Patents

Literature

258 results about "Titanium tetraisopropoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium isopropoxide, also commonly referred to as titanium tetraisopropoxide or TTIP, is a chemical compound with the formula Ti{OCH(CH3)2}4. This alkoxide of titanium(IV) is used in organic synthesis and materials science.

Carbon nitride/titanium dioxide nanosheet array heterojunction photocatalyst and preparation method

InactiveCN106944116AImprove photocatalytic hydrogen production activityImprove photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionDiethylenetriamine

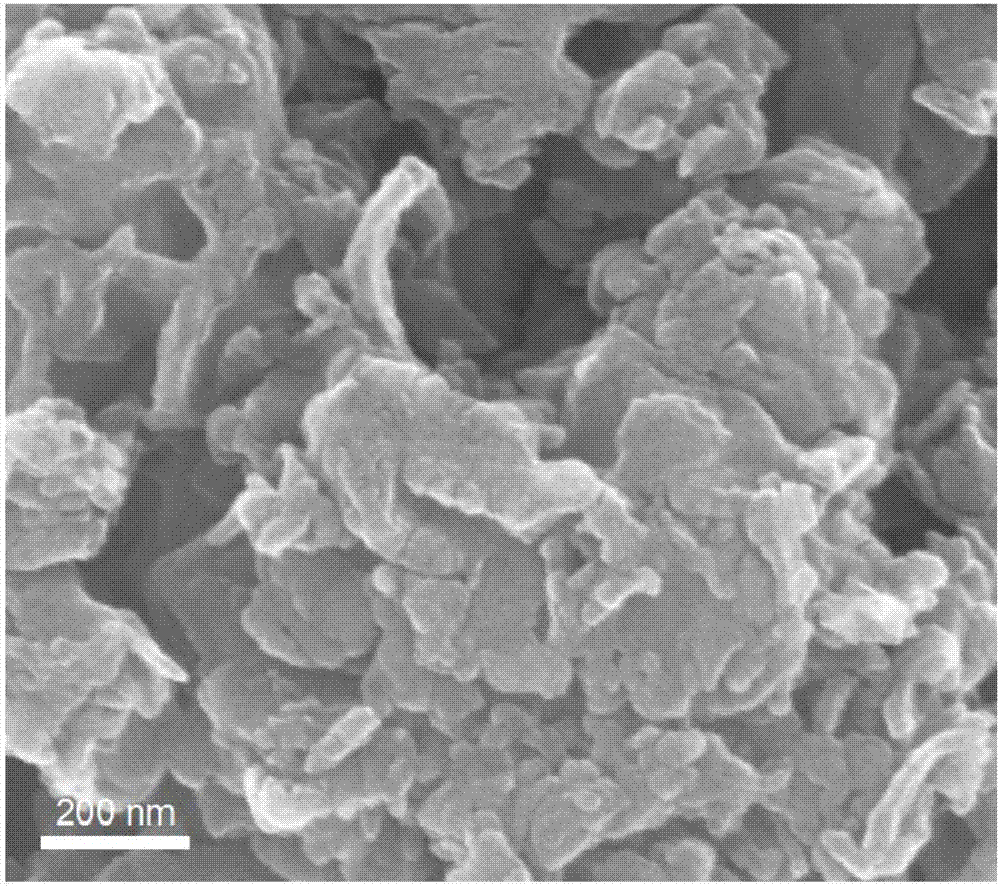

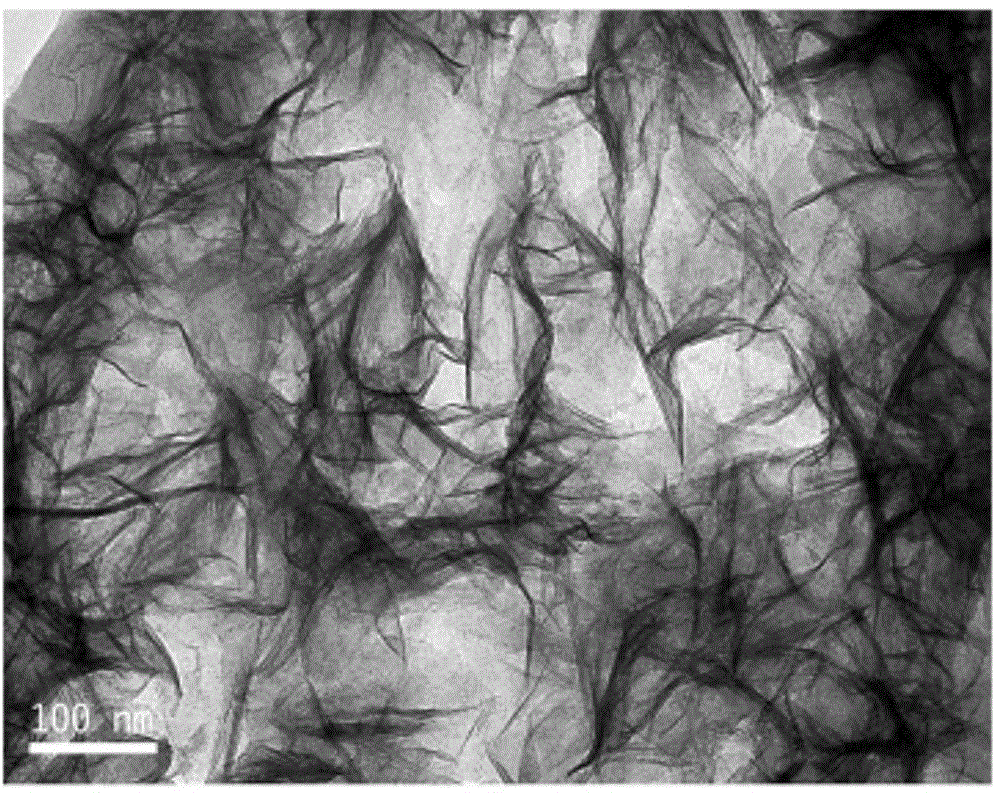

The invention relates to a carbon nitride / titanium dioxide nanosheet array heterojunction photocatalyst and a preparation method, belonging to the technical field of photocatalysis of nanometer materials. The catalyst is prepared through the following steps: with g-C3N4 as a carrier, titanium isopropoxide as a titanium source, diethylenetriamine as a morphology controlling agent and isopropanol as a solvent, performing a solvothermal method so as to prepare a g-C3N4 / TiO2 precursor, and carrying out calcination treatment so as to obtain a g-C3N4 / TiO2 nanosheet array heterojunction composite photocatalyst for the first time. The heterojunction composite photocatalyst shows pure and significantly-improved photocatalytic hydrogen production activity to g-C3N4 and anatase TiO2 nanosheet mesoporous spheres in a photocatalytic hydrogen production reaction. The preparation method has the advantages of simple and convenient operation, easy control, greenness, environmental protection and good application prospects. The series of catalysts has multilevel structure; and a g-C3N4 / TiO2 nanosheet array heterojunction structure is formed through vertical and staggered growth of anatase TiO2 nanosheets with regular shape and uniform size on the surface of g-C3N4. The catalyst has excellent photocatalytic hydrogen production activity, good stability, high repeatability and facilitation large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

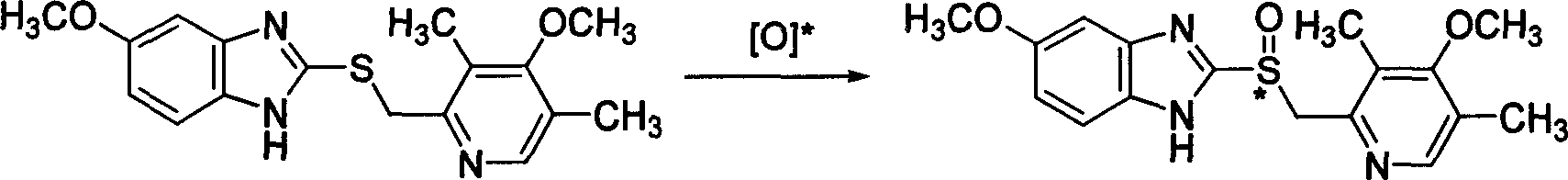

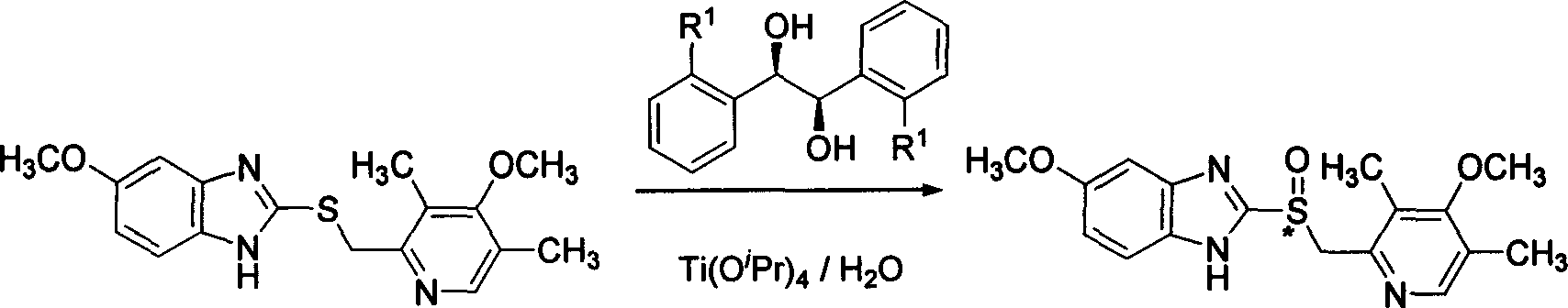

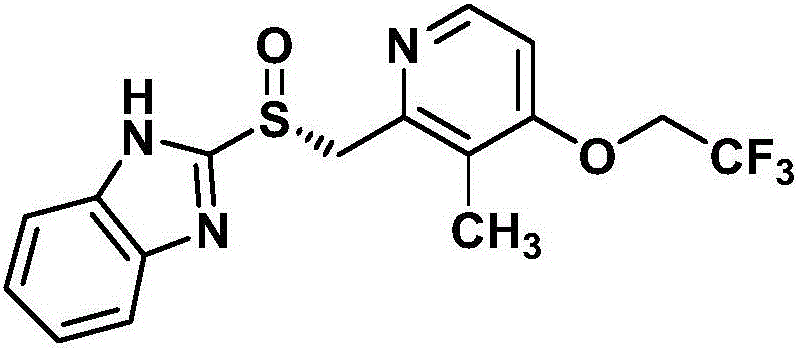

Selective prepn process of (S)-Omeprazole with high antimer

The present invention relates to antimer selective catalytic oxidation process for preparing optical active antimer or optically pure antimer (S)-omeprazole. In the presence of the titanium containing catalyst in-situ created with metal titanium reagent and chiral glycol ligand and the oxidant, omeprazole sulfide is catalytically oxidized with antimer. Compared with the process utilizing tetraisopropanol titanium-diethyl tartrate system, the process of the present invention has the advantages of cheap material, high antimer selectivity and high yield. The present invention also relates to the preparation of (S)-omeprazole in neutralized state, partial crystallized state or completely crystallized state.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

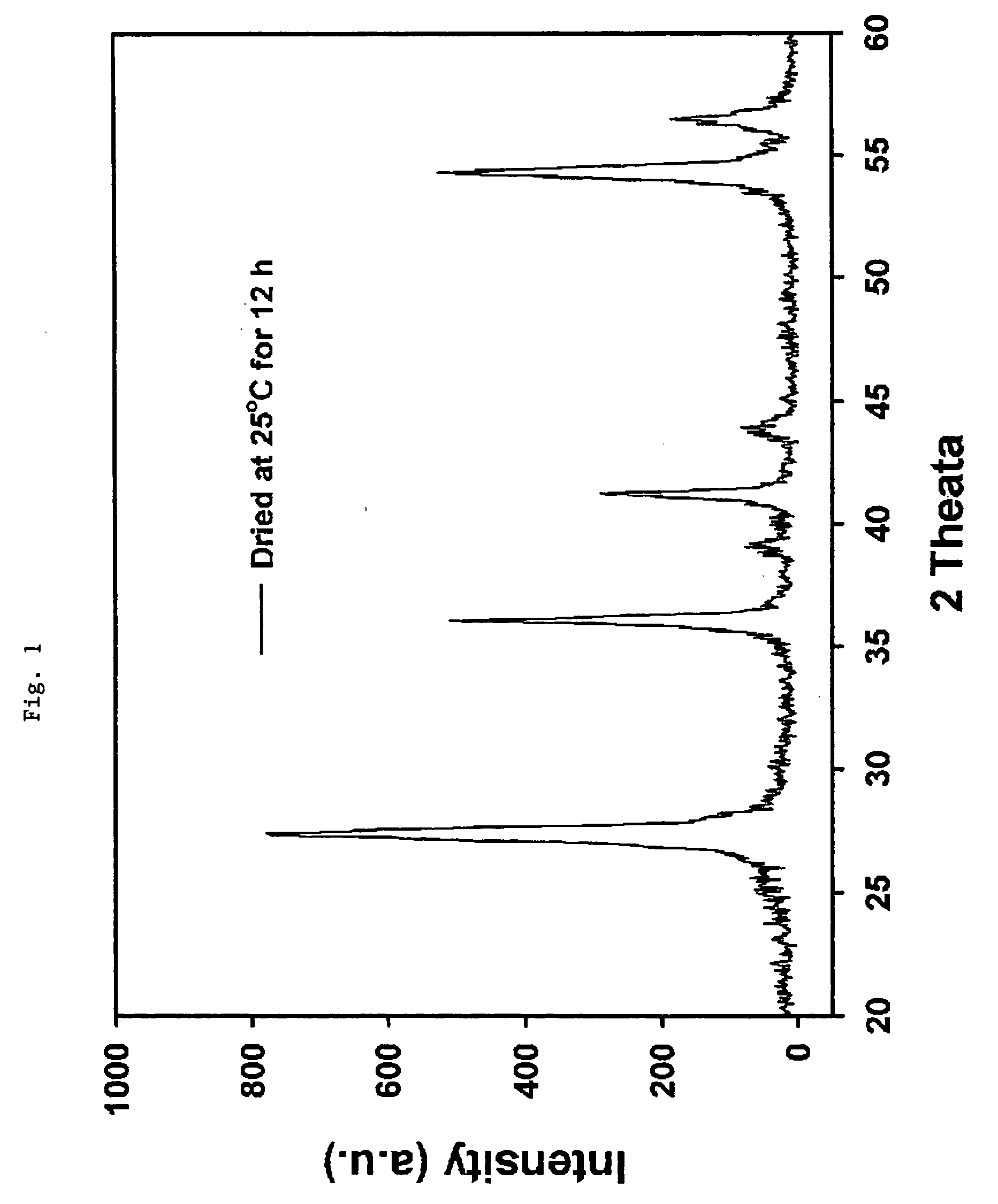

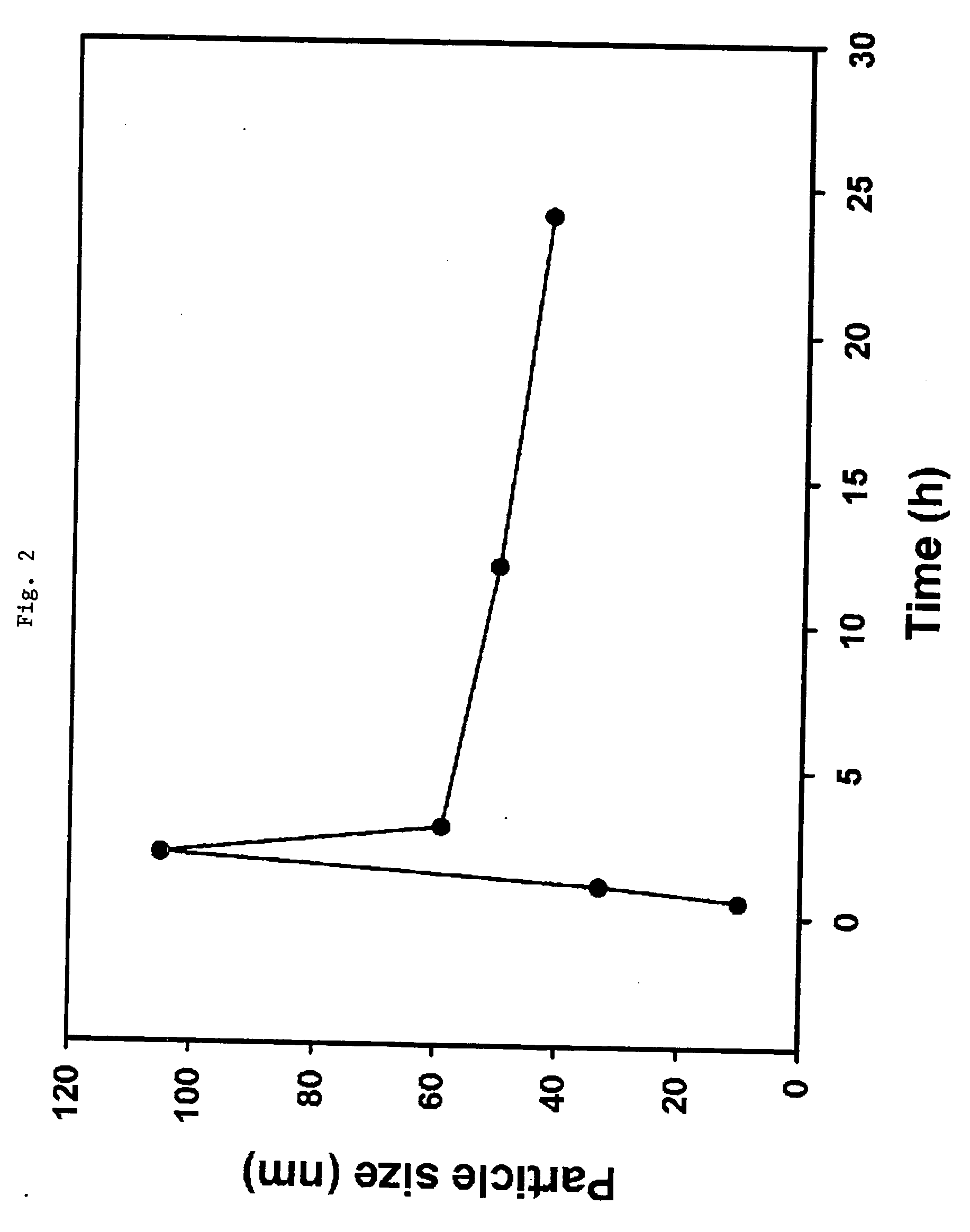

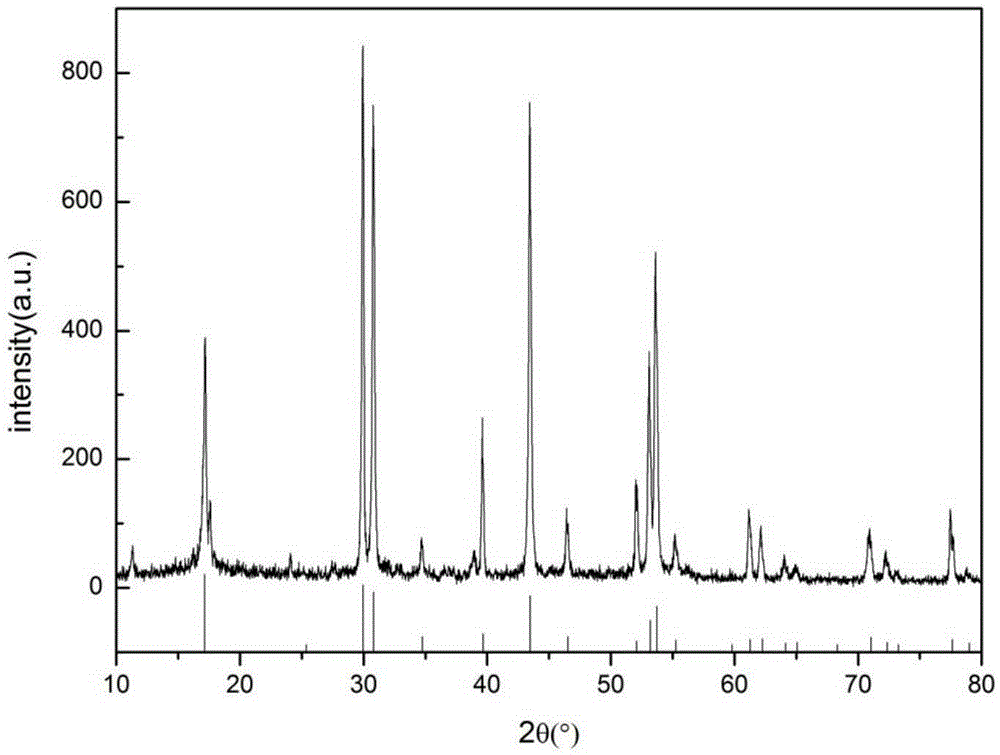

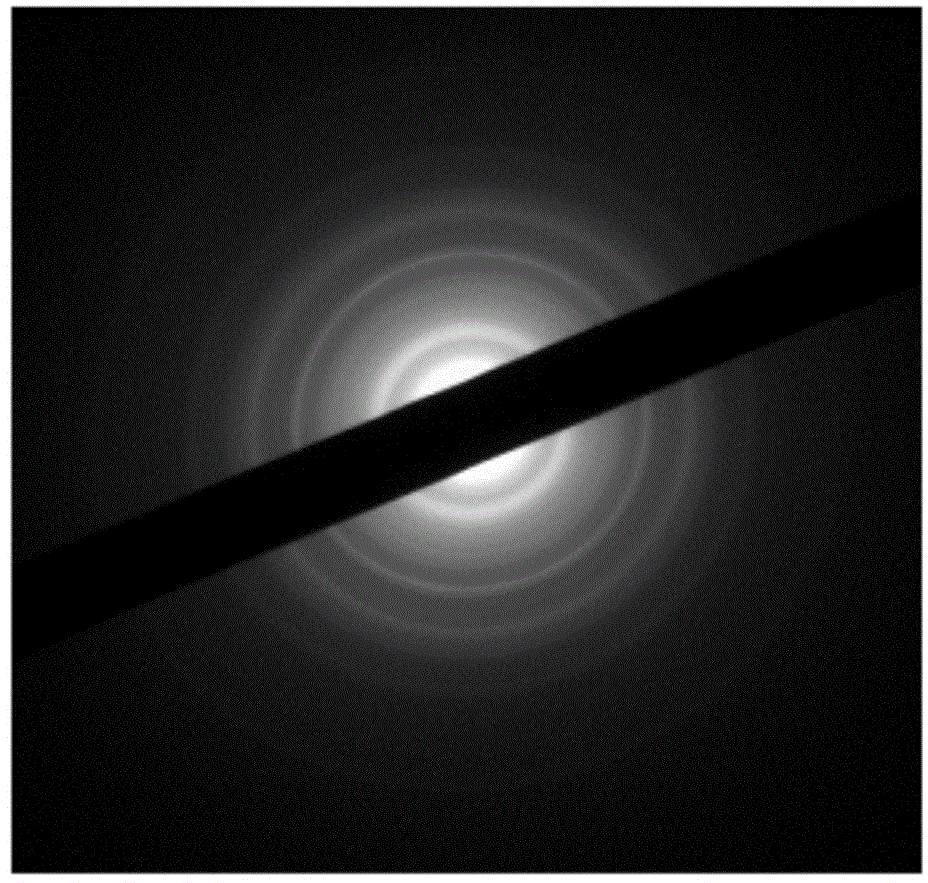

Rutile titania nano sols and process for manufacturing the same

InactiveUS20060110319A1Material nanotechnologyNanostructure manufactureTitanium tetraisopropoxideHydrolysis

The present invention is related to a process of manufacturing rutile high-purity titania nano sols in a pure aqueous medium having no ionic impurities. In more detail, the present invention is related to a process for manufacturing titania nano sols, in which high-purity rutile titania nano particles are dispersed stably, through the hydrolysis of titanium tetraisopropoxide in an aqueous solution containing hydrogen peroxide (H2O2), and simultaneously with the hydrolysis, formation of peroxotitanate precursors, and hydrothermal treatment of them at 50-120° C.

Owner:KOREA RES INST OF CHEM TECH

Method for performing surface modification on polytetrafluoroethylene separation membrane

InactiveCN102423645AImprove surface propertiesHigh retention rateSemi-permeable membranesWater vaporReaction temperature

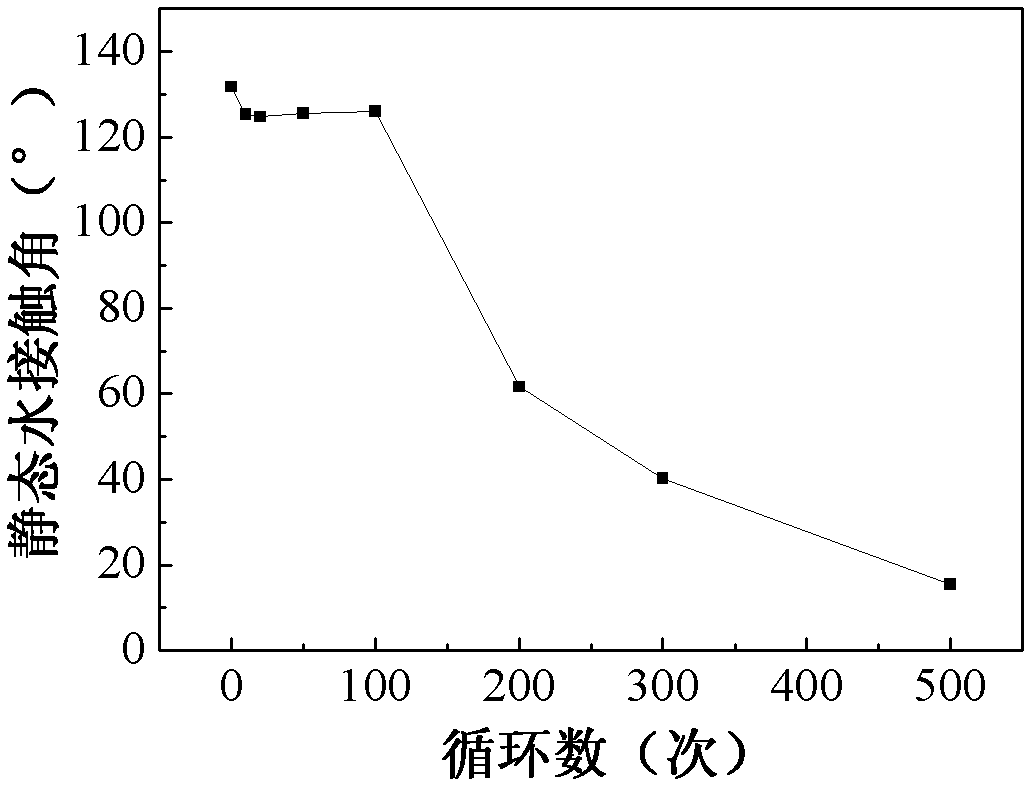

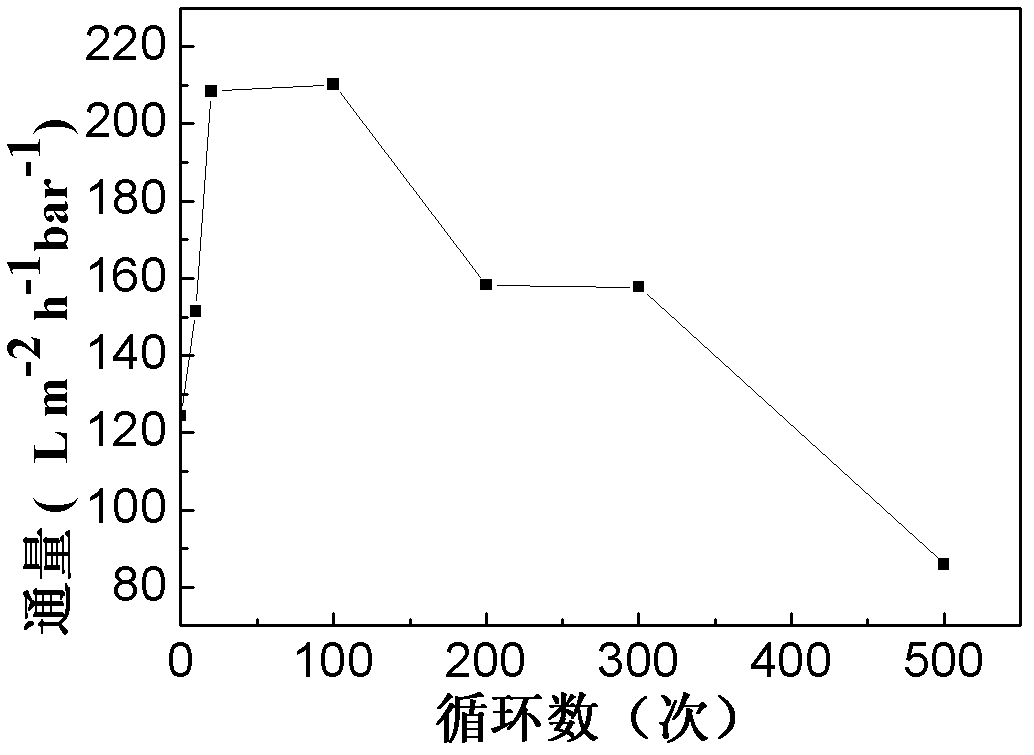

The invention relates to a method for performing surface modification on a polytetrafluoroethylene (PTFE) separation membrane, belongs to the field of membrane materials, and solves the problems of poor hydrophilicity, small flux, high probability of pollution and complex modification process existing in the polytetrafluoroethylene separation membrane. In the method, an oxide thin layer is continuously deposited on the surfaces of PTFE separation membrane pore paths by using an atomic layer deposition technology, so that precise adjustment and control over the aperture and the surface property of the separation membrane are realized. The method mainly comprises the following specific steps of: (1) controlling certain reaction temperature, and keeping the membrane into a reaction chamber for a period of time; (2) sequentially introducing trimethyl aluminum, titanium tetrachloride or titanium isopropoxide, cleaning gas and vapor or ozone and cleaning gas into the reaction chamber; and (3) preparing an organic / inorganic composite membrane with different cycle indexes according to requirements. By using the method, the hydrophilicity, the pure water flux and the anti-pollution capacity of the PTFE separation membrane are greatly improved; the method has a simple process; and the property is kept for a long time.

Owner:NANJING UNIV OF TECH

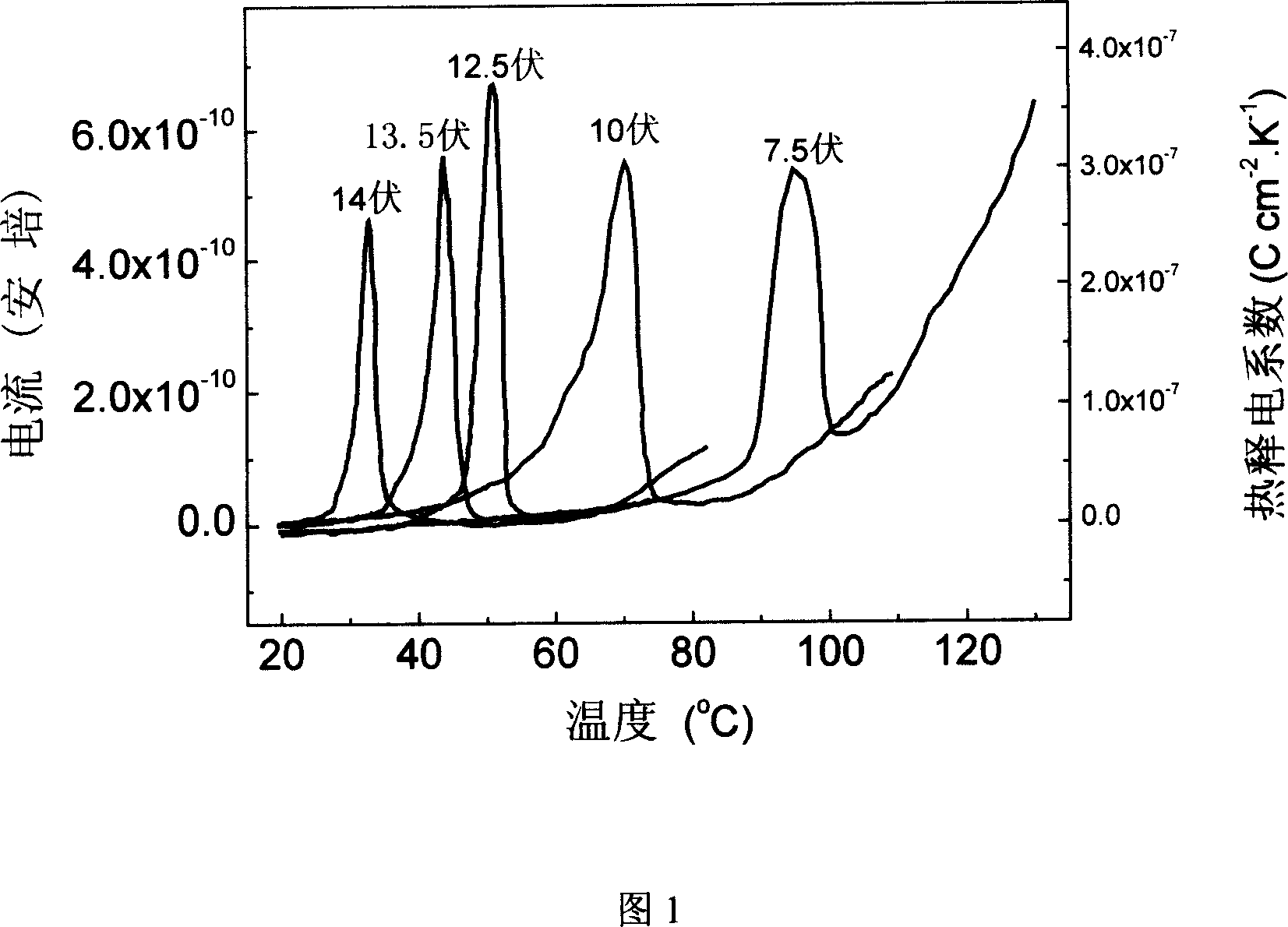

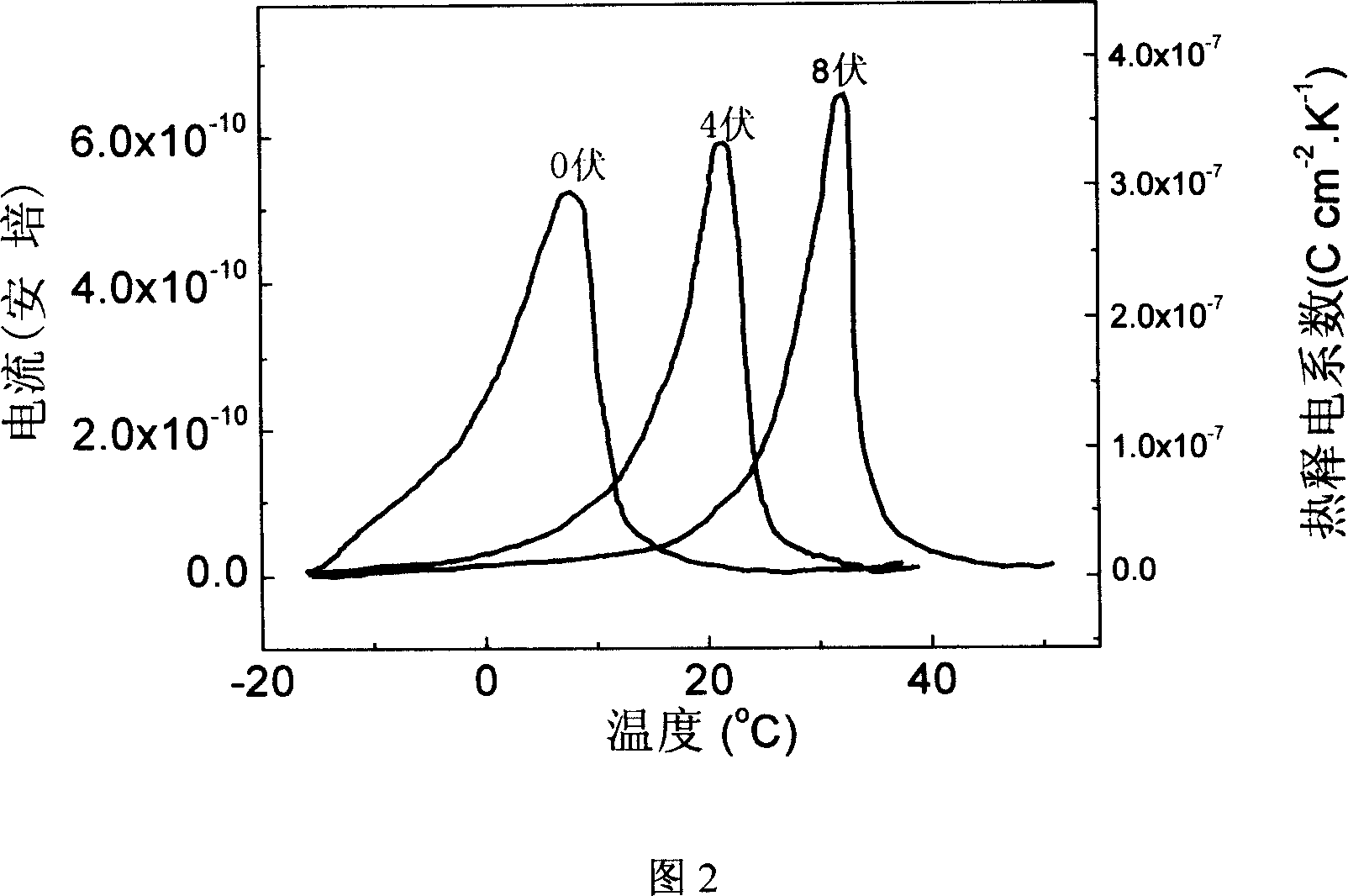

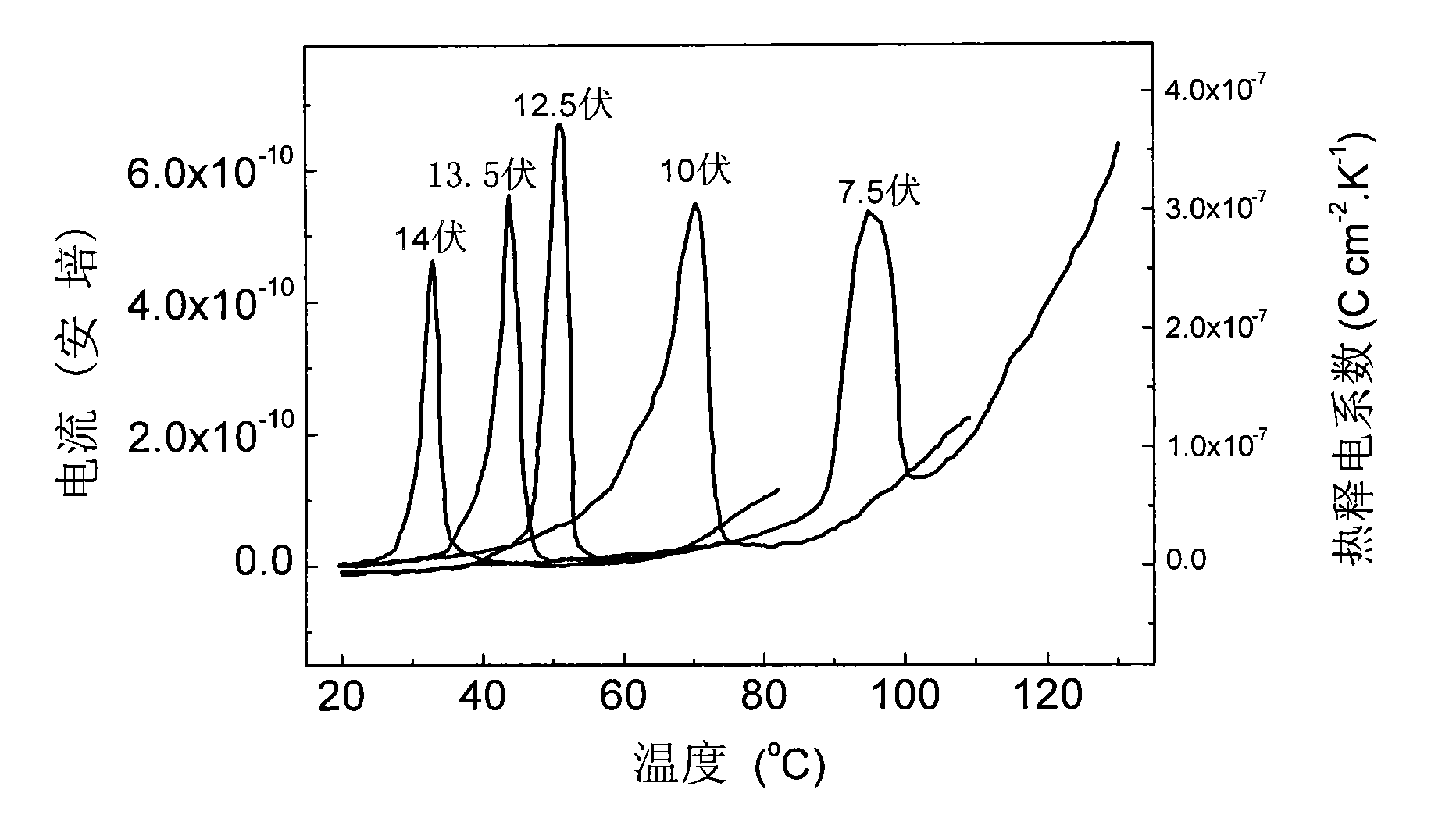

Anti-ferroelectric thin film used as thermoelectrical material and preparing method and use thereof

InactiveCN1990418AAdjust working temperatureHigh sensitivityPhotometry using electric radiation detectorsPyrometry using electric radation detectorsPyroelectric detectorsFerroelectric thin films

The invention discloses an anti-ferroelectric membrane with adjustable working temperature area and large heat-releasing rate, and the method for preparing the same and its application. It applies sol-gel method to prepare said anti-Ferroelectric membrane ((Pb, La or Nb) (Zr, Sn, Ti) O3, the solute of precursor comprises acetate lead, the acetate lanthanum or ethanol nb, acetate tin, zirconium iso-propoxide and titanium iso-propoxide; the solvent comprises acetic acid, glycol ethylene ether and water; the final concentration of precursor is controlled between 0.2-0.4 M. the bed piece is LaNiO3 / Pt / Ti / SiO2 / Si and Pt / Ti / SiO2 / Si. The product is mainly used for infrared heat-releasing electrical detector, smart device and system.

Owner:TONGJI UNIV

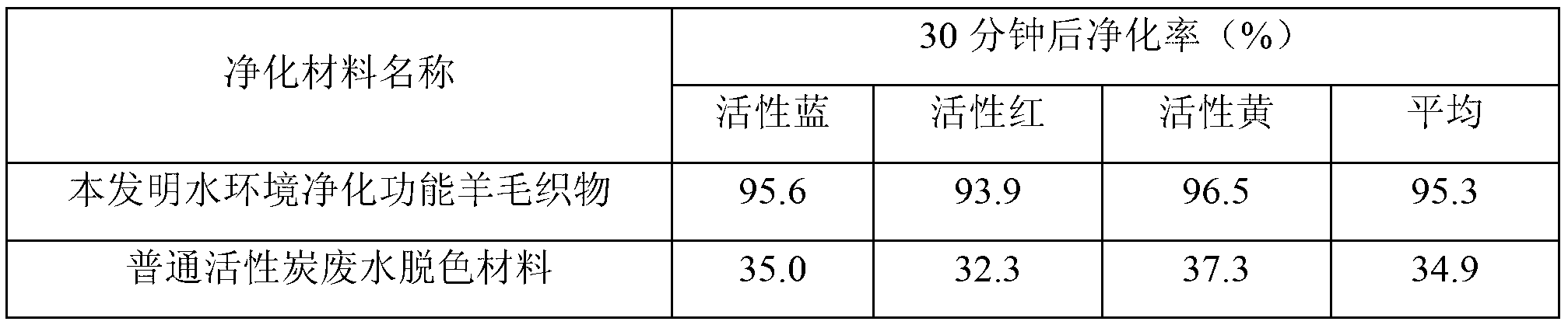

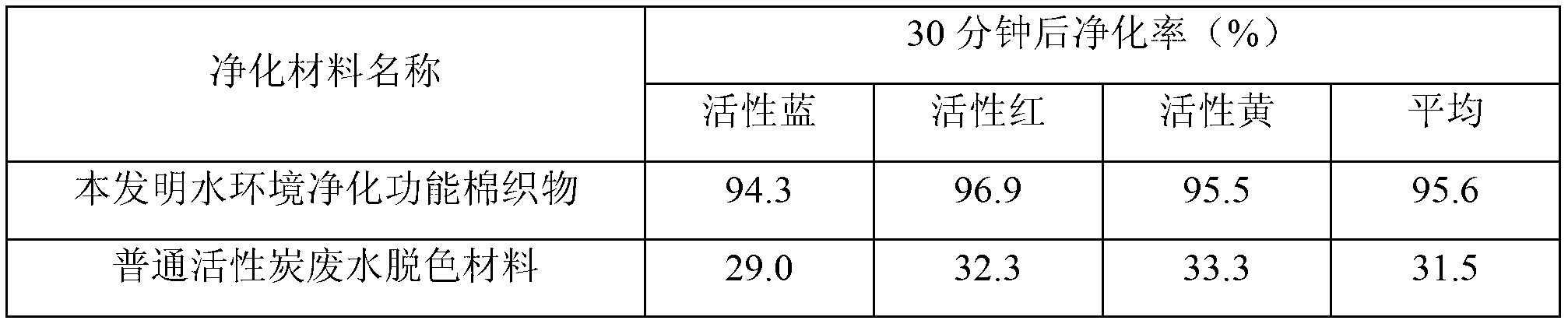

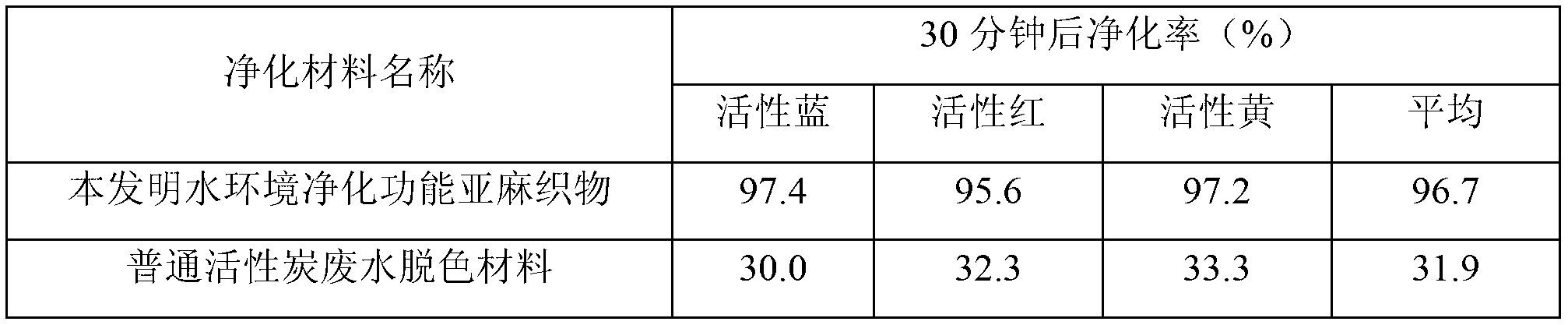

Preparation method of multi-phase heterogeneous visible light catalysis functional fabric

InactiveCN103194886AImprove pollutionSolve pollutionVegetal fibresMetal/metal-oxides/metal-hydroxide catalystsDyeing wastewaterPollution

The invention relates to a preparation method of a multi-phase heterogeneous visible light catalysis functional fabric. The preparation method comprises the following steps of: (1) washing a fabric; (2) dropwise adding titanium tetraisopropoxide to deionized water, and heating the solution to 60-80 DEG C to react for 1-2 hours to obtain a solution A; (3) adding bismuth nitrate into a nitric acid solution and dropwise adding a wetting agent and a metal chelator to the solution to obtain a solution B; (4) adding metavanadate to the deionized water, heating the solution to 50-60 DEG C, and stirring the solution to obtain a solution C; (5) adding the solution B and the solution C to the solution A in sequence for reacting for 2-3 hours, and adjusting the pH of the solution mixture to alkalinity to obtain a heterogeneous photocatalyst finishing solution D; and (6) dipping the washed fabric to the finishing solution D, heating the finishing solution to 70-90 DEG C for reacting for 6-8 hours, and drying the fabric to obtain the multi-phase heterogeneous visible light catalysis functional fabric. The preparation method is simple and free of secondary pollution; and the functional fabric can be used for effectively purifying dyeing wastewater and air pollution under visible light irradiation.

Owner:DONGHUA UNIV +1

Ordered mesoporous polyoxometallate-titanium dioxide composite and preparation method

InactiveCN101612589ANo decrease in activityWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryTitanium tetrachloride

An ordered mesoporous polyoxometallate-titanium dioxide composite and a preparation method belong to the chemical industry field. The composite comprises the following formula: H3PW12O40 / TiO2. The preparation method combines such technologies as sol-gel chemistry, template self-assembly and programmed temperature hydrothermal treatment, etc. The method takes H3PW12O40 as an inorganic former body, a mixture of purity titanium tetraisopropoxide (TTIP) and titanium tetrachloride (TiCl4) as a titanium source and a nonionic surfactant (Pluronic P123) with structure of HO (CH2CH2O)20(CH2CH(CH3)O)70(CH2CH2O)20H) as a structure-guiding agent. The improvement effect of the catalytic property of the composite is very obvious and the life of the catalyst is prolonged.

Owner:NORTHEAST NORMAL UNIVERSITY

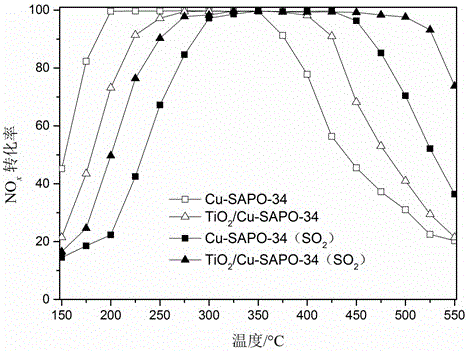

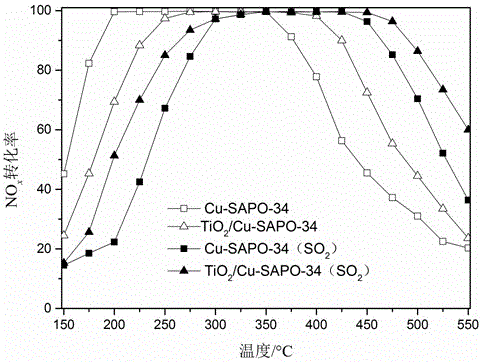

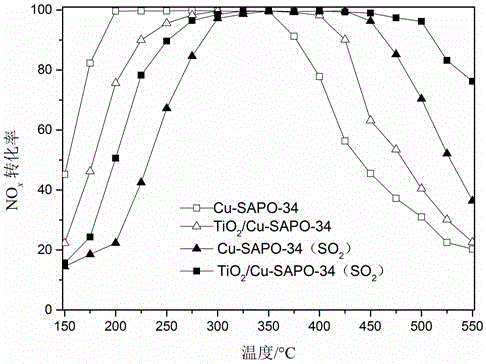

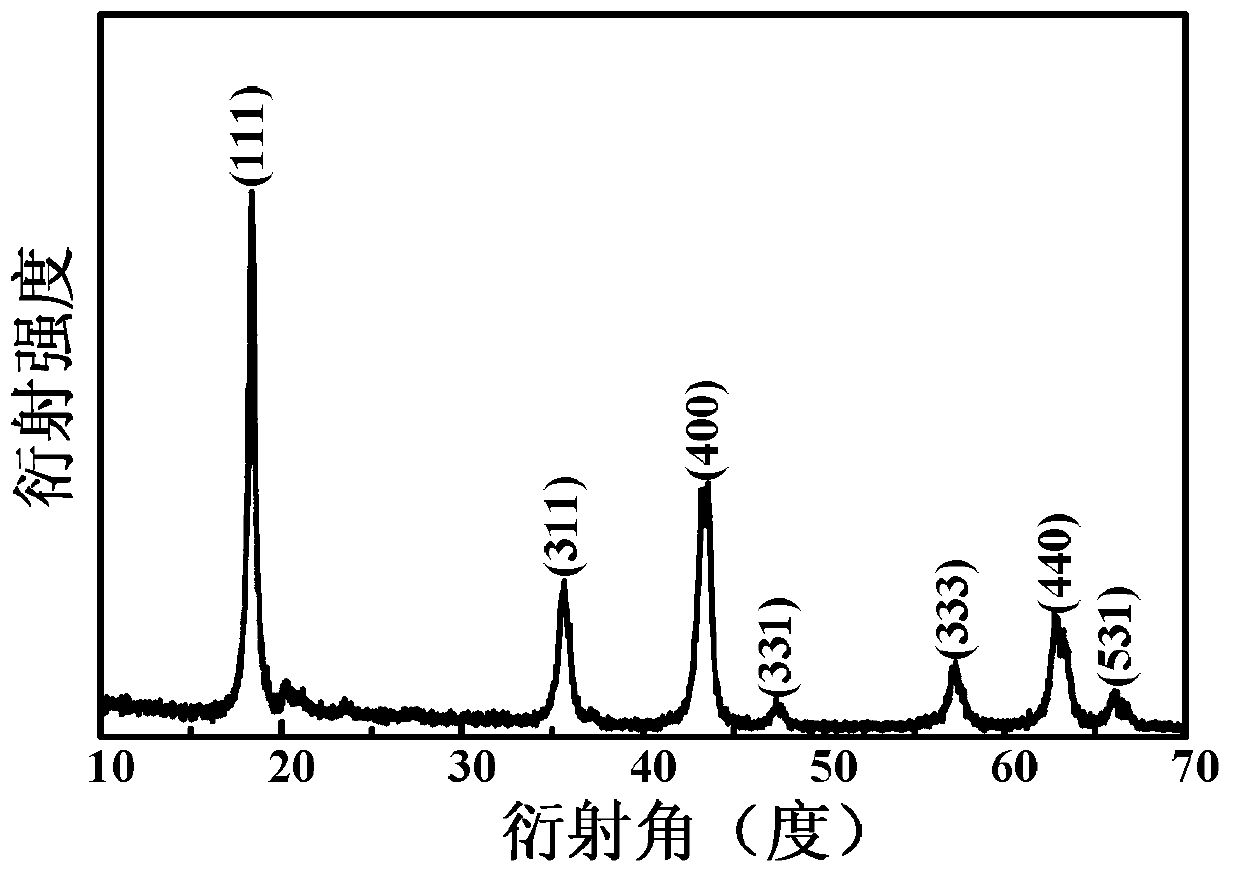

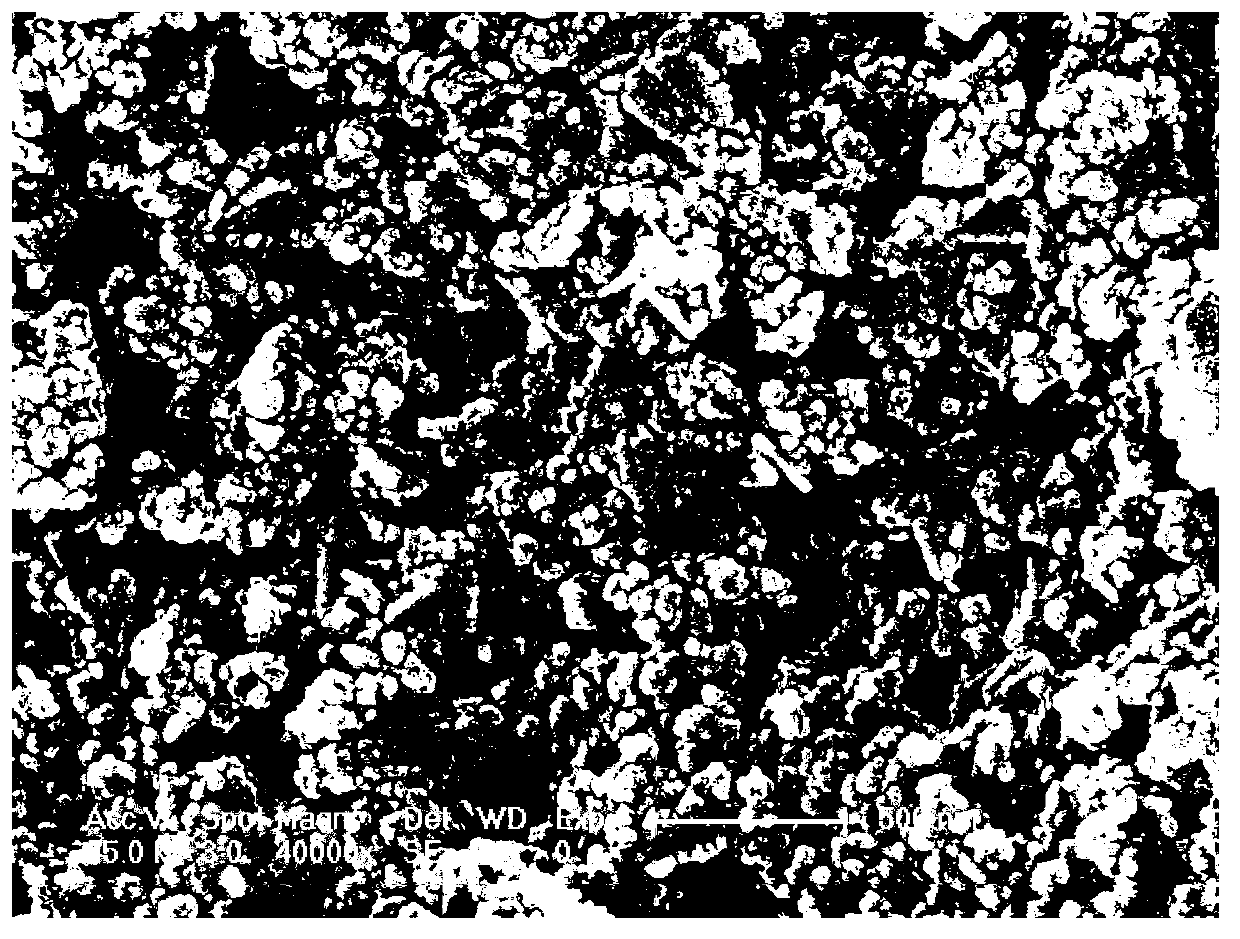

Preparation method of low-temperature NH3-SCR sulfur-resistant denitration catalyst

InactiveCN105944755AImprove purification efficiencyImprove sulfur resistanceMolecular sieve catalystsDispersed particle separationTitanium tetraisopropoxideSulfur

The invention discloses a preparation method of a low-temperature NH3-SCR sulfur-resistant denitration catalyst. The preparation method is characterized in that titanium tetrachloride, titanium(IV) isopropoxide, isopropyl titanate and butyl titanate are used as the titanium sources of the sulfur-resistant denitration catalyst, and a chemical vapor deposition method or aqueous phase method to precipitate a TiO2 sulfur-resistant layer on the surface of a Cu-SAPO-34 catalyst or wrap the surface of the Cu-SAPO-34 catalyst with the TiO2 sulfur-resistant layer so as to form a TiO2 / Cu-SAPO-34 compound catalyst. The prepared catalyst keeps the low-temperature high-activity feature of the Cu-SAPO-34 catalyst and adopts the TiO2 sulfur-resistant layer to evidently enhance of the sulfur resistance. At 300-500 DEG C, SO2 (100-500ppm) is fed into a reaction system, and the conversion rate of NOx in the NH3-SCR reaction is above 80%. Compared with a common catalyst, the compound catalyst is wider in temperature operation window, excellent in low-temperature activity and high in sulfur resistance.

Owner:KUNMING UNIV OF SCI & TECH

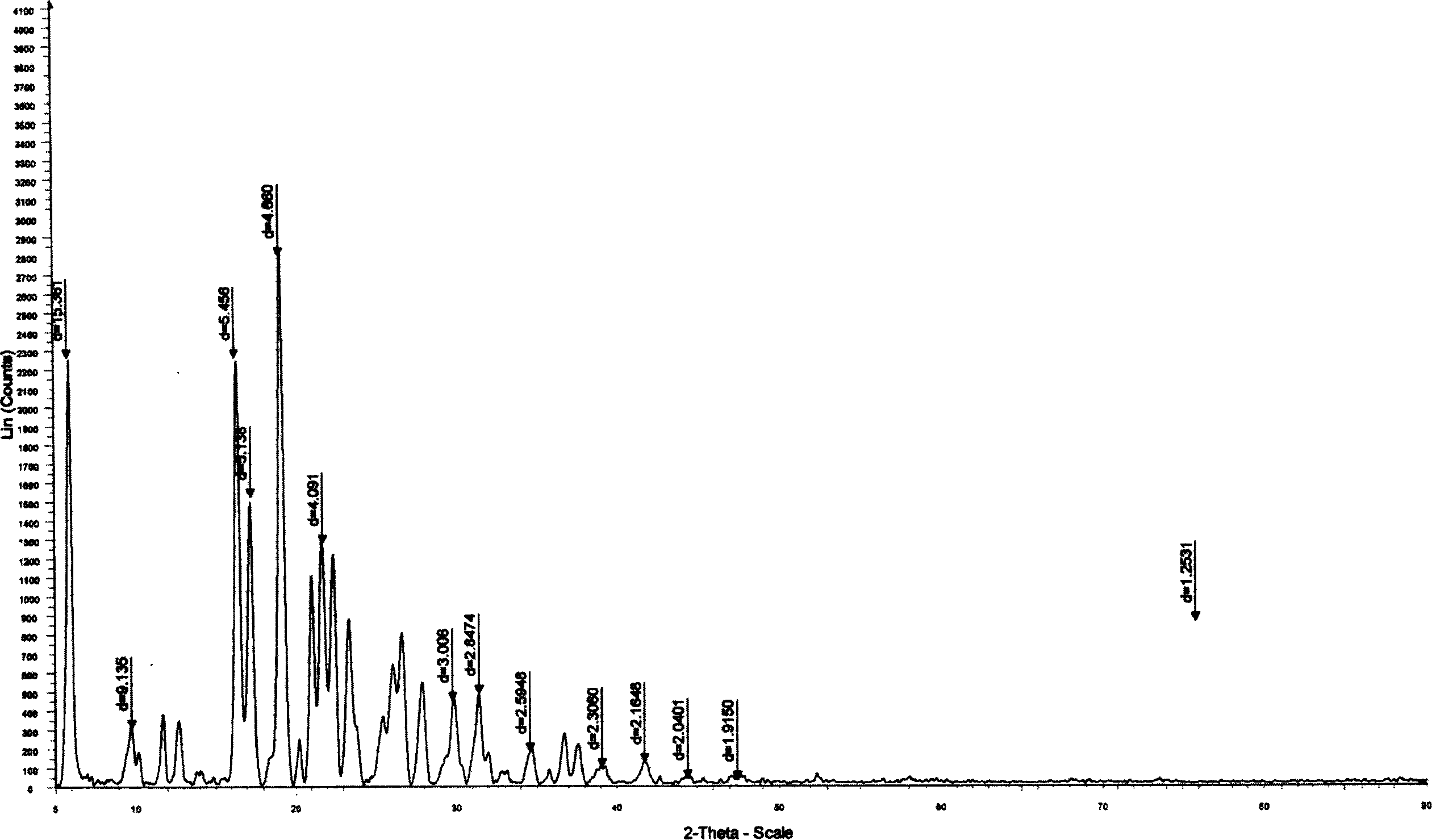

Hydrothermal synthesis method of micro-emulsion of nano lithium titanate

InactiveCN103274454AHigh crystallinityEffective control of particle sizeCell electrodesTitanium compoundsLithium hydroxideHigh pressure

The invention discloses a hydrothermal synthesis method of a micro-emulsion of nano lithium titanate. According to the method disclosed by the invention, the micro-emulsion is prepared from cetyltrimethylammonium bromide, n-hexanol, cyclohexane and a water phase, and tetrabutyl titanate and lithium hydroxide are used as reaction materials. The method comprises the steps of: (1) preparing the 0.02-2.0 mol / L lithium hydroxide micro-emulsion and 0.025-2.5 mol / L titanium tetraisopropoxide micro-emulsion respectively; and (2) mixing the micro-emulsions in two concentrates, stirring for 5-120 minutes at the room temperature, then transferring a mixture into a 50 ml high-pressure reactor which is lined with polytetrafluoroethylene, carrying out hydrothermal reaction at the temperature of 60-240 DEG C for 1-70 hours, and then carrying out centrifugal separation, washing, drying and thermal treatment on a reactant to obtain spinel type lithium titanate. The method has the characteristics of controllable grain size, controllable morphology, simple process, simple equipment and the like.

Owner:JILIN UNIV

Preparation and application method of titanium dioxide loaded highly dispersed platinum composite photocatalytic material

InactiveCN106238043APromote degradationGood dispersionWater/sewage treatment by irradiationWater contaminantsDispersityOrganic dye

The invention discloses a preparation and application method of a titanium dioxide loaded highly dispersed platinum composite photocatalytic material, and belongs to the field of titanium dioxide photocatalysis. The preparation method comprises following steps: tetrabutyl titanate and hydrofluoric acid are stirred to be uniform at room temperature, an obtained mixture is reacted for 15 to 24h at 150 to 220 DEG C in a hydrothermal reaction kettle, and titanium dioxide nanosheets are obtained via separation, washing, and drying; the titanium dioxide nanosheets are dispersed in absolute ethanediol uniformly, and is subjected to reflux condensation stirring for 10 to 60min at 80 to 150 DEG C, polyvinylpyrrolidone and chloroplatinic acid are added, an obtained mixed material is subjected to reflux condensation stirring for 3 to 10h at 80 to 150 DEG C, and the titanium dioxide nanosheet loaded platinum nanoparticle composite material is obtained via separation, washing, and drying. The preparation method is capable of obtaining titanium dioxide nanosheets with a morphology easy to control; ethanediol is taken as a reducing agent, and 2 to 3nm platinum quantum dots with uniform particle size and high dispersity are obtained; the preparation parameters are easy to control; and repeatability is high. The titanium dioxide loaded highly dispersed platinum composite photocatalytic material is especially suitable to be used for catalytic degradation organic dyes under ultraviolet irradiation, and relatively high degradation rate is achieved.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of upconversion material of core shell structure and application of conversion material in perovskite solar cell

ActiveCN105428541AImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellTitanium tetraisopropoxide

The invention relates to a preparation method of an upconversion material of a core shell structure. The method comprises that NaYF4:Yb3+, Er3+ is dispersed into isopropanol, deionized water and ammonia water are added, and stirring is carried out to obtain a first mixed solution; ethyl orthosilicate is added into isopropanol, the isopropanol added with the ethyl orthosilicate is added into the first mixed solution slowly drop by drop, stirring, washing and centrifugal collection are carried out to obtain NaYF4:Yb3+, Er3+@SiO2; and the obtained NaYF4:Yb3+, Er3+@SiO2 deposition is re-dispersed into an isopropanol and DETA mixed solution, mixing is carried out to obtain a second mixed solution, titanium isopropoxide is added into isopropanol, and the isopropanol added with the titanium isopropoxide is added into the second mixed solution slowly drop by drop, stirring is carried out, the obtained solution is added into a hydro-thermal reactor for hydro-thermal processing, washing is carried out via deionized water and ethanol after cooling, the drying is carried out to obtain the upconversion material NaYF4:Yb3+, Er3+@SiO2@TiO2 of the core shell structure. The upconversion material of the core shell structure can serve as material of an upconversion layer of the perovskite solar cell, the perovskite solar cell can absorb infrared light more effectively via the upconversion material, and the efficiency of the cell is effectively improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

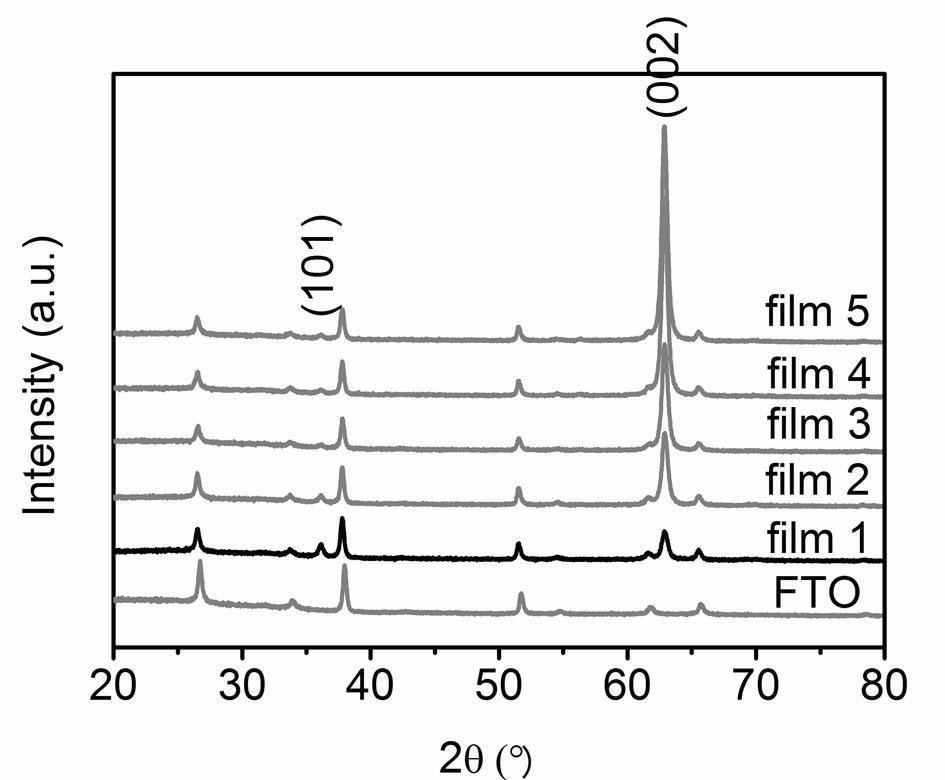

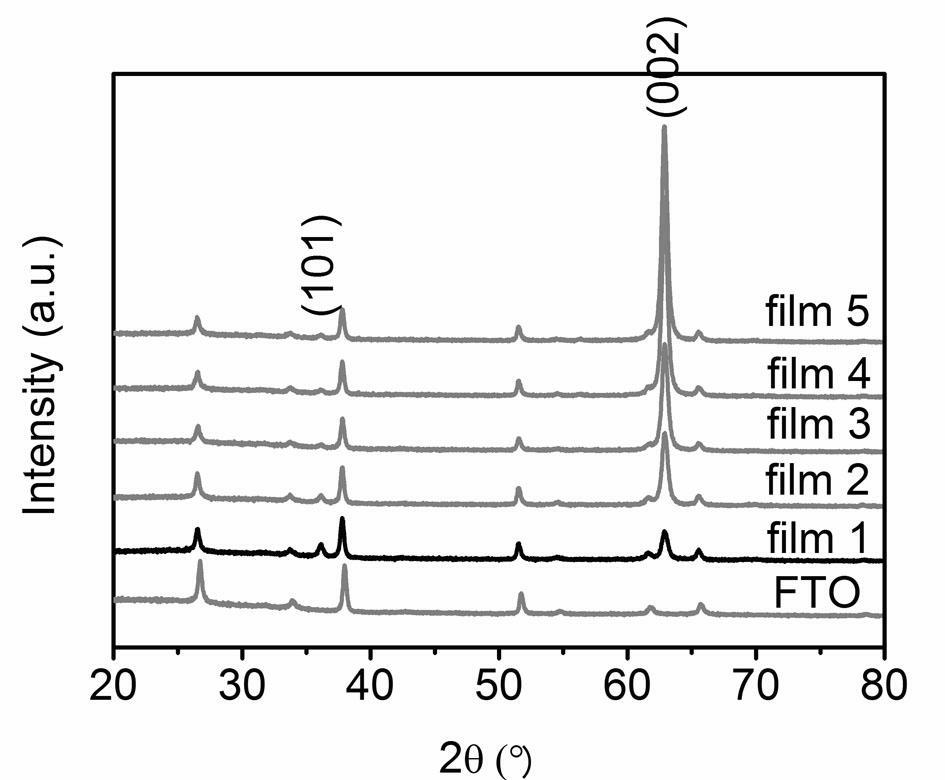

Titanium dioxide (TiO2) nano-rod single-crystal array thin film as well as preparation method and application thereof

InactiveCN102122577AImprove adsorption capacityImprove performance indicatorsLight-sensitive devicesSolid-state devicesSingle crystalHydrolysis

The invention belongs to the technical field of solar cells, and in particular relates to a titanium dioxide (TiO2) nano-rod single-crystal array thin film as well as a preparation method and an application thereof. A hydrochloric acid solution of titanium tetraisopropoxide is taken as a titanium source, acetic acid is utilized for controlling the acidity so as to further control the hydrolysis rate of TiO2, and a hydrothermal method is adopted for preparing the TiO2 nano-rod array thin film on a fluorine-doped tin oxide (FTO) conductive glass substrate. The one-dimensional nano-rod structure of the TiO2 can provide a direct transmission path for electrons and can be used for improving the transmission property of the electrons; after the acidity is reduced through dilution with the acetic acid, the titanium dioxide nano-rod single-crystal array thin film with larger specific surface area can be obtained; and the array thin film is utilized for packaging a dye-sensitized solar cell and performing performance testing, and then the short circuit current and photoelectric conversion efficiency of the cell can be greatly improved.

Owner:FUDAN UNIV

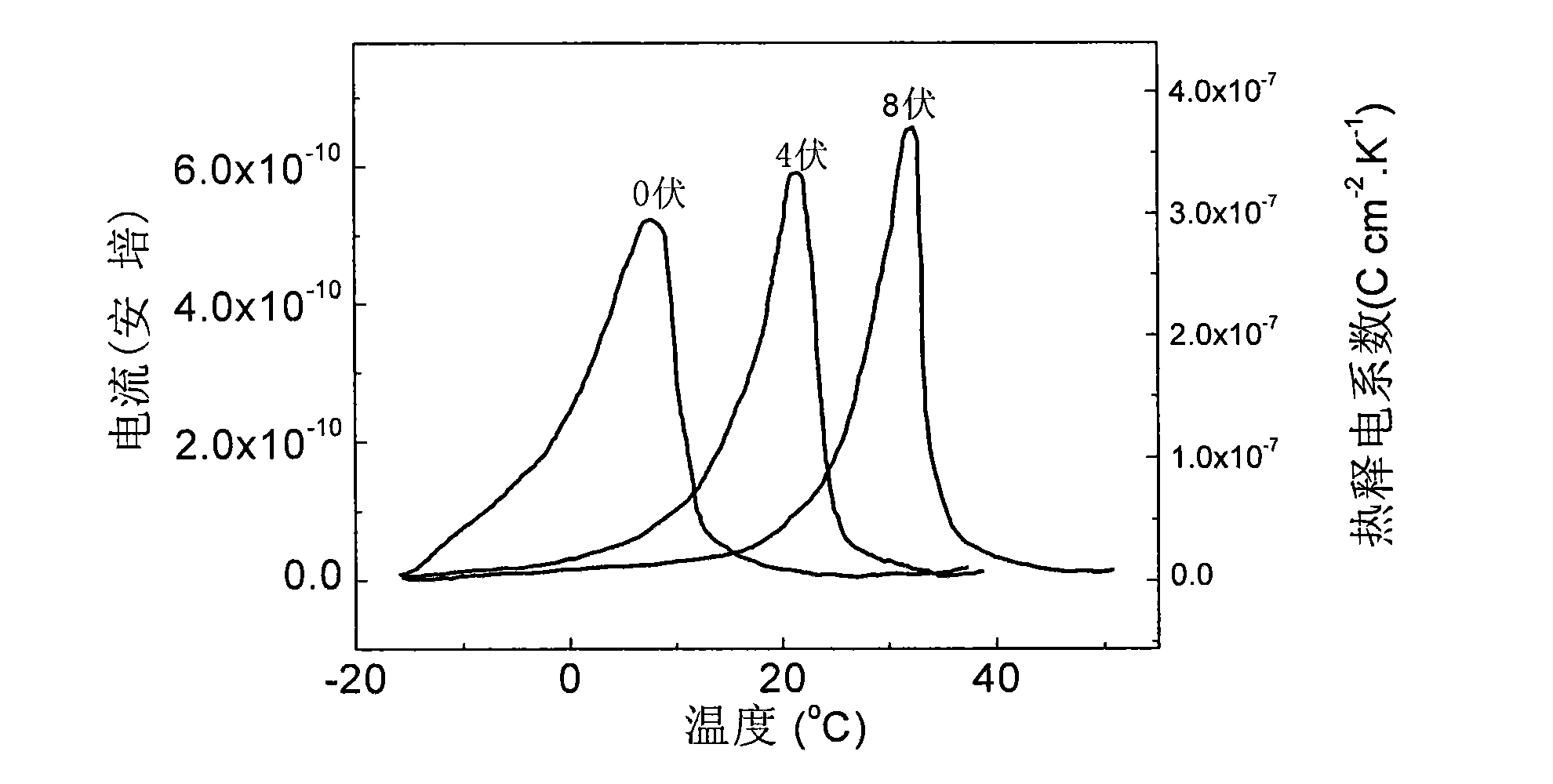

Antiferroelectric film with adjustable working temperature zone and higher pyroelectric coefficient and preparation method thereof

InactiveCN101670691AAdjust working temperatureHigh sensitivityLayered productsPyrometry using electric radation detectorsPyroelectric detectorsNiobium

The invention discloses an antiferroelectric film with adjustable working temperature zone and higher pyroelectric coefficient and a preparation method and application thereof. The antiferroelectric film (Pb,Nb)(Zr,Sn,Ti)O3 taken as the pyroelectric material is prepared by a sol gel method, the solute of precursor solution can be lead acetate, lanthanum acetate or niobium ethoxide, stannic acetate, zirconium isopropoxide and titanium isopropoxide, the solvent includes glacial acetic acid, ethylene glycol ethyl ether, acetylacetone and water, the final concentration of the precursor solution is controlled between 0.2-0.4 M, and the substrate comprises LaNiO3 / Pt / Ti / SiO2 / Si and Pt / Ti / SiO2 / Si. The antiferroelectric film is high in thermally stimulated current and adjustable in temperature andcan be used for a pyroelectric infrared detector, a smart device and a system.

Owner:TONGJI UNIV

CoS graded nano-bubble composite sulfur positive electrode material of lithium sulfur battery and preparation method of positive electrode material

ActiveCN108448093AImprove charge and discharge response abilityImprove conductivityMaterial nanotechnologyCell electrodesVulcanizationCharge discharge

The invention discloses a CoS graded nano-bubble composite S positive electrode material of a lithium sulfur battery, and belongs to the technical field of the lithium sulfur battery. The preparationmethod of the CoS graded nano-bubble composite S positive electrode material comprises the steps of firstly, synthesizing TiO2 composite hexadecylamine nanoparticle by hydrolysis of titanium isopropoxide; secondly, coating a surface of the TiO2 composite hexadecylamine nanoparticle with a layer of MOF-loying PVP so that the TiO2 composite nanoparticle can be absorbed during the growth process of ZIF67 and a surface is embedded and an interior are buried onto ZIF-67 to form a Chinese data structure; and finally, performing vulcanization to obtain a CoS graded nano-bubble material with a plurality of CoS hollow spheres sleeving a CoS hollow polyhedron by hydrothermal method of thioacetamide, and injecting S into the CoS graded nano bubbles by a melting method to obtain a final material. TheCoS graded nano-bubble composite S provided by the invention is used as a lithium sulfur battery positive electrode, relatively high charge-discharge performance and stable cycle property are shown, and the important application value in the field of the lithium sulfur battery is achieved.

Owner:CHINA JILIANG UNIV

Carbon nanofiber/zinc titanate composite for personal protection and production method of carbon nanofiber/zinc titanate composite for personal protection

InactiveCN102560890ALarge specific surface areaImprove adsorption capacityHeating/cooling textile fabricsNon-woven fabricsSpinningTitanium isopropoxide

The invention discloses a production method of carbon nanofiber / zinc titanate composite for personal protection, and the composite obtained by the production method. The production method is characterized by including the steps of: adding titanium isopropoxide and zinc acetate into ethanol solvent, and adding polyvinylpyrrolidone to obtain spinning dope A; adding polyacrylonitrile into N, N-dimethyl formamide solvent to obtain spinning dope B; subjecting the spinning dope A and the spinning dope B to electrostatic spinning to obtain composite fibrous membranes; and allowing the drawn composite fibrous membranes to stand in air to be pre-oxidized, and carbonizing the membranes under nitrogen protection. The carbon nanofiber / zinc titanate composite has the advantages of light weight, high rate of biochemical disintegration, and fine mechanical properties.

Owner:DONGHUA UNIV

Mildew-resistant paint and preparation method thereof

InactiveCN104559369AEasy to makeEasy to useAntifouling/underwater paintsPaints with biocidesTitanium tetraisopropoxidePolyvinyl chloride

The invention discloses a mildew-resistant paint which comprises the following components in parts by weight: 10-16 parts of titanium tetraisopropoxide, 80-120 parts of isopropanol, 8-16 parts of tetrapropoxyzirconium, 6-12 parts of polyvinyl chloride, 10-30 parts of dibutyl phthalate and 10-30 parts of ethylenediamine methyl propionate. The mildew-resistant paint is simple to prepare, and selects nontoxic production raw materials; and thus, the paint has the advantages of favorable use effect and environment friendliness. When being applied to a metal surface, the mildew-resistant paint can prevent the metal surface from mildewing, and can enhance the storage stability of metals.

Owner:姜云华

Filtering membrane prepared with 3d printing technology and preparation method of filtering membrane

InactiveCN106582570ARapid Active Absorption AdsorptionWith high temperature and high pressure resistanceGas treatmentOther chemical processesFiberCarbon fibers

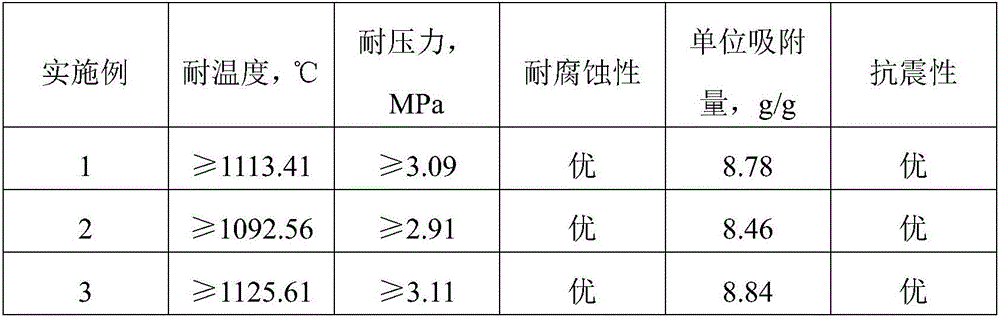

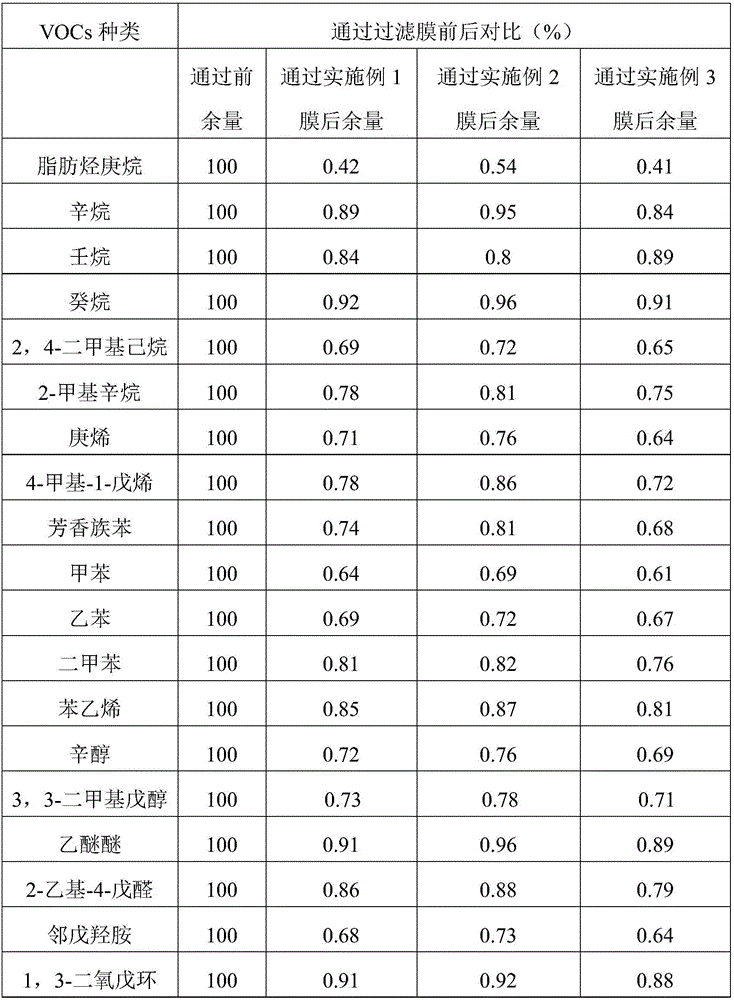

The invention discloses a filtering membrane prepared with a 3d printing technology and a preparation method of the filtering membrane. The filtering membrane is prepared from raw materials as follows: montmorillonite, hydrotalcite, sodium silicate, activated carbon, zeolite, kaolin, carbon fibers, titanium isopropoxide, methyl isobutyl ketone, glass fibers, graphene, an initiator, a catalyst, a tackifier, a flexibilizer, a flocculation agent and a stabilizer through steps including decontamination, drying, mixing, laser scanning forming, cooling and the like. The filtering membrane prepared with the 3d printing technology contains graphene, silicate and other mixed ingredients and has the characteristics of good high-temperature resistance, high-pressure resistance, corrosion resistance, seismic resistance and the like; the filtering membrane prepared with the 3d printing technology has high efficiency when adsorbing VOCs and other toxic gases, is prepared with a simple process and is low in preparation cost.

Owner:NANNING MENGHUAN 3D ENVIRONMENTAL PROTECTION TECH CO LTD

Ultraviolet resisting agent for acrylic fabric

InactiveCN102330338AImproves UV resistanceDoes not affect the feelAnimal fibresSilanesTitanium tetraisopropoxide

The invention discloses an ultraviolet resisting agent for an acrylic fabric, which is composed of the following components by weight parts: 138 parts of methacryloyl oxide propyl trimethoxy silane; 30 parts of benzophenone; 36 parts of titanium isopropoxide; 42 parts of methyl salicylate; 20 parts of carbamide; and 15 parts of fatty alcohol-polyoxyethylene ether. Products prepared by the ultraviolet resisting agent are produced with low cost via simple technology, and clothes or fabrics processed by the ultraviolet resisting agent has the advantages of having excellent and durable ultraviolet resisting effect without influencing original feel and appearance of the textile, and the like.

Owner:SUZHOU KAQITE TEXTILE

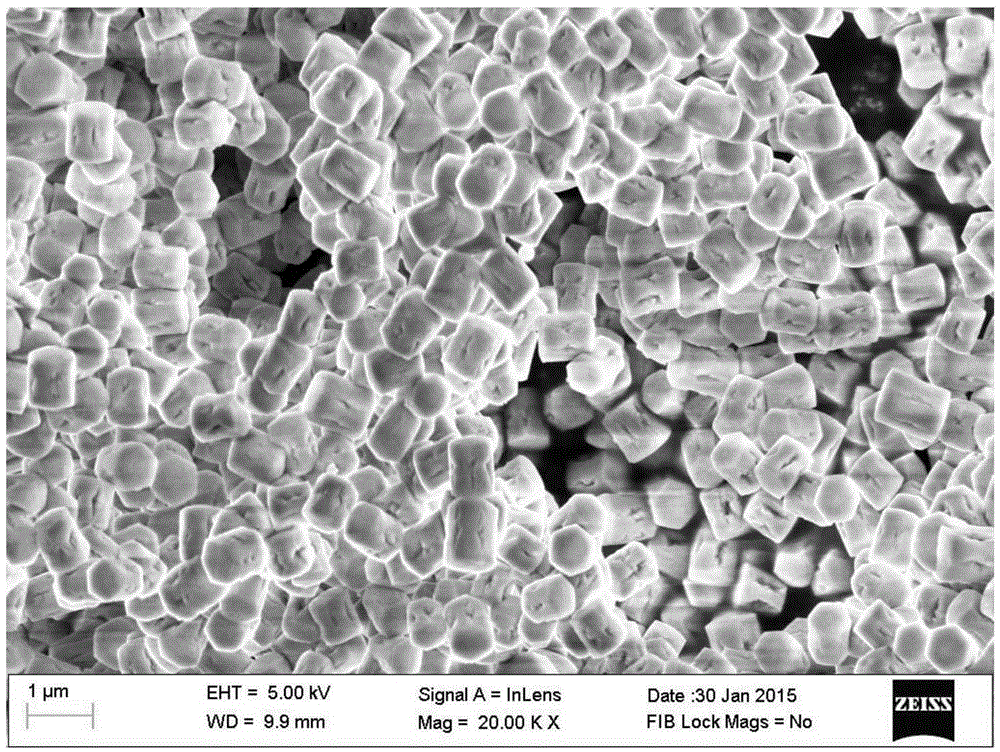

Preparation method of hollow porous TiO2 nanocubic material and application thereof

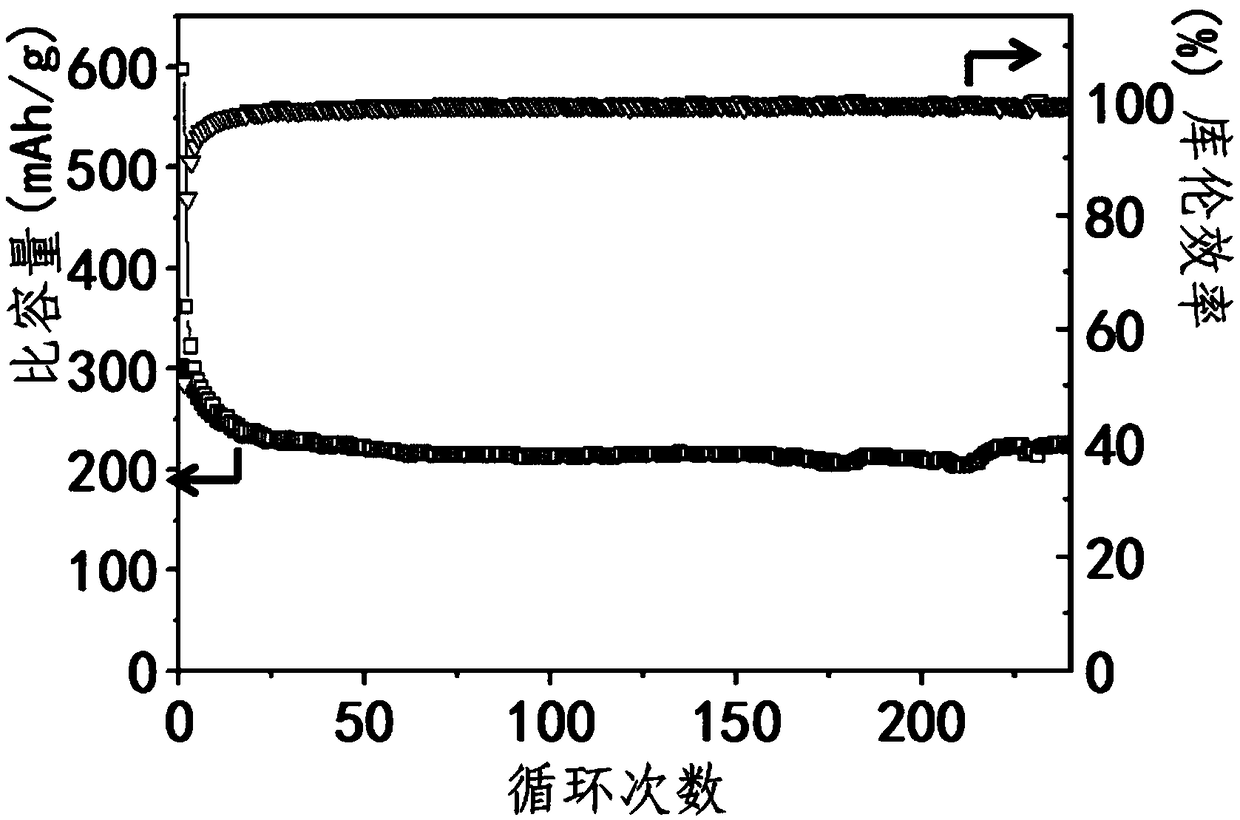

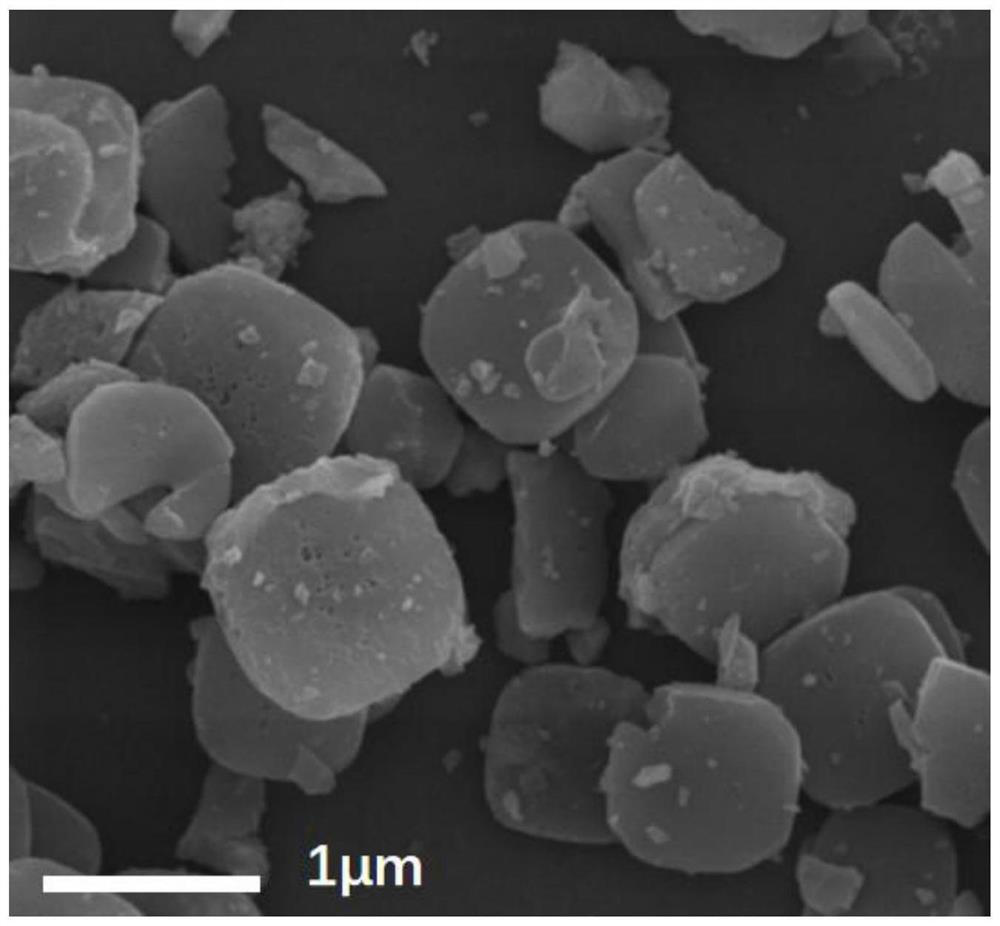

InactiveCN109286015ALow costEasy to prepareMaterial nanotechnologyCell electrodesN dimethylformamideTitanium isopropoxide

The invention discloses a preparation method of a hollow porous TiO2 nanocubic material. The method firstly mixes titanium isopropoxide and methanol, adds into a mixture of 2-aminoterephthalic acid and N,N-dimethylformamide for a reaction, obtains an amino-modified Ti-MIL-125 nanocube material, conducts stirring for the reaction after water, sodium hydroxide and absolute ethanol are added, obtainsa nano-precursor material, and finally conducts heat-treating to obtain the hollow porous TiO2 nanocubic material; the invention discloses application of the hollow porous TiO2 nanocubic material ina lithium ion battery. The method utilizes the characteristics that acidic ligands constituting the amino-modified Ti-MIL-125 nanometer material are not stable under the alkaline condition to conductself-etching, thereby ensuring the stability of the structure and performance; the hollow porous TiO2 nanocubic material is applied to the lithium ion battery to increase the specific capacity of thelithium ion battery.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

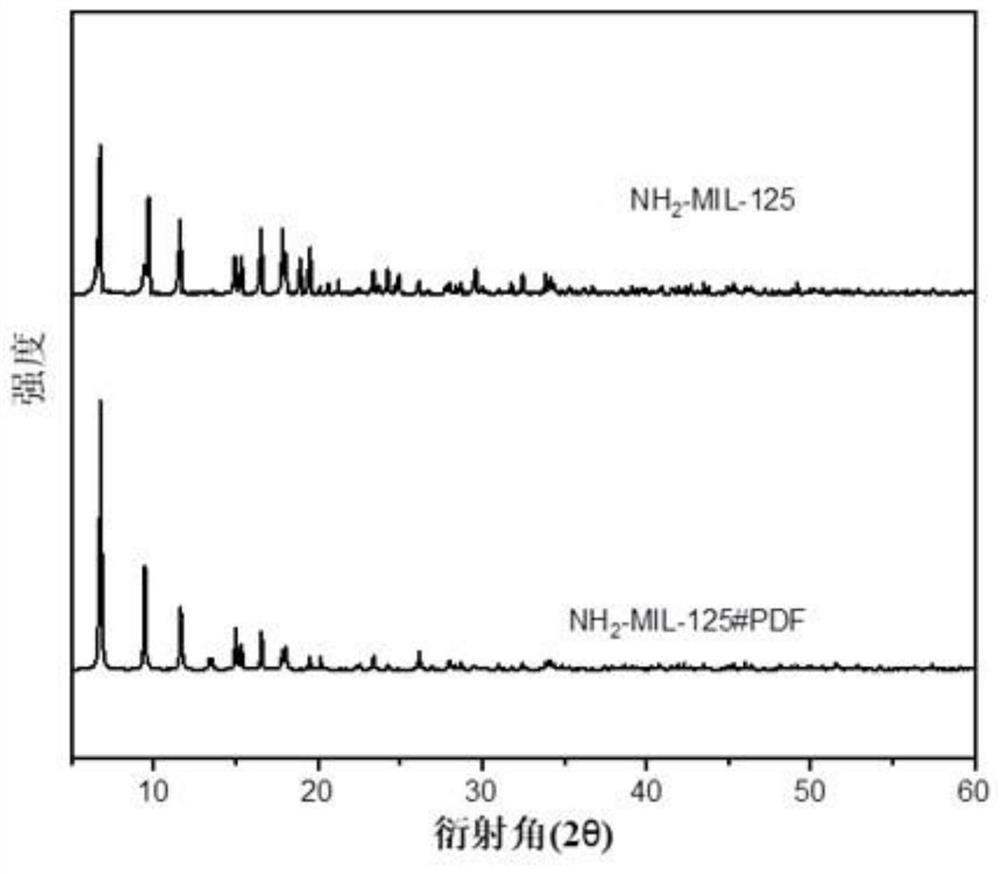

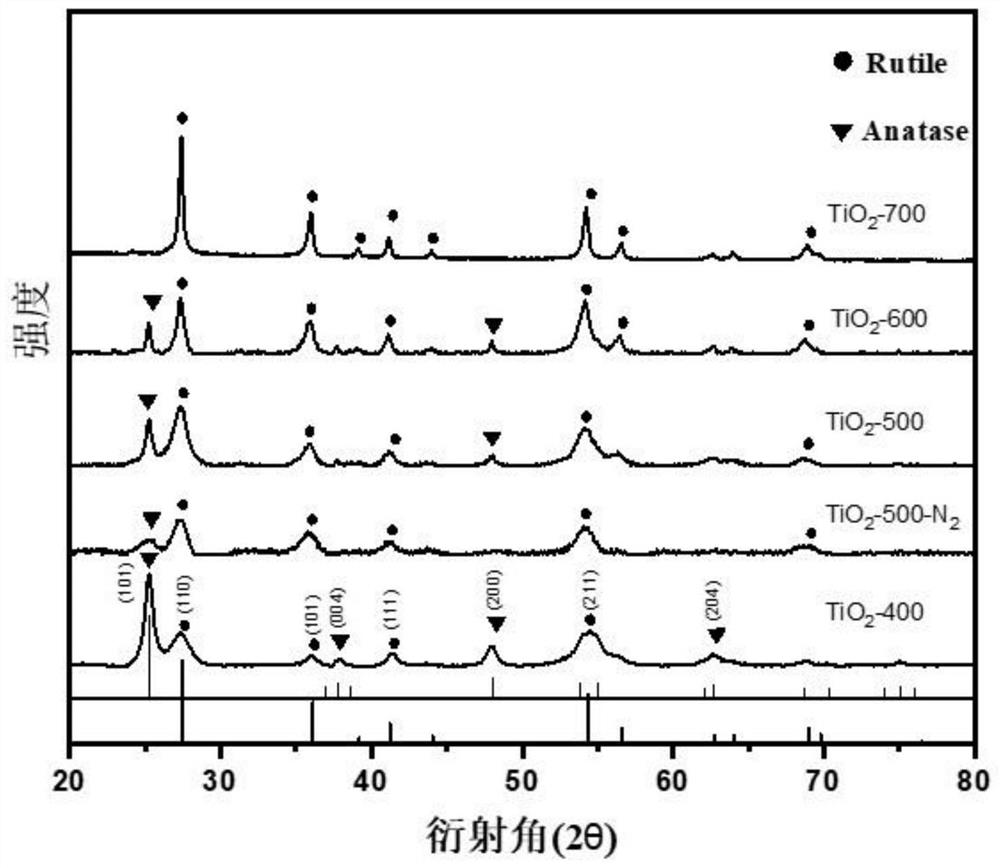

Preparation method of mixed-phase titanium dioxide visible-light-induced photocatalyst derived from MOF

ActiveCN112007629AGood photocatalytic degradation activitySimple manufacturing methodPhysical/chemical process catalystsWater/sewage treatment by irradiationWater methanolPtru catalyst

The invention relates to a preparation method of a mixed-phase titanium dioxide visible-light-induced photocatalyst derived from MOF. The preparation method comprises the following steps: dissolving 2-aminoterephthalic acid and titanium isopropoxide in a mixed solvent of N,N-dimethylformamide (DMF) and absolute methanol, transferring the obtained mixture into a high-pressure kettle, and keeping the temperature at 150 DEG C for 48 hours to prepare NH2-MIL-125; calcining the prepared NH2-MIL-125 at a high temperature under the protection of nitrogen so as to obtain the visible-light-induced photocatalyst. The preparation method has the beneficial effects that the preparation method is simple, the preparation conditions are easy to control, and the feasibility is high. The prepared MOF-derived mixed-phase titanium dioxide visible-light-induced photocatalyst is relatively good in photocatalytic degradation efficiency under visible light, and has a certain application prospect.

Owner:CHANGZHOU UNIV

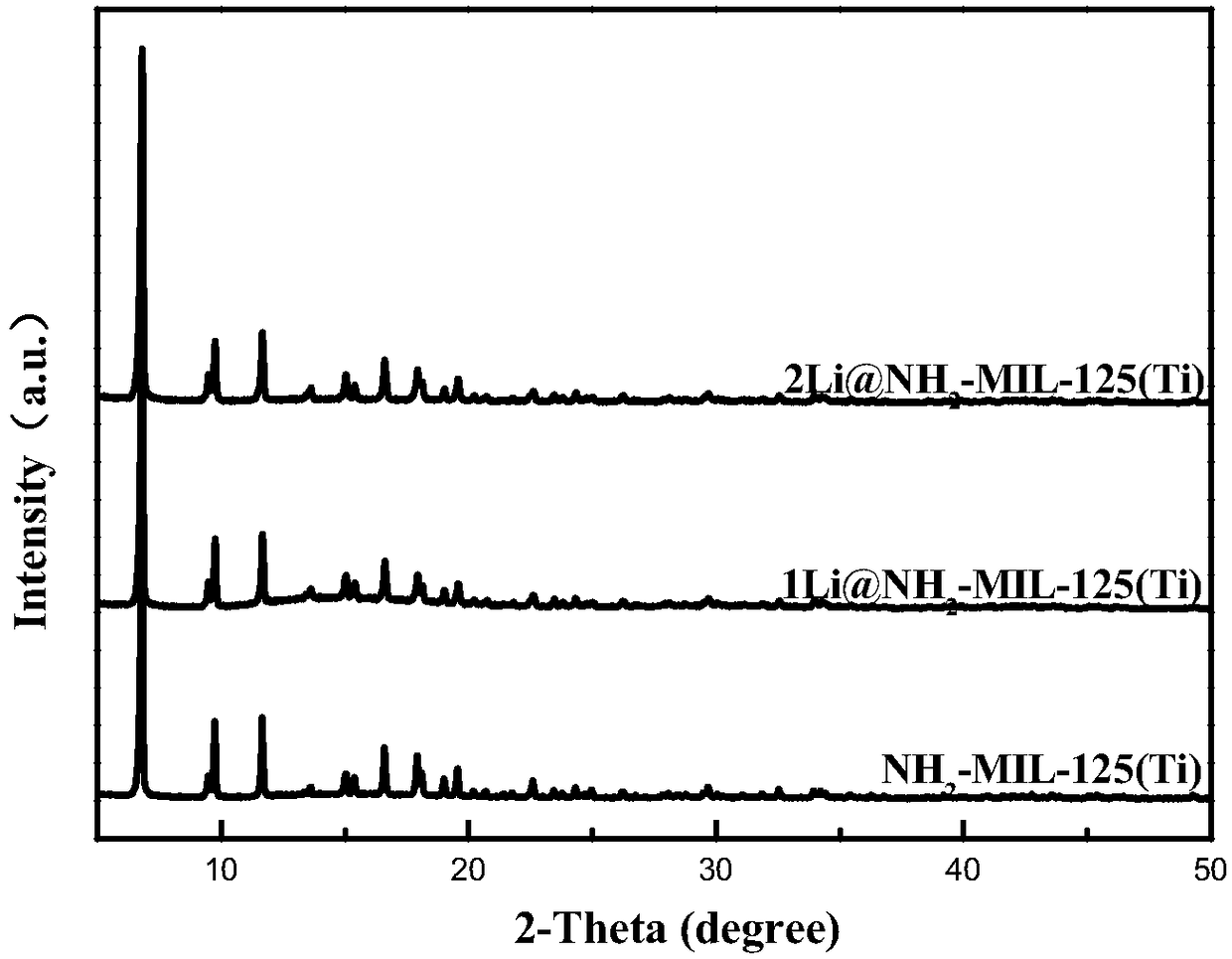

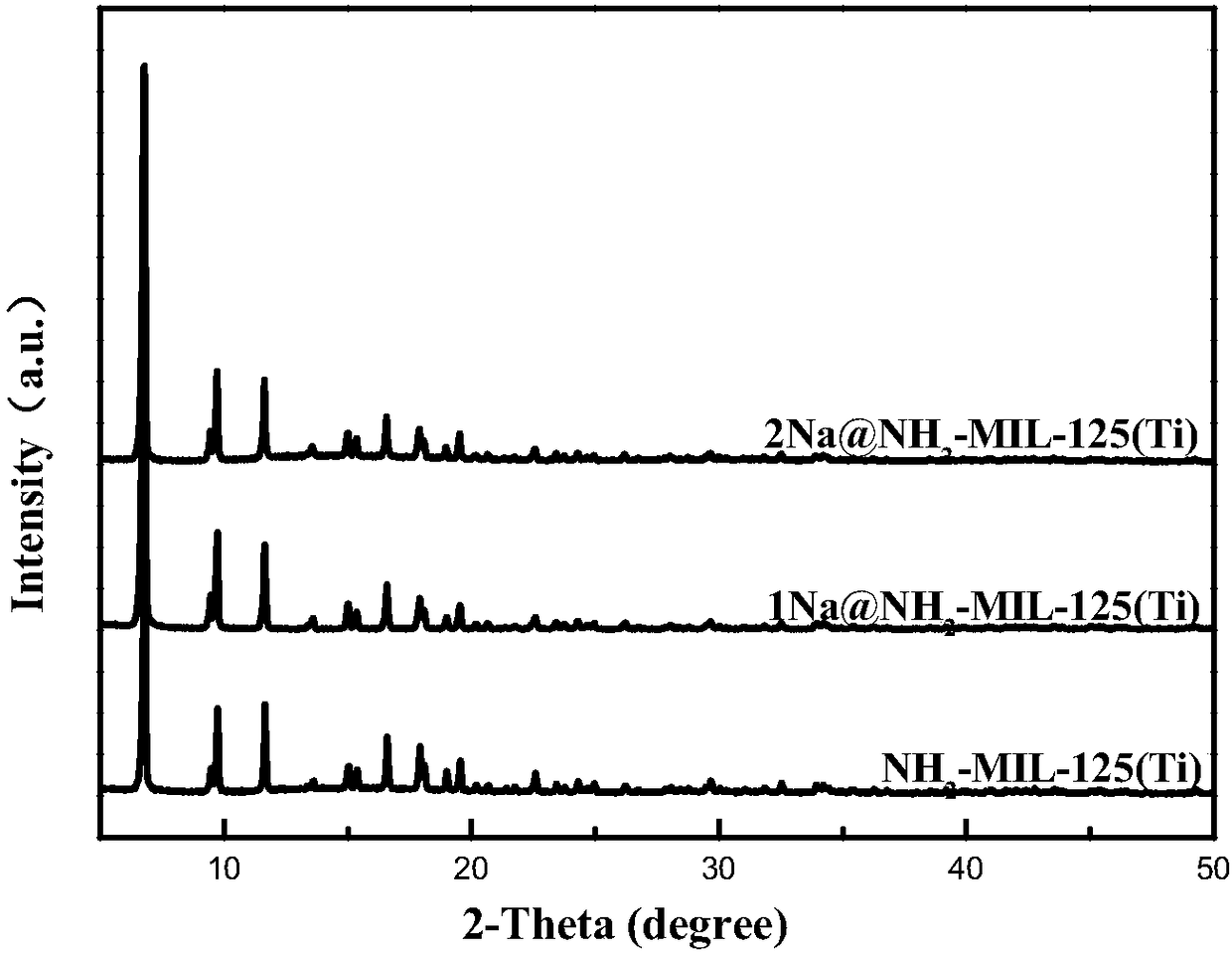

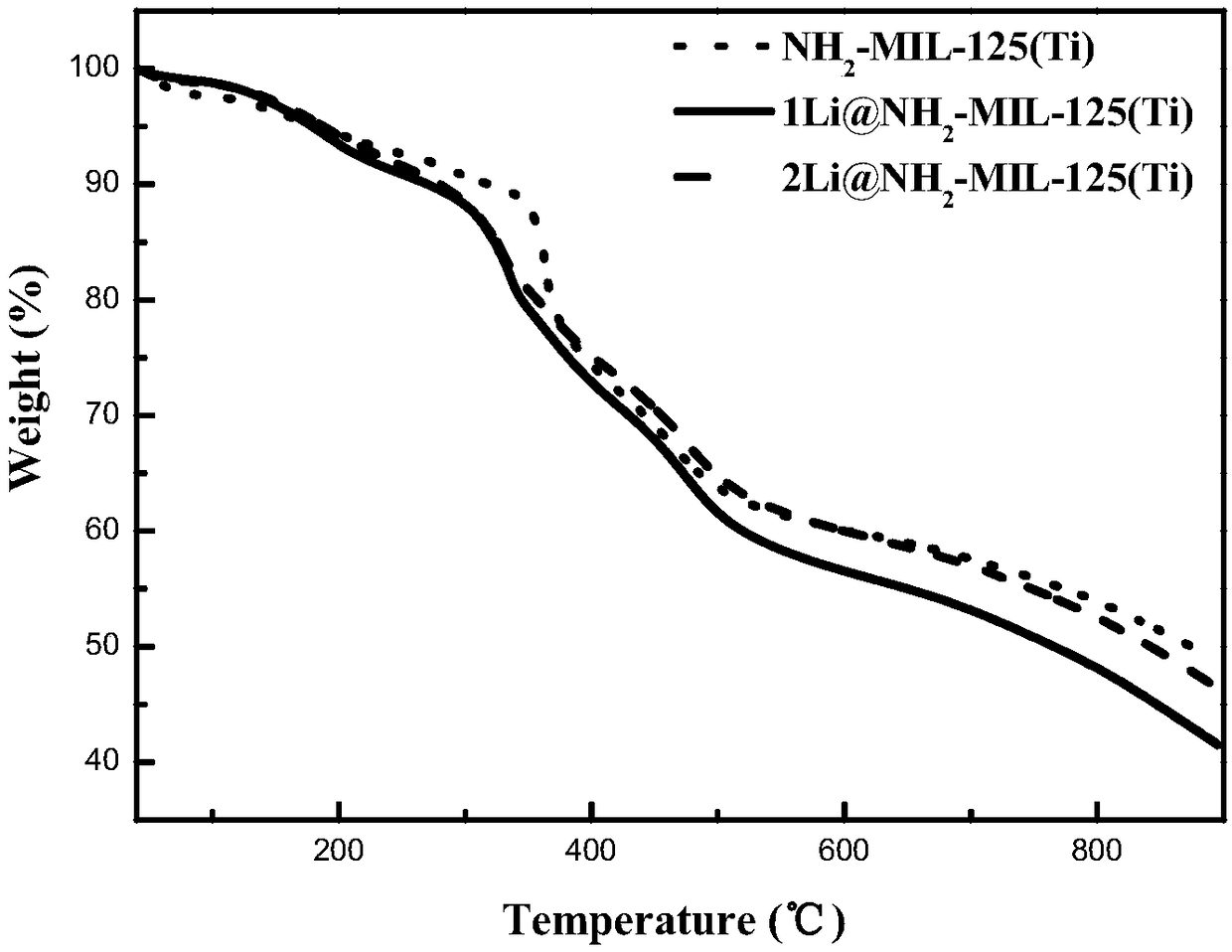

Alkali metal cation doping-based NH1-MIL-125 (Ti) material and preparation method thereof

ActiveCN108404868ARaise the reaction temperatureIncrease productivityOther chemical processesAlkali metal oxides/hydroxidesLithium chlorideMetal-organic framework

The invention discloses an alkali metal cation doping-based NH1-MIL-125 (Ti) material and a preparation method thereof. The alkali metal cation doping-based NH1-MIL-125 (Ti) material is prepared by heating in oven, activating through organic solvent, centrifuging, washing and drying 2-aminoterephthalic acid, isopropyl titanate, lithium chloride, sodium chloride, N, N-dimethyl formamide and methylalcohol under neural conditions. The specific surface area range of the alkali metal cation doping-based NH1-MIL-125 (Ti) material is 808.138-1470.044 m<2> / g<-1>. The preparation method of the alkalimetal cation doping-based NH1-MIL-125 (Ti) material comprises 1) preparation of organic solvent, 2) doping of nitrogen-containing ligands, 3) doping of alkali metal cations, 4) doping of metal centerand 5) preparation of the alkali metal cation doping-based NH1-MIL-125 (Ti) material. Compared with the shortcomings of low reaction time and poor microwave synthesizing precision in the prior art, the alkali metal cation doping-based NH1-MIL-125 (Ti) material has the outstanding advantage of increasing the reaction temperature through a solvothermal method to achieve synthesis within a short time, and adopting a simple alkali metal cation doping method to greatly increase the specific surface area, thereby having a broad application prospect in the field of metal-organic frameworks.

Owner:CHANGAN UNIV

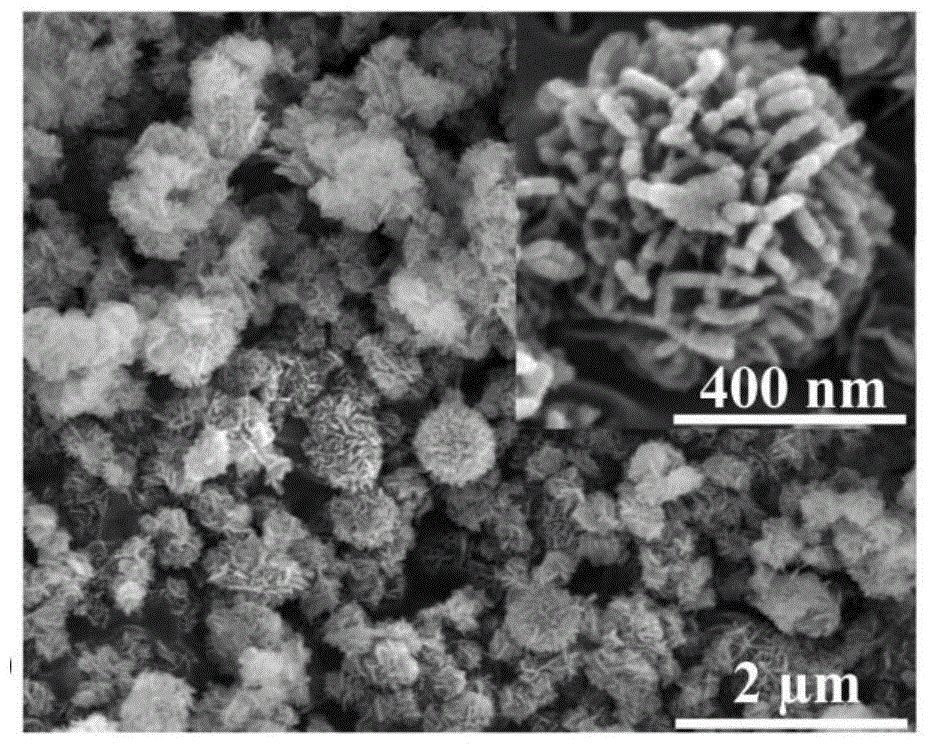

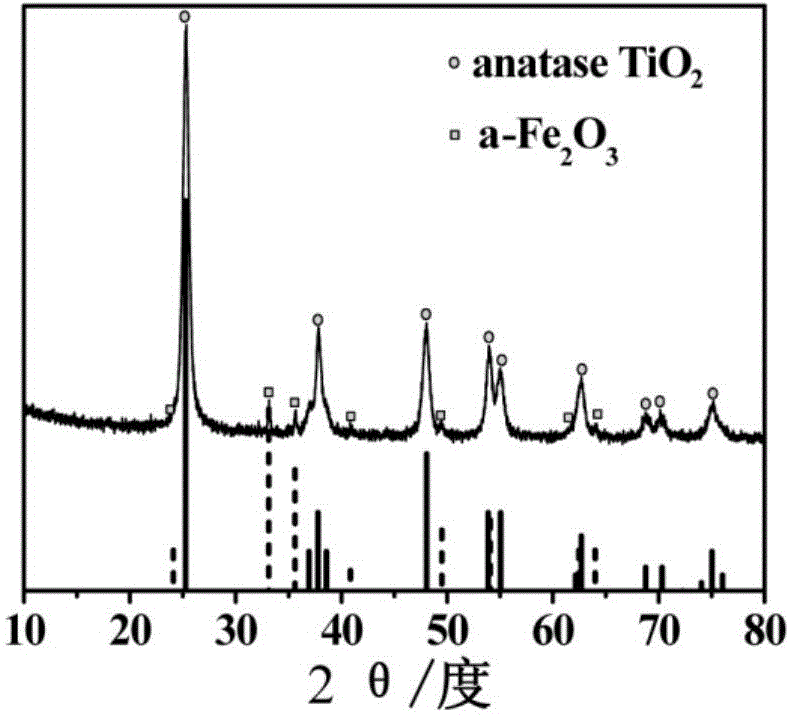

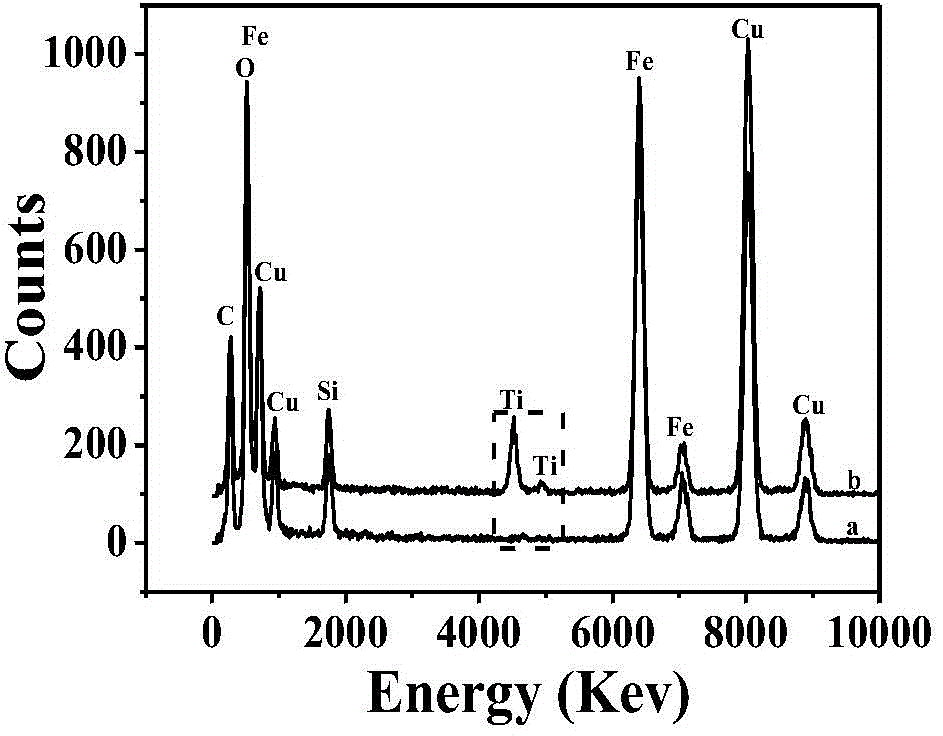

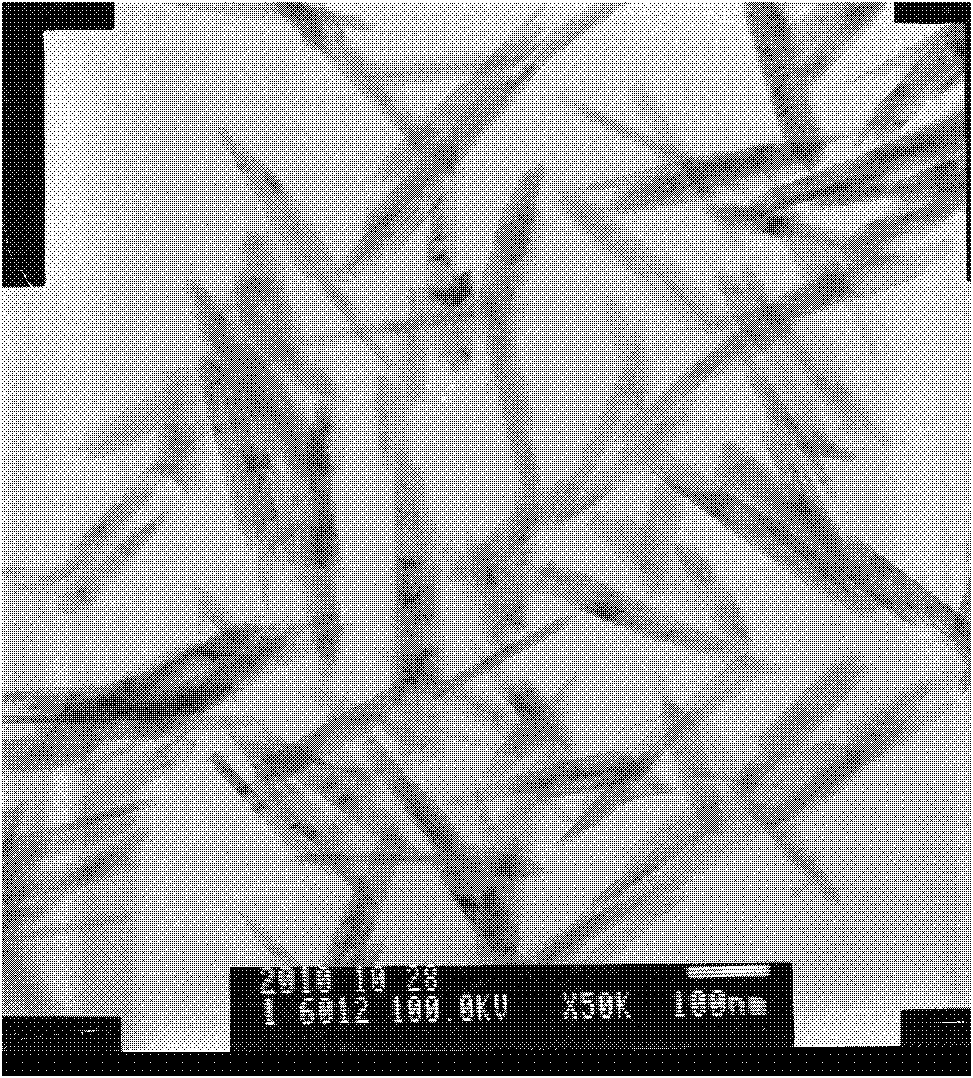

Hierarchical alpha-Fe2O3/TiO2 hollow sphere dual-functional photocatalyst and application thereof

ActiveCN104437495AImprove adsorption capacityEasy to recycleWater/sewage treatment by irradiationOther chemical processesPhotocatalytic reactionSulfate

The invention provides a hierarchical alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst. The alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst with a hierarchical structure is prepared by virtue of hydrothermal reaction from FeOOH as a substrate, and butyl titanate, titanium tetrachloride, titanyl sulfate or isopropyl titanate as a titanium source; next, the alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst is dispersed in water containing heavy metal ions and adsorption and light-catalyzed reaction are performed under the irradiation of simulated sunlight. The invention also provides new application of the hierarchical alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst in treating of heavy metal ion pollution in the water.

Owner:HEBEI UNIV OF TECH

Mildew-proof wear-resistant asphalt paint and preparation method thereof

InactiveCN104293069AGood weather resistanceImprove wear resistanceAntifouling/underwater paintsPaints with biocidesXylyleneTitanium isopropoxide

The invention discloses mildew-proof wear-resistant asphalt paint which is characterized by being prepared from the following raw materials in parts by weight: 17-23 parts of E-22 epoxy resins, 6-9 parts of benzyl transparent silicon resins, 8-11 parts of polyether acrylate, 4-7 parts of tetraethylenepentamine, 3-5 parts of tricresyl phosphate, 1-3 parts of nano bamboo fibers, 2-4 parts of zinc chromate, 37-43 parts of modified asphalt, 5-7 parts of modified waste resin sand, 1-2 parts of ammonium bromide, 2-4 parts of fungacetin, 3-4 parts of catechinic acid, 4-6 parts of epoxy linseed oil, 8-11 parts of amyl acetate, 6-9 parts of xylene, 5-7 parts of glycol, 1-2 parts of tri(dioctylphosphoryloxy) titanium isopropoxide and 2-4 parts of powdered aluminum. The mildew-proof wear-resistant asphalt paint is prepared by adding the epoxy resins on the basis of the modified asphalt, so that the characteristics of high corrosion resistance, weather fastness, waterproofness and thermal stability of the pain are ensured; the added tricresyl phosphate has the characteristics of favorable wear resistance, weather fastness, mildew resistance and radiation resistance; and the added modified waste resin sand has favorable fire resistance, antifouling property and anti-ageing property, so that the quality of the paint is improved and the waste is recycled to solve the problem of environment pollution.

Owner:TIANCHANG YINHU PAINT

Preparation method of magnetic nano silver phosphate/titanium dioxide composite photocatalytic material

ActiveCN103894216AEasy to synthesizeTightly boundMaterial nanotechnologyCatalyst carriersSilver phosphateCalcination

The invention discloses a preparation method of magnetic nano silver phosphate / titanium dioxide composite photocatalytic material. The method comprises the following specific steps: dissolving titanium tetraisopropoxide into a methanol solution; feeding silver nitrate, ferric nitrate and ferrous nitrate into the mixed solution, and continuously mixing until the mixture is dissolved; dropwise adding ammonia water into the obtained solution while mixing until the pH value is 9-10, and heating up to 50-55 DEG C; continuously mixing for 1-2 hours, carrying out precipitation separation, washing the product with methyl alcohol for 2-3 times, and drying at the temperature of 70-80 DEG C; grinding the dried product into powder; heating up to 600-850 DEG C at the heating rate of 10-20 DEG C / min, and carrying out calcination for 1-3 hours to obtain the magnetic nano silver phosphate / titanium dioxide composite photocatalytic material. The magnetic nano silver phosphate / titanium dioxide composite photocatalytic material is simple in synthetic process; titanium and silver are doped with each other and closely combined together, so that the mutual synergistic effect can be effectively exerted.

Owner:溧阳常大技术转移中心有限公司

Method of preparing iron oxide yellow by using titanium dioxide by-product

ActiveCN103145194AGood dispersionEffective control of nucleationFerric oxidesIron sulfatesTitanium tetraisopropoxideManganese

The invention provides a method of preparing iron oxide yellow by using a titanium dioxide by-product ferrous sulphate, belonging to a field of chemistry. The method comprises refining of ferrous sulphate, neutralization reaction, seed preparation, and oxidation synthesis; and the method controls a pH value of a solution during refining of the ferrous sulphate, and thus effectively removes impurities such as manganese, magnesium and zinc. In addition, by separating a seed preparation process into a neutralization reaction process and a seed preparation process, a preparation process of Fe(OH)2 suspension and an oxidation process are separated, thereby effectively controlling the seed to be spindle-shaped or needle-shaped, and improving dispersibility of the seed. The method is good in impurity removal effects, and can effectively control the seed to be spindle-shaped or needle-shaped and improve dispersibility of the seed; and the prepared iron oxide yellow has advantages of good color and high tinting strength.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

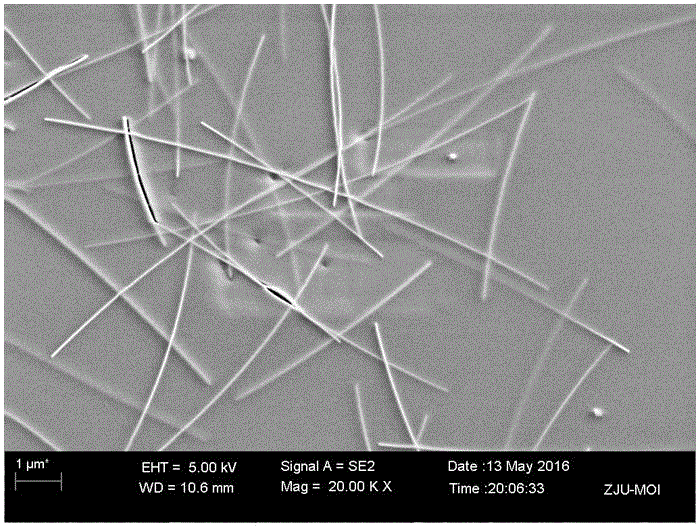

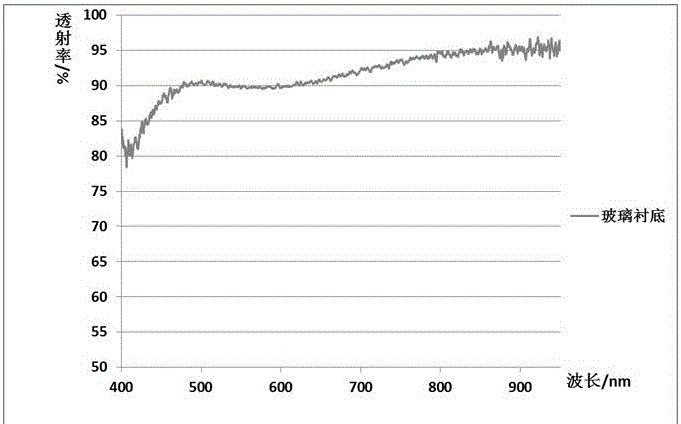

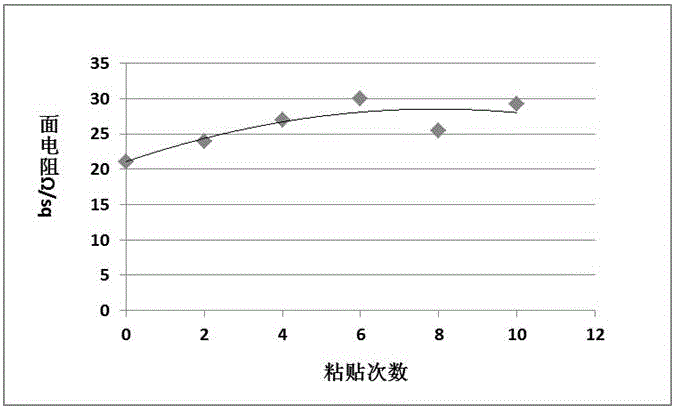

Method for preparing silver nanowire-titanium dioxide composite transparent electrode and transparent electrode

InactiveCN106057357AImprove conductivityImprove transmittanceMaterial nanotechnologyConductive layers on insulating-supportsPliabilityHYDROSOL

The invention discloses a method for preparing a silver nanowire-titanium dioxide composite transparent electrode and a transparent electrode. The method comprises the steps of: taking silver nanowire-ethyl alcohol suspension, adding titanium tetraisopropoxide and ethanolamine into the suspension, shaking until silver nanowires are uniformly dispersed in the suspension, and forming silver nanowire-titanium dioxide sol gel; uniformly spin-coating the sol gel on a transparent substrate to form a silver nanowire-titanium dioxide sol gel thin film; and heating the transparent substrate spin-coated with the gel thin film, and until solution on the surface of the transparent substrate is volatilized and titanium dioxide sol gel is decomposed into titanium dioxide, cooling to the room temperature so as to form a random silver nanowire network completely coated with the titanium dioxide thin film. The transparent electrode not only has excellent electrical conductivity, transmittance and mechanical property, but also has excellent thermal and chemical stability due to coating of titanium dioxide; the method is unrelated to the substrate area, the substrate surface appearance and substrate flexibility, and is simple in process, high in repeatability and reliability and suitable for large-area batch production.

Owner:ZHEJIANG UNIV

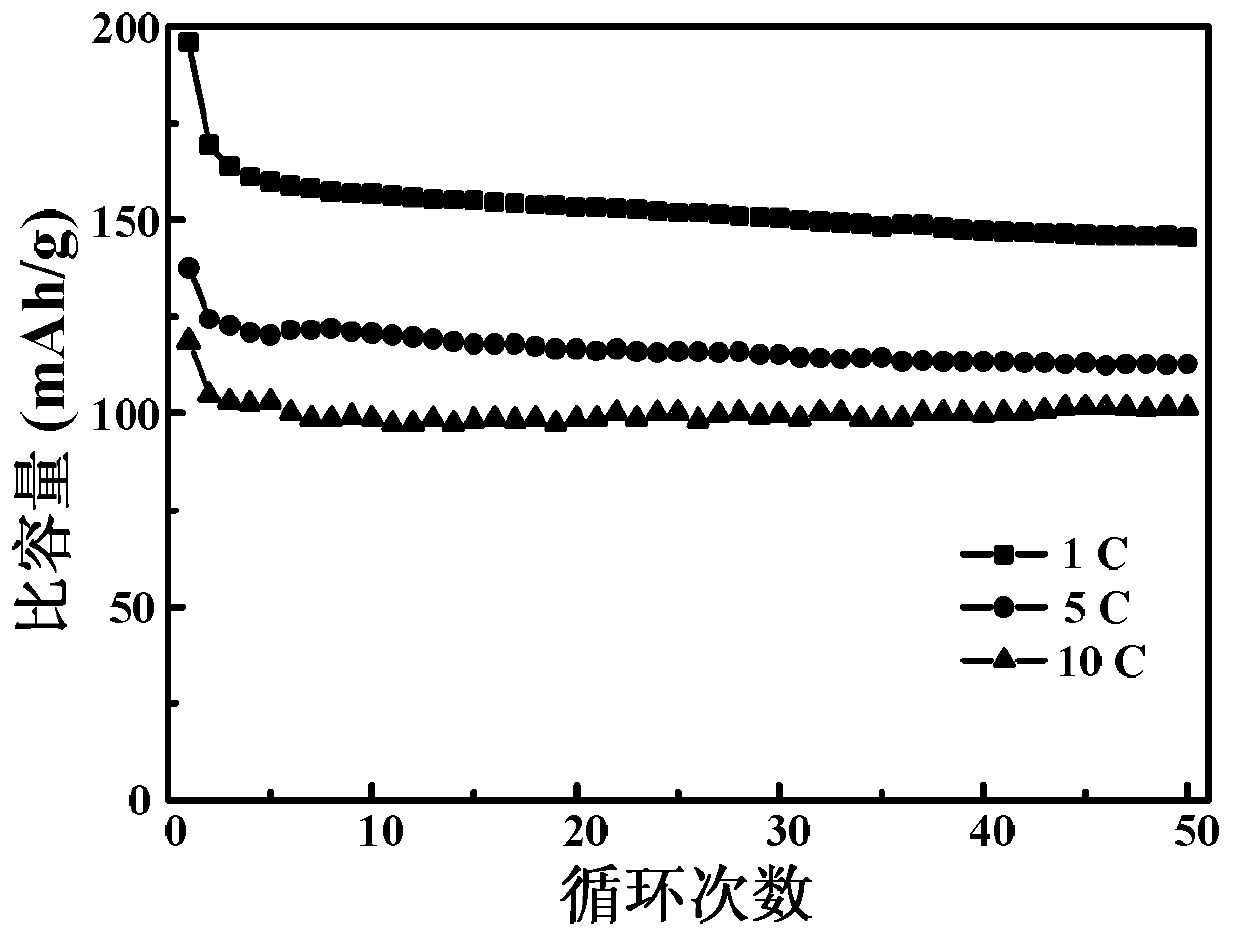

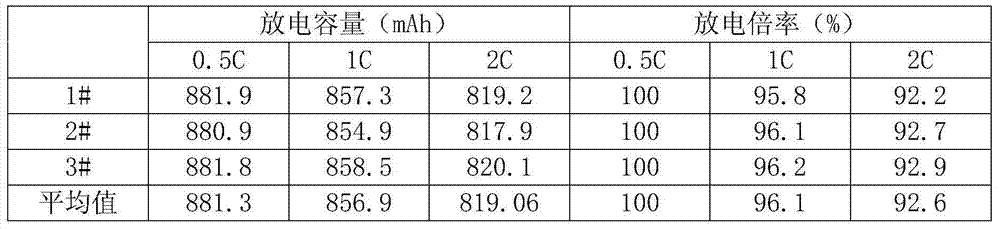

Manufacturing method for La-doped Ti-coated ternary cathode material

InactiveCN104733722AImproved magnification performanceImprove cycle performanceSecondary cellsPositive electrodesAlcoholFiltration

The invention relates to a manufacturing method for a lithium ion battery cathode material, in particular to a manufacturing method for a La-doped Ti-coated ternary cathode material. The manufacturing method comprises the following steps: (1), preparing a ternary precursor; (2), preparing a ternary cathode material; (3), mixing the ternary cathode material and La2O3; (4), secondary sintering a mixed material; (5), adding alcohol to a material obtained in the step (4) to disperse; (6), adding titanium isopropylate to absolute ethyl alcohol to completely dissolve the titanium isopropylate, and adding the mixture in the mixed solution obtained in the step (5), uniformly mixing, performing extraction filtration and drying; (7), sintering dried raw materials; crushing the sintered raw materials to obtain the final-products. The manufacturing method for the lithium ion battery cathode material has the advantages that due to La doping and Ti coating, the rate capability and the cycle performance of the ternary cathode material are remarkably improved, and a low-cost and high-performance lithium ion battery cathode material can be obtained.

Owner:宁夏科捷锂电池股份有限公司

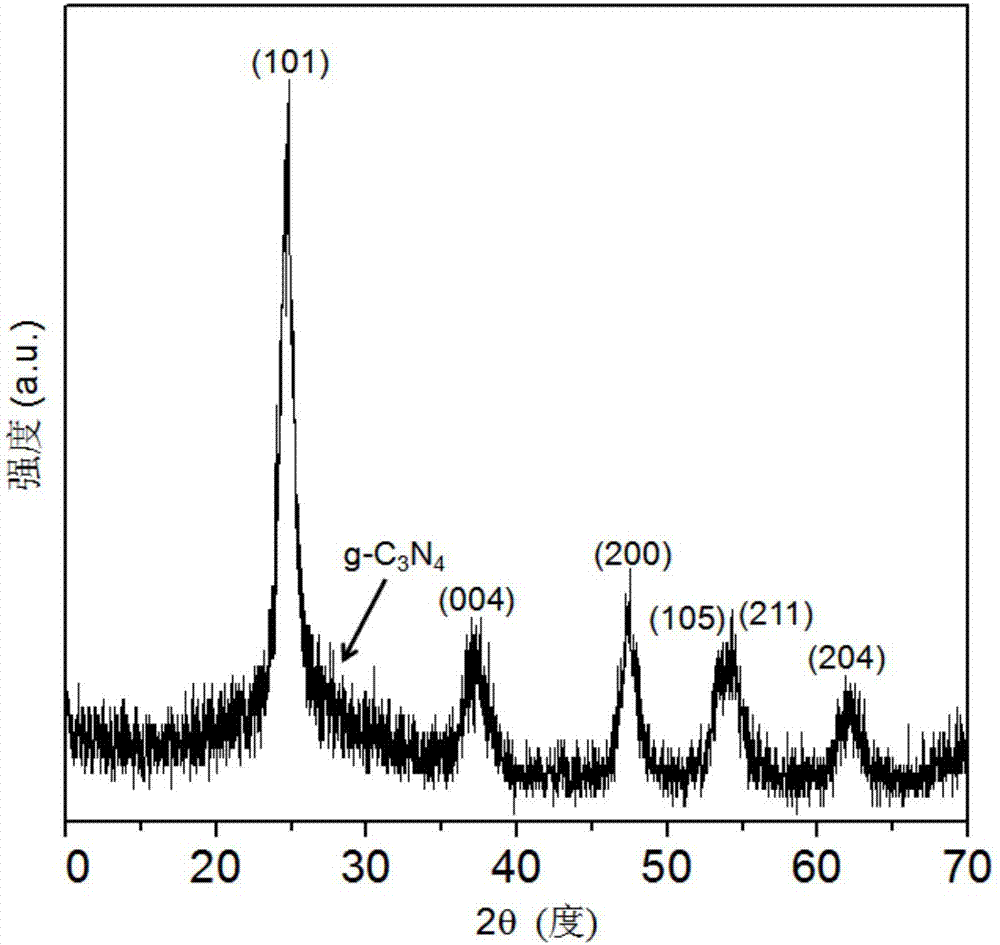

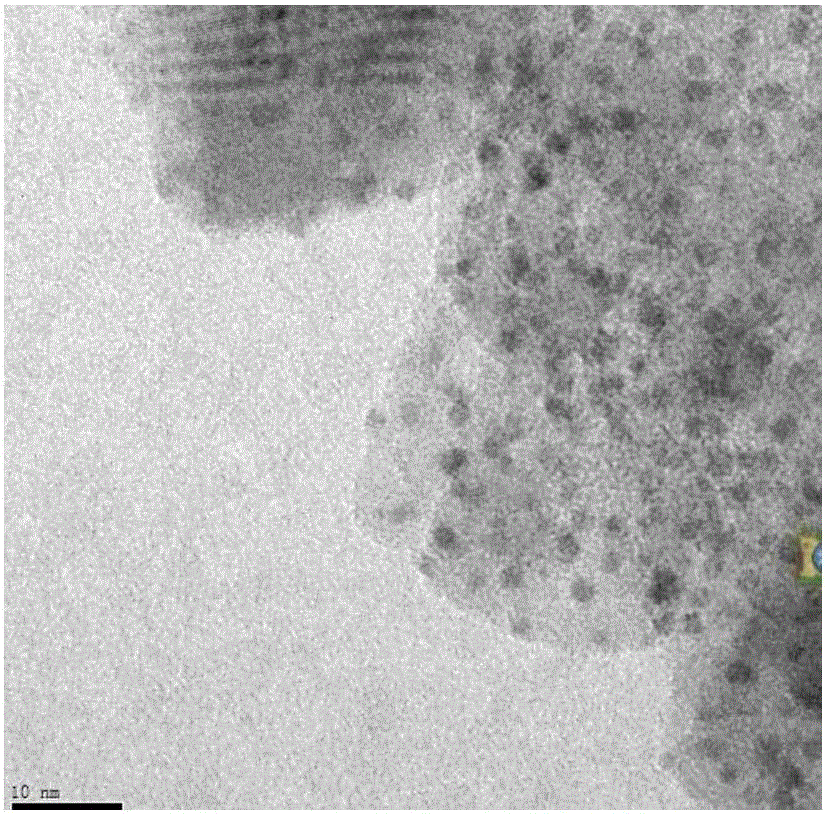

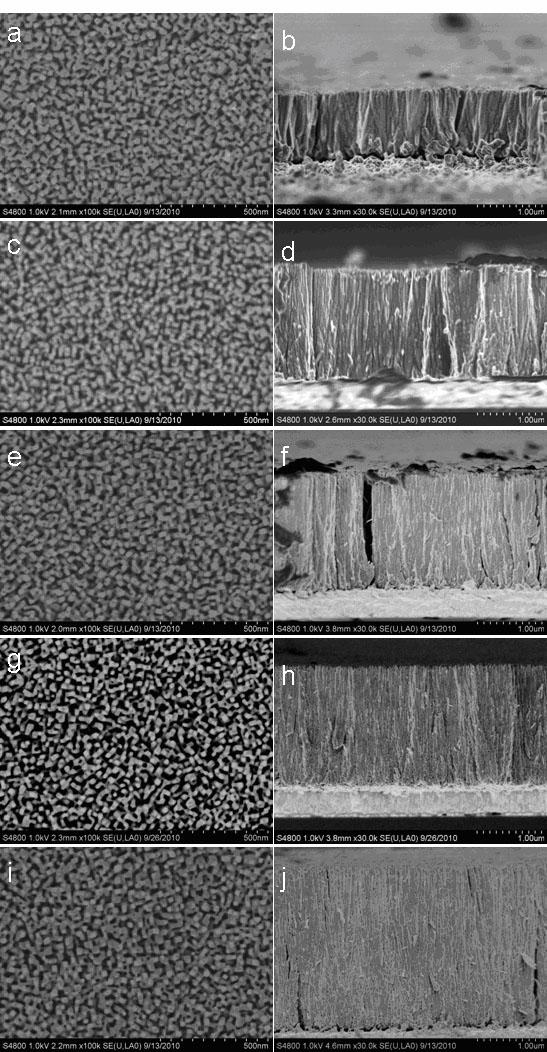

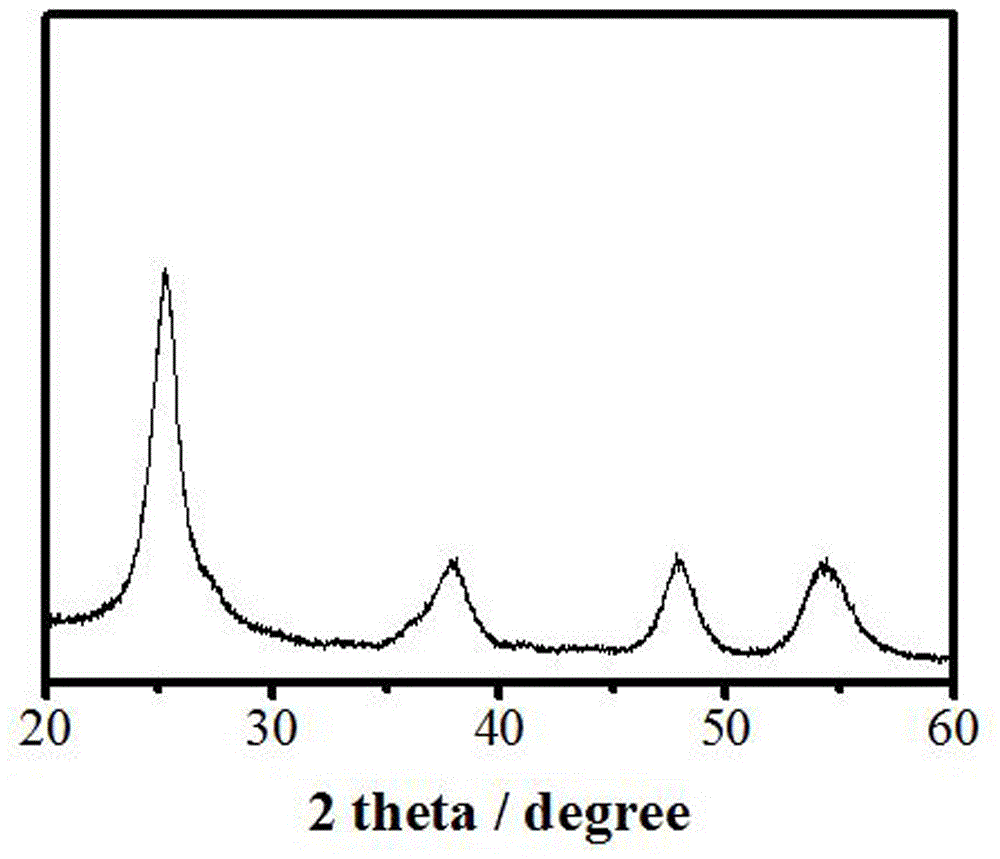

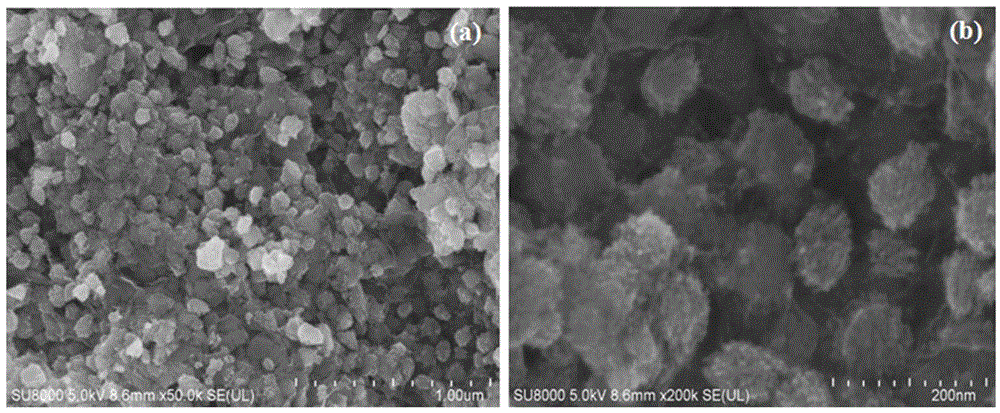

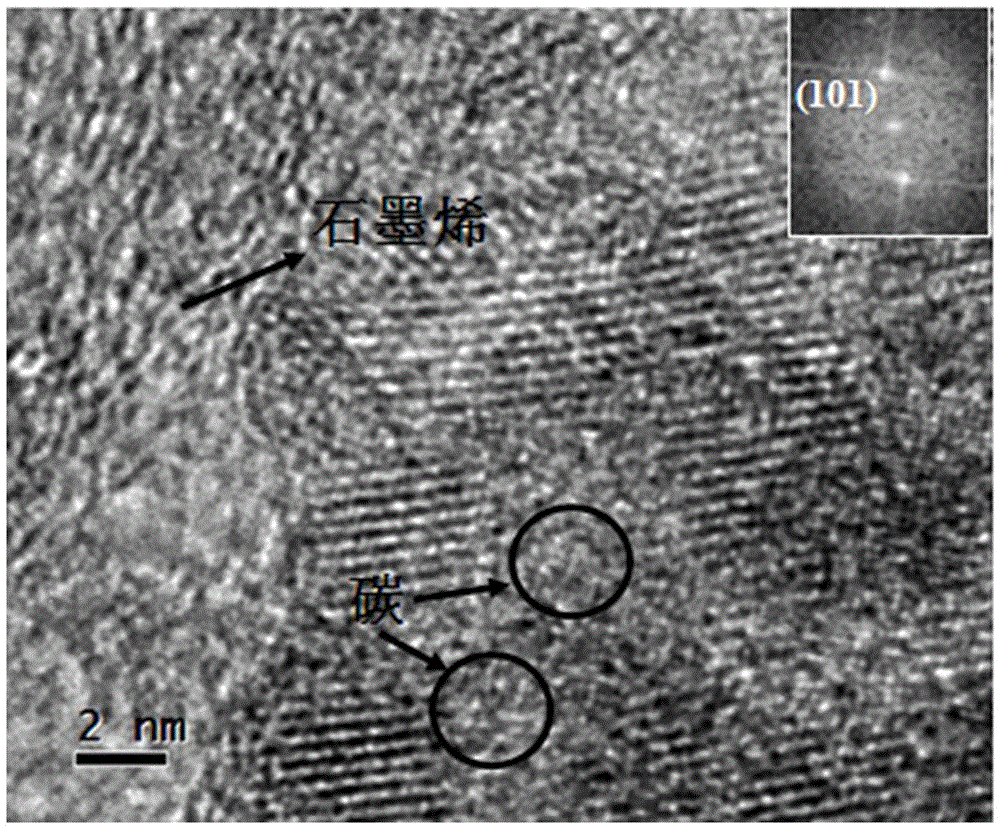

Method and application of in-situ synthesized TiO2 mesomorphase-carbon-graphene nanocomposite

InactiveCN105810918ALarge specific surface areaImprove performanceMaterial nanotechnologyCell electrodesGraphene nanocompositesTitanium isopropoxide

The invention relates to a method and application of in-situ synthesized TiO2 mesomorphase-carbon-graphene nanocomposite. The method includes the steps of dispersing and dissolving polyvinylpyrrolidone, adding graphene oxide, cetyl sodium sulfate and titanium isopropoxide respectively, centrifuging, washing, annealing and carbonizing to obtain the nanocomposite. In the composite electrode material, the TiO2 mesomorphase is anatase TiO2, micro nanocrystallines are uniformly dispersed and embedded in the graphene, and then the graphene is uniformly coated with a layer of amorphous carbon, and the mixro nanocrystallines are in alignment along the direction of (101). The in-situ synthesized TiO2 mesomorphase-carbon-graphene nanocomposite has a very large surface area up to 280-290m<2>g<-1>. The nanocomposite has great electrical conductivity and good tenacity, is easy to operate, low in cost, high in purity, excellence in property and capable of large-scale synthesis, which can be popularized and applied to other fields of energies and catalysis.

Owner:FUJIAN NORMAL UNIV

Preparation method for dexlansoprazole

InactiveCN106543146AImprove product qualityShort reaction timeOrganic chemistryOrganic synthesisDexlansoprazole

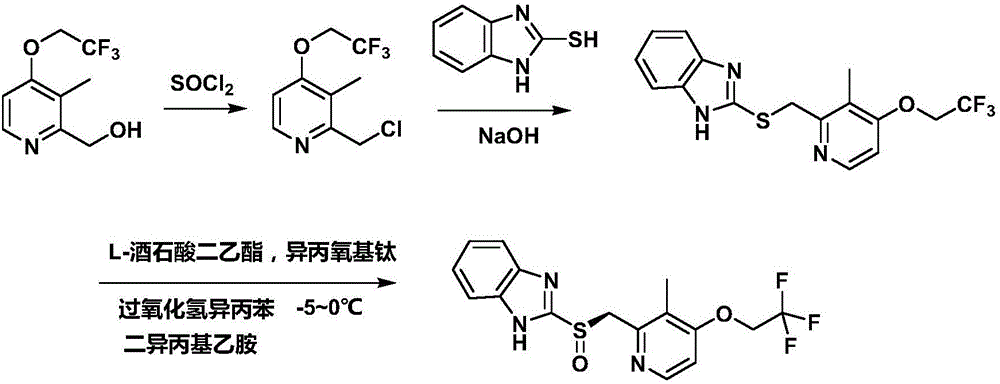

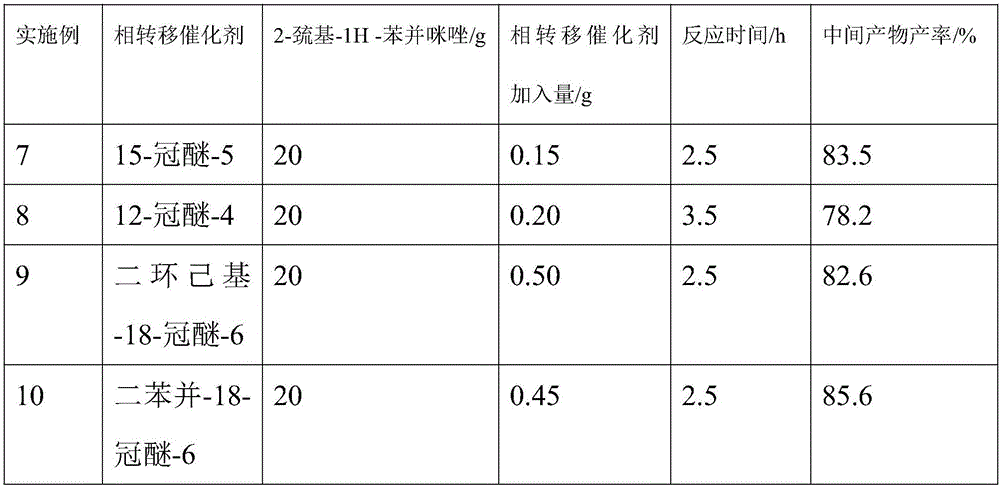

The invention discloses a preparation method for dexlansoprazole, belonging to the field of organic synthesis. The method comprises the following steps: (1) carrying out reaction on 2-hydroxymethyl-3-methyl-4-(2,2,2-trifluoro ethyoxyl) pyridine and thionyl chloride, and compounding 2-chloromethyl-3-methyl-4-(2,2,2-trifluoro ethyoxyl) pyridine; (2) putting 2-chloromethyl-3-methyl-4-(2,2,2-trifluoro ethyoxyl) pyridine acquired in the step (1) and 2-sulfydryl-1H-benzimidazole into an aqueous liquid, and then adding a phase transfer catalyst and sodium hydroxide, thereby acquiring 2-[[3-methyl-4-(2,2,2-trifluoro ethyoxyl) pyridine-2-group] methylmercapto]-1H-benzimidazole; (3) taking L-ethyl tartrate as a chiral assistant agent, titanium isopropoxide and diisopropylethylamine as a catalyst and cumyl hydroperoxide as an oxidizing agent and reacting with 2-[[3-methyl-4-(2,2,2-trifluoro ethyoxyl) pyridine-2-group] methylmercapto]-1H-benzimidazole acquired in the step (2) at low temperature, thereby acquiring dexlansoprazole. The preparation method for dexlansoprazole disclosed by the invention is simple and efficient, is capable of obviously shortening the reaction time under the condition of guaranteeing the product yield and is capable of improving the product quality.

Owner:石家庄市度智医药科技有限公司

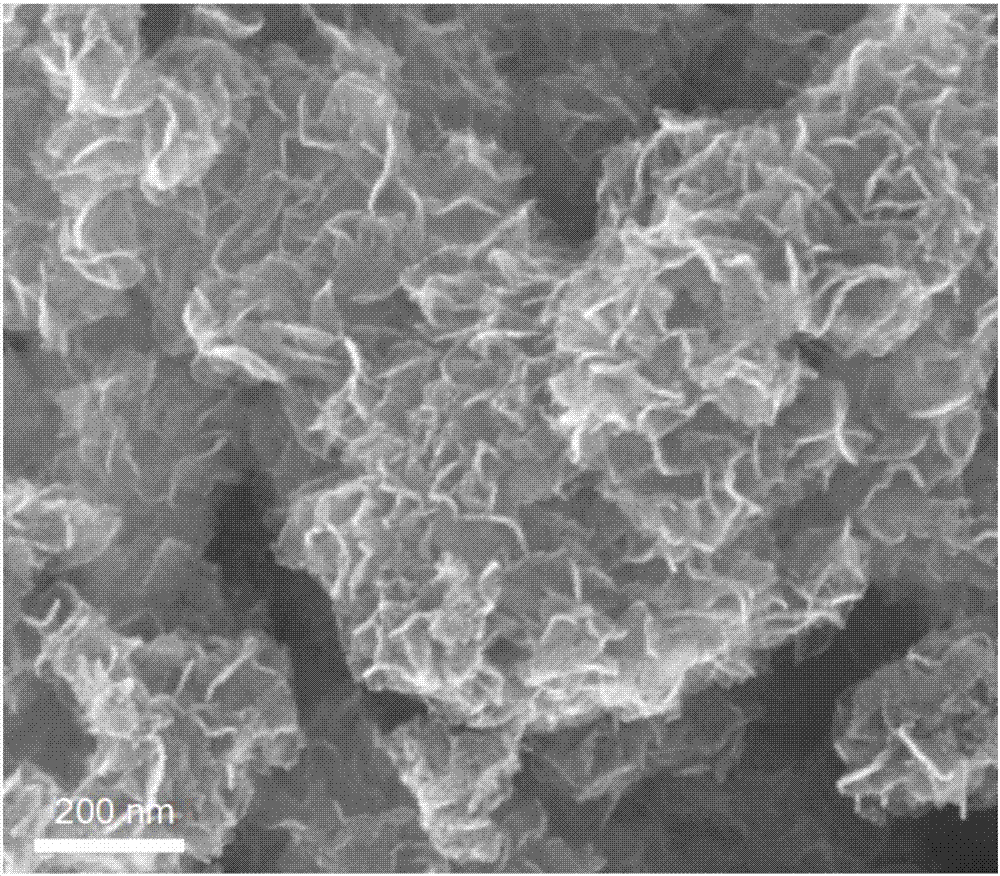

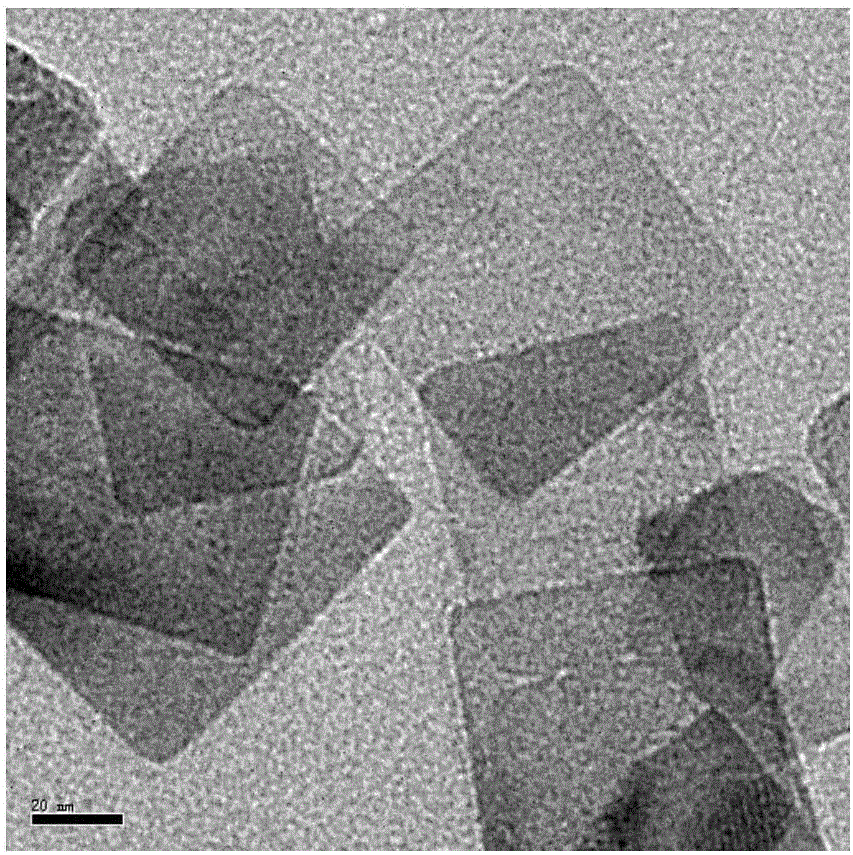

Fluoride-free preparation method of titanium dioxide of similar graphene structure

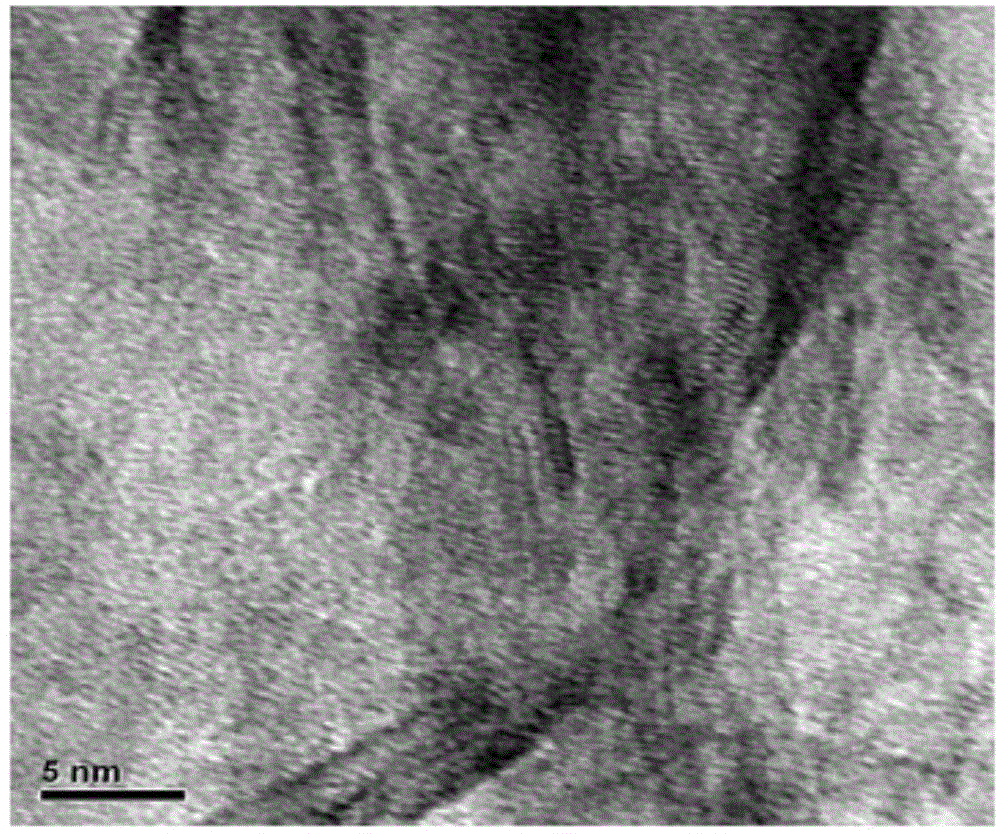

The invention provides a fluoride-free preparation method of titanium dioxide of a similar graphene structure and belongs to the technical field of nanomaterial preparation. The material is composed of titanium dioxide nanosheets having the size of greater than 500nm. The preparation method mainly comprises the following steps: by taking ethylene glycol and ethanol as reaction solvents, inhibiting quick decomposition of titanium isopropylate by use of concentrated hydrochloric acid under the action Pluronic P123, performing a solvothermal reaction, growing micro flake titanium dioxide by virtue of self-assembly, and further growing to obtain titanium dioxide having a large area and an ultra-thin similar graphene structure. According to the preparation method, titanium dioxide having the large area and the ultra-thin similar graphene structure is synthesized for the first time and can be widely applied to photo / electro / chemocatalysis, the electrode materials of new energy batteries and the like.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com