Manufacturing method for La-doped Ti-coated ternary cathode material

A cathode material and coating technology, which is applied in the field of preparation of La-doped Ti-coated ternary cathode materials, can solve the problems of poor rate performance and cycle performance, and achieve the effect of low cost, rate performance and cycle performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

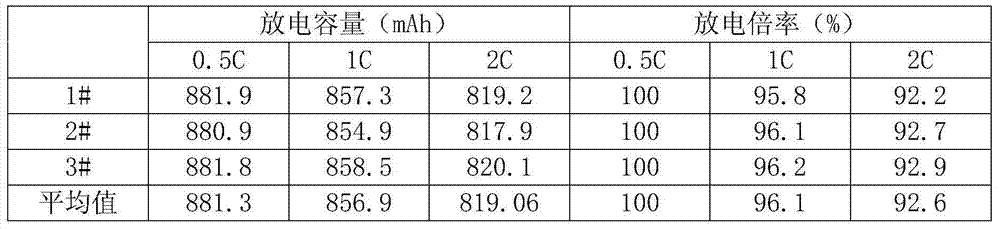

Examples

Embodiment Construction

[0013] The steps of the embodiment of the present invention are as follows:

[0014] 1) The ternary precursor (Ni 0.45 co 0.2 Mn0 .35 )(OH) 2 ;

[0015] 2) The ternary precursor (Ni 0.45 co 0.2 mn 0.35 )(OH) 2 , battery grade lithium carbonate, mixed and sintered according to the molar ratio of 1:1.04 to obtain the ternary cathode material Li(Ni 0.45 co 0.2 mn 0.35 )O 2

[0016] 3) Sinter the mixed raw materials in an air atmosphere muffle furnace, first pre-sinter at 620°C for 6 hours; then sinter at 900°C for 12 hours; cool naturally with the furnace, take it out; crush it and pass it through a 200-mesh screen ;

[0017] 4) Li(Ni 0.45 co 0.2 mn 0.35 )O 2 and La 2 o 3 Mix in a three-dimensional mixing tank for 4 hours, ball:material=1.5:1, wherein the mass of La accounts for 0.03% of the total mass of the mixed material.

[0018] 5) Place the mixed material in an air atmosphere muffle furnace for secondary sintering, raise the temperature to 900°C at a rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com