Patents

Literature

76results about "Fuses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nontoxic, noncorrosive phosphorus-based primer compositions and an ordnance element including the same

A primer composition that includes red phosphorus having an acid scavenger and a polymer thereon. The primer composition includes at least one other component that is substantially free of lead. The other component is at least one oxidizer, or at least one oxidizer and at least one of at least one secondary explosive composition and at least one energetic binder. The primer composition optionally includes at least one element having an ionic charge to ionic radius ratio of 4 or of 8, such as magnesium, zirconium, aluminum, silicon, titanium, tungsten, alloys thereof, and combinations thereof. The red phosphorus and the at least one oxidizer are present in the primer composition at approximately stoichiometric amounts. An ordnance element including the primer composition is also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

Supplemental-restraint-system gas generating device with water-soluble polymeric binder

InactiveUS6224099B1Easy to manufactureSelectable characteristicLoomsPedestrian/occupant safety arrangementSystems designIn vehicle

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

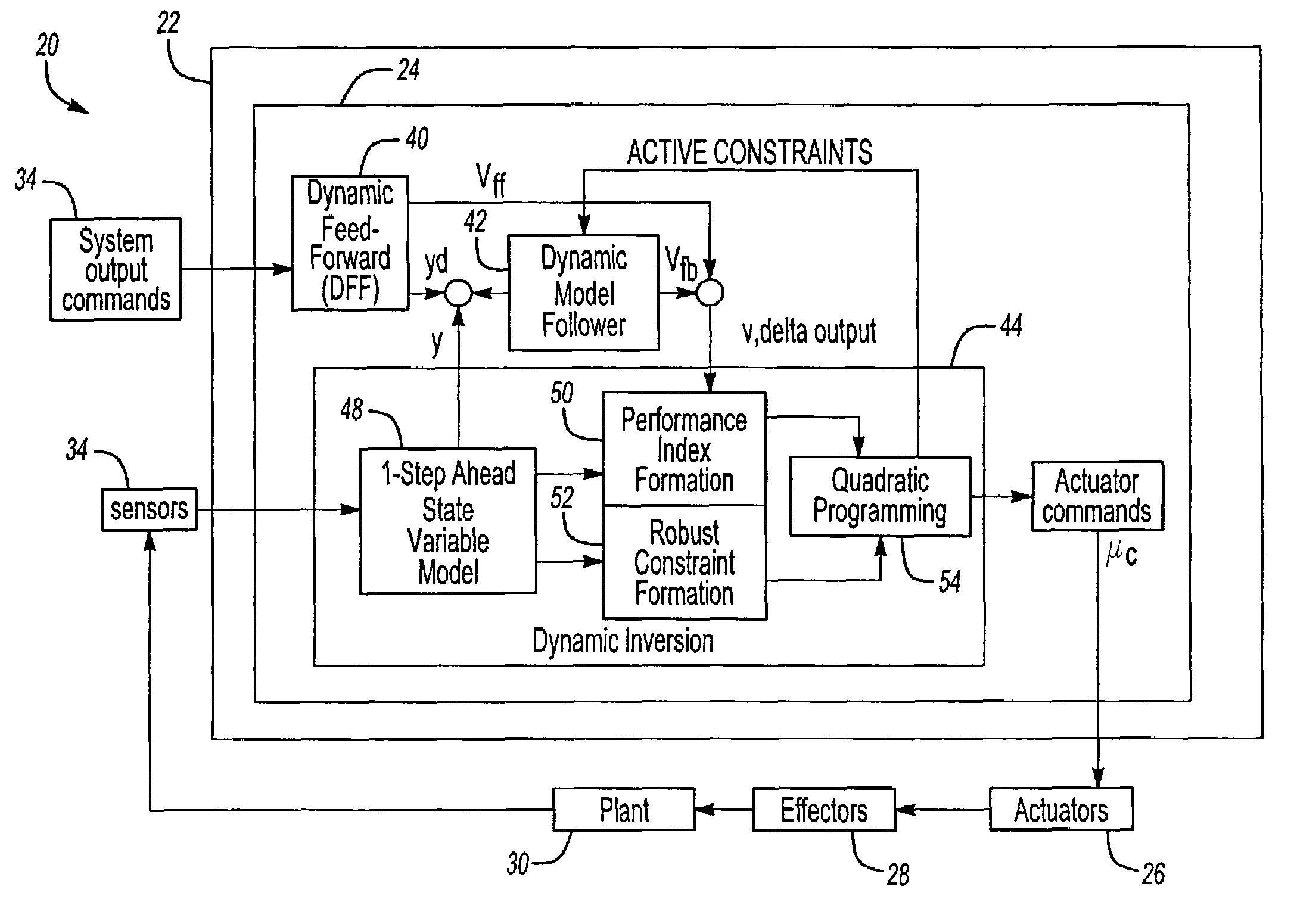

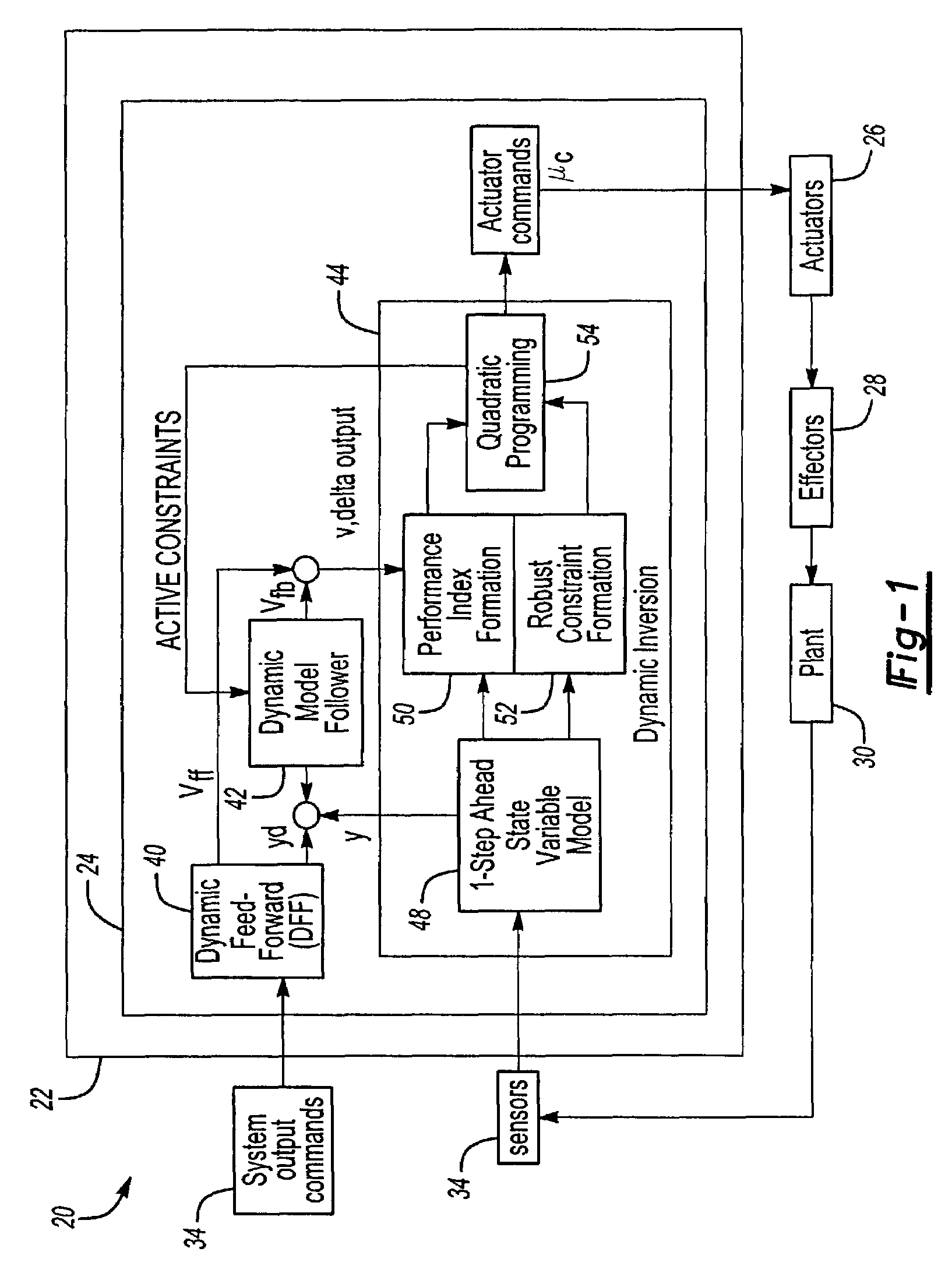

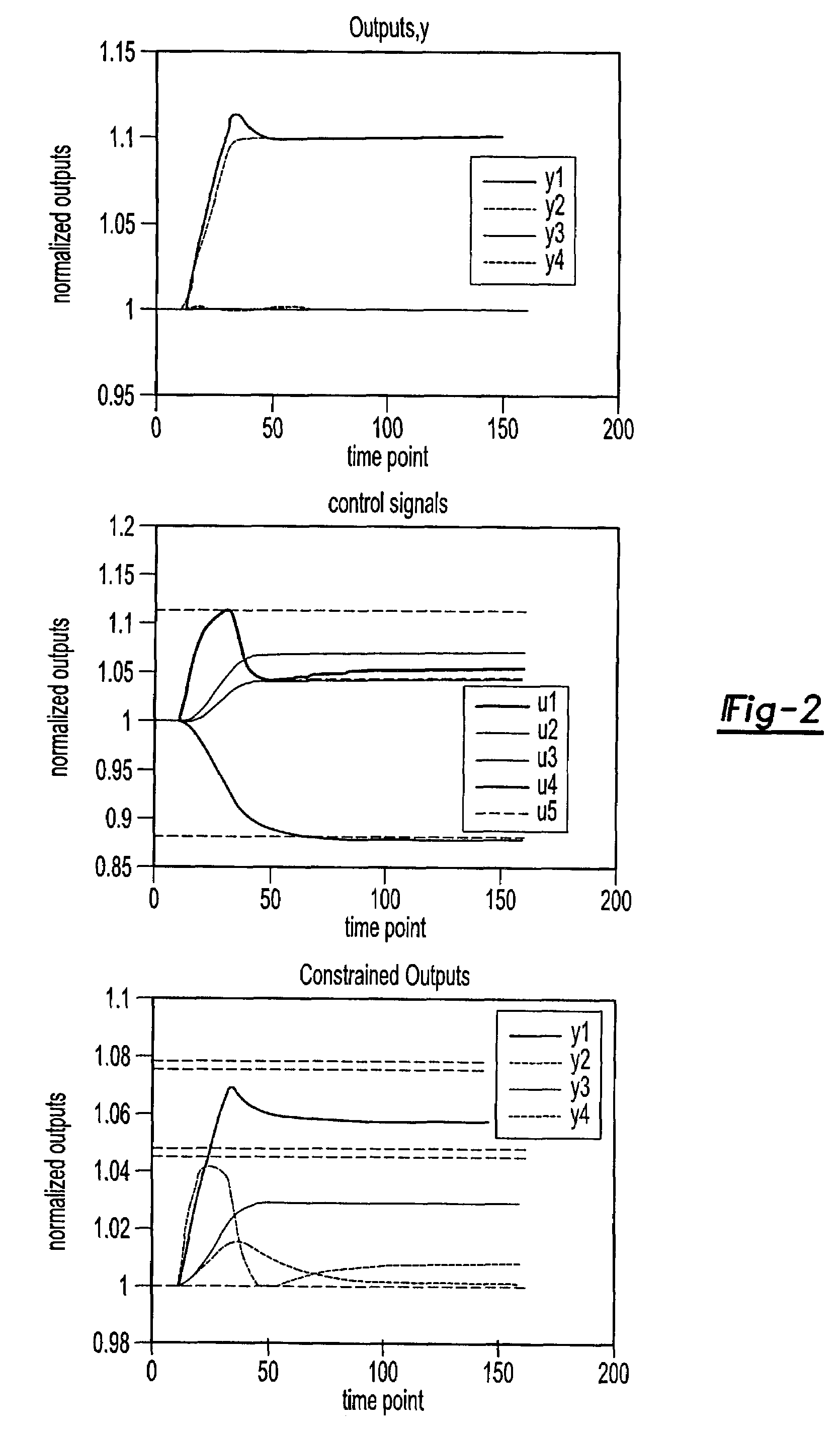

Real-time quadratic programming for control of dynamical systems

ActiveUS7328074B2Increase valueFast convergenceSampled-variable control systemsMotor/generator/converter stoppersRandom dynamical systemOptimal control

Real-time control of a dynamical system is provided by determining control variables that get as close as possible to producing a desired response. Additional consideration of physical limitations leads to a convex Quadratic Program with inequality constraints that needs to be solved in real-time. A new active set algorithm is described to solve the convex Quadratic Program efficiently that meets real-time requirements. Based on the key observation that the physical limitations of the system translate to optimal active sets that remain relatively unchanged over time (even though the actual optimal controls may be varying), starting guesses for the active set obtained from the final iterate in the previous time period greatly reduces the number of iterations and hence allows the Quadratic Programs to be solved to convergence in real-time.

Owner:RTX CORP

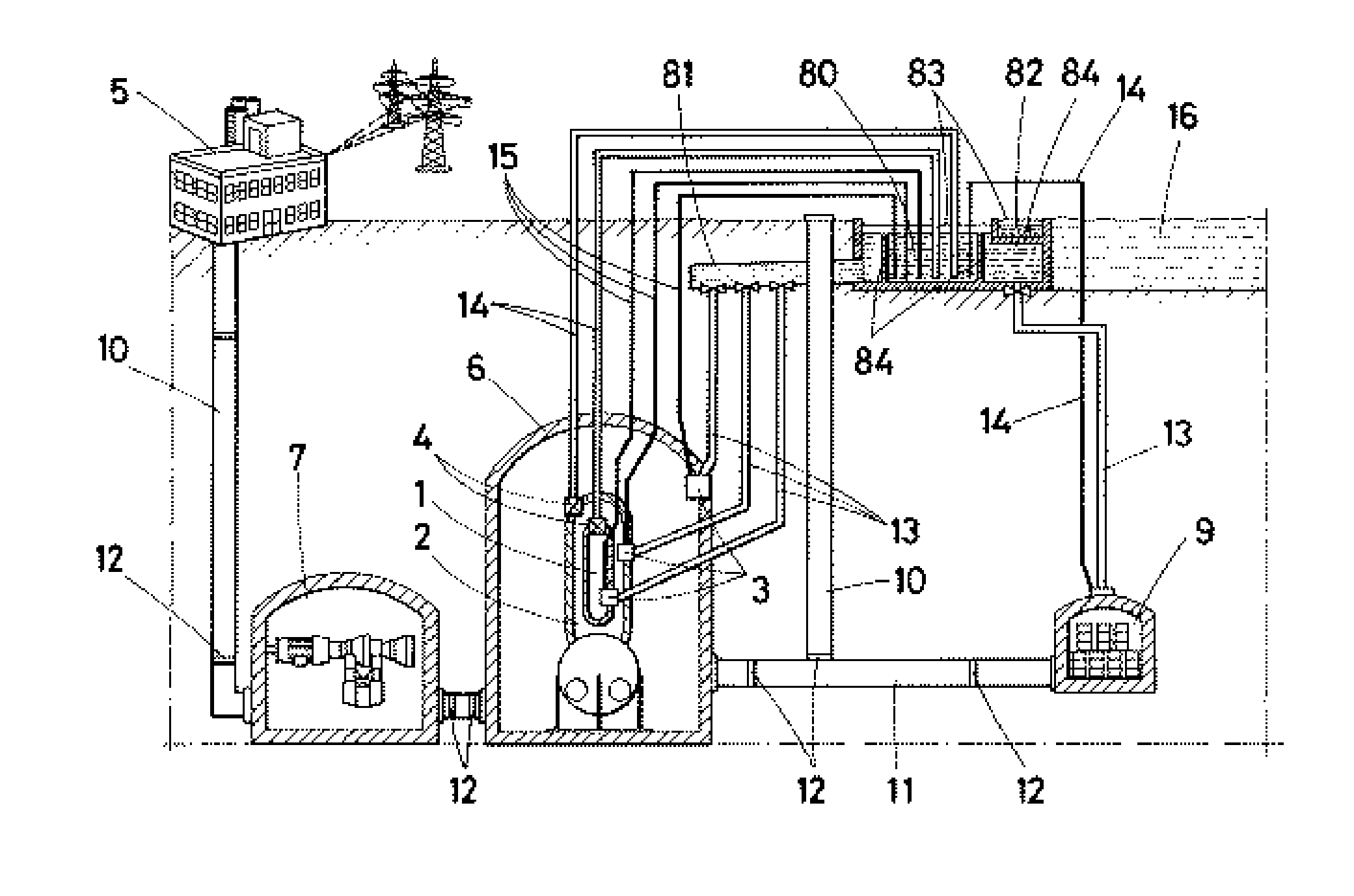

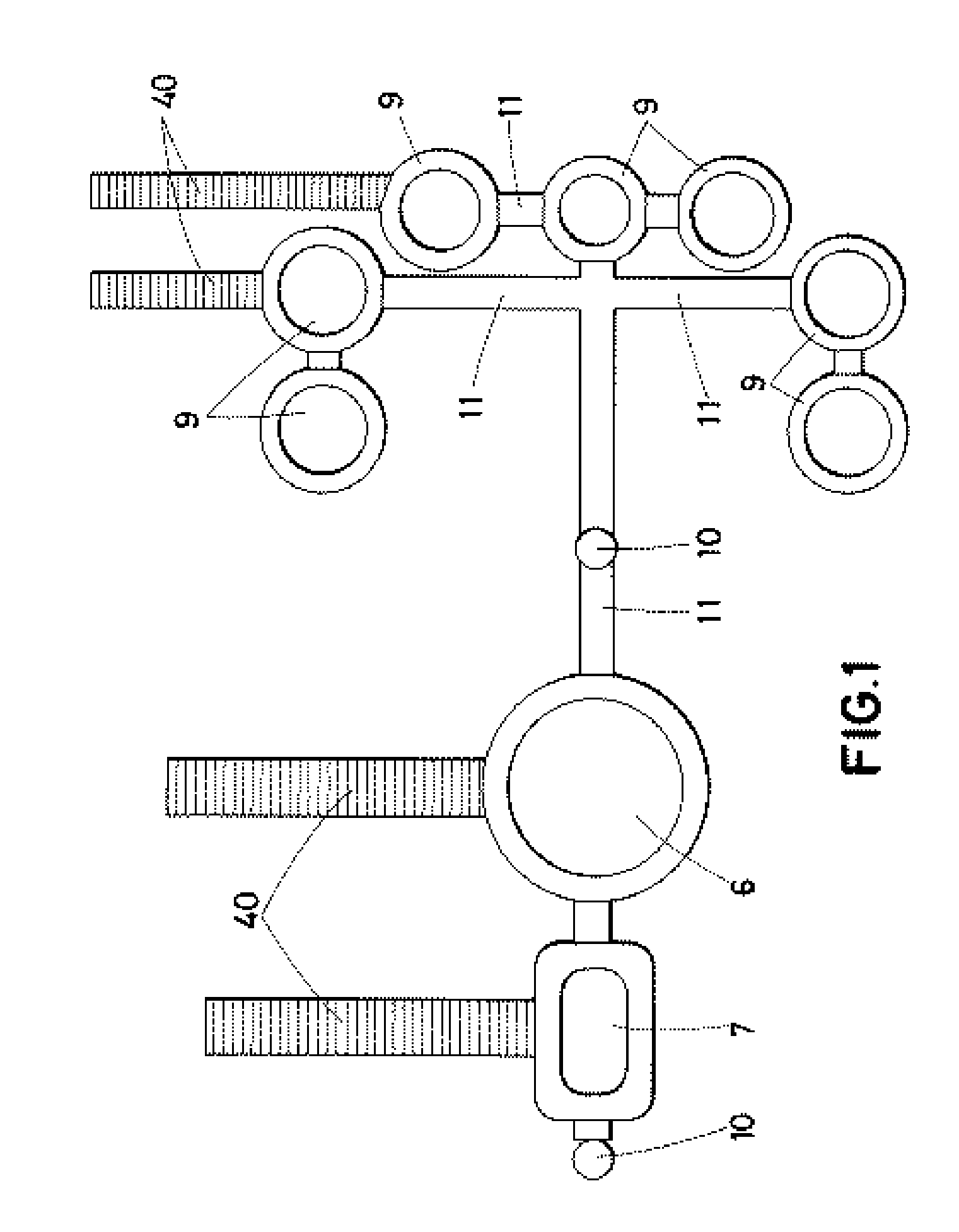

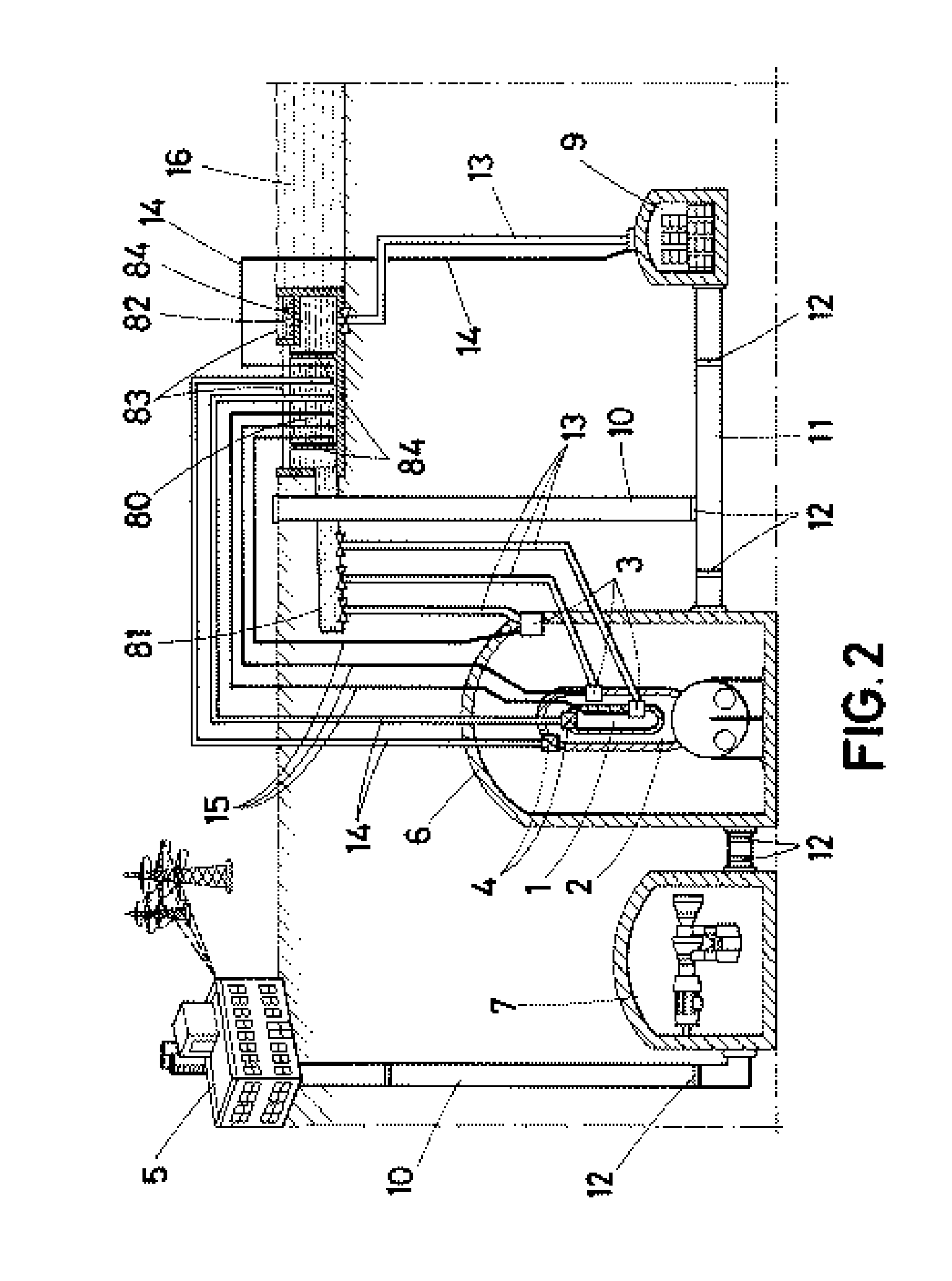

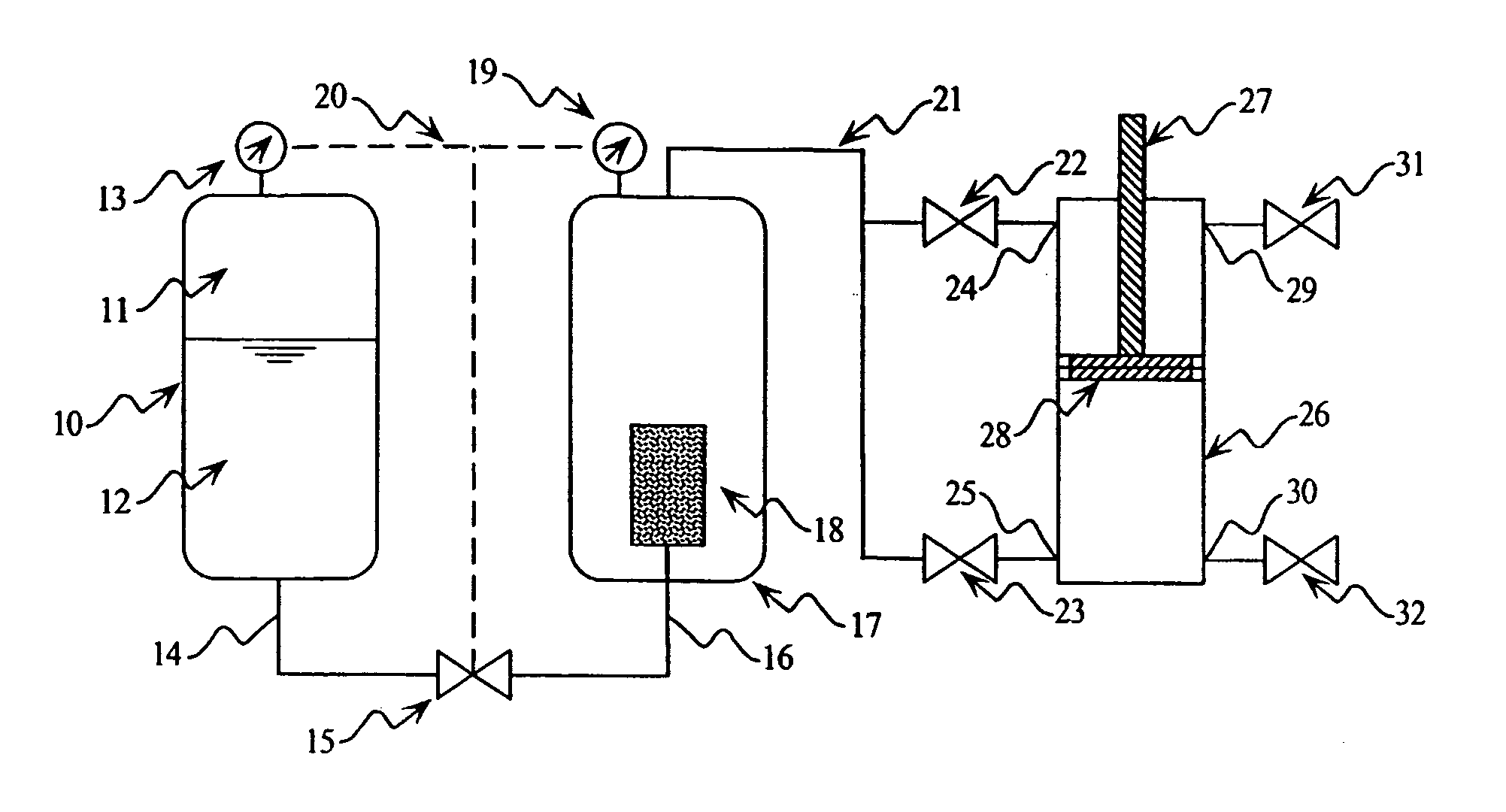

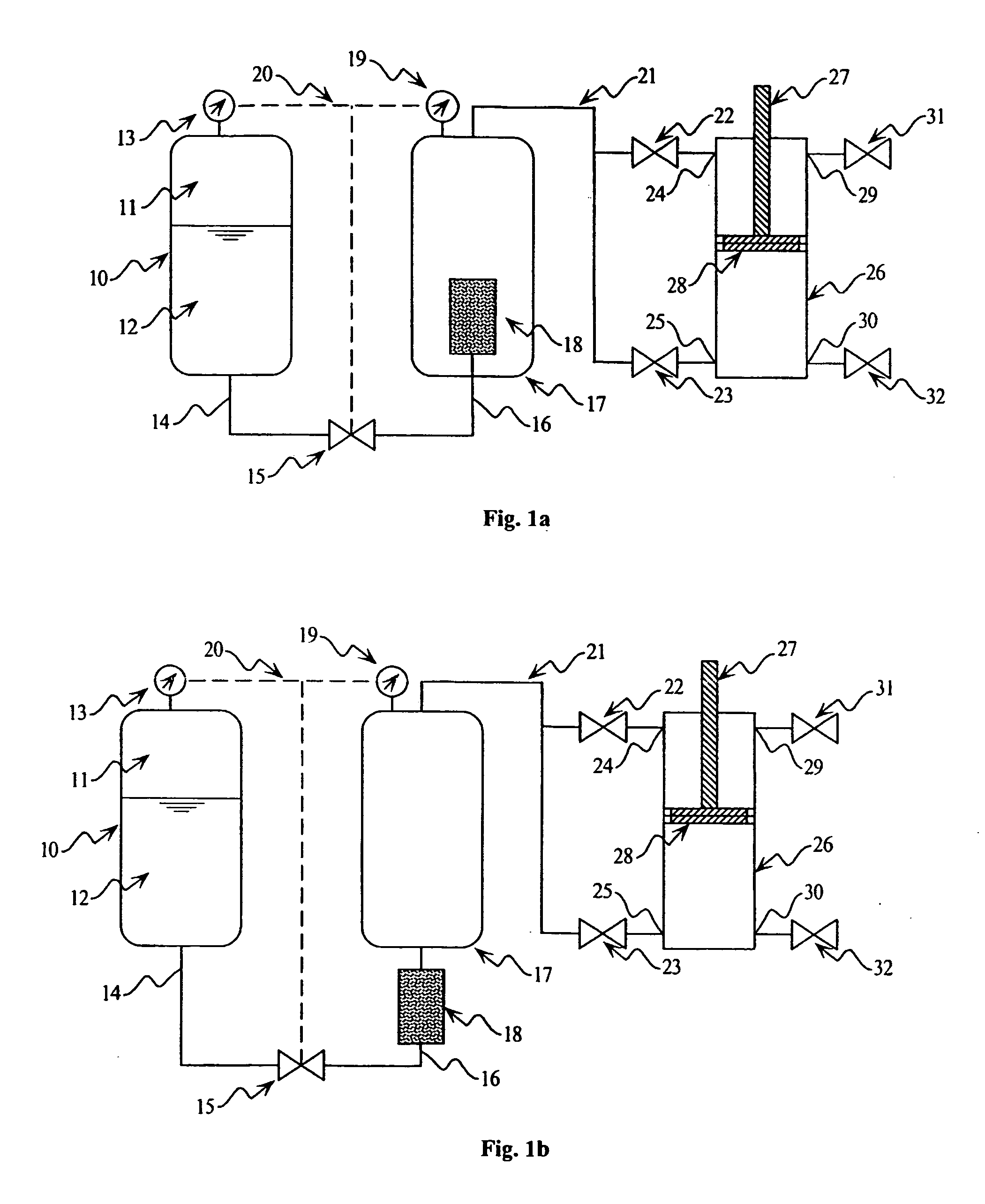

Nuclear power plant, safety system with fuse element and gravity elevator

ActiveUS20150131769A1Power plant safety arrangementNuclear energy generationPower stationNuclear engineering

The present invention relates to a nuclear power plant and safety system with fuse element and gravity elevator, the buildings of the power plant subjected to contamination being buried below sea level and under borated water basins, and having a safety system free of electrical and electronic components to act in the event of possible accidents comprising, among others, means for flooding the buildings of the power plant with thermal fuses and gravity elevators for operator evacuation in the event of an emergency.

Owner:SERBEX TECH Y VALORES SL

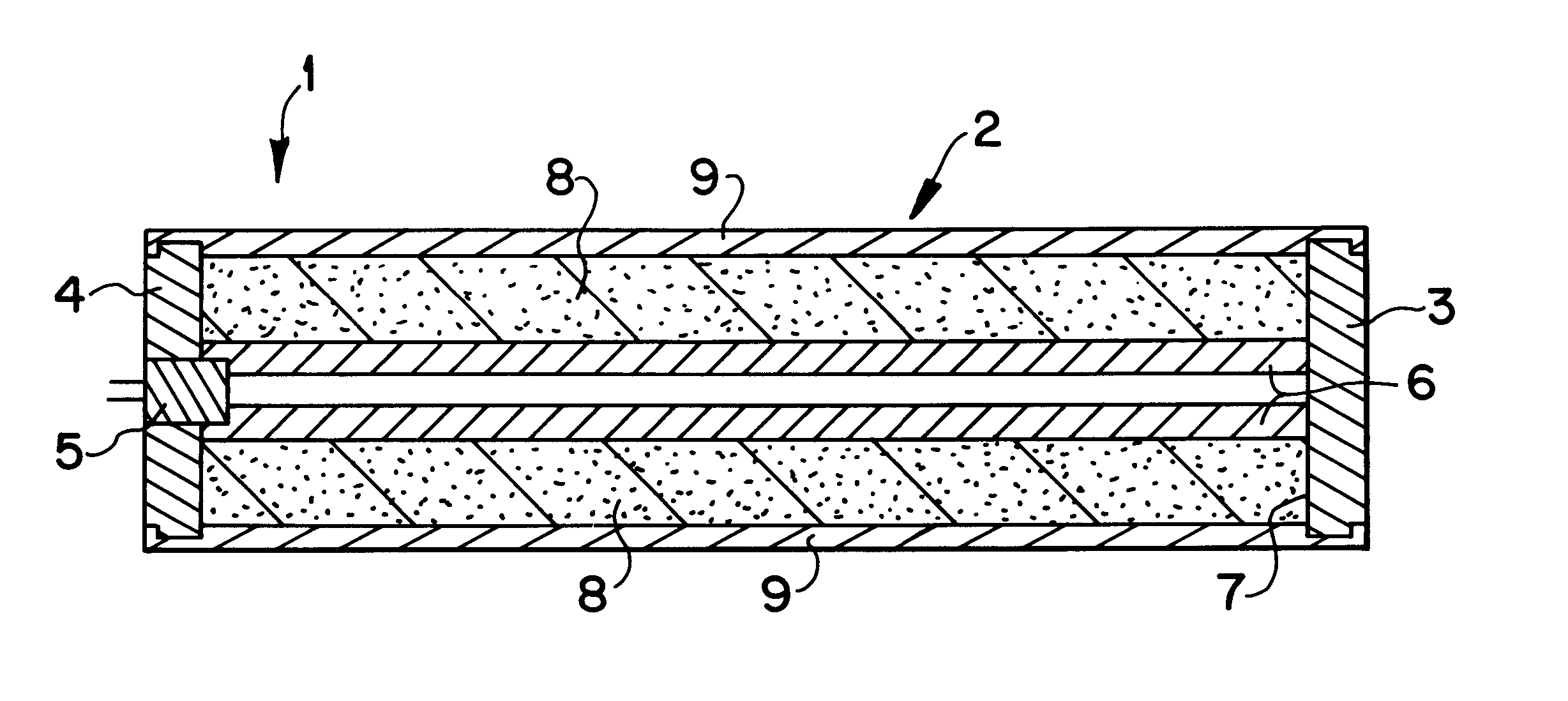

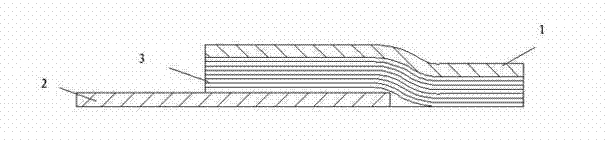

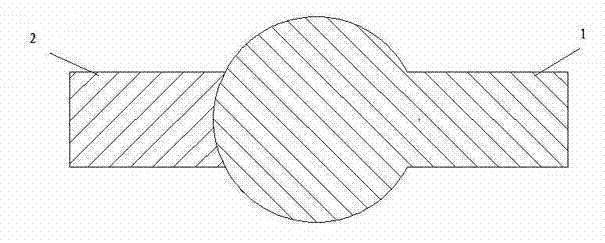

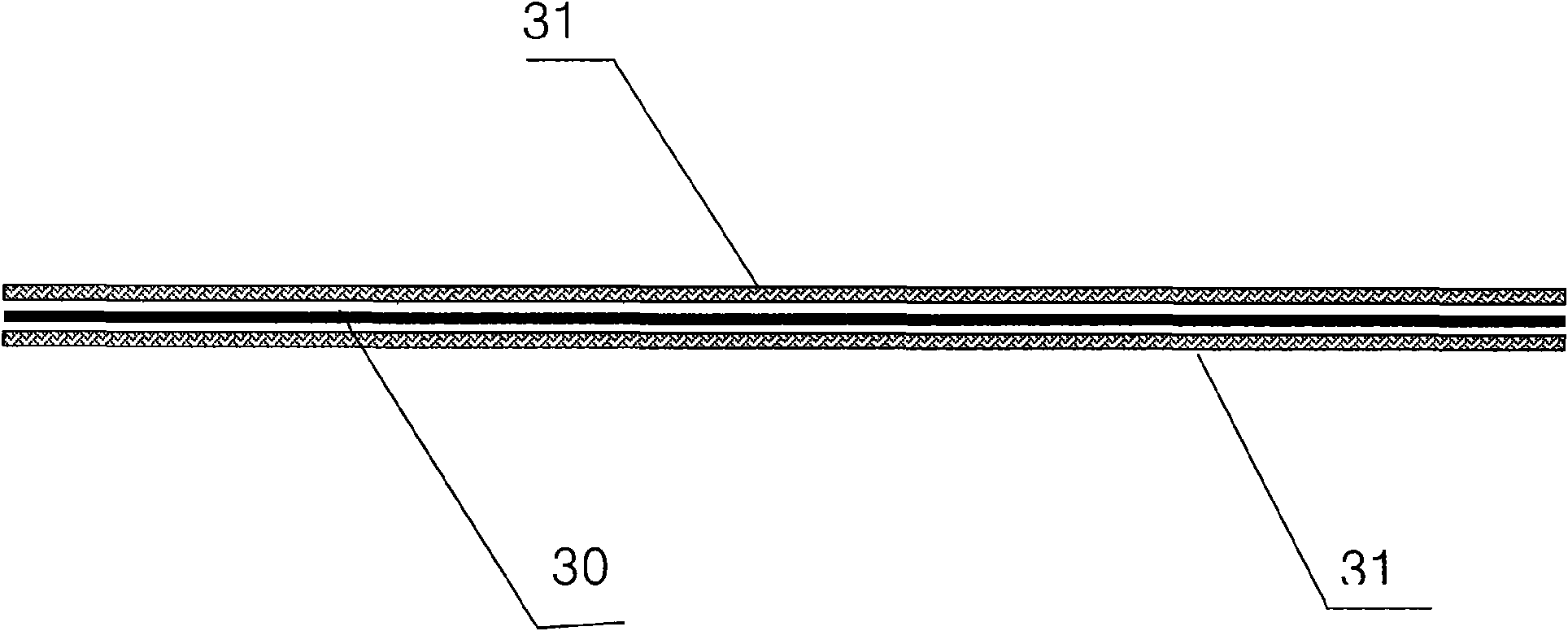

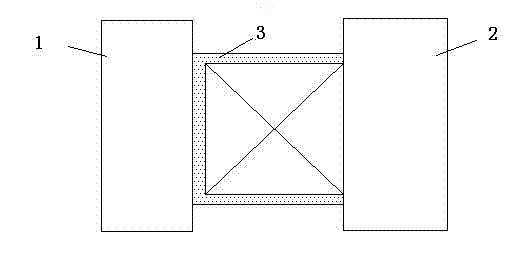

Dielectric Al/CuO composite film energetic electric ignition bridge and ignition bridge array

The invention discloses a dielectric Al / CuO composite film energetic electric ignition bridge and an ignition bridge array. The bridge body of the ignition bridge is formed by overlapping an upper electrode, a lower electrode and a dielectric layer; two layers of metal films with the same size and different directions serve as the upper electrode and the lower electrode; an Al / CuO composite film layer with the same size and direction as the upper electrode metal film is sandwiched between the two layers of metal films to serve as the dielectric layer; partial Al / CuO composite film layer is coated and overlapped on the lower electrode metal film; and the upper electrode metal film is completely coated and overlapped on the Al / CuO composite film layer. In the ignition array taking the dielectric Al / CuO composite film energetic electric ignition bridge as a basic unit, a plurality of dielectric Al / CuO composite film energetic electric ignition bridges are connected through leads preparedfrom Au metal films or Cu metal films to form the ignition array. The invention has the advantages of high safety, high ignition capacity and good compatibility.

Owner:NANJING UNIV OF SCI & TECH

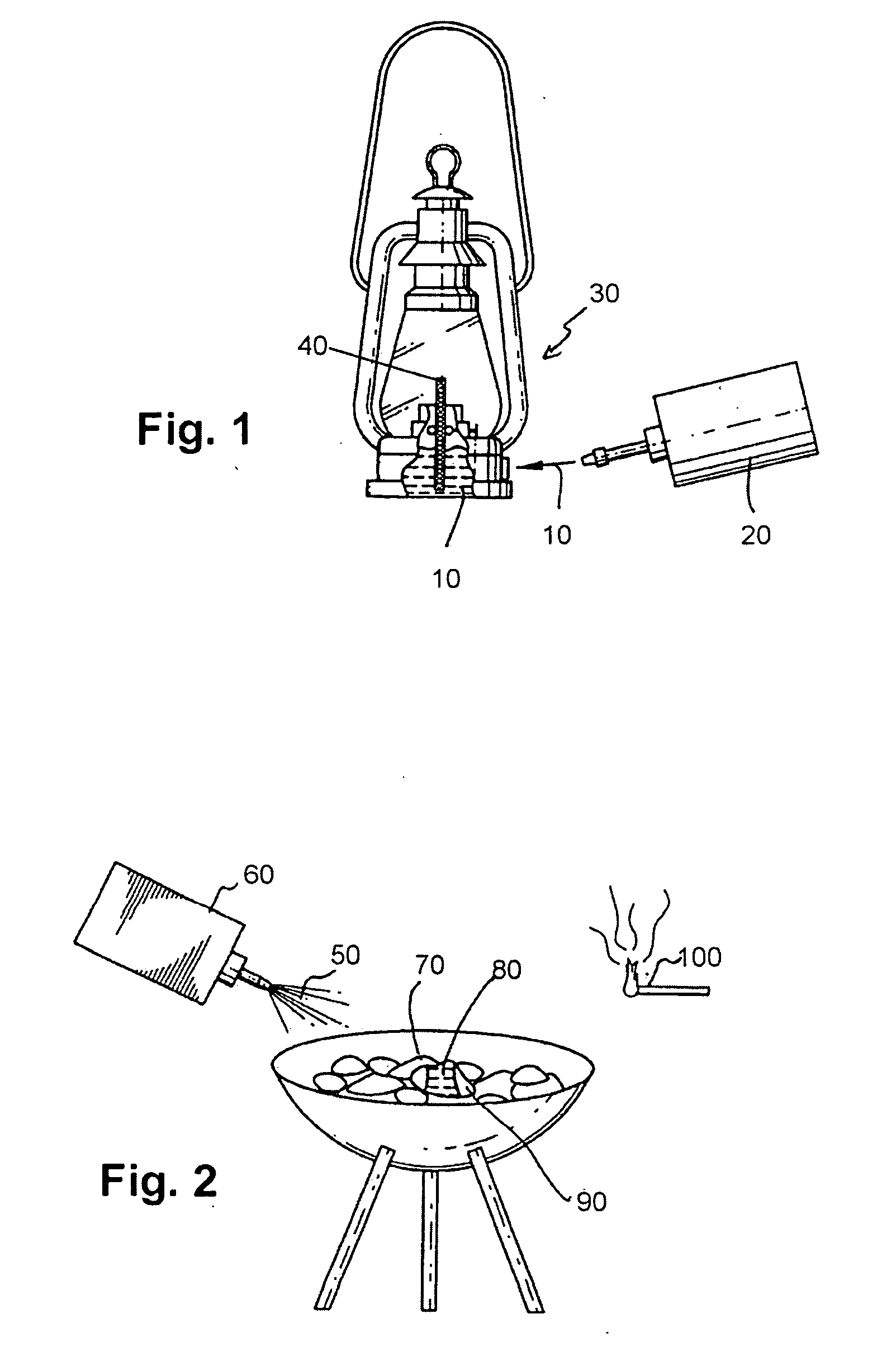

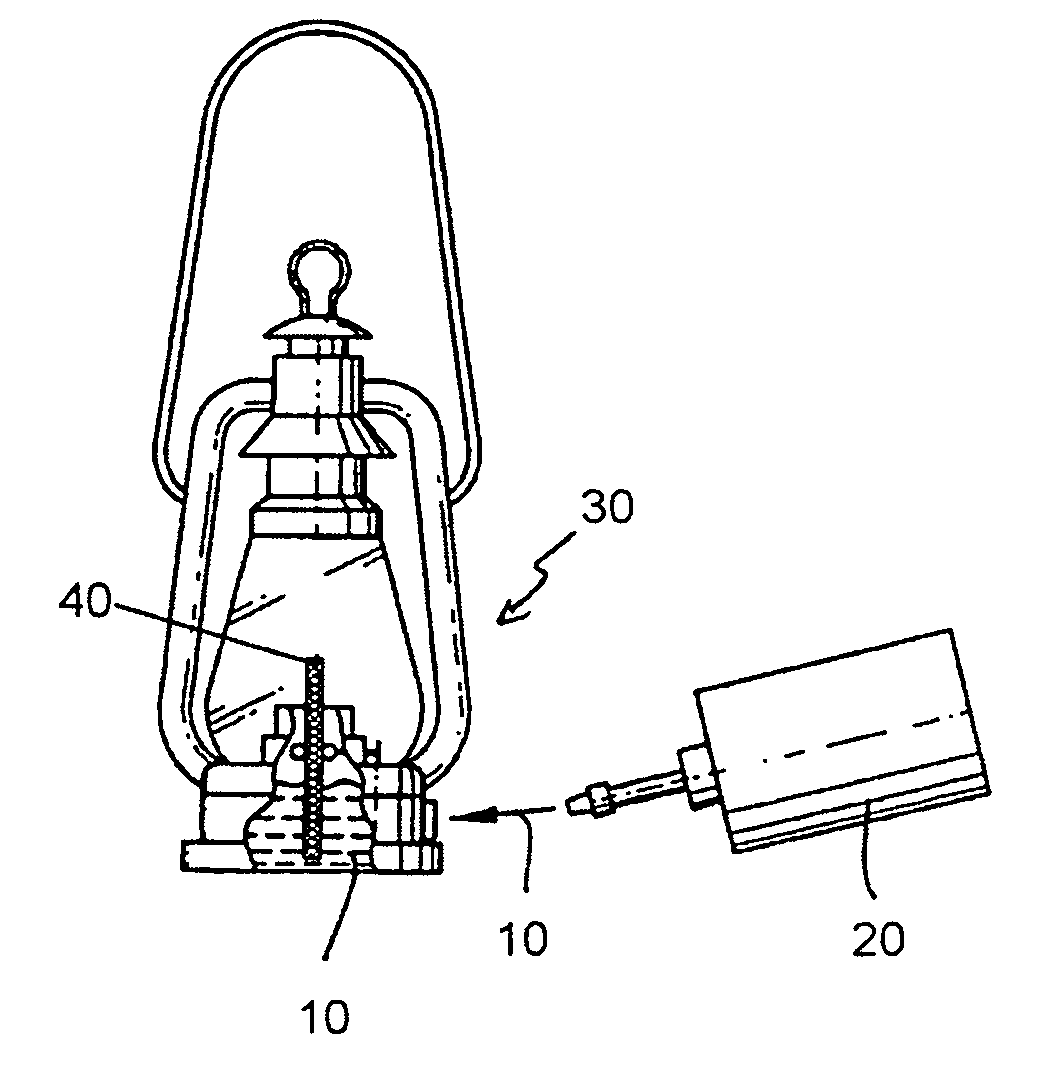

Lamp oil composition and lighter fluid composition

InactiveUS20050115145A1SaferEasy to manufactureCapillary burnersLiquid carbonaceous fuelsAlcoholLighter fuel

Lamp oil compositions including methyl palmitate, methyl stearate, myristyl alcohol, an alcohol with less than six carbons, preferably ethyl alcohol, and fragrance. Also disclosed herein are lighter fluid compositions which include methyl laurate, methyl stearate, ethyl alcohol and fragrance.

Owner:LUMETIQUE

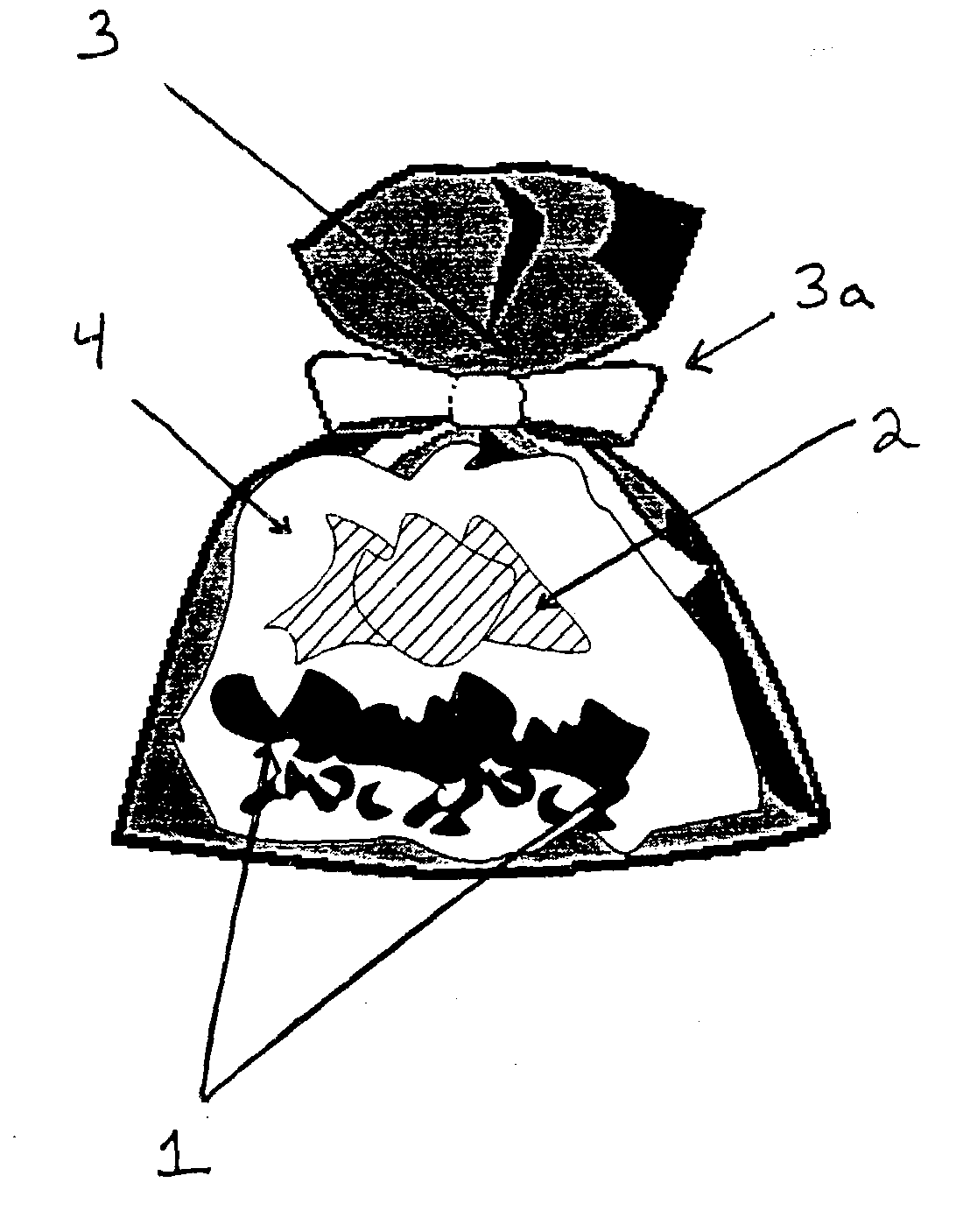

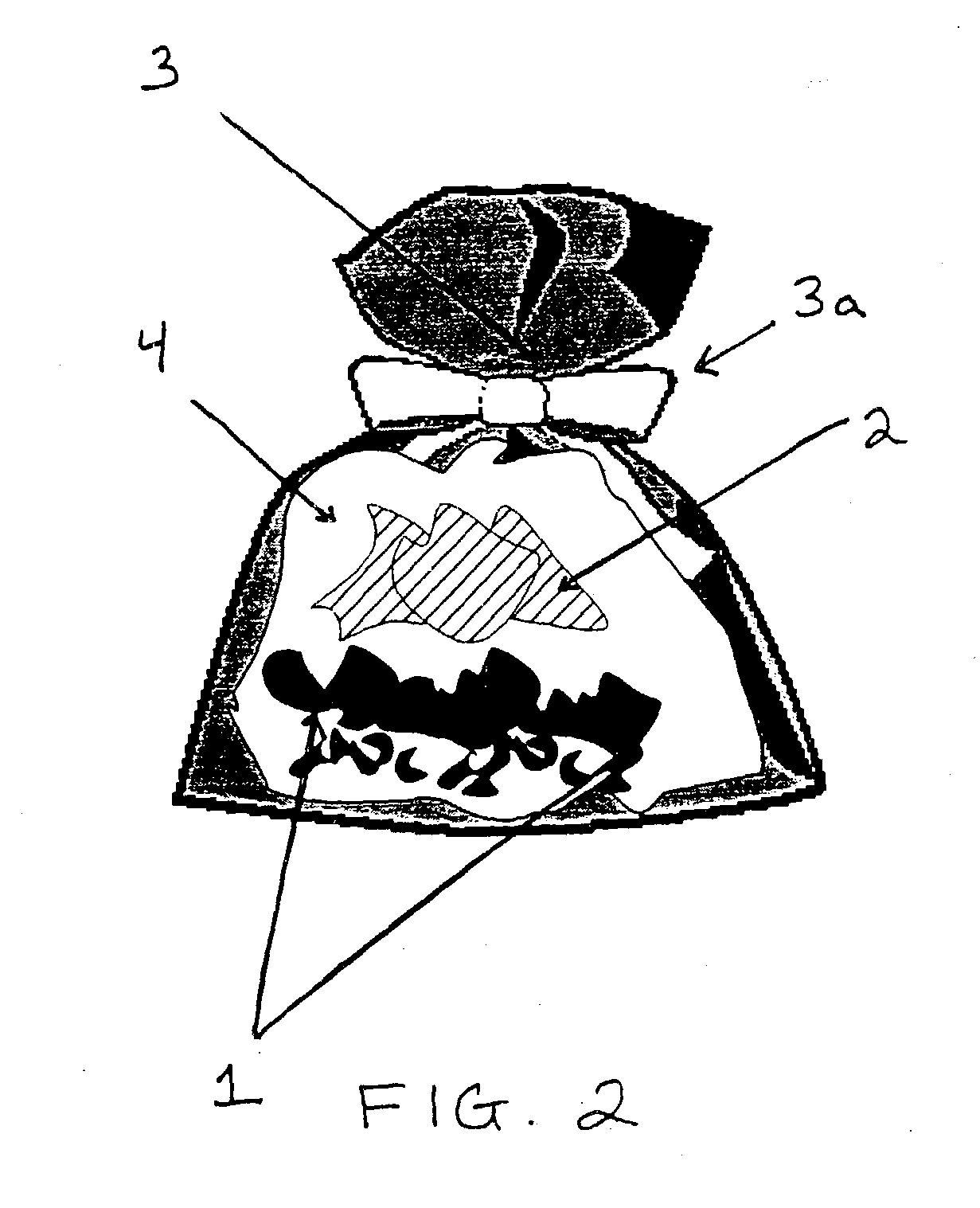

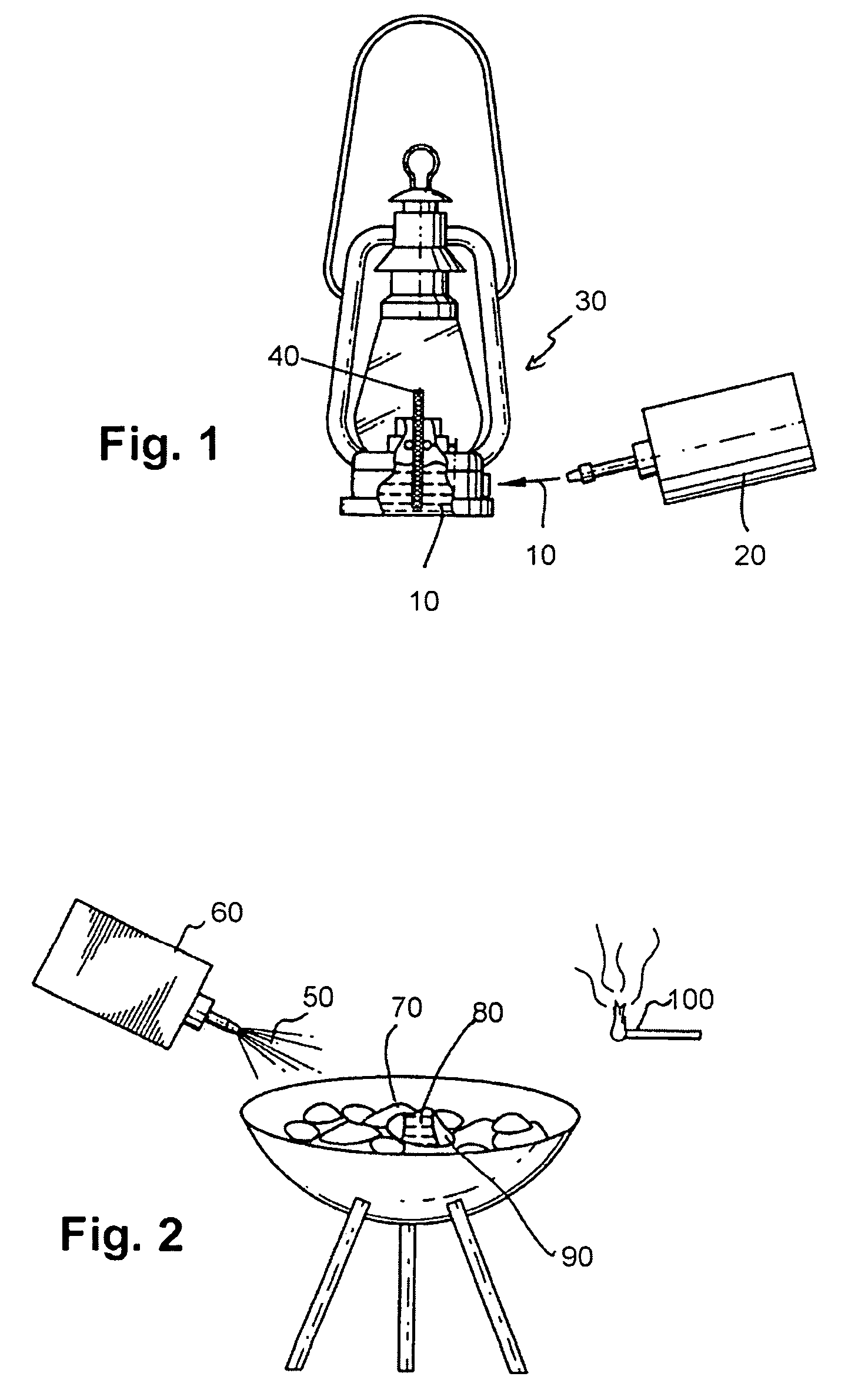

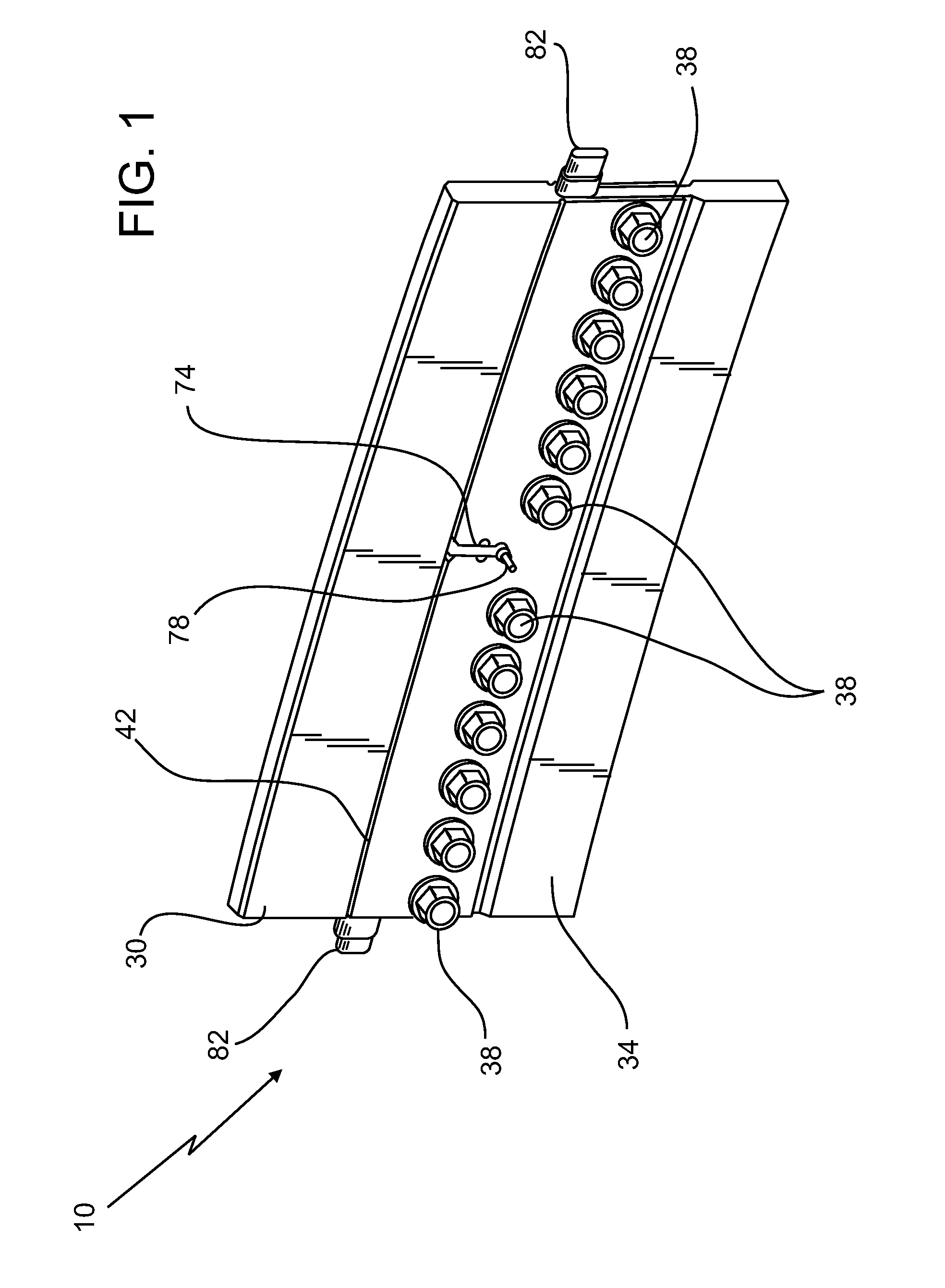

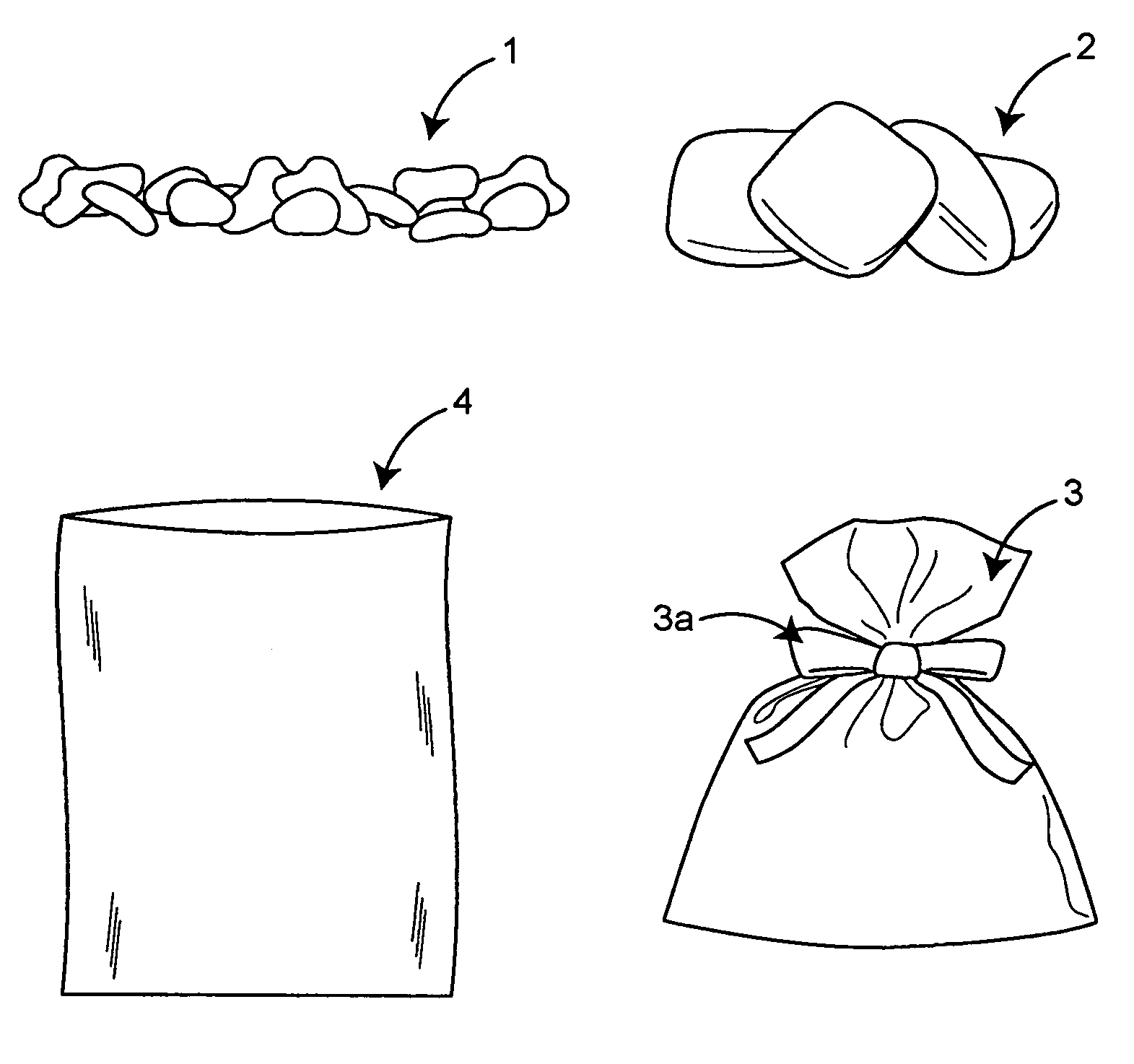

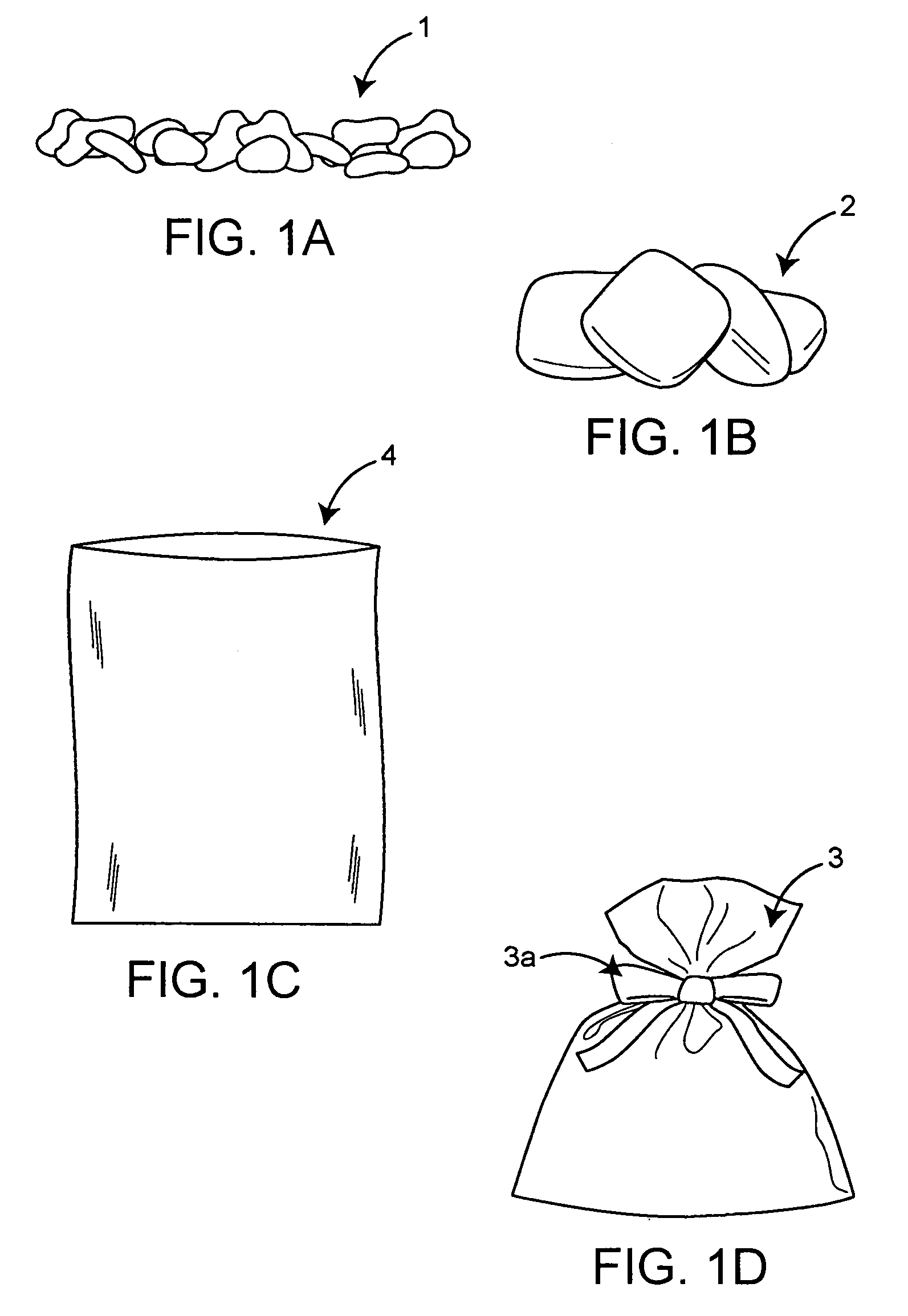

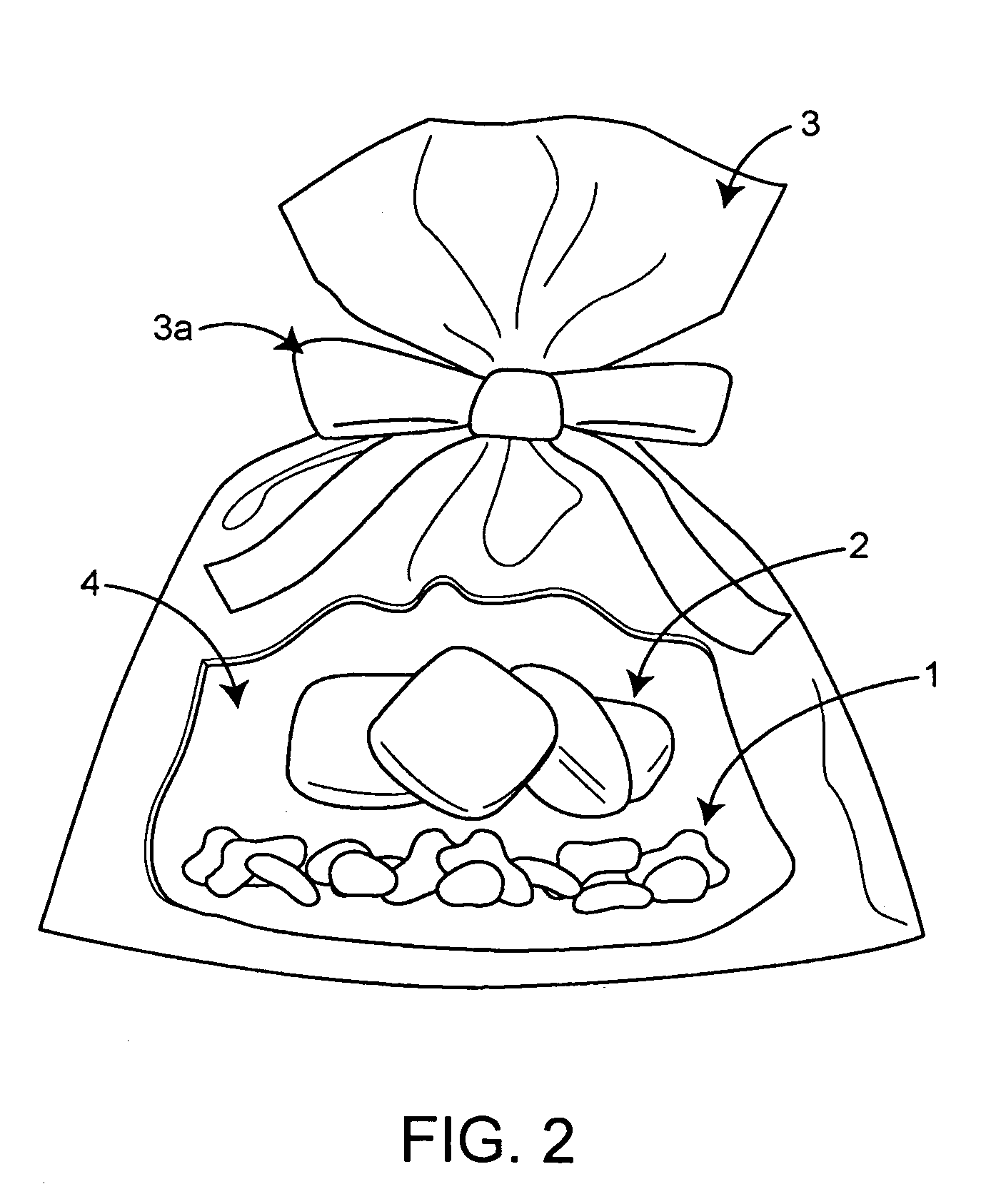

Method and apparatus for packaging charcoal fuel and other fuels for easy lighting

A combustible charcoal fuel package is disclosed which includes an outer wrapper, preferably formed from burlap or other similar woven material that encloses large pieces of charcoal material, medium pieces of charcoal material and smaller pieces of charcoal material coated or otherwise soaked in a vegetable wax to form an aggregate. The aggregate is disposed at or near the bottom of the burlap wrapper, with the medium-size pieces of charcoal material disposed thereon with the larger pieces of charcoal material disposed on top of the medium-sized pieces of charcoal material. Preferably, all charcoal materials are fabricated from all-natural charcoal logs fabricated from compressed charcoal particles without the use of odor causing binders.

Owner:SUMMIT VIEWS

Igniter for exothermic torch rod

An igniter's housing is bored continuously there through to define, in succession, several bore regions. A firing pin, slidingly fit in the first bore region, terminates in a tip that protrudes into a primer-filled second bore region when the firing pin is fully seated in the first bore region. An air-filled third bore region follows the second bore region. An open-ended cup is fitted substantially in and sealed to the fourth bore region with the cup's closed end being structurally weakened at a portion thereof. A bored out slug of pyrotechnic material is fitted in the cup.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

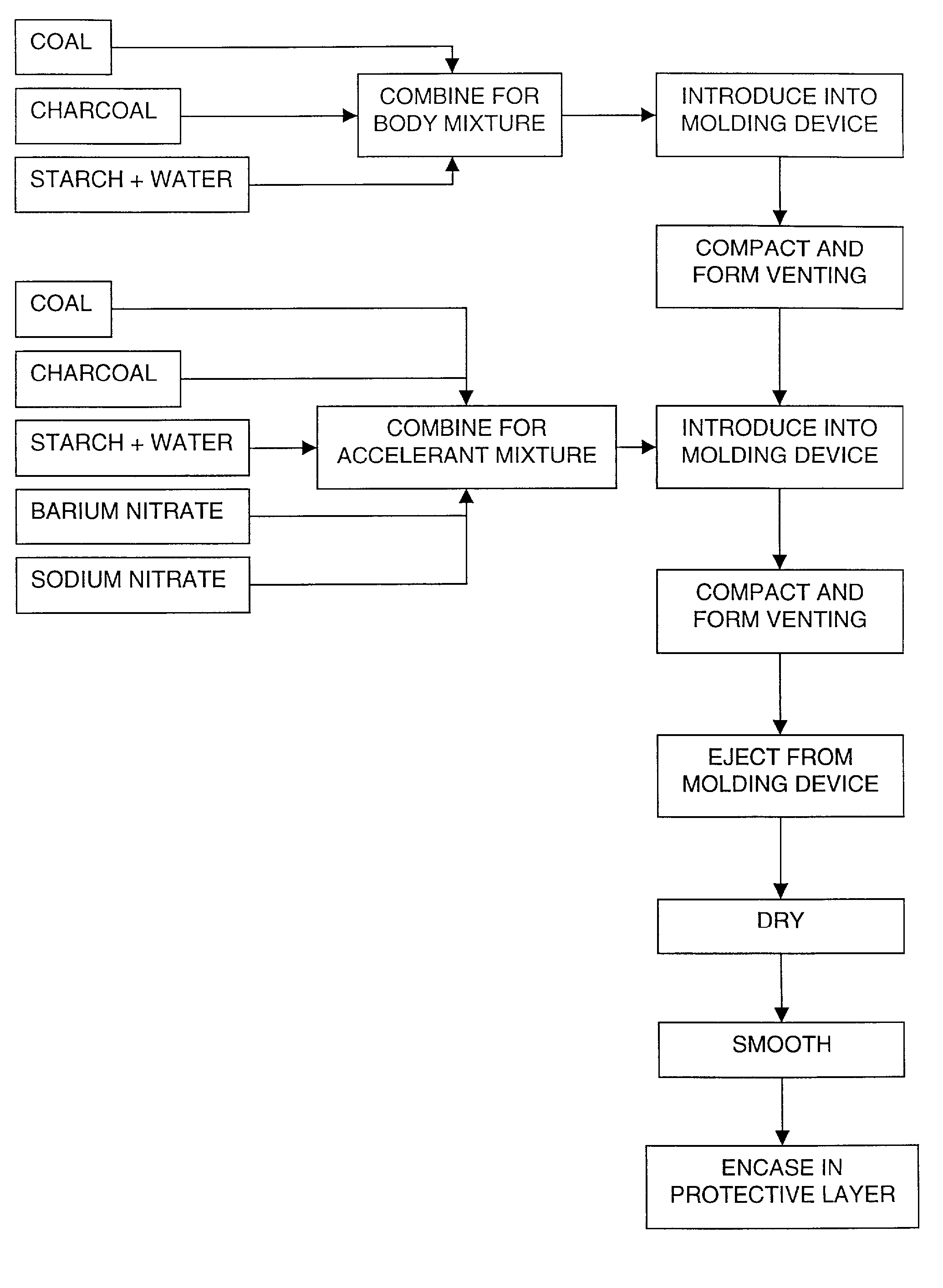

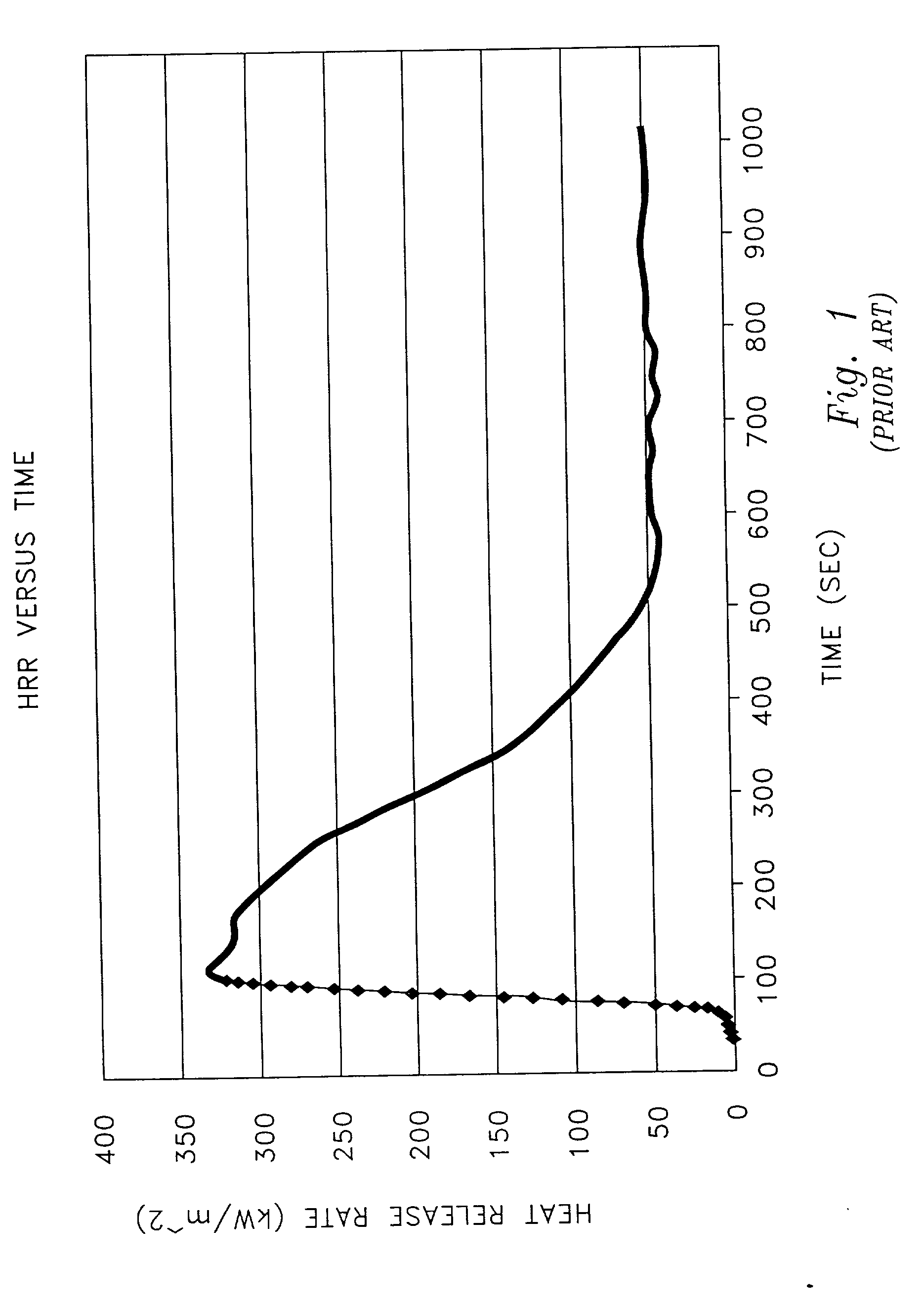

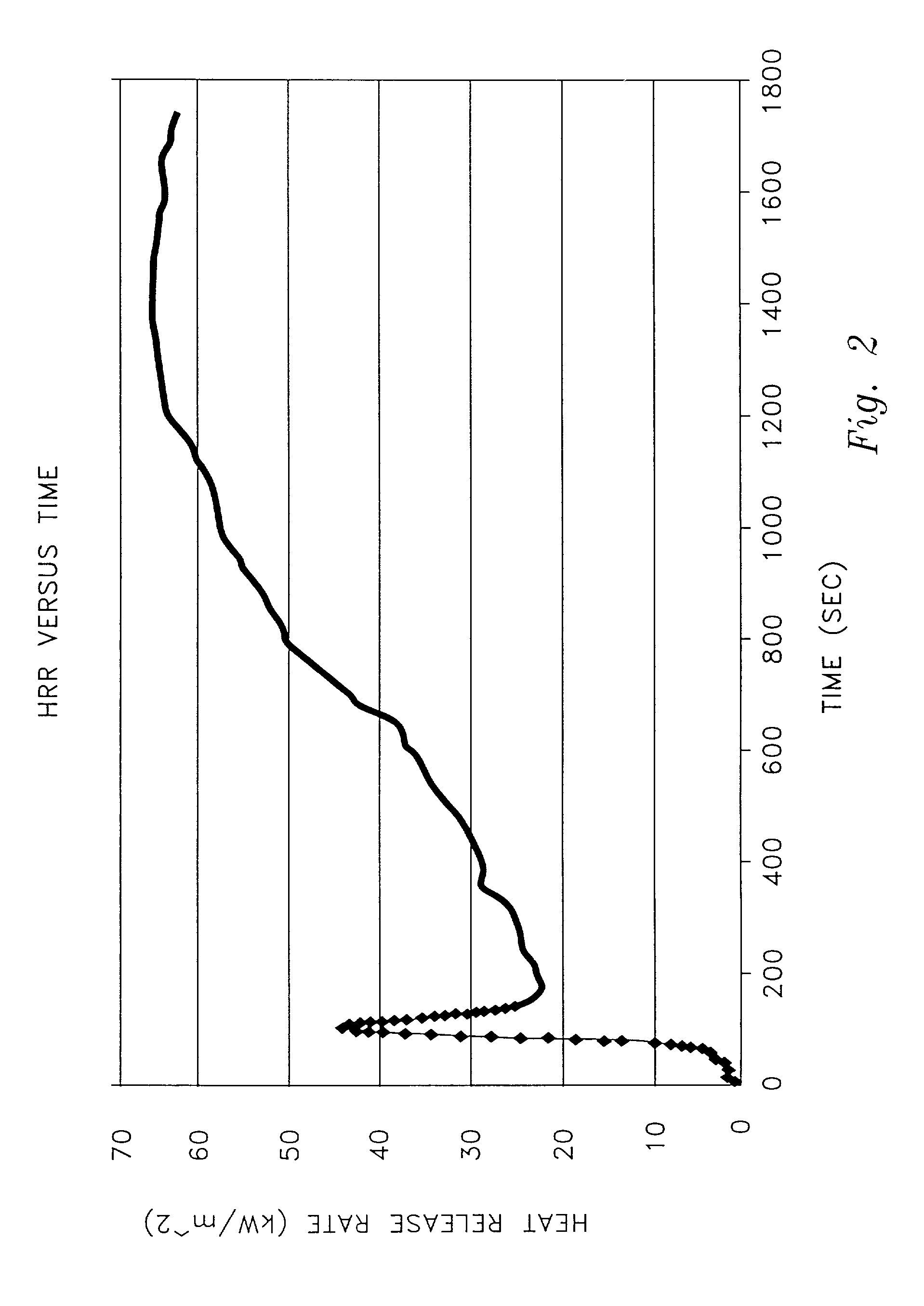

Combustible fuel composition and method

InactiveUS20030080456A1Convenient lightingDeteriorating effectivenessSolid fuelsFusesNitrateAnthracite

A fuel article, suitable for barbecuing, allowing greater burning efficiency and the method of making such a fuel article. The fuel article includes anthracite coal for cleaner burning and utilizes an accelerant covering containing nitrates to be amenable to easy ignition.

Owner:MBZQ

Lamp oil composition and lighter fluid composition

InactiveUS7524339B2Not to damageTransportation safetyCapillary burnersLiquid carbonaceous fuelsAlcoholLighter fuel

Lamp oil compositions including methyl palmitate, methyl stearate, myristyl alcohol, an alcohol with less than six carbons, preferably ethyl alcohol, and fragrance. Also disclosed herein are lighter fluid compositions which include methyl laurate, methyl stearate, ethyl alcohol and fragrance.

Owner:LUMETIQUE

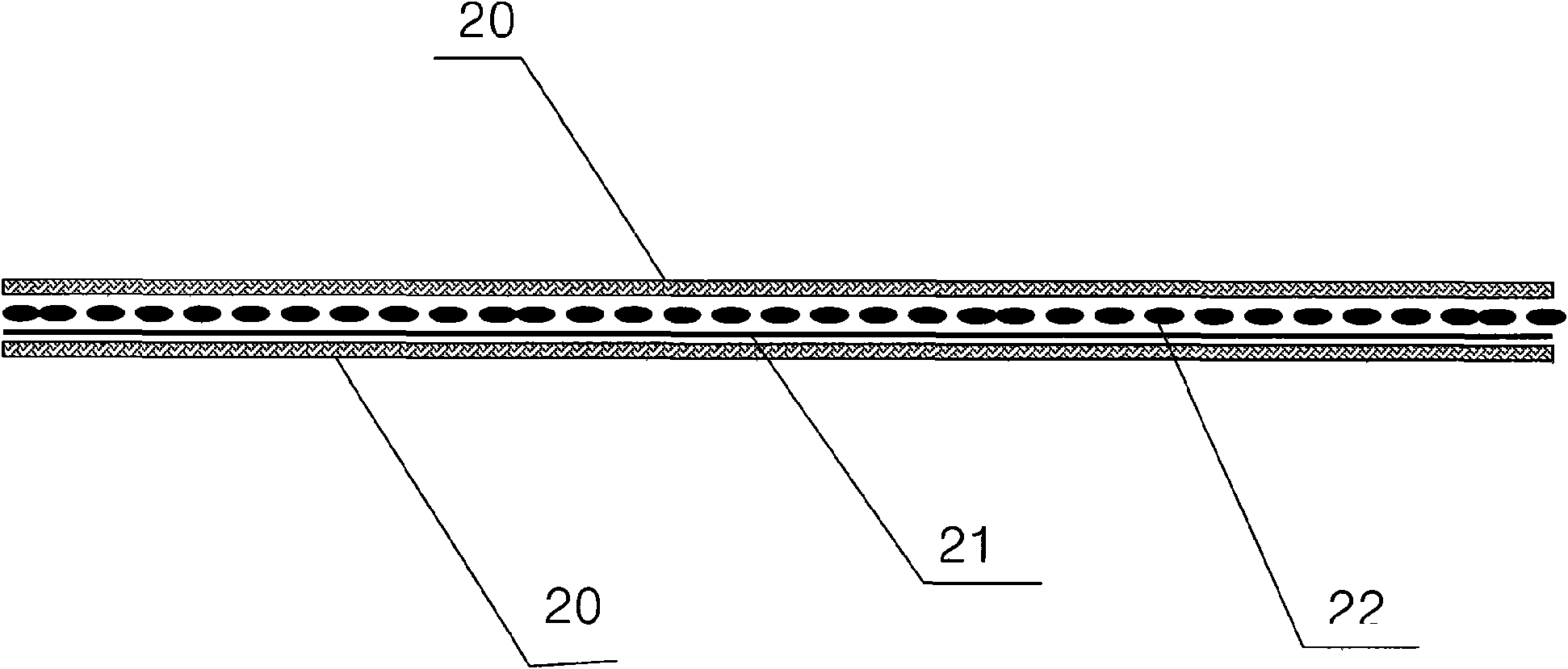

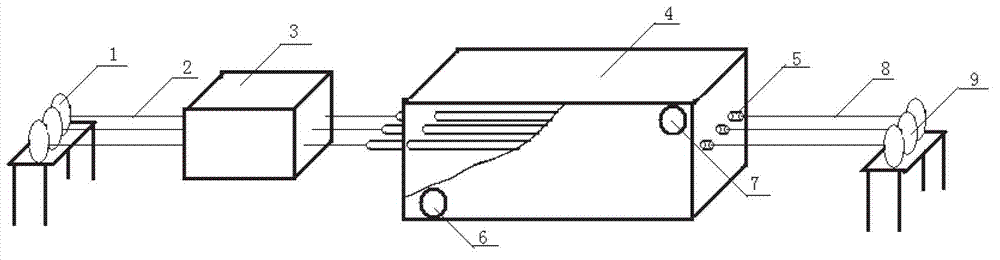

Fireworks safety firing cable and manufacturing method thereof

InactiveCN101619009APut an end to the malpractice scattered in the production siteReduction of more hazardous processesFusesYarnOrganic solvent

The invention discloses a fireworks safety firing cable and a manufacturing method thereof. The fireworks safety firing cable comprises an ignition-composition core and cotton yarn attached with firing cable compositions; and the manufacturing method is mainly characterized by comprising the following steps: adding an appropriate amount of organic solvents into the prior firing cable compositions, and evenly stirring to enable the compositions to be in a thick fluid flurry state; and evenly attaching the fluid slurry onto priming cotton yarn as a firing cable composition core by improving the structure of a priming machine. The invention has the advantages that a plurality of process flows with higher hazards are reduced in the processing process of firing cable compositions, the defect that composition powder is interspersed in production places is avoided in the cotton yarn wrapping process, and the production security is improved qualitatively; the quality of the product is improved, and the phenomena of composition interruption, shortage and leakage are prevented from generating; no dust pollution is generated in production and application, and production personnel are avoided from being injured by occupational diseases, such as silicosis, and the like.

Owner:鲁向华

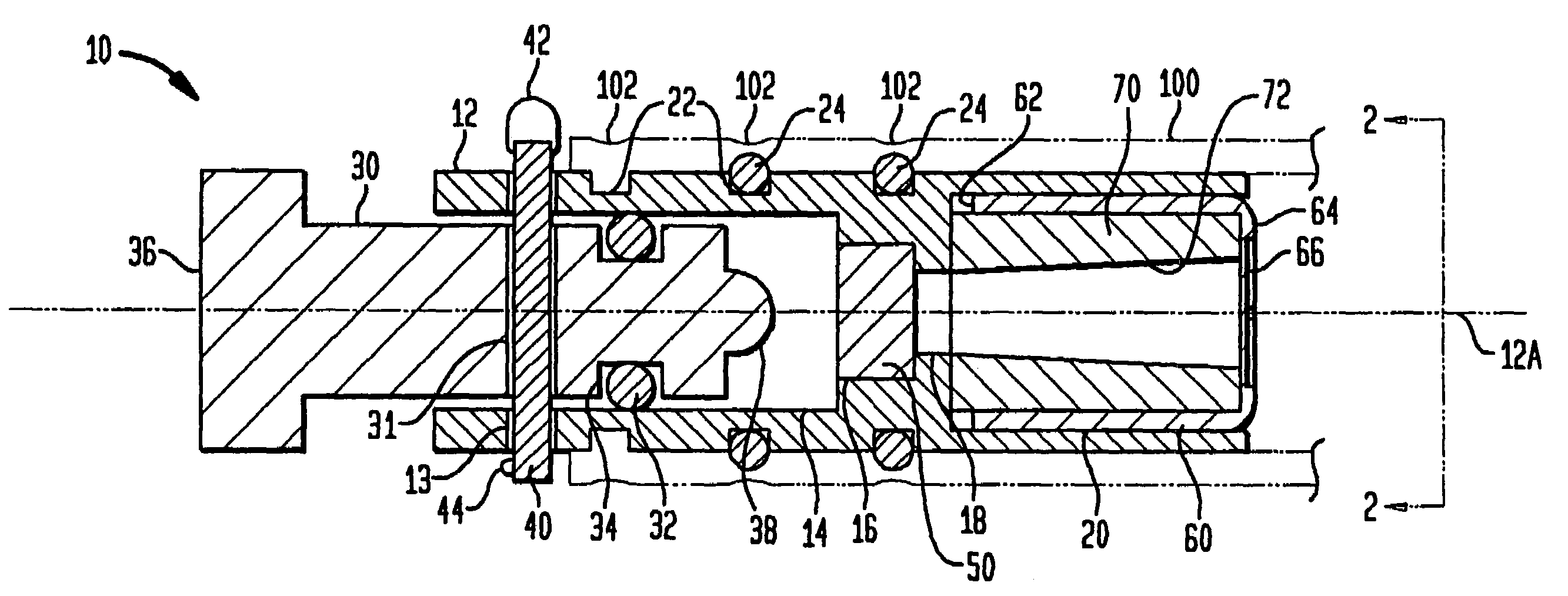

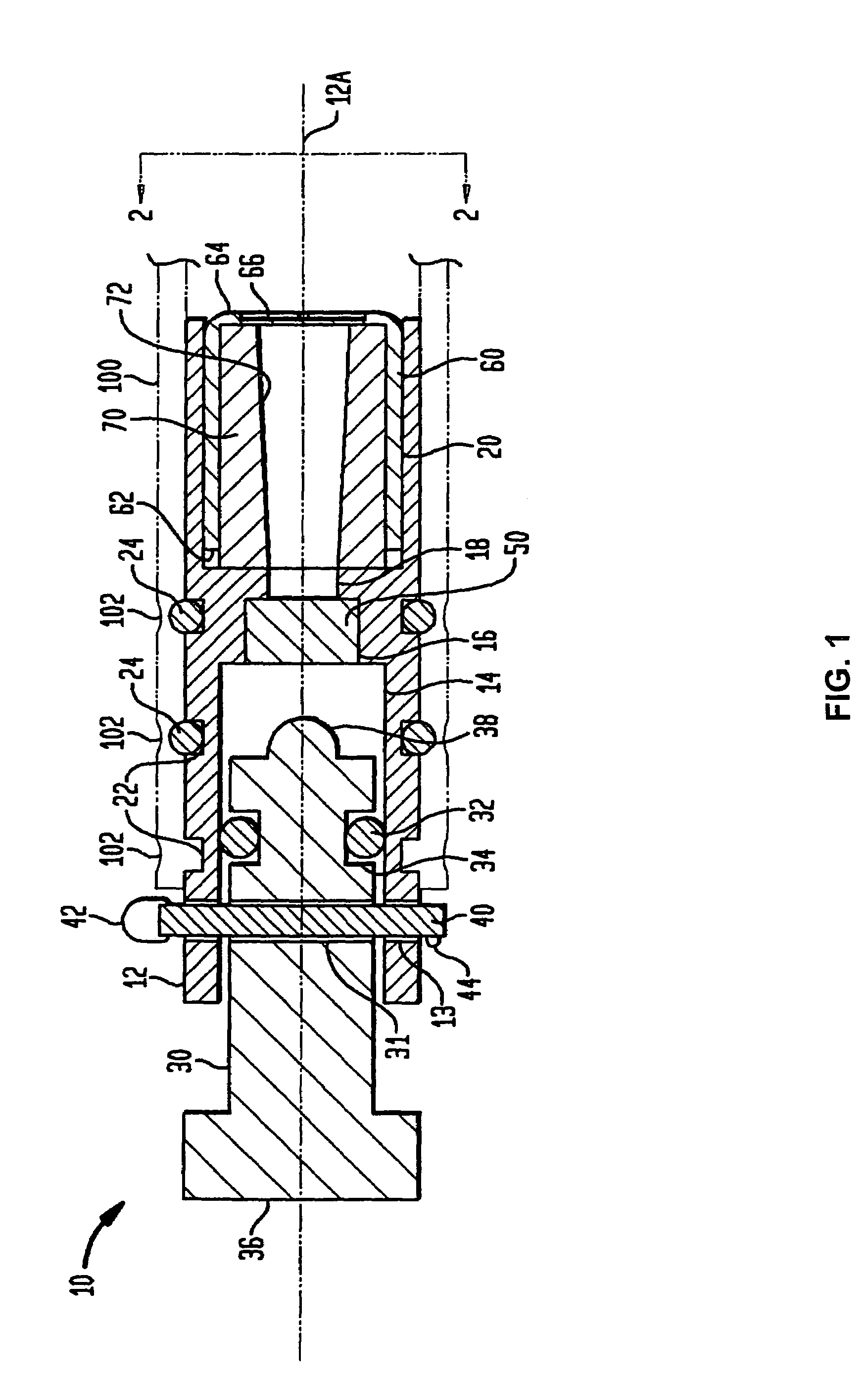

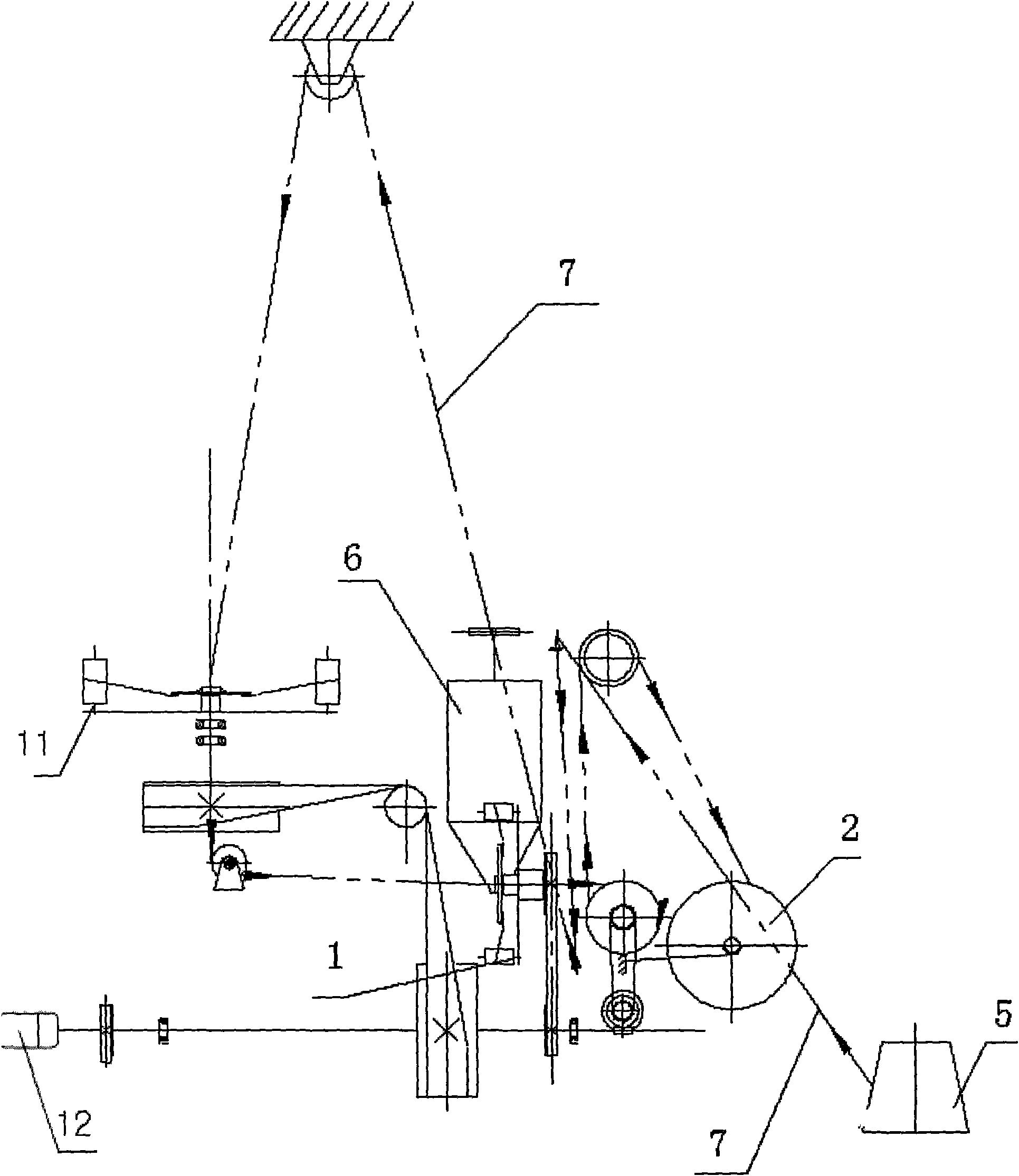

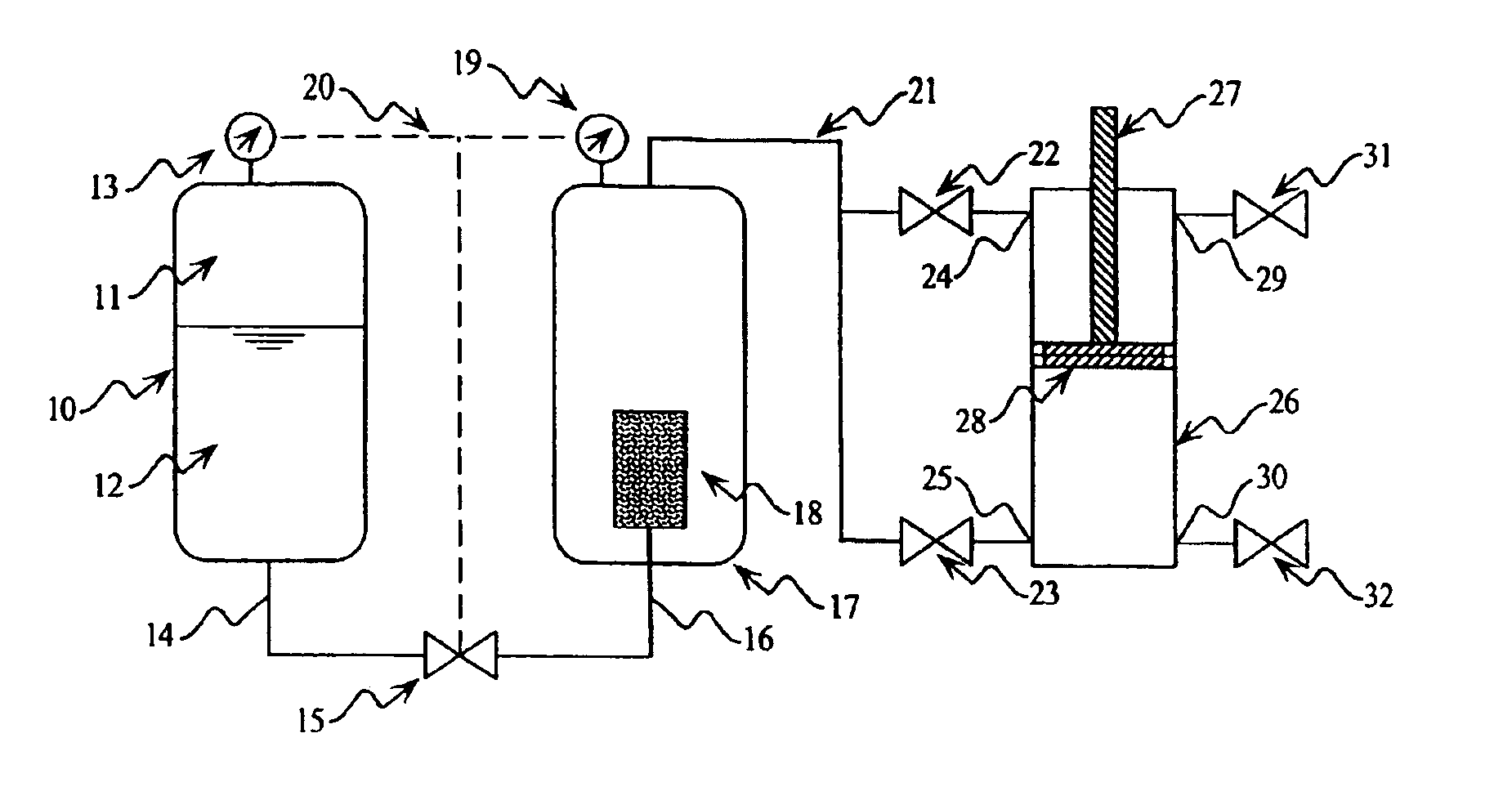

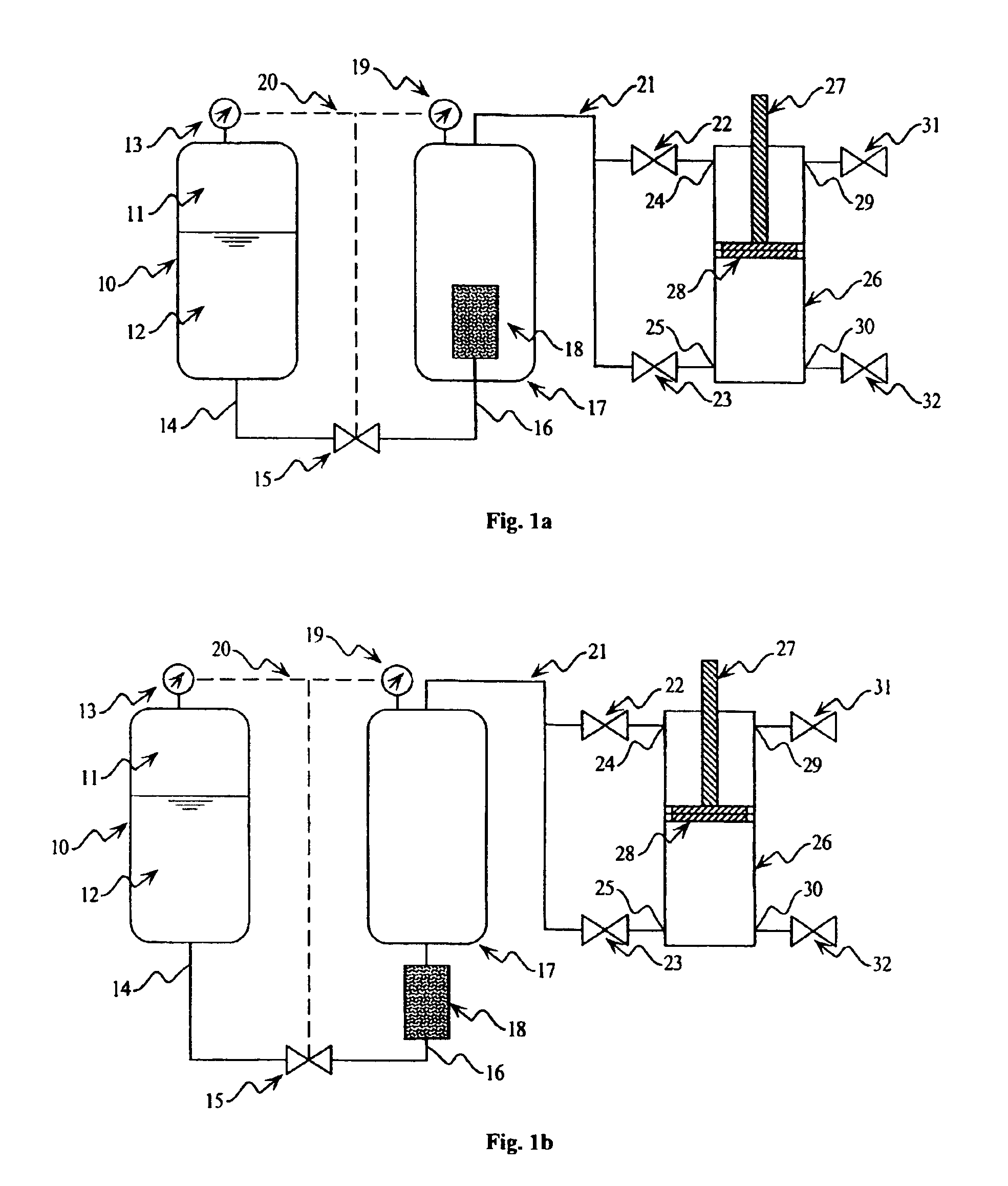

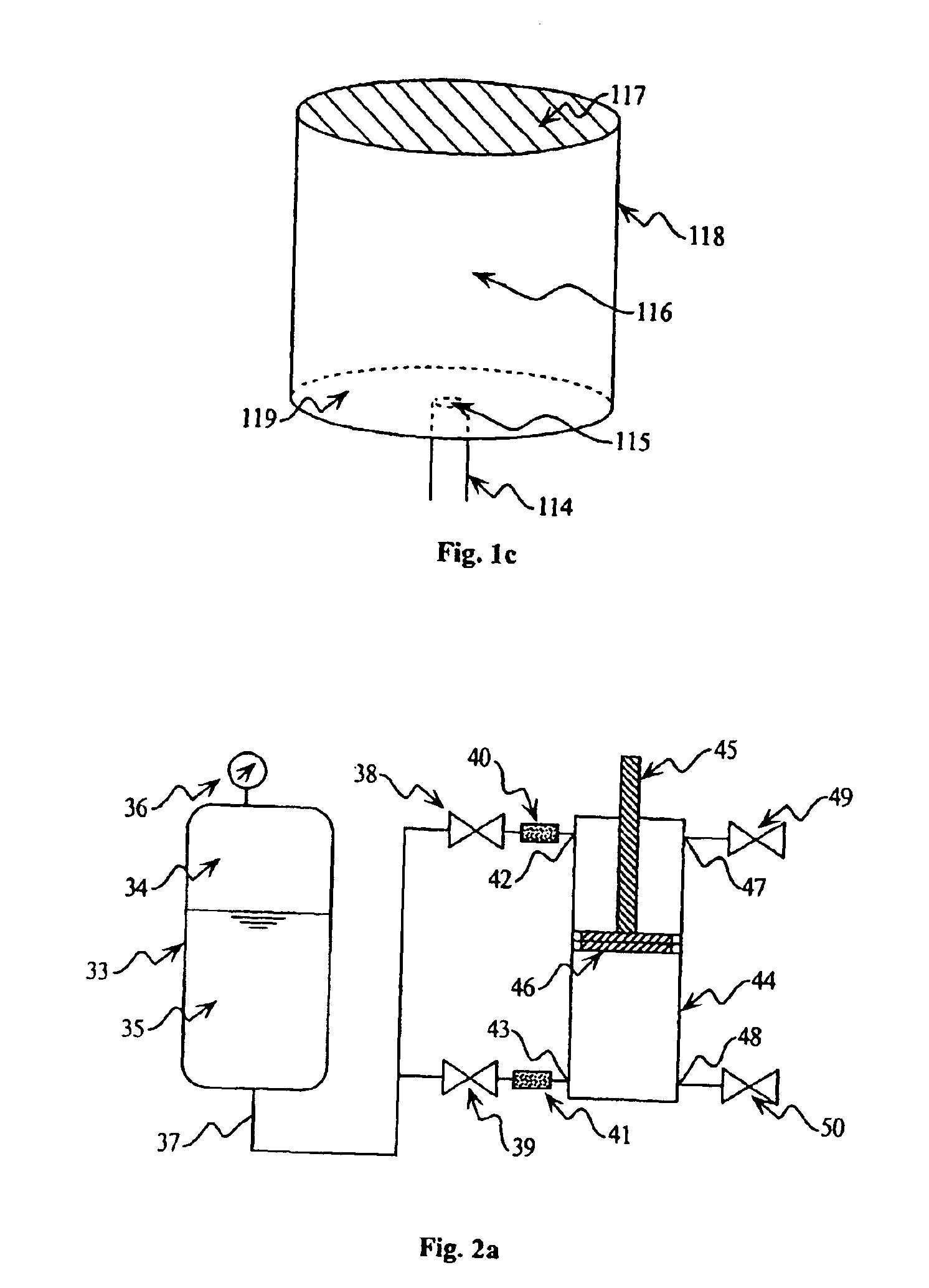

Monoprolellant/hypergolic powered proportional actuator

InactiveUS20050044851A1Reduce energy lossSimple designProgramme-controlled manipulatorInternal combustion piston enginesHigh pressureActuator

Systems and methods involving monopropellant and hypergolic powered proportional actuators that may be used in applications such as robotics. A blowdown tank delivers fuel to a reaction site, produce gaseous products. Those gaseous products are transported to a pressure reservoir or directly to the actuator. The gaseous products are controllably introduced into the actuator to actuate a piston. The piston may be used to power a host of devices including robots.

Owner:VANDERBILT UNIV

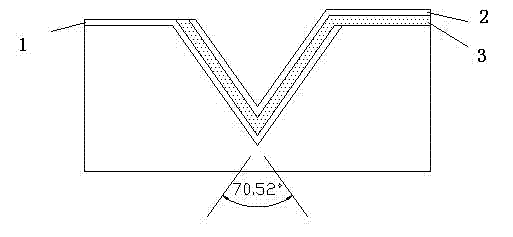

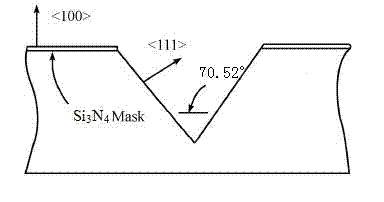

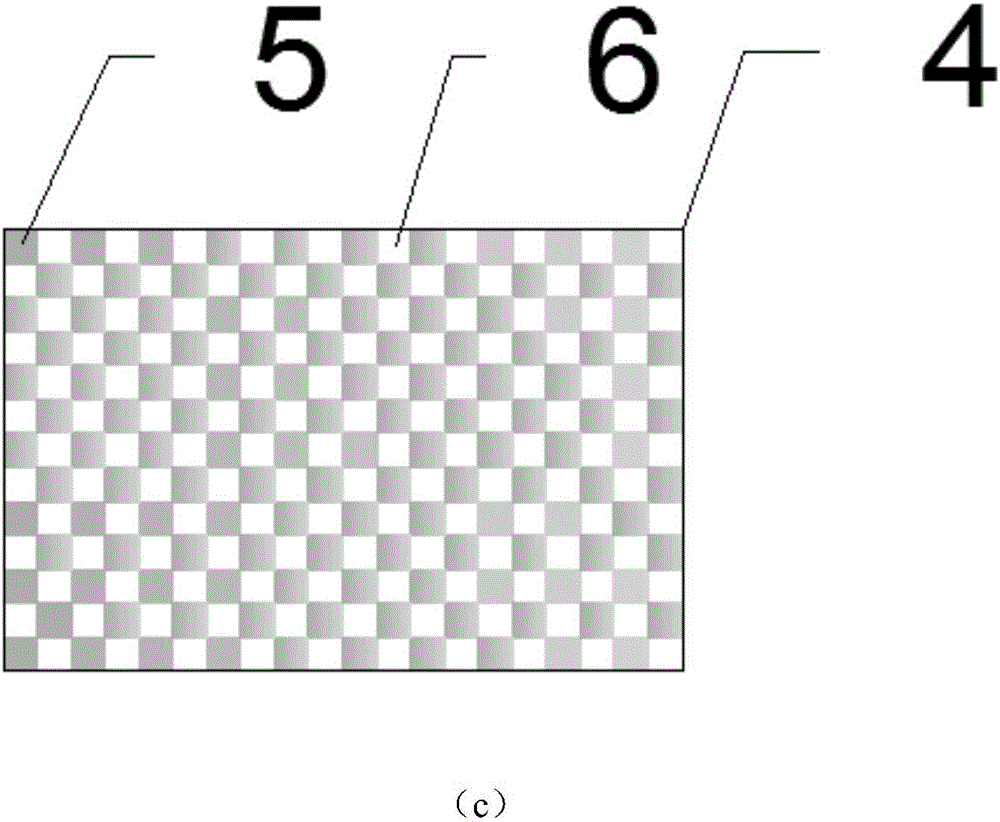

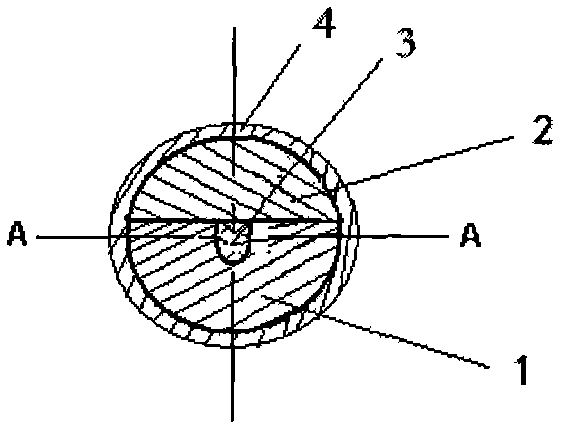

Silicon-cup energy-accumulation Al/CuO composite film ignition bridge and ignition bridge array

InactiveCN102249830AImprove the ability of anti-radio frequencyImprove ignition performanceFusesElectricityComposite film

The invention discloses a silicon-cup energy-accumulation Al / CuO composite film ignition bridge and an ignition bridge array. A silicon cup with equilateral tetragonal pyramid slopes is made on a silicon chip by an anisotropic etching technique. The ignition bridge is formed by superposing an upper electrode, a lower electrode and a dielectric layer, wherein two metal films with the same size in opposite directions are respectively used as the upper electrode and the lower electrode, and an Al / CuO composite film layer which has the same size and direction as the upper electrode metal film is sandwiched between the two metal films as the dielectric layer; the Al / CuO composite film layer is partially covered and superposed on the lower electrode metal film, and the upper electrode metal film is completely covered and superposed on the Al / CuO composite film layer; and an Au metal film or Cu metal film is made into a lead for connecting a plurality of silicon-cup energy-accumulation Al / CuO composite film ignition bridges, so that the silicon-cup energy-accumulation Al / CuO composite film ignition bridges are arranged to form an ignition array. The invention has the functions of high self anti-RF capability, strong ignition capability, and favorable integration level with other components of the initiating explosive device.

Owner:NANJING UNIV OF SCI & TECH

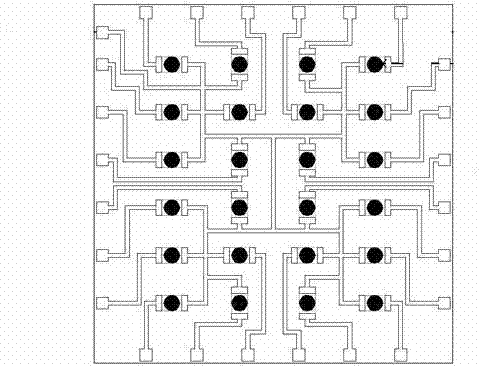

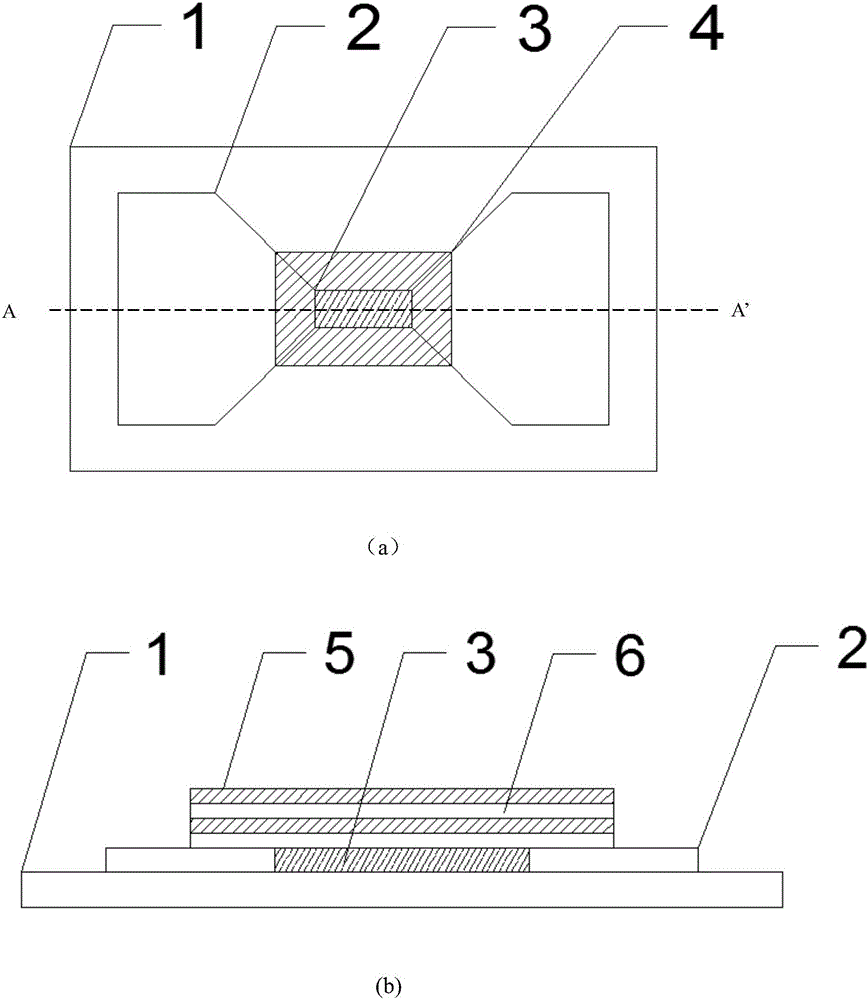

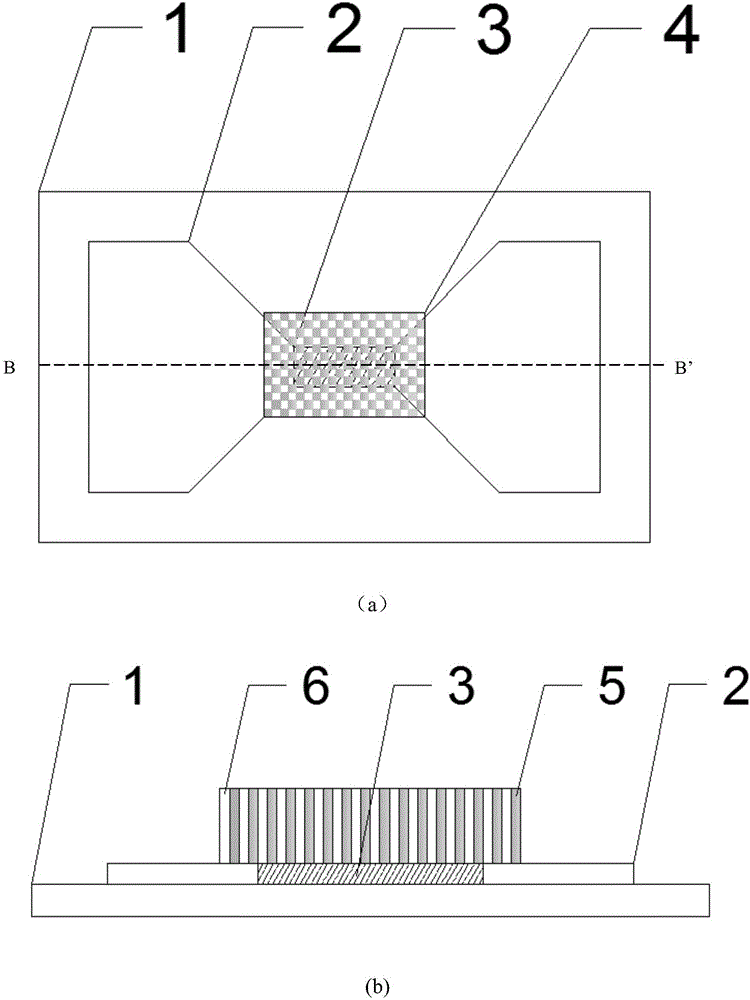

Ignition bridge with lattice-shaped energy-containing thin film

InactiveCN105693442AIncrease contact areaDiffusion spreads fasterFusesUtilization rateHeating energy

The invention discloses an ignition bridge with a lattice-shaped energy-containing thin film, and belongs to the field of basic components for initiating explosive devices. The ignition bridge comprises a substrate, an electrode, an ignition bridge area and an energy-containing thin film layer, wherein the electrode and the ignition bridge area are located on the substrate, and the energy-containing thin film layer is located on the ignition bridge area. The ignition bridge with the lattice-shaped energy-containing thin film is characterized in that the energy-containing thin film layer is of a lattice-shaped structure; a single grid of lattice is filled with an energy-containing material A or an energy-containing material B; further, the grid filled with the energy-containing material A is only in contact with the grid filled with the energy-containing material B; the grid filled with the energy-containing material B is only in contact with the grid filled with the energy-containing material A; each contact surface between the energy-containing material A and the energy-containing material B is perpendicular to the substrate. According to the ignition bridge with the lattice-shaped energy-containing thin film, through changing a contact form between energy-containing materials, heat energy needed for ignition is effectively improved by sufficiently utilizing chemical energy from a reaction of the energy-containing thin film; the utilization rate and the conversion efficiency of energy are improved; the reliability and the stability of the ignition are guaranteed.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

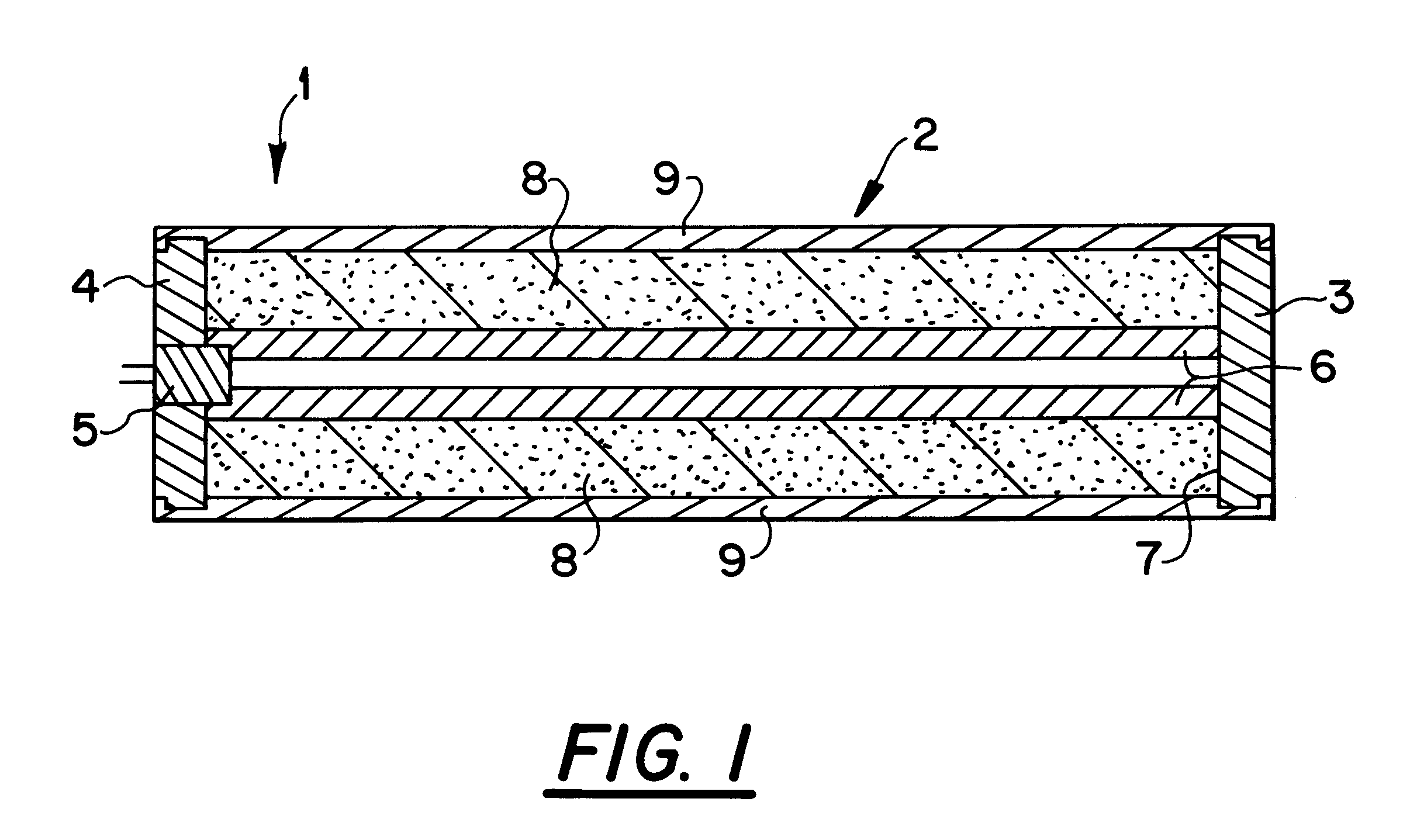

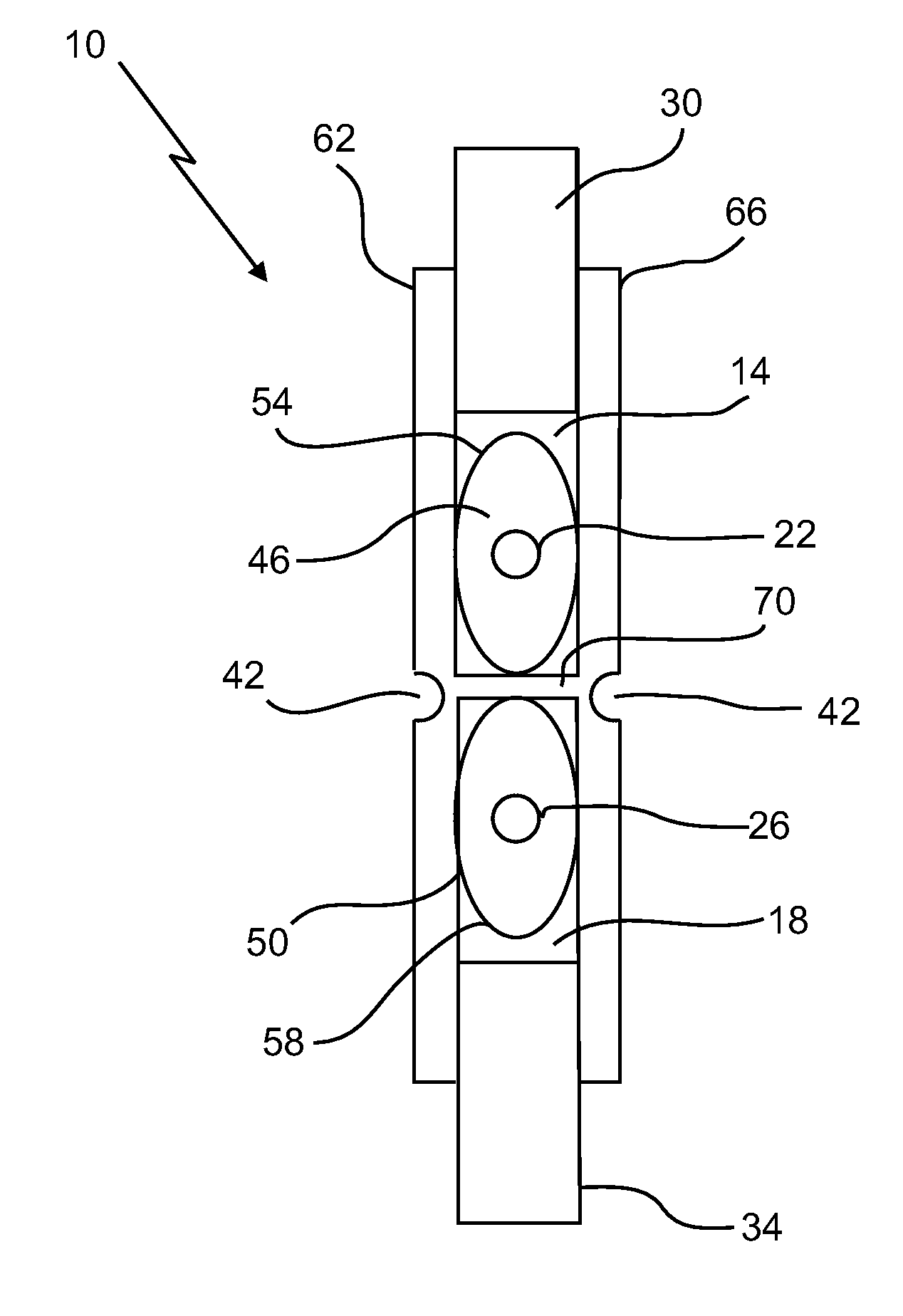

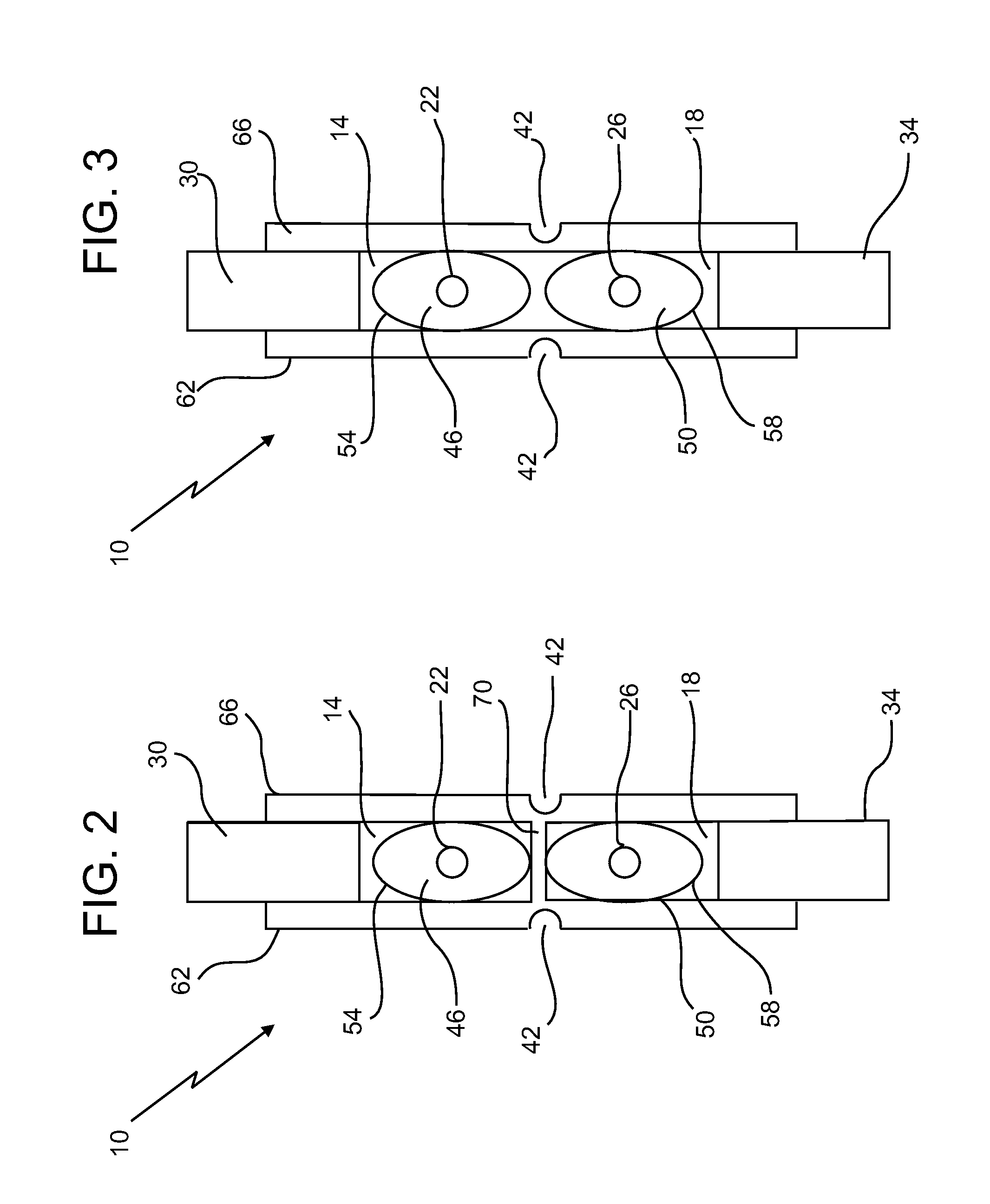

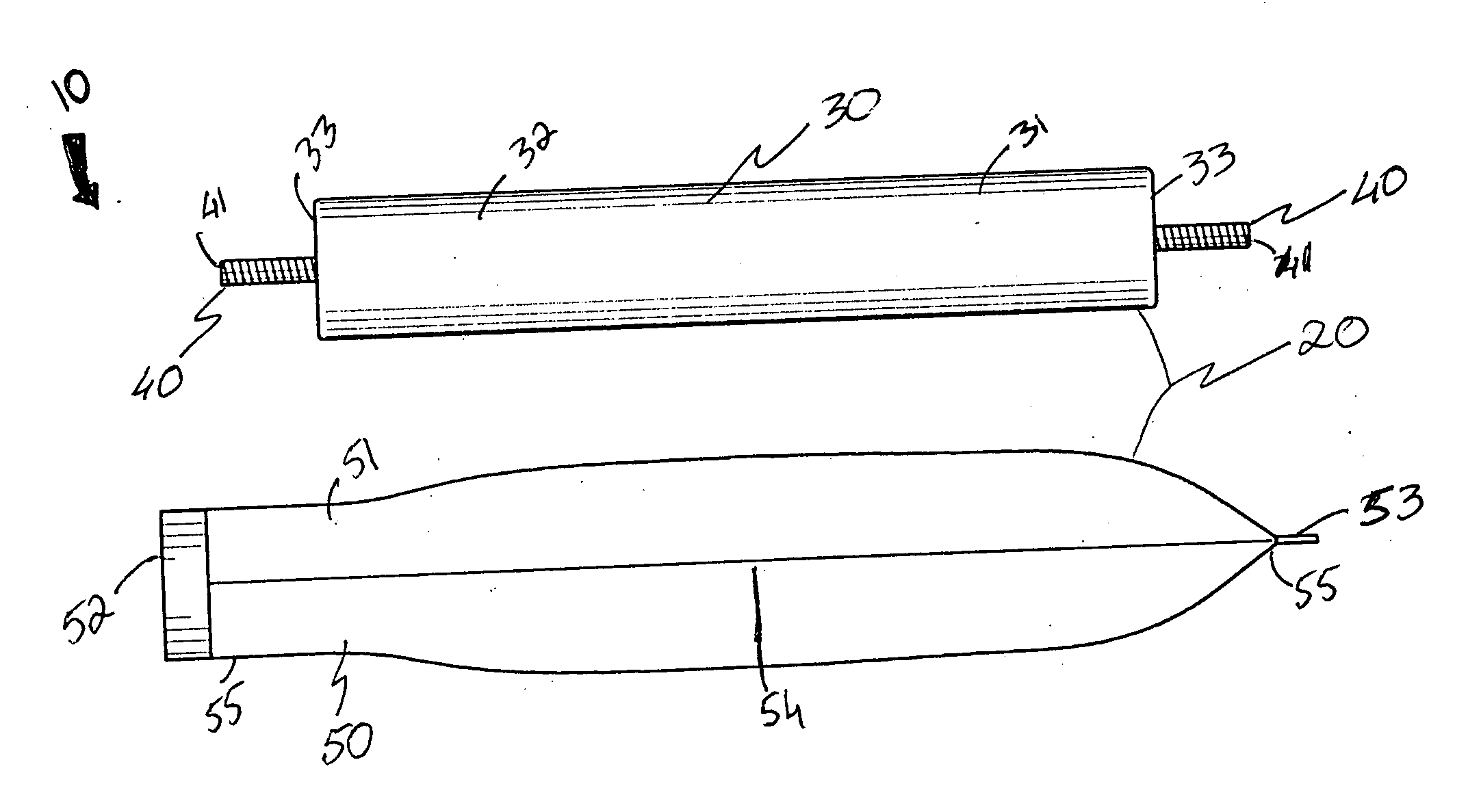

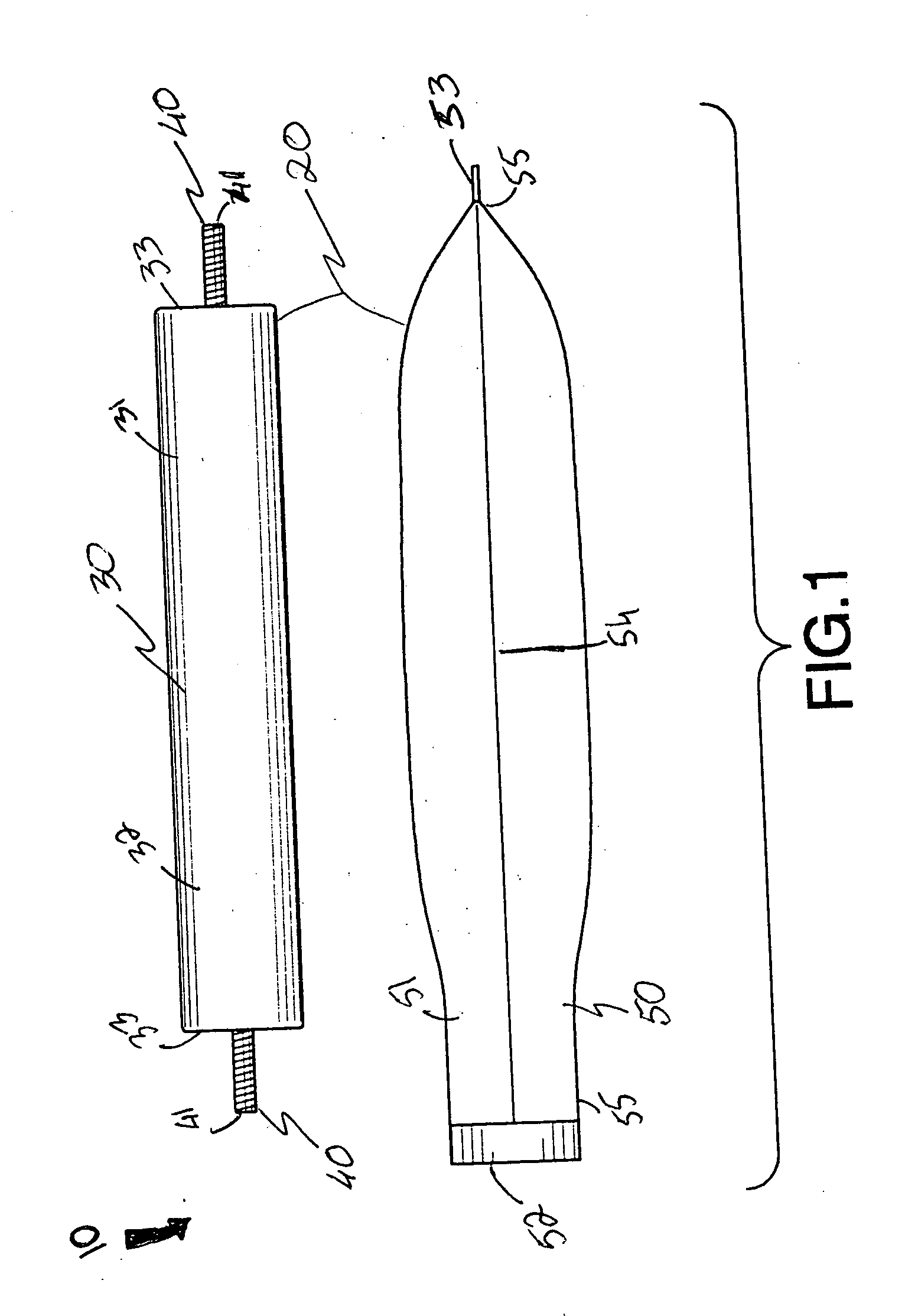

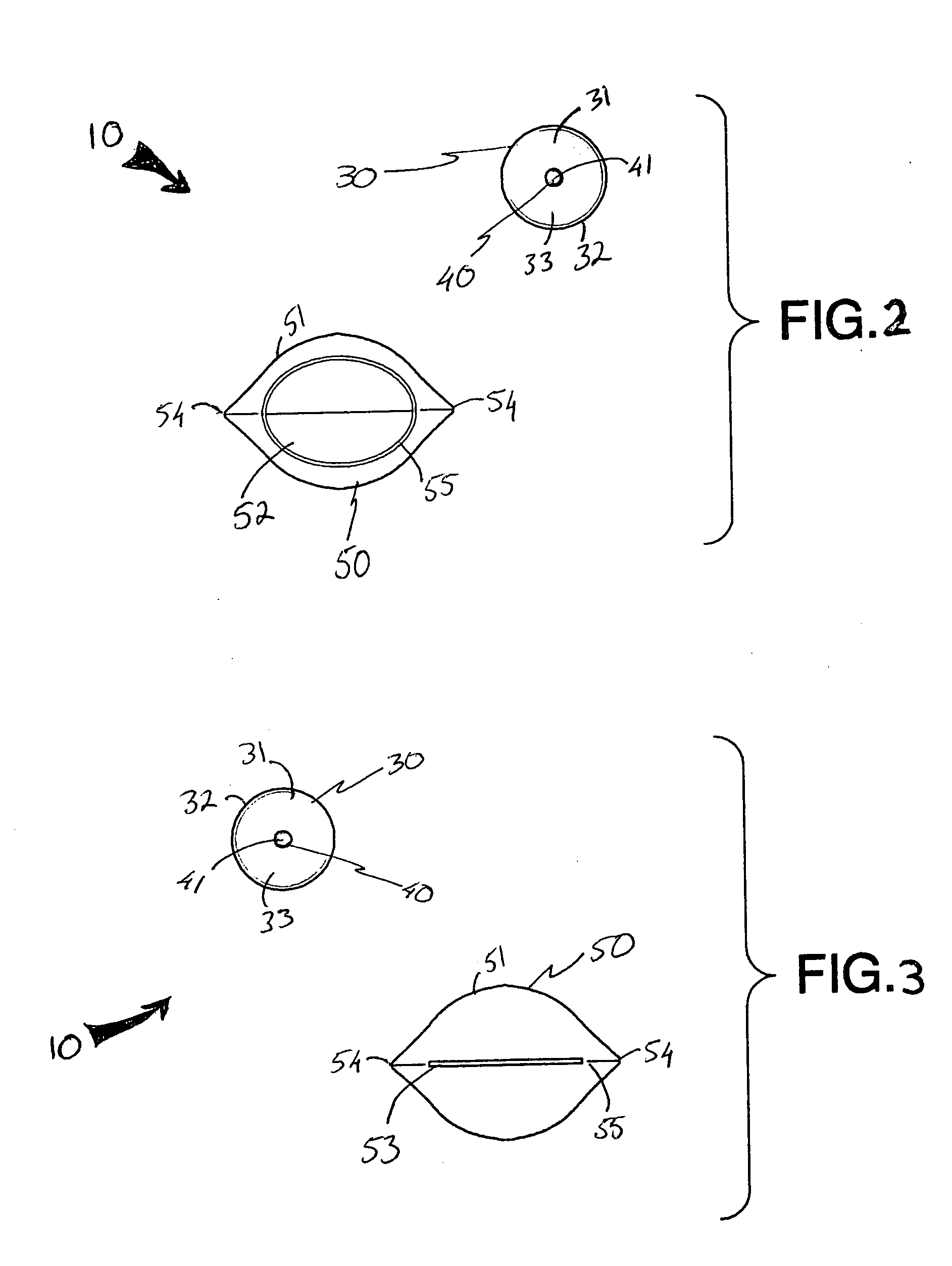

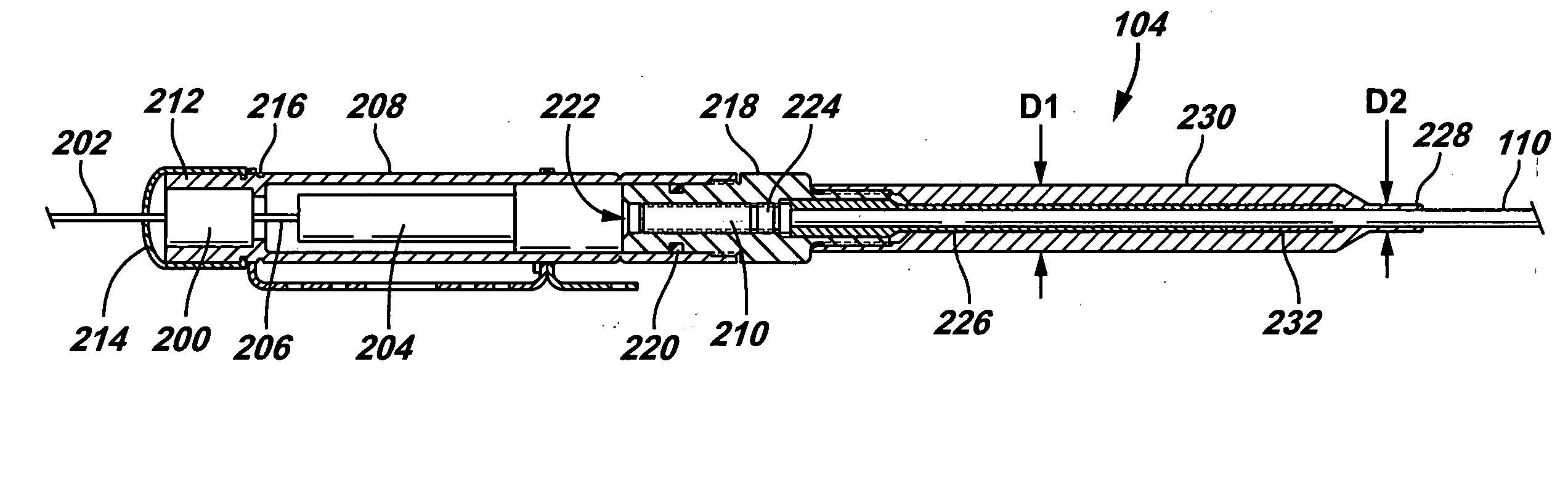

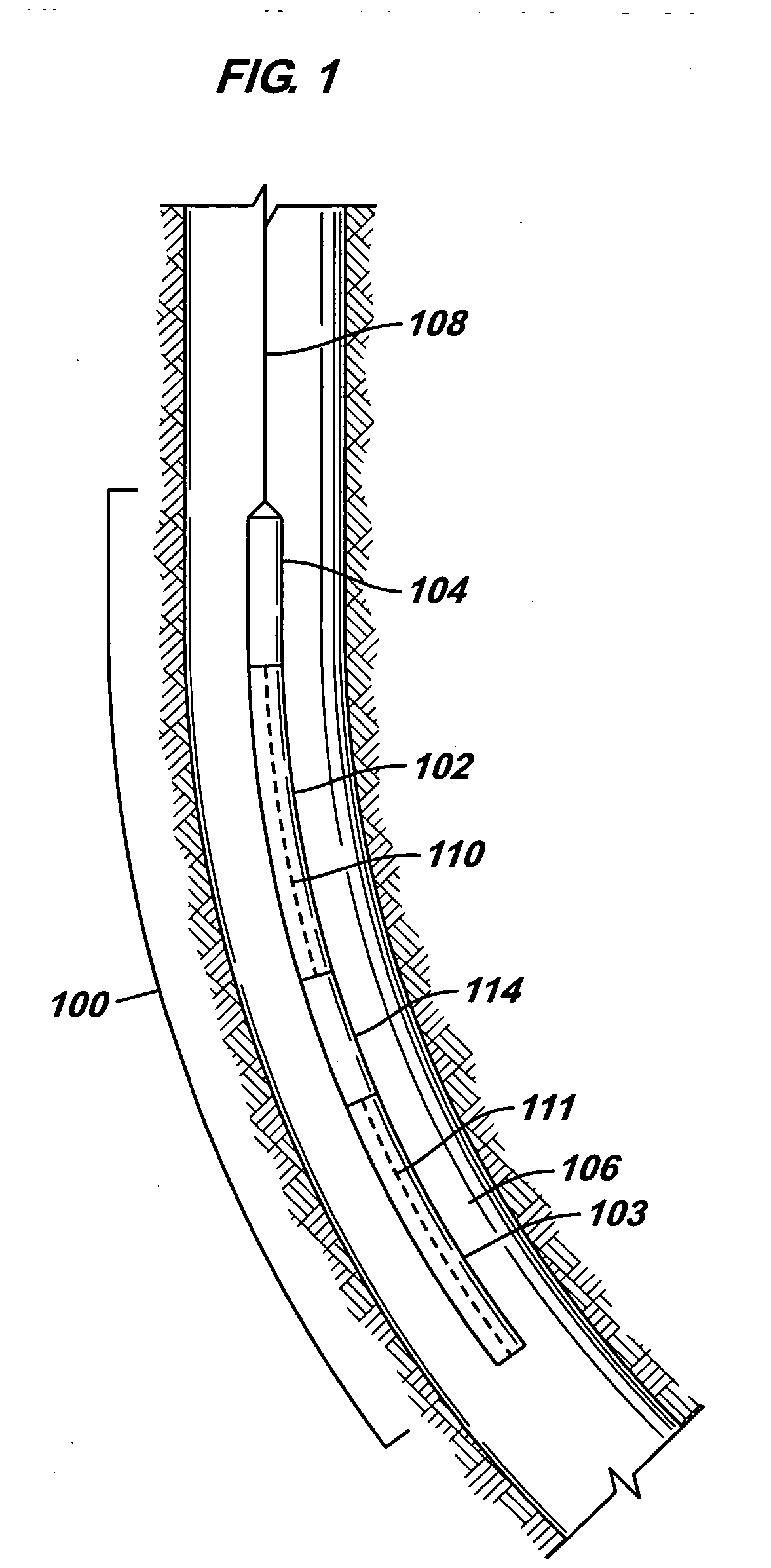

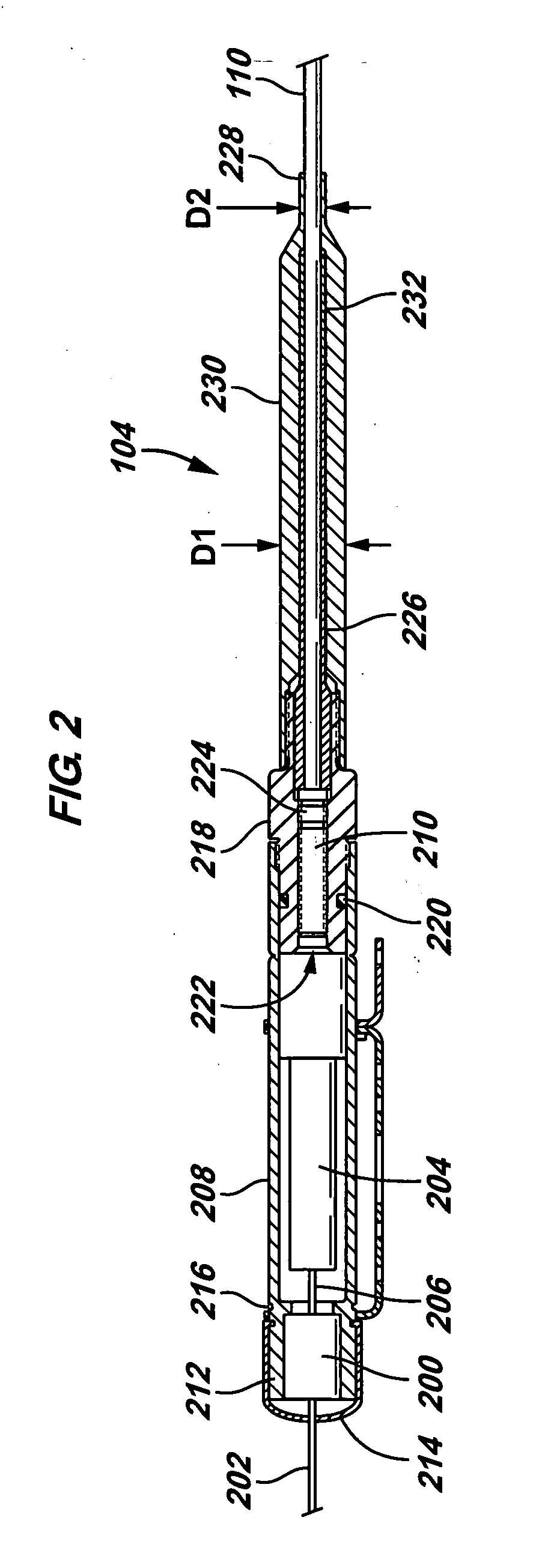

Dual tube frangible joint

InactiveUS20130236234A1Cosmonautic vehiclesCouplings with disconnecting safety membersDouble tubeElectrical and Electronics engineering

Owner:ENSIGN BICKFORD AEROSPACE & DEFENSE

Production process for firecracker fuse

The invention relates to a production process for a firecracker fuse. The process is characterized by comprising the steps of weighing out crude drugs in proportion and mixing crude drugs uniformly; adding water in uniformly mixed crude drugs and preparing crude drugs into paste; and enabling a nitrified cotton thread to penetrate through the prepared crude paste and to be stained with fuse drugs uniformly, drying the cotton thread by airing or by baking, cutting the cotton thread into sections, packaging sections, and placing sections indoors for storage. The firecracker inserting fuse produced by a wet method is simple to operate, the production efficiency is high, and technical links such as starching, thread reversion and drying are omitted.

Owner:利川市忠路烟花爆竹产销有限责任公司

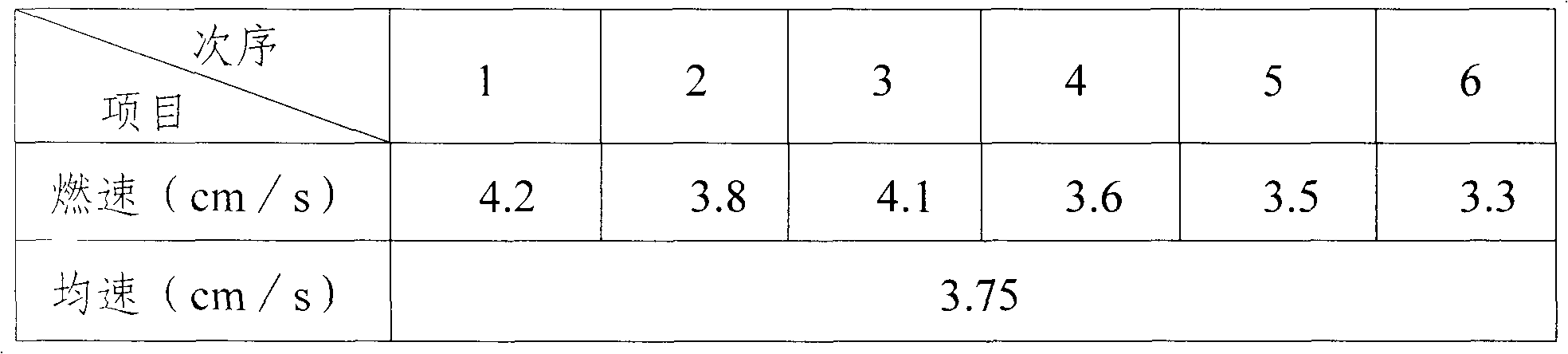

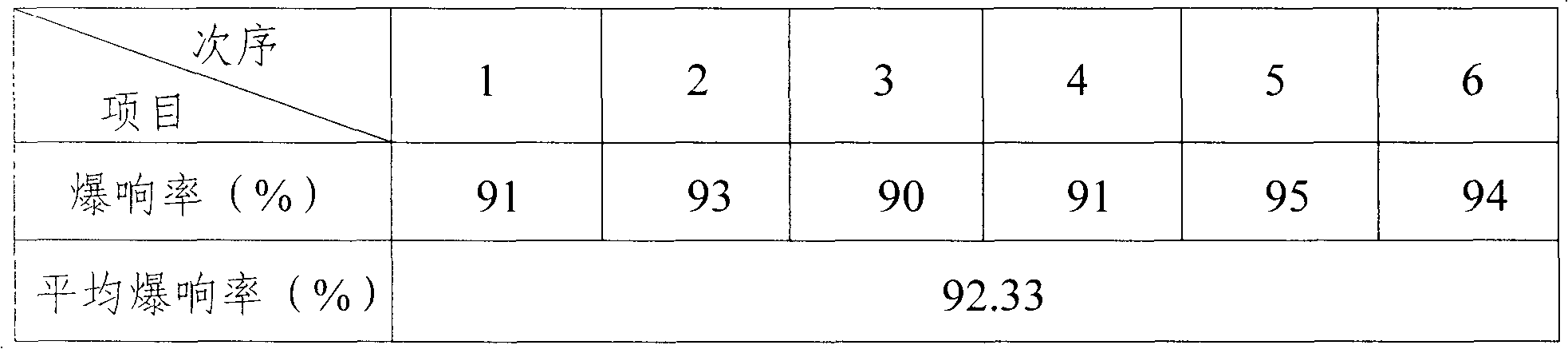

Novel potassium perchlorate paper firing line for firecrackers

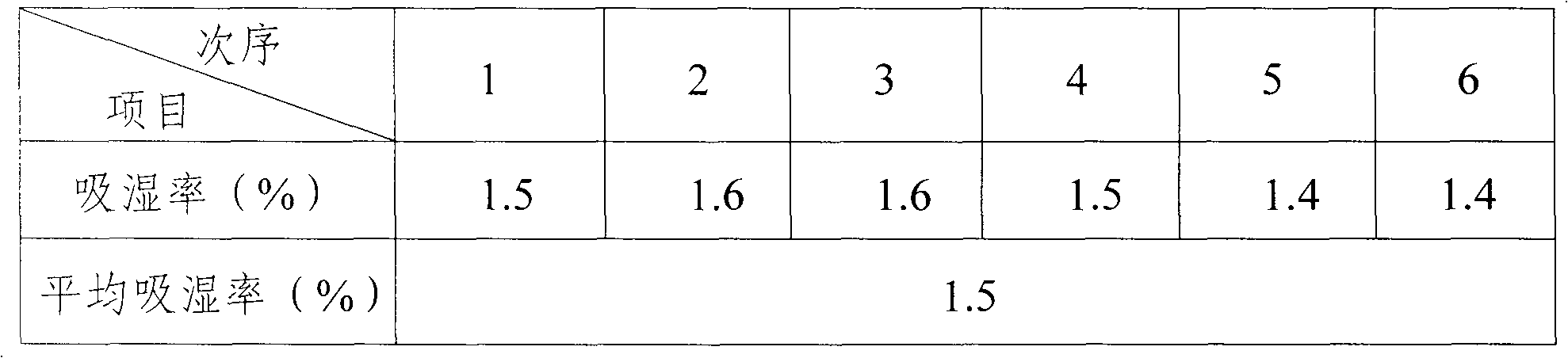

InactiveCN101973828ALight weightLow hygroscopicityInorganic oxygen-halogen salt explosive compositionsFusesFirecrackerPulp and paper industry

The invention discloses a novel potassium perchlorate paper firing line for firecrackers. Firing powders of the paper firing line are made of potassium perchlorate, hemp stem carbon and magnesium oxide by mass percent. The production process comprises the following steps of: uniformly mixing the hemp stem carbon with the magnesium oxide by adopting a mixing machine by mass percent, and then uniformly mixing with the potassium perchlorate to obtain the firing powders; twisting the firing powders in the step one with firing line paper into a semi-finished paper firing line by adopting a firing line twisting machine, wherein the usage of the firing powders is 0.8 catty to 1.2 catties firing powders / 1 kilometer firing lines; and starching the semi-finished paper firing line of the step 2, and air drying, cutting and pouring disks after starching to prepare the finished paper firing line. The invention has the advantages of stable performance, safe and reliable production and transport, simple production process, high burning rate, low rate of moisture absorption, low friction sensitivity and low impact sensitivity, and the performance and the selected materials are all in line with standards in China.

Owner:陕西省蒲城县新型花炮技术推广中心

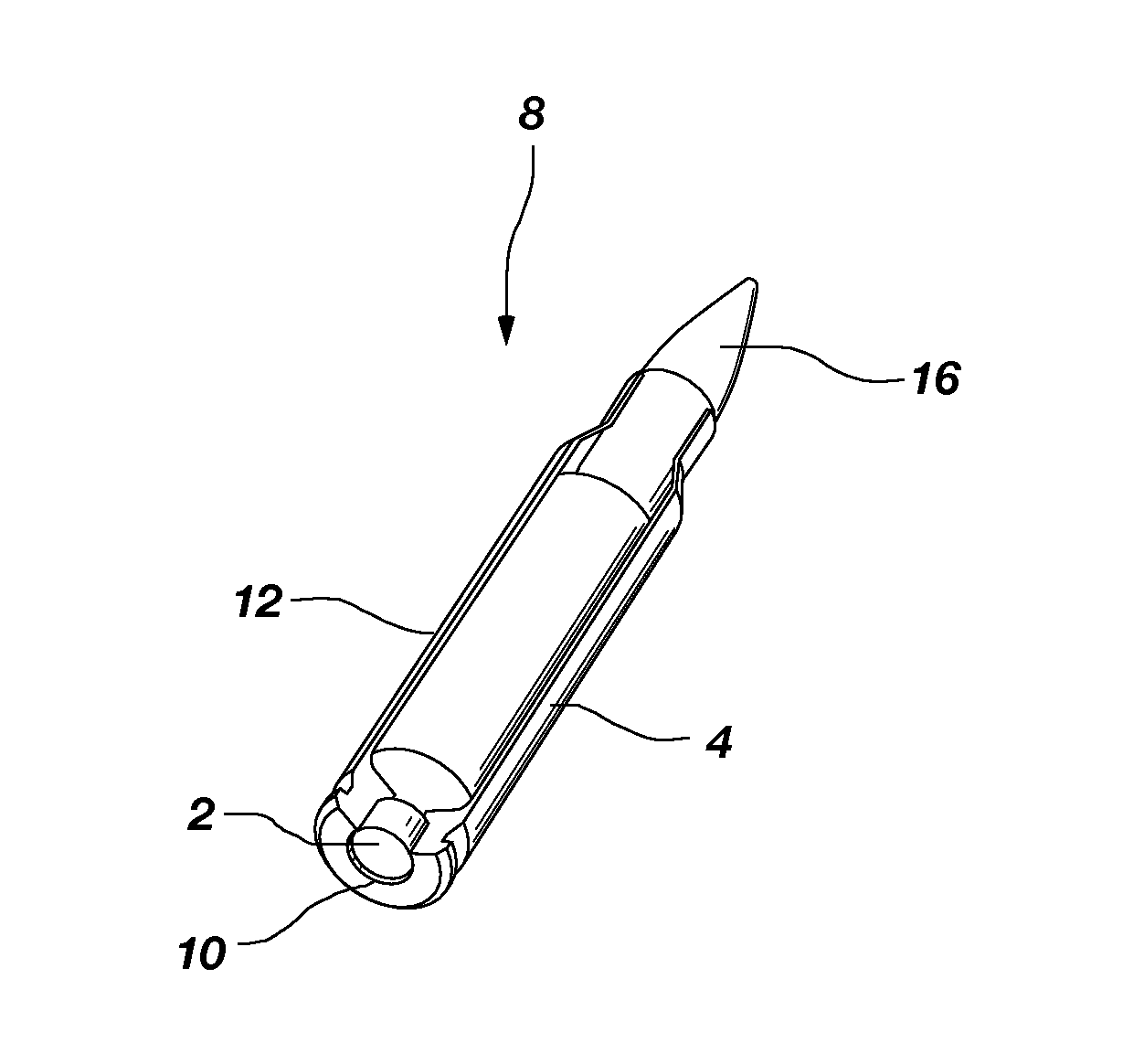

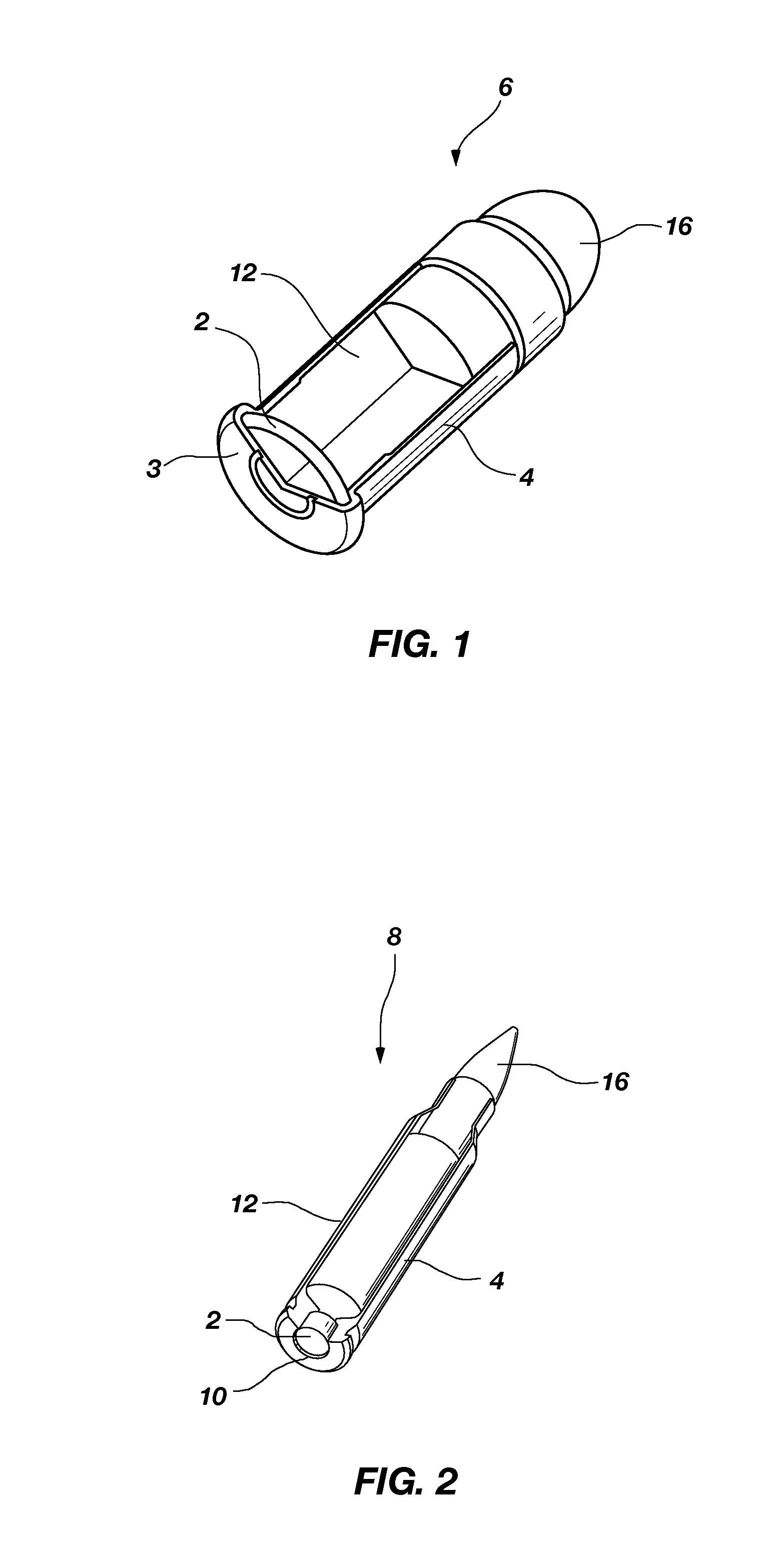

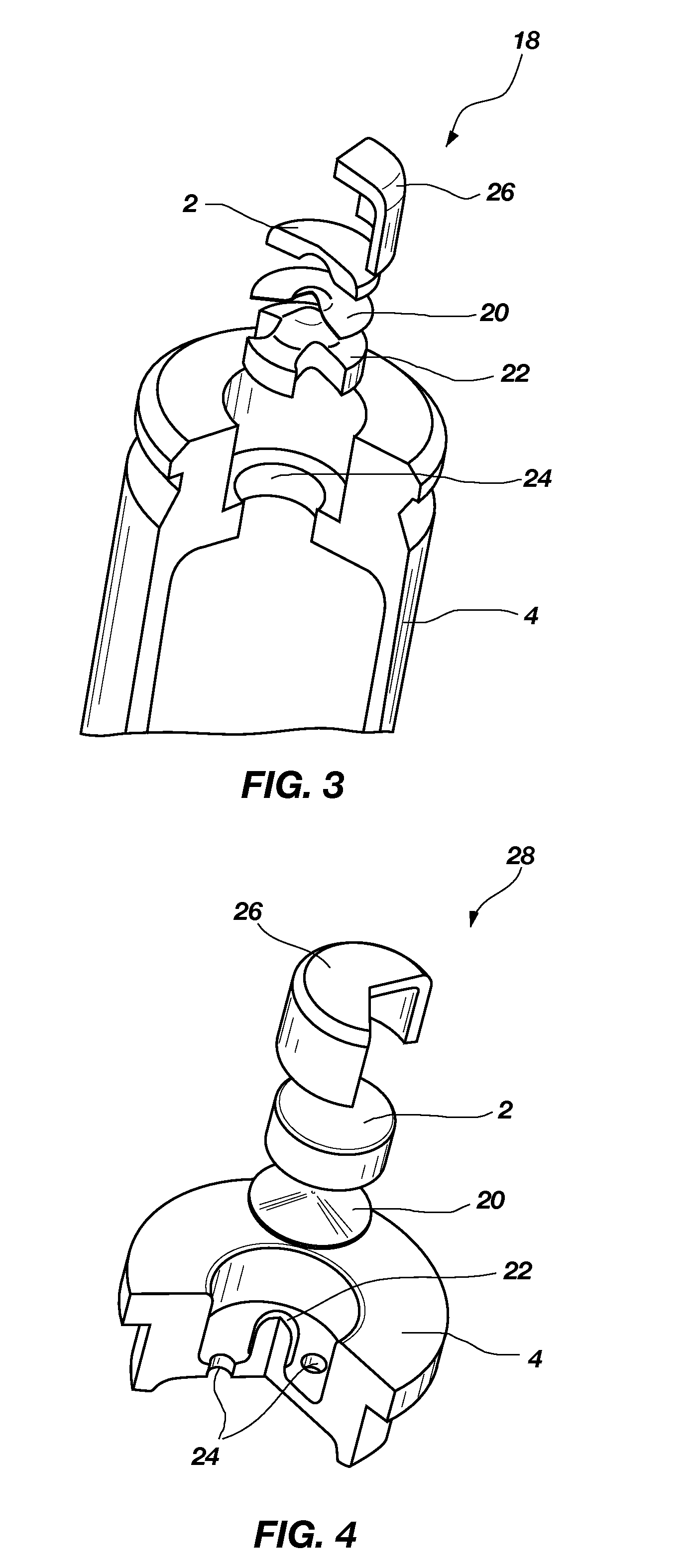

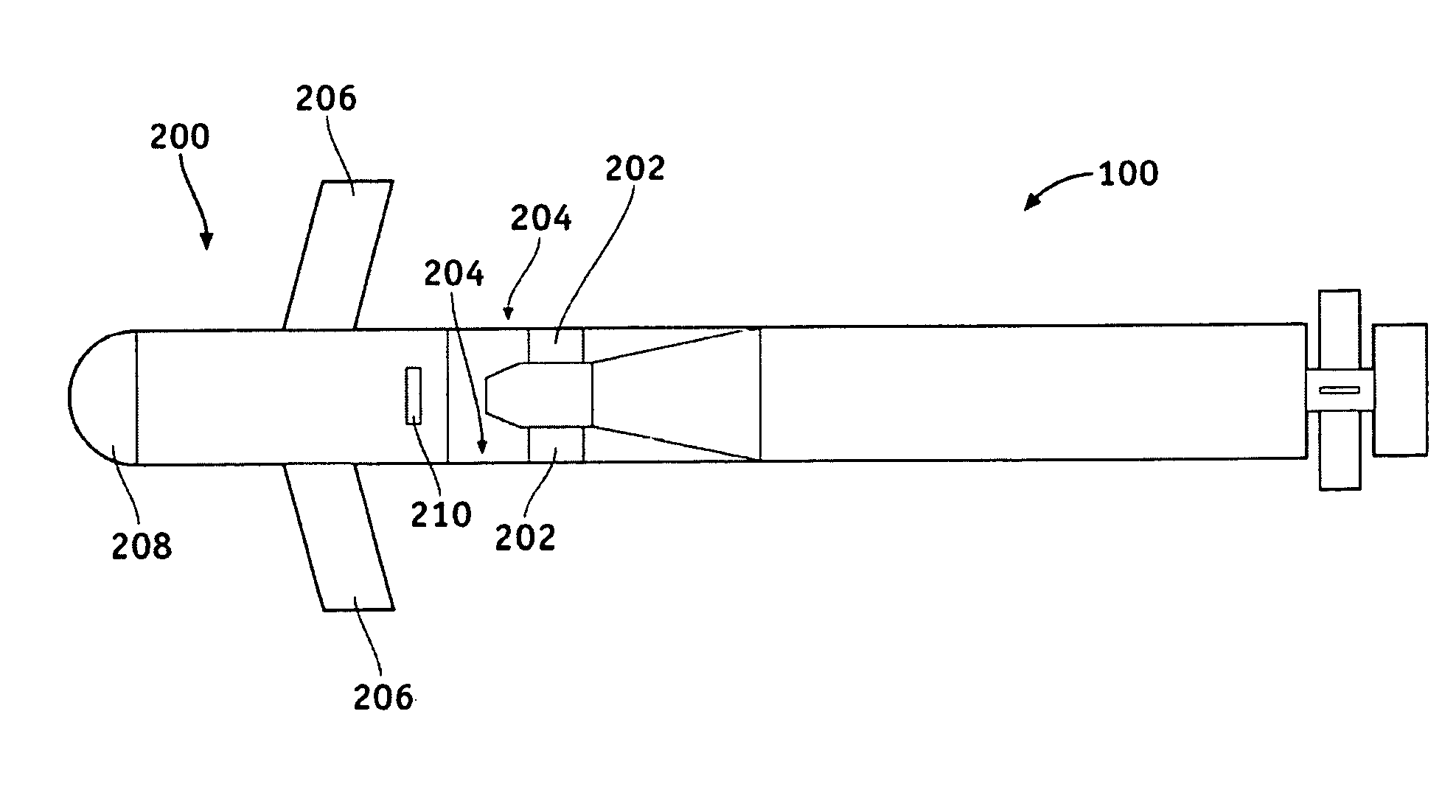

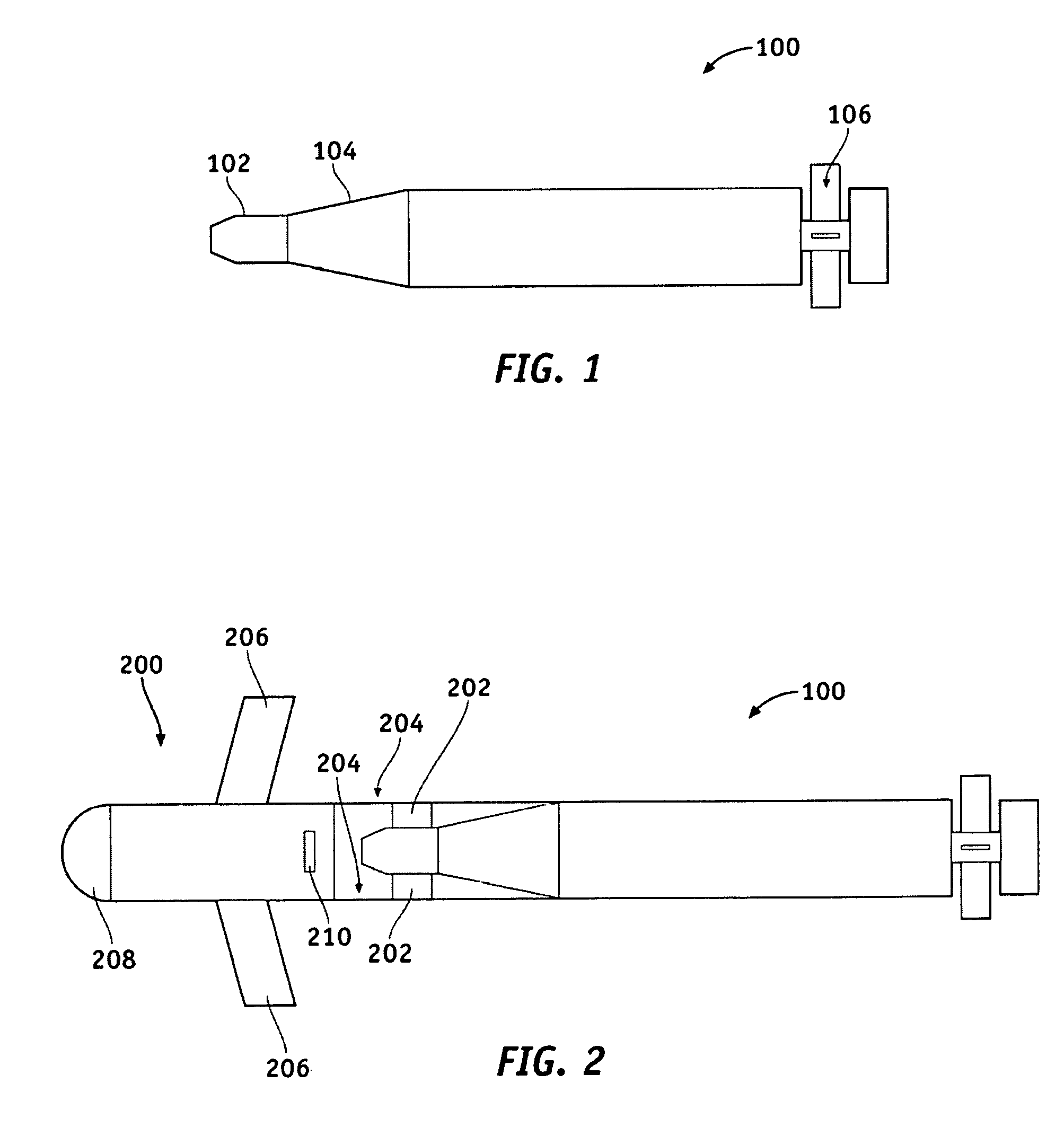

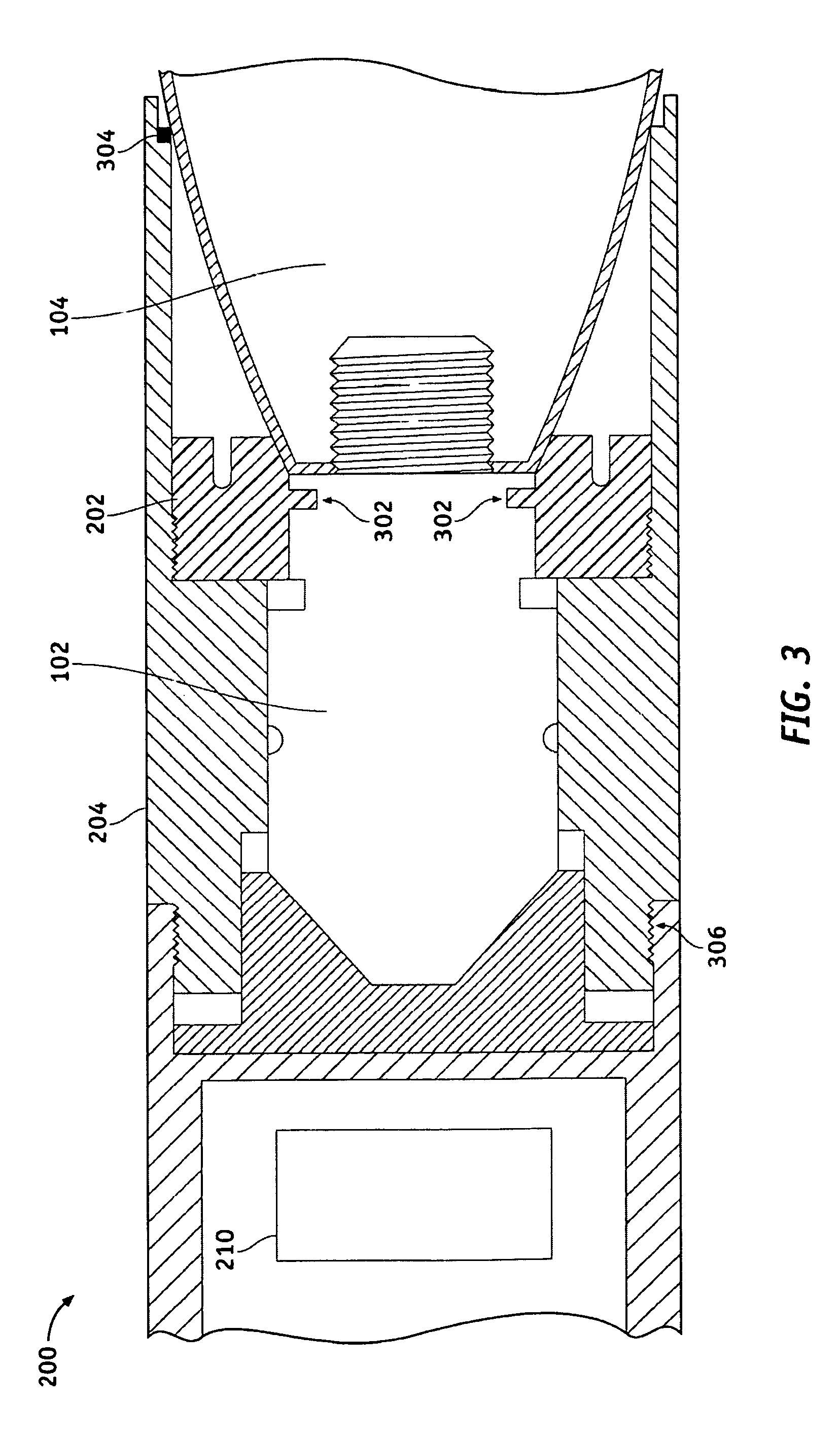

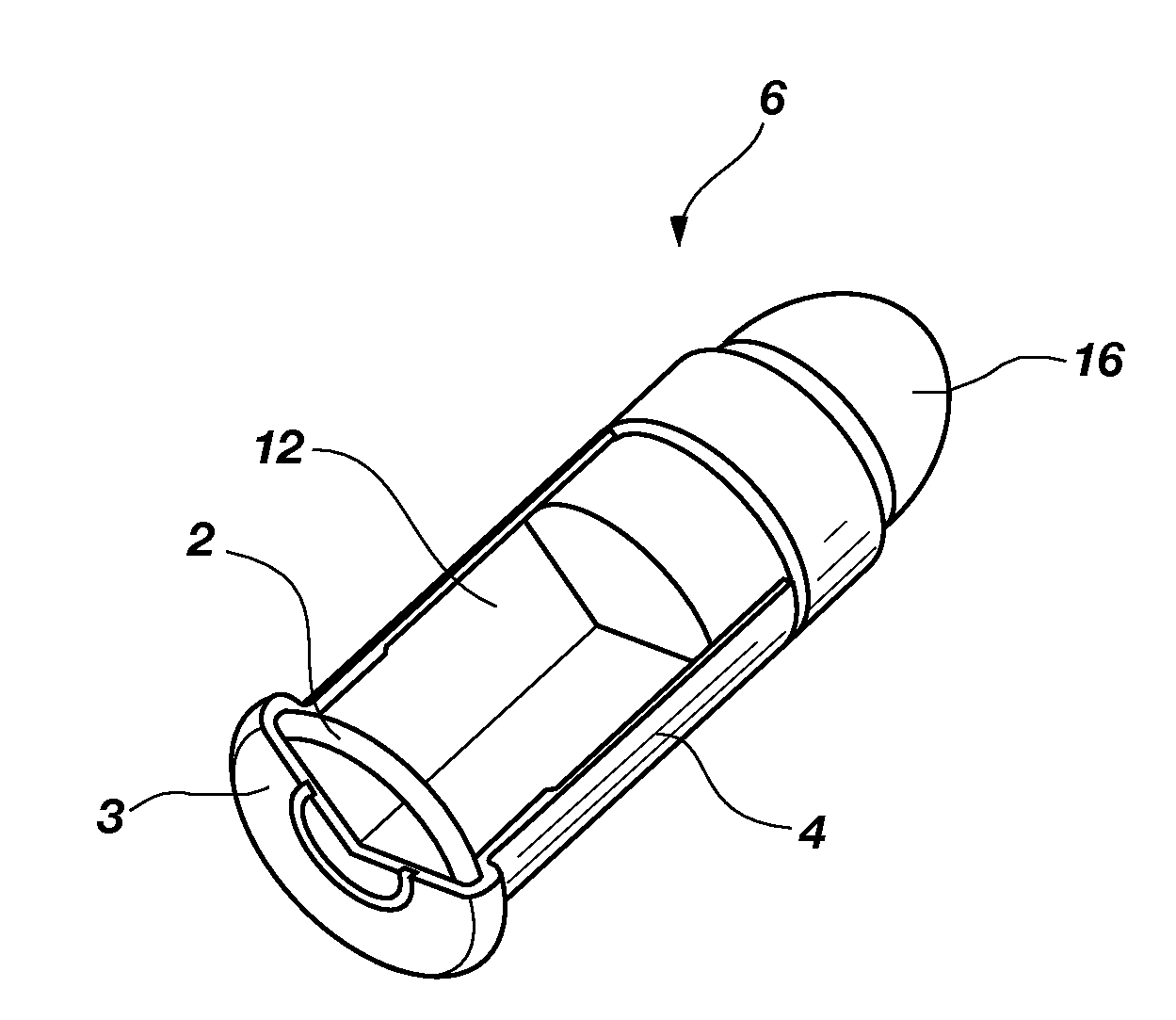

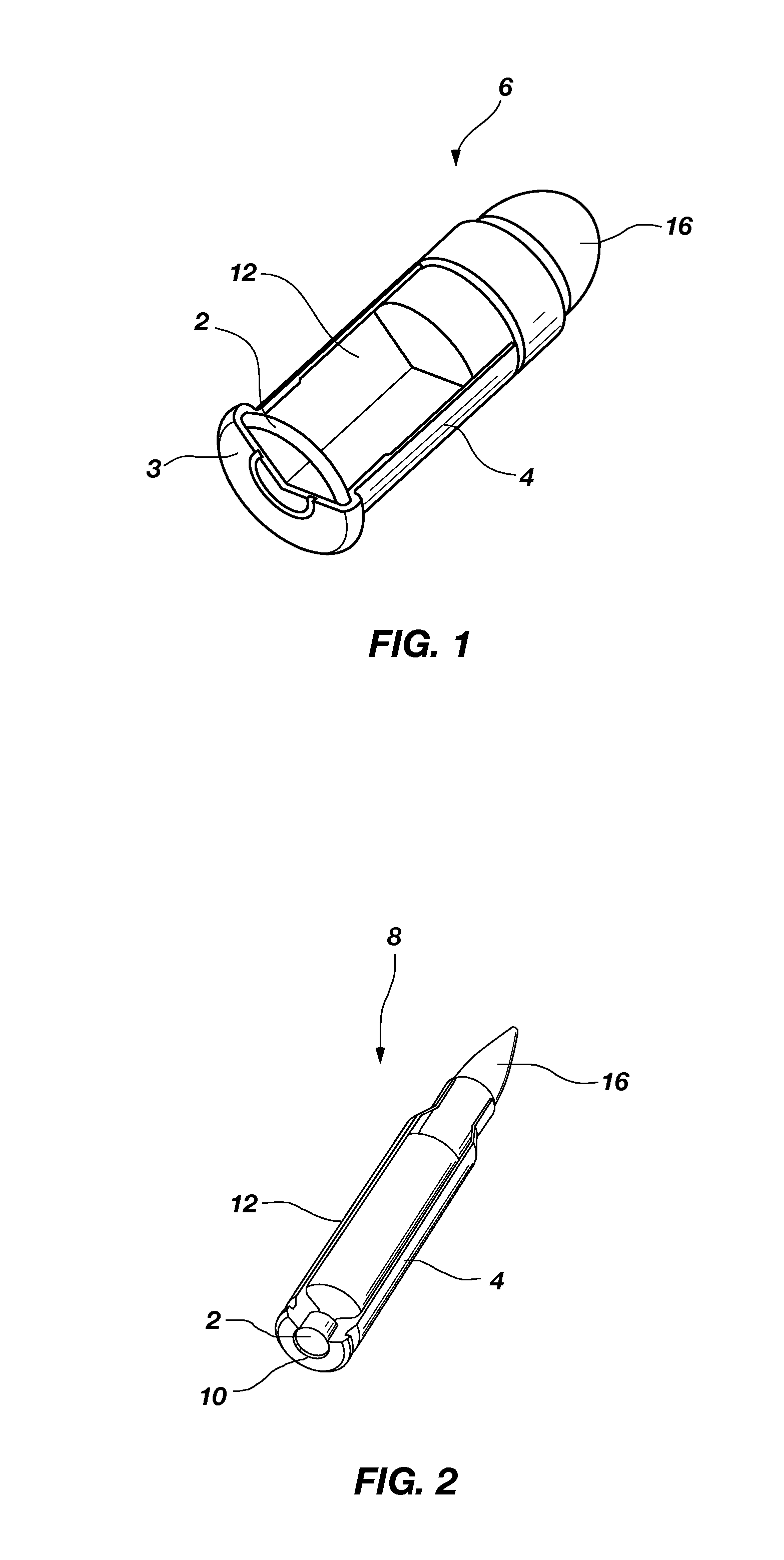

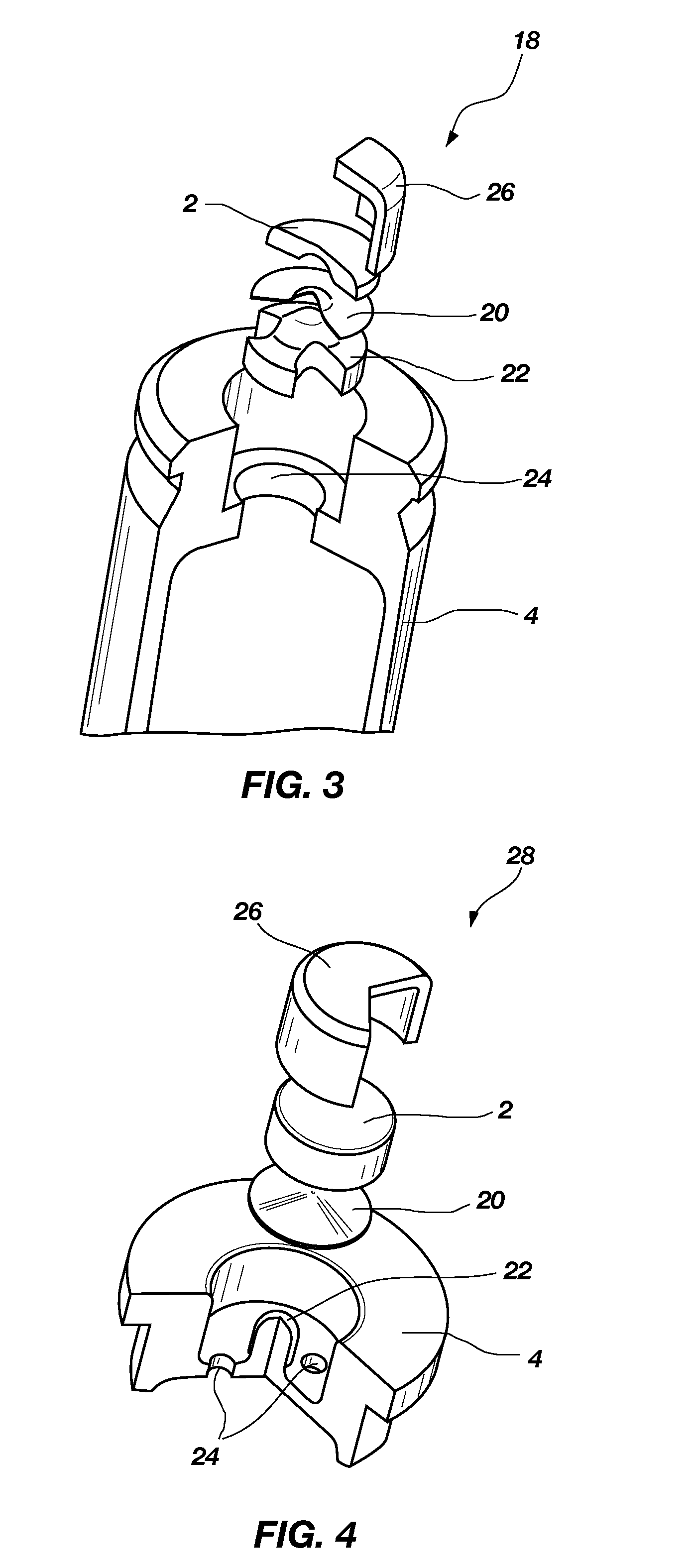

Methods and apparatus for attachment adapter for a projectile

Methods and apparatus for mounting a secondary system on a projectile according to various aspects of the present invention operate in conjunction with a collar. The collar is adapted to at least partially receive a fuze assembly or other projectile structure within the collar. The collar may be adapted to attach to a cover.

Owner:RAYTHEON CO

Monoprolellant/hypergolic powered proportional actuator

InactiveUS6935109B2Reduce energy lossSimple designProgramme-controlled manipulatorInternal combustion piston enginesActuatorControl theory

Owner:VANDERBILT UNIV

Method and apparatus for packaging charcoal fuel and other fuels for easy lighting

Owner:SUMMIT VIEWS

Novel delay element

The invention relates to a novel delay element, which relates to a structure of the delay element and a powder packaging and producing process. Glue is added into delay powder so that the delay powder is made into paste which can be applied into a groove on a plastic strip, the plastic strip is adhered with another plastic strip after the paste is dried, and accordingly, the delay element body is formed. The delay powder in the delay element body is uniform in density, stable in burning and fine in delay accuracy. Lead is omitted, so that lead pollution is avoided. The novel delay element is simple in manufacturing process, low in cost, can be used for millisecond, half-second and one-second delay detonators and delay devices in fireworks, fire or cartridges.

Owner:ANHUI UNIV OF SCI & TECH

Production technology of rigid fuse

InactiveCN1724488AImprove product qualityFacilitate automatic processingFusesDetonatorsDetonatorSoldering

The invention relates to the manufacturing technique for detonators, especially the process for preparing rigid igniting head which comprises the following steps, pressing comb teeth, injection molding, shaping, soldering bridge wires, automatically dipping powder, drying the igniting heads and soldering leg wires. The process can realize production automation, increased production efficiency, and guaranteed quality of products.

Owner:云南燃一有限责任公司

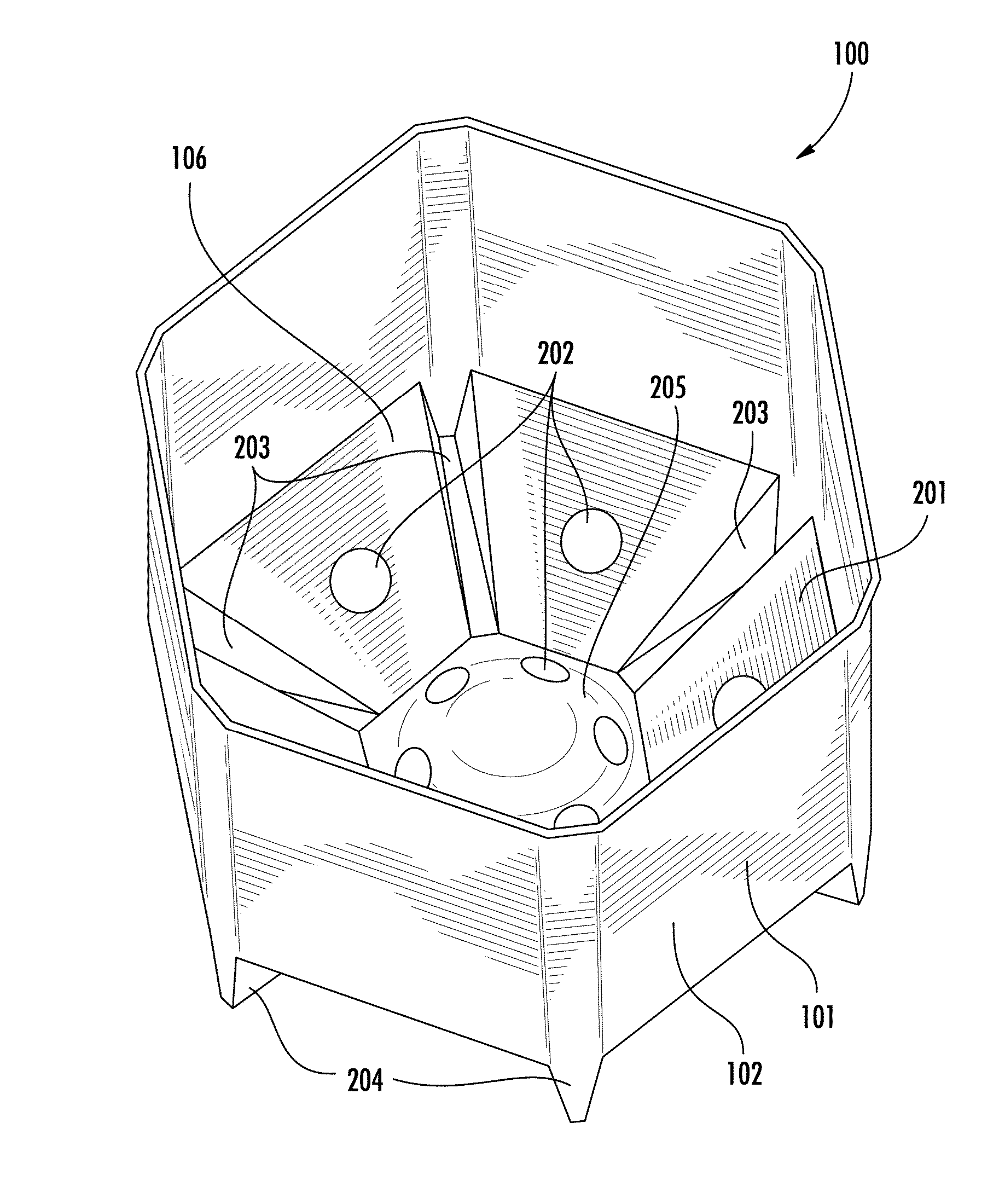

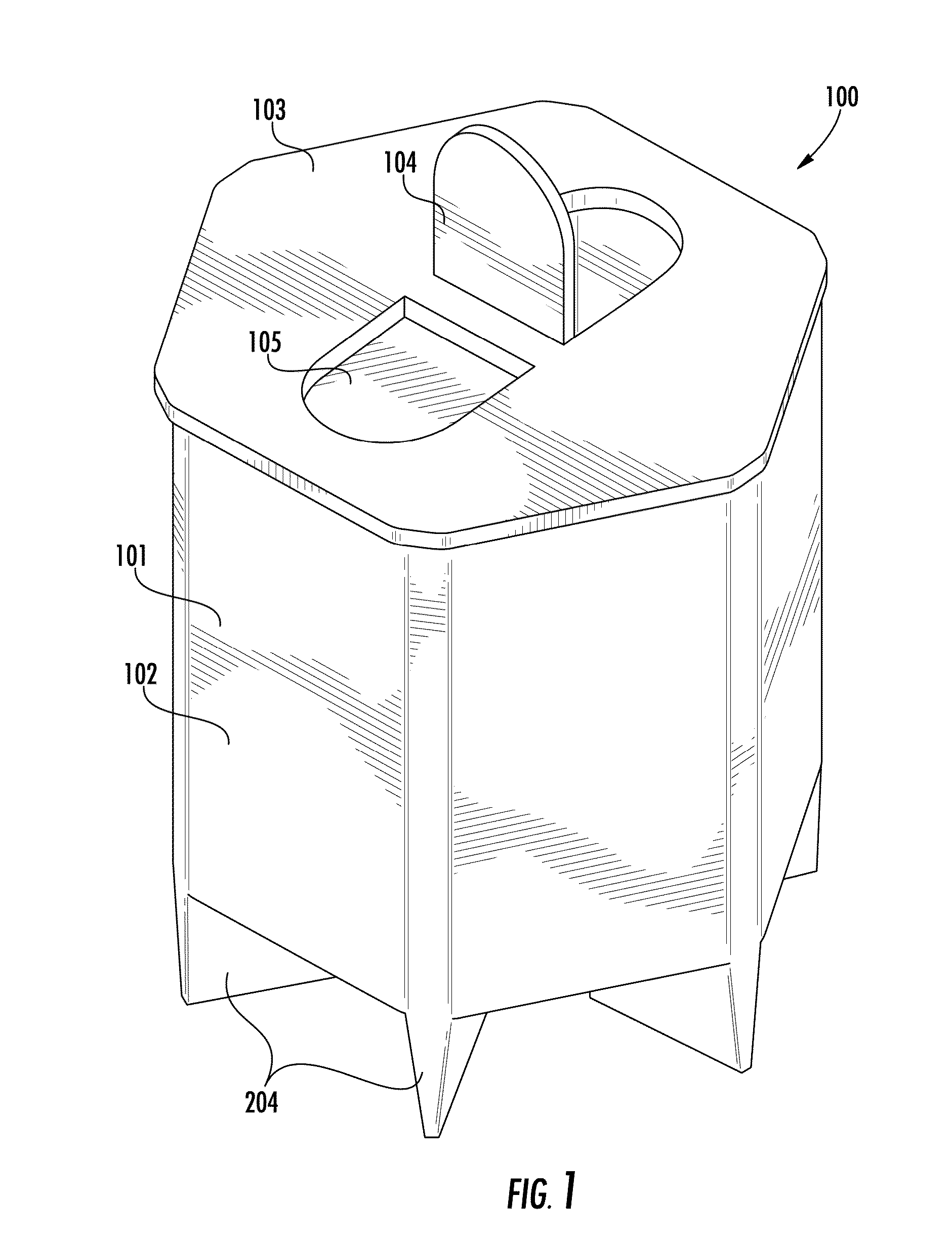

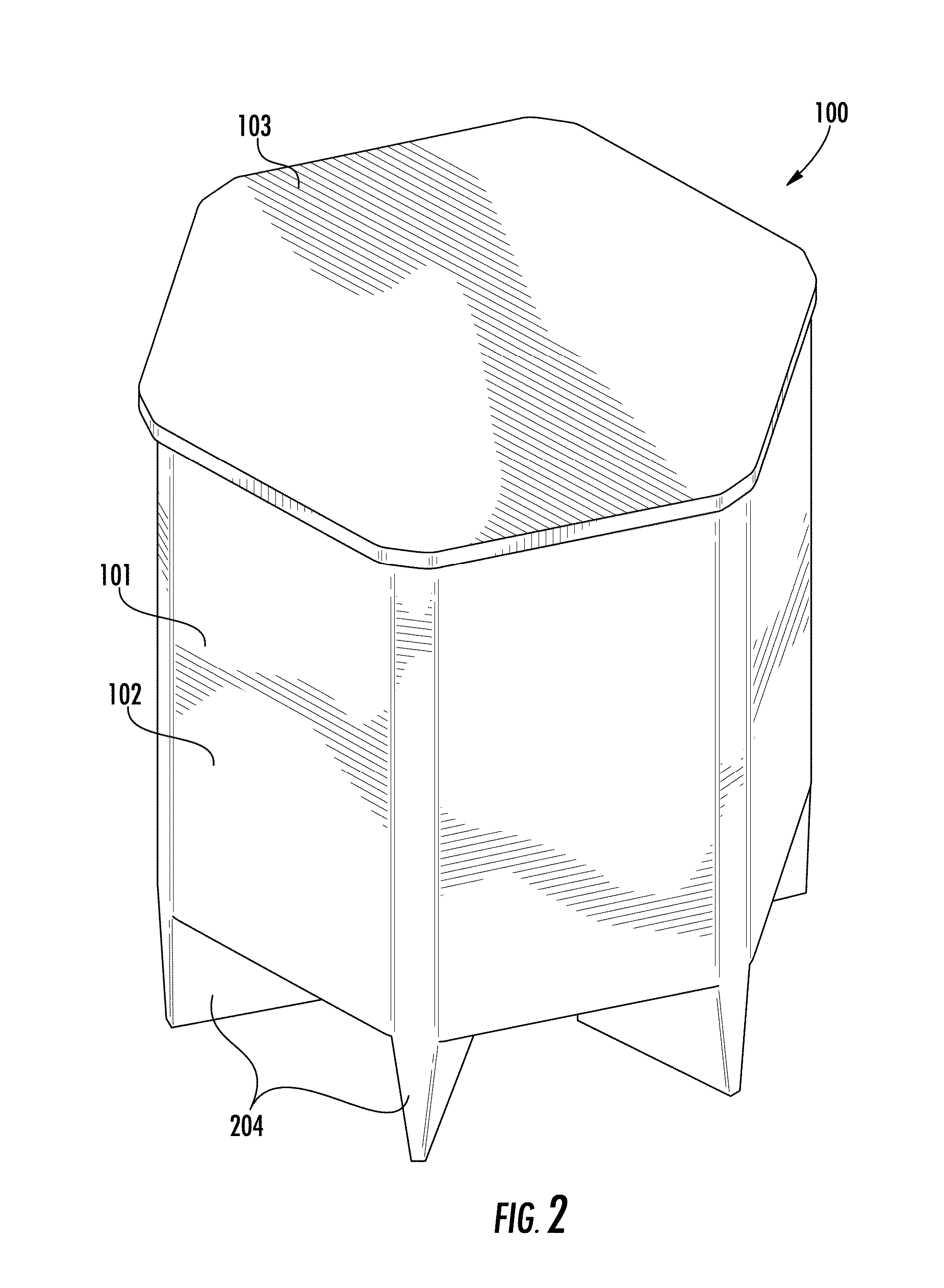

Charcoal chimney

InactiveUS20160075961A1Delayed ignitionDomestic stoves or rangesLighting and heating apparatusIgnition delayFire retardant

Embodiments described herein are generally directed to a charcoal chimney that may hold charcoal. The charcoal chimney may be formed of a material that is combustible. The charcoal chimney is generally intended as a single use chimney. The charcoal chimney may be associated with a non-toxic fire-retardant or ignition delay substance that delays combustion of the chimney for at least an initial heating phase. The ignition delay substance may be a coating on one or more surfaces of the charcoal chimney. The ignition delay substance may be impregnated or otherwise formed into the material forming the charcoal chimney. The ignition delay substance may be both coated onto and impregnated into the charcoal chimney. The fire-retardant or ignition delay substance is generally intended to delay the combustion of the charcoal chimney for a period of time. The chimney may be provided with suitable air holes to facilitate airflow around the charcoal and within the chimney.

Owner:HOTTROX

Disposable fuel pack

InactiveUS20050139205A1Large widthEasy maintenanceDomestic stoves or rangesLighting and heating apparatusMechanical engineeringCharcoal

A fuel pack for igniting charcoal includes an elongated member formed from combustible material that includes an elongated wick passing through it. Advantageously, the ignitable member and wick are saturated with a non-petroleum oil for providing a catalyst to ignite the fuel pack. The fuel pack further includes a package for receiving and storing the ignitable member. The package includes an open end for moving the ignitable member into and out of the package. The package further includes a sealed end portion for maintaining the ignitable member at a substantially stable position.

Owner:PAEZ DELFIN E

Gas generator ignition agent and preparation method thereof, and gas generator for vehicle safety airbag

ActiveCN108456126AImprove ignitabilityIncrease gas production ratePedestrian/occupant safety arrangementExplosive working-up apparatusStart timePotassium

The invention provides a gas generator ignition agent and a preparation method thereof, and a gas generator for a vehicle safety airbag. The gas generator ignition agent contains a fuel, an oxidant, abinder and an additive, wherein the additive is an oxazole-based energy-containing ionic compound. According to the present invention, by adding 5-aminotetrazole nitrate to a boron / potassium nitrateignition agent, on the basis of the ensuring of the combustion heat and the combustion temperature of the agent, the high-temperature and high-pressure gas amount can be increased, the output pressureof the ignition agent can be increased, and the output performance of the ignition pipe can be increased, such that the pressure starting time of the gas generator is advanced to less than 2 ms, andthe pressure value at 10 ms is increased by about 20 Kpa so as to improve the gas generating performance of the gas generator.

Owner:BYD CO LTD

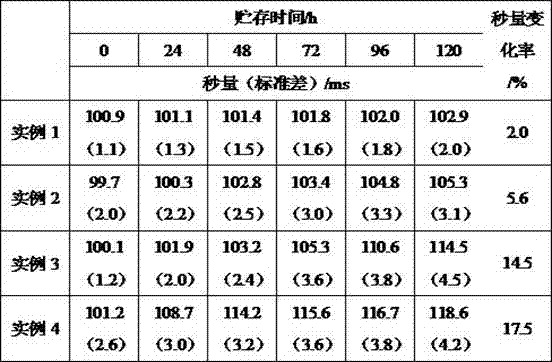

Preparation method of blasting delay composition

InactiveCN107188770AImprove adsorption capacityIncrease touch pointsExplosivesFusesPolyvinyl alcoholTitanium tetraisopropoxide

The invention discloses a preparation method of a blasting delay composition, and belongs to the technical field of preparation of blasting materials. The preparation method comprises the following steps: firstly, corroding silicon powder by utilizing corrosive acid liquid to form porous silicon powder; then modifying the porous silicon powder by utilizing dopamine to obtain modified porous silicon powder; then corroding and mixing by utilizing the acid liquid, and corroding red lead, so as to form porous red lead; modifying by utilizing the dopamine to prepare modified porous red lead; then mixing the modified porous silicon powder and the modified porous red lead with a barium nitrate solution, a polyvinyl alcohol solution and the like; generating barium sulfate sediment in a system by taking sodium sulfate as a precipitant; after ageing, filtering, washing and drying; then treating by utilizing nitrogen gas loaded with titanium isopropoxide and water-containing nitrogen gas in sequence to obtain the blasting delay composition. The blasting delay composition prepared by the preparation method has high delay precision and good storage stability, and a condition that the delay precision is drifted along storage time can be effectively avoided.

Owner:常州武城服饰有限公司

High-Pressure Explosive Retention Device

Owner:SCHLUMBERGER TECH CORP

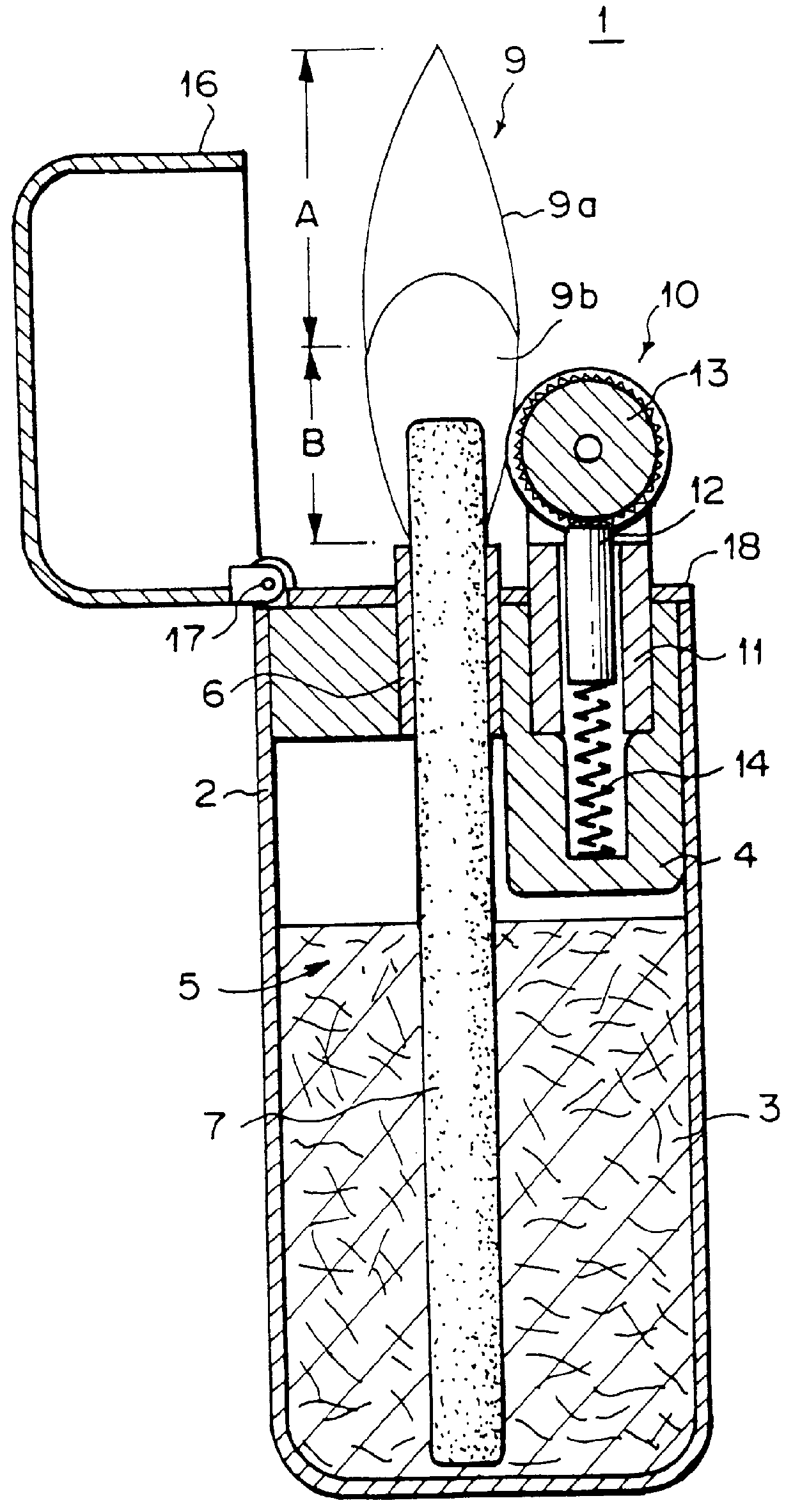

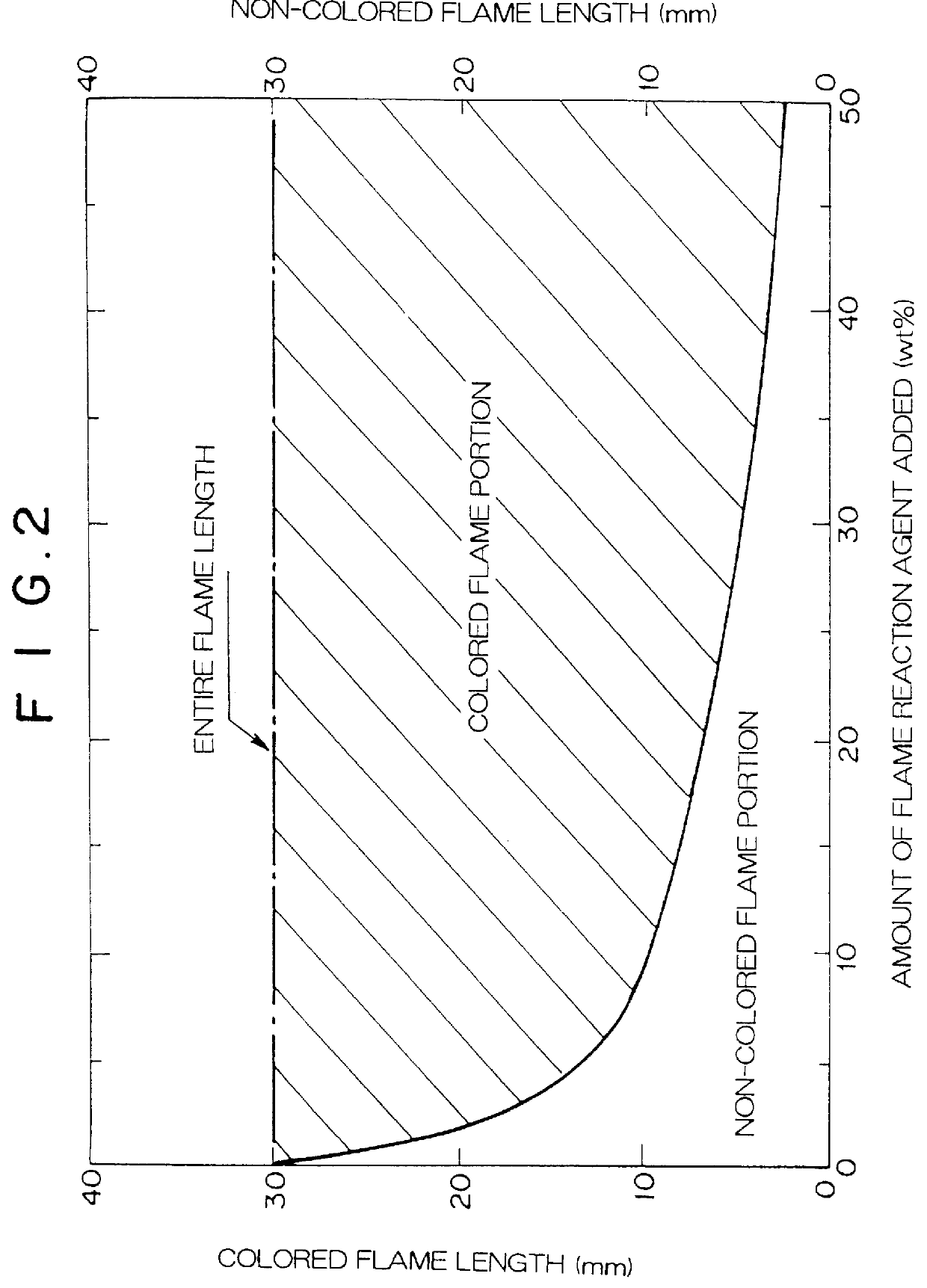

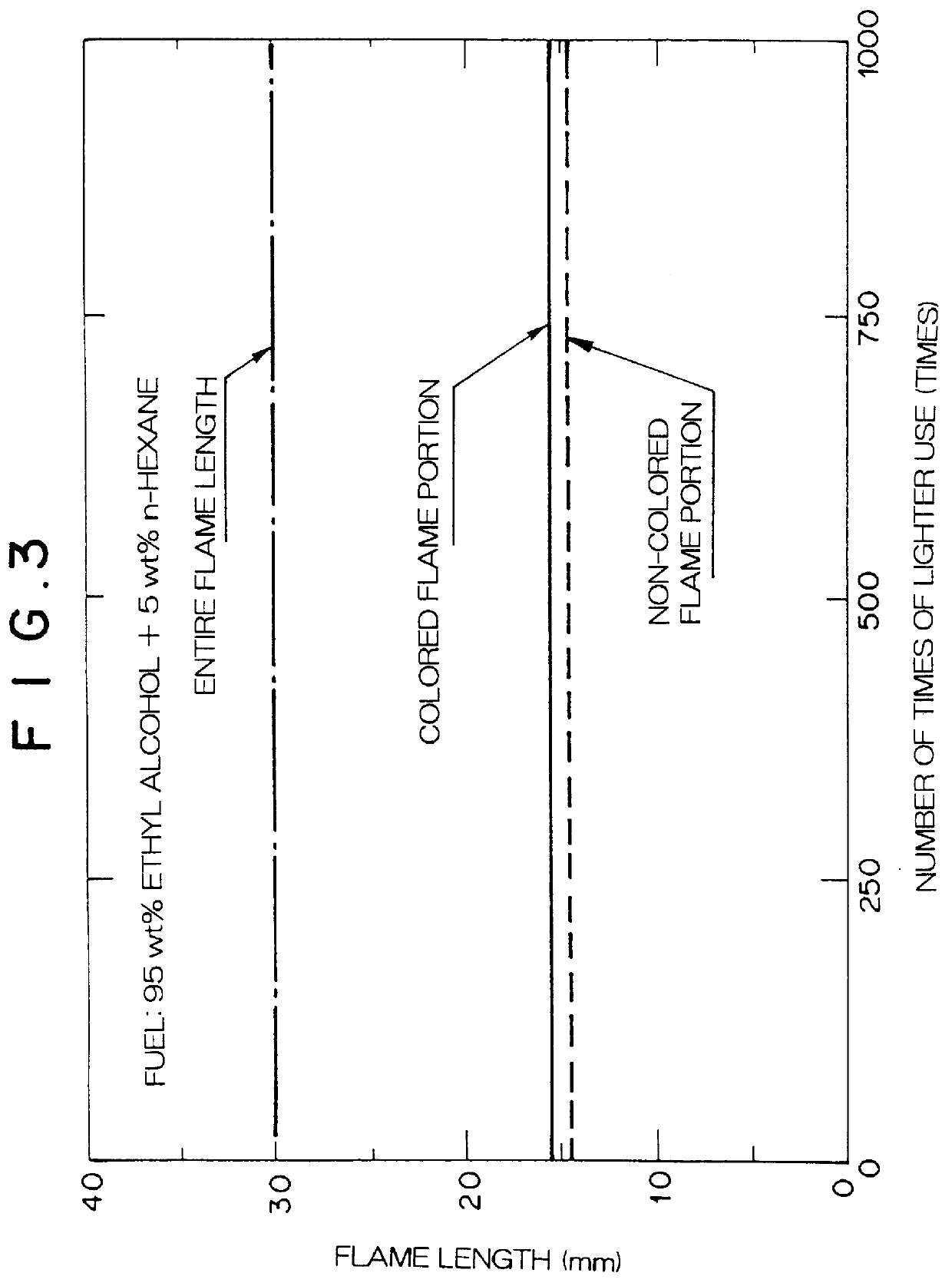

Liquid fuel for combustion appliances and combustion appliance using the same

InactiveUS6120566AEasily be perceived visuallyStable flame lengthGaseous fuelsCapillary burnersBoiling pointEngineering

PCT No. PCT / JP97 / 03119 Sec. 371 Date Jul. 23, 1998 Sec. 102(e) Date Jul. 23, 1998 PCT Filed Sep. 5, 1997 PCT Pub. No. WO98 / 11176 PCT Pub. Date Mar. 19, 1998A liquid fuel for combustion appliances, in which a combustion wick for sucking up the fuel by the utilization of capillarity is used, contains an alcohol as a principal constituent and contains a hydrocarbon compound, which has approximately the same boiling point as that of the principal constituent, as a flame reaction agent. By the addition of the flame reaction agent, which is not accompanied by the occurrence of clogging of the combustion wick, the combustion flame of an alcohol, which otherwise produces a colorless flame, is colored and its visual perceptibility is thereby enhanced, such that the structure of the combustion appliance may be kept simple and the flame stability may be obtained reliably.

Owner:TOKAI

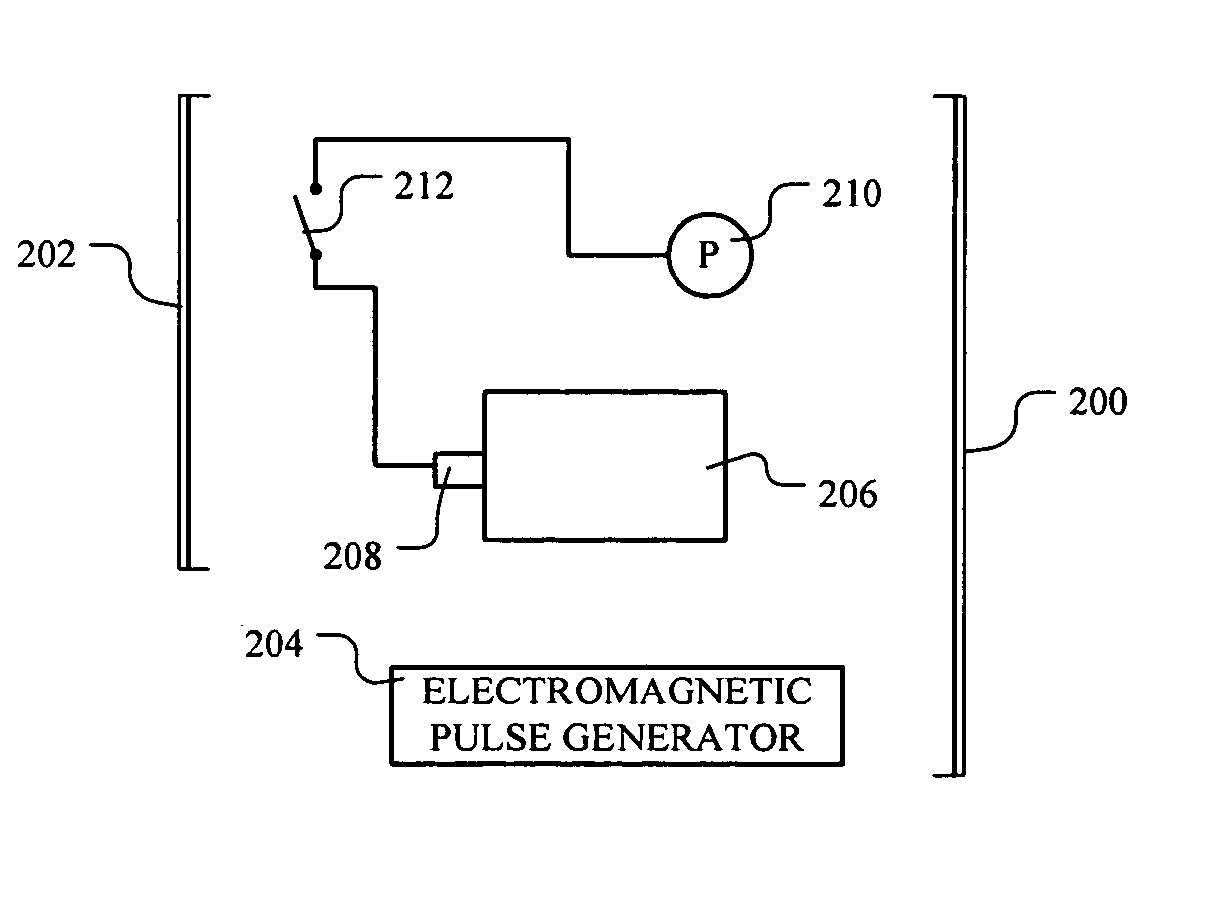

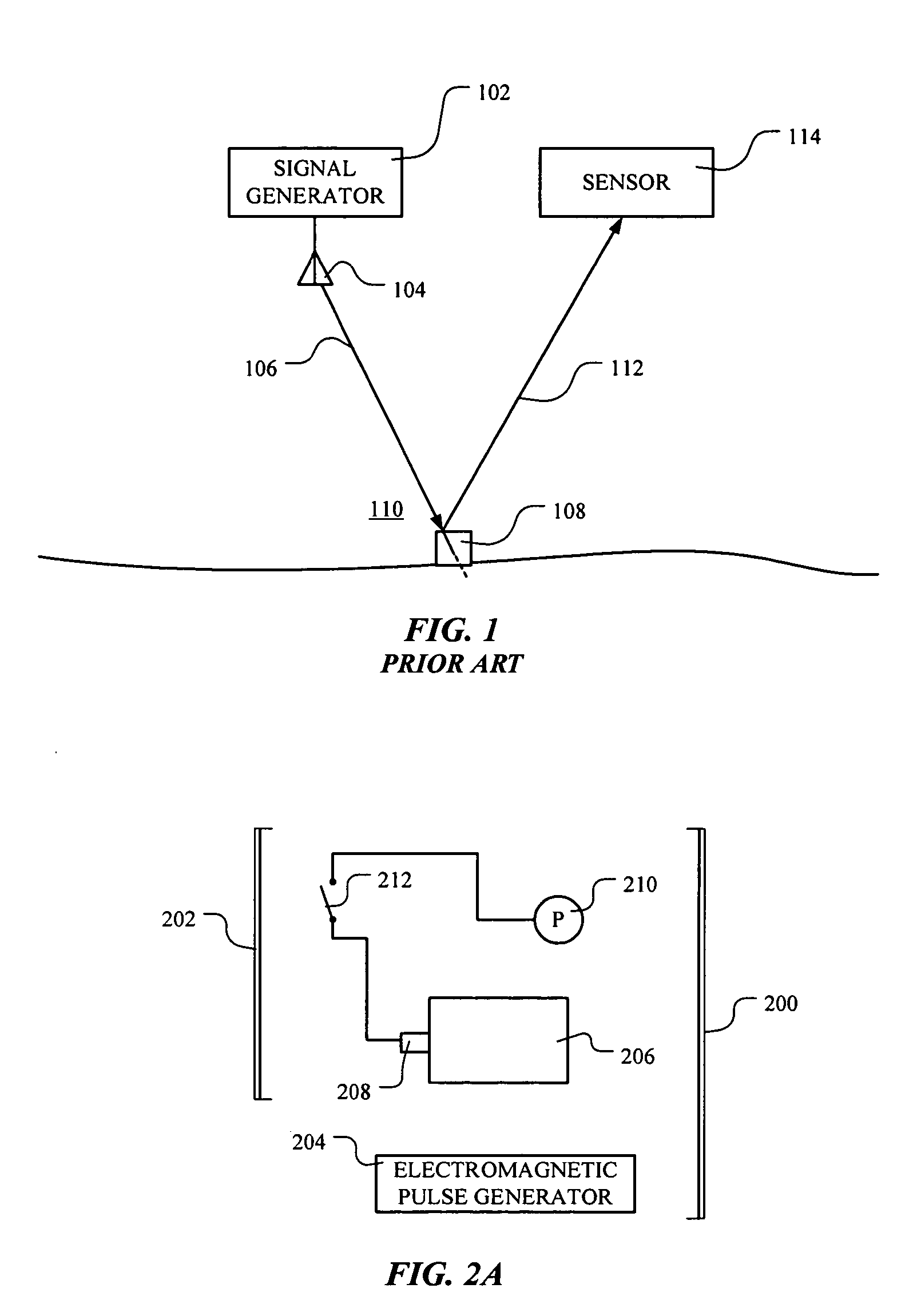

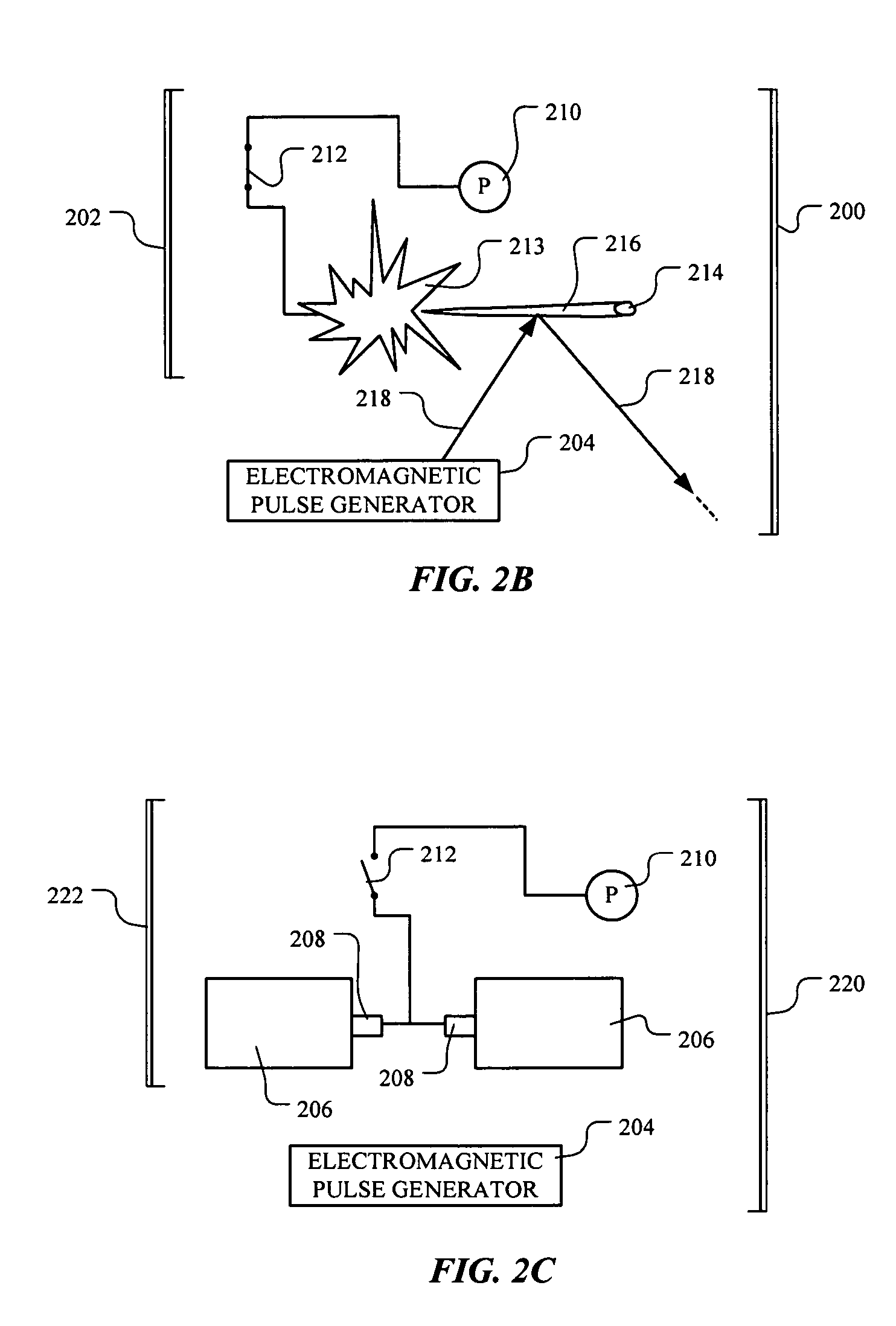

Electromagnetic pulse transmitting system and method

A plasma antenna generator includes an ionizable material, an explosive charge capable of projecting the ionizable material upon detonation, and a detonator coupled with the explosive charge. An electromagnetic pulse transmitting system includes an electromagnetic pulse generator and a plasma antenna generator capable of reradiating an electromagnetic pulse emitted from the electromagnetic pulse generator. A method includes providing an explosive device comprising an ionizable material, detonating the explosive device to propel the ionizable material, and ionizing the ionizable material to form at least one plasma trail. A sensing system includes an electromagnetic pulse generator, a plasma antenna generator capable of reradiating an electromagnetic pulse emitted from the electromagnetic pulse generator, and a sensing system capable of receiving and analyzing at least a portion of the electromagnetic pulse after being reflected from an interface.

Owner:LOCKHEED MARTIN CORP

Nontoxic, noncorrosive phosphorus-based primer compositions and an ordnance element including the same

A primer composition that includes red phosphorus having an acid scavenger and a polymer thereon. The primer composition includes at least one other component that is substantially free of lead. The other component is at least one oxidizer, or at least one oxidizer and at least one of at least one secondary explosive composition and at least one energetic binder. The primer composition optionally includes at least one element having an ionic charge to ionic radius ratio of 4 or of 8, such as magnesium, zirconium, aluminum, silicon, titanium, tungsten, alloys thereof, and combinations thereof. The red phosphorus and the at least one oxidizer are present in the primer composition at approximately stoichiometric amounts. An ordnance element including the primer composition is also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com