Method and application of in-situ synthesized TiO2 mesomorphase-carbon-graphene nanocomposite

A nanocomposite material and in-situ synthesis technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of negative electrode materials restricting practical applications, and achieve good cycle stability and excellent storage Sodium performance, effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An in-situ synthesized TiO 2 The method for the mesogen-carbon-graphene nanocomposite material specifically comprises the following steps:

[0028] (1) Disperse and dissolve 0.2g of polyvinylpyrrolidone in 35mL of 1.5mol / L nitric acid solution, and stir for 5 minutes;

[0029] (2) Add 20 mg of graphene oxide to the solution prepared in step (1), and stir for 30 minutes while ultrasonicating;

[0030] (3) Add 1.5 g of sodium cetyl sulfate to the solution prepared in step (2), stir to disperse and dissolve;

[0031] (4) Add 0.7mL isopropyl titanate dropwise to the solution prepared in step (3), and react at 60°C for 30h;

[0032] (5) The reaction system in step (4) was centrifuged and washed to obtain an off-white solid, and the solid was annealed and carbonized at 500°C to obtain the TiO 2 Mesogen-carbon-graphene nanocomposites.

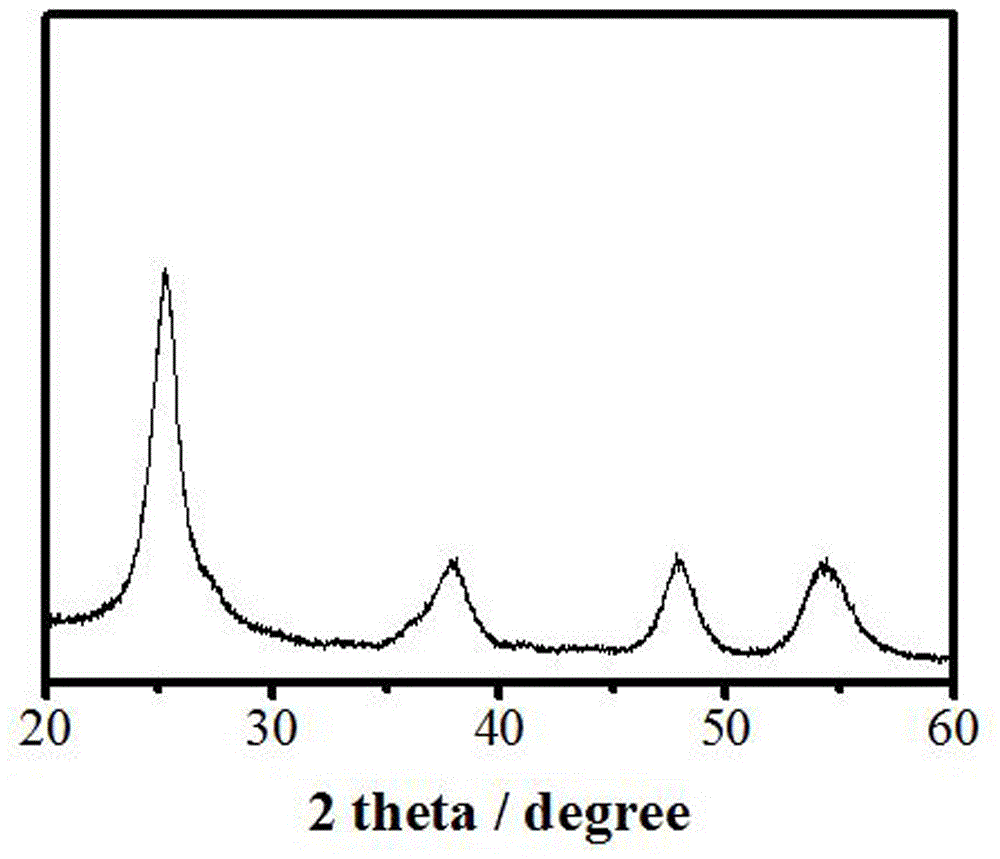

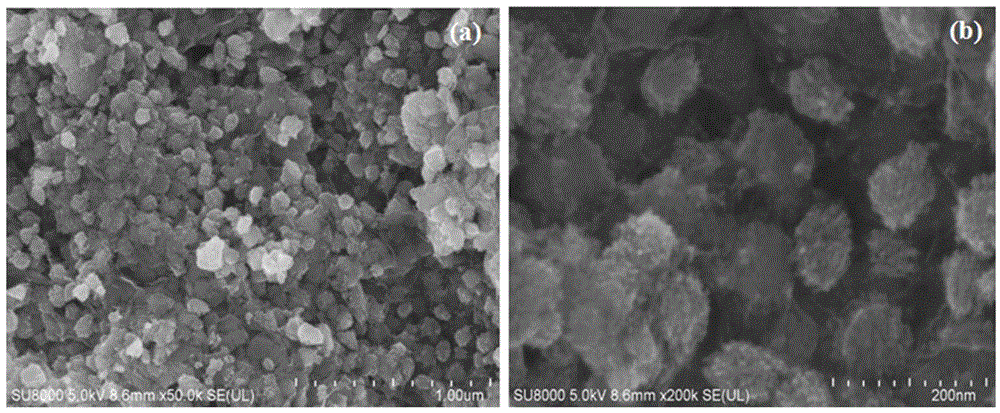

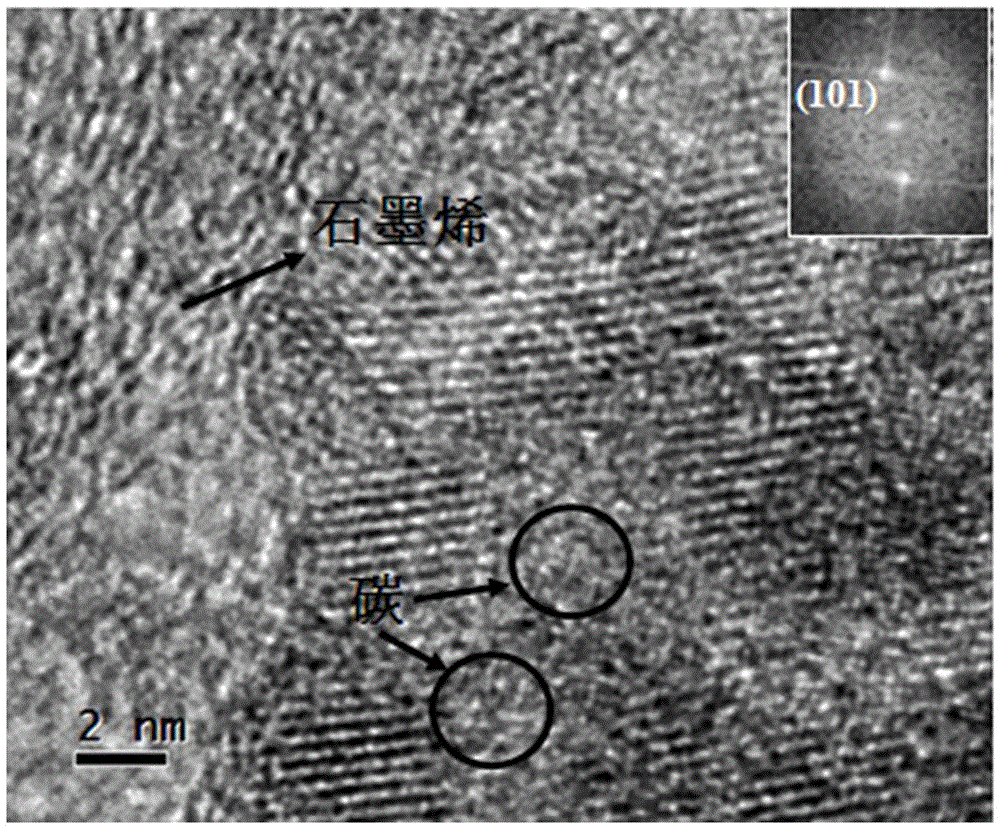

[0033] An in-situ synthesized TiO 2 TiO prepared by mesogenic-carbon-graphene nanocomposite method 2 Mesogen-carbon-graphene nanocomposi...

Embodiment 2

[0043] An in-situ synthesized TiO 2 The method for the mesogen-carbon-graphene nanocomposite material specifically comprises the following steps:

[0044] (1) Disperse and dissolve 0.6g of polyvinylpyrrolidone in 40mL of 2.0mol / L nitric acid solution, and stir for 8 minutes;

[0045] (2) Add 30 mg of graphene oxide to the solution prepared in step (1), and stir for 40 minutes while ultrasonicating;

[0046] (3) Add 1.8g of sodium cetyl sulfate to the solution prepared in step (2), stir to disperse and dissolve;

[0047] (4) Add 1.1 mL of isopropyl titanate dropwise to the solution prepared in step (3), and react at 70°C for 40 hours;

[0048] (5) The reaction system in step (4) was centrifuged and washed to obtain an off-white solid, and the solid was annealed and carbonized at 600°C to obtain the TiO 2 Mesogen-carbon-graphene nanocomposites.

[0049] An in-situ synthesized TiO 2 TiO prepared by mesogenic-carbon-graphene nanocomposite method 2 Mesogen-carbon-graphene nan...

Embodiment 3

[0054] An in-situ synthesized TiO 2 The method for the mesogen-carbon-graphene nanocomposite material specifically comprises the following steps:

[0055] (1) Disperse and dissolve 0.8g of polyvinylpyrrolidone in 60mL of 2.5mol / L nitric acid solution, and stir for 10 minutes;

[0056] (2) Add 40 mg of graphene oxide to the solution prepared in step (1), and stir for 50 minutes while ultrasonicating;

[0057] (3) Add 2.5g of sodium cetyl sulfate to the solution prepared in step (2), stir to disperse and dissolve;

[0058] (4) Add 1.5mL of isopropyl titanate dropwise to the solution prepared in step (3), and react at 90°C for 60h;

[0059] (5) The reaction system in step (4) was centrifuged and washed to obtain an off-white solid, and the solid was annealed and carbonized at 700°C to obtain the TiO 2 Mesogen-carbon-graphene nanocomposites.

[0060] An in-situ synthesized TiO 2 TiO prepared by mesogenic-carbon-graphene nanocomposite method 2 Mesogen-carbon-graphene nanocomp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com