High-plasticity five-element refractory high-entropy alloy and preparation method thereof

A high-entropy alloy and high plasticity technology, applied in the field of metal materials, can solve the problems of high-entropy alloy plasticity is not very good, and achieve the effect of less impurities, convenient operation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

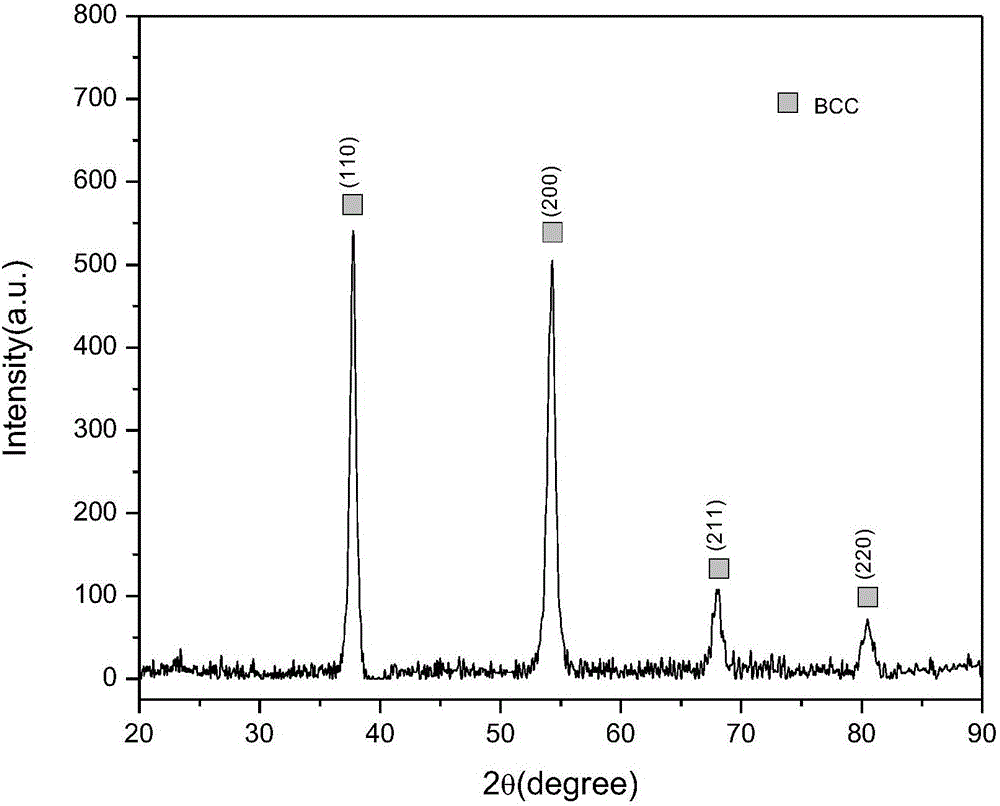

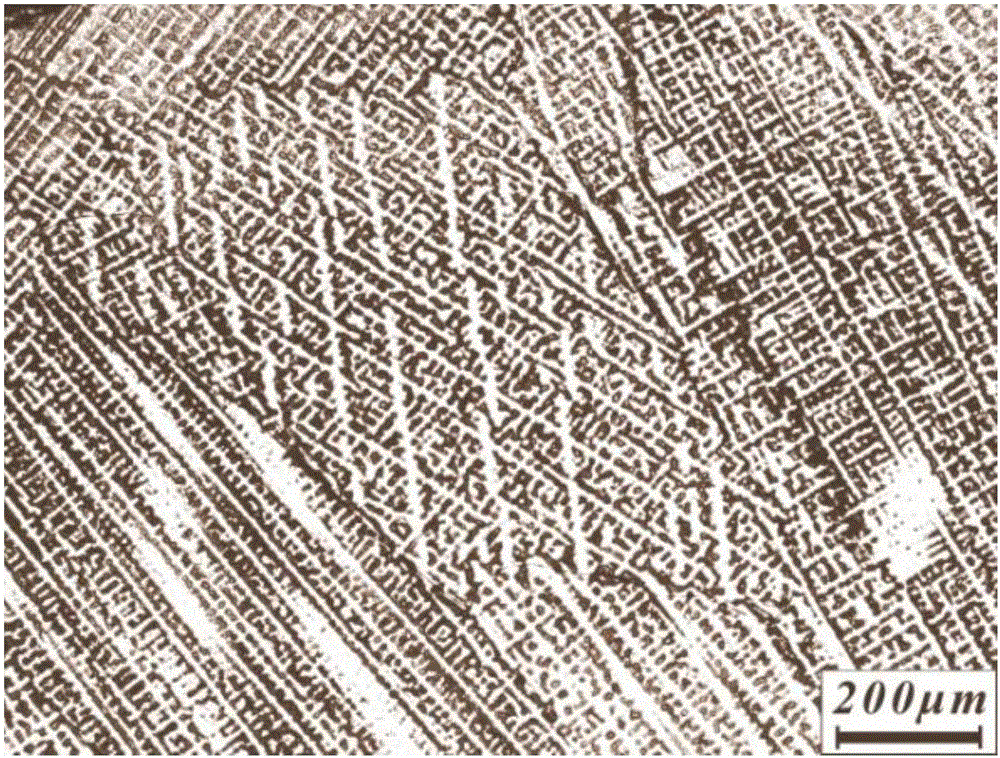

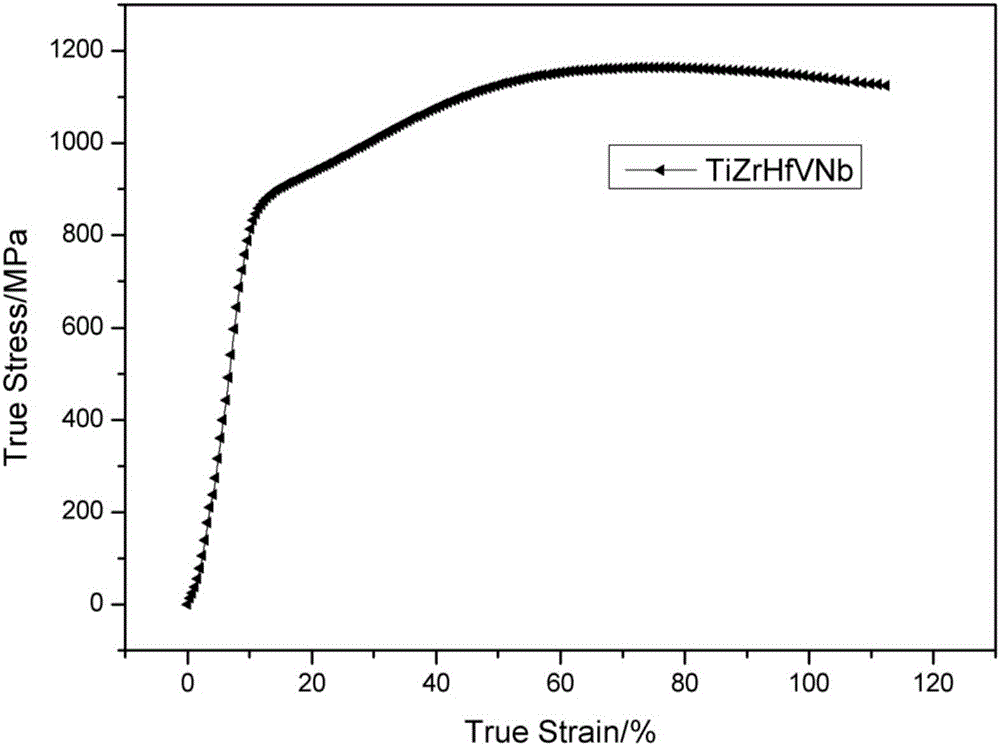

[0032] A five-element refractory high-entropy alloy with high plasticity, the high-entropy alloy is composed of zirconium (Zr), titanium (Ti), hafnium (Hf), vanadium (V) and niobium (Nb) in equimolar amounts, namely ZrTiHfVNb , wherein, the purity of the constituent elements is above 99%, and have the same crystal structure.

[0033] The raw materials are weighed with an electronic balance of 1 / 10,000 to reduce the experimental error. According to the order of melting point from low to high, they are titanium (Ti), zirconium (Zr), vanadium (V), hafnium (Hf), niobium (Nb), Put it into the water-cooled copper crucible of the non-consumable high vacuum arc melting furnace, the element with the lowest melting point titanium (Ti) is placed at the bottom, and the element with the highest melting point niobium (Nb) is placed at the top. Vacuum to 10 -4 MPa, then filled with argon gas to 0.05MPa, arc smelting; repeated smelting 6 times to ensure that the five elements in the raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com