultrahigh temperature oxidation resistant coating and preparation method thereof

The invention discloses a carbon / carbon composite material ultrahigh temperature oxidation resistant coating. The coating comprises the following components, by volume, 40-60% of ZrB2, 15-25% of SiC, 15-20% of TaB2 and 10-15% of Sc2O3. In addition, the invention also provides a preparation method of the coating. According to the invention, TaB2 and Sc2O3 are added to make the melting point of an external layer oxidation product borosilicate glass be risen, the viscosity of the borosilicate glass be risen, the evaporation rate of the borosilicate glass be reduced, the oxygen dispersion coefficient of the borosilicate glass be reduced, an internal layer oxidation product ZrO2 phase be stable, the melting point of ZrO2 be risen, and the oxygen diffusion coefficient of ZrO2 be reduced, so thecoating can satisfy requirements of the ultrahigh temperature oxidation resistance of a carbon / carbon composite material, the coating can be sintered without applying a pressure through adding TaB2 and Sc2O3, the coating has the advantages of high combination strength, compactness, and good ultrahigh temperature mechanical property, and the preparation process has no damages to matrixes.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com