Preparation method of blasting delay composition

A technology of delaying charge and preparation steps, applied in the field of blasting delaying charge preparation, can solve the problems of delaying accuracy easily drifting with time, poor storage stability, etc., and achieve the effects of reducing porosity, reducing porosity and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

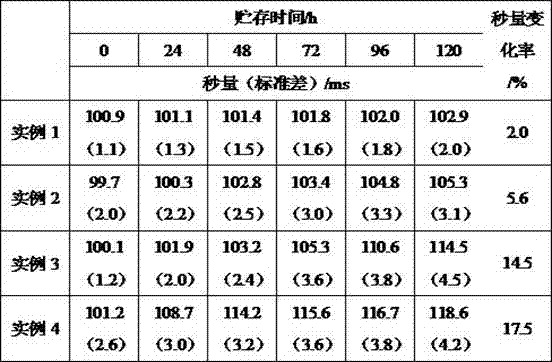

example 1

[0022]Pour silicon powder and corrosive acid solution into a beaker at a mass ratio of 1:30, then move the beaker into an ultrasonic oscillator, and oscillate ultrasonically for 2 hours at an ultrasonic frequency of 40kHz, then filter the material in the beaker to obtain a filter residue, and Wash with 10% hydrofluoric acid solution for 3 times and deionized water for 3 times, then move the filter residue after washing with deionized water into an oven, and dry it to constant weight at 105°C. Silicon powder, then mix porous silicon powder and dopamine solution with a mass concentration of 2g / L at a mass ratio of 1:60 for 30 minutes, then filter, wash and dry to obtain modified porous silicon powder; then mass ratio of 1: 40 Mix the red lead with the acid solution and move it into a magnetic stirrer with digital display speed measurement and constant temperature. Under the condition of temperature of 45°C and rotation speed of 300r / min, stir and react at constant temperature for...

example 2

[0024] Pour silicon powder and corrosive acid solution into a beaker at a mass ratio of 1:30, then move the beaker into an ultrasonic oscillator, and oscillate ultrasonically for 2 hours at an ultrasonic frequency of 40kHz, then filter the material in the beaker to obtain a filter residue, and Wash with 10% hydrofluoric acid solution for 3 times and deionized water for 3 times, then move the filter residue after washing with deionized water into an oven, and dry it to constant weight at 105°C. Silica powder; then mix the lead red and the acid solution according to the mass ratio of 1:40, then move it into a digital display speed measuring constant temperature magnetic stirrer, under the condition of temperature 45 ℃ and speed 300r / min, stir and react at constant temperature for 30min, and then filter , washing and drying, porous red lead; in parts by weight, 200 parts of mass fraction are added successively in the reactor to be 12% barium nitrate solution, 100 parts of mass fra...

example 3

[0026] Pour silicon powder and corrosive acid solution into a beaker at a mass ratio of 1:30, then move the beaker into an ultrasonic oscillator, and oscillate ultrasonically for 2 hours at an ultrasonic frequency of 40kHz, then filter the material in the beaker to obtain a filter residue, and Wash with 10% hydrofluoric acid solution for 3 times and deionized water for 3 times, then move the filter residue after washing with deionized water into an oven, and dry it to constant weight at 105°C. Silicon powder, then mix porous silicon powder and dopamine solution with a mass concentration of 2g / L at a mass ratio of 1:60 for 30 minutes, then filter, wash and dry to obtain modified porous silicon powder; then mass ratio of 1: 40 Mix the red lead with the acid solution and move it into a magnetic stirrer with digital display speed measurement and constant temperature. Under the condition of temperature of 45°C and rotation speed of 300r / min, stir and react at constant temperature fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com