Low-melting-point packaging film and low-melting-point packaging bag

A low-melting point, packaging film technology, applied in the field of low-melting point packaging films and low-melting point packaging bags, can solve the problems of large vertical and horizontal strength differences, affect applications, and low sealing strength, achieve consistent vertical and horizontal physical properties, and improve bag making method, the effect of high sealing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for making a low-melting point packaging bag, the method comprising the following steps:

[0036] (1) Mixing granules: According to the preset mass percentage, mix the following raw materials evenly to obtain the mixed material:

[0037] Ethylene vinyl acetate copolymer 75%, barium sulfate 2%, low density polyethylene 15%, composite opening masterbatch 8%;

[0038] (2) Film blowing: Use a film blowing machine to heat and melt the mixture and process it into a raw film with an inflation ratio of 3:1;

[0039] Then, the raw material film is cooled at 20°C by using the internal and external cooling method of the film bubble to obtain a low-melting point packaging film;

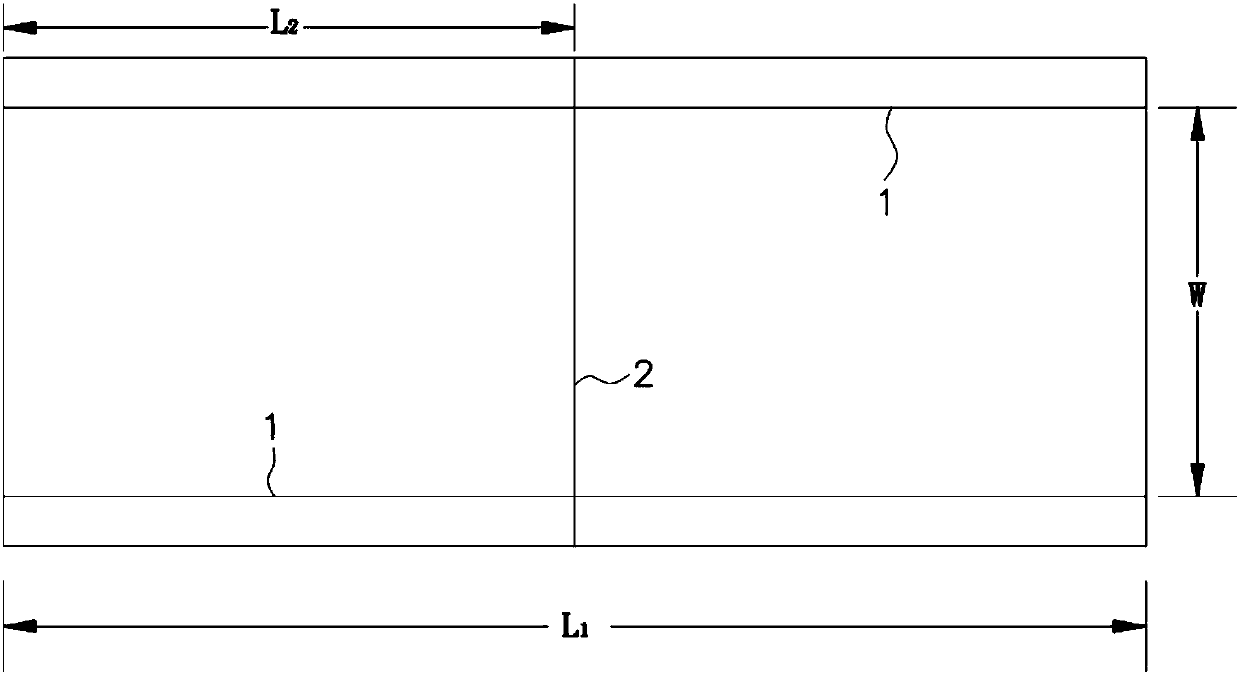

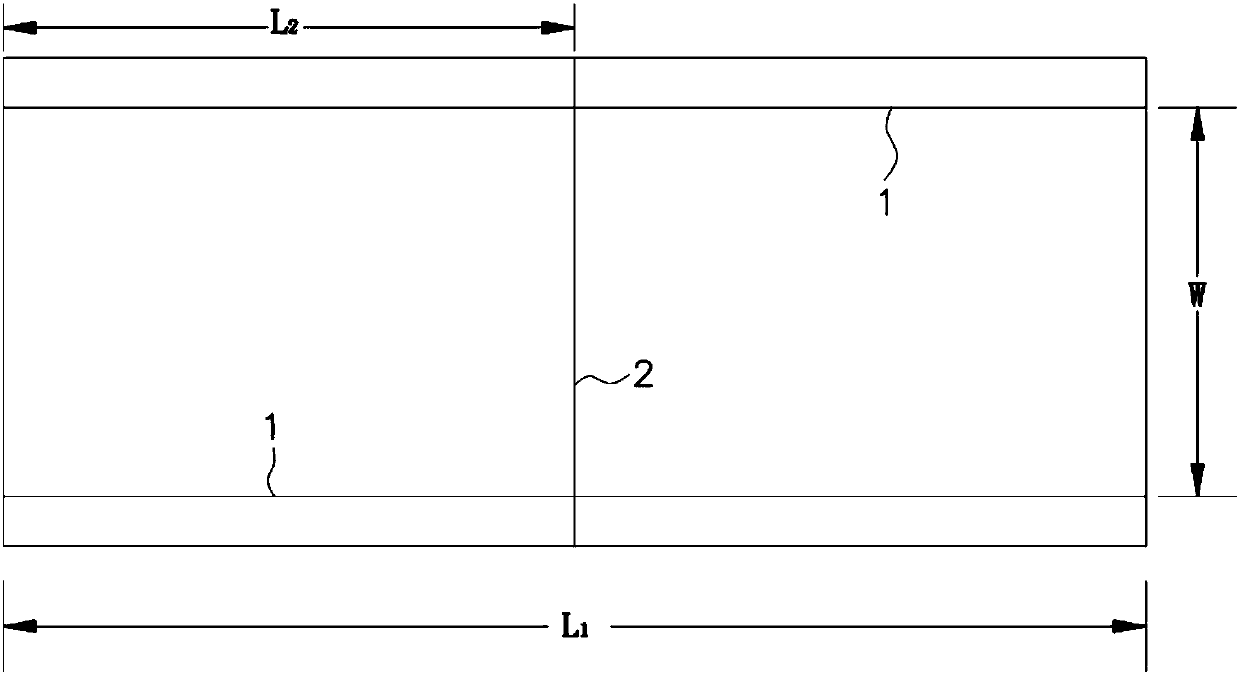

[0040] (3) bag making (such as figure 1 shown):

[0041] 1) Cutting the low-melting-point packaging film according to the preset bag width W (400 mm) along the length extension direction of the low-melting-point packaging film to obtain multiple small-sized low-melting-point packaging films;

...

Embodiment 2

[0044] A method for making a low-melting point packaging bag, the method comprising the following steps:

[0045] (1) Mixing granules: According to the preset mass percentage, mix the following raw materials evenly to obtain the mixed material:

[0046] Ethylene vinyl acetate copolymer 75%, barium sulfate 2%, low density polyethylene 15%, composite opening masterbatch 8%;

[0047] (2) Film blowing: Use a film blowing machine to heat and melt the mixture and process it into a raw film with an inflation ratio of 5:1;

[0048] Then, the raw material film is cooled at 10°C by using the internal and external cooling method of the film bubble to obtain a low-melting point packaging film;

[0049] (3) bag making (such as figure 1 shown):

[0050] 1) Cut the low-melting-point packaging film according to the preset bag width W (300mm) along the length extension direction of the low-melting-point packaging film to obtain a plurality of small-sized low-melting-point packaging films; ...

Embodiment 3

[0053] A method for making a low-melting point packaging bag, the method comprising the following steps:

[0054] (1) Mixing granules: According to the preset mass percentage, mix the following raw materials evenly to obtain the mixed material:

[0055] Ethylene vinyl acetate copolymer 75%, barium sulfate 2%, low density polyethylene 15%, composite opening masterbatch 8%;

[0056] (2) Film blowing: Use a film blowing machine to heat and melt the mixture and process it into a raw film with an inflation ratio of 4:1;

[0057] Then, the raw material film is cooled at 15°C by using the internal and external cooling method of the film bubble to obtain a low-melting point packaging film;

[0058] (3) bag making (such as figure 1 shown):

[0059] 1) Cut the low-melting-point packaging film according to the preset bag width W (250mm) along the length extension direction of the low-melting-point packaging film to obtain a plurality of small-sized low-melting-point packaging films; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com