Tackifier capable of improving gluing property of EVA hot melt adhesive

A tackifier, hot melt adhesive technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of general thermal stability, large amount of tackifier, and decreased adhesion Fast speed and other problems, to achieve the effects of good thermal stability, improved adhesion, improved fluidity and diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

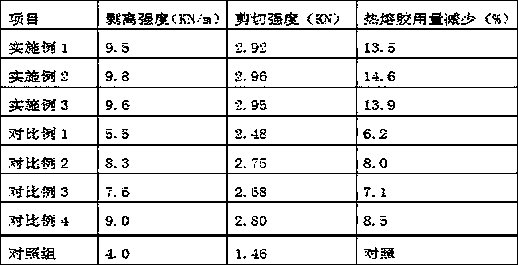

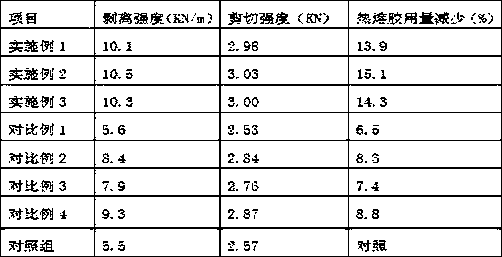

Examples

Embodiment 1

[0018] A tackifier for improving the bonding performance of EVA hot-melt adhesives, made of the following components in parts by weight: 80 parts of bisphenol A epoxy resin, 25 parts of polydimethylsiloxane, and 1.4 parts of sodium methacrylate , 0.3 parts of nano zinc oxide, 1.0 parts of silane coupling agent, 0.3 parts of sodium laurate, 1.5 parts of triethanolamine, 0.6 parts of boron nitride, 12 parts of xylene, 5 parts of sodium bicarbonate aqueous solution, 18 parts of sodium chloride solution, 120 parts of ethanol, the preparation method comprises the following steps:

[0019] (1) Put nano-zinc oxide in a high-speed mixer, add triethanolamine and sodium laurate at 1200 rpm, stir for 20 minutes, increase the speed to 1800 rpm, and add silane coupling agent at the same time and stir for 15 minutes, Then heat treatment at 200°C for 2 hours to obtain pretreated nano-zinc oxide;

[0020] (2) In an ice-water bath at 0°C, add bisphenol A epoxy resin and polydimethylsiloxane i...

Embodiment 2

[0028] A tackifier for improving the bonding performance of EVA hot-melt adhesives, made of the following components in parts by weight: 82 parts of bisphenol A epoxy resin, 27 parts of polydimethylsiloxane, and 1.5 parts of sodium methacrylate , 0.35 parts of nano zinc oxide, 1.1 parts of silane coupling agent, 0.4 parts of sodium laurate, 1.55 parts of triethanolamine, 0.7 parts of boron nitride, 13 parts of xylene, 6 parts of sodium bicarbonate aqueous solution, 19 parts of sodium chloride solution, 135 parts of ethanol, the preparation method comprises the following steps:

[0029] (1) Put nano-zinc oxide in a high-speed mixer, add triethanolamine and sodium laurate at 1250 rpm, stir for 25 minutes, increase the speed to 1900 rpm, and add silane coupling agent at the same time and stir for 18 minutes, Then heat treatment at 215°C for 2.5 hours to obtain pretreated nano-zinc oxide;

[0030] (2) In an ice-water bath at 2°C, add bisphenol A epoxy resin and polydimethylsiloxa...

Embodiment 3

[0038] A tackifier for improving the bonding performance of EVA hot-melt adhesives, made of the following components in parts by weight: 85 parts of bisphenol A epoxy resin, 28 parts of polydimethylsiloxane, and 1.6 parts of sodium methacrylate , 0.4 parts of nano zinc oxide, 1.2 parts of silane coupling agent, 0.5 parts of sodium laurate, 1.6 parts of triethanolamine, 0.8 parts of boron nitride, 15 parts of xylene, 8 parts of sodium bicarbonate aqueous solution, 20 parts of sodium chloride solution, 150 parts of ethanol, the preparation method comprises the following steps:

[0039] (1) Put nano-zinc oxide in a high-speed mixer, add triethanolamine and sodium laurate at 1300 rpm, stir for 30 minutes, increase the speed to 2000 rpm, and add silane coupling agent at the same time and stir for 20 minutes, Then heat treatment at 230° C. for 3 hours to obtain pretreated nano-zinc oxide;

[0040] (2) In an ice-water bath at 5°C, add bisphenol A epoxy resin and polydimethylsiloxane i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com