Patents

Literature

204results about How to "Reduce thickness difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroplating solution for acid copper-plating for printed circuit board as well as preparation method and application method for same

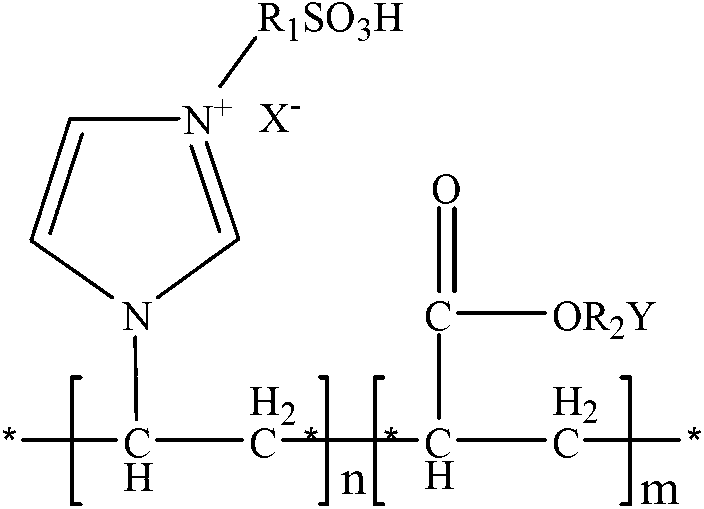

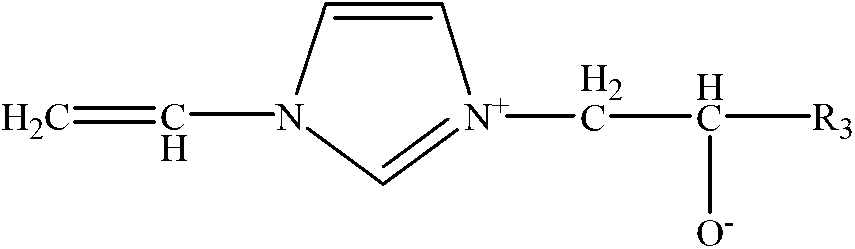

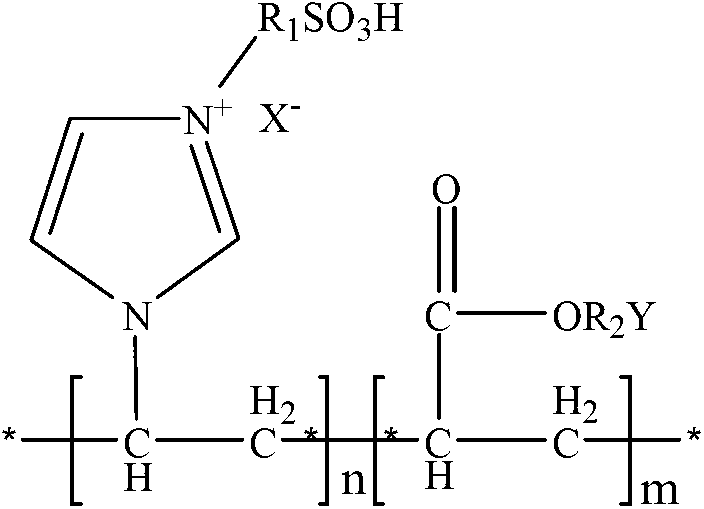

The invention discloses an electroplating solution for acid copper-plating for a circuit board as well as a preparation method and an application method for the same. The electroplating solution disclosed by the invention is characterized in that a home-made synthesised levelling agent is added, and the levelling agent is matched with water-soluble copper salt, sulphuric acid, a brightening agent, chloride ions, a gloss agent and a surfactant to form the electroplating solution. The home-made levelling agent is one or more of the copolymer of N-vinyl imidazole onium salt and propenyl esters, and the polymer of N-vinyl imidazole and epoxides. The electroplating solution containing the home-made synthesised levelling agent is great in covering power and the dispersing power, capable of improving the uniform distribution of copper layers in the through holes of the printed circuit board, and capable of effectively reducing the ratio of the thickness of the surface copper layers to the thickness of the copper layers in the centres of the holes.

Owner:CENT SOUTH UNIV

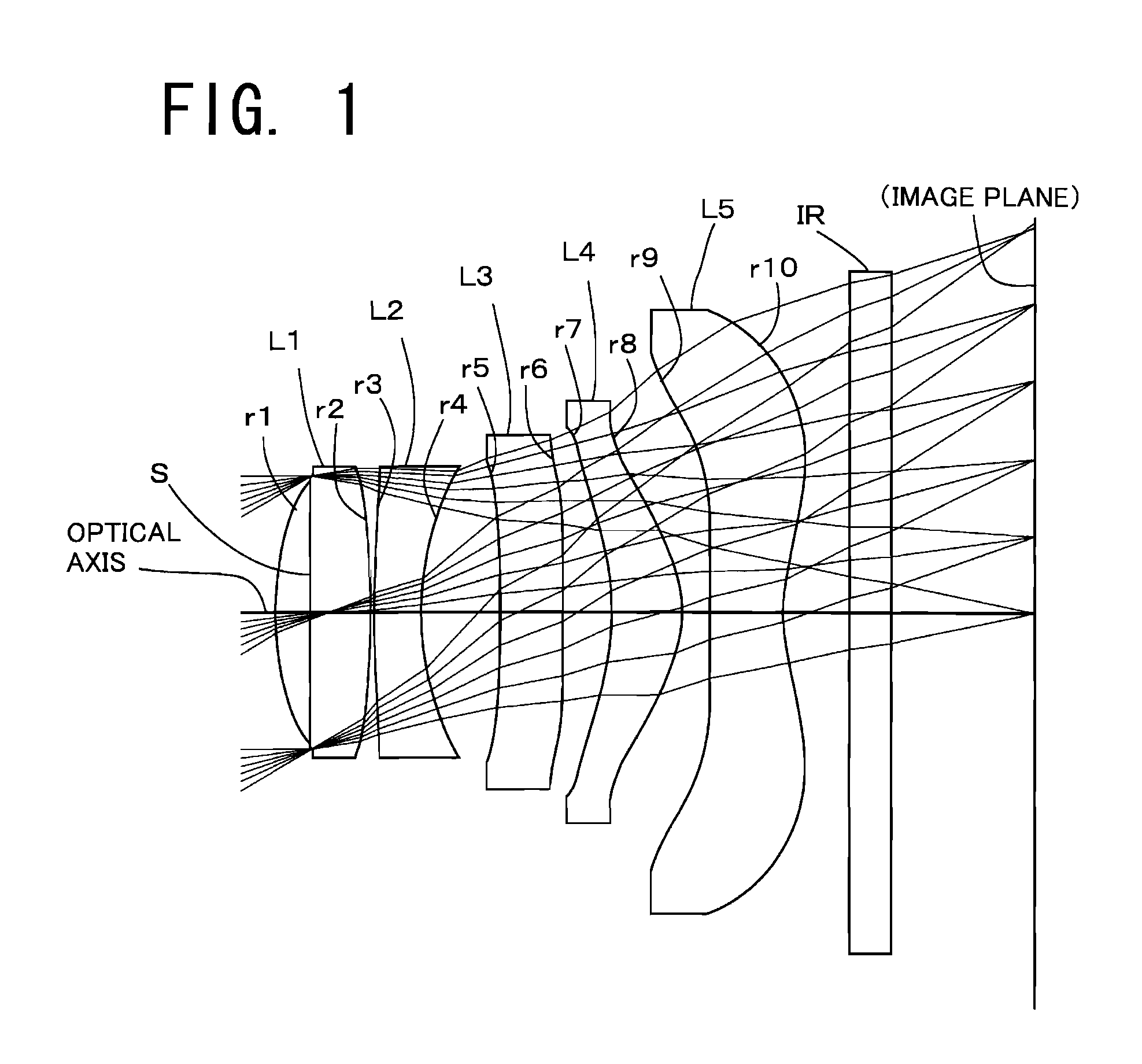

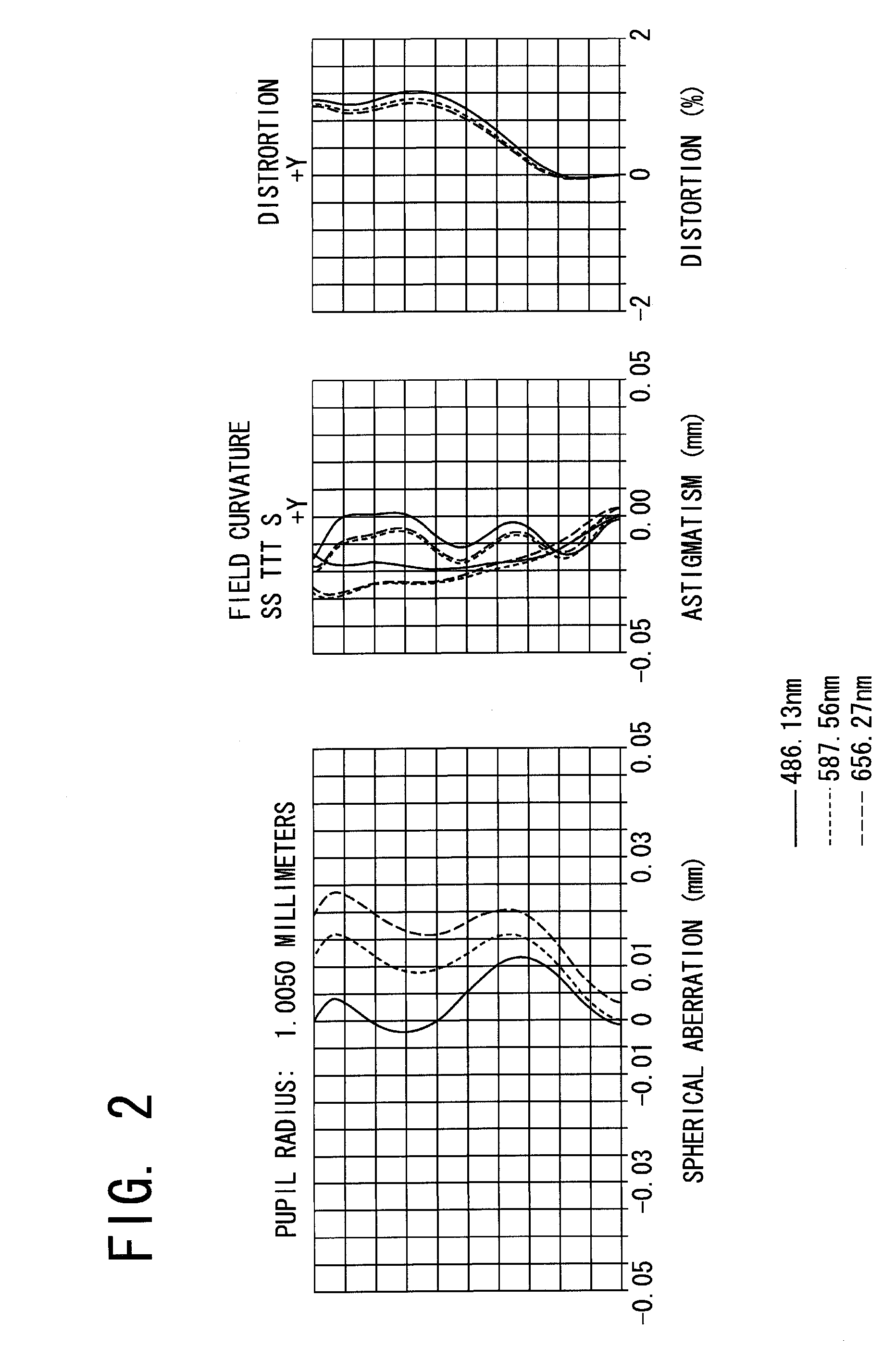

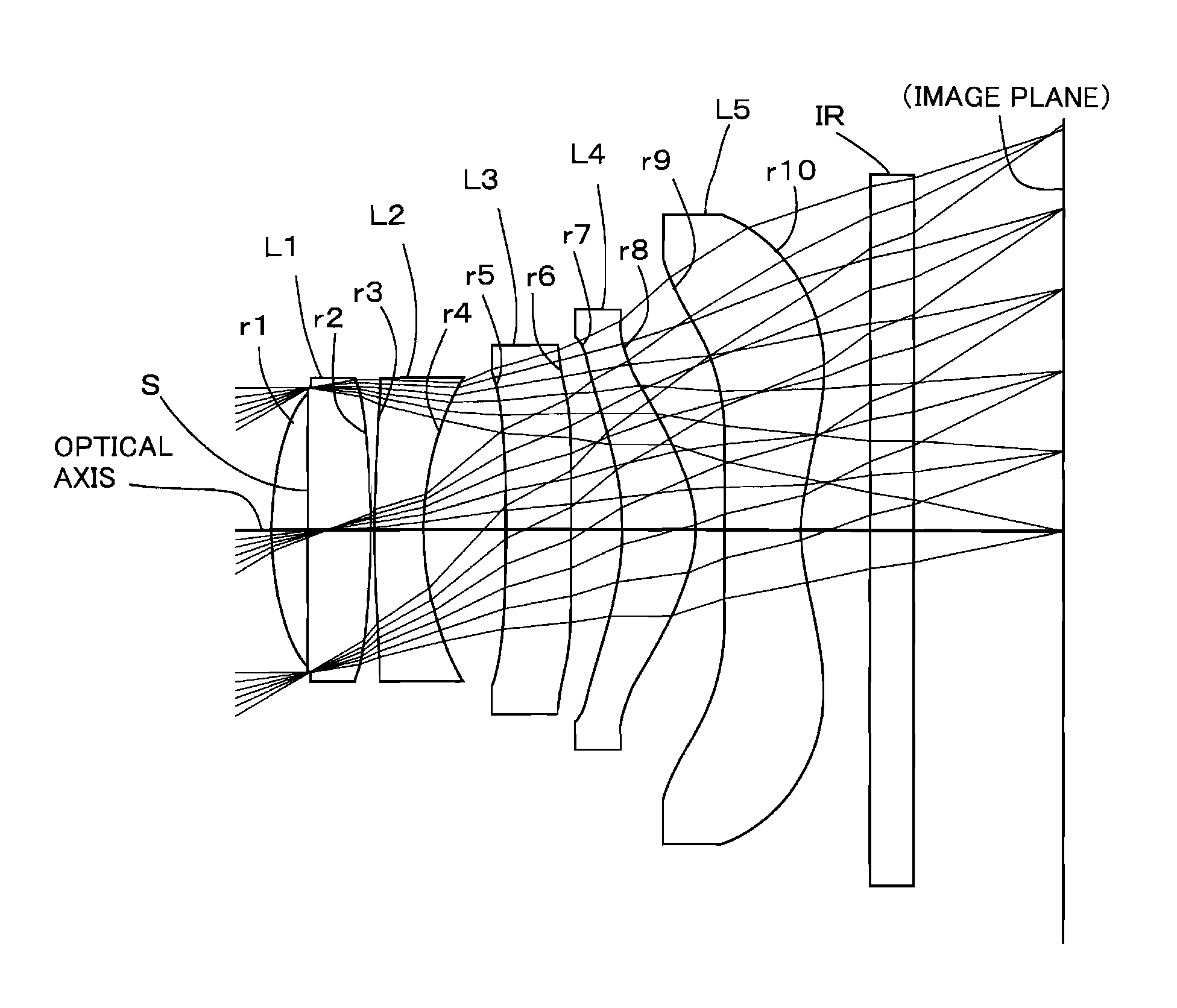

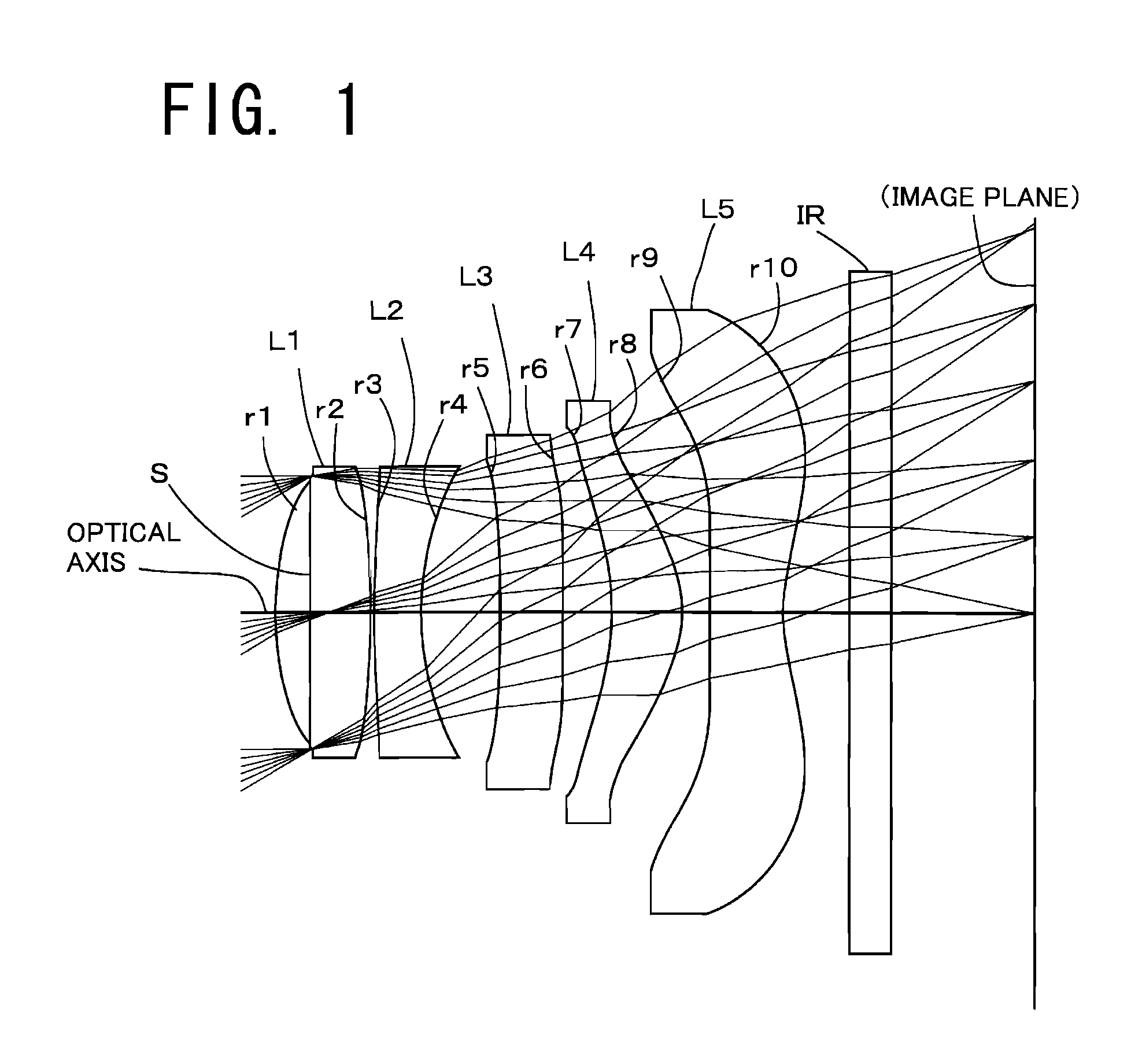

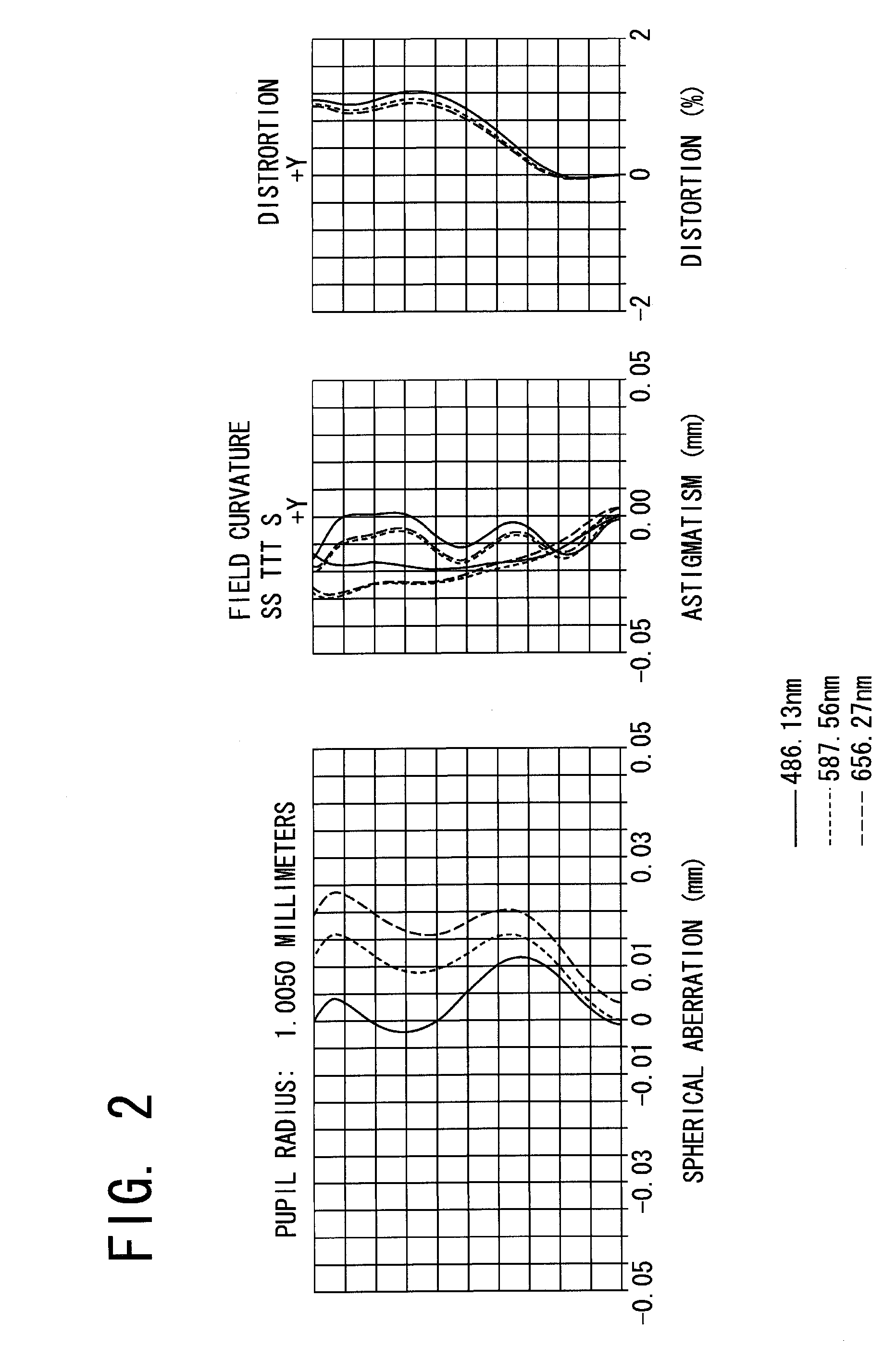

Imaging lens unit

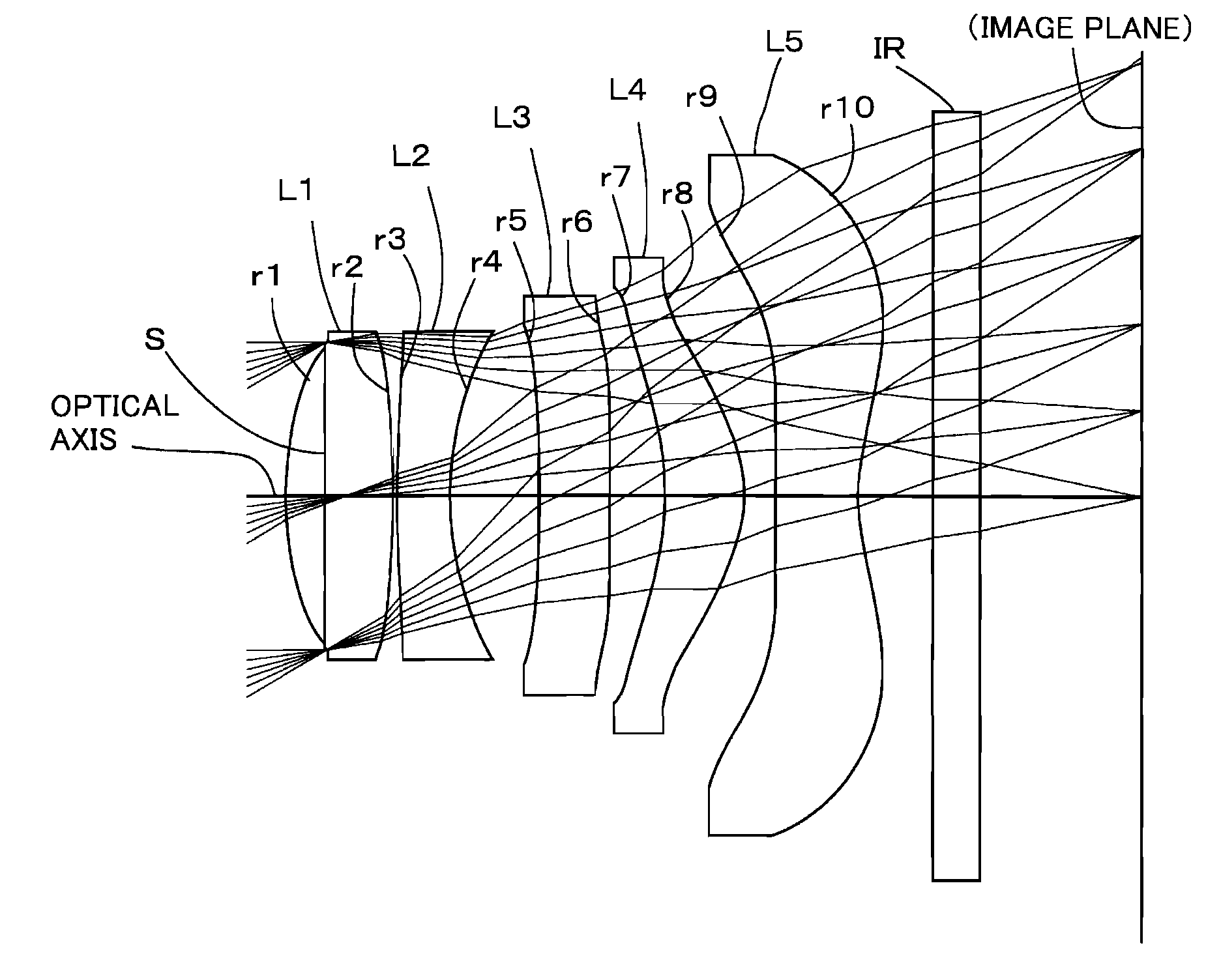

A compact low-cost imaging lens unit for a solid-state image sensor which corrects various aberrations adequately and produces a high-resolution high-definition image. The components of the unit are arranged from an object side to an image side in the following order: an aperture stop, a first lens with positive refractive power having a convex surface facing the object side, a second lens with negative refractive power having a convex surface facing the object side near an optical axis, a third lens with negative refractive power having a convex surface facing the object side near the optical axis, a fourth lens as a meniscus lens with positive refractive power having a convex surface facing the image side near the optical axis; and a fifth lens with negative refractive power having a concave surface facing the image side near the optical axis.

Owner:TOKYO VISIONARY OPTICS CO LTD

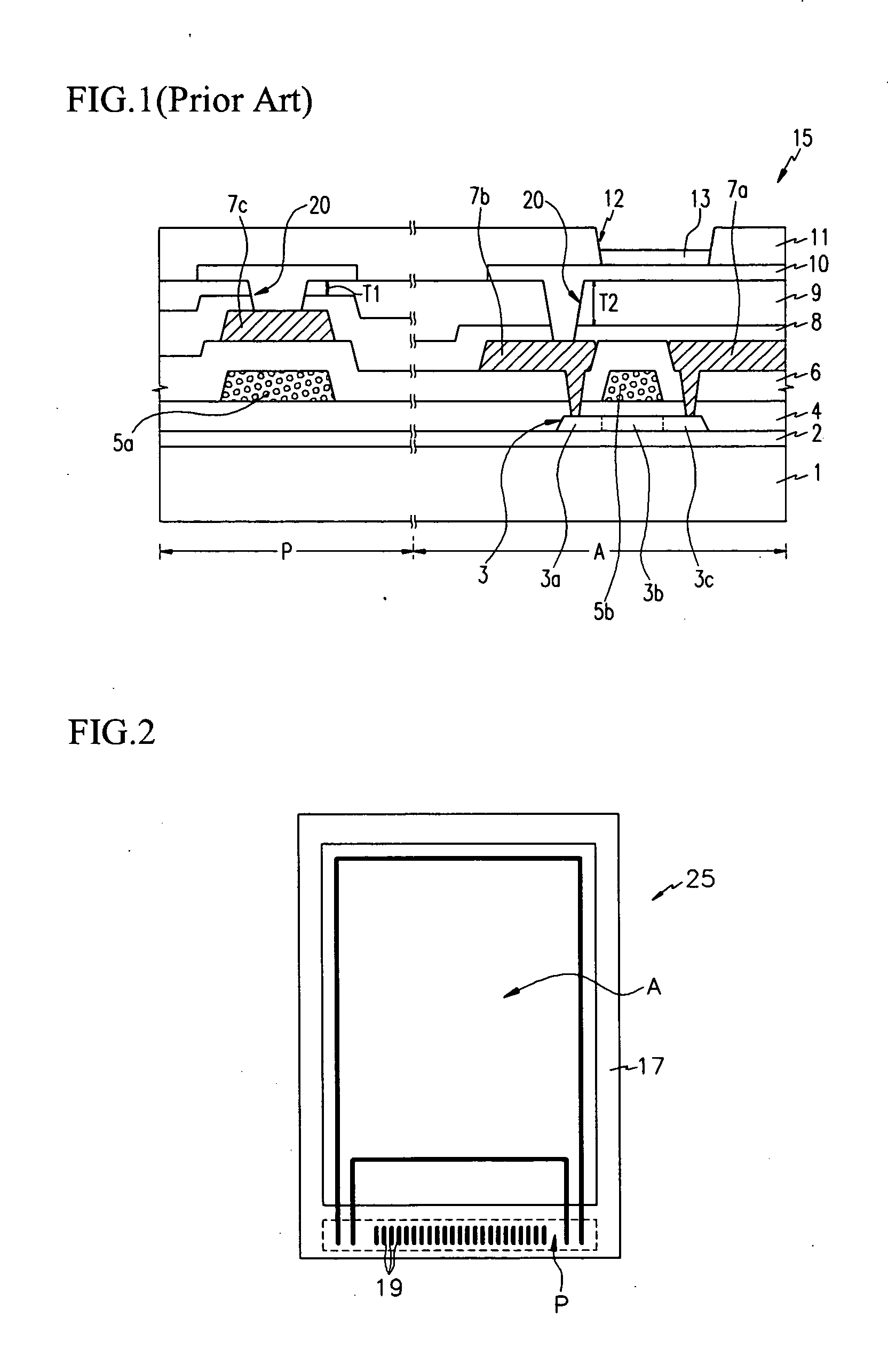

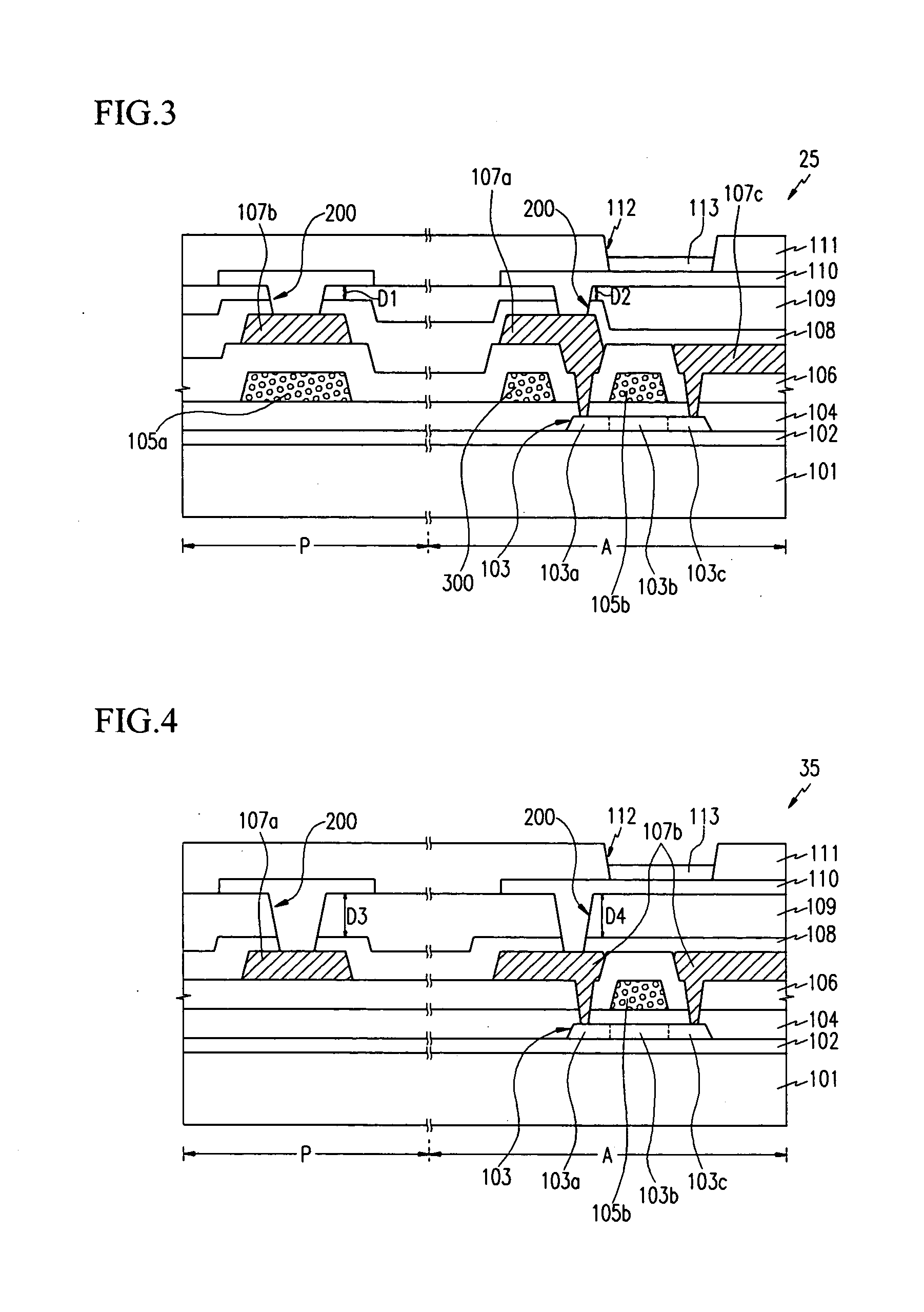

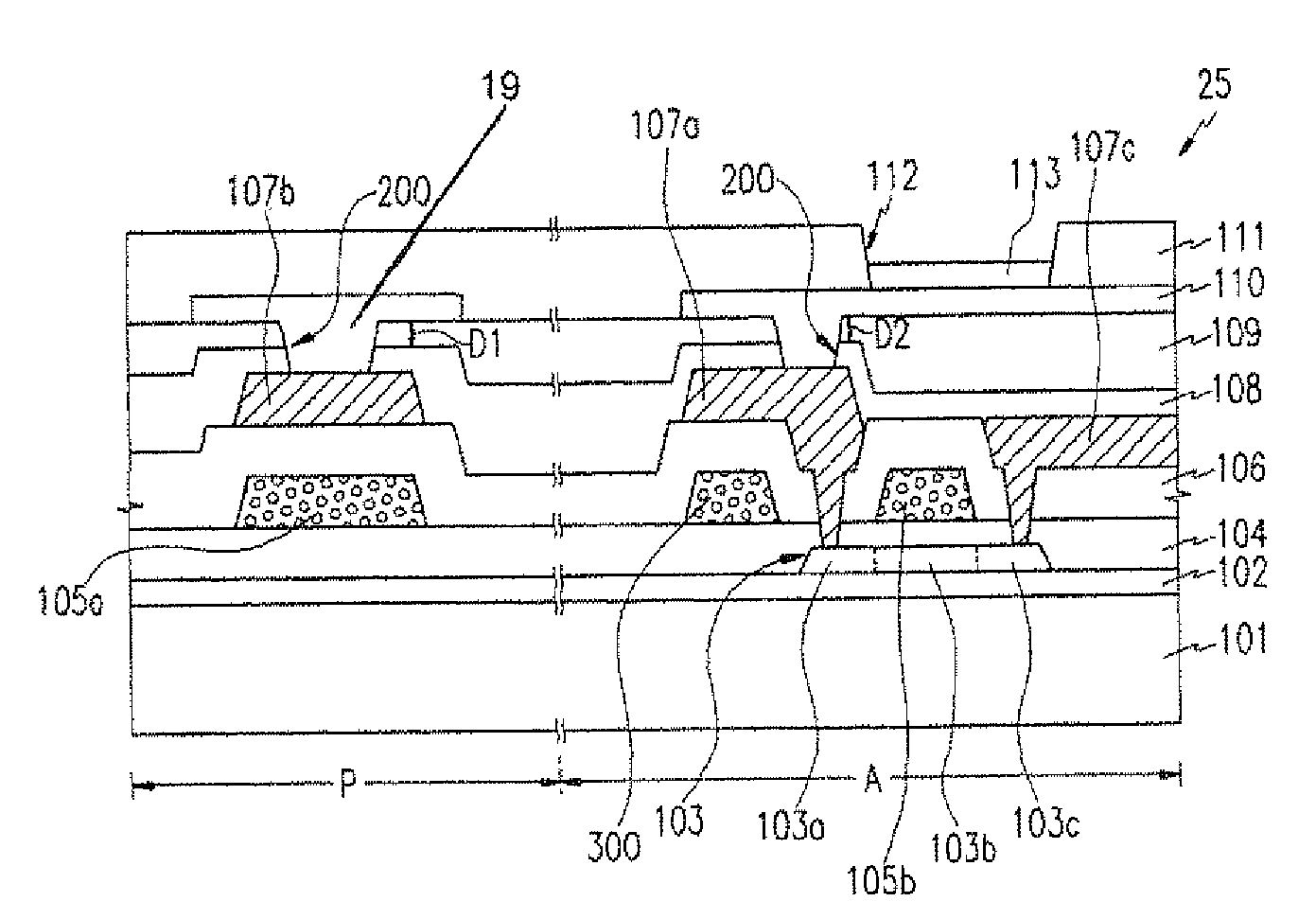

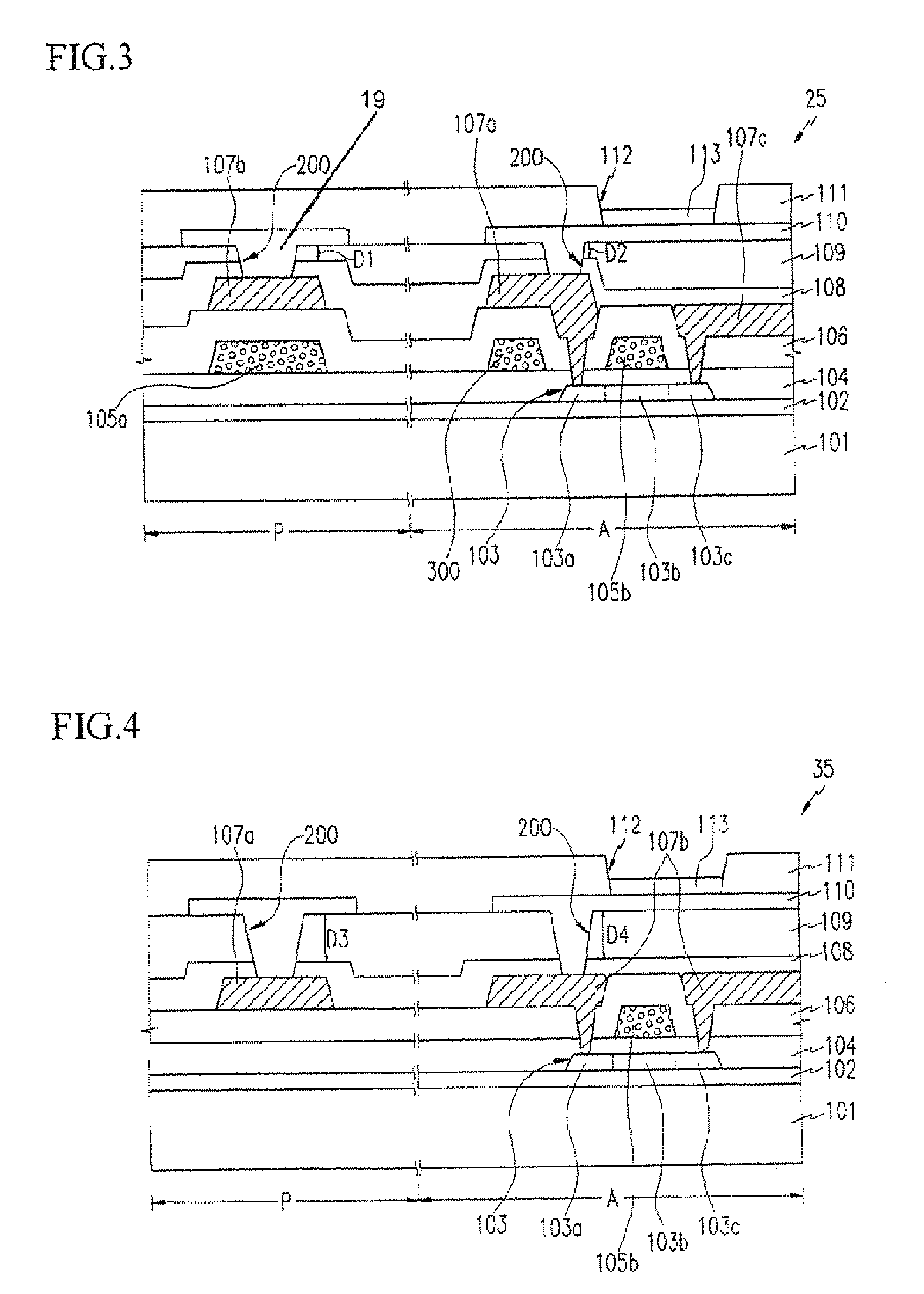

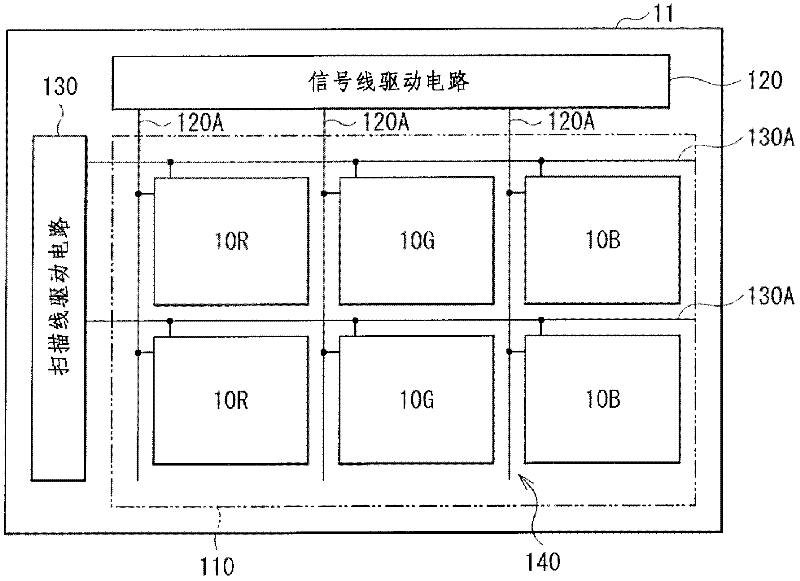

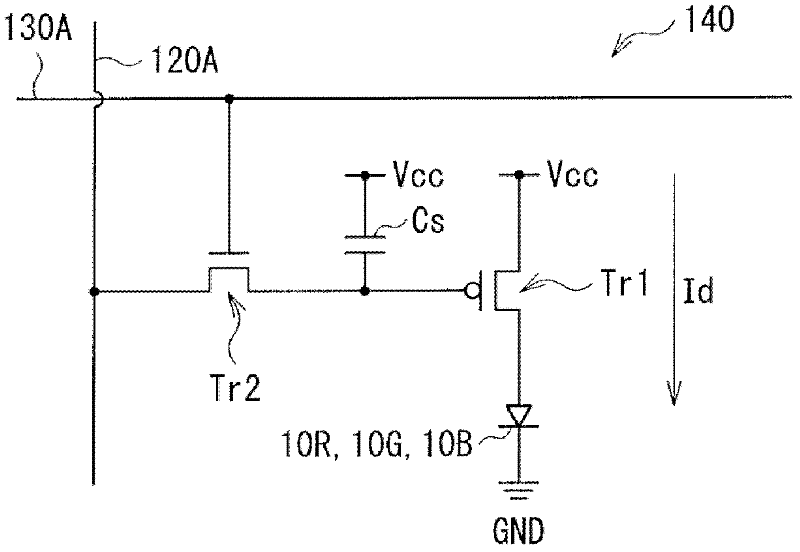

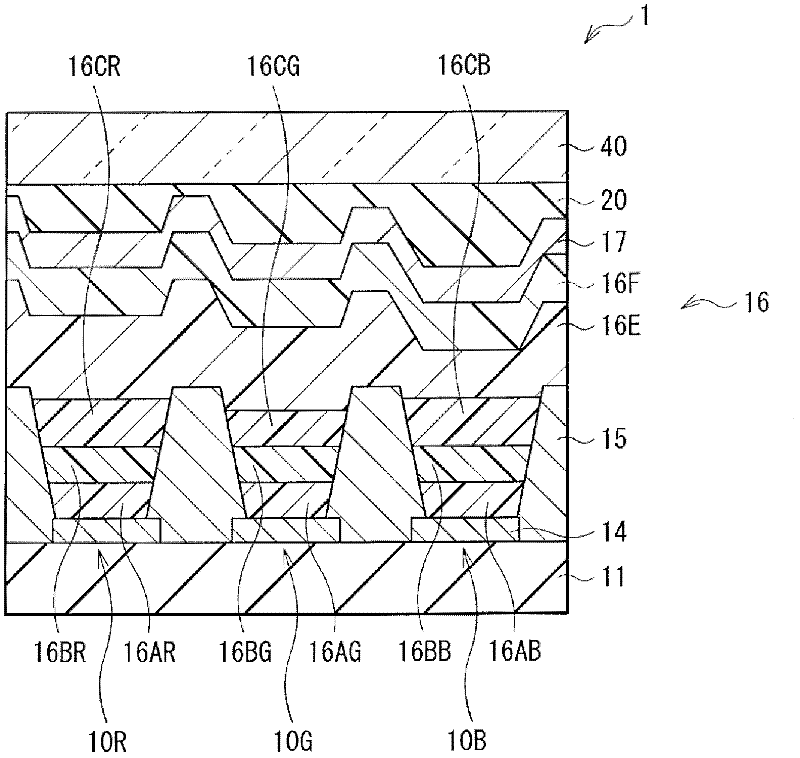

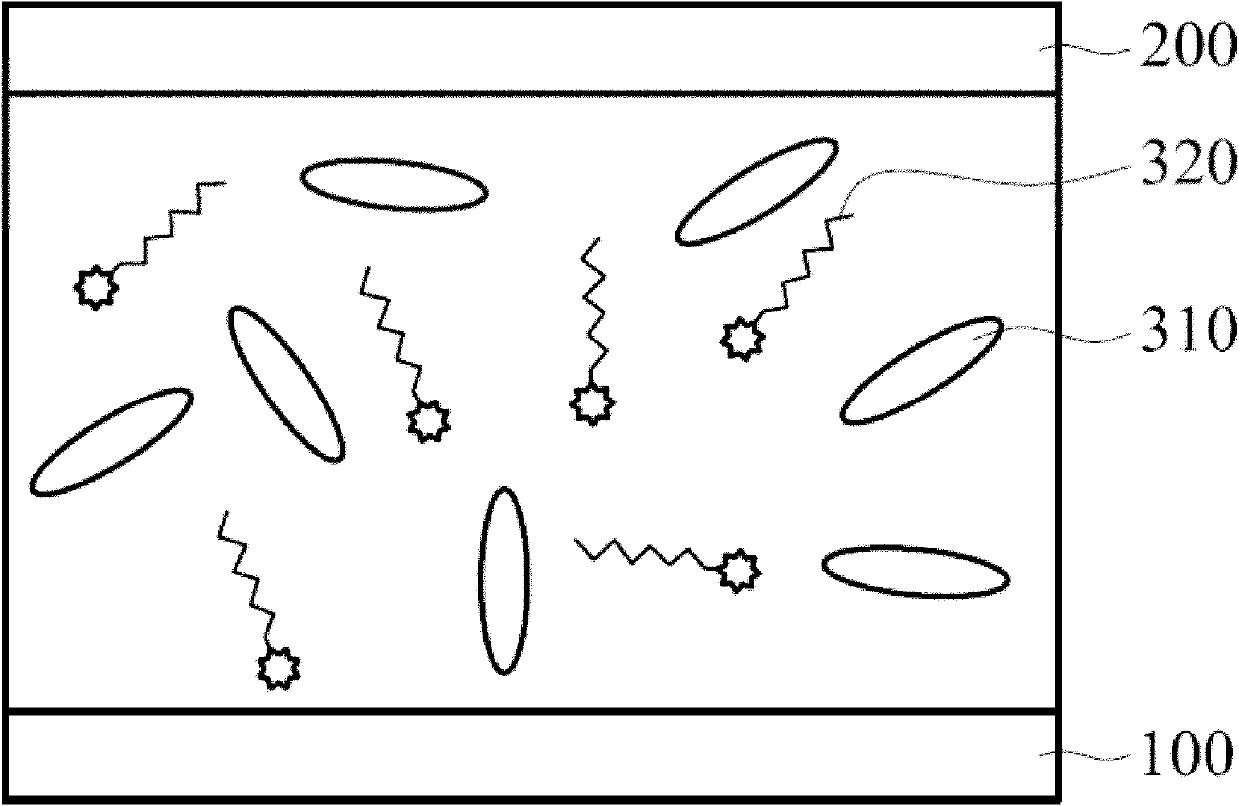

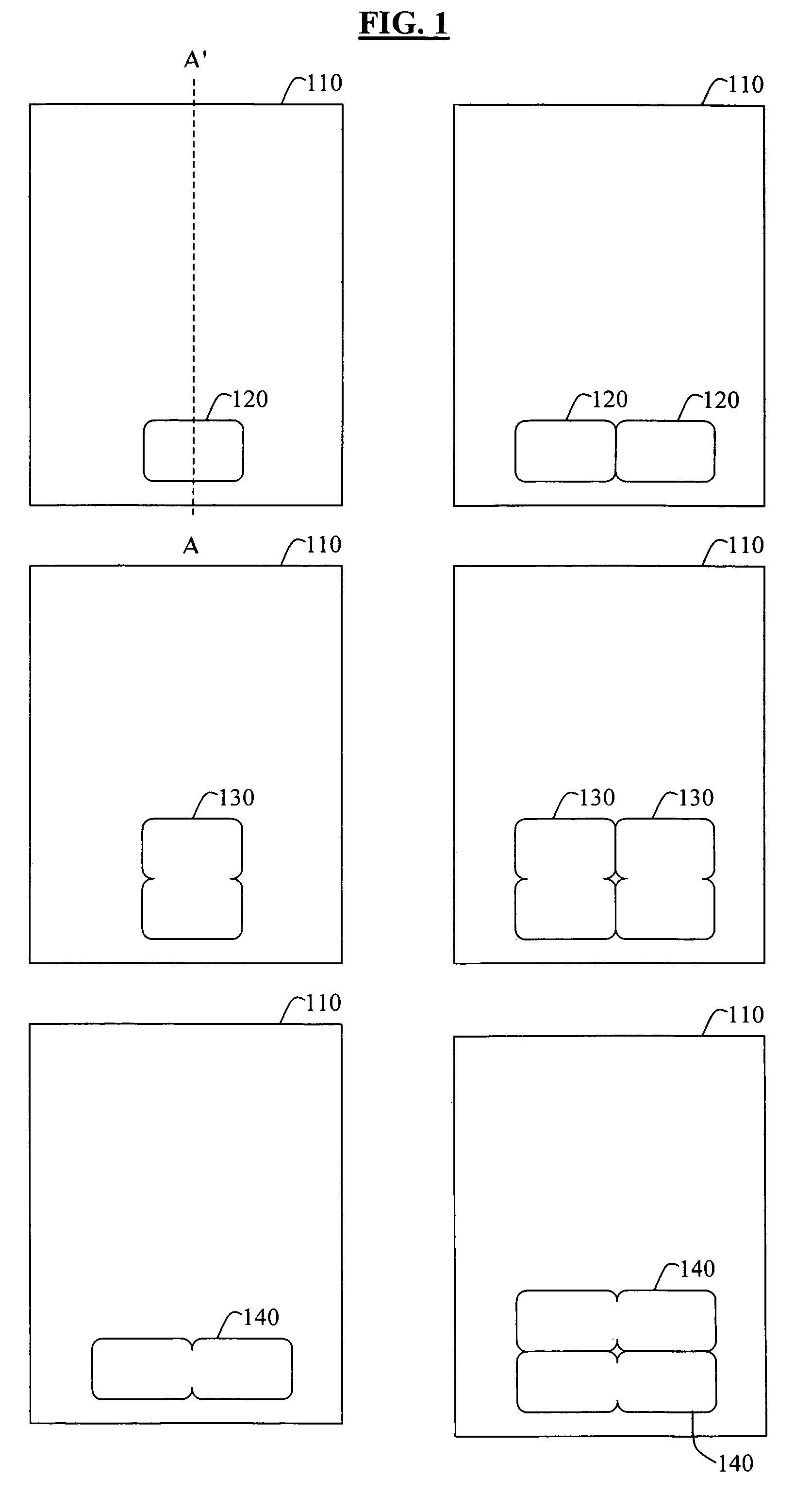

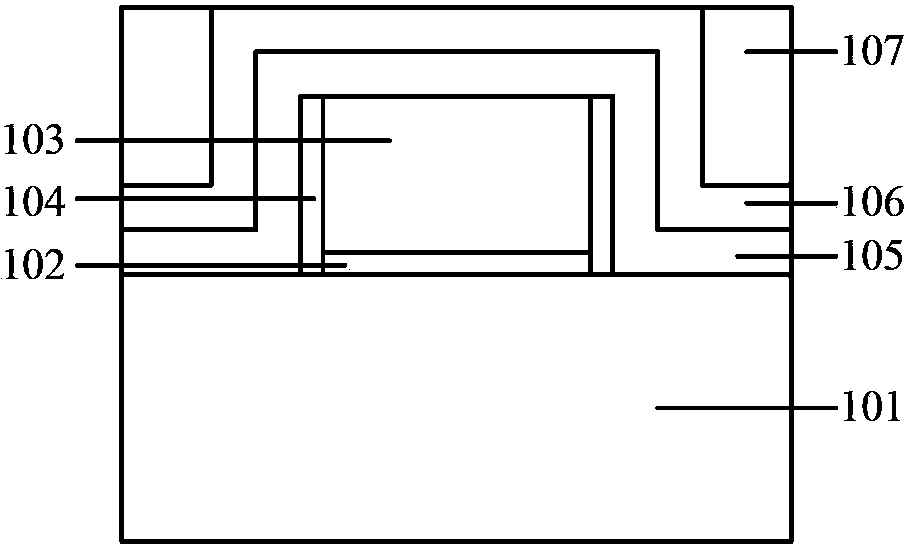

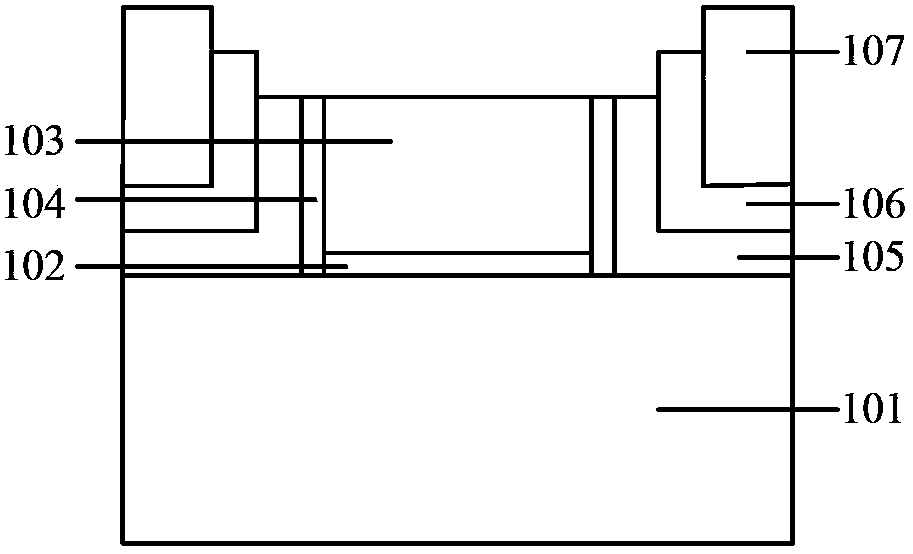

Organic electroluminescent display

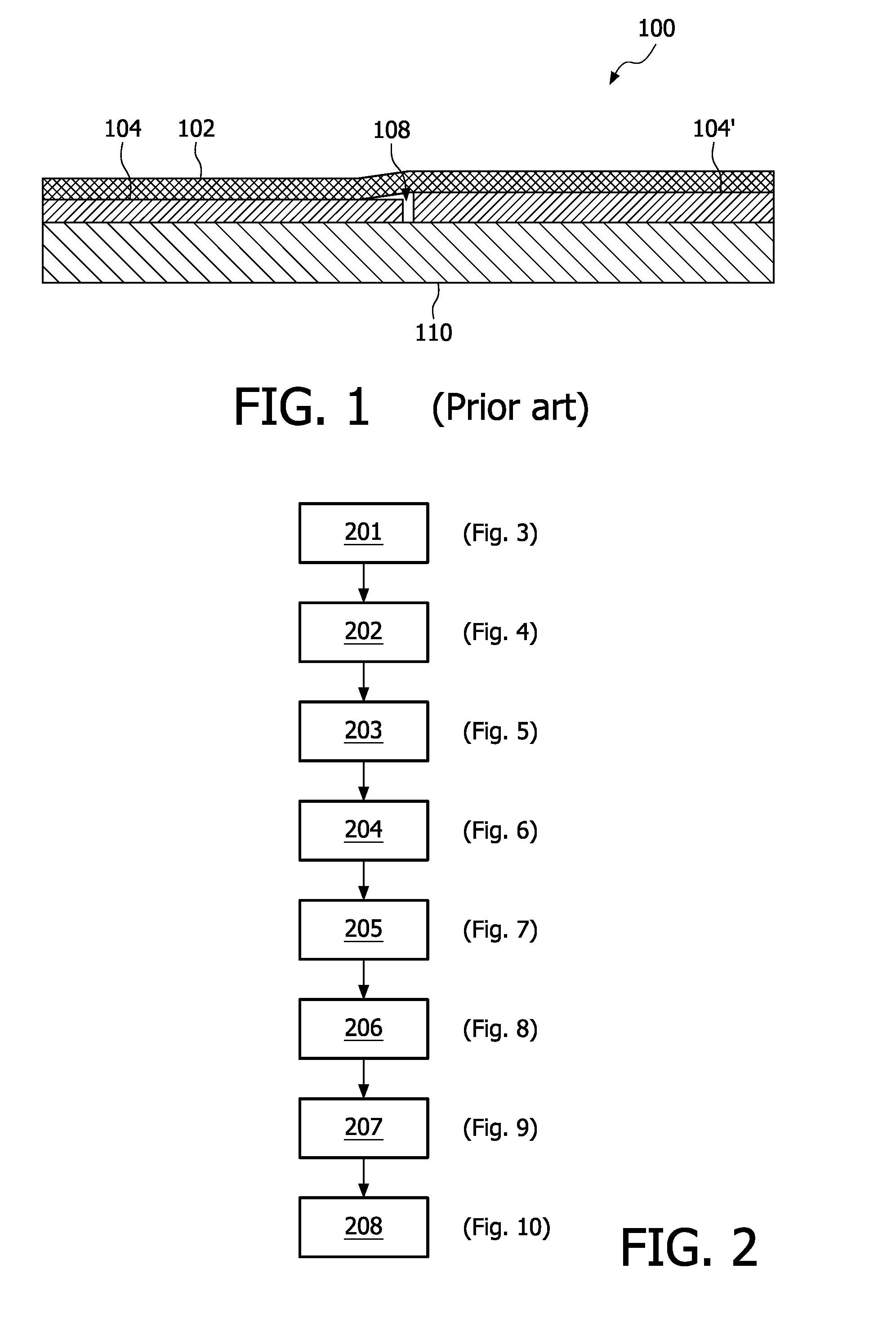

ActiveUS20050045882A1Reduce thickness differenceElectroluminescent light sourcesSolid-state devicesSemiconductor structureOrganic electroluminescence

An organic electroluminescent display includes a substrate having an array portion with pixels, and a pad portion coupled to an external power supply. A semiconductor structure is formed on the substrate with a source electrode, a drain electrode and a pad. A passivation layer is formed on the semiconductor structure with via holes exposing regions of the source and the drain electrodes at the array portion and the pad at the pad portion. Portions of the passivation layer contacting the via holes between the array portion and the pad portion have the same thickness. A conductive layer fills the via holes. A pixel defining layer is formed over the entire surface of a flattening layer and the conductive layer with pixel regions exposing regions of the conductive layer at the array portion. An organic electroluminescent film is formed at each pixel region.

Owner:SAMSUNG DISPLAY CO LTD

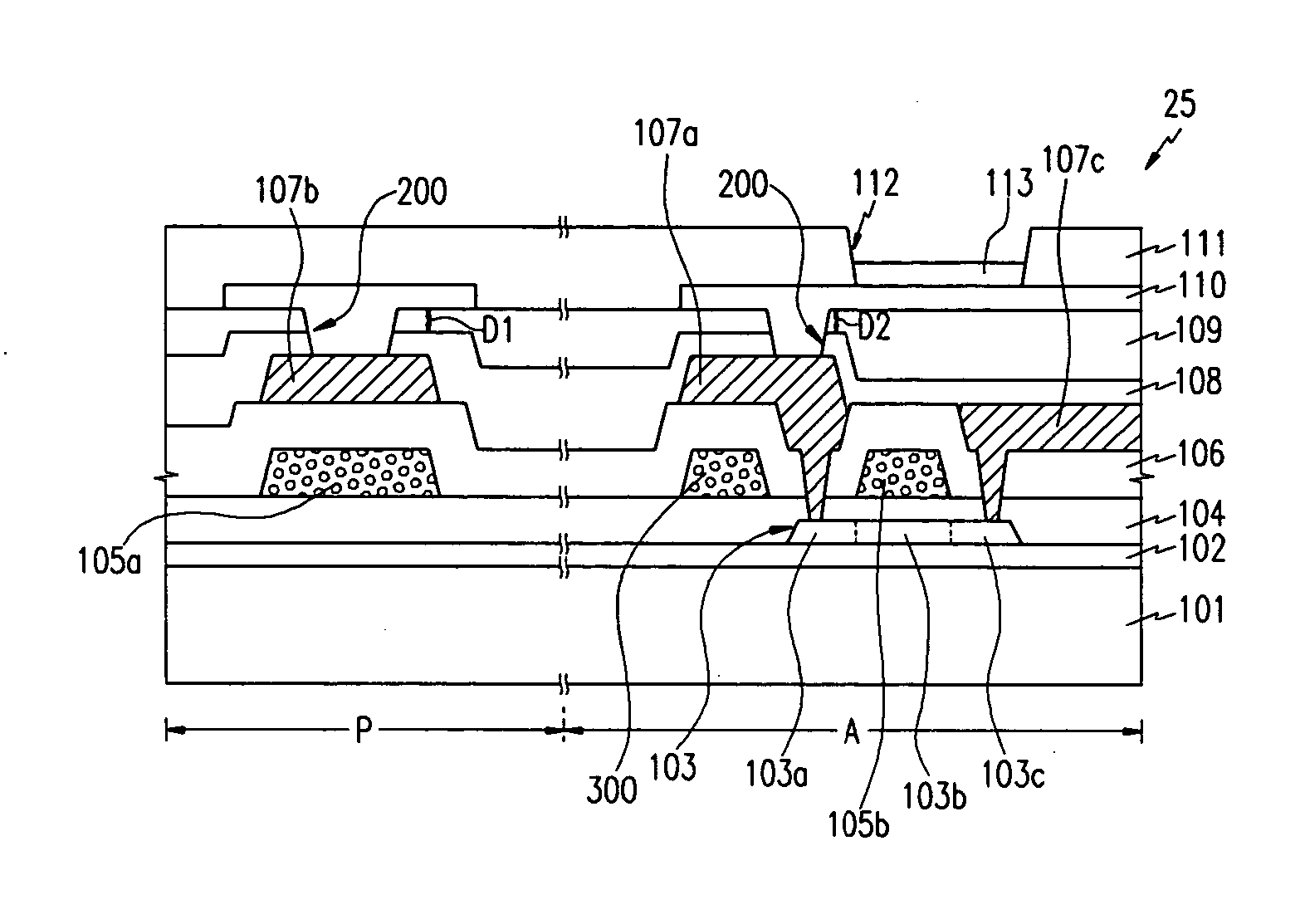

Organic electroluminescent display

ActiveUS7211826B2Reduce thickness differenceElectroluminescent light sourcesSolid-state devicesSemiconductor structureOrganic electroluminescence

An organic electroluminescent display includes a substrate having an array portion with pixels, and a pad portion coupled to an external power supply. A semiconductor structure is formed on the substrate with a source electrode, a drain electrode and a pad. A passivation layer is formed on the semiconductor structure with via holes exposing regions of the source and the drain electrodes at the array portion and the pad at the pad portion. Portions of the passivation layer contacting the via holes between the array portion and the pad portion have the same thickness. A conductive layer fills the via holes. A pixel defining layer is formed over the entire surface of a flattening layer and the conductive layer with pixel regions exposing regions of the conductive layer at the array portion. An organic electroluminescent film is formed at each pixel region.

Owner:SAMSUNG DISPLAY CO LTD

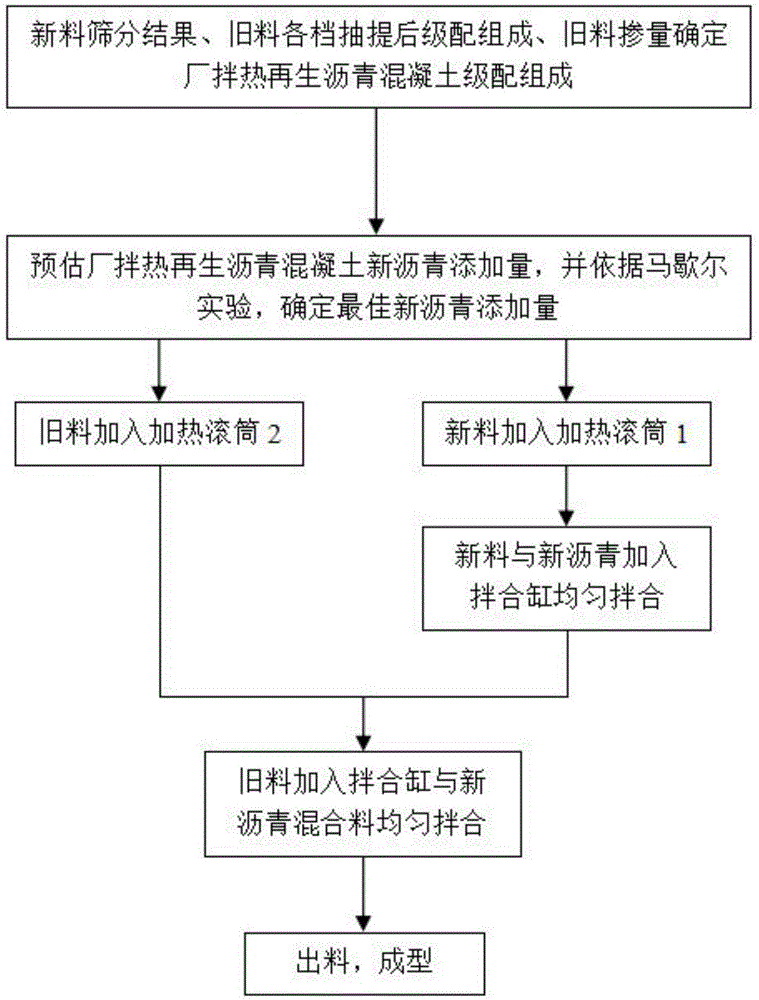

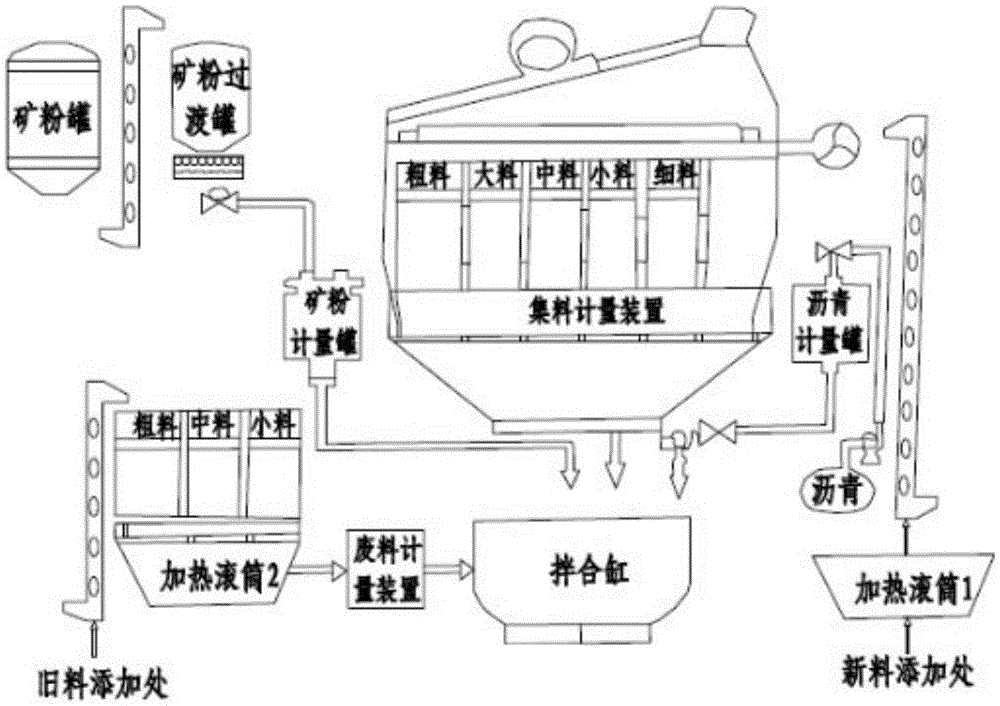

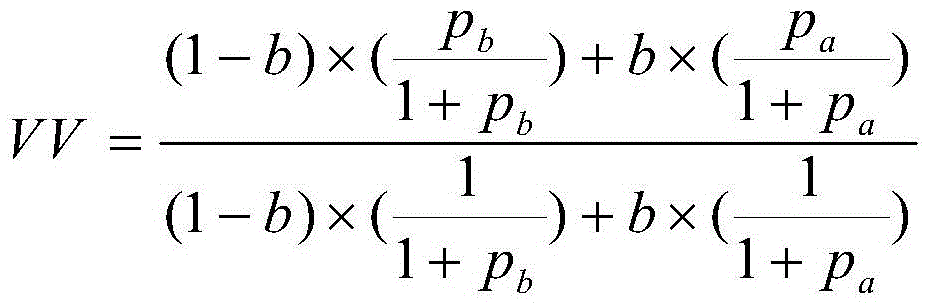

Production method of plant-mixed hot recycled asphalt concrete

ActiveCN105601176AAchieve recyclingReduce pollutionSolid waste managementEstimation methodsNew materials

The invention provides a production method of plant-mixed hot recycled asphalt concrete. The method comprises a plant-mixed hot recycled asphalt concrete gradation determining method, a plant-mixed hot recycled asphalt concrete asphalt-aggregate ratio determining method and a plant-mixed hot recycled asphalt concrete preparation technology. Old materials are divided into three grades, the effect of variability of the old materials on the pavement performance of the plant-mixed hot recycled asphalt concrete is avoided, and meanwhile, plant-mixed hot recycled asphalt concrete with different pavement performance can be obtained by controlling the key sieve mesh passing rate. The test amount for determining the best asphalt adding amount is greatly decreased with the new asphalt adding amount estimation method of the plant-mixed hot recycled asphalt concrete; in the preparation process of the method, new materials and new asphalt are uniformly mixed, then heated old materials are added, the thickness difference between asphalt films of the new and old asphalt mixture is reduced, the asphalt amount is effectively reduced, and uneven mixing is avoided.

Owner:安徽省交通勘察设计院有限公司

Organic electroluminescence display unit and electronic device

InactiveCN102386206AImprove uniformityGuaranteed accuracySolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerOptoelectronics

Owner:JOLED INC

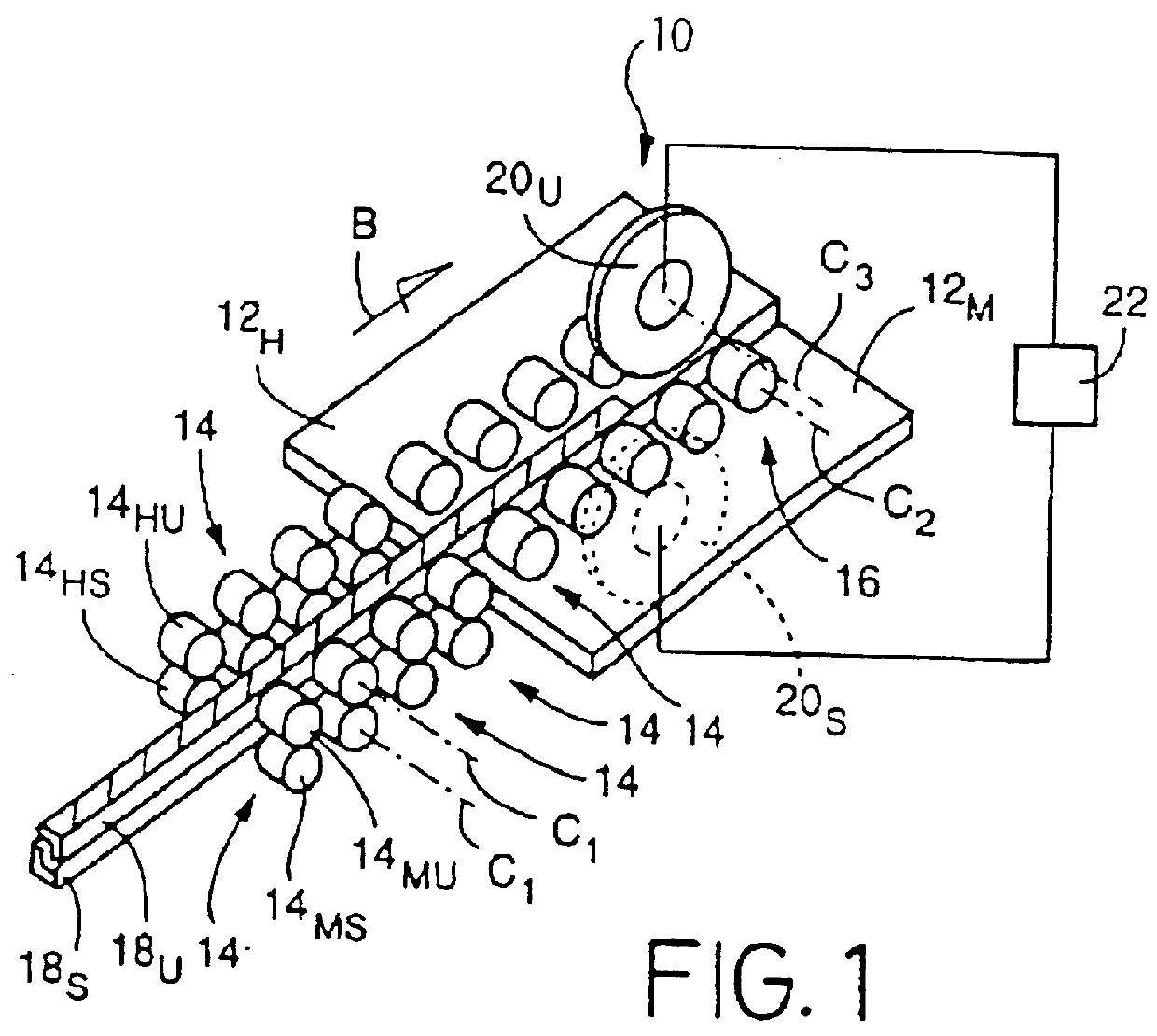

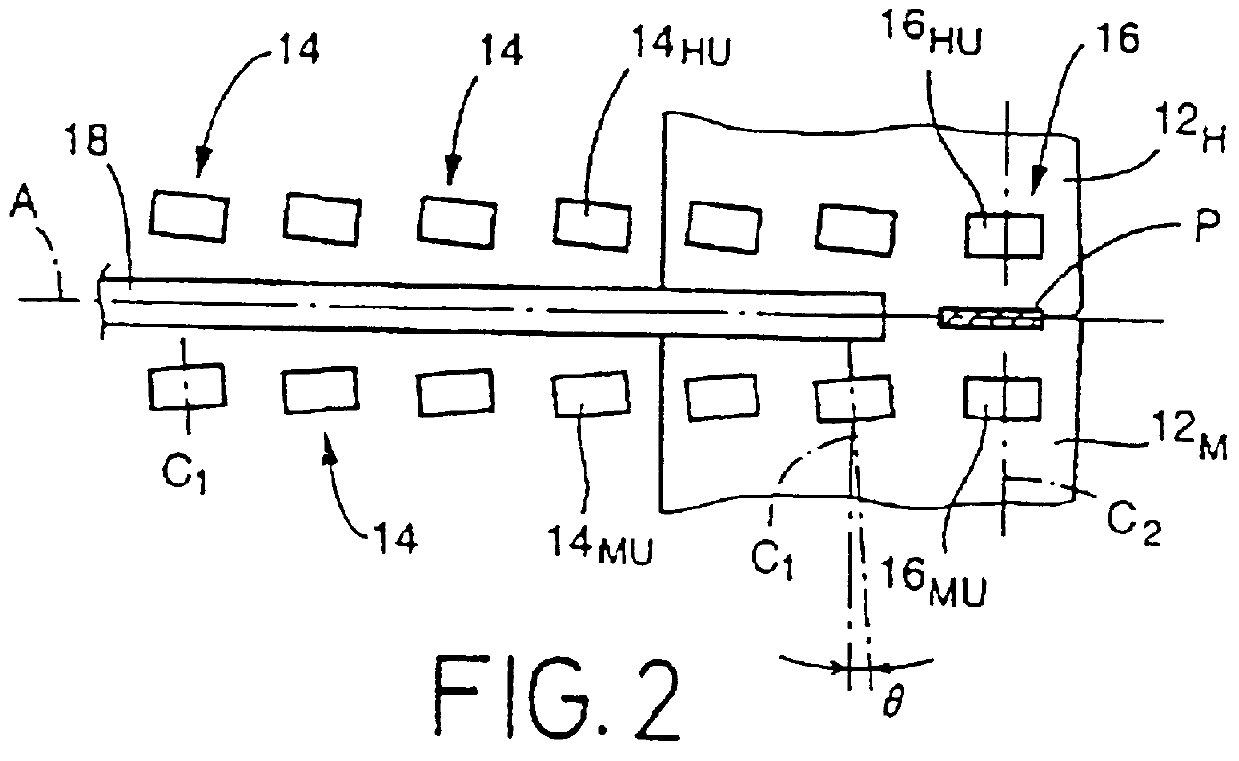

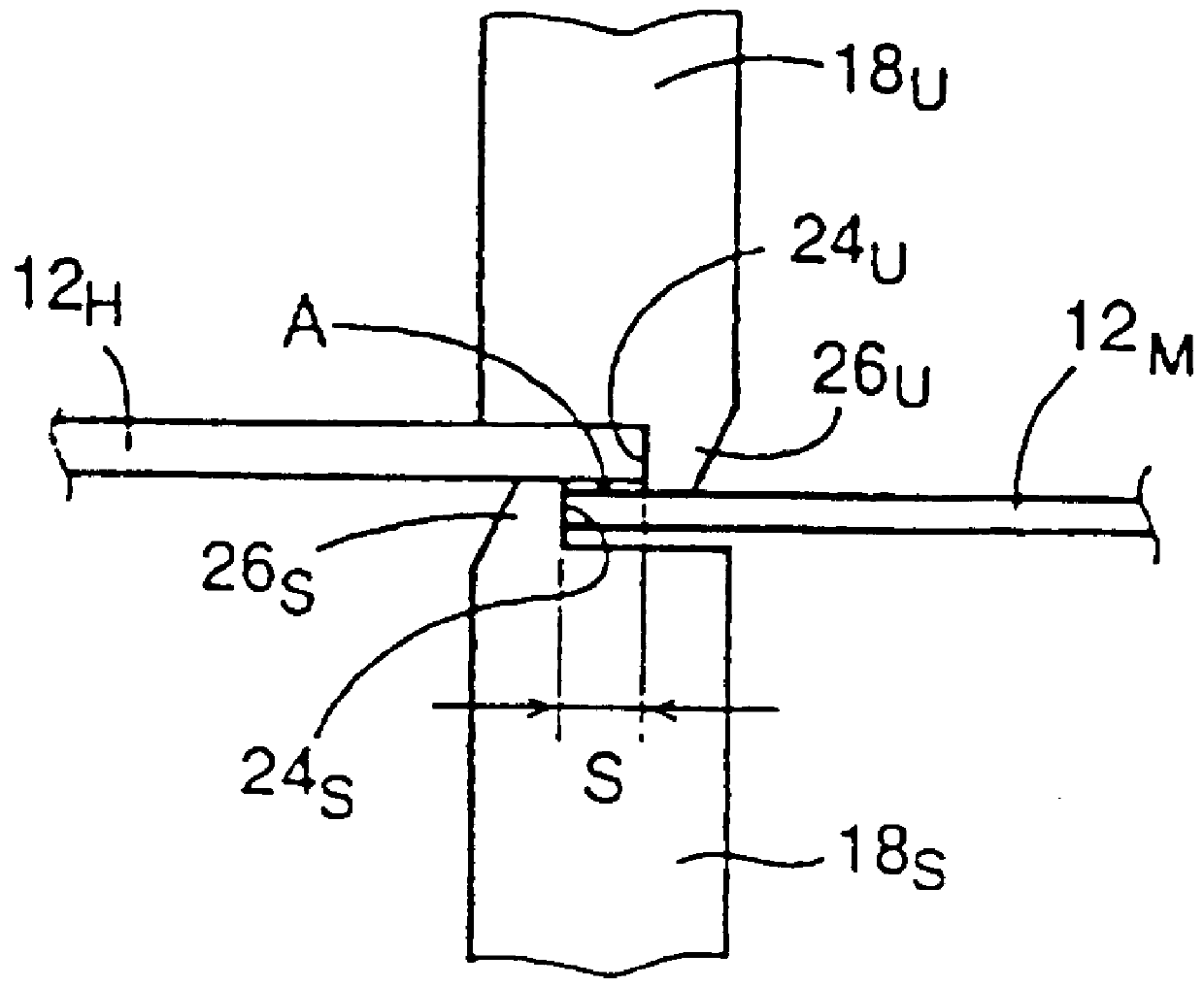

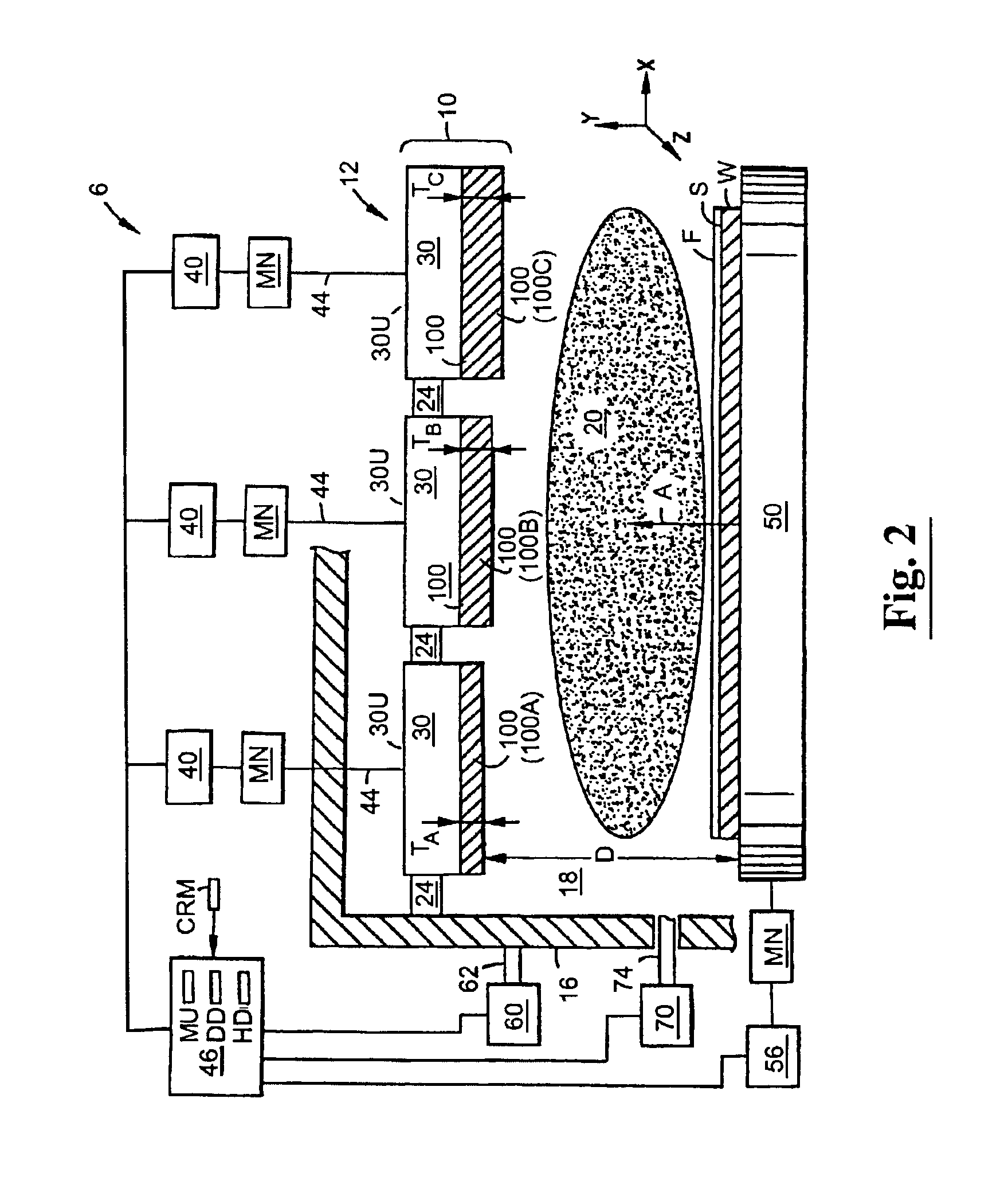

Mash seam welding process and mash seam welding apparatus

InactiveUSRE36612E1Improve welding strengthHigh strengthRectilinear seam weldingWelding/soldering/cutting articlesThick plateEngineering

PCT No. PCT / JP96 / 00410 Sec. 371 Date Dec. 24, 1996 Sec. 102(e) Date Dec. 24, 1996 PCT Filed Feb. 23, 1996 PCT Pub. No. WO96 / 26037 PCT Pub. Date Aug. 29, 1996Mash seam welding process and apparatus, wherein two plate-like workpieces having different thickness values are fed and guided by a guiding device such that a length WH of contact of the thick plate-like workpiece with one of two roller electrodes is smaller than a length WM of contact of the thin plate-like workpiece with the other roller electrode. In this arrangement, the amount of mashing of the thick plate-like workpiece by the roller electrode is made larger than that of the thin plate-like workpiece by the other roller electrode, so that an interface of the two plate-like workpieces is positioned intermediate between the pair of roller electrodes, whereby a weld nugget formed intermediate between the roller electrodes extends across the interface, permitting the weld to have a sufficient strength owing to a nugget ratio, which is a ratio of a width dimension WN of the weld nugget in the direction of the interface to a width dimension WG of the interface.

Owner:TOYOTA JIDOSHA KK

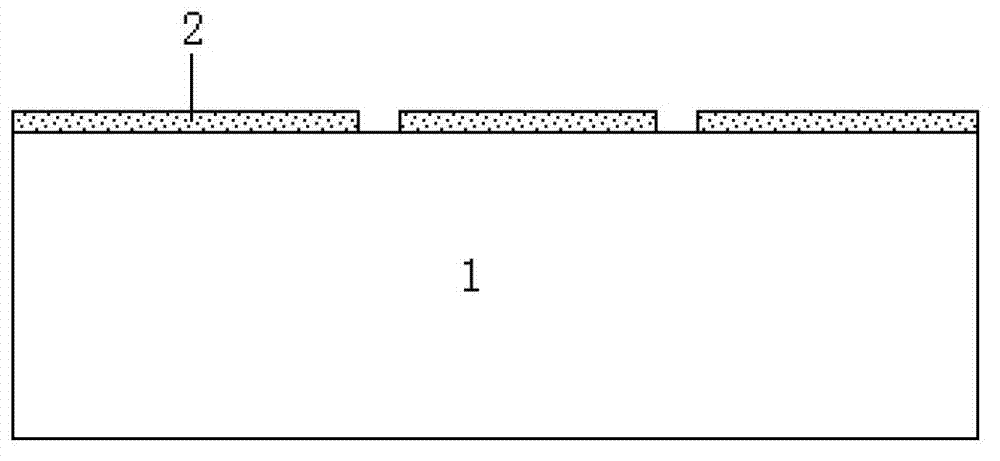

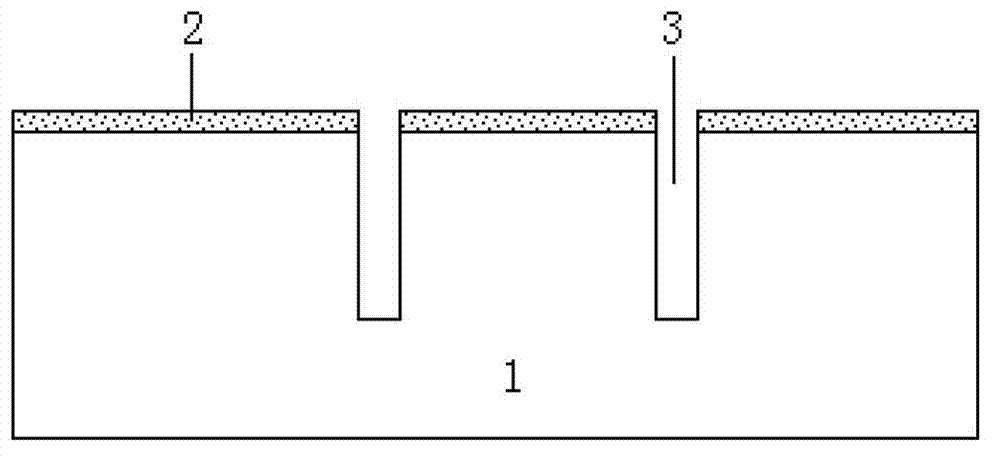

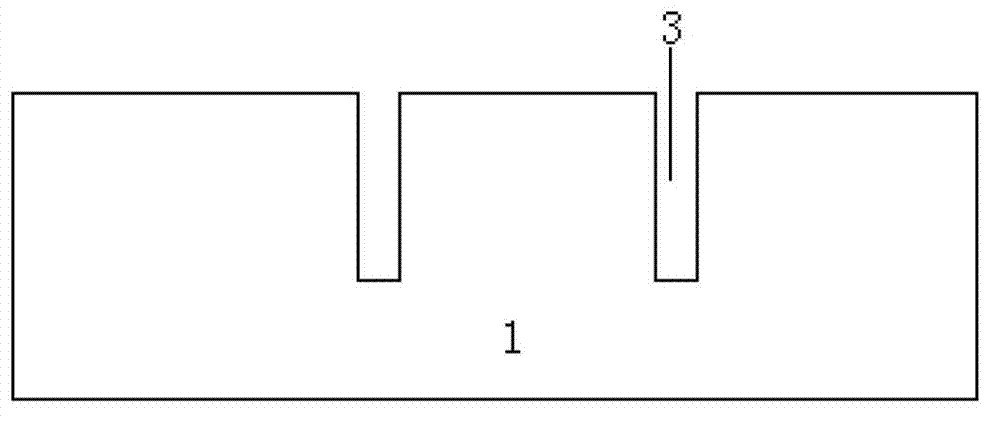

Method for precisely controlling thinning of wafer

ActiveCN103035489AControl thicknessReduce thickness differenceSemiconductor/solid-state device manufacturingEtchingEngineering

The invention discloses a method for precisely controlling thinning of a wafer. The method for precisely controlling thinning of the wafer includes that a step of etching of a silicon wafer groove is added in a chip machining process, fillers are arranged in the groove, after the machining process of a front-side chip of a wafer is completed, the back side of the silicon wafer is thinned to the bottom of the groove, and precision control of wafer thinning is achieved. The method for precisely controlling thinning of the wafer can precisely control the thinning of the wafer, differences of thickness among wafers are reduced, and influence of the thickness of a blue film on thinning precision is prevented.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

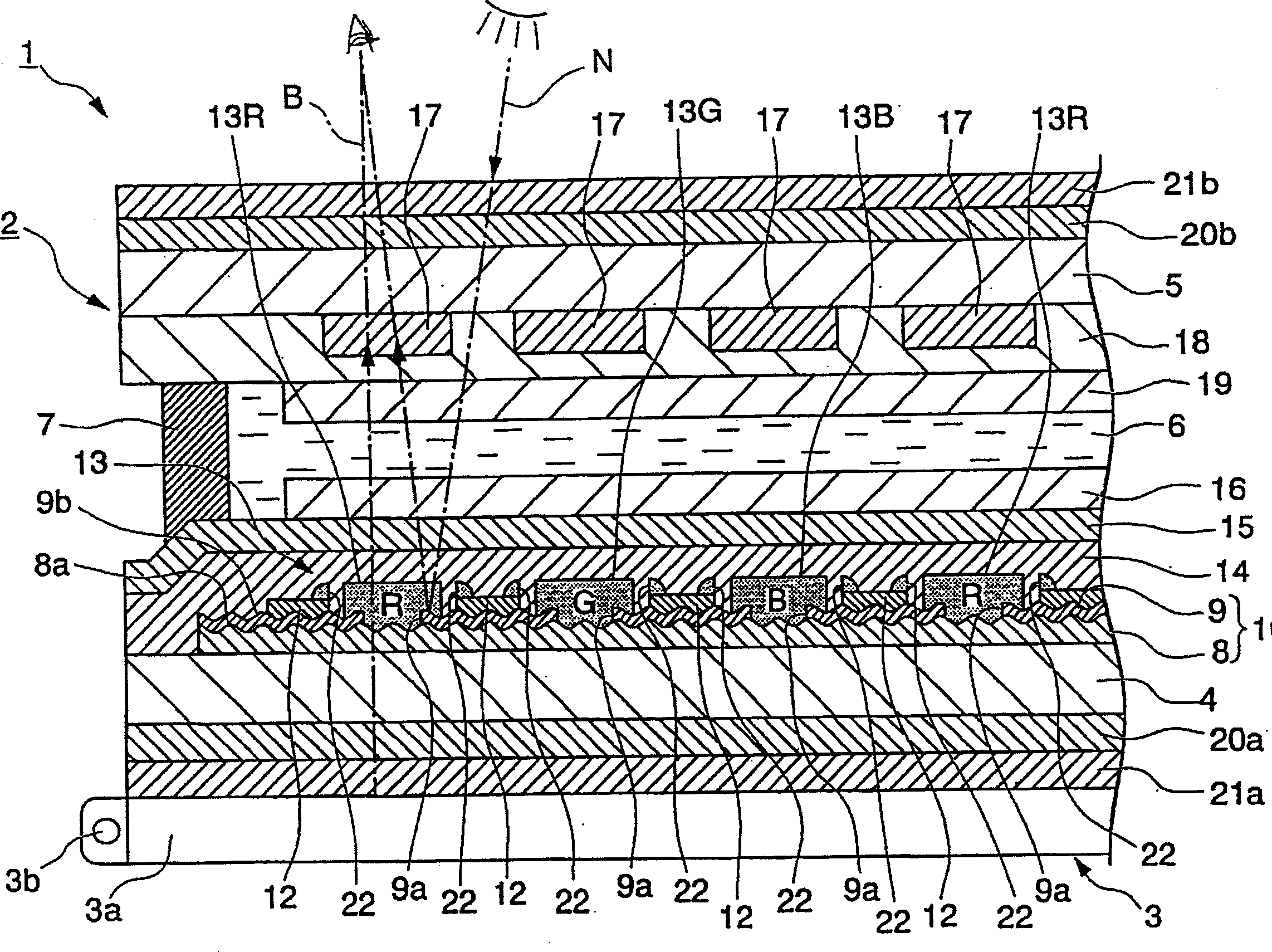

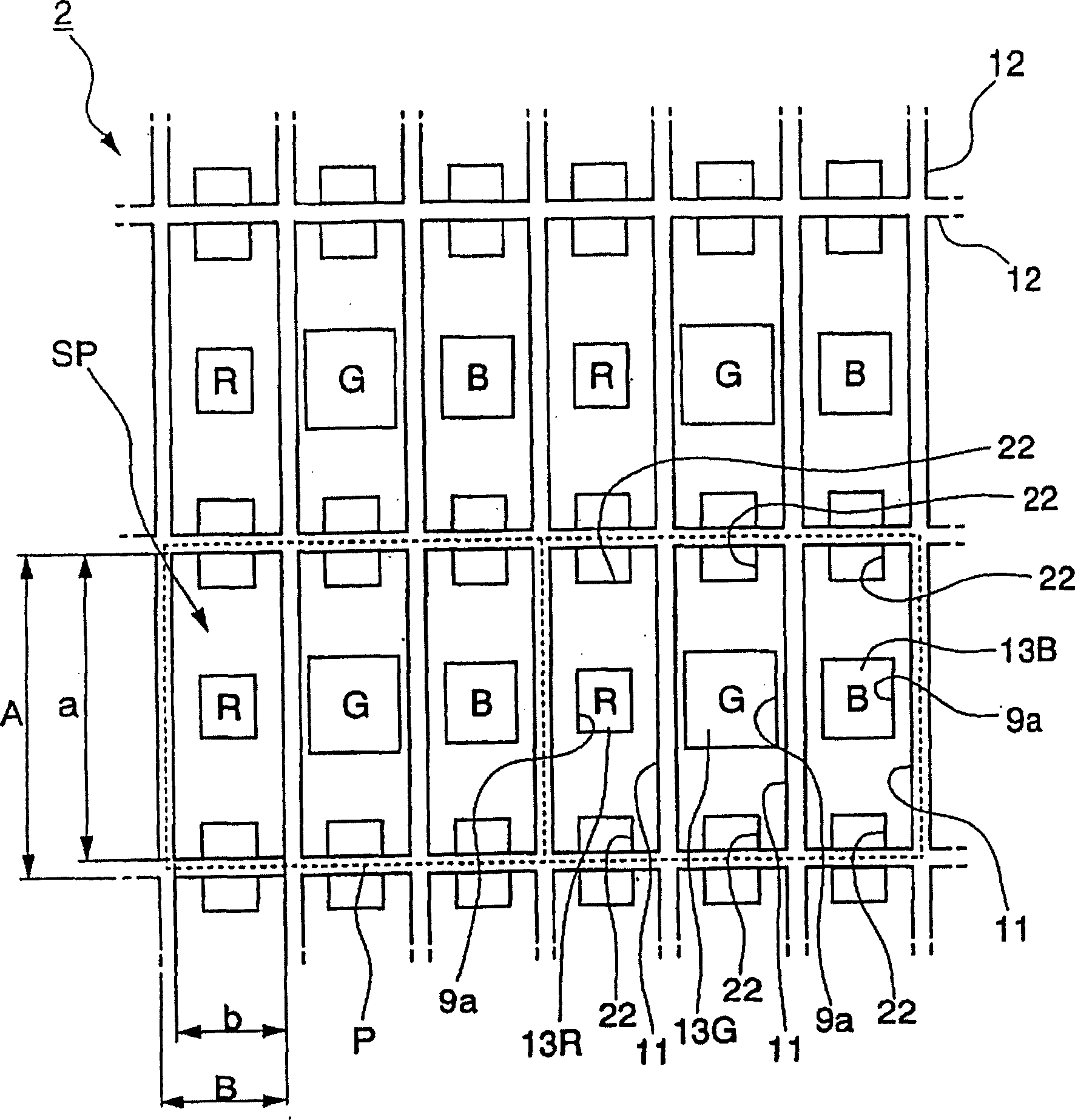

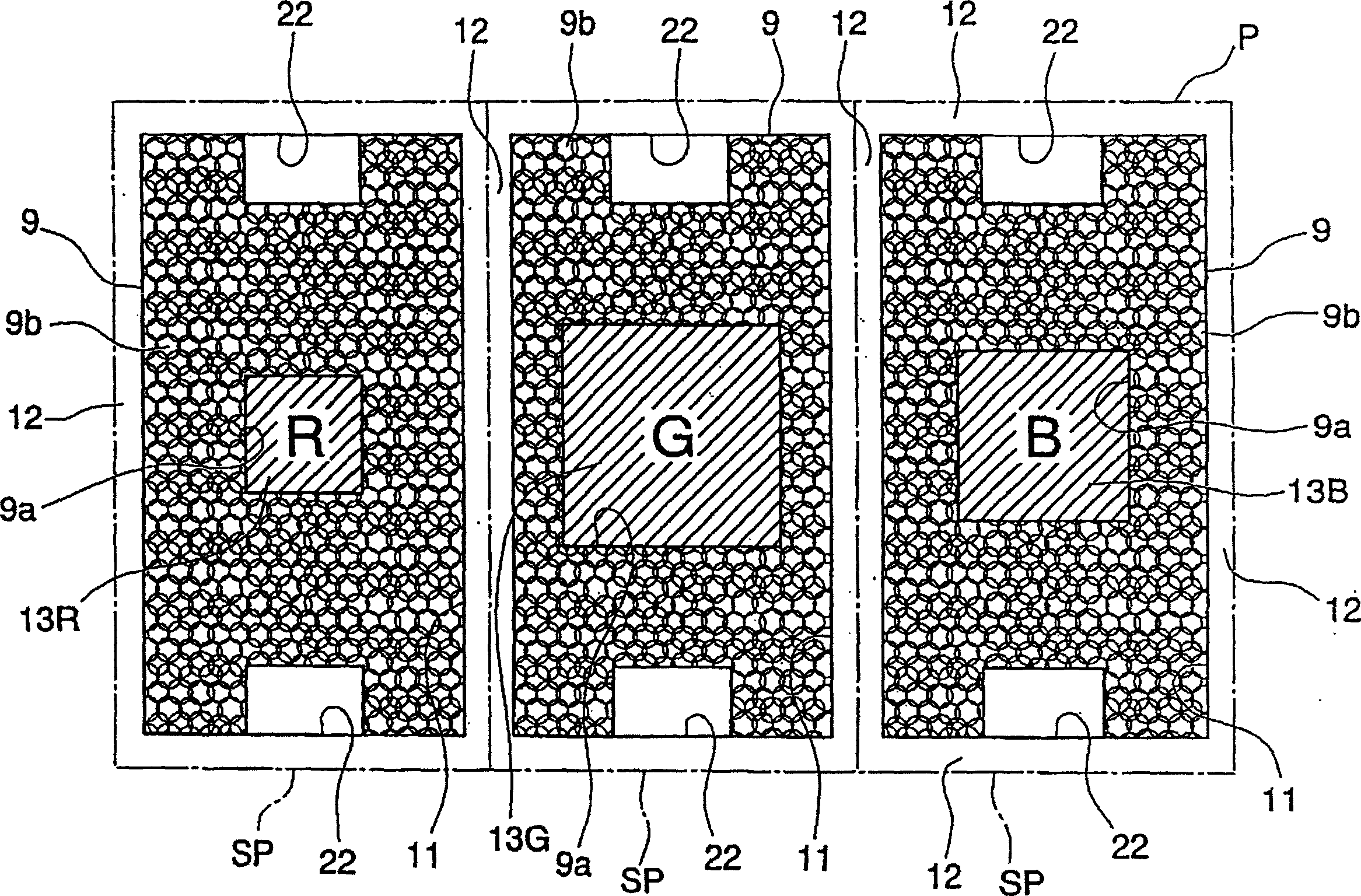

Transflective liquid crystal display panel and color liquid crystal display device

InactiveCN1841147AIncrease brightnessHigh color reproductionStatic indicating devicesNon-linear opticsLiquid-crystal displayColor filter array

There provide a semitransmissive liquid crystal display panel and a color liquid crystal display device capable of providing high-luminance and high-reproducibility color display in any of transmission mode and reflection mode. The semitransmissive liquid crystal display panel has a semitransmissive reflecting layer 10 on which a reflecting film 9 reflecting light made incident from the side of a 2nd substrate 5 is formed and an opening part 9a for transmission transmitting light made incident from the side of a 1st substrate 4 is formed in a portion of the reflecting film 9, and a color filter layer 13 which has color filters 13R, 13G, and 13B of different colors buried in dot-corresponding regions 11 of the semitransmissive reflecting layer 10 sectioned by a black matrix layer 12, and the color filter layer 13 has opening parts 22 for reflection which expose a portion of the reflecting film 9.

Owner:ONANOVICH GROUP

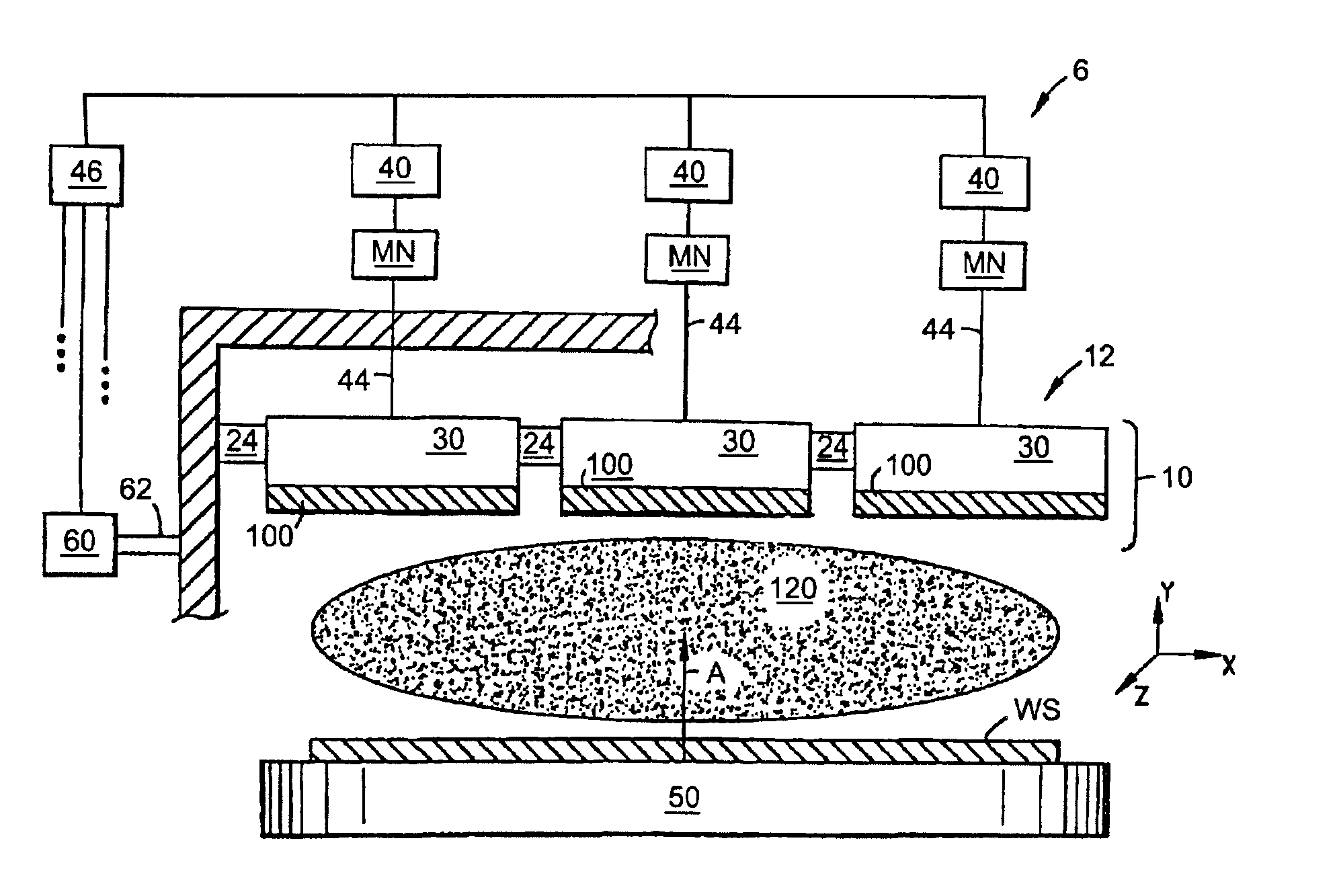

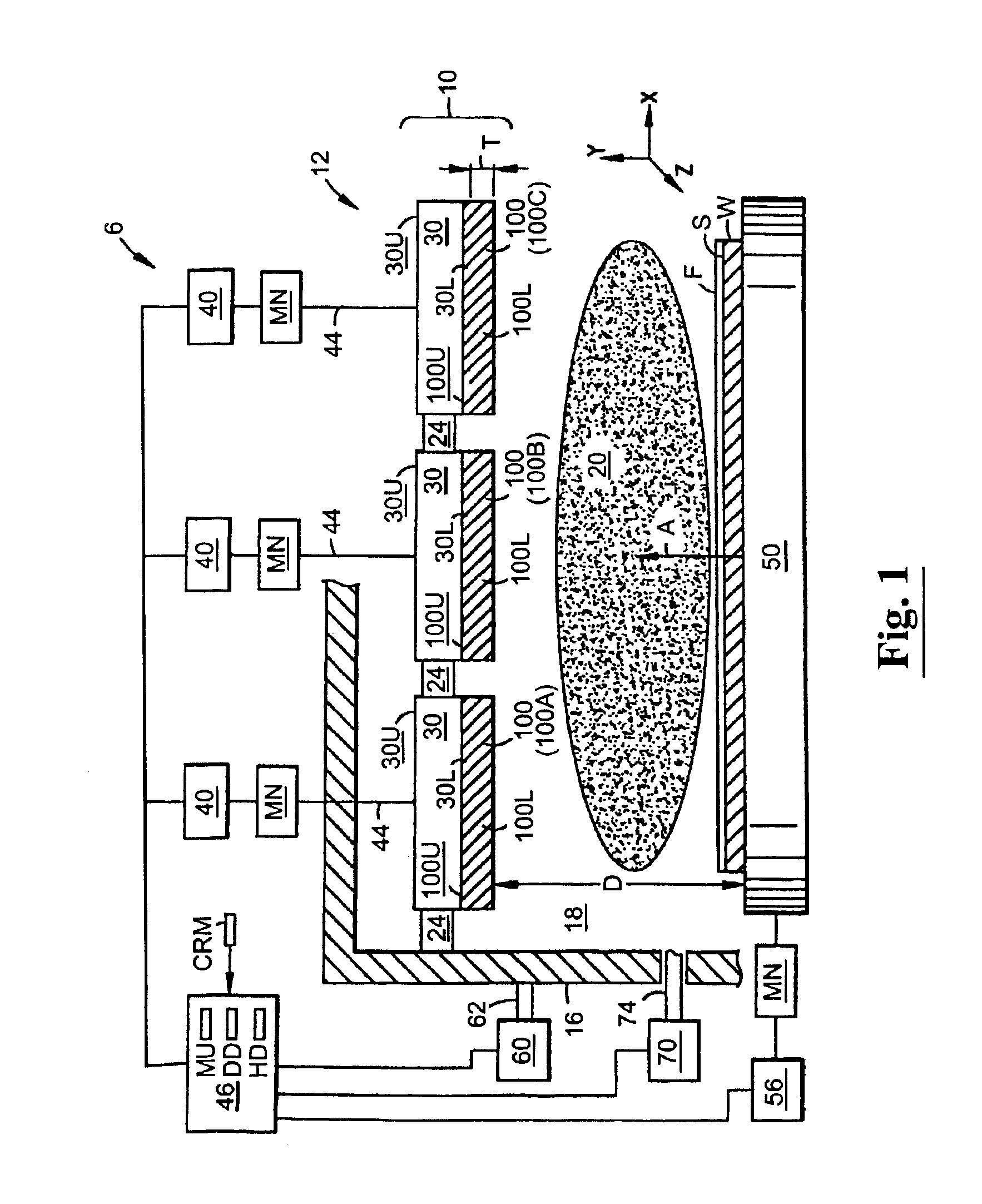

Method of adjusting the thickness of an electrode in a plasma processing system

InactiveUS6913703B2Reduce thickness differenceReduce variationElectric discharge tubesVacuum gauge using ionisation effectsTransducerEngineering

A method of adjusting the relative thickness of an electrode assembly (10) in a plasma processing system (6) capable of supporting a plasma (20, 120) in a reactor chamber (16). The electrode assembly is arranged in the reactor chamber and includes at least one electrode having a lower surface that may have defined by at least one sacrificial protective plate (100). The electrode has a nonuniform thickness resulting from a plasma processing operation performed in the reactor chamber. The method includes a step of forming a plasma (120) designed to selectively etch the at least one electrode at the lower surface, followed by a step of etching the electrode with the aid of the plasma to reduce the nonuniformity in thickness (T(X,Z)) of the at least one electrode. The thickness of the electrode may be measured in situ using an acoustic transducer (210) during the processing of workpieces as well as during the restorative plasma etching of the electrode.

Owner:TOKYO ELECTRON LTD

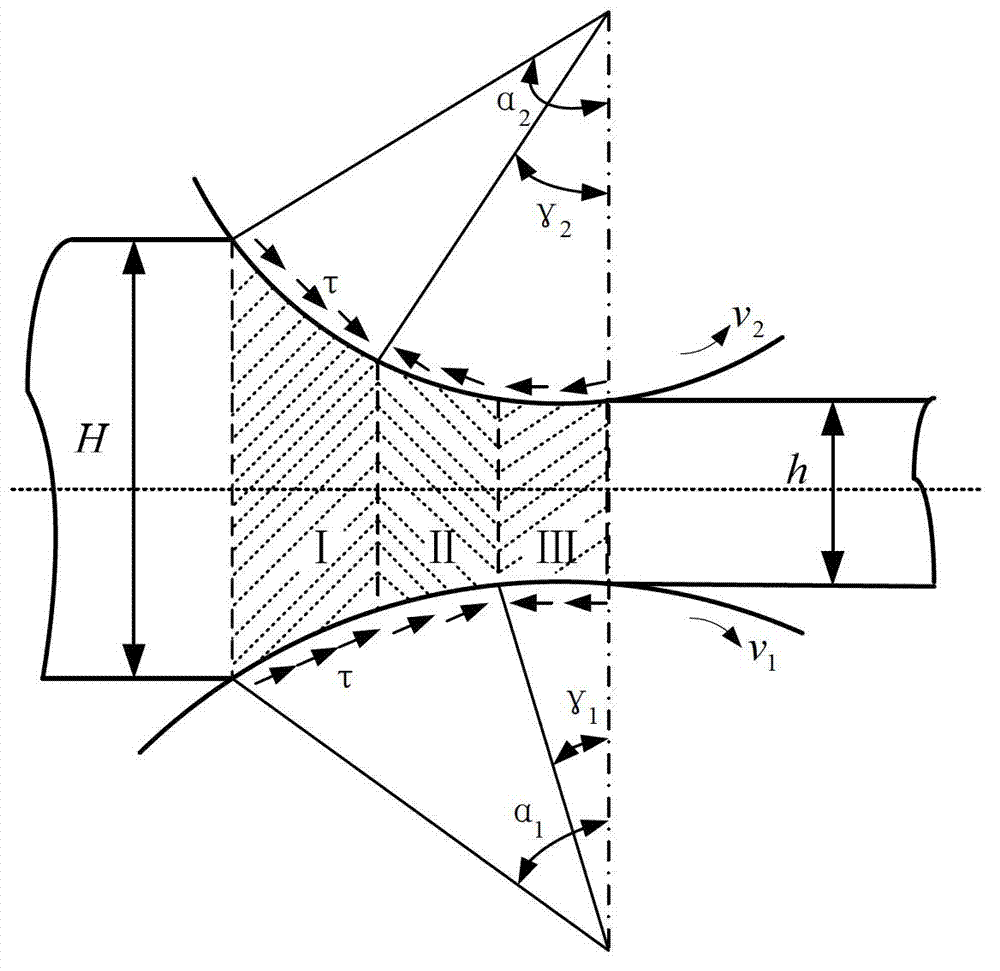

Continuous asynchronous rolling device of magnesium alloy sheet strip coil

InactiveCN102773255AStable rolling tensionRealized strip rollingMetal rolling arrangementsEngineeringEnergy consumption

The invention relates to a continuous asynchronous rolling device of a magnesium alloy sheet strip coil and belongs to the field of magnesium alloy materials. The continuous asynchronous rolling device conducts decoiling on the magnesium alloy strip coil through a decoiling device, the magnesium alloy strip coil enters a flattening machine to be flattened through a tension pinch roller and enters a strip coil preheating device through the tension pinch roller after being corrected to be heated to preset temperature, feeding material thickness is measured through a thickness gauge, then the strip coil enters a continuous asynchronous rolling machine for rolling, the rolled strip coil passes through the thickness gauge to measure thickness of a finished product and enters a rolling machine to be rolled through the tension pinch roller, and the whole coiling rolling is achieved after stable rolling tension is finished. The continuous asynchronous rolling device has the advantages of reducing rolling pressure and rolling torque, reducing energy consumption, increasing gate transformation quantity, improving rolling efficiency and the like, thereby being favorable for rolling production of strip coils of magnesium alloy which is hard to deform.

Owner:UNIV OF SCI & TECH BEIJING

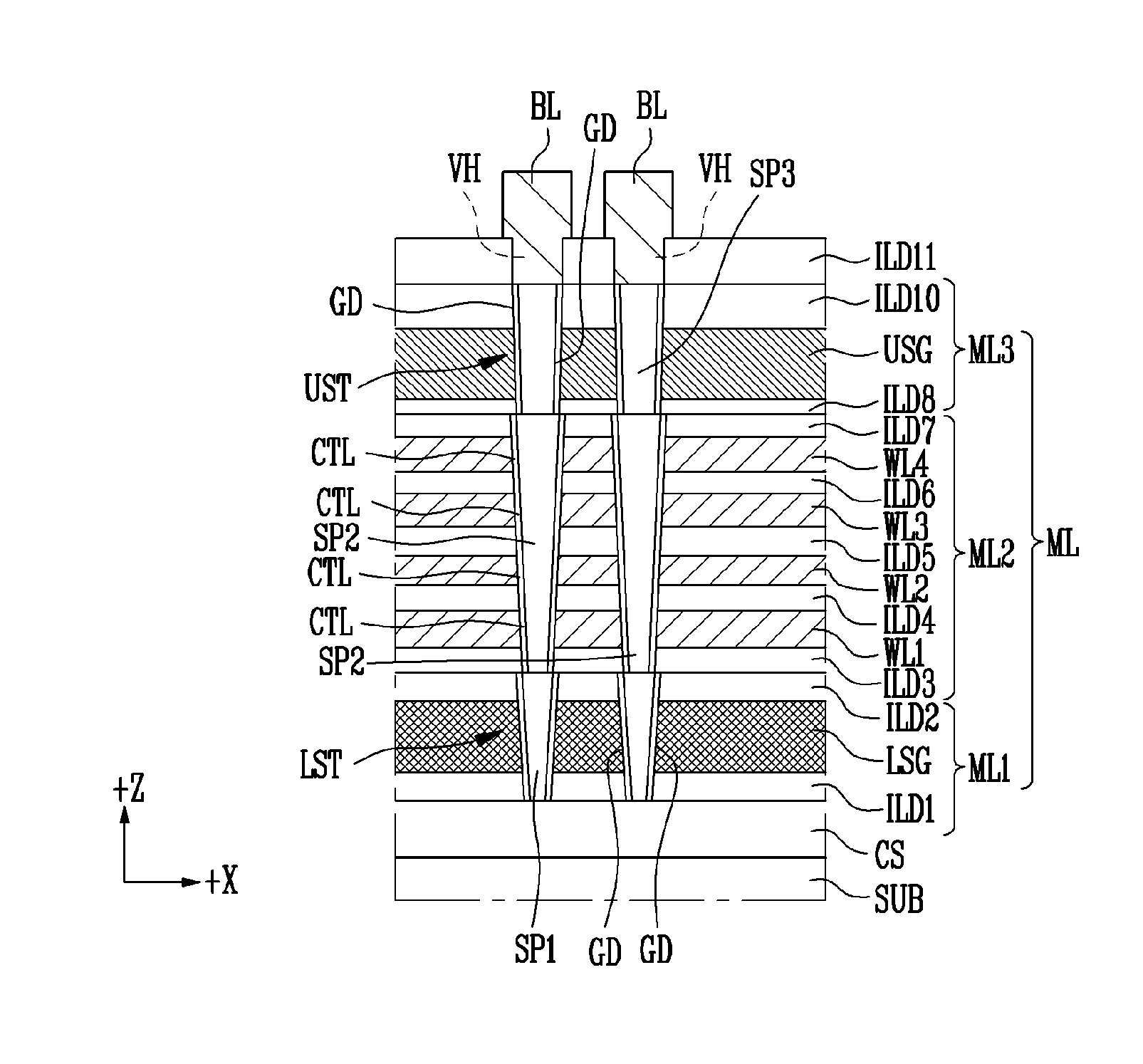

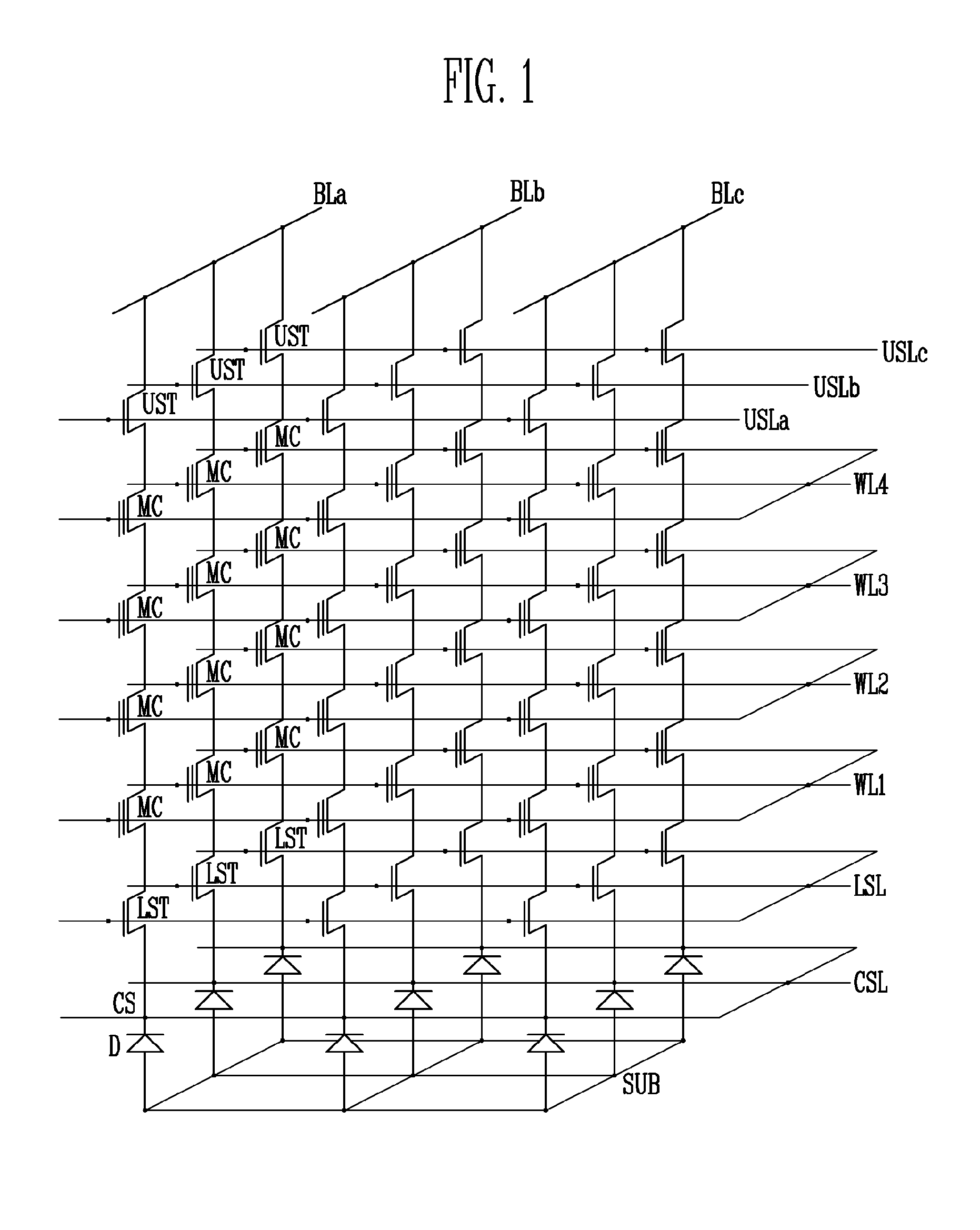

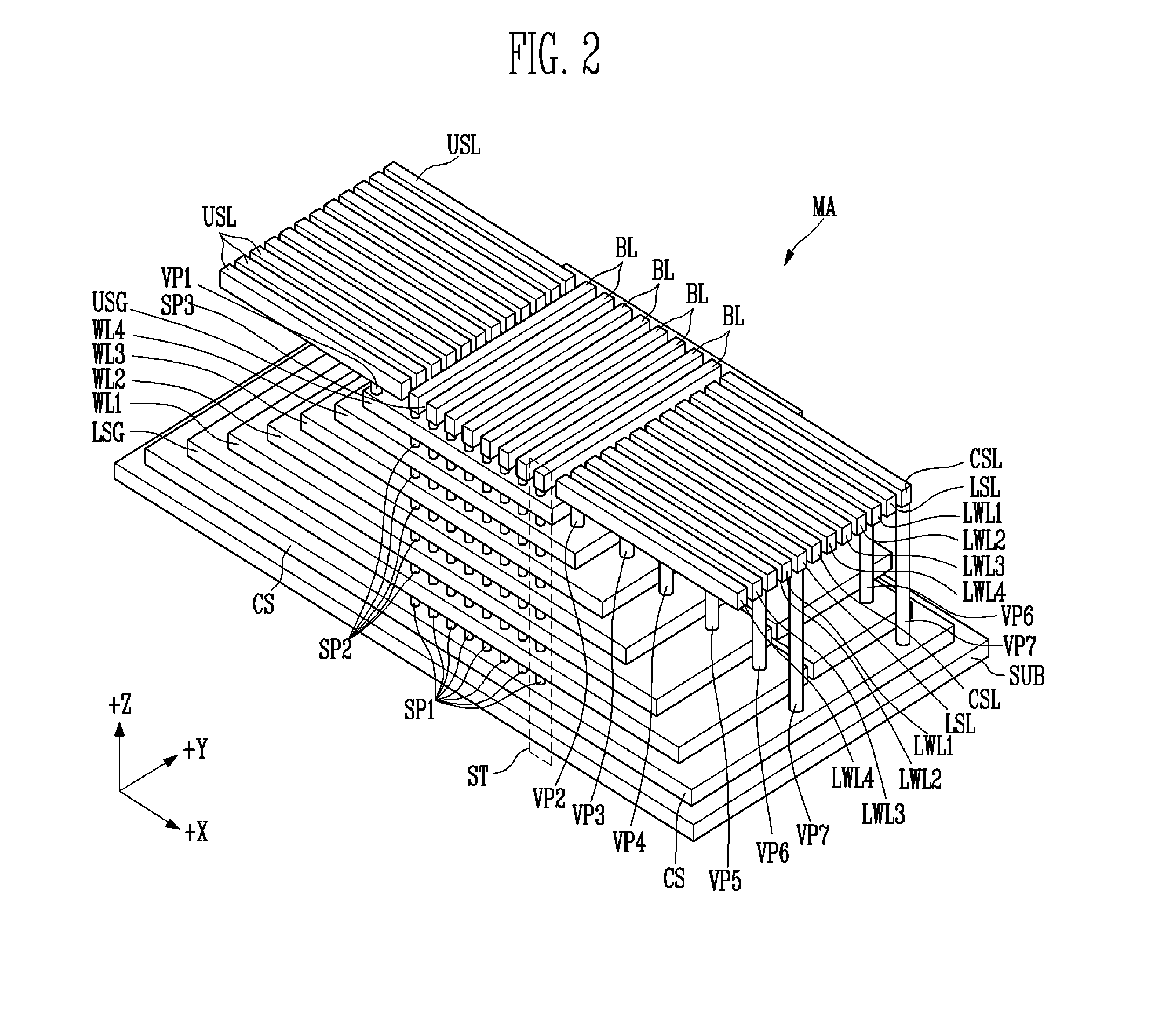

Semiconductor memory device and method of manufacturing the same

ActiveUS8735967B2Well formedDifference in thicknessSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor memory device includes a lower select transistor formed within a semiconductor substrate, memory cells stacked over the lower select transistors, and an upper select transistor formed over the memory cells.

Owner:SK HYNIX INC

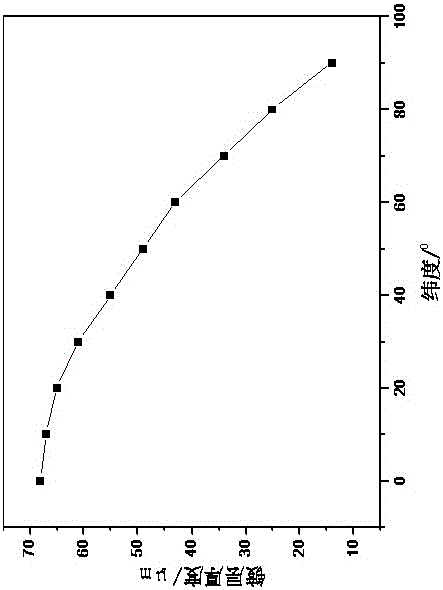

One-step producing technique for high-purity gold

InactiveCN101122032AReduce thickness differencePhotography auxillary processesProcess efficiency improvementElectrolysisProcessing cost

A one-step high purity gold production process includes four procedures, namely gold electrolyte making, gold electrolyte preparation, high purity gold electrolysis and finished product treatment. The one-step high purity gold production process of the invention well solves the problems of cathode verticality and smoothness, so the high purity gold produced in appropriately adjusted proportion of electrolyte has even surface, with thickness difference less than 0.1mm; meanwhile, the physical specification of the electrolyzed gold can be well controlled and the quality high purity gold (containing 99.999percent gold) can be produced one step by simple means of controlling the electrolyzing time and current density, etc, with the recovery rate up to 99.95percent and the processing cost of only 0.1 to 0.12yuan / g.

Owner:JIANGXI COPPER CORP

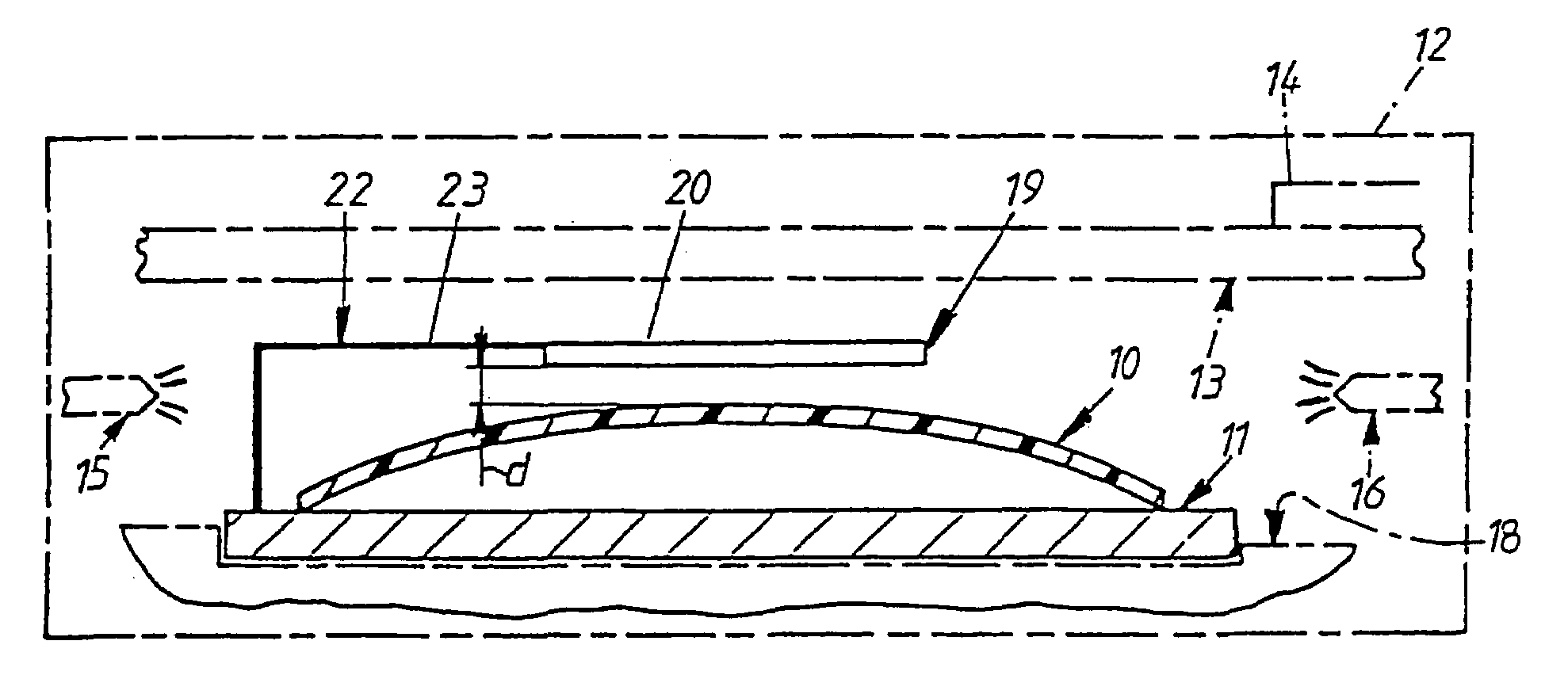

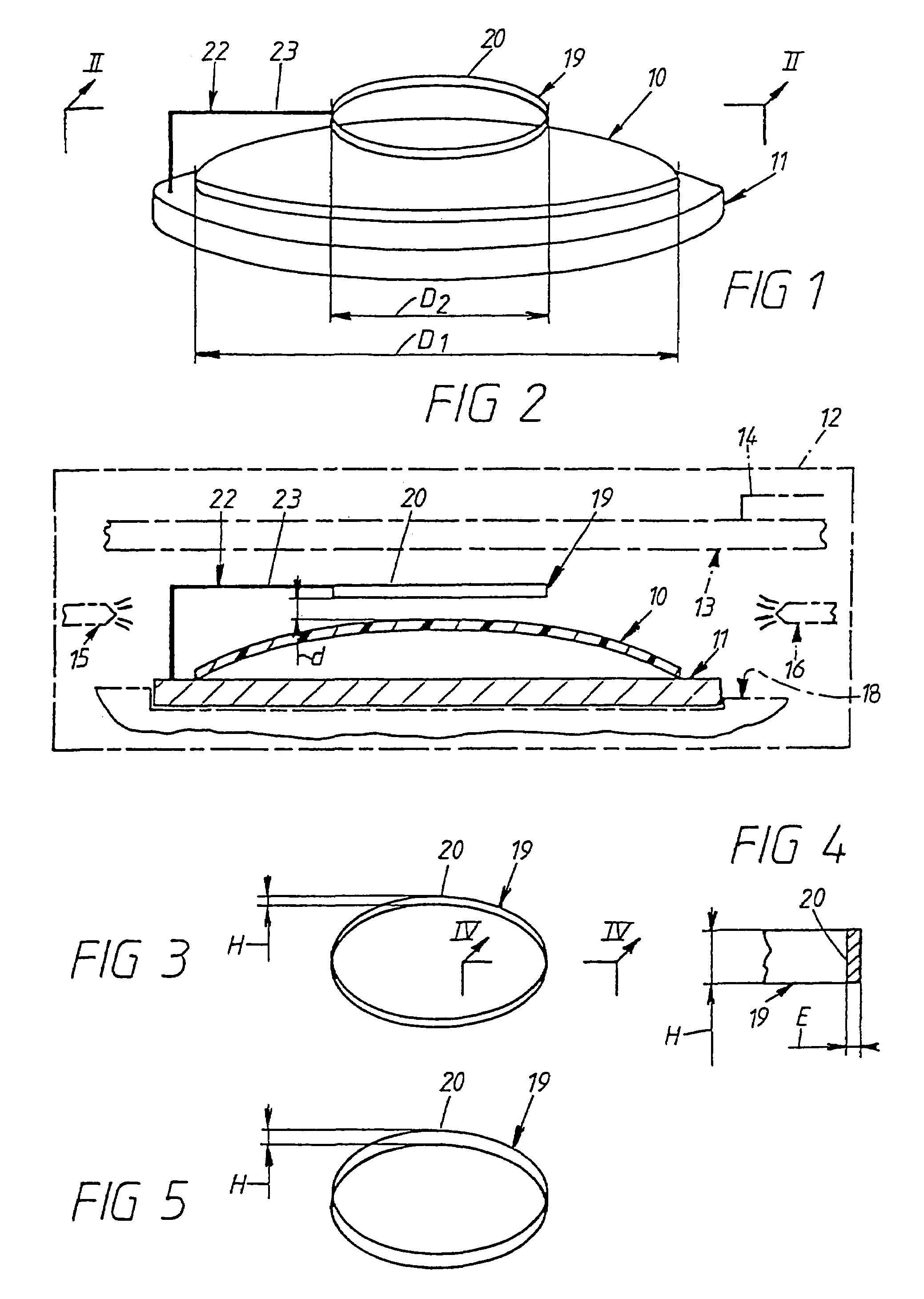

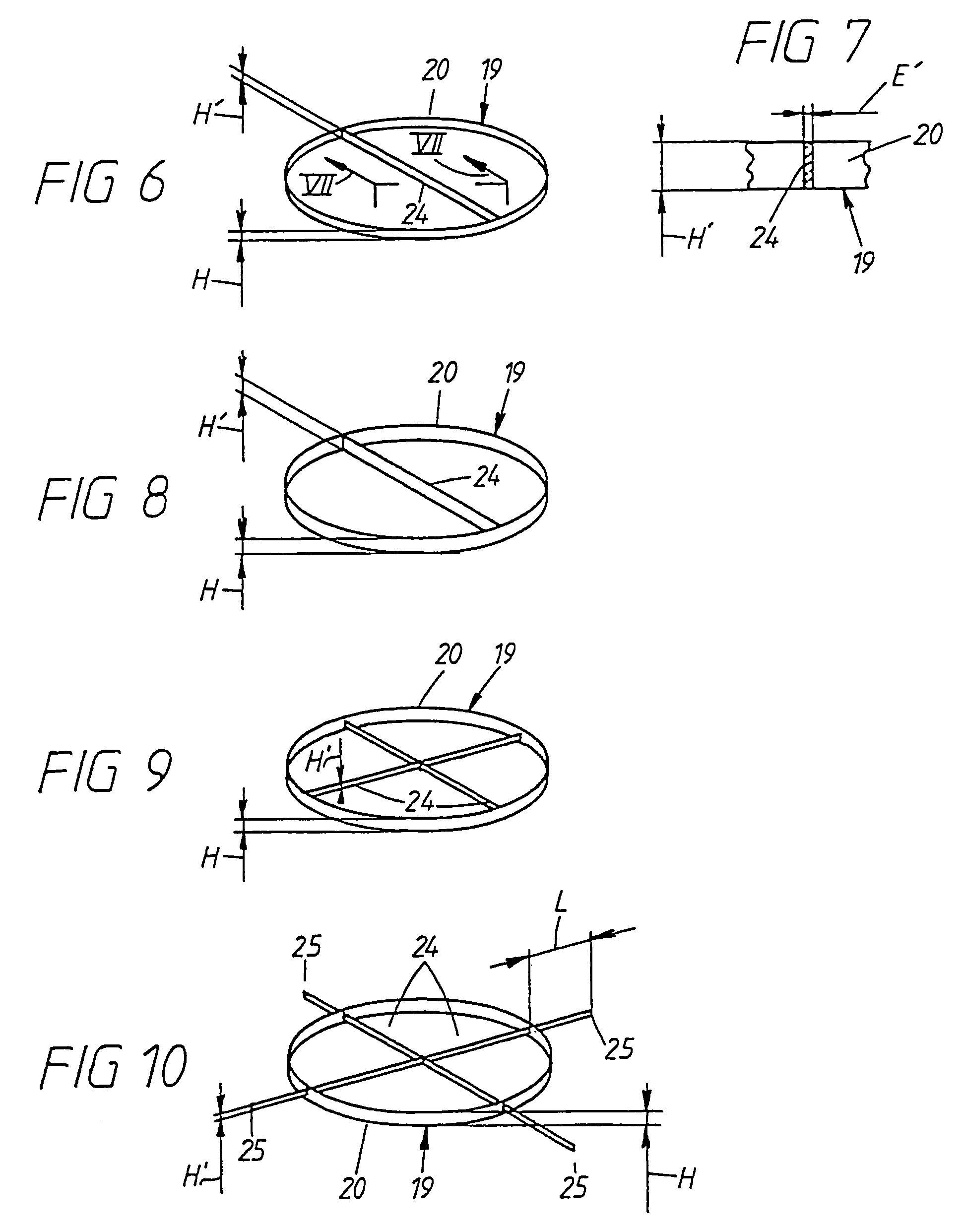

Method for vacuum deposit on a curved substrate

InactiveUS7122223B1Reduce thickness differenceAvoid difficultyVacuum evaporation coatingSputtering coatingEngineeringVacuum deposition

The invention concerns a method which consists in a process known per se in producing, on the curved substrate (10) to be treated, a film of material derived from a specific material source (13). The invention is characterized in that it consists in inserting, between the curved substrate (10) and the material source (13), a mask (19) relative to the curved substrate (10), preferably selecting as mask (19), a mask comprising a ring-shaped part (20). The invention is particularly useful for providing lenses with antiglare treatment.

Owner:ESSILOR INT CIE GEN DOPTIQUE

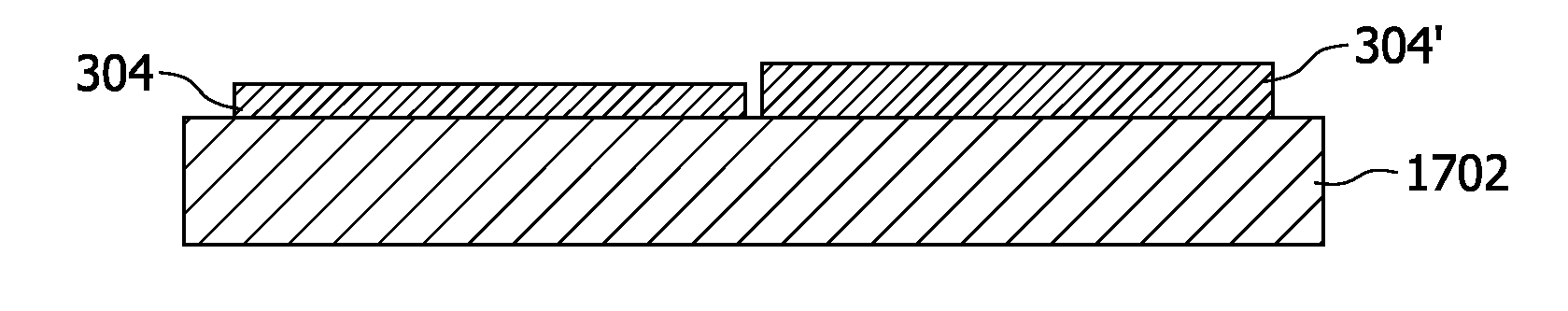

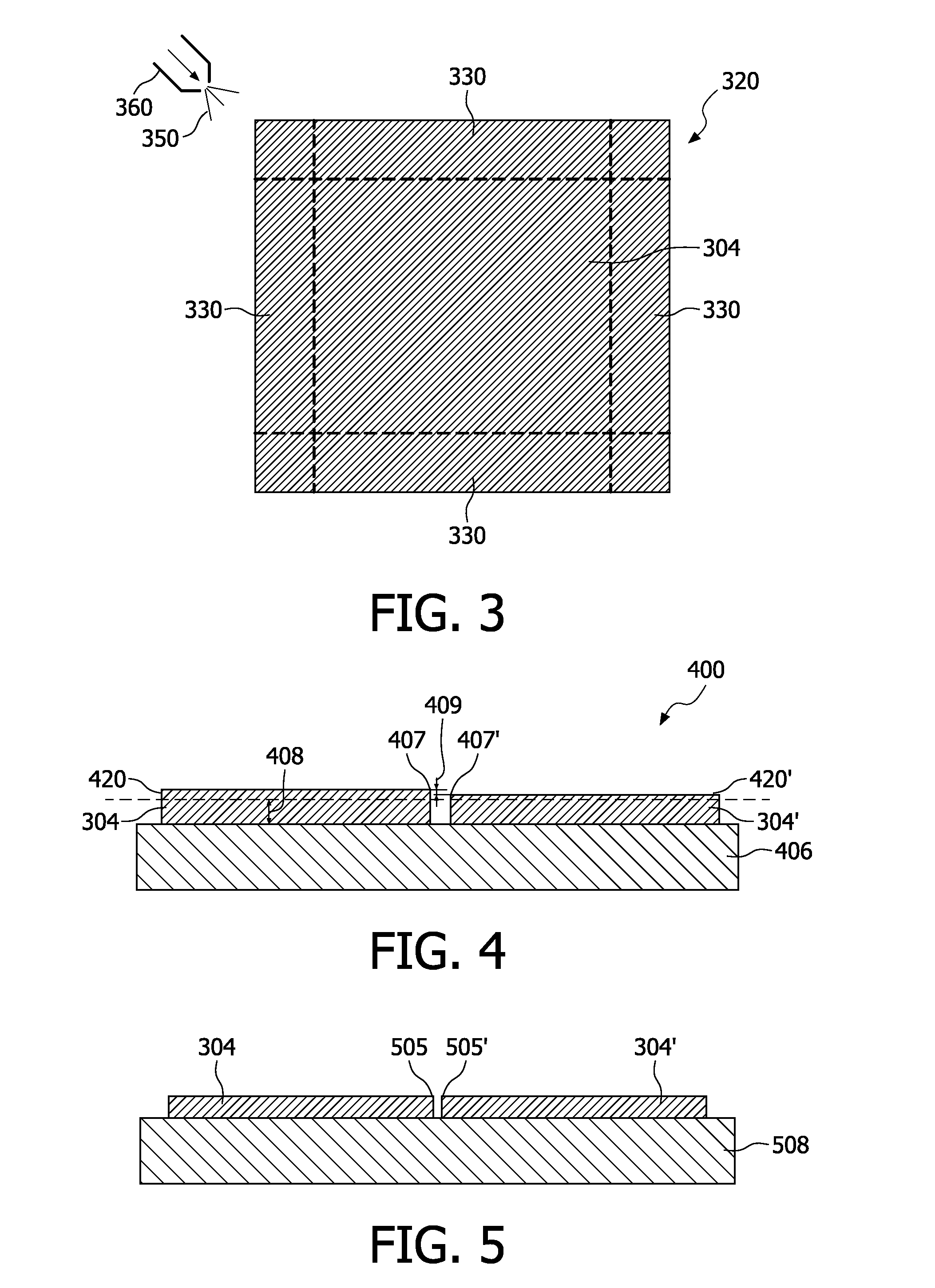

Assembly method for a tiled radiation detector

InactiveUS20110222659A1Avoid entrapmentCompensation differenceElectronic circuit testingMaterial analysis by optical meansImage ArtifactPhysics

A tiled detector assembly (1000) and a method for making a tiled radiation detector (1000) is described. The innovative feature of this method is that the xyz misalignment of the detector tiles (304, 304′), the origin of various image artifacts, can be significantly reduced by accurate sizing and alignment of the detector tiles (304, 304′). Consequently, image quality, yield and reliability of as-produced tiled radiation detectors are considerably improved.

Owner:TRIXELL S

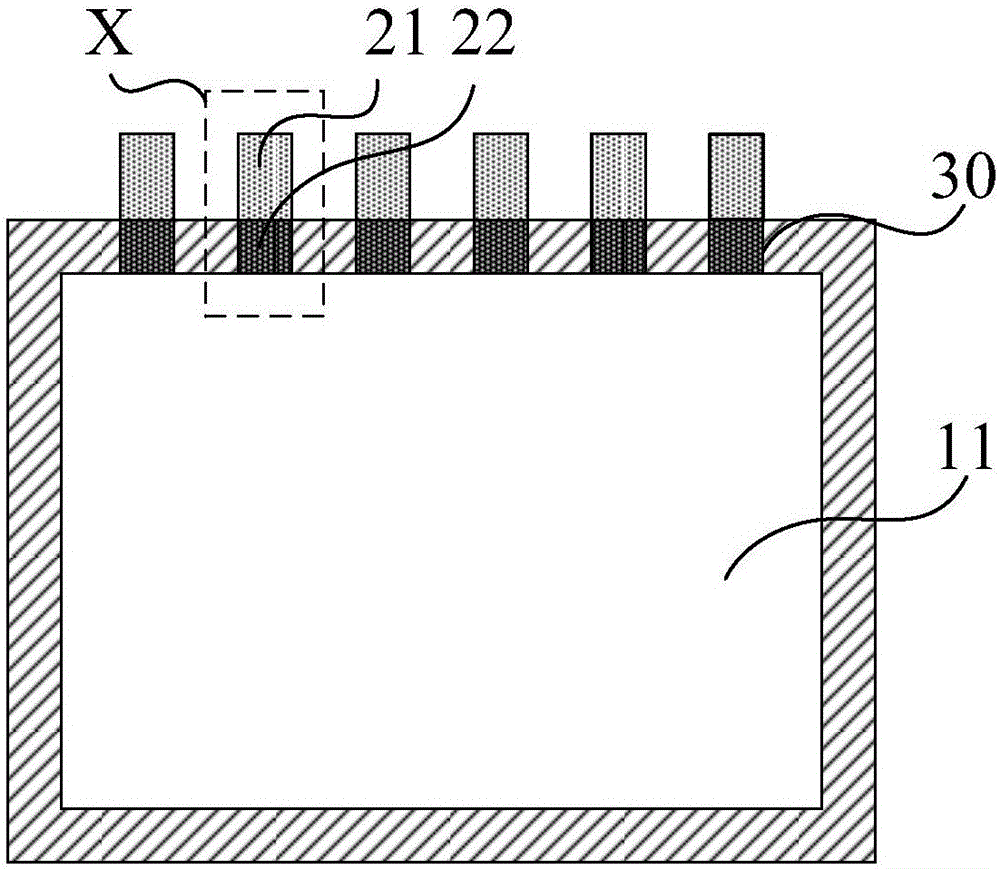

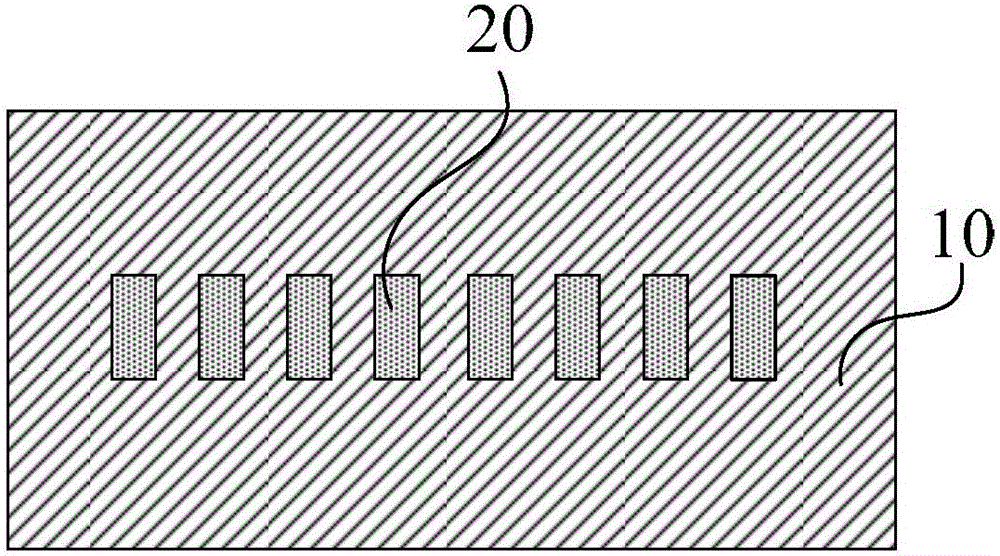

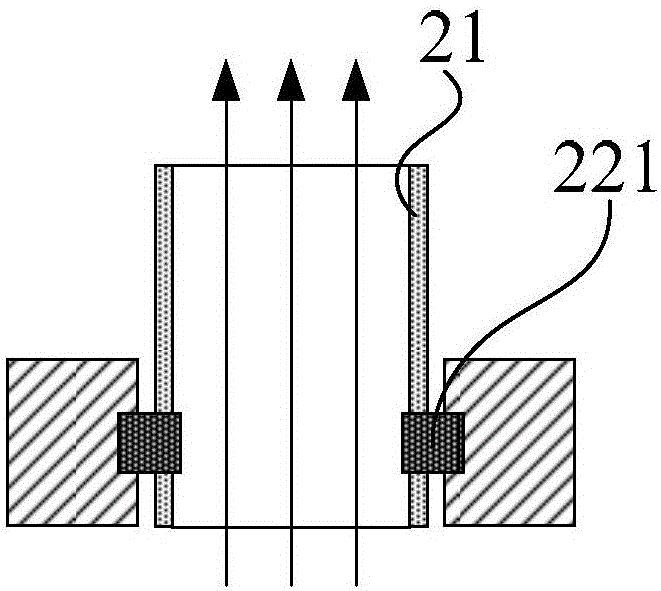

Evaporation source, evaporation device and evaporation method

ActiveCN106835028AReduce thickness differenceImprove uniformityVacuum evaporation coatingSputtering coatingChemistrySprayer

An embodiment of the invention provides an evaporation source, an evaporation device and an evaporation method, relates to the field of vacuum evaporation coating and can solve the problem of non-uniform evaporation coating thickness at different evaporation areas of a to-be-evaporated substrate in the process of evaporation due to existing linear or planar evaporation sources. The evaporation device comprises an evaporation crucible and multiple evaporation nozzles arranged on the outlet side of the evaporation crucible in one row at least. An evaporation material cavity is formed inside the evaporation crucible, and the side wall on the outlet side of the evaporation crucible is provided with a through cavity communicated with the evaporation material cavity; each evaporation nozzle comprises a sprayer and a moving portion fixedly connected with the sprayer, each sprayer is communicated with the evaporation material cavity through the through cavity, and each moving portion is arranged in the through cavity and can rotate in the same to enable the corresponding sprayer to be driven by the moving portion to swing.

Owner:BOE TECH GRP CO LTD

Imaging lens unit

A compact low-cost imaging lens unit for a solid-state image sensor which corrects various aberrations adequately and produces a high-resolution high-definition image. The components of the unit are arranged from an object side to an image side in the following order: an aperture stop, a first lens with positive refractive power having a convex surface facing the object side, a second lens with negative refractive power having a convex surface facing the object side near an optical axis, a third lens with negative refractive power having a convex surface facing the object side near the optical axis, a fourth lens as a meniscus lens with positive refractive power having a convex surface facing the image side near the optical axis; and a fifth lens with negative refractive power having a concave surface facing the image side near the optical axis.

Owner:TOKYO VISIONARY OPTICS CO LTD

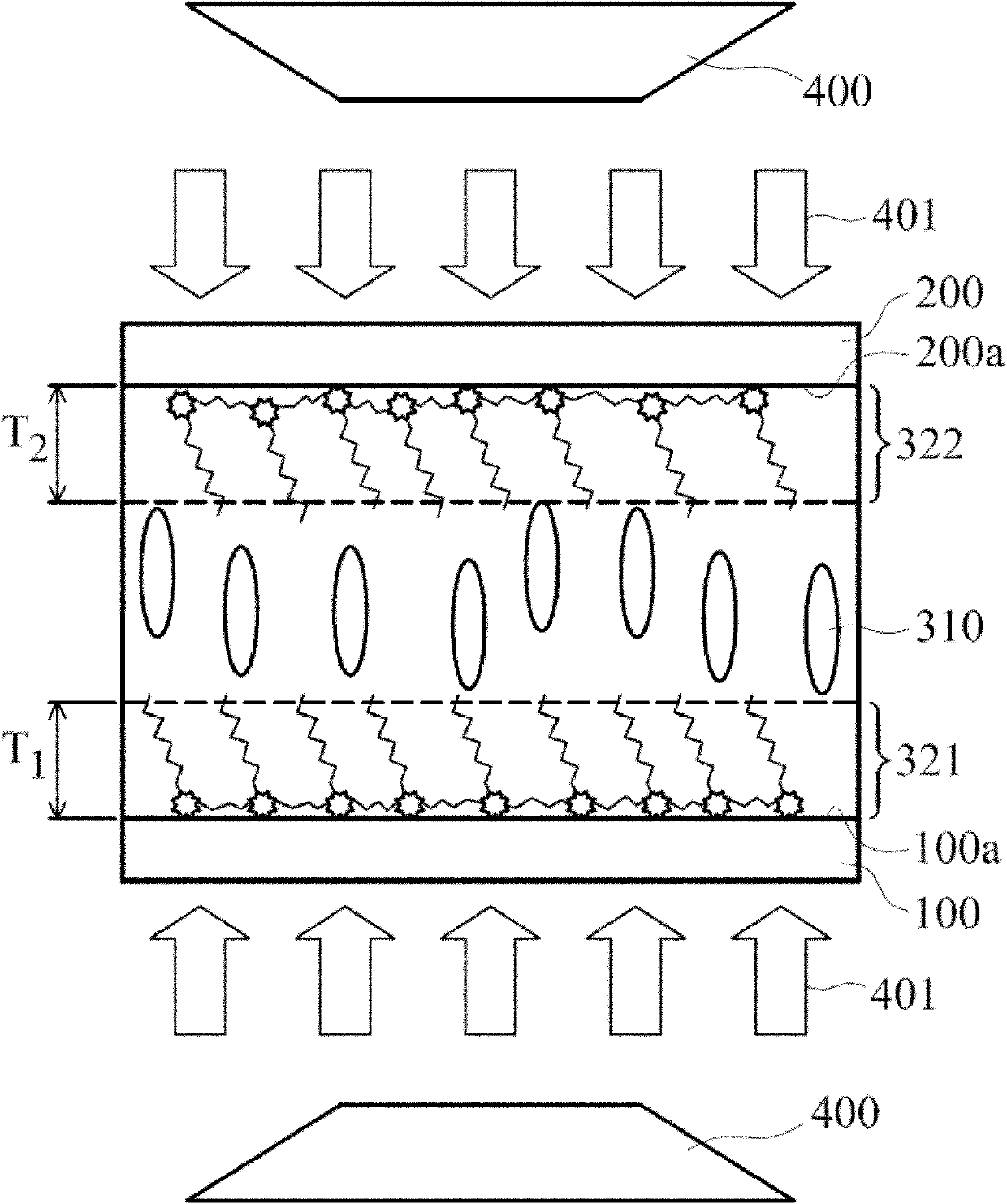

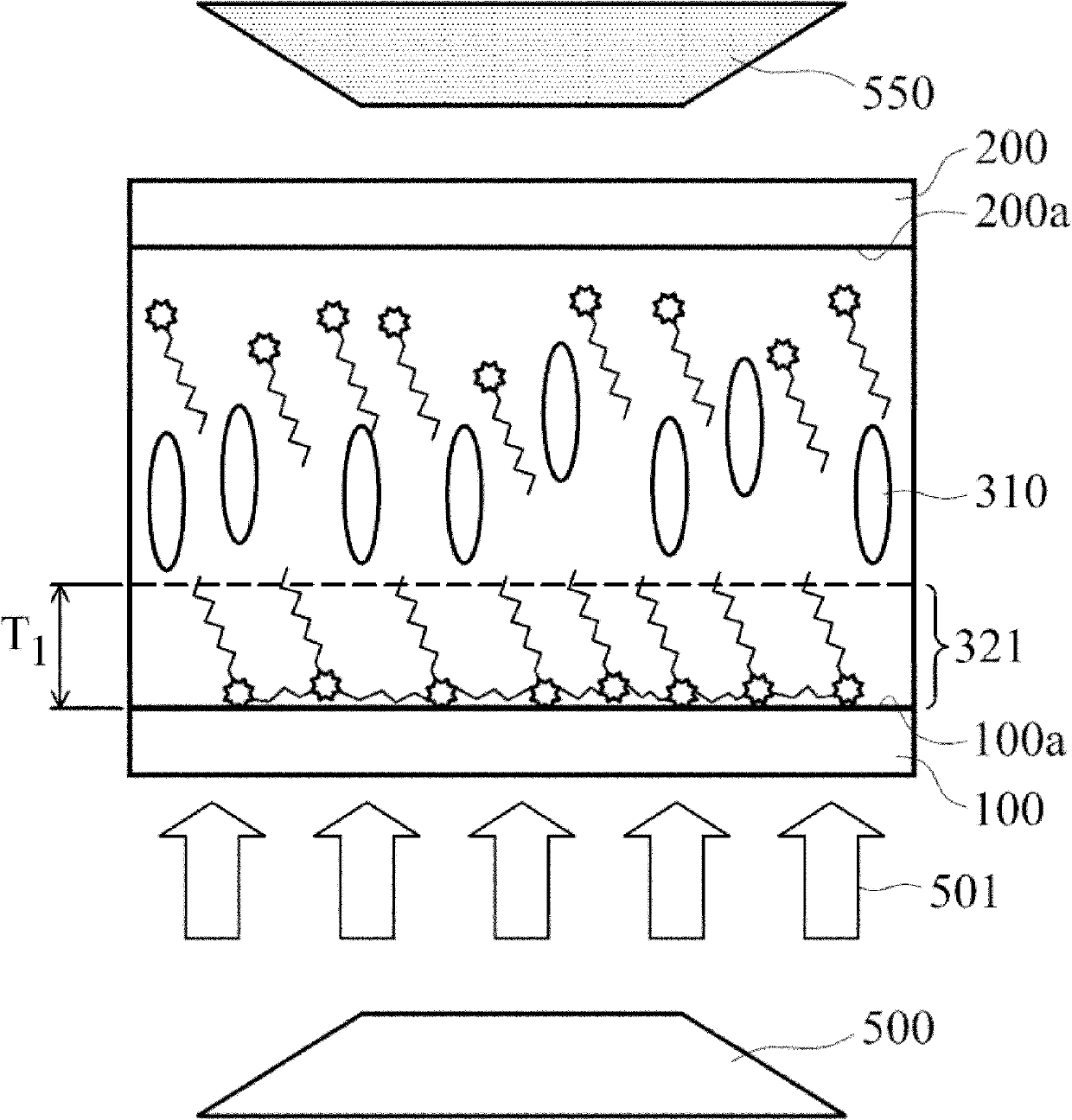

Method for producing liquid crystal display

ActiveCN102707495AReduce thickness differenceSolve the problem of bright point in local area (domain)Non-linear opticsCrystallographyControl layer

The invention provides a method for producing a liquid crystal display, which comprises the following steps that a first baseplate and a second baseplate are arranged, wherein the first and second baseplates are oppositely arranged; a mixed solution is filled between the first and second baseplates, and comprises a plurality of liquid crystal molecules and a plurality of monomers; and the mixed solution is subjected to an ultraviolet irradiation technology, the monomers are polymerized to form a first alignment control layer on the surface of the first baseplate, which faces the liquid crystal molecules, and a second alignment control layer on the surface of the second baseplate, which faces the liquid crystal molecules, wherein the ratio of the thickness of the first alignment control layer to the thickness of the second alignment control layer is (1:2)-(2:1). According to the method, double-sided ultraviolet irradiation is carried out simultaneously, or the first and second baseplates are alternatively irradiated for reducing the thickness difference of the alignment control layers on the two baseplates, the bright spot problem of the local domain of a liquid crystal display panel can be solved, and further, the process yield is improved.

Owner:INNOLUX CORP +1

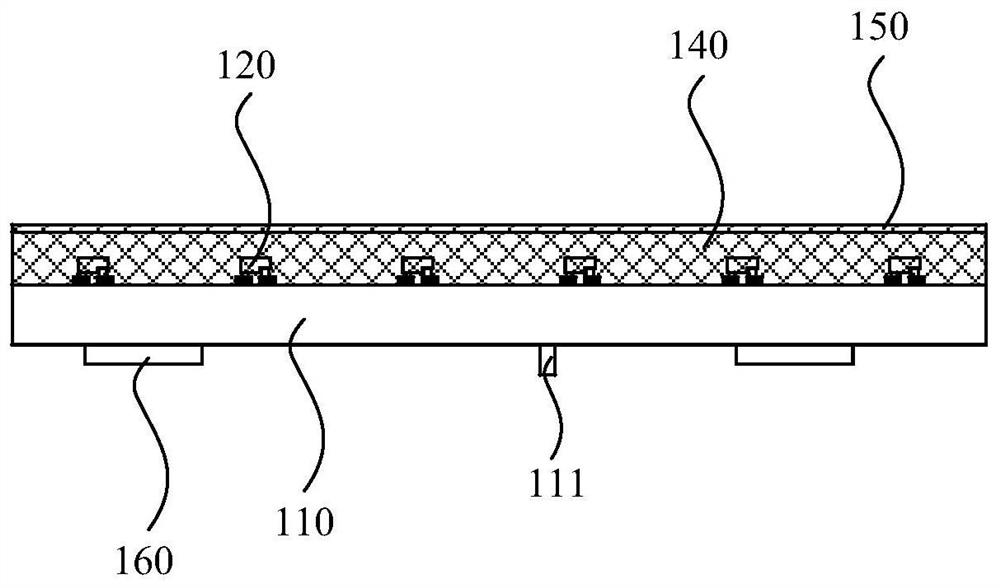

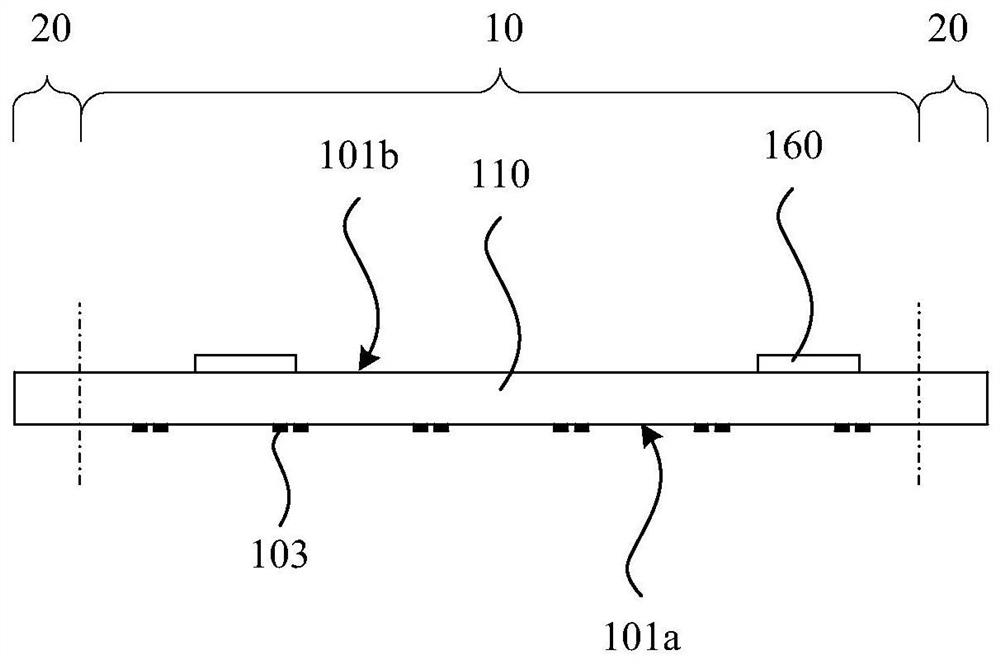

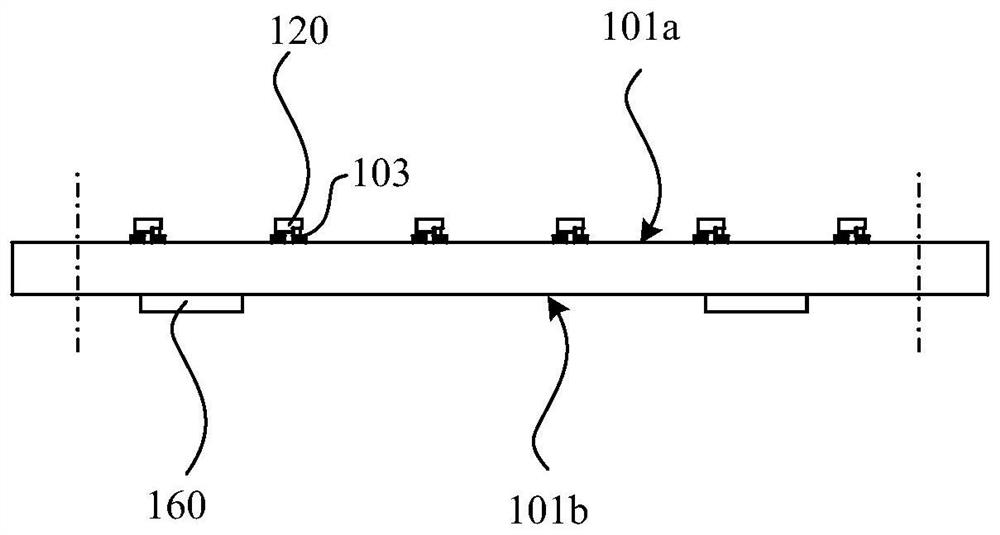

LED display module and manufacturing method thereof, LED display screen and manufacturing method thereof

PendingCN111816649AGuaranteed flatnessGuaranteed no color differenceSemiconductor/solid-state device detailsSolid-state devicesPhysicsEngineering

The invention discloses an LED display module and a manufacturing method thereof, and an LED display screen and a manufacturing method thereof. The LED display module comprises a PCB (Printed CircuitBoard), a plurality of LED chips which are positioned on a first surface of the PCB and are electrically connected with the PCB, a packaging layer which is located on the first surface of the PCB andcovers each LED chip, and a panel which is located on a surface of the packaging layer, wherein the surface, close to the panel, of the packaging layer is a polished surface. The LED display module isadvantaged in that the surface of the packaging layer is planarized, so the thickness difference of the LED display module is reduced, the panel is arranged on the surface of the LED module, surfaceappearance consistency of the LED module is improved, and the display effect is improved.

Owner:HANGZHOU MULTI COLOR OPTOELECTRONICS

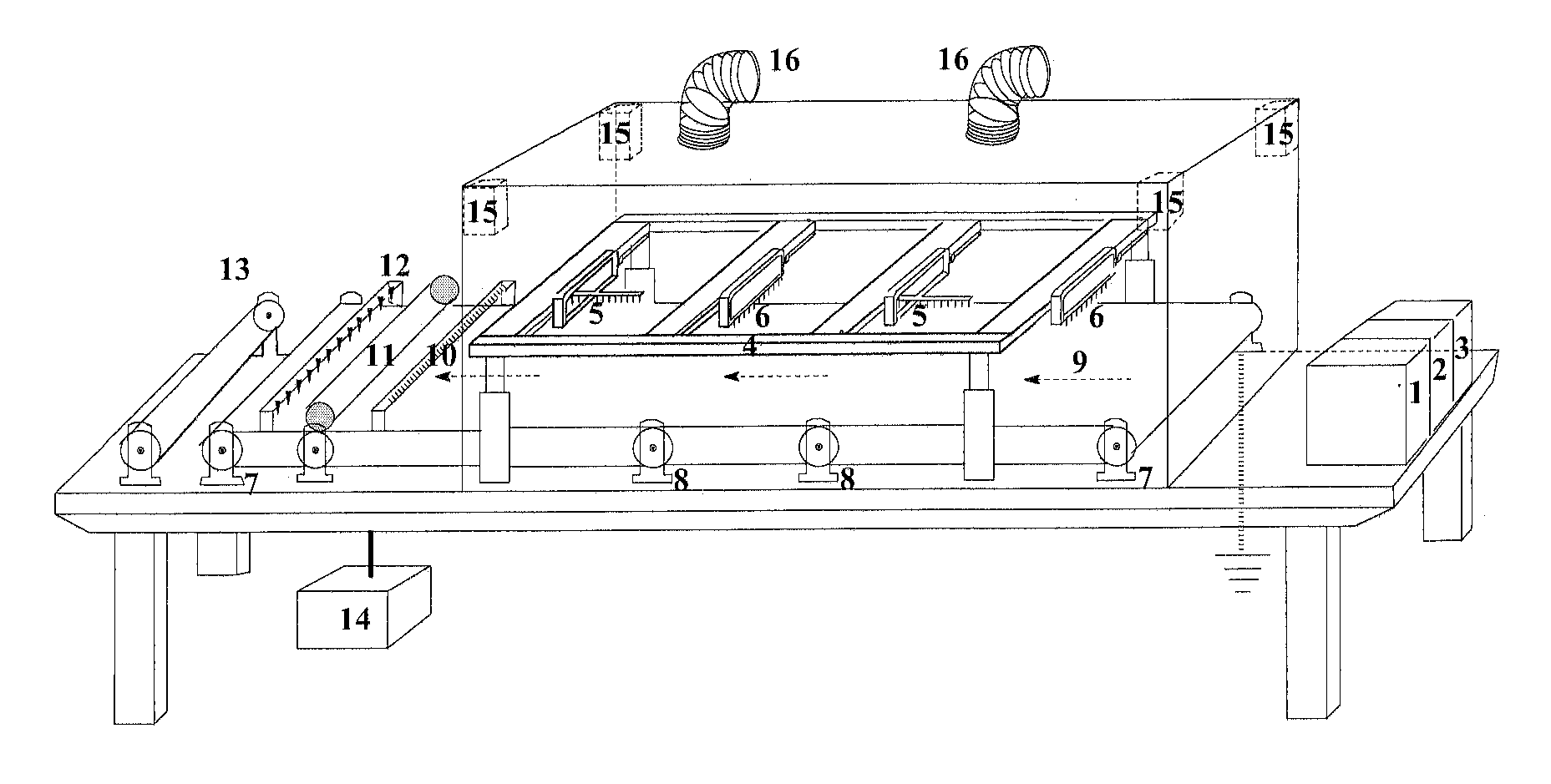

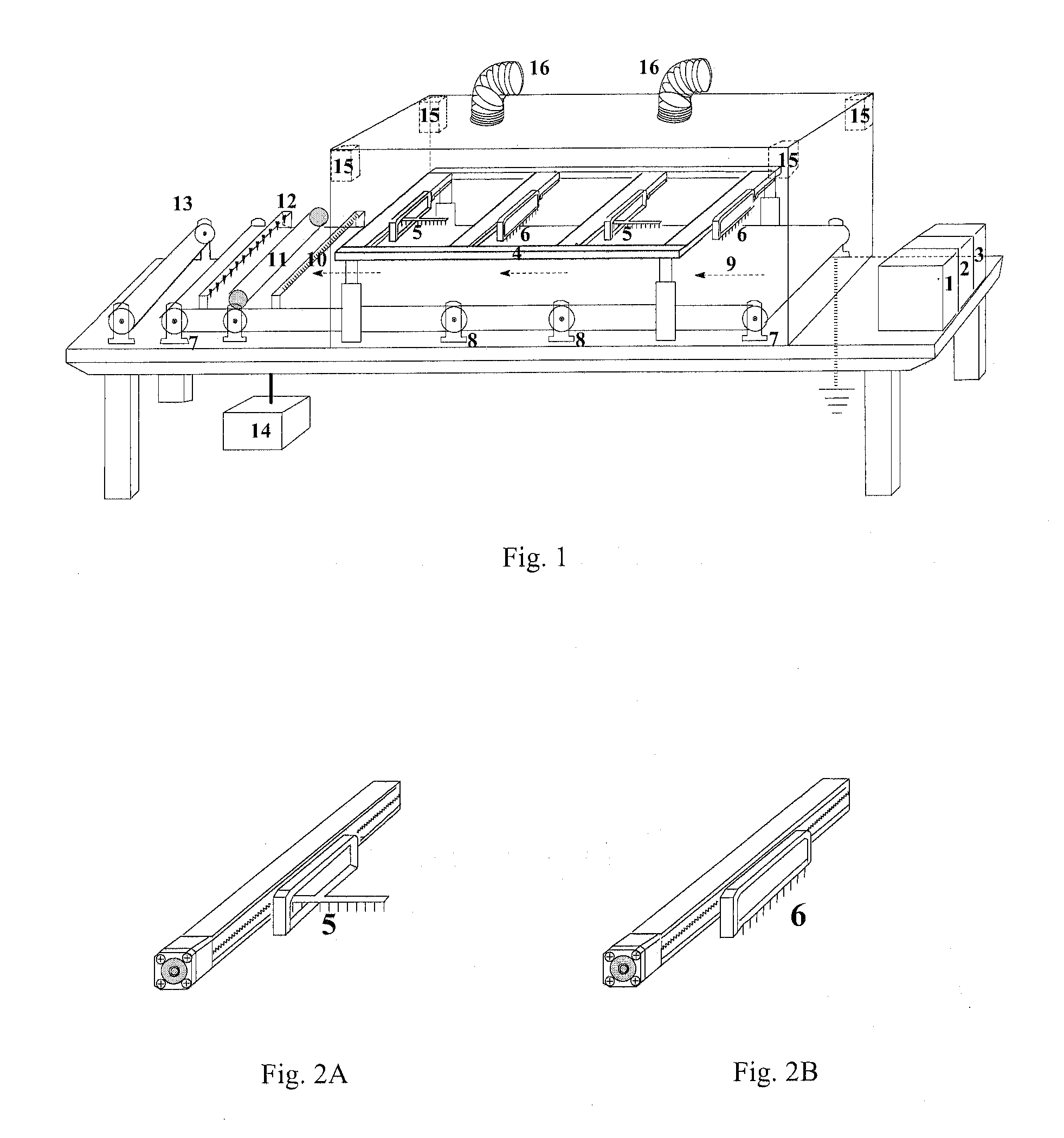

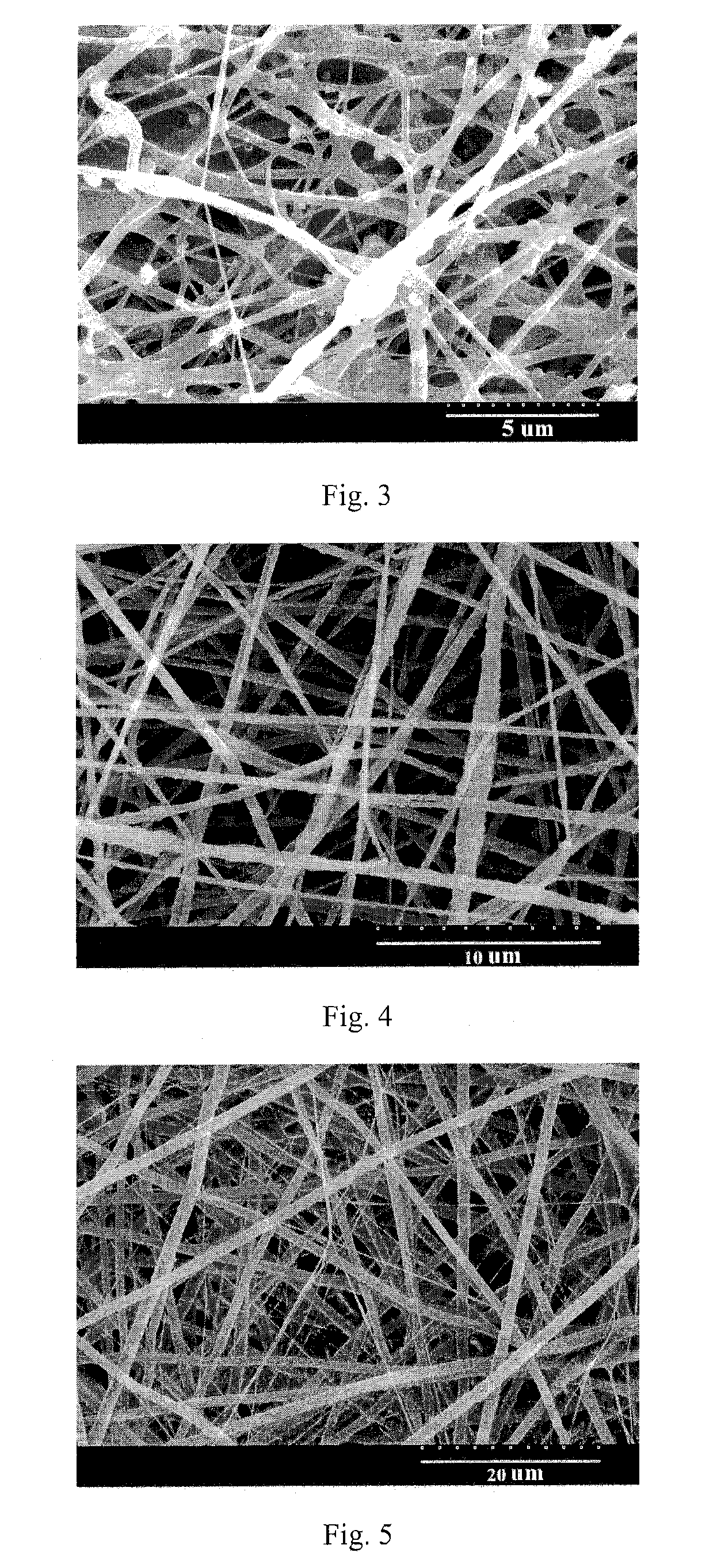

Electrospinning membrane machine in warp and weft directions and application process thereof

InactiveUS20120112389A1High mechanical strengthImprove uniformityElectric discharge heatingElectro-spinningHigh-voltage direct currentEngineering

The present invention relates to an electrospinning device for fabricating a membrane, in particular, to an electrospinning device for fabricating membrane by using spinnerets aligned in machine direction (MD) and transverse direction (TD) in a high-voltage DC electric field, and to method for using the same. In addition to producing a single-layer nanofiber membrane from a polymer composite, the electrospinning device according to the present invention can also conveniently produce a multilayer composite nanofiber membrane from more than one polymer composites. The electrospinning device comprises a control section, an electrospinning section and an ancillary section. The electrospinning section comprises a MD spinnerets set and a TD spinnerets set that are alternately arranged and moves above a membrane collecting device in a to-and-fro scanning manner so as to improve the evenness and strength of the obtained membrane. The high-voltage DC electric field is applied between the MD and TD spinnerets sets and a stainless steel conveyer belt for collecting the membrane. A polymer solution supplied to the MD and TD spinnerets sets is split into nanoflows under the action of the electric field, accumulated on the stainless steel conveyer belt to form a membrane and carried to a collecting roller to be collected.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

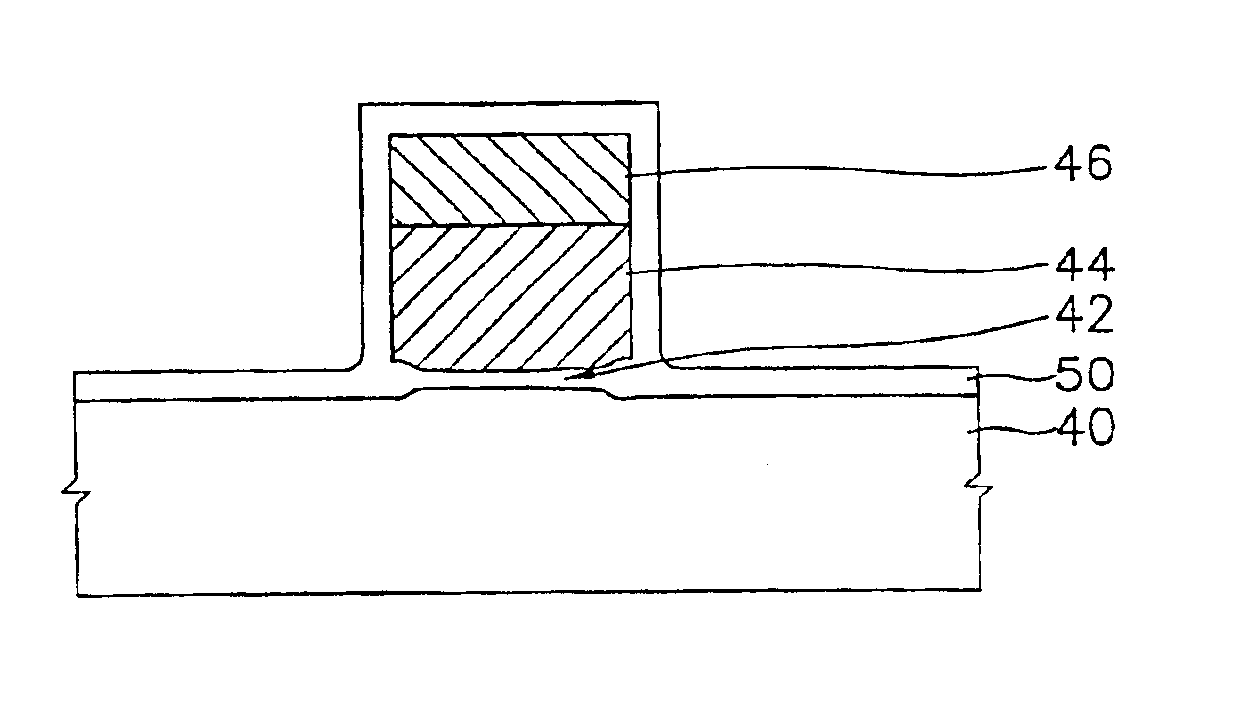

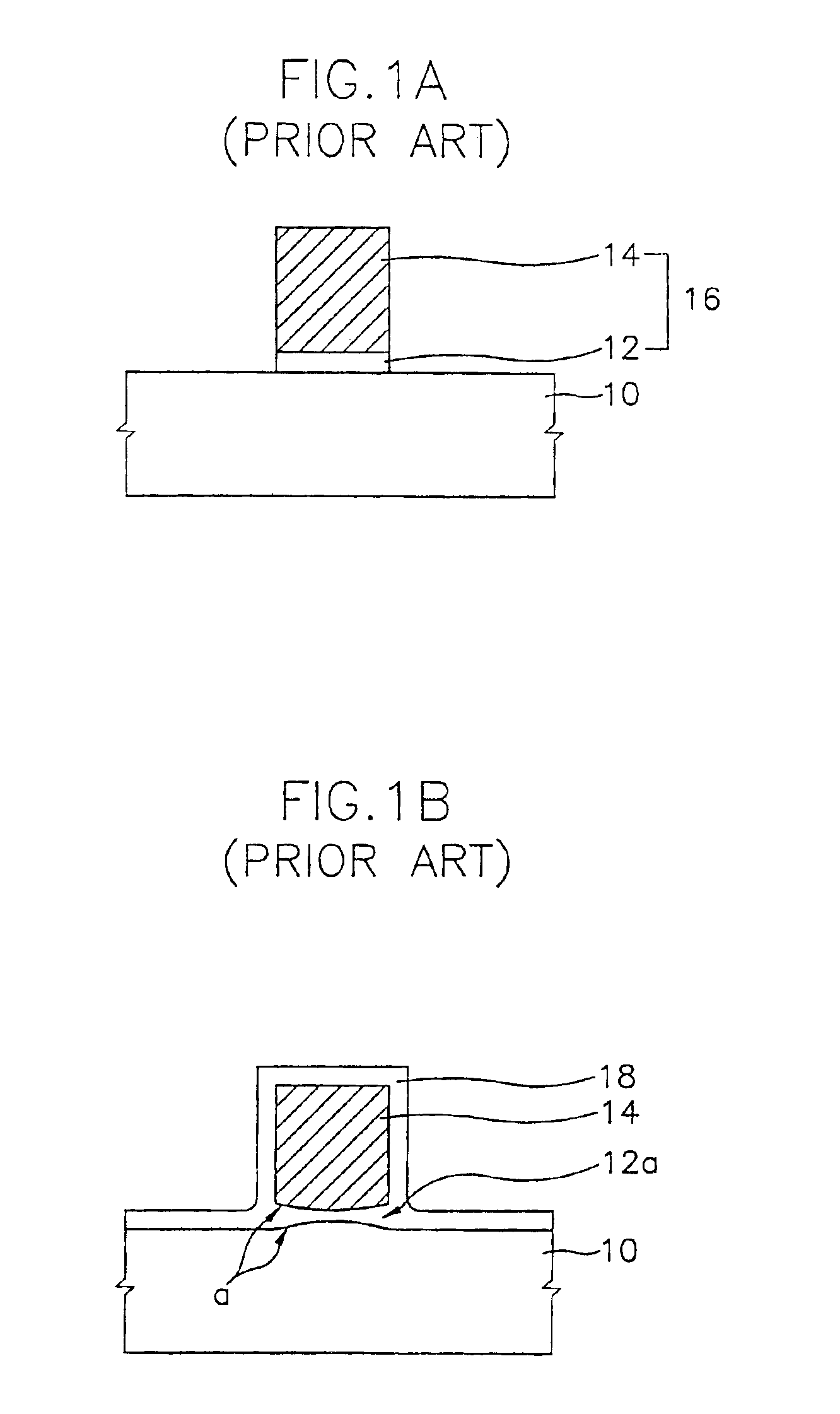

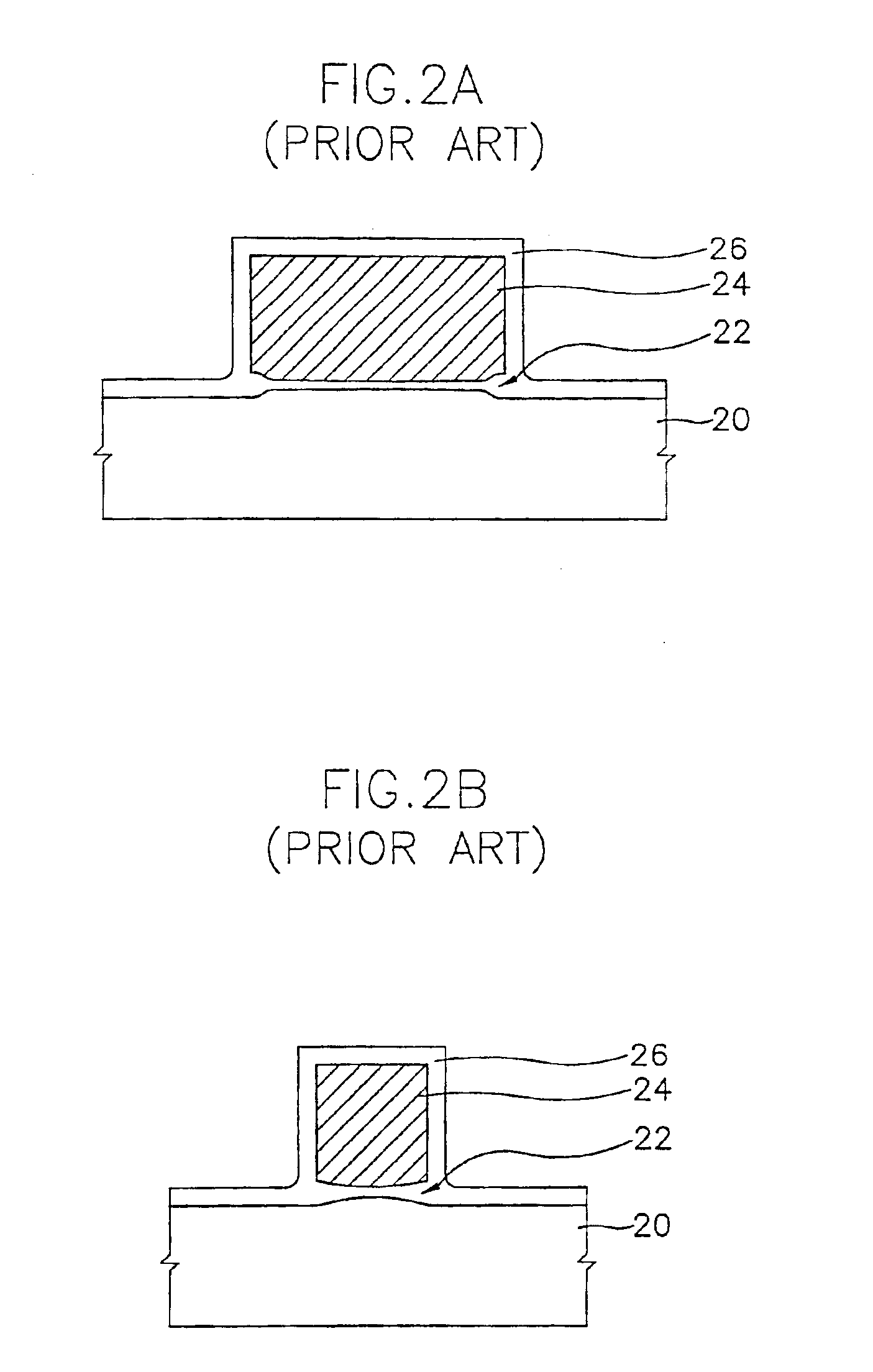

Method for forming a gate electrode in a semiconductor device including re-oxidation for restraining the thickness of the gate oxide

InactiveUS6905927B2Reduce thickness differenceImprove variationSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialGate oxide

A semiconductor device and method of production are disclosed, the method including forming a preliminary gate electrode on a semiconductor substrate, the preliminary gate electrode including a gate oxide layer pattern and a conductive layer pattern stacked on the gate oxide layer pattern, and performing a re-oxidation process for curing damage of the semiconductor substrate and / or a sidewall of the conductive layer pattern, when the preliminary gate electrode is formed by forming an oxide layer on an outer surface of the preliminary gate electrode and on the semiconductor substrate, by supplying an oxygen gas and a chlorine-including gas while restraining a thickness of the gate oxide layer pattern from being increased; and the semiconductor device comprising a preliminary gate electrode formed on a semiconductor substrate, the preliminary gate electrode including a gate oxide layer pattern and a conductive layer pattern stacked on the gate oxide layer pattern, and a re-oxidized semiconductor substrate and / or a sidewall of the conductive layer pattern, with damage cured therein by supplying an oxygen gas and a chlorine-including gas while restraining a thickness of the gate oxide layer pattern from being increased.

Owner:SAMSUNG ELECTRONICS CO LTD

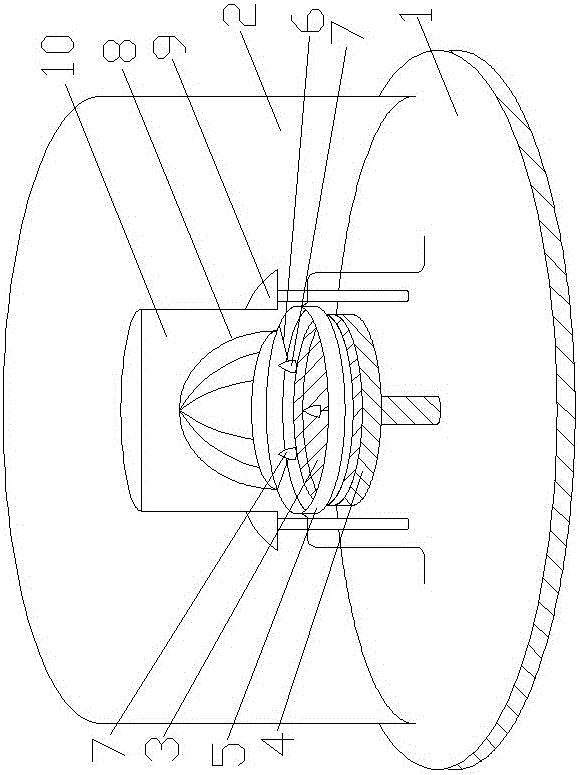

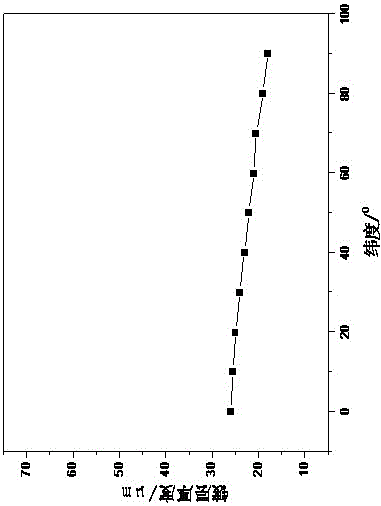

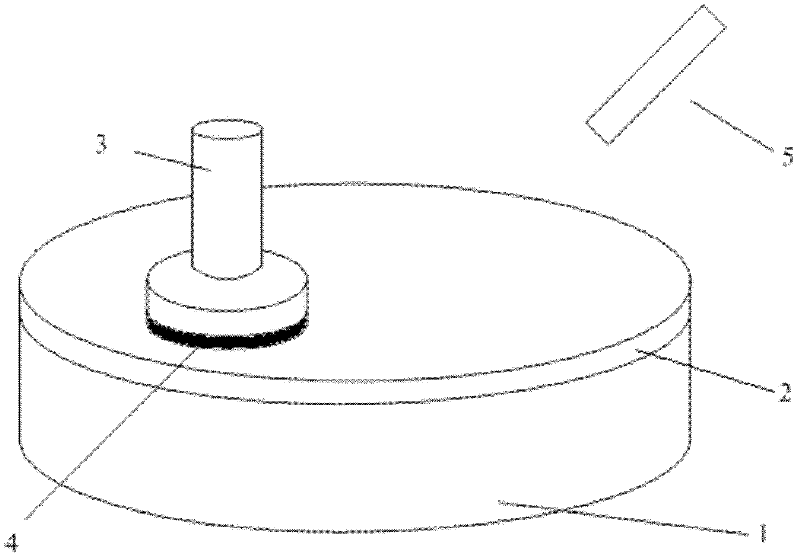

Method and device for uniform magnetron sputtering deposition on inner surface of axisymmetric curved member

InactiveCN104988464AReduce thickness differenceImprove thickness uniformityVacuum evaporation coatingSputtering coatingTarget surfaceOptoelectronics

The invention discloses a method and a device for uniform magnetron sputtering deposition on the inner surface of an axisymmetric curved member, and aims to solve the problem that energy is lost due to gravity and collision between deposition atoms and working gas during the preparation of a clad layer on the inner surface of the axisymmetric curved member according to the conventional magnetron sputtering method, so that the longer the distance from the member to a target surface is, the less deposition atoms can reach the target surface and the lower the deposition rate of the clad layer is, the thickness of the clad layer on the workpiece inner surface (member inner surface) at different latitudes is larger, and the uniformity of the clad layer is poor. The method and the device can effectively overcome defects of traditional methods, and the thickness uniformity of the clad layer on the inner surface of the axisymmetric curved member can be improved to 70% or above, so that the uniform magnetron sputtering clad layer can be formed on the workpiece inner surface. Meanwhile, the method is simple, the process is controllable, the repeatability is good, and the requirements on industrialized and large-scale preparation of uniform clad layers on inner surfaces of axisymmetric curved members can be met.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

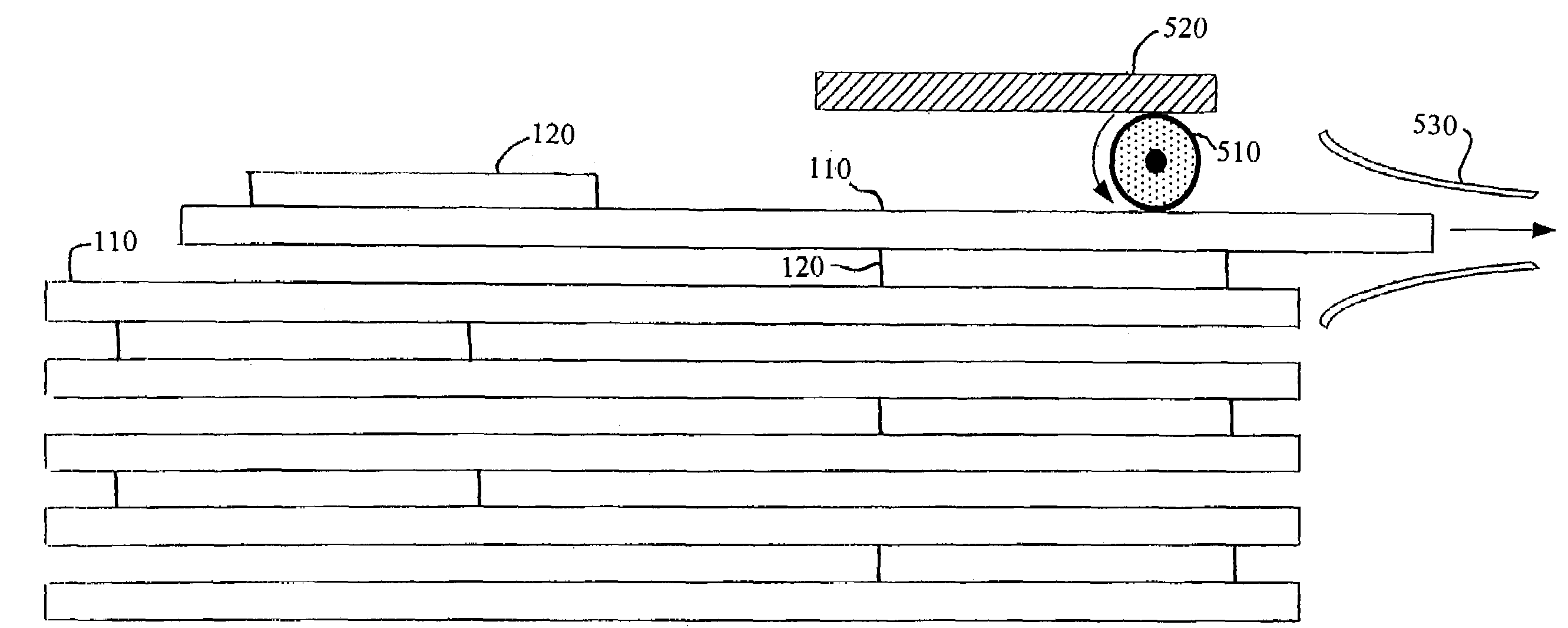

System, method, and program for alternating sheets of media

ActiveUS7411602B2Simple processReduce thickness differenceOther printing apparatusLabeled dataComputer science

Owner:XEROX CORP

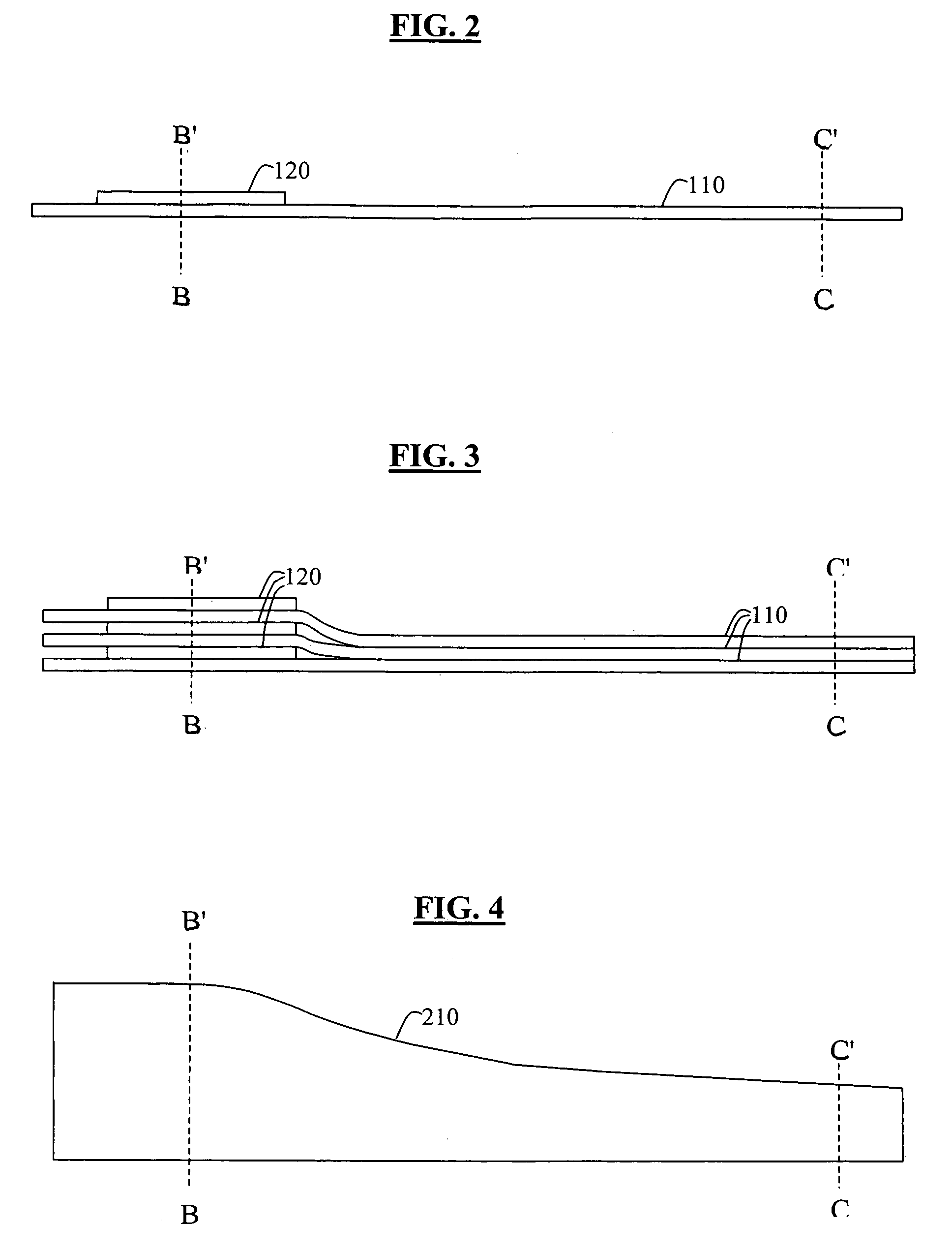

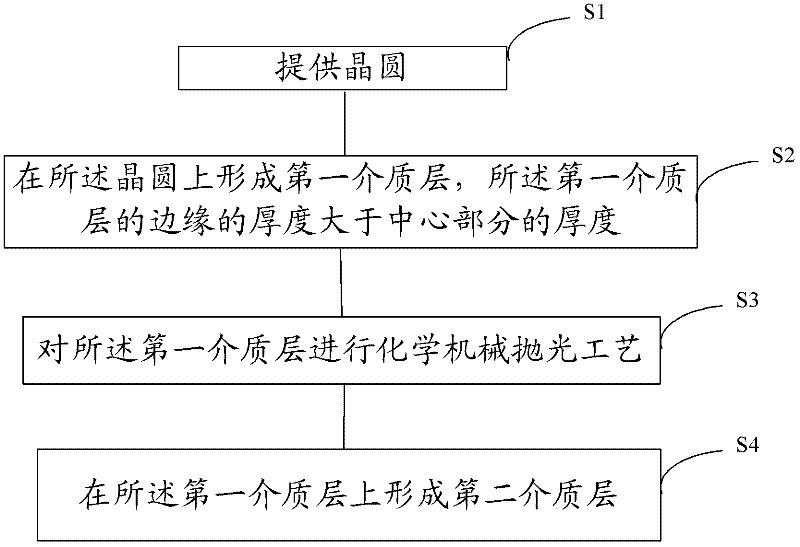

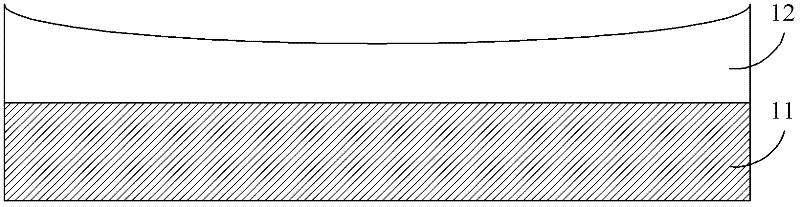

Method for forming flat dielectric layer

ActiveCN102339746AReduce thickness differenceReduce pre-thicknessSemiconductor/solid-state device manufacturingDevice formOptoelectronics

The invention discloses a method for forming a flat dielectric layer. The method comprises the following steps of: providing a wafer, forming a first dielectric layer on the wafer, wherein the thickness of the edge of the dielectric layer is greater than that of the central part of the dielectric layer; performing chemical and mechanical polishing on the first dielectric layer; and forming a second dielectric layer on the first dielectric layer, wherein the thickness of the edge of the second dielectric layer is greater than that of the central part of the second dielectric layer. For the first dielectric layer formed by the method provided by the embodiment of the invention, the thickness difference between the central part and the edge of the wafer is effectively decreased, and the yield of a final device formed on the edge of the water is effectively improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

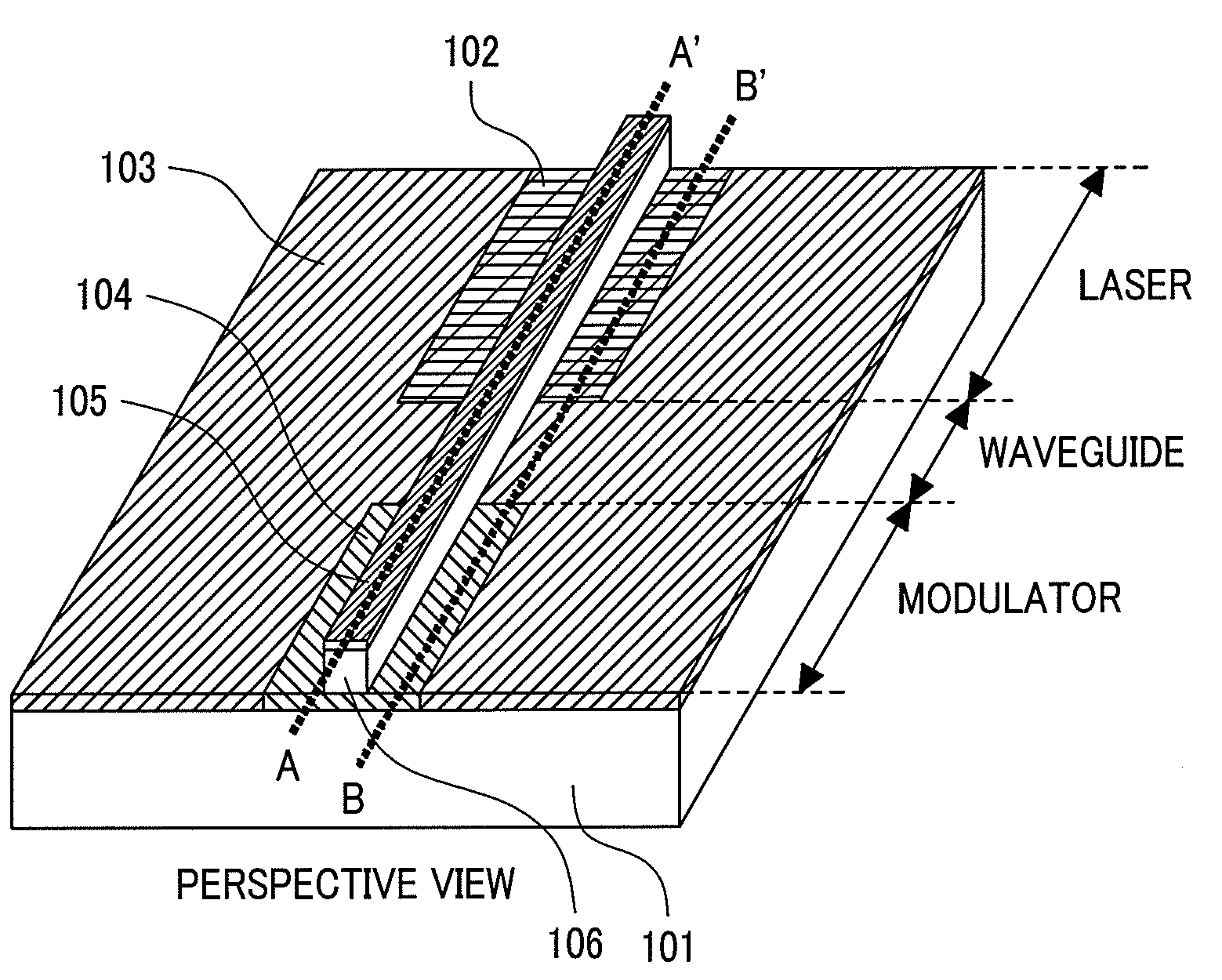

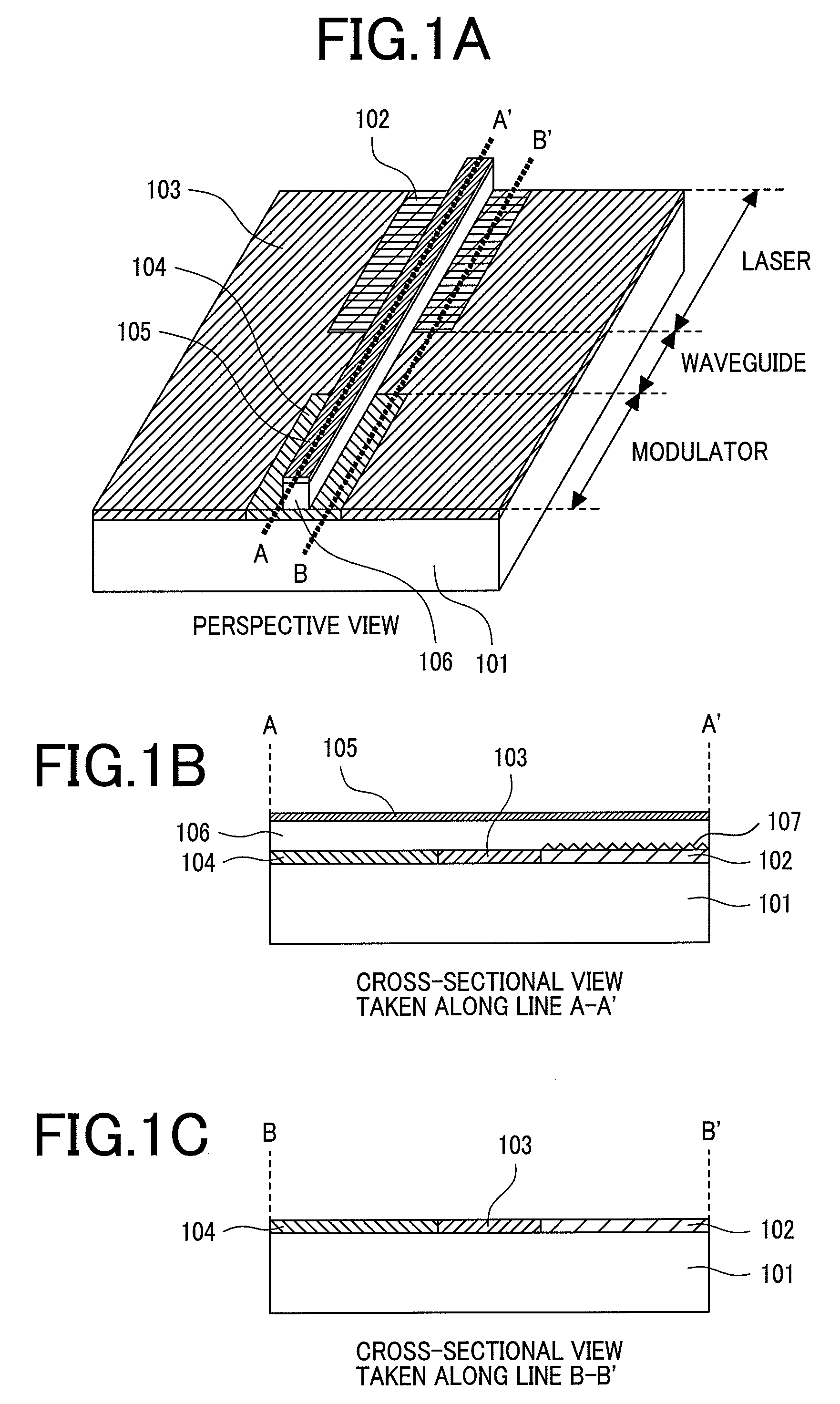

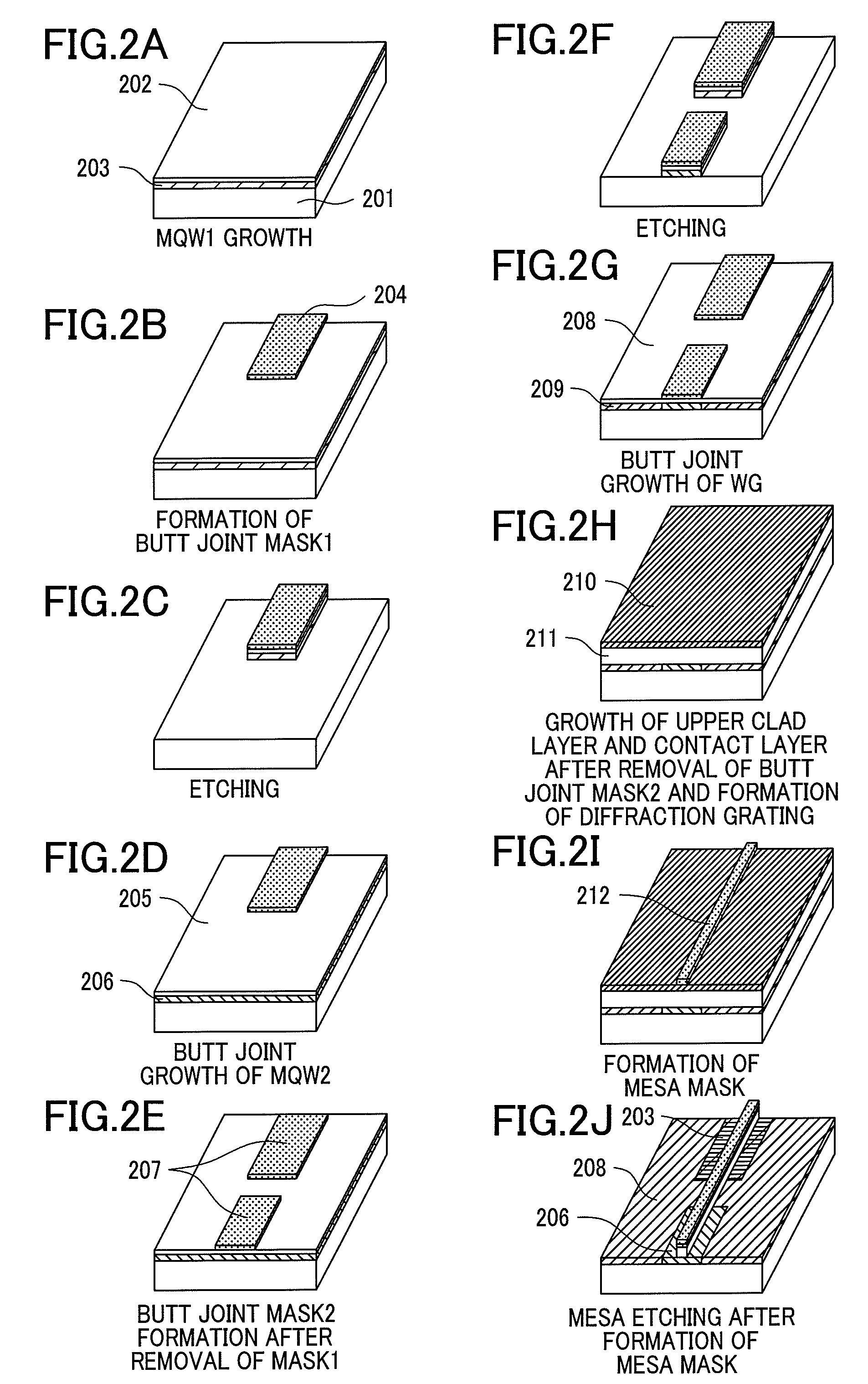

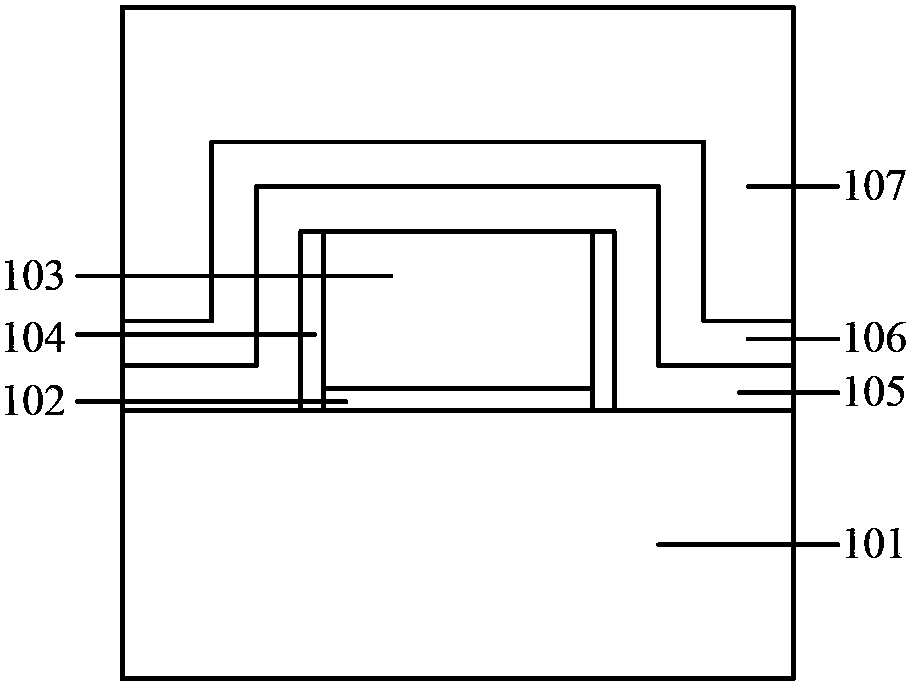

Optical integrated device and manufacturing method thereof

ActiveUS20080317422A1Easily buryDefect generationSemiconductor/solid-state device manufacturingCoupling light guidesEtching selectivityEngineering

In the optical integrated devices with ridge waveguide structure based on the conventional technology, there occur such troubles as generation of a recess in a BJ section to easily cause a crystal defect due to the mass transport phenomenon of InP when a butt joint (BJ) is grown, lowering of reliability of the devices, and lowering in a yield in fabrication of devices. In the present invention, a protection layer made of InGaAsP is provided on the BJ section. The layer has high etching selectivity for the InP cladding layer and remains on the BJ section even after mesa etching.

Owner:LUMENTUM JAPAN INC

MOS device, manufacturing method of MOS device and manufacturing method of CMOS devices

ActiveCN103578989AReduce parasitic capacitanceImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSParasitic capacitance

The invention provides an MOS device, a manufacturing method of the MOS device and a manufacturing method of two kinds of CMOS devices. The manufacturing method of the MOS device comprises the step of providing a substrate comprising a polysilicon gate, the step of sequentially forming a middle layer, an isolation layer and a first interlayer dielectric layer on the substrate and the polysilicon gate, the step of enabling the upper surface of the first interlayer dielectric layer to be flush with the upper surface of the isolation layer, the step of removing the isolation layer on the polysilicon gate, the middle layer above the polysilicon gate and the polysilicon gate to form a groove, the step of forming a metal grid in the groove, the step of carrying out the planarization processing to enable the upper surface of the metal grid, the upper surface of the first interlayer dielectric layer, the upper surface of the isolation layer and the upper surface of the middle layer to be flush with one another, the step of removing the middle layer on the side wall of the metal grid to form a gap and the step of forming second interlayer dielectric layers on the upper surface of the first interlayer dielectric layer, the upper surface of the isolation layer, the upper surface of the gap and the upper surface of the metal grid. The thickness of the metal grid can be accurately controlled, stray capacitance can be reduced, and the performance of the device can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for inhibiting polycrystallizing of ridges of monocrystal diamond

ActiveCN108977881AFast growthImprove growth qualityPolycrystalline material growthFrom chemically reactive gasesTemperature controlSingle crystal

The invention belongs to the technical field of preparation of monocrystal diamonds, and particularly relates to a method for inhibiting polycrystallizing of ridges of a monocrystal diamond. The method for inhibiting the polycrystallizing of the ridges of the monocrystal diamond comprises the following steps of (1) preparation and selection of a substrate: slicing the monocrystal to obtain a plurality of substrates, wherein each substrate is oriented as shown in (100), and the thickness is 300 to 350mum; (2) pretreatment of the substrate: sequentially performing acid treatment, acetone and alkaline ultrasonic cleaning on the substrates in step (1), and selecting one surface with higher quality and no impurity defect as the growth surface; (3) growth of crystals. The method has the advantages that by strictly controlling the ratio of flow rate of gas in each step and the power / pressure ratio in the preparation process, the corresponding parameter ratio is designed according to each growth stage; by matching with the strict temperature control, the deposition quality of the monocrystal diamond is finally improved.

Owner:ZHONGNAN DIAMOND CO LTD

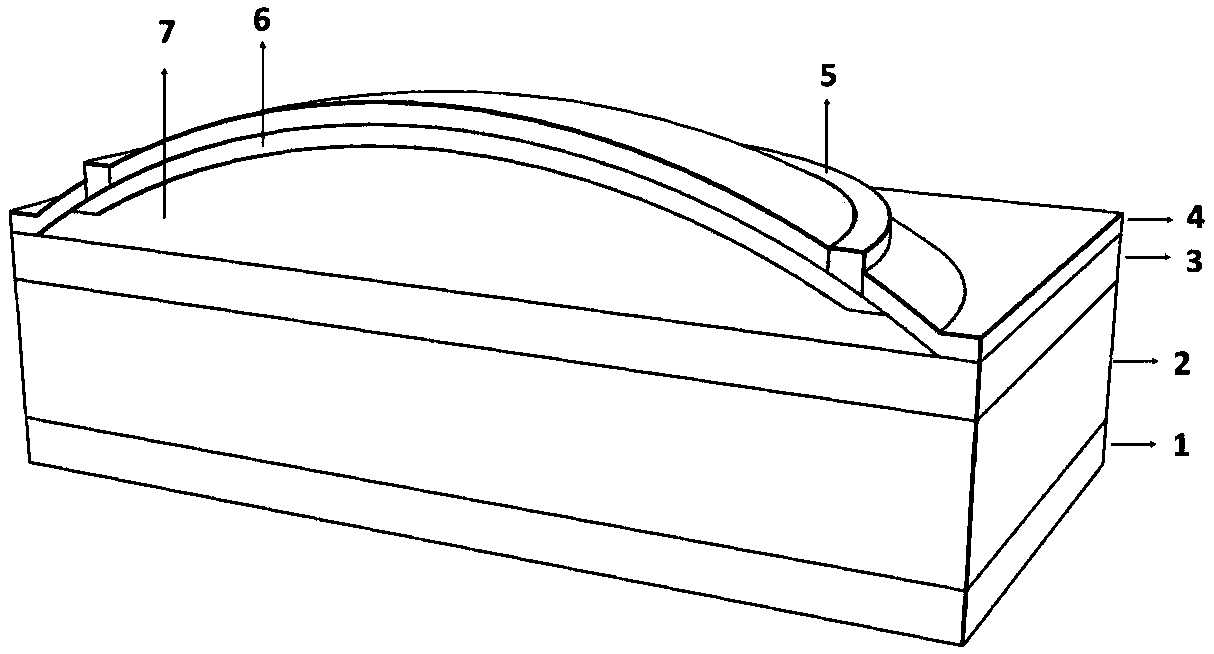

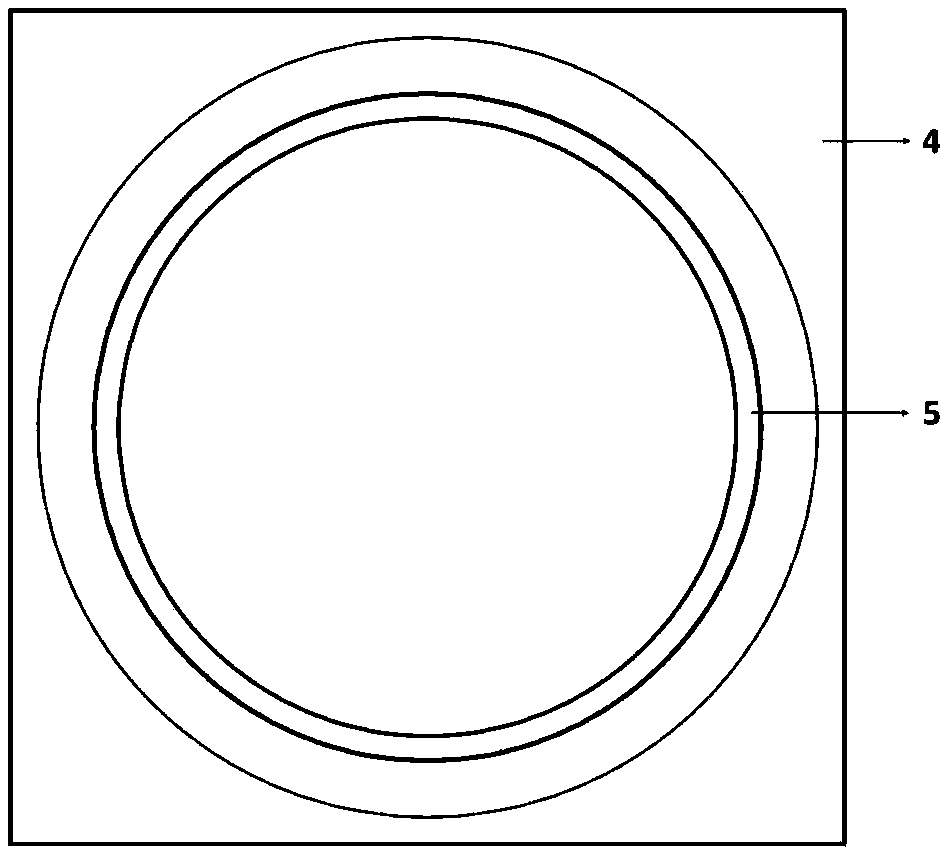

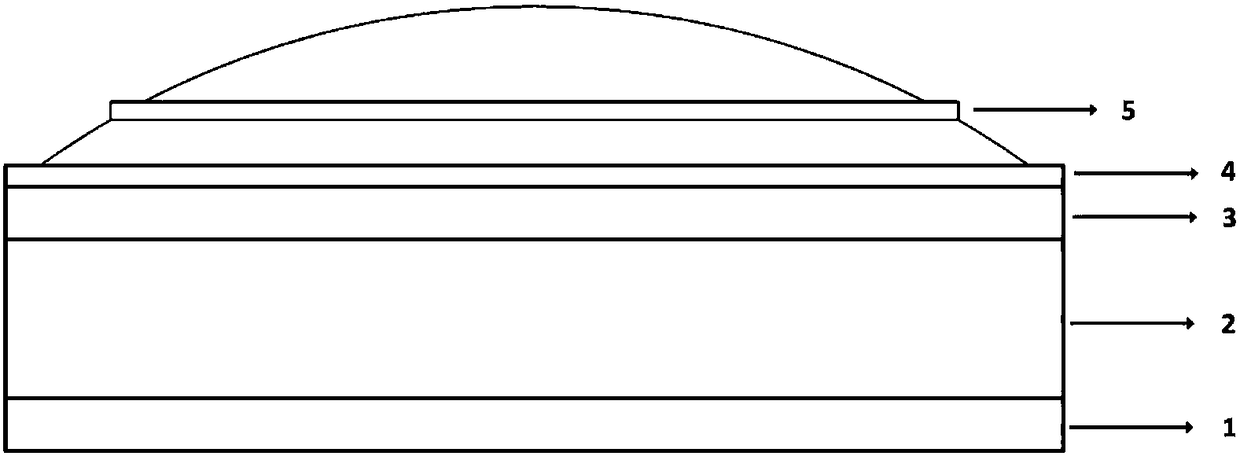

4H-SiC ultraviolet photoelectric detector with spherical crown structure, and preparation method

ActiveCN108400197AImprove detection abilityImprove practicalityFinal product manufactureSemiconductor devicesSputteringPhotovoltaic detectors

Disclosed are a 4H-SiC ultraviolet photoelectric detector with a spherical crown structure, and a preparation method. The ultraviolet photoelectric detector adopts a p-i-n structure; an N type bufferlayer and an i type absorption layer are grown on a highly-doped four-degree-off-axis double parabolic N+ type 4H-SiC substrate in sequence; an arc-shaped inclined table surface is formed on the i type absorption layer to form a spherical crown-shaped i type absorption layer surface; by adopting an injection and high-temperature annealing activation process, a P+ layer is formed on the upper surface of the spherical crown-shaped i type absorption layer; next, through a thermal oxidization method, a silicon dioxide passivation layer is grown on the surface of the P+ layer; through a photoetching process, an ICP etching process and a stripping process, a P type annular electrode window is etched in the silicon dioxide passivation layer of the P+ layer, and a P type electrode is formed by adopting a magnetron sputtering process; and the highly-doped four-degree-off-axis double parabolic N+ type 4H-SiC substrate on the back surface is etched, and an N type electrode is formed by adopting amagnetron sputtering process, so as to obtain the 4H-SiC ultraviolet photoelectric detector with the spherical crown structure.

Owner:XIAMEN UNIV

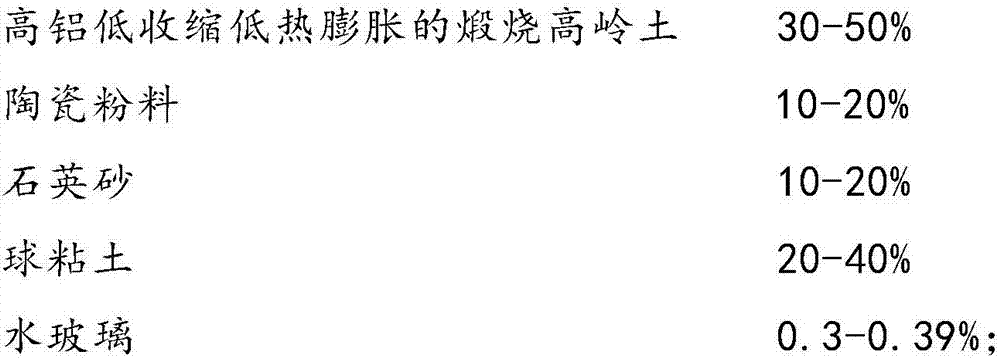

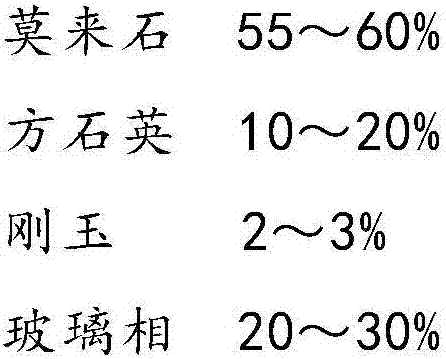

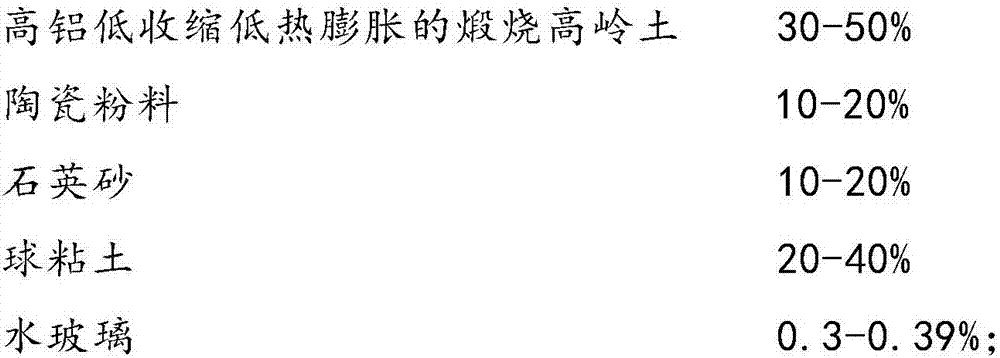

Ceramic forming slurry and high-pressure forming method

The invention relates ceramic forming slurry which comprises the following components in percentage by mass: 76%-80% of a raw material and 20%-24% of water. The raw material comprises the following components in percentage by weight: 30%-50% of high-aluminum low-shrink low-thermal-expansion calcined kaolin, 10%-20% of ceramic powder, 10%-20% of quartz sand, 20%-40% of ball clay and 0.3%-0.39% of water glass, wherein the molar ratio of the water glass is 1.5-3.5. The thickening degree of the slurry is increased from 50-80 degrees to 70-100 degrees by adding 0.3%-0.39% of water glass, and meanwhile, the viscosity of the slurry is also improved, so that the bonding property among blank bodies is greatly improved, a layering phenomenon, which is likely to happen (for example F-611), at double-sided pulp sucking parts in the prior art is substantially avoided, and the green blank rejection rate is reduced by about 3%; in addition, the permeability is improved, the grouting time is shortened, and the production efficiency is increased.

Owner:LIXIL AS SANITARY MFG (SHANGHAI) CO LTD

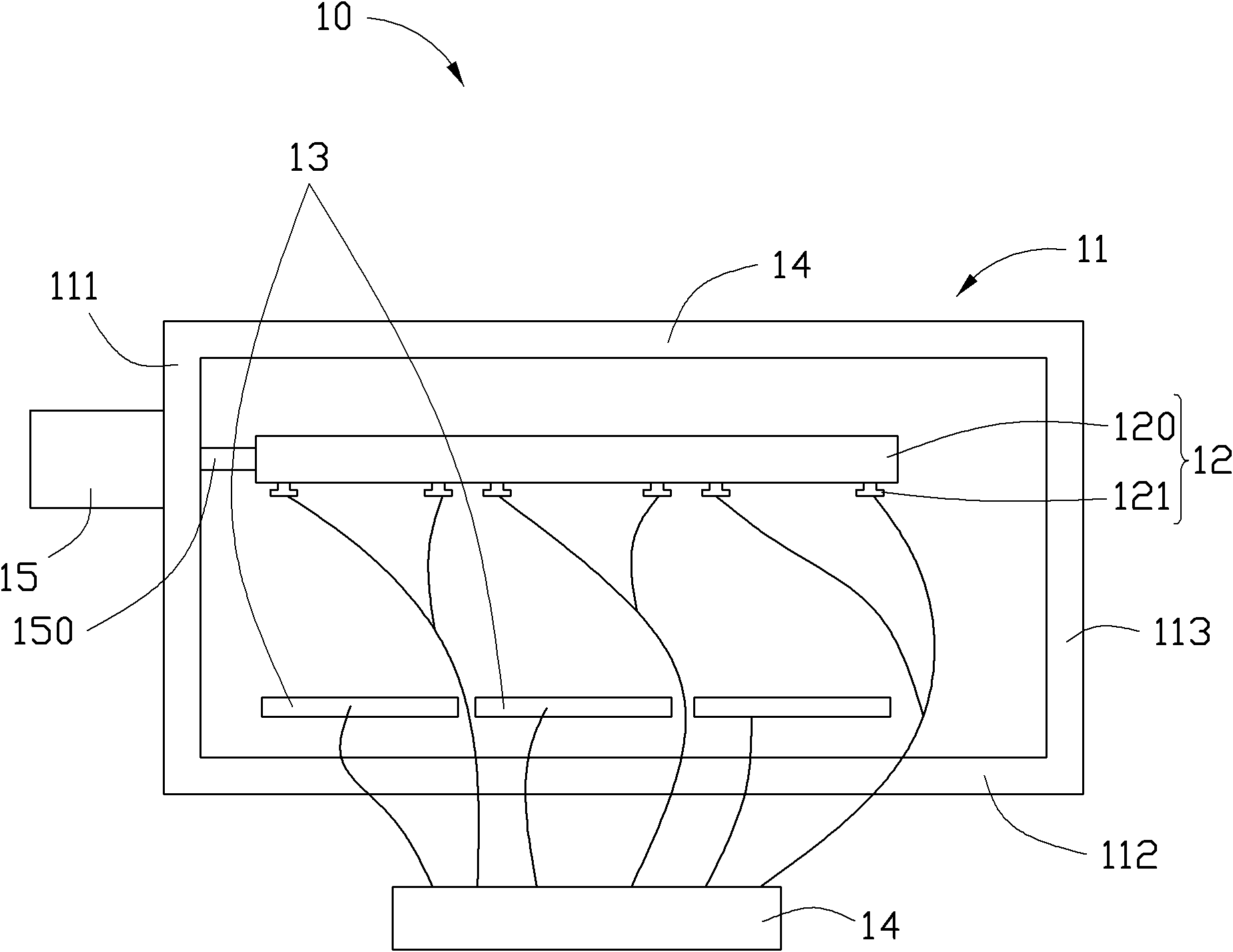

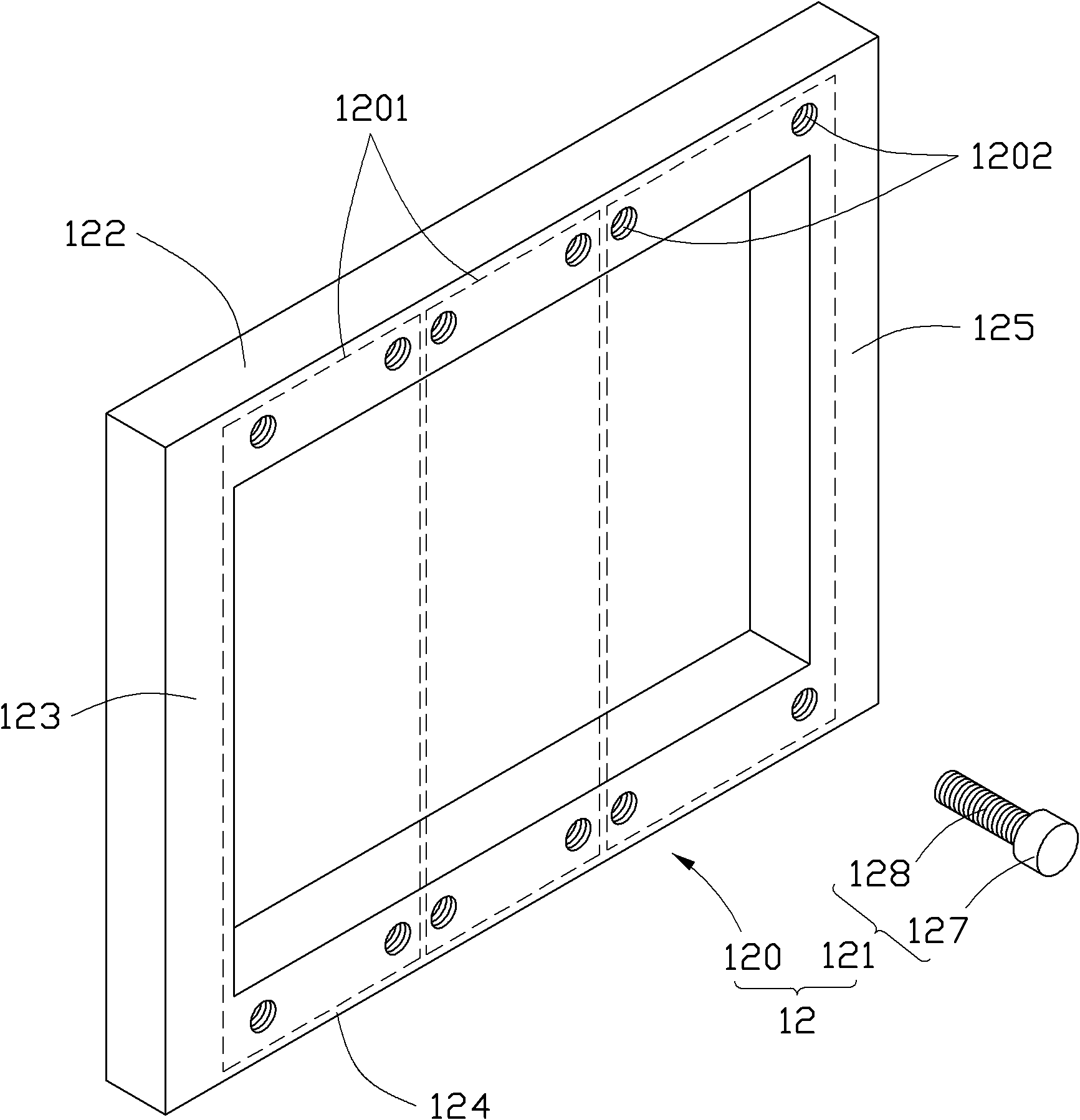

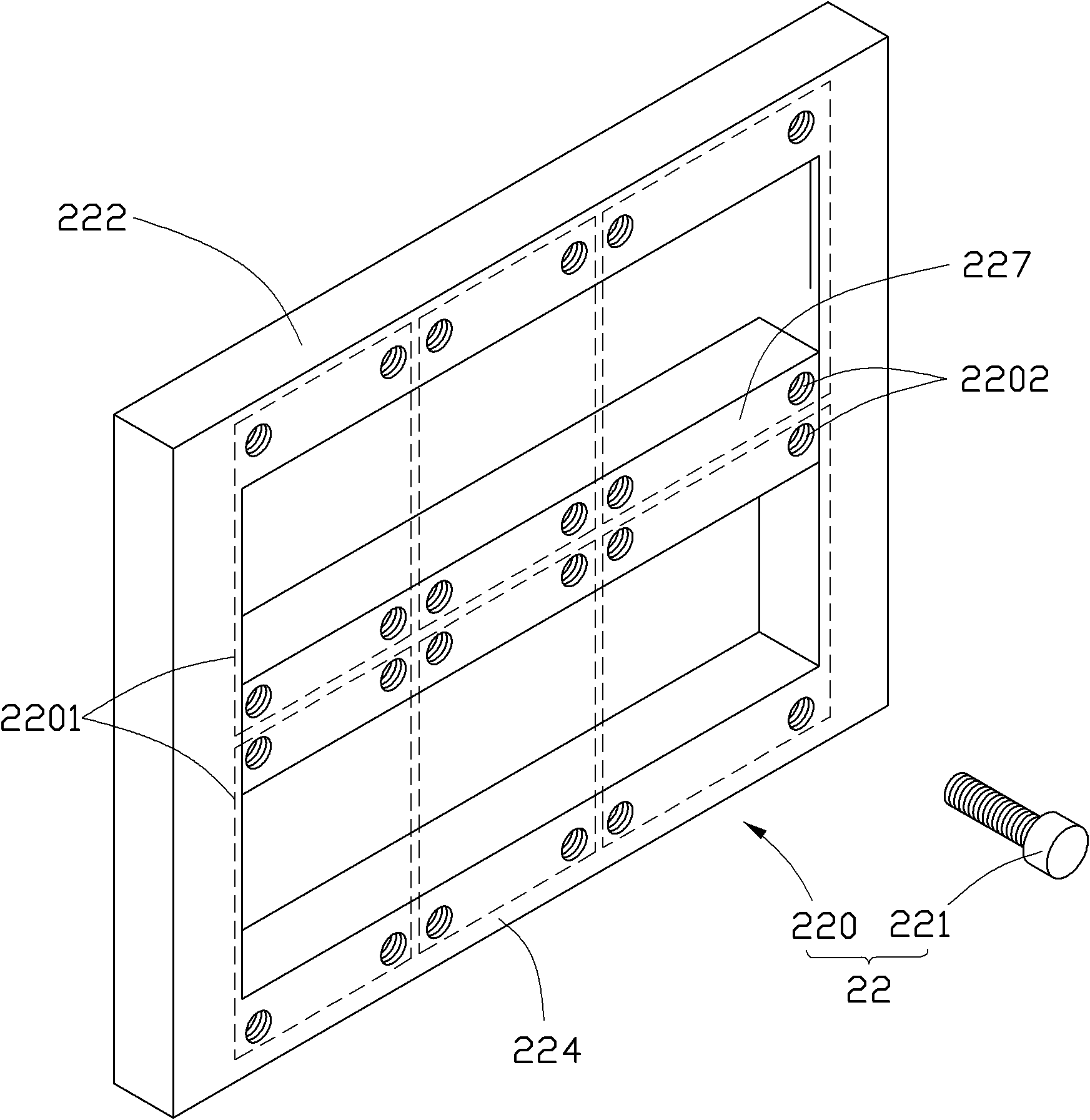

Electroplating apparatus and electroplating method thereof

The invention relates to an electroplating apparatus, which is provided for electroplating a substrate comprising a plurality of areas requiring electroplating, wherein the areas requiring electroplating are electrically insulated. The electroplating apparatus comprises an electroplating bath, a cathode fixation structure, a plurality of anodes and a voltage controller. The cathode fixation structure comprises an installation frame and a plurality of electrical conductivity fixation components. The electrical conductivity fixation components are provided for installing the substrate on the installation frame, and conducting current to the substrate. Each electroplating-required area of the substrate is provided with at least an electrical conductivity fixation component. Each anode is corresponding to an electroplating-required area of the substrate arranged on the installation frame. The voltage controller forms electrical connections with a plurality of the anodes and a plurality of the electrical conductivity fixation components. The voltage controller is provided for controlling the electrifying status of each anode and at least an electrical conductivity fixation component arranged on the electroplating-required area corresponding to the anode so as to control the voltage between each anode and the electroplating-required area corresponding to the anode. The technical scheme further provides an electroplating method for using the electroplating apparatus.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com