Electroplating solution for acid copper-plating for printed circuit board as well as preparation method and application method for same

A printed circuit board and acid copper plating technology, which is applied in the field of copper plating of printed circuit boards, can solve the problems of high cost, low additive depth capability and dispersion capability, and high cost, and achieve low cost of use and strong depth capability and dispersing ability, the effect of reducing the difference in thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

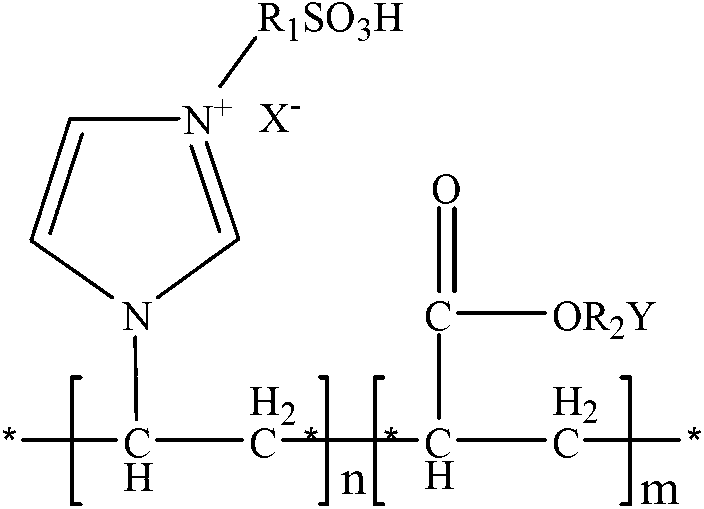

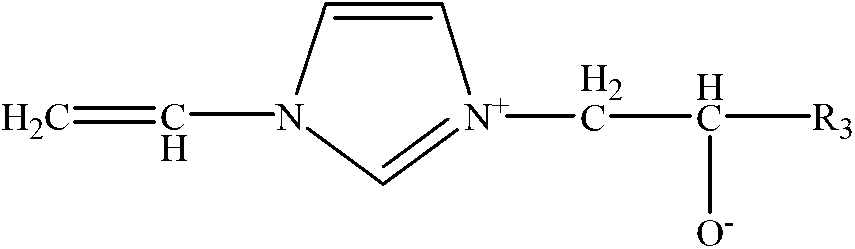

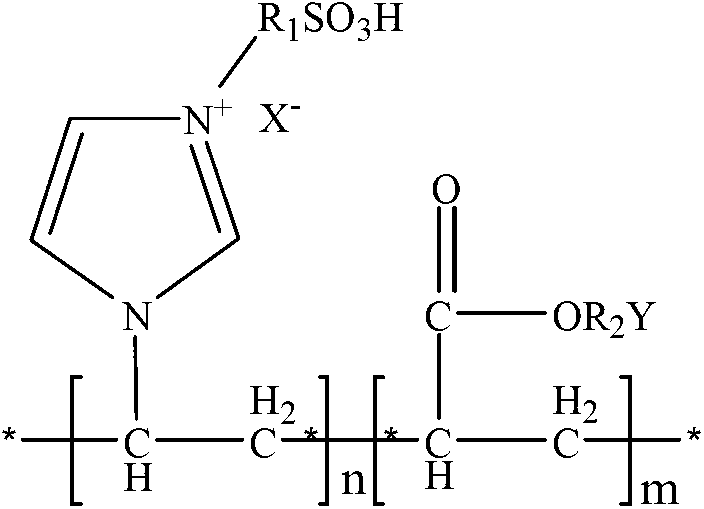

[0028] The synthesis of the copolymer of N-vinylimidazolium salt and propenyl lipid: put 9.4g (0.1mol) vinylimidazole into 250ml three-necked flask, put the flask into 0 ℃ ice-water bath, slowly under stirring Add 12.2g (0.1mol) of 1,3-propyl sultone, continue to stir for half an hour, a white solid precipitates, filter the solid, wash the solid with ether three times, and obtain 18.2g (about 0.0843mol) of solid after vacuum drying , Dissolve the dried solid in a small amount of deionized water, put it in an ice-water bath at 0°C, slowly add concentrated hydrochloric acid equal to the amount of substance, and then stir in a water bath at 60°C for 12 hours, wash the obtained solution with ether, and distill it under reduced pressure to remove water , after vacuum drying, 17.4g (about 0.0689mol) of light red viscous liquid (denoted as VIS) was obtained. Take 8.64g (0.04mol) of the above-prepared red viscous liquid (VIS), 5g (0.04mol) of propenyl butyl ), 50ml benzene and 0.5g fr...

Embodiment 2

[0030] The molar ratio of VIS and propenyl butyl was changed to 2:1, and the other synthesis steps were the same as in Example 1, and a yellow film-like solid was finally obtained.

Embodiment 3

[0032] The propenyl ethyl ester was used to replace the propenyl butyl ester in Example 1, and the other synthesis steps were the same as in Example 1 to finally obtain a pale yellow film-like solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com